Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment

Abstract

1. Introduction

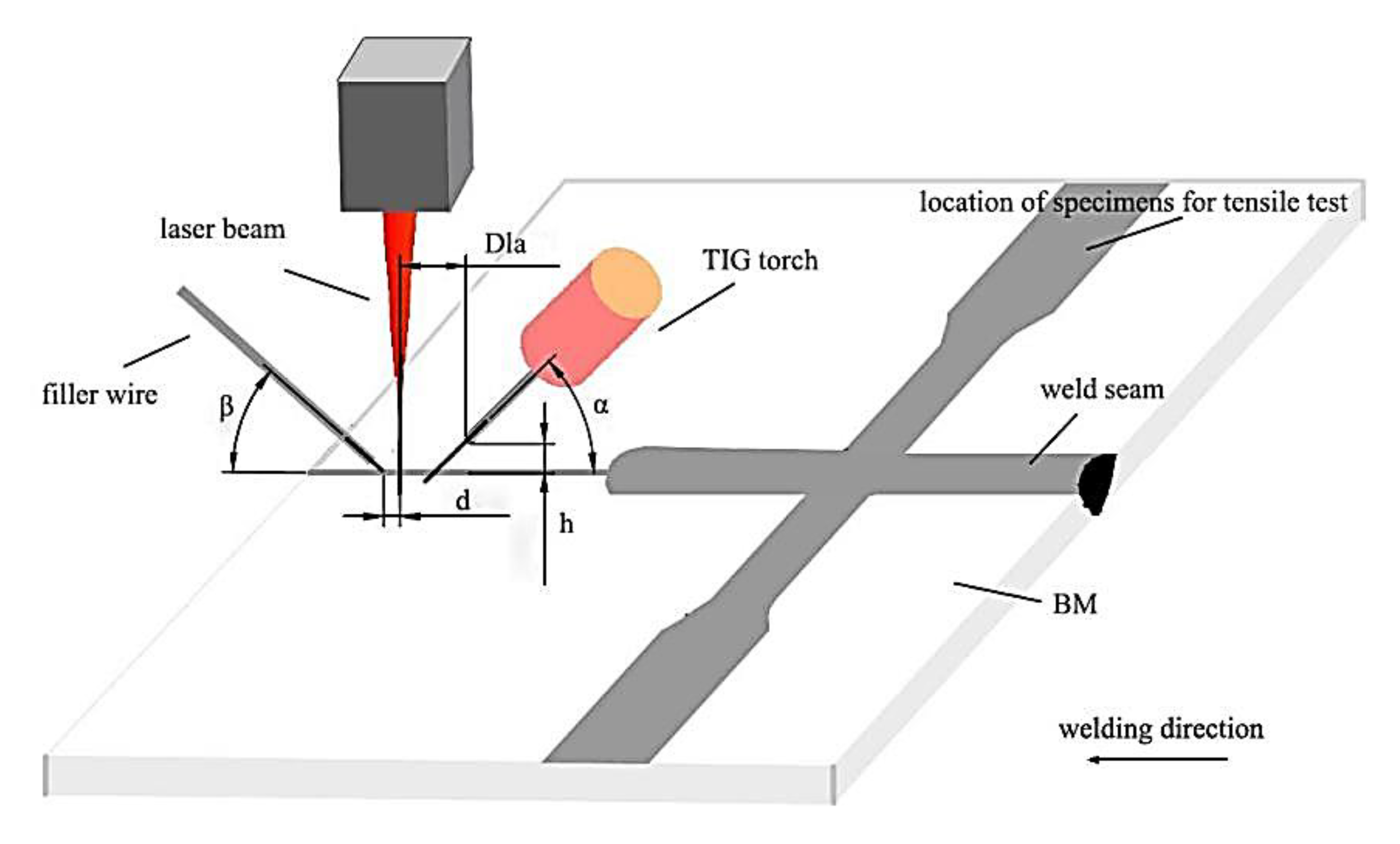

2. Experiments

3. Results

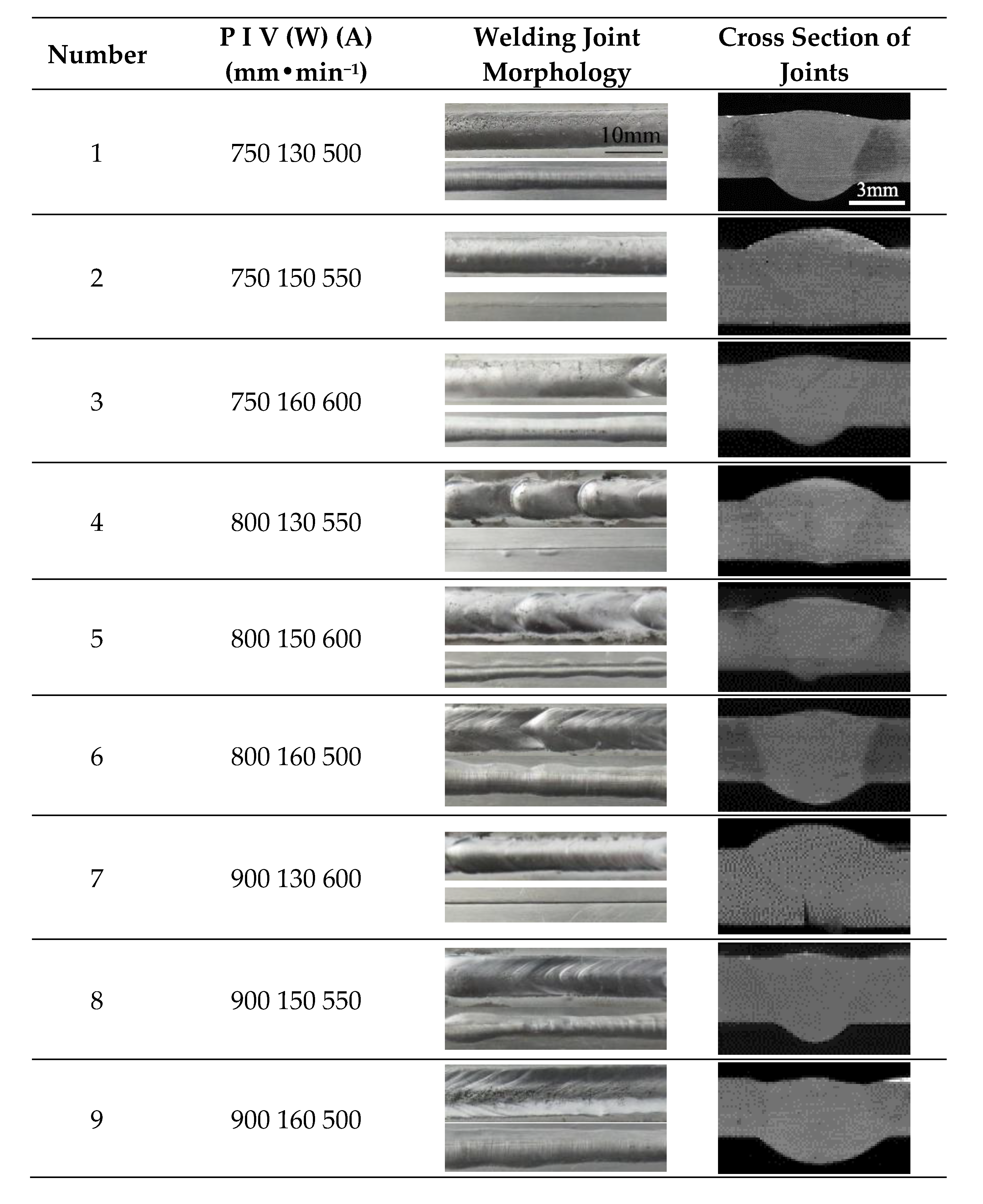

3.1. Welding Process

3.2. Tensile Properties

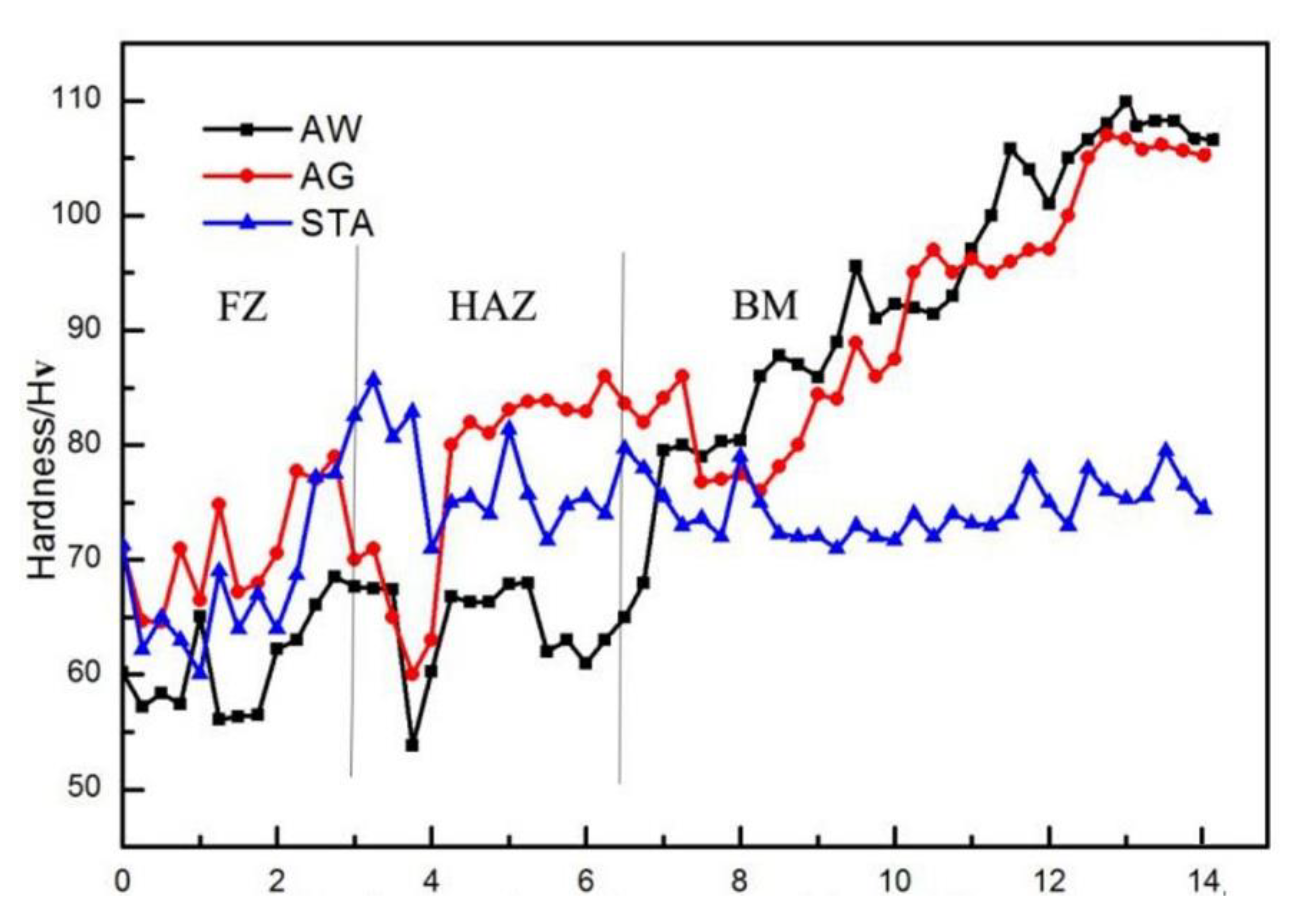

3.3. Hardness

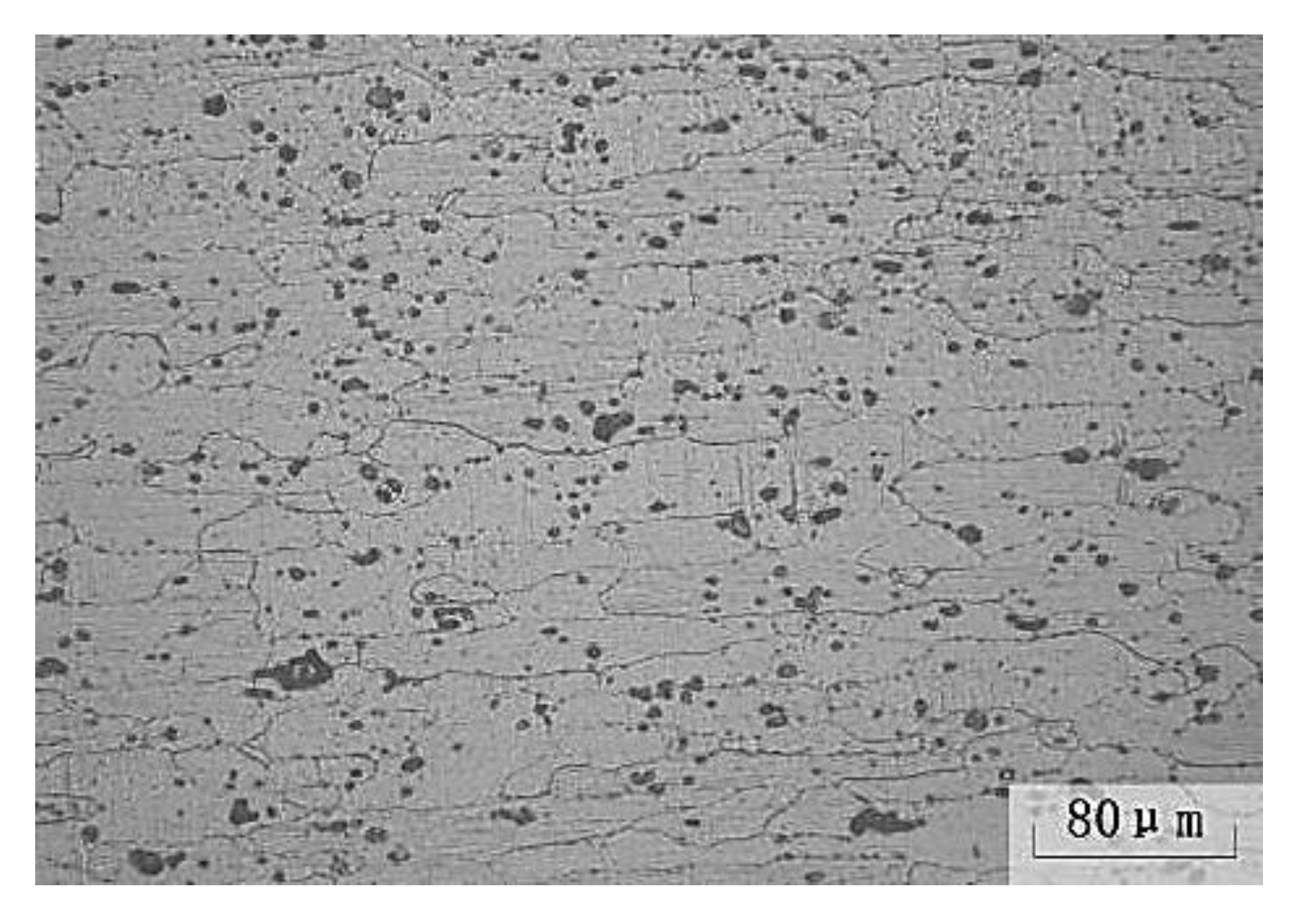

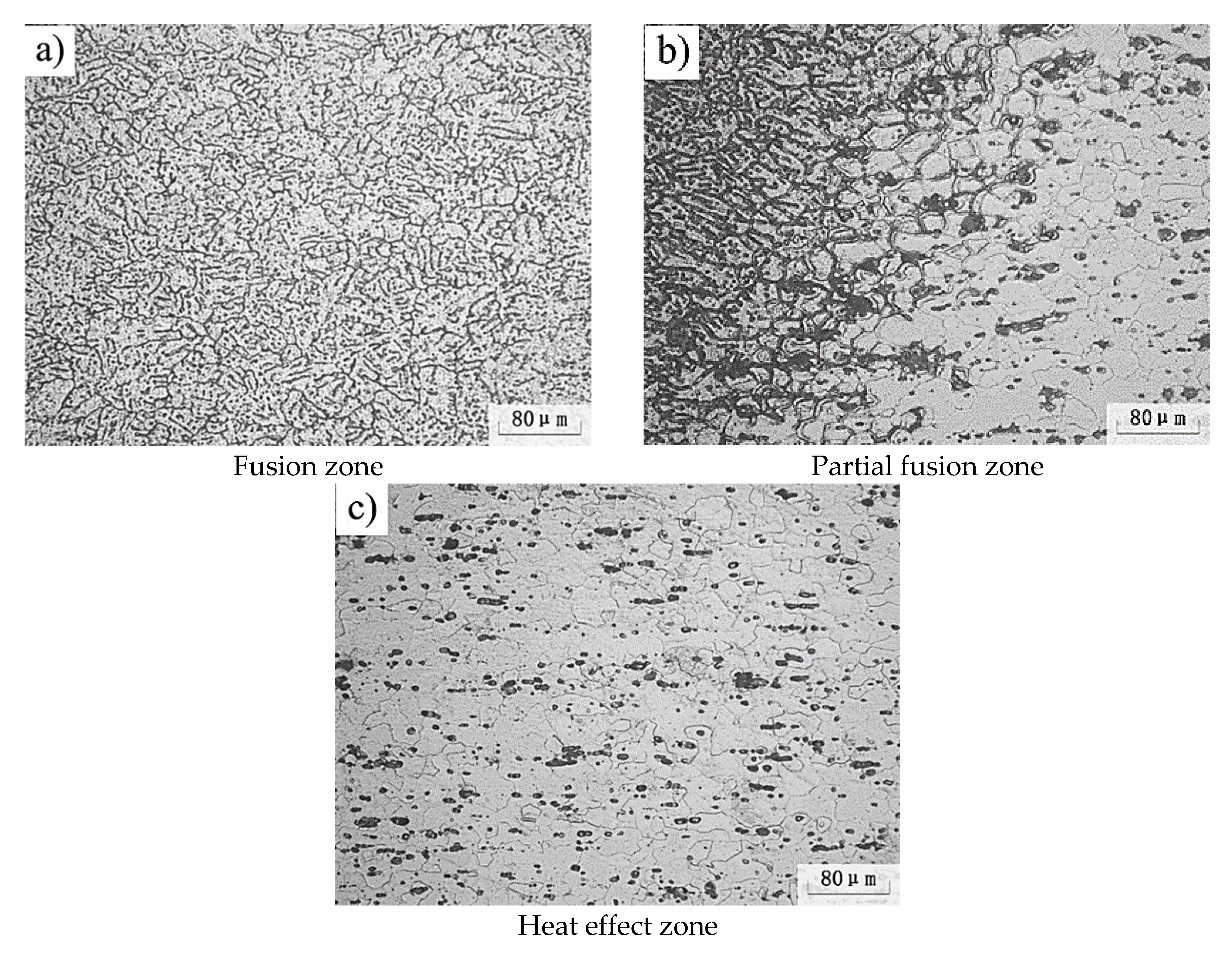

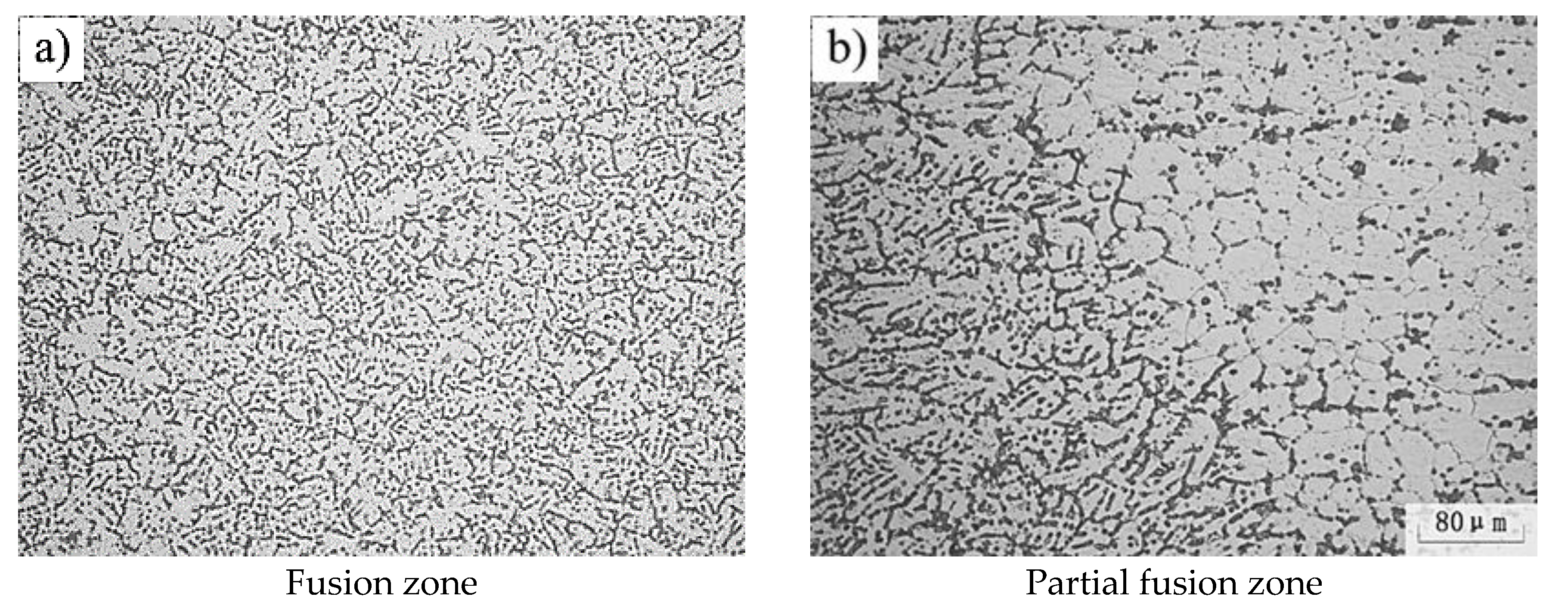

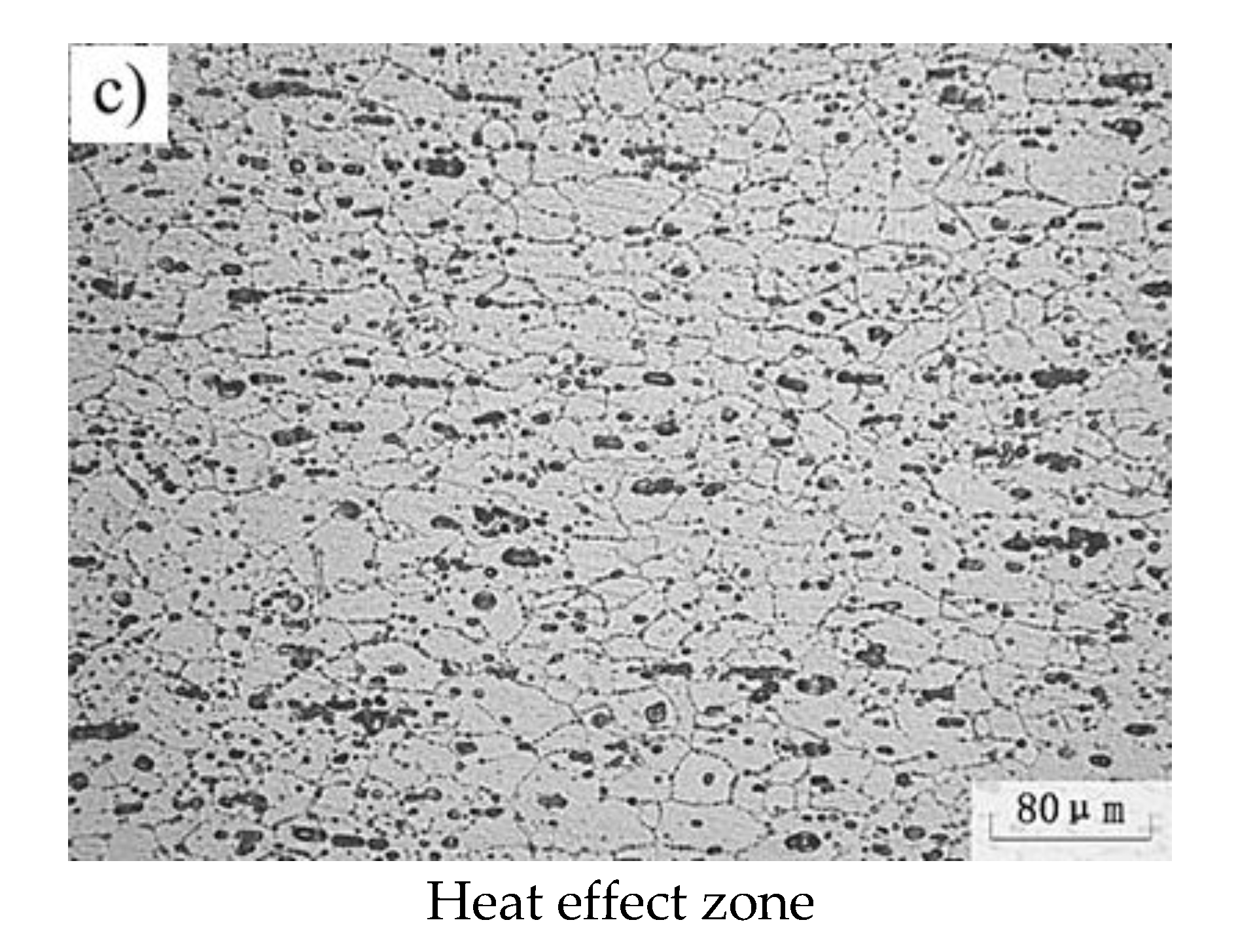

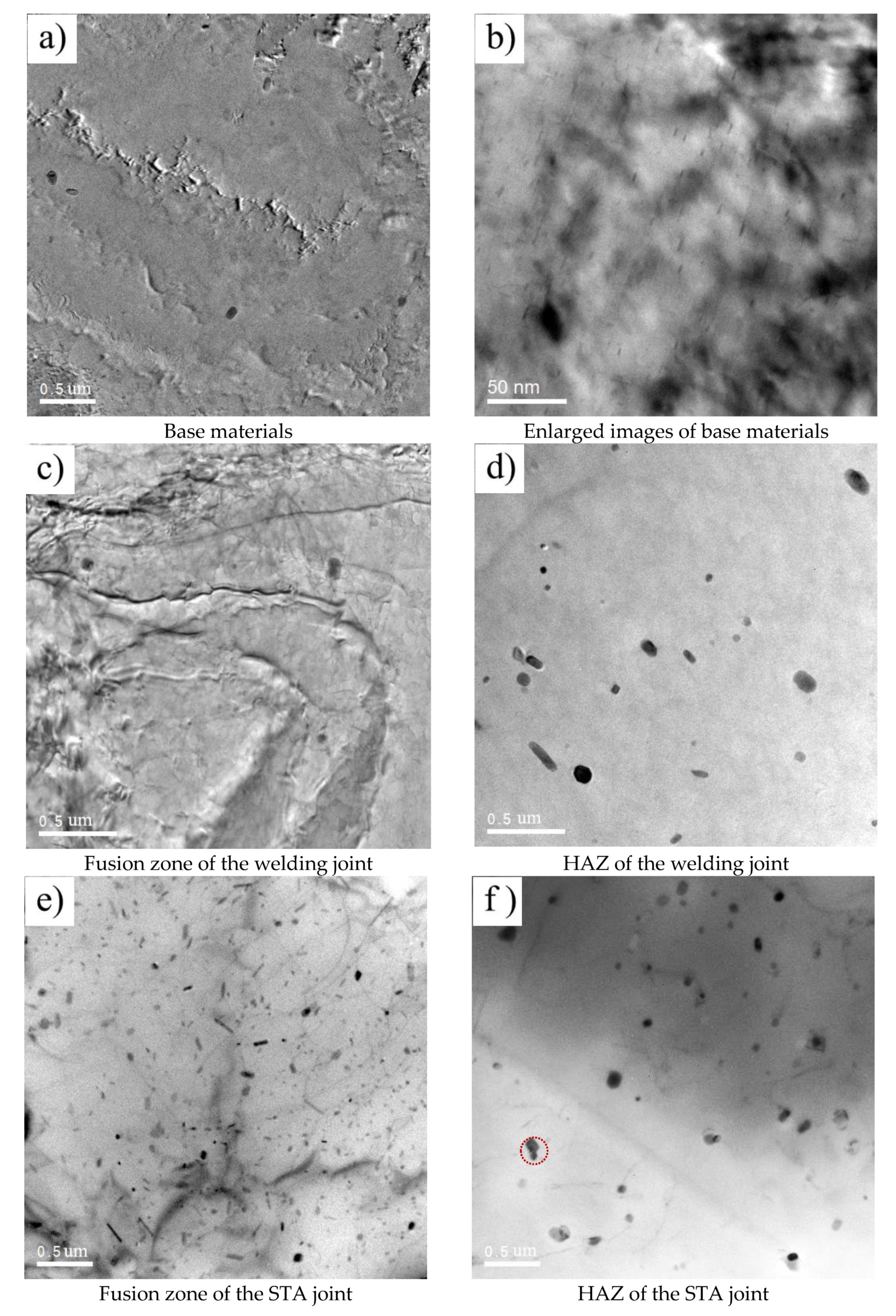

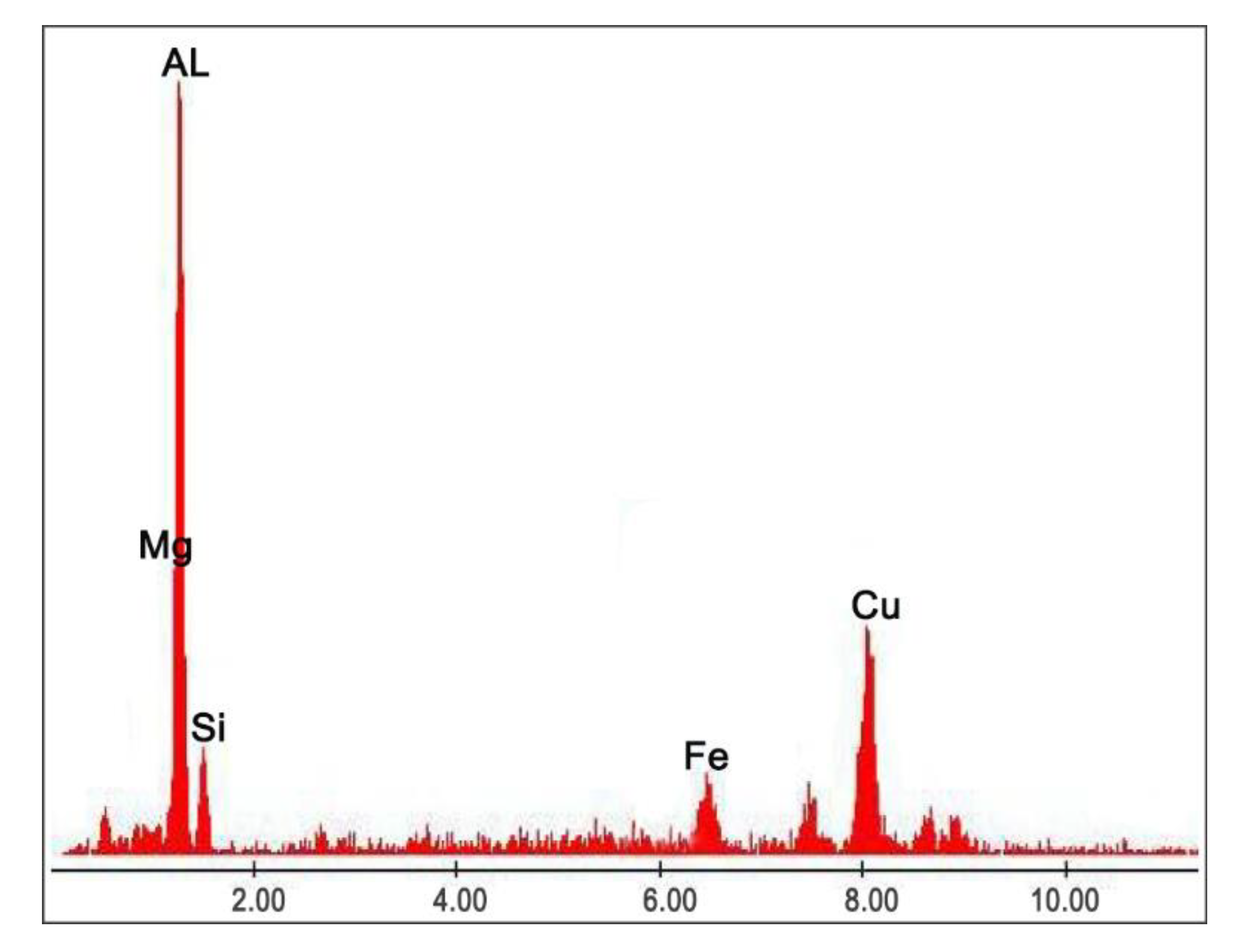

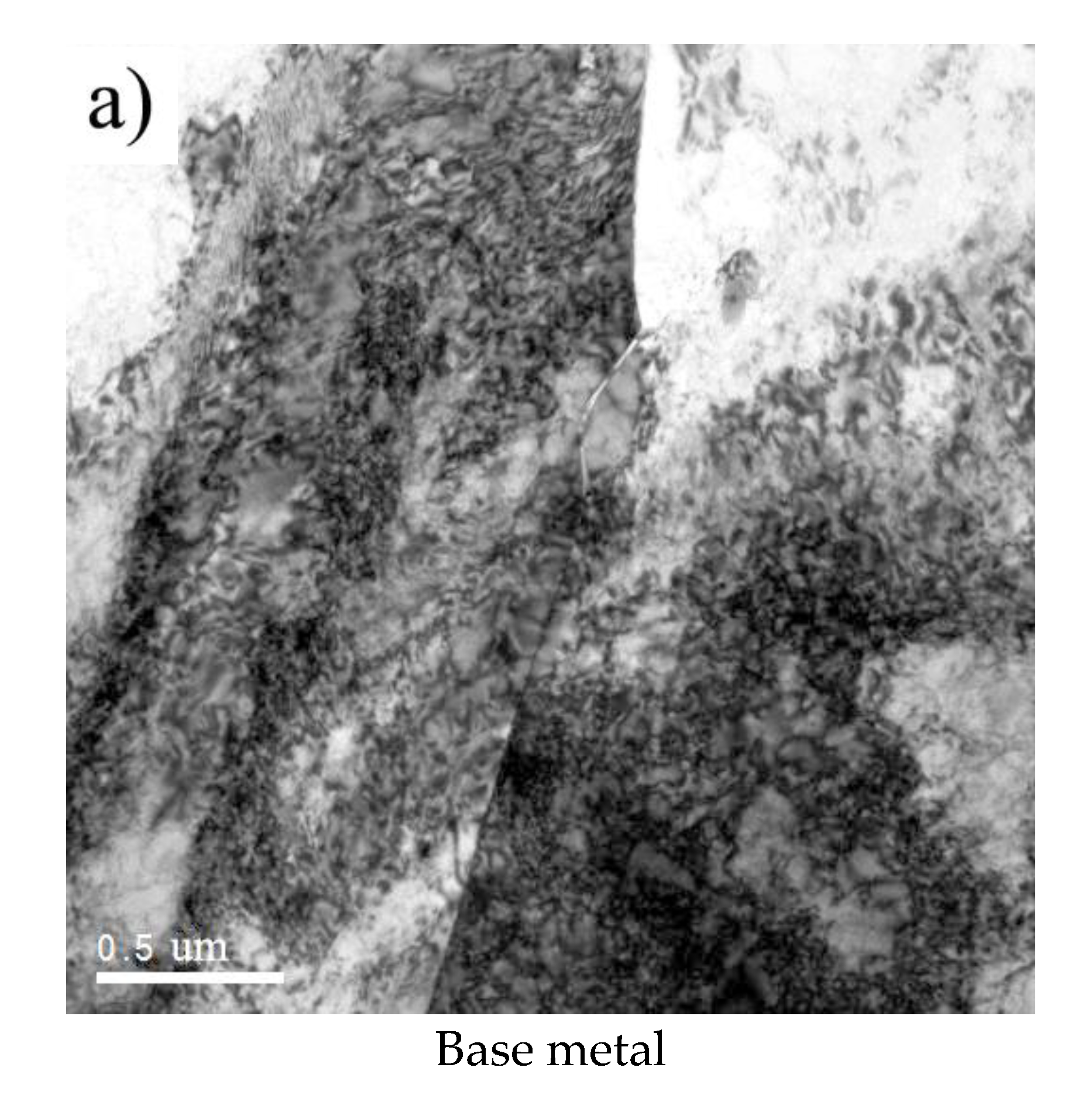

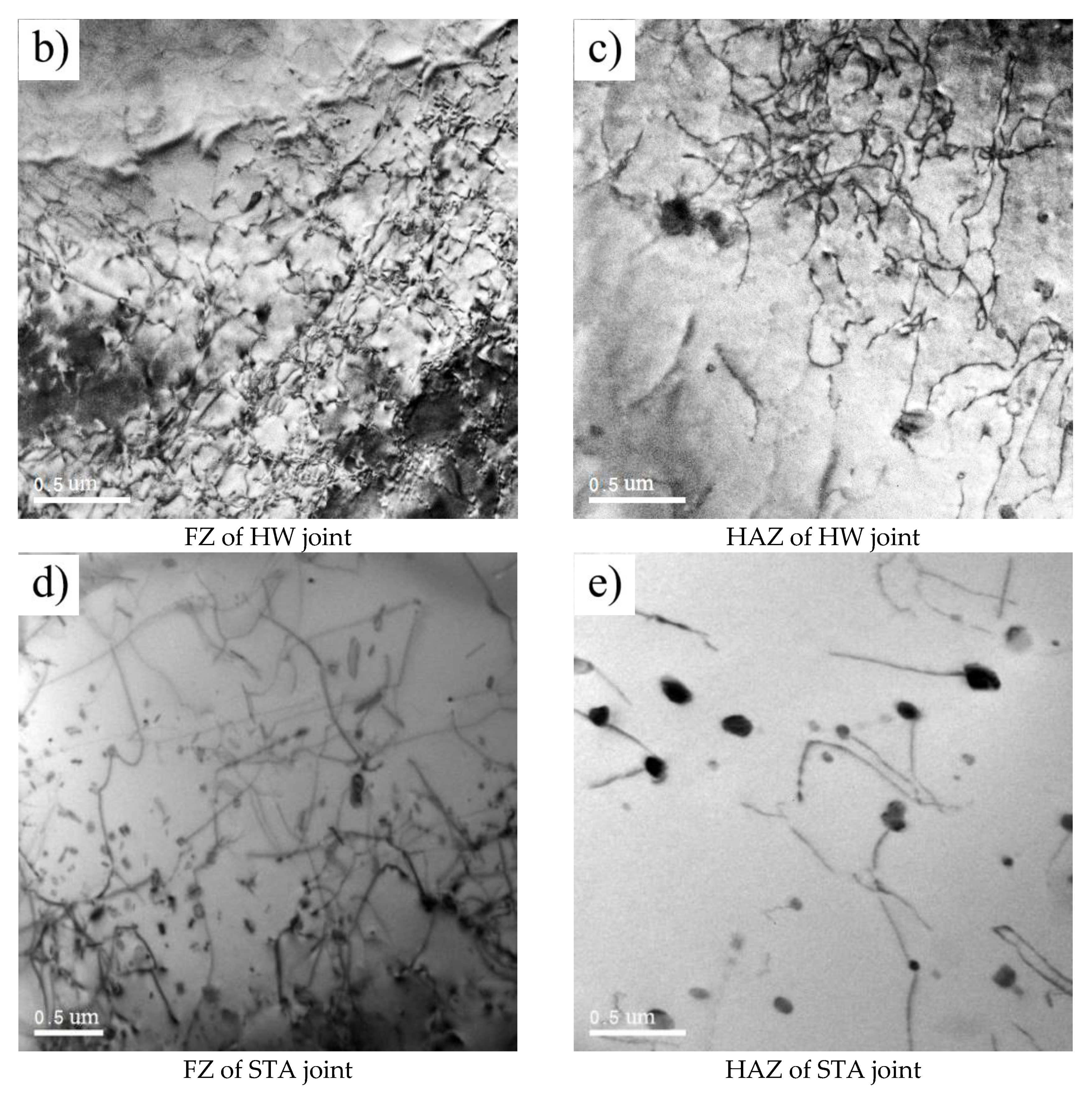

3.4. Microstructure

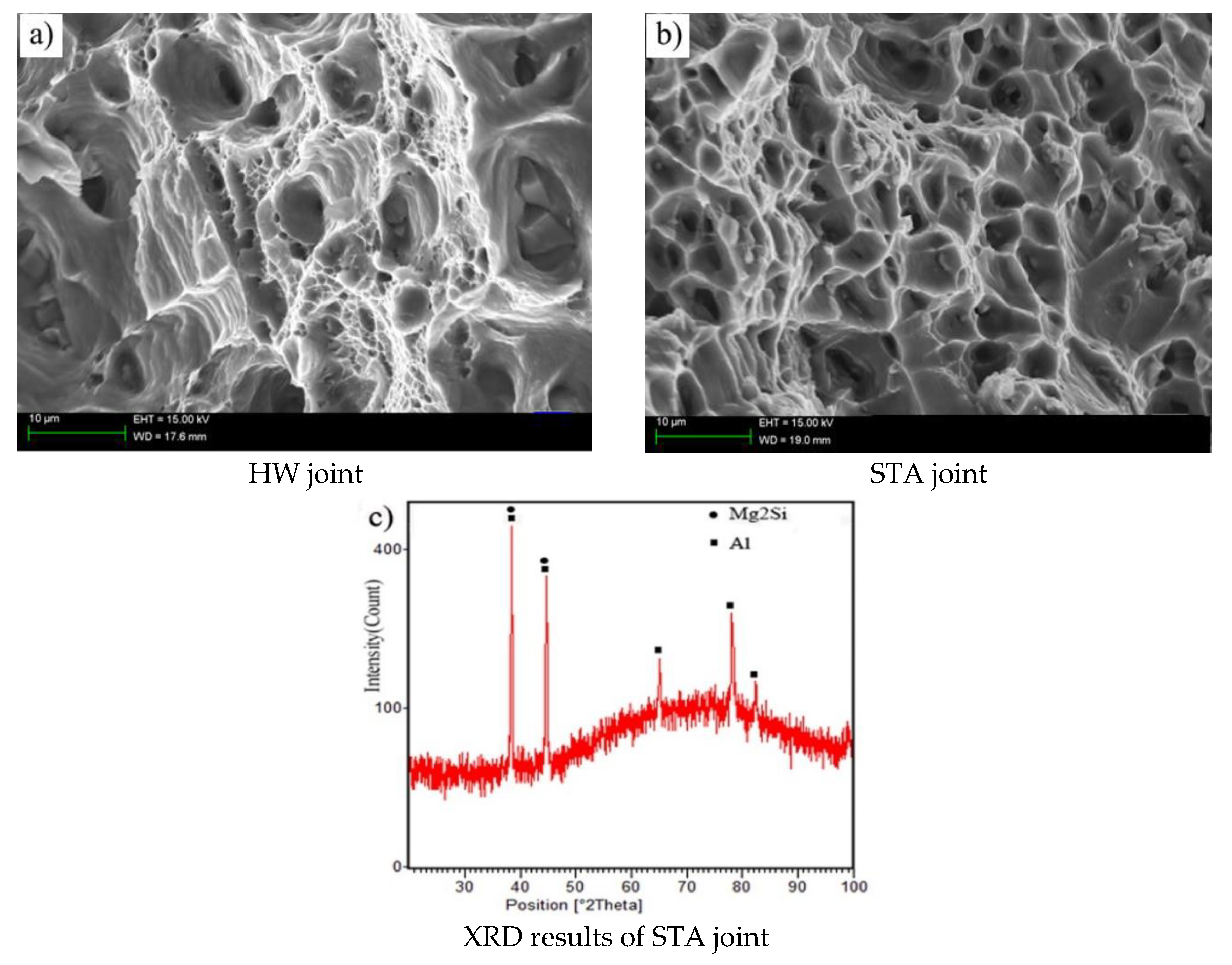

3.5. Fracture

3.6. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wona, S.; Seoa, B.; Parka, J.M.; Kim, H.K.; Song, K.H.; Min, S.-H.; Ha, T.K.; Park, K. Corrosion behaviors of friction welded dissimilar aluminum alloys. Mater. Charact. 2018, 144, 652–660. [Google Scholar] [CrossRef]

- Monazzah, A.H.; Pouraliakbar, H.; Bagheri, R.; Reihani, S.S. Toughness behavior in roll-bonded laminates based on AA6061/SiCp composites. Mater. Sci. Eng. A 2014, 598, 162–173. [Google Scholar] [CrossRef]

- Monazzah, A.H.; Bagheri, R.; Reihani, S.S.; Pouraliakbar, H. Toughness enhancement in architecturally modified Al6061-5 vol.% SiCp laminated composites. Int. J. Damage Mech. 2014, 24, 245–262. [Google Scholar] [CrossRef]

- Monazzah, A.H.; Pouraliakbar, H.; Bagheri, R.; Reihani, S.M.S. Al-Mg-Si/SiC laminated composites: Fabrication, architectural characteristics, toughness, damage tolerance, fracture mechanisms. Compos. Part B Eng. 2017, 125, 49–70. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Nazari, A.; Fataei, P.; Livary, A.K.; Jandaghi, M. Predicting Charpy impact energy of A16061/SiCp laminated nanocomposites in crack divider and crack arrester forms. Ceram. Int. 2013, 39, 6099–6106. [Google Scholar] [CrossRef]

- Karunakaran, N. Effect of Pulsed Current on Temperature distribution and characteristics of GTA welded magnesium alloy. IOSR J. Mech. Civ. Eng. 2013, 4, 1–8. [Google Scholar] [CrossRef]

- Najiha, M.S.; Rahman, M.M.; Kamal, M.; Yusoff, A.R.; Kadirgama, K. Minimum quantity lubricant flow analysis in end milling processes: A computational fluid dynamics approach. J. Mech. Eng. Sci. 2012, 3, 340–345. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Crispim, B.; Zeng, Z.; Omori, T.; Braz Fernandes, F.M.; Miranda, R.M. Microstructure and mechanical properties of gas tungsten arc welded Cu-Al-Mn shape memory alloy rods. J. Mater. Process. Technol. 2019, 271, 93–100. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Schell, N.; Zhou, N.; Wood, L.; Benafan, O. Laser welding of precipitation strengthened Ni-rich NiTiHf high temperature shape memory alloys: Microstructure and mechanical properties. Mater. Des. 2019, 162, 229–234. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Hamedi, M.; Kokabi, A.H.; Nazari, A. Designing of CK45 carbon steel and AISI 304 stainless steel dissimilar welds. Mater. Res. 2014, 17, 106–114. [Google Scholar] [CrossRef]

- Golezani, A.S.; Barenji, R.V.; Heidarzadeh, A.; Pouraliakbar, H. Elucidating of tool rotational speed in friction stir welding of 7020-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2015, 81, 1155–1164. [Google Scholar] [CrossRef]

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Wang, Z.M.; Oliveira, J.P.; Zeng, Z.; Bu, X.Z.; Peng, B.; Shao, X.Y. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2019, 111, 58–65. [Google Scholar] [CrossRef]

- Khorrami, M.S.; Mostafaei, M.A.; Pouraliakbar, H.; Kokabi, A.H. Study on microstructure and mechanical characteristics of low-carbon steel and ferritic stainless steel joints. Mater. Sci. Eng. A 2014, 608, 35–45. [Google Scholar] [CrossRef]

- David, S.A.; Babu, S.S.; Vitek, J.M. Welding: Solidification and microstructure. JOM 2003, 55, 14–20. [Google Scholar] [CrossRef]

- Khalaj, G.; Pouraliakbar, H.; Jandaghi, M.R.; Gholami, A. Microalloyed steel welds by HF-ERW technique: Novel PWHT cycles, microstructure evolution and mechanical properties enhancement. Int. J. Press. Vessel. Pip. 2017, 152, 15–26. [Google Scholar] [CrossRef]

- LH, S.; AR, R. Investigation of aluminum-stainless steel dissimilar weld quality using different filler metals. Int. J. Automot. Mech. Eng. (IJAME) 2013, 8, 1121–1131. [Google Scholar]

- Ahmad, R.; Bakar, M.A. Effect of a post-weld heat treatment on the mechanical and microstructure properties of AA6061 joints welded by the gas metal arc welding cold metal transfer method. Mater. Des. 2011, 32, 5120–5126. [Google Scholar] [CrossRef]

- Kulekci, M.K.; Kaluç, E.; Sik, A.; Basturk, O. Experimetal Comparison of MIG and Friction Stir Welding Processes for En AW-6061-T6 (Al Mg-1 Si Cu) Aluminium Alloy. Arab. J. Sci. Eng. 2010, 35, 322. [Google Scholar]

- Narsimhachary, D.; Bathe, R.N.; Padmanabham, G.; Basu, A. Influence of temperature profile during laser welding of aluminum alloy 6061 T6 on microstructure and mechanical properties. Mater. Manuf. Process. 2014, 29, 948–953. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Zeng, X. Effect of microstructural characteristics on high cycle fatigue properties of laser-arc hybrid welded AA6082 aluminum alloy. J. Mater. Process. Technol. 2016, 231, 479–487. [Google Scholar] [CrossRef]

- Dewan, M.W.; Okeil, A.M. Influence of Weld Defects and Post-Weld Heat Treatment (PWHT) of Gas Tungsten Arc (GTA)-Welded AA-6061-T651 Aluminum Alloy. J. Manuf. Sci. Eng. 2015, 137. [Google Scholar] [CrossRef]

- Peng, D.; Shen, J.; Tang, Q.; Wu, C.-p.; Zhou, Y.-b. Effects of aging treatment and heat input on the microstructures and mechanical properties of TIG-welded 6061-T6 alloy joints. Int. J. Miner. Metall. Mater. 2013, 20, 259–265. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater. Charact. 2008, 59, 1168–1177. [Google Scholar] [CrossRef]

- Song, G.; Li, T.; Chen, L. Interface bonding mechanism of immiscible Mg/steel by butt fusion welding with filler wire. Mater. Sci. Eng. A 2018, 736, 306–315. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H. Study on the effect of post-annealing on the microstructural evolutions and mechanical properties of rolled CGPed Aluminum-Manganese-Silicon alloy. Mater. Sci. Eng. A 2017, 679, 493–503. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Jandaghi, M.R.; Baygi, S.J.M.; Khalaj, G. Microanalysis of crystallographic characteristics and structural transformations in SPDed Al Mn Si alloy by dual-straining. J. Alloys Compd. 2017, 696, 1189–1198. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Khalaj, G.; Khalaj, M.-J.; Heidarzadeh, A. Study on the post-rolling direction of severely plastic deformed Aluminum-Manganese-Silicon alloy. Arch. Civ. Mech. Eng. 2016, 16, 876–887. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø. Process modelling applied to 6082-T6 aluminium weldments—I. Reaction kinetics. Acta Metall. Mater. 1991, 39, 2693–2702. [Google Scholar] [CrossRef]

- Hu, B.; Richardson I, M. Microstructure and mechanical properties of AA7075 (T6) hybrid laser/GMA welds. Mater. Sci. Eng. A 2007, 459, 94–100. [Google Scholar] [CrossRef]

- Moor, P.L.; Howse, D.S.; Wallach, E.R. Development of Nd: YAG laser and laser/MAG hybrid welding for land pipeline application. Weld. Cut. 2004, 3, 174–180. [Google Scholar]

| Elements | Mg | Si | Fe | Zn | Cu | Al |

|---|---|---|---|---|---|---|

| 6061-T6 (BM) | 1.00 | 0.55 | 0.36 | 0.01 | 0.26 | Bal |

| ER5356 (filler wire) | 5.10 | 0.20 | 0.20 | 0.10 | 0.01 | Bal |

| Material | Ultimate Tensile Strength (MPa) | Elongation (%) | Vickers Hardness (Hv) |

|---|---|---|---|

| 6061-T6 (BM) | 340 | 19 | 115 |

| Arc Current (A) | Average Laser Power (W) | Welding Speed (mm·min−1) | Pulse Repetition Rate (Hz) | Peak Power (W) |

|---|---|---|---|---|

| 100–150 | 800–1000 | 500–700 | 40 | 6000~8500 |

| β (°) | h (mm) | d (mm) | α (°) | Dla (mm) |

| 50 | 1.5 | 1.5 | 45 | 2 |

| Arc Current (A) | Average Laser Power (W) | Welding Speed (mm·Min−1) | Pulse Repetition Rate (Hz) | Pulse Peak Power (W) | Filler Speed m/Min |

|---|---|---|---|---|---|

| 150 | 900 | 600 | 40 | 8000 | 2 |

| Joints | Ultimate Tensile Strength (MPa) | Elongation (%) | Joint Efficiency (%) | Fracture Positions of Tensile Specimens |

|---|---|---|---|---|

| BM | 330~340 | 18.7~19.4 | 100 | BM |

| HW | 230~240 | 14.30~15.71 | 66.8~70.8 | HAZ |

| AW (155 °C, 8 h) | 235~245 | 13.8~16.1 | 71.2~74.2 | HAZ |

| STA (520 °C) | 283~288 | 19.01~22.02 | 83.2~87 | FZ (Fusion zone) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Liu, X.; Liu, L. Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment. Metals 2020, 10, 130. https://doi.org/10.3390/met10010130

Wang H, Liu X, Liu L. Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment. Metals. 2020; 10(1):130. https://doi.org/10.3390/met10010130

Chicago/Turabian StyleWang, Hongyang, Xiaohong Liu, and Liming Liu. 2020. "Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment" Metals 10, no. 1: 130. https://doi.org/10.3390/met10010130

APA StyleWang, H., Liu, X., & Liu, L. (2020). Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment. Metals, 10(1), 130. https://doi.org/10.3390/met10010130