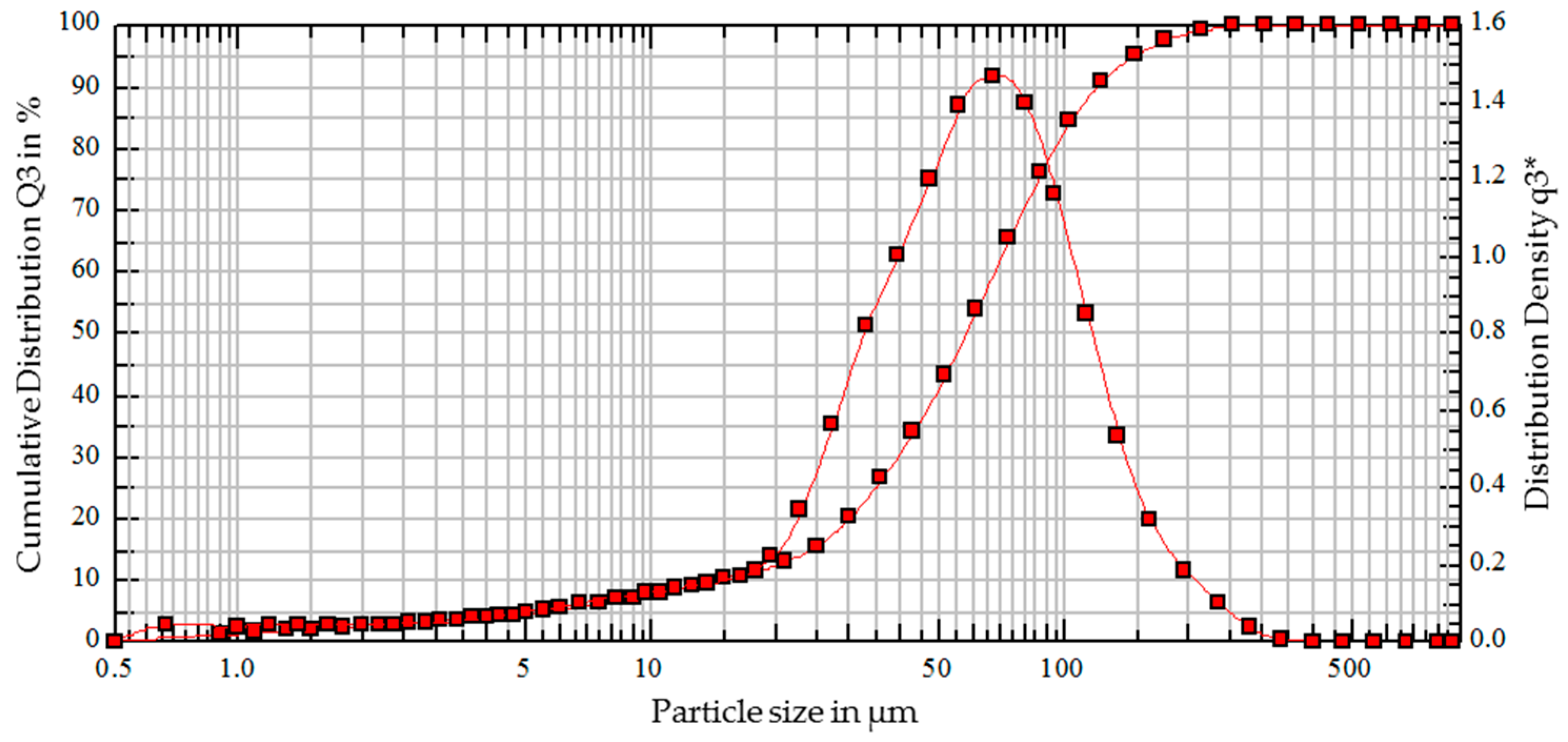

Figure 1.

Particle size distribution of the monazite concentrate used in the experiments (x10 = 14.80 µm, x50 = 57.55 µm, and x90 = 120.47 µm).

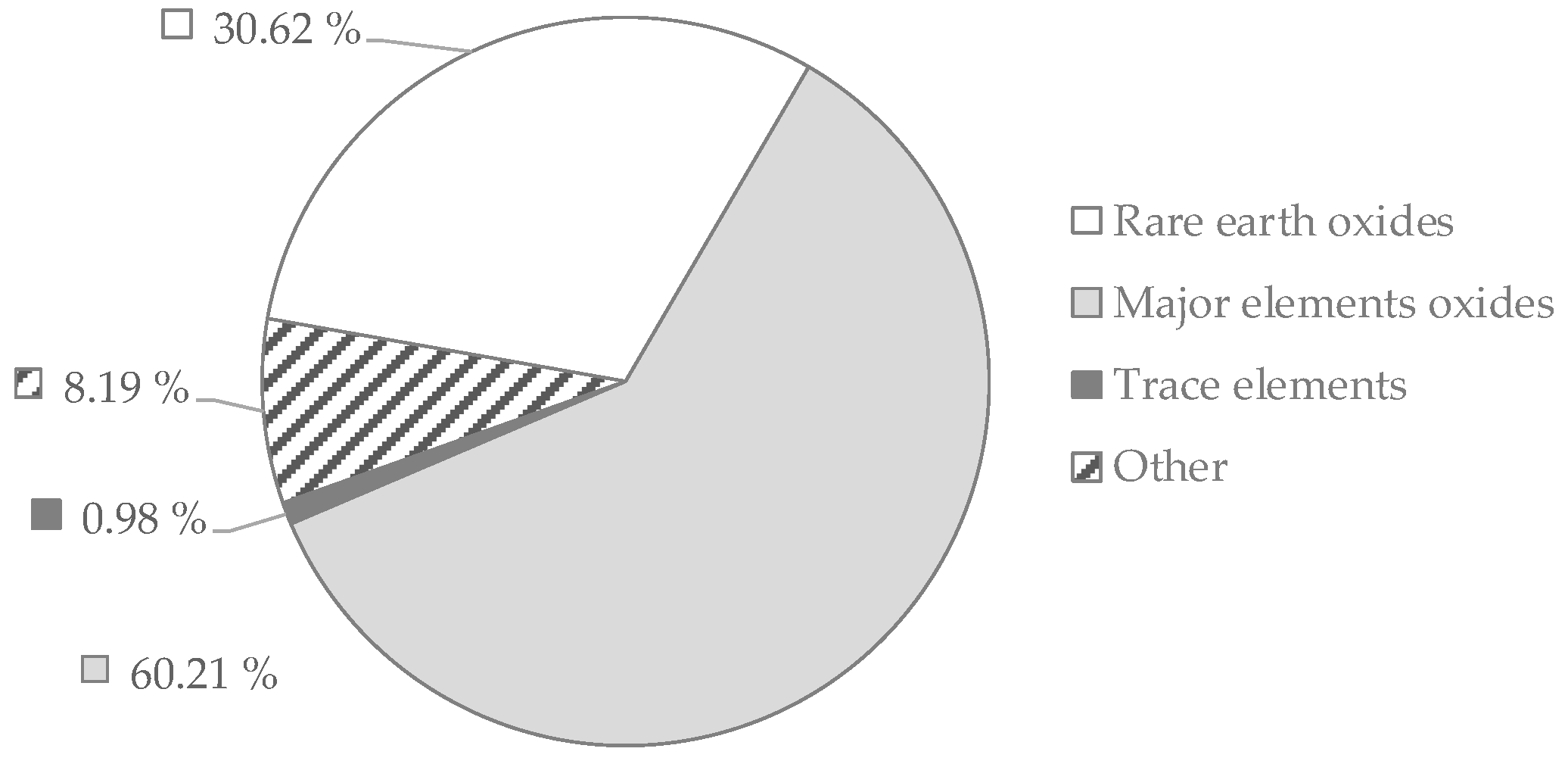

Figure 2.

Overview of the chemical composition of the monazite concentrate (MEO = oxides of major elements).

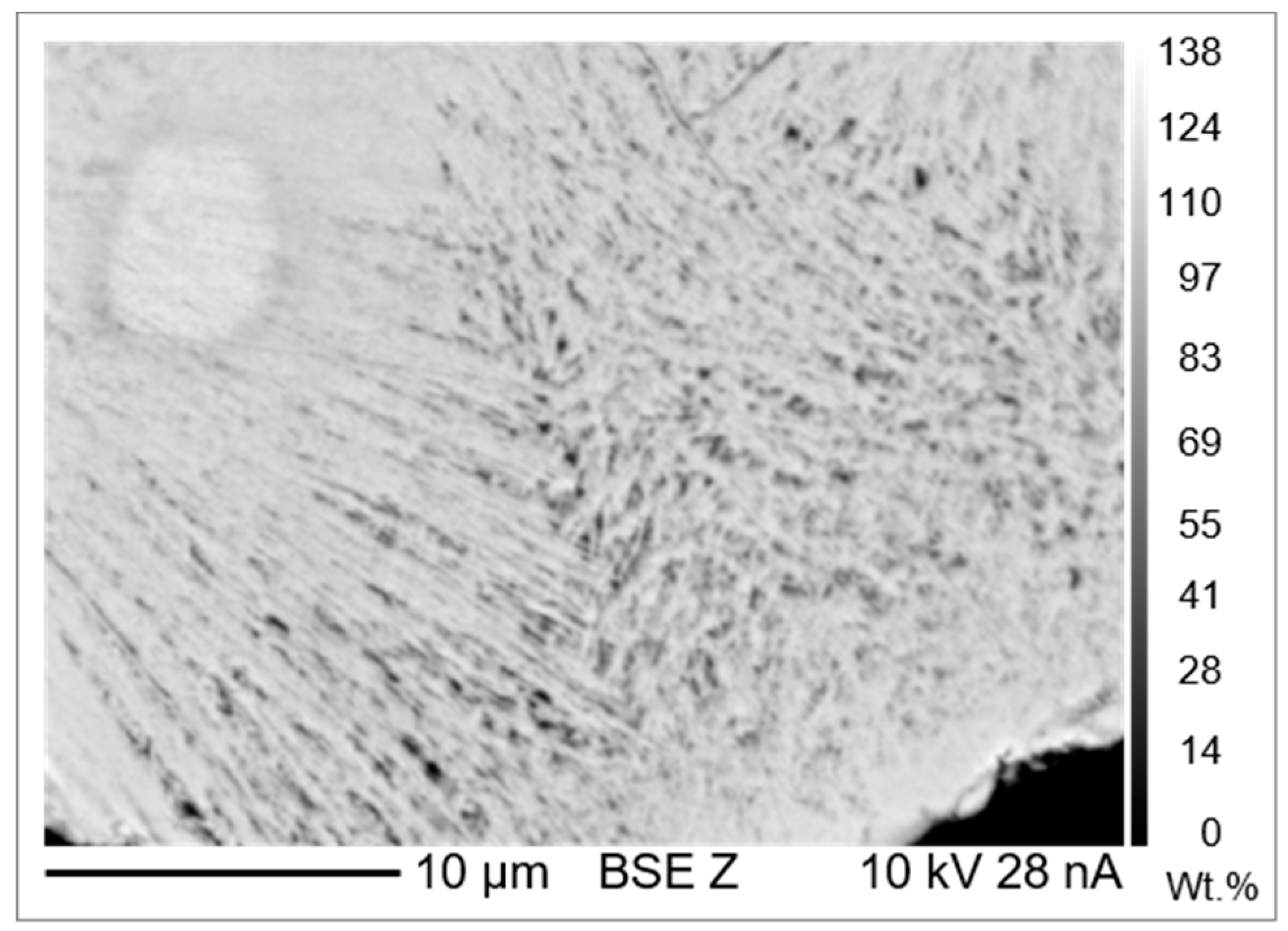

Figure 3.

Backscattered electron micrograph (BSE(Z)) image of a particle of the monazite concentrate showing the typical needle shaped crystallites of the monazite.

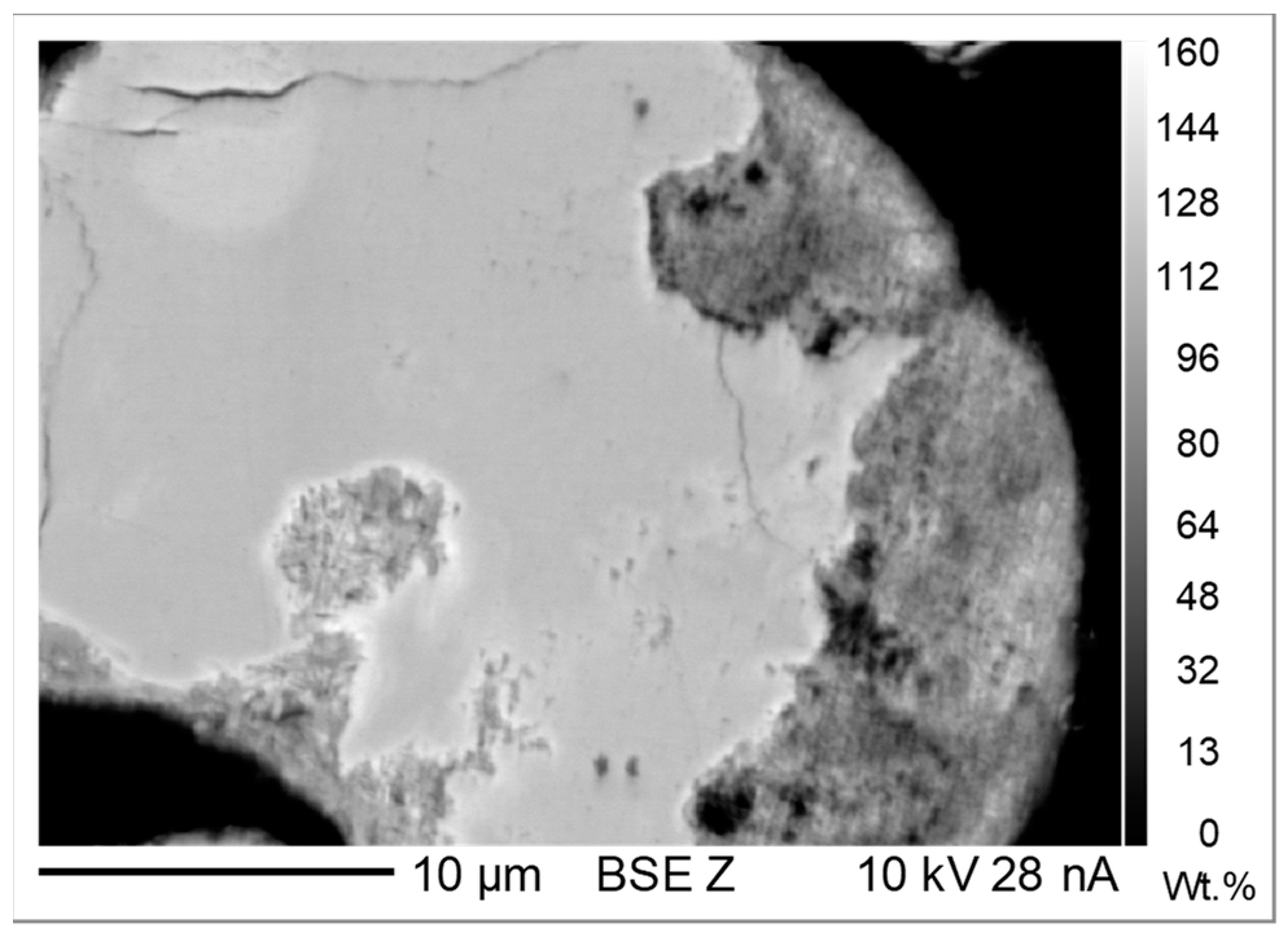

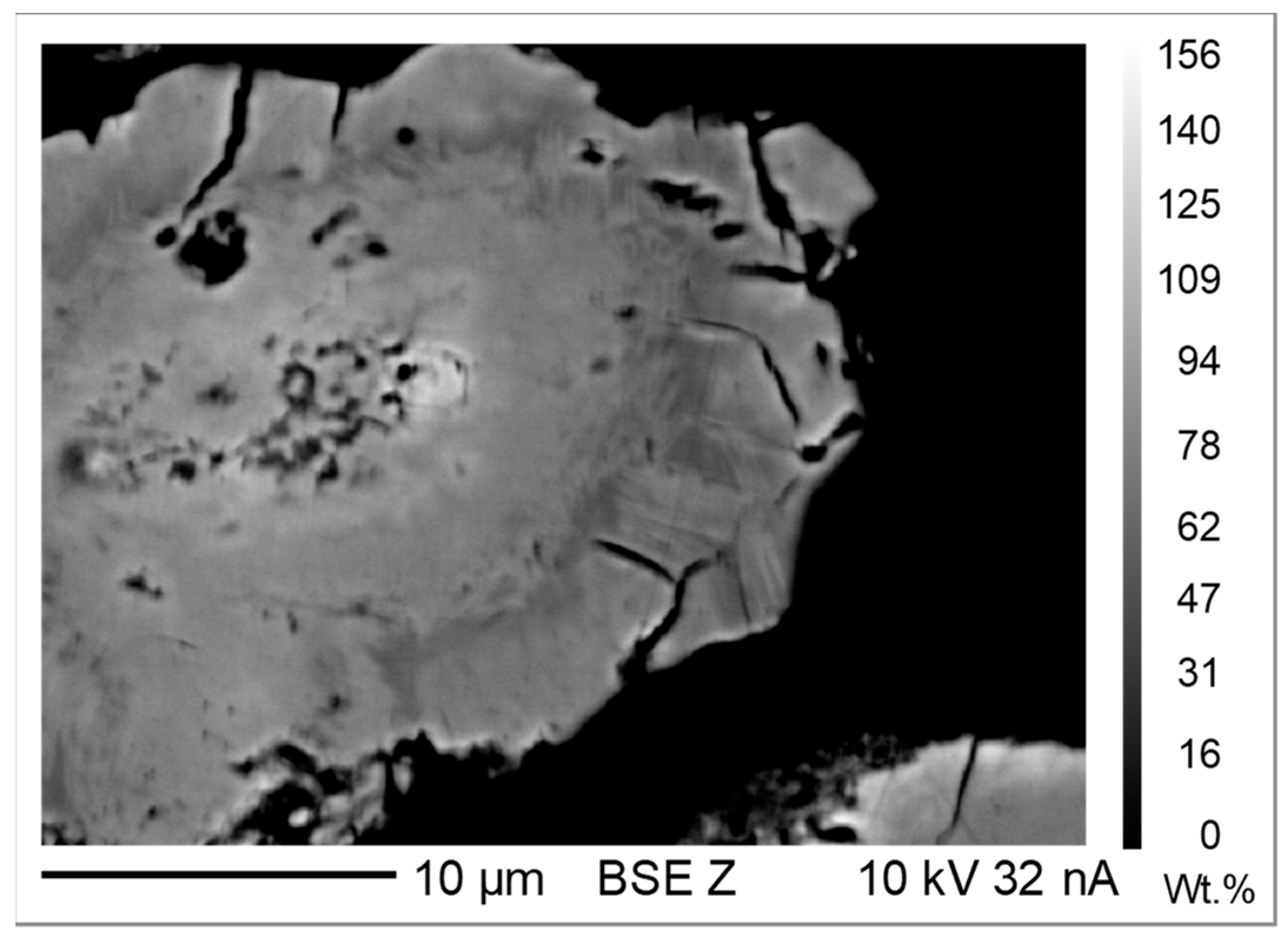

Figure 4.

Backscattered electron micrograph (BSE(Z)) of a monazite grain. The edges seem to be damaged by the sulfuric acid treatment.

Figure 5.

Backscattered electron micrograph (BSE(Z)) of the mineral phase containing up to 10.4 wt% thorium.

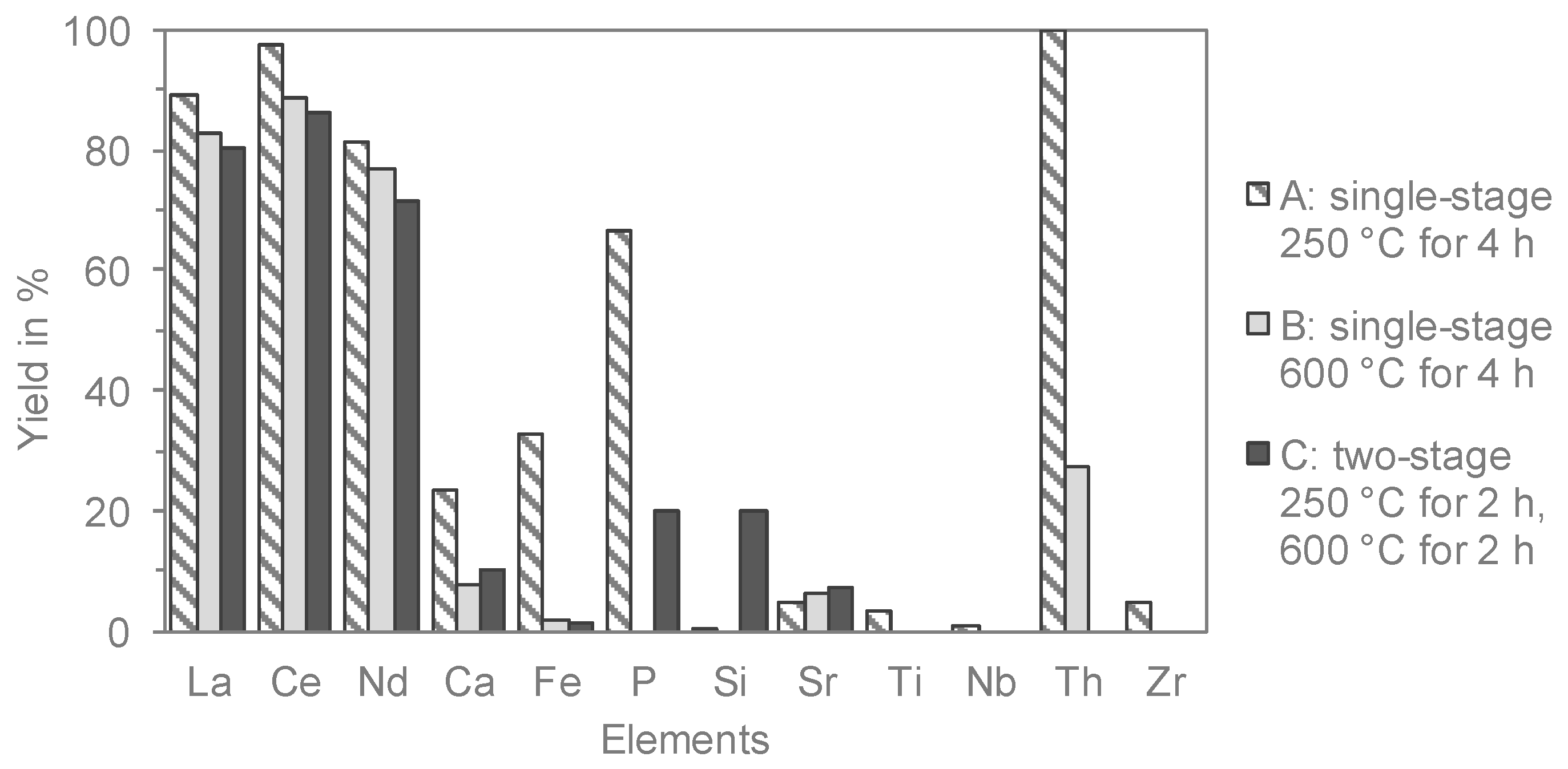

Figure 6.

Yields of elements after digestion with concentrated sulfuric acid at different temperatures and times. In all experiments, the ratio of concentrated sulfuric acid to rare earth oxide (REO) was 5. After digestion, the cake was leached with water at a solid:liquid (S:L) ratio of 10 for 1 h at room temperature.

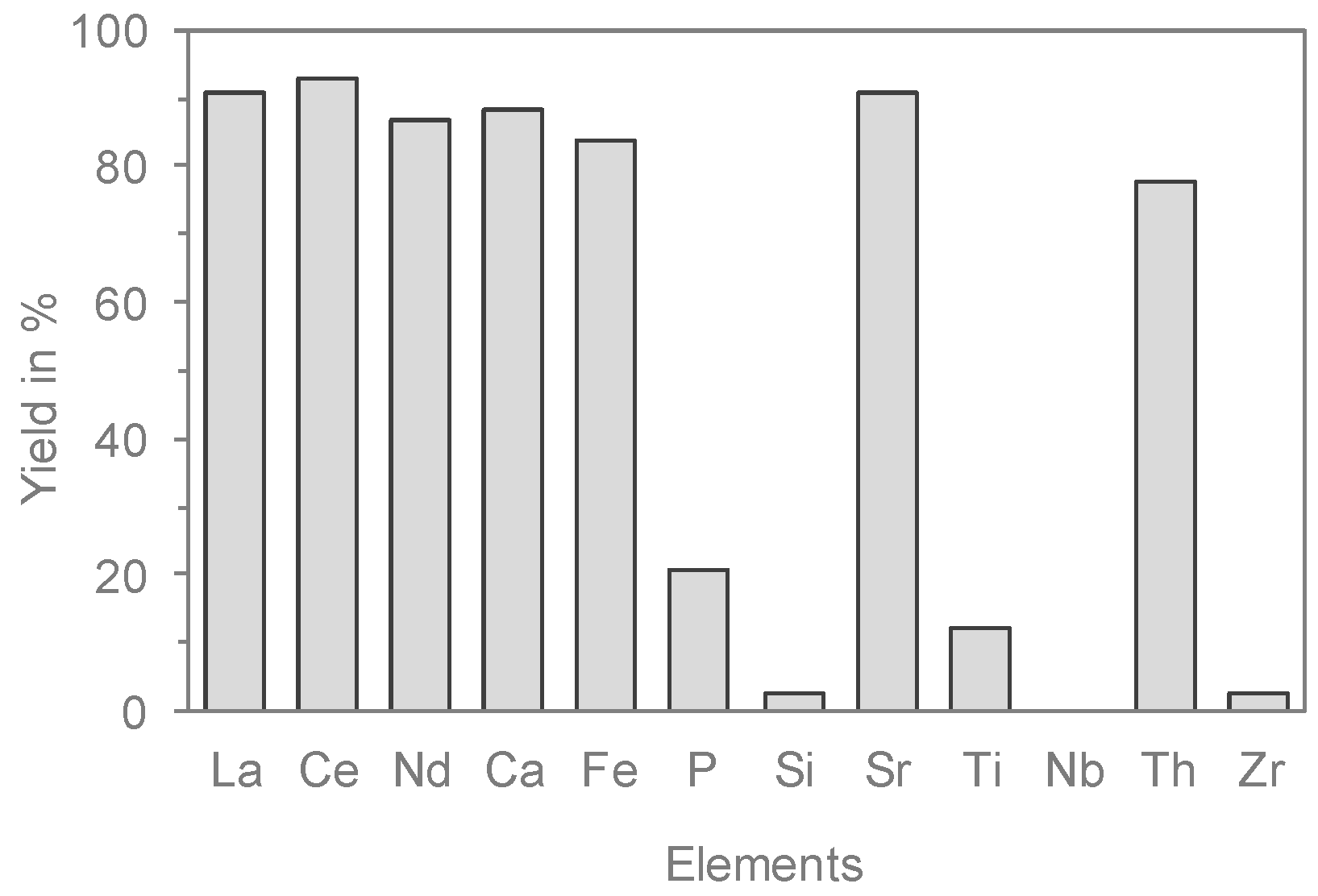

Figure 7.

Yields of elements after digestion with caustic soda. The concentrate was mixed with a ratio of caustic soda to REO of 5 and baked for 4 h at 150 °C. After baking, the residue was leached with deionized water at a S:L ratio of 20 for 30 min at 80 °C. Then, the residue was leached in 6 M hydrochloric acid at a S:L ratio of 25 for 1 h at room temperature.

Figure 8.

Normal plot of residuals for the response “Yield Ce.”

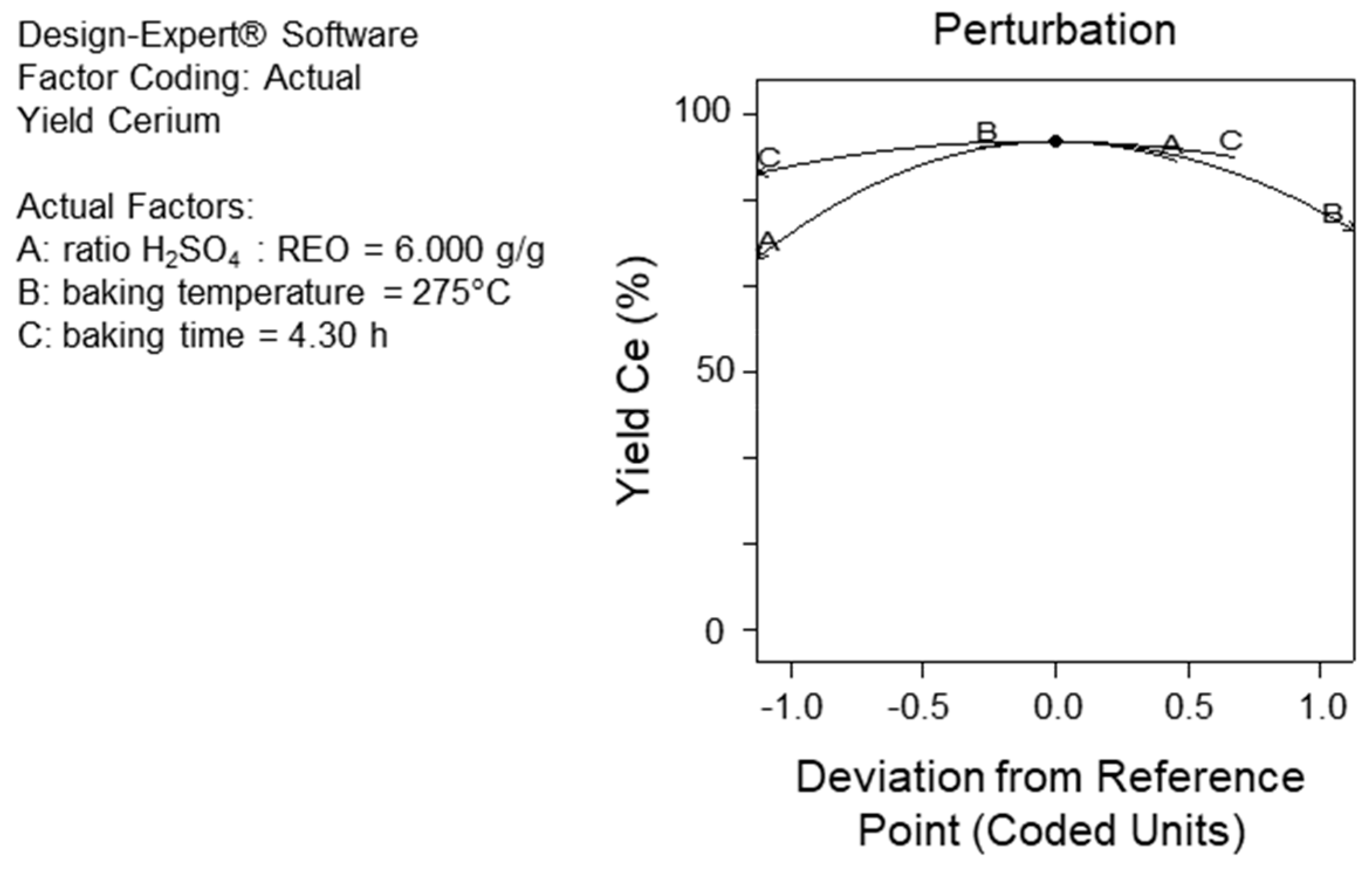

Figure 9.

Perturbation plot for the response “Yield Ce.”

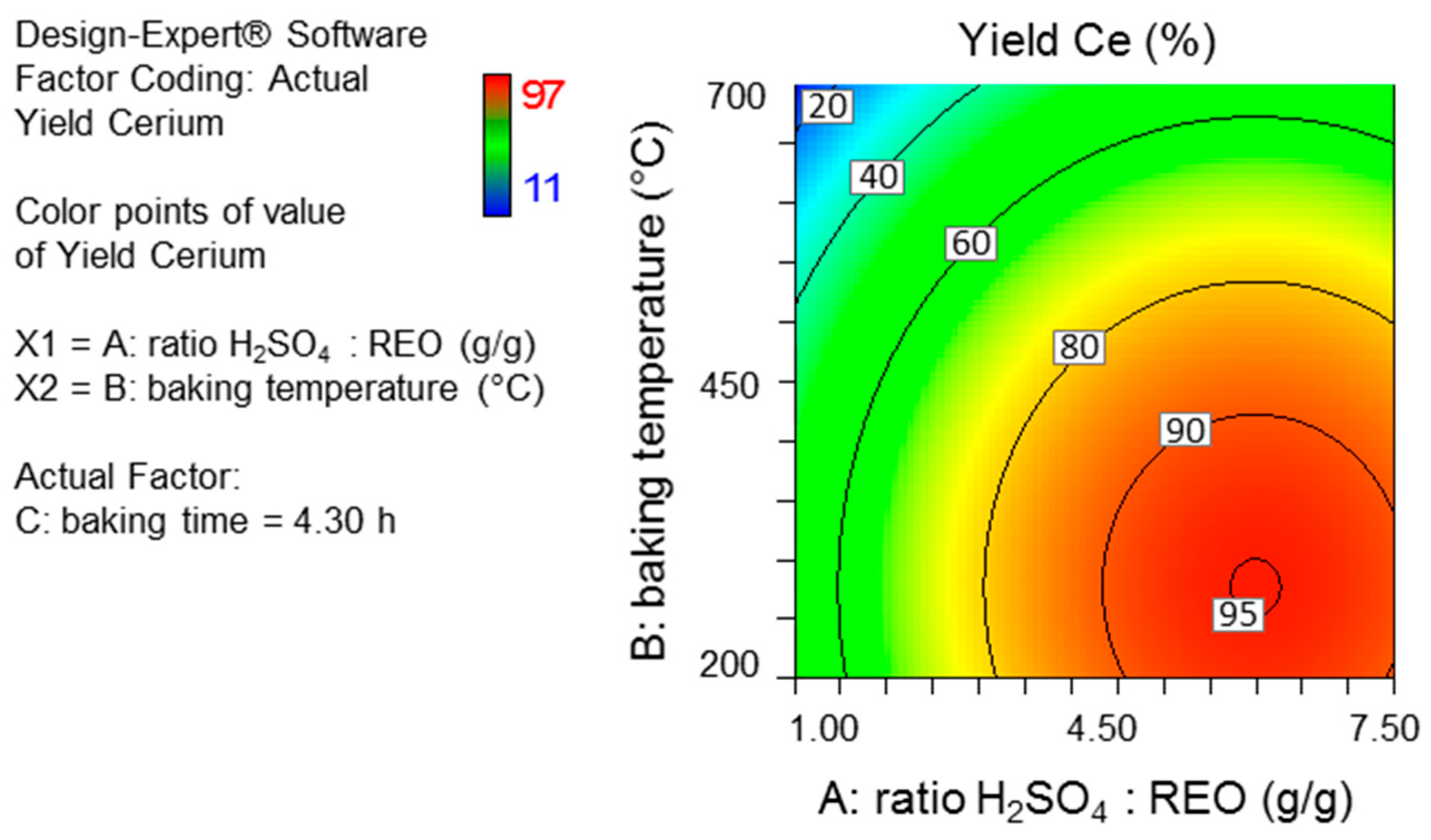

Figure 10.

Contour diagram for the response “Yield Ce” for the combined effects ratio of H2SO4 to REO and baking temperature. The baking time was set to 4.3 h.

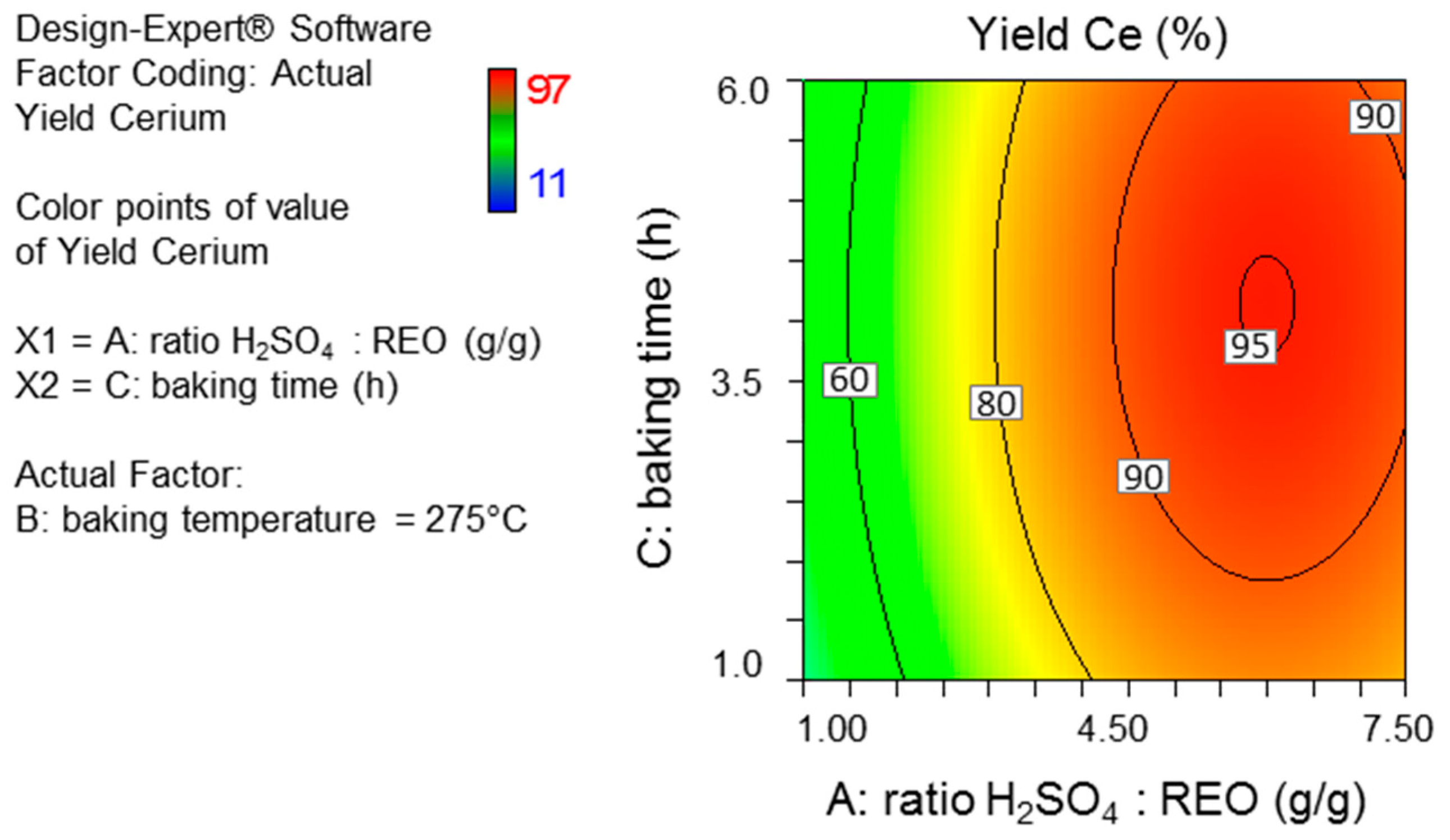

Figure 11.

Contour diagram for the response “Yield Ce” for the combined effects of ratio of H2SO4 to REO and baking time. The baking temperature is set to 275 °C.

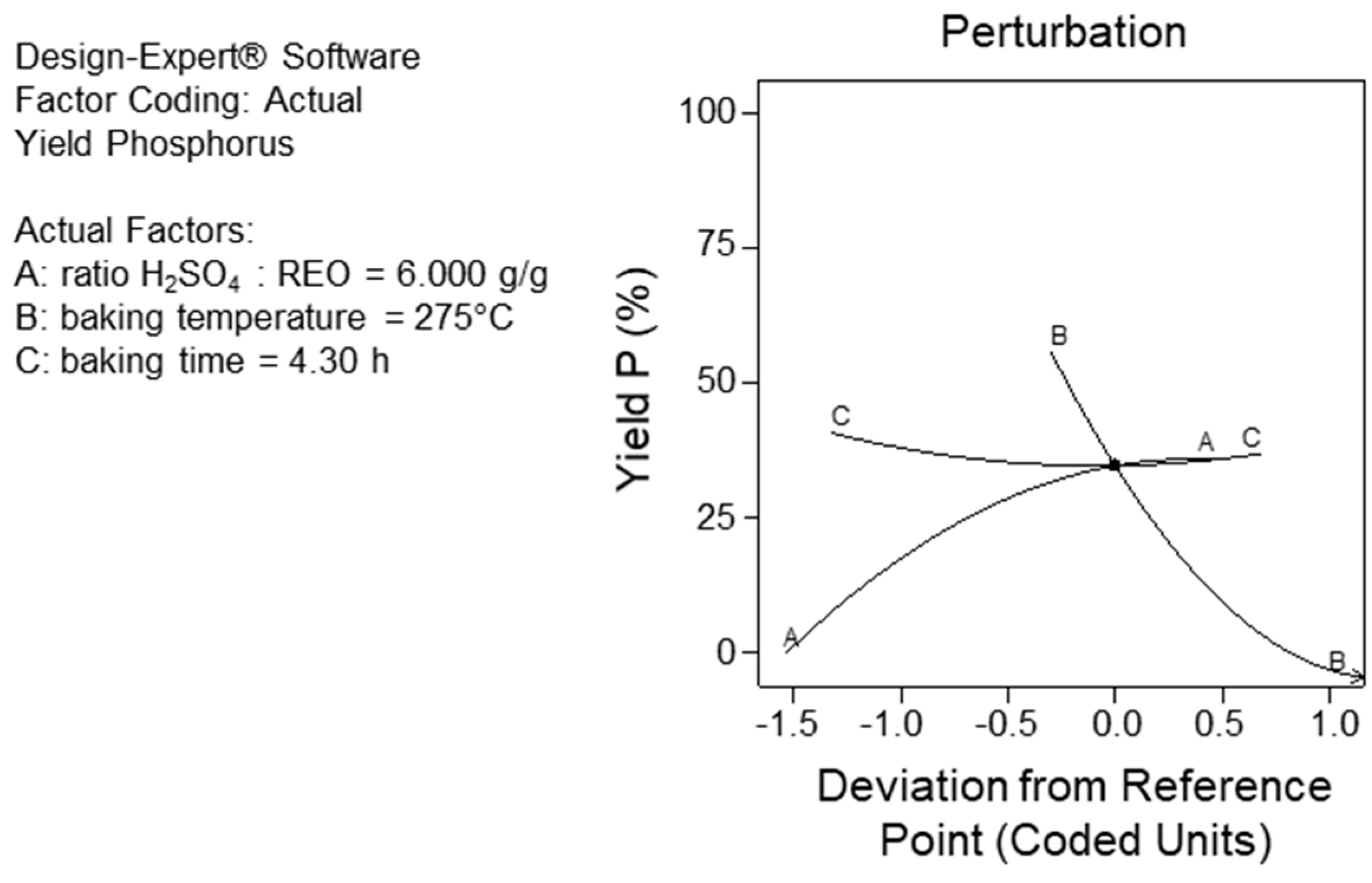

Figure 12.

Perturbation plot for the response “Yield P.”

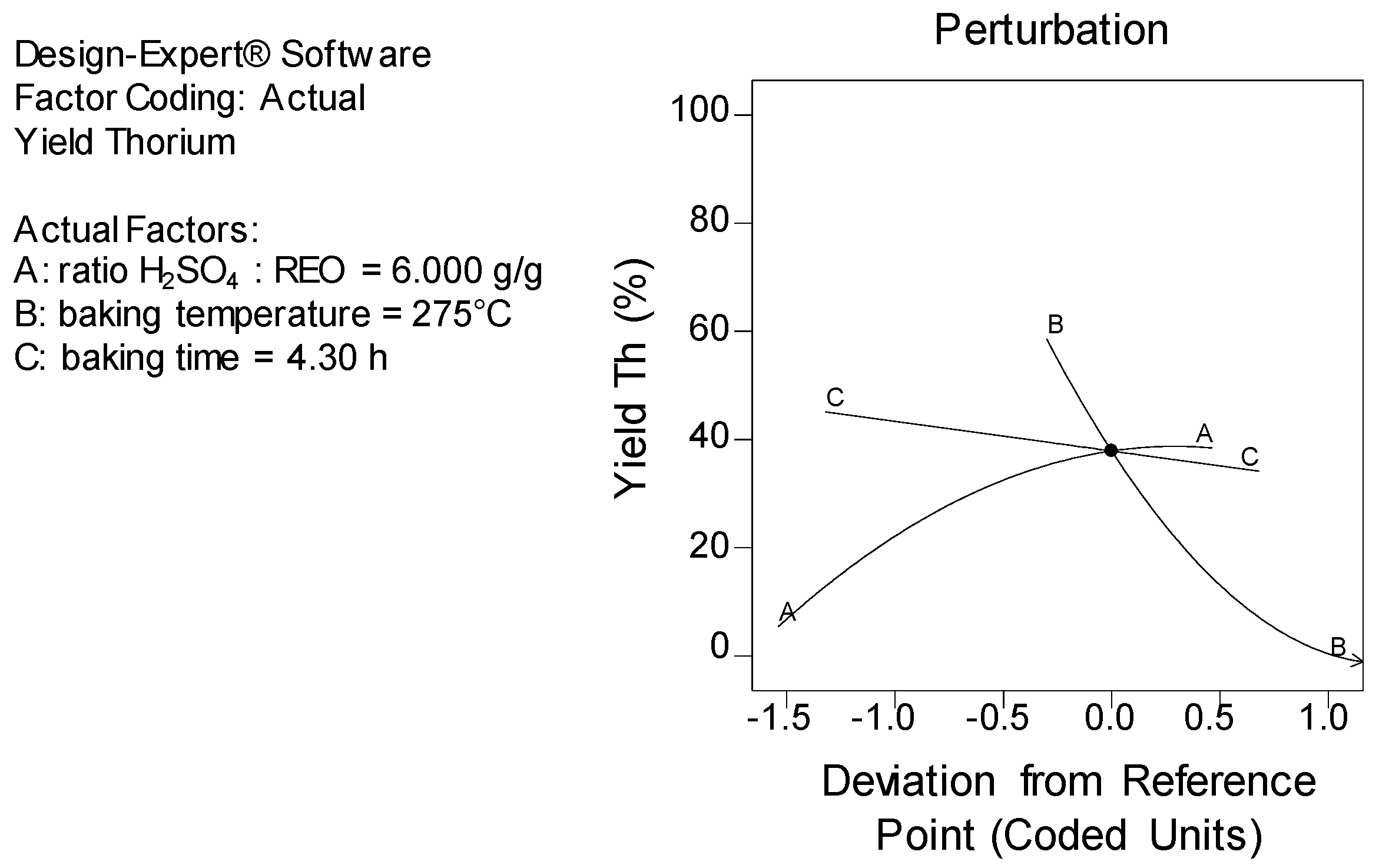

Figure 13.

Perturbation plot for the response “Yield Th.”

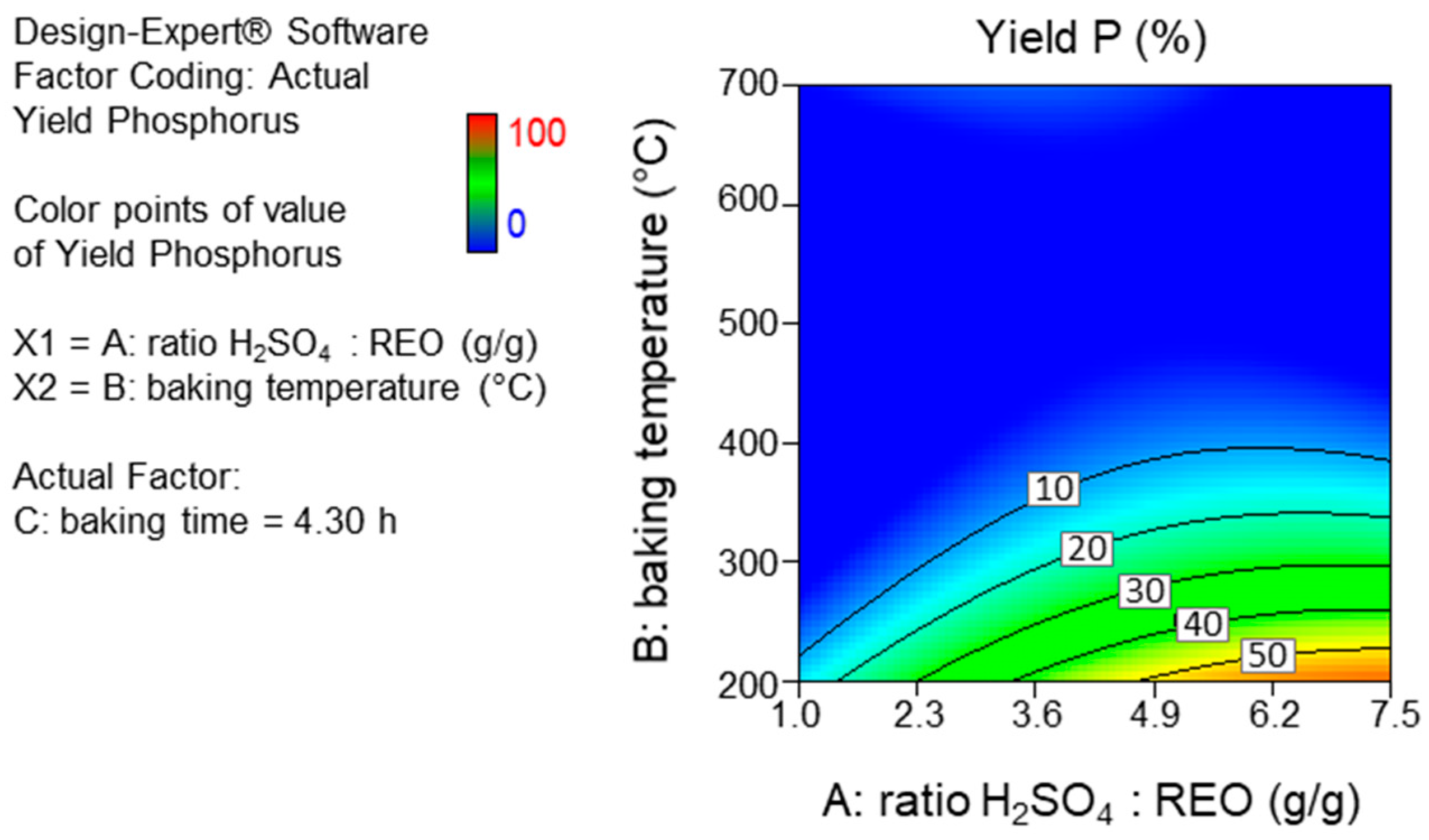

Figure 14.

Contour diagram for the response “Yield P” for the combined effects of ratio of H2SO4 to REO and baking temperature. The baking time was set to 4.3 h.

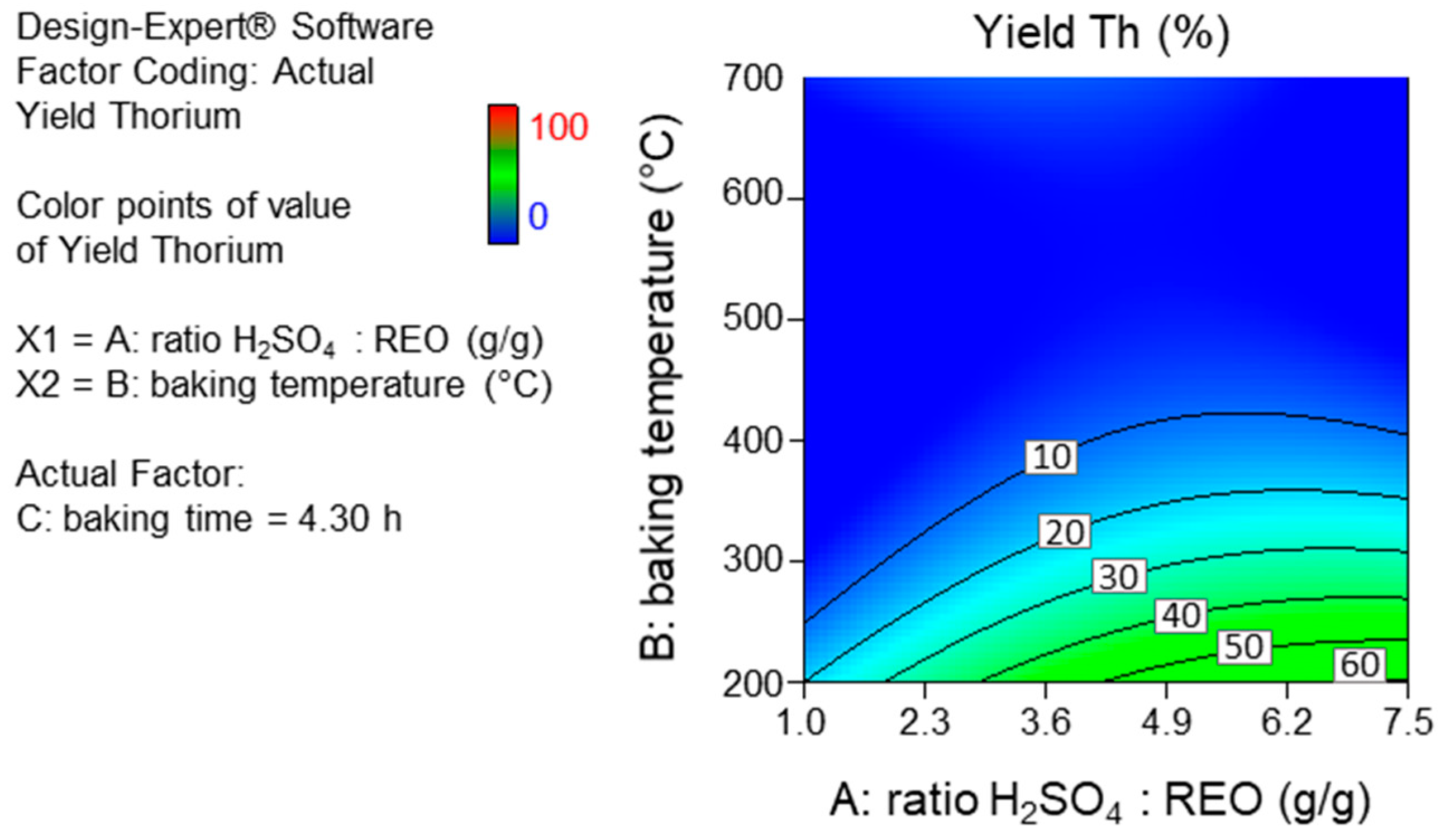

Figure 15.

Contour diagram for the response “Yield Th” for the combined effects of ratio of H2SO4 to REO and baking temperature. The baking time was set to 4.3 h.

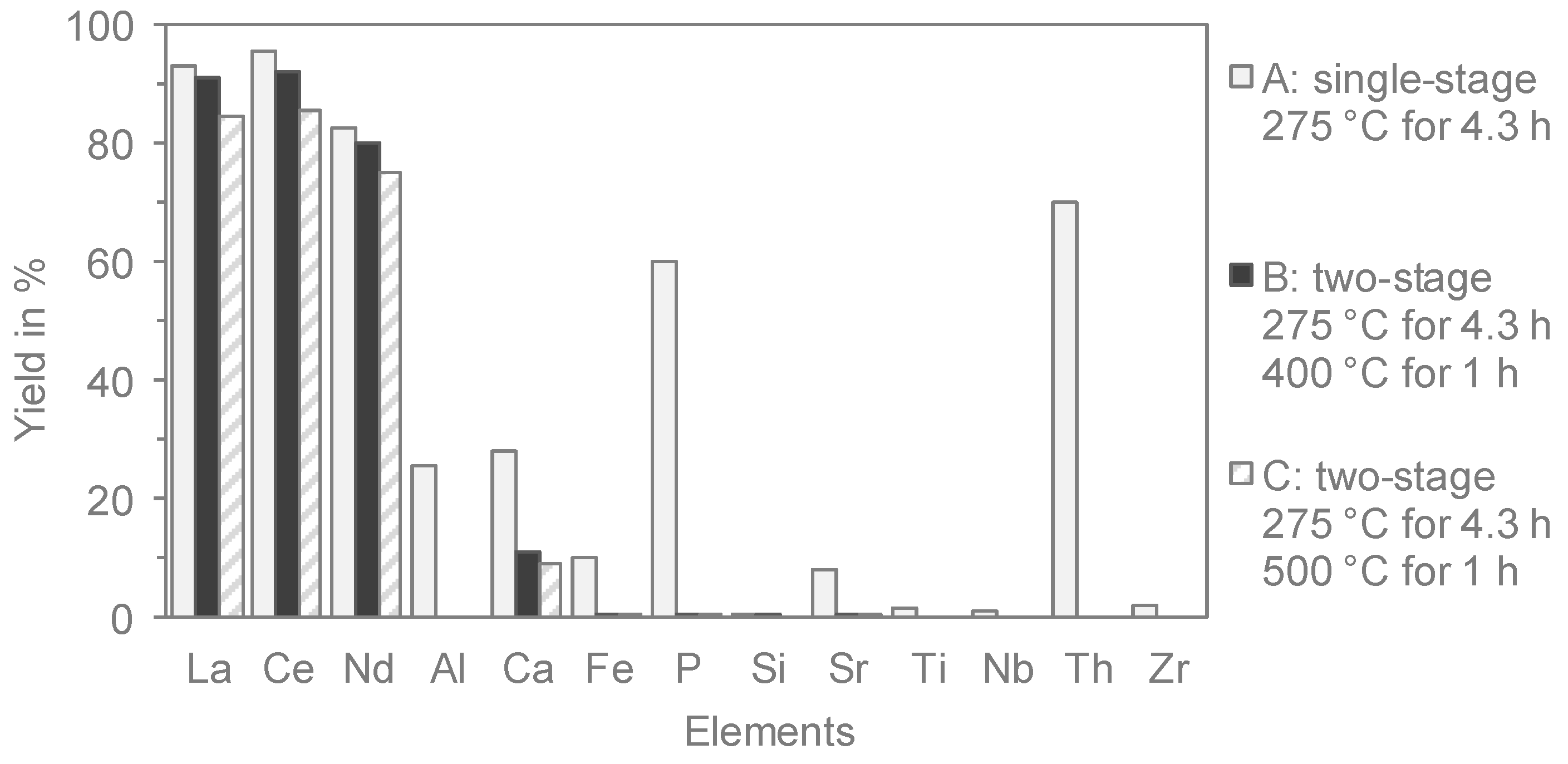

Figure 16.

Yield of elements after digestion with concentrated sulfuric acid. In all experiments, the concentrated ratio of sulfuric acid to REO was 6. In Experiment A, a single-stage digestion was executed. In Experiments B and C, a second temperature stage was added. After digestion, the cake was leached with water at a S:L ratio of 10 for 1 h at room temperature.

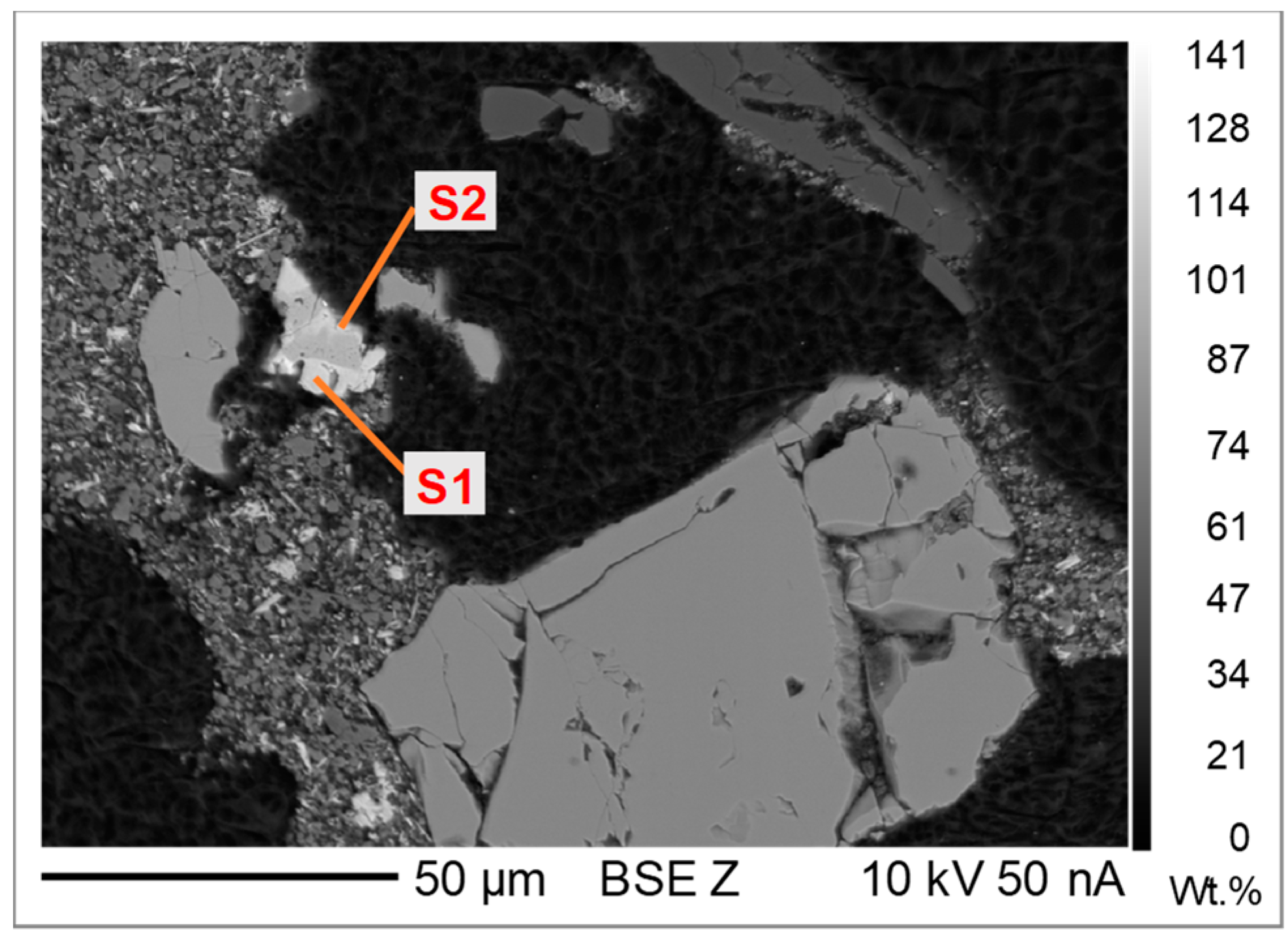

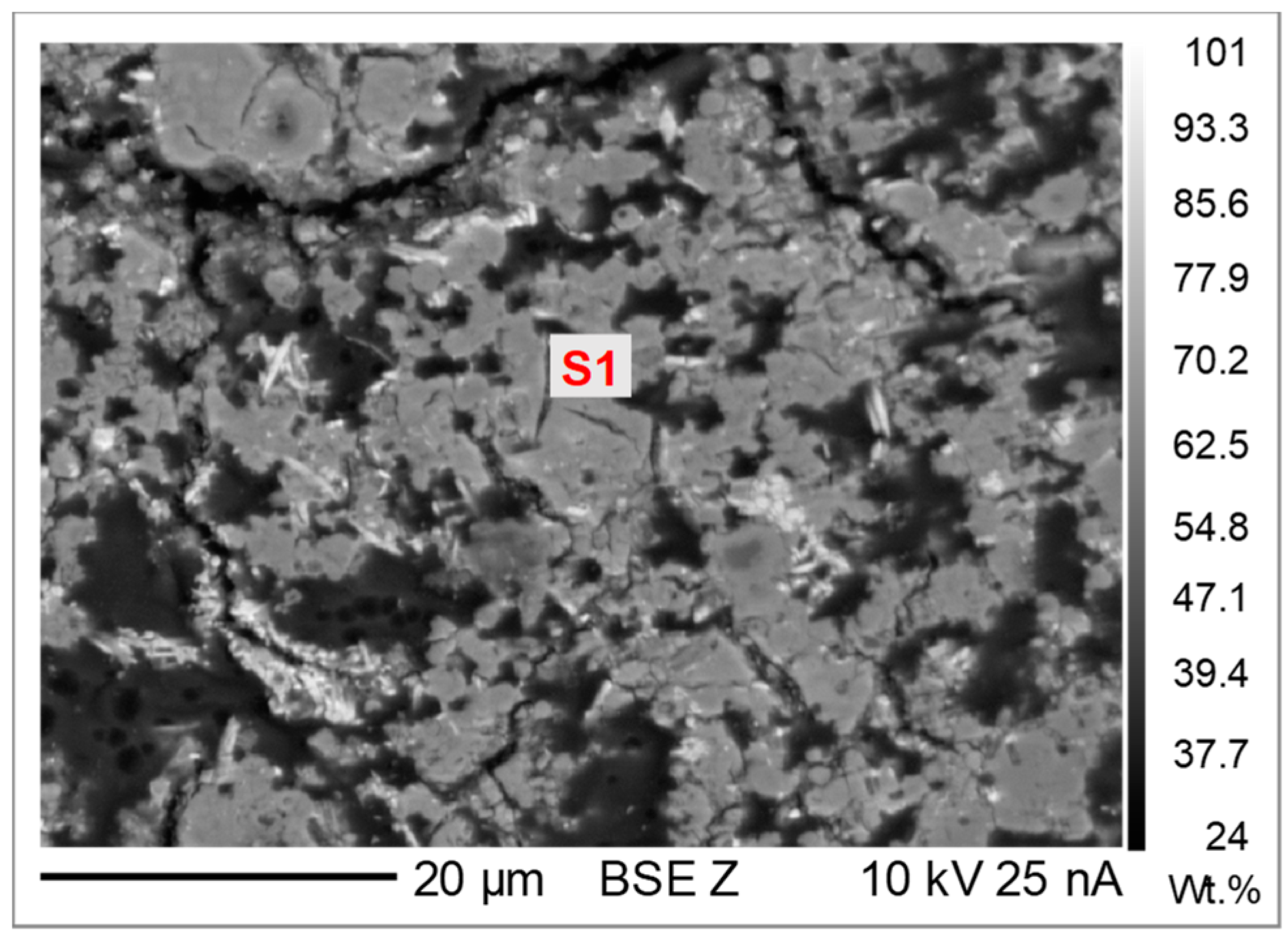

Figure 17.

Backscattered electrons image of insoluble (Sr,Ba,Ca)SO4 crystals marked with S1 and S2.

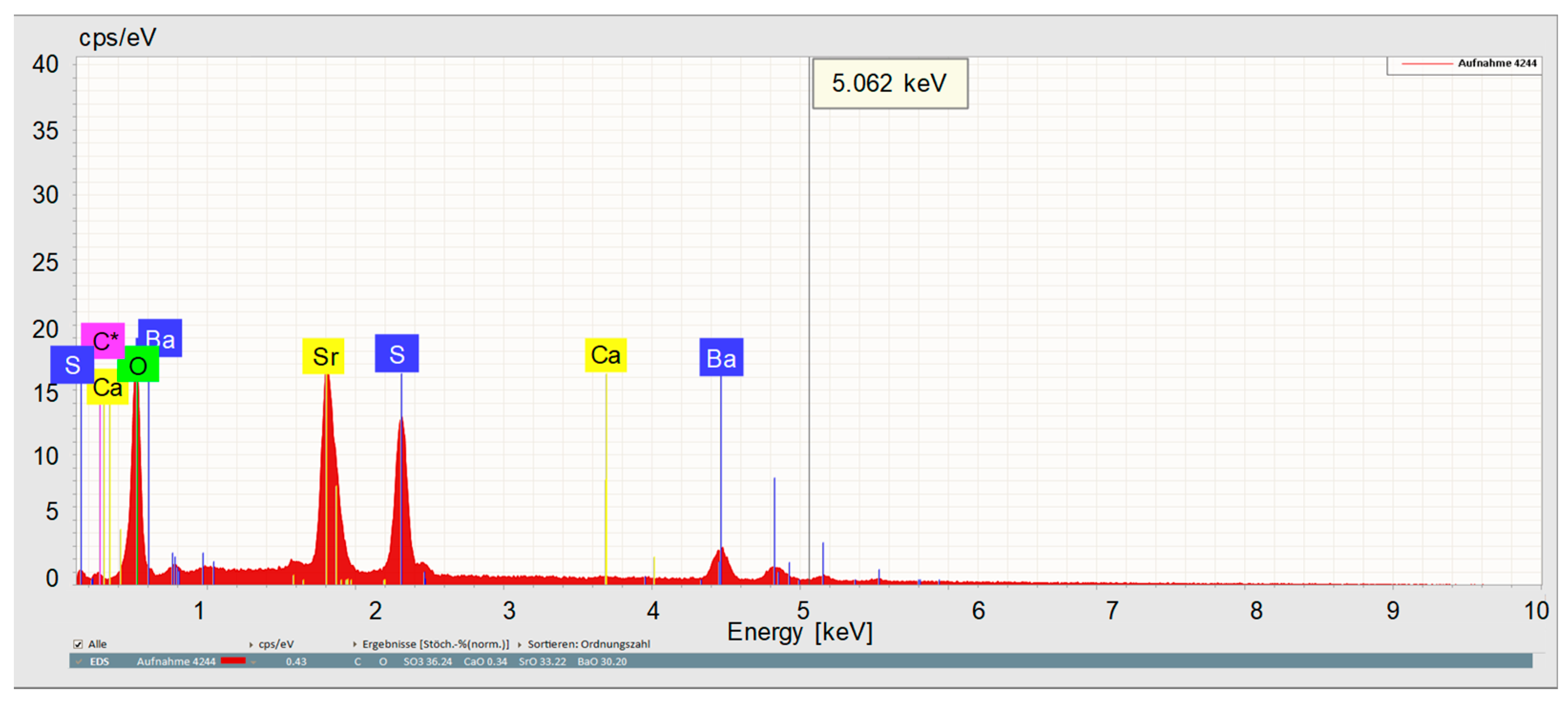

Figure 18.

Spectrum of the sulfate crystal S1 shown in

Figure 17.

Figure 19.

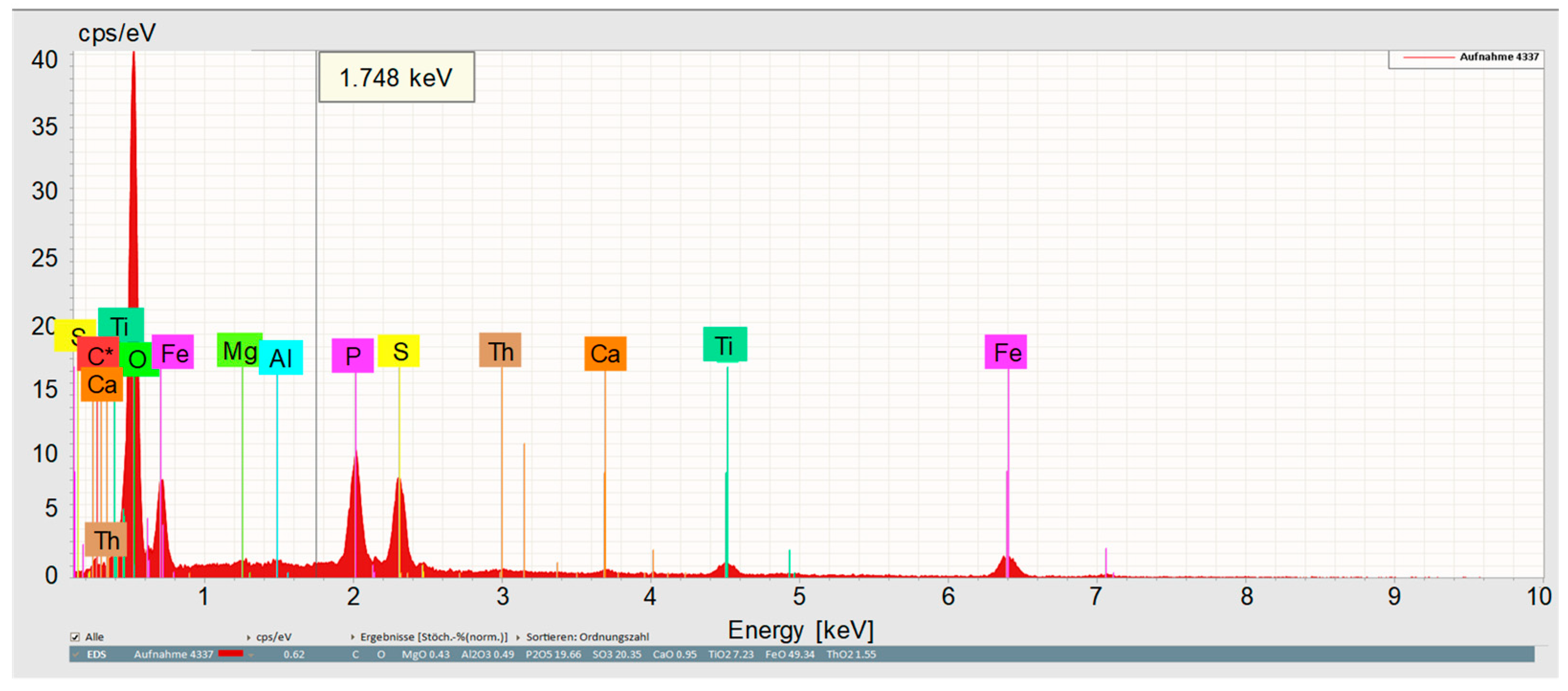

Backscattered electron image of the delicate flakes found in the residue.

Figure 20.

Spectrum of the flake shown in

Figure 19, showing phosphorus and sulfur peaks.

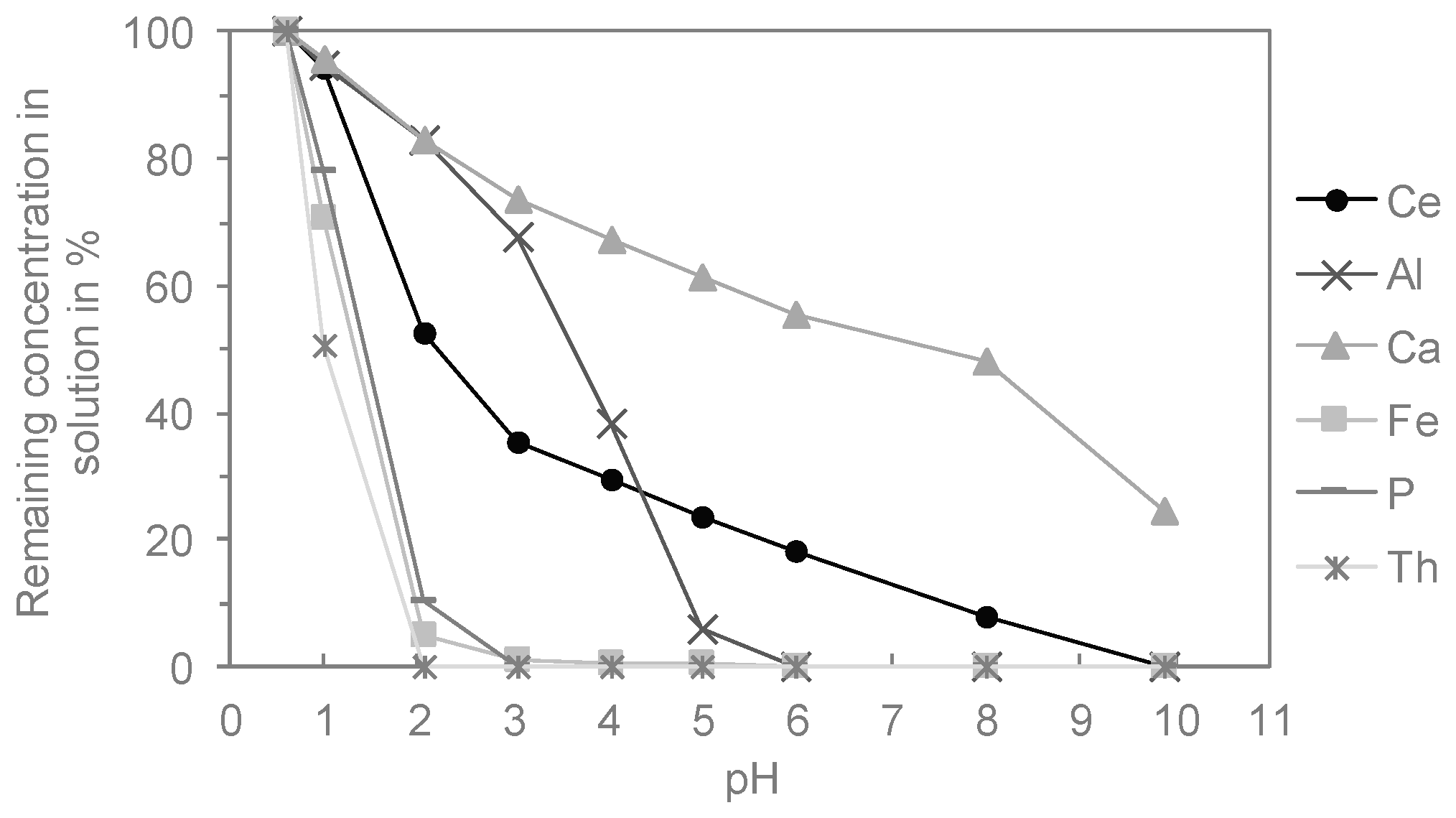

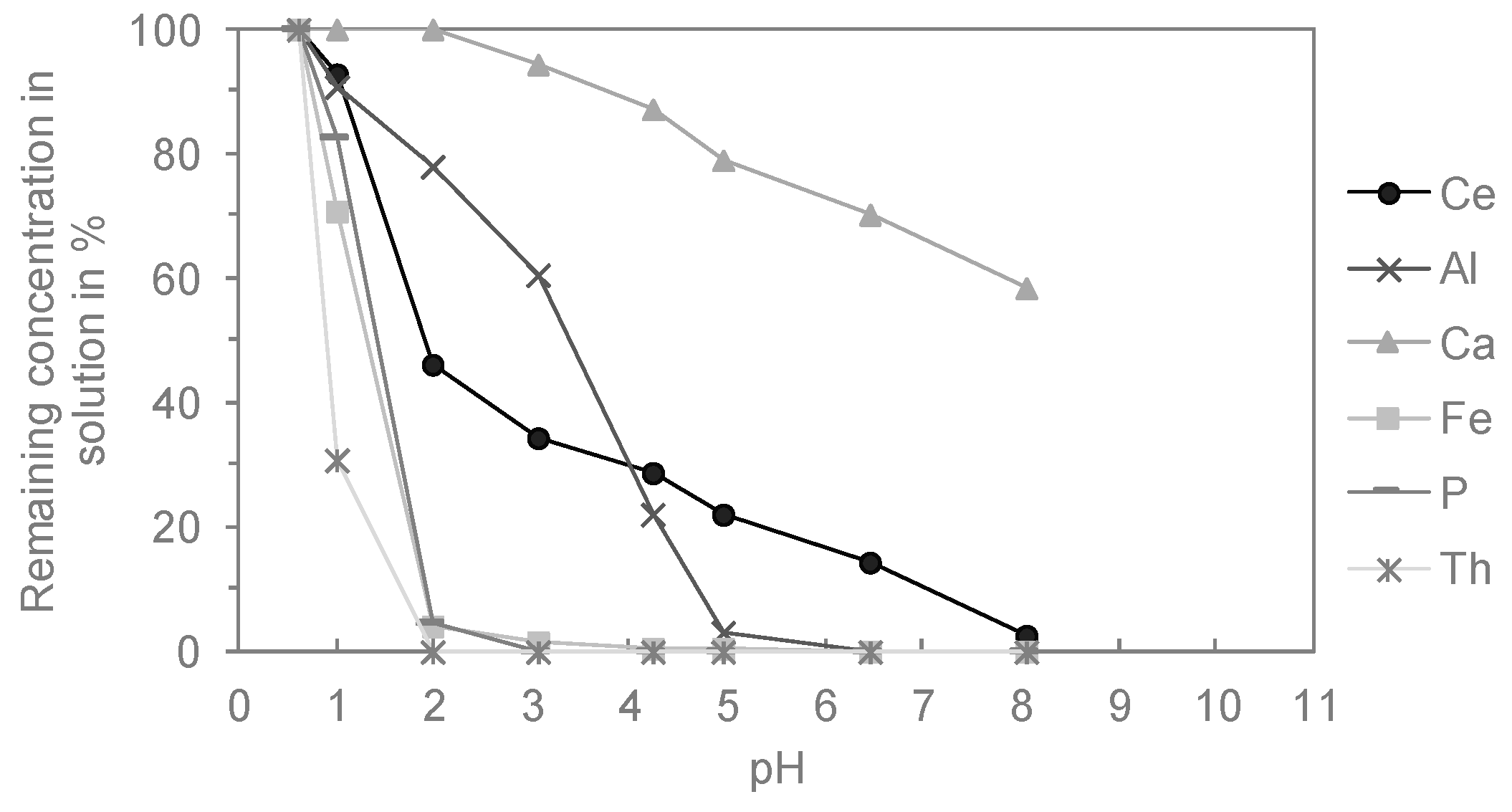

Figure 21.

Purification of the leachate solution with high impurity content. Ammonium solution (10 wt%) was used as precipitation agent.

Figure 22.

Purification of the leachate solution with high impurity content. Magnesium oxide suspension (100 g/L) was used as precipitation agent.

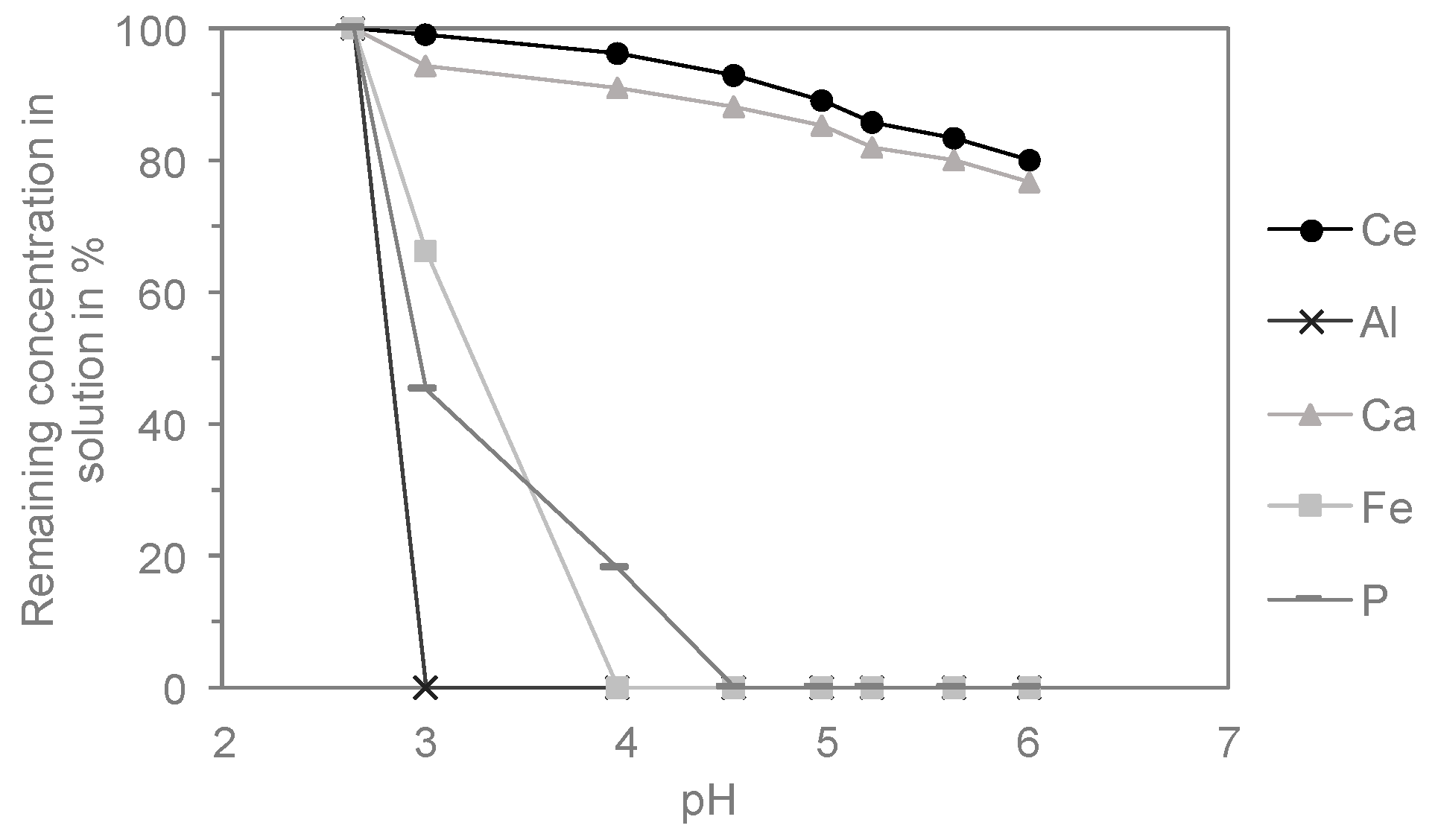

Figure 23.

Purification of the leachate solution with low impurity content. An ammonium solution (3 wt%) was used as the precipitation agent.

Table 1.

Chemical composition of the monazite concentrate. All elements with a weight percentage ≥0.1 wt%, and uranium, are given.

| Rare Earth Elements | Content | Major Elements | Content | Trace Elements | Content |

|---|

| | wt% | | wt% | | wt% |

|---|

| La | 7.92 | Al | 0.13 | Nb | 0.45 |

| Ce | 11.80 | Ba | 1.22 | Th | 0.20 |

| Pr | 1.21 | Ca | 5.57 | U | 0.03 |

| Nd | 4.31 | Fe | 5.74 | Zr | 0.28 |

| Sm | 0.39 | K | 0.28 | | |

| Gd | 0.18 | Mg | 0.25 | | |

| Y | 0.18 | Mn | 0.16 | | |

| | | P | 6.13 | | |

| | | Si | 1.88 | | |

| | | Sr | 2.35 | | |

| | | Ti | 5.53 | | |

Table 2.

Average composition of the monazite in the concentrate measured by electron microprobe analysis compared to the typical composition of a monazite standard reference [

25].

| Elements | EPMA | Analyzed Reference [25] |

|---|

| | wt% | wt% |

|---|

| La | 15.71 | 8.12 |

| Ce | 20.87 | 19.43 |

| Th | 0.07 | 9.24 |

| P | 12.30 | 12.13 |

| Nd | 6.32 | 9.58 |

Table 3.

Factors and chosen levels of the digestion for the design of experiment.

| Factor | Units | Low Level | High Level |

|---|

| A: ratio H2SO4: REO | g/g | 1 | 7.5 |

| B: baking temperature | °C | 200 | 700 |

| C: baking time | h | 1 | 6 |

Table 4.

Confirmation report for confirmation experiment with the following settings: 6.0 g/g ratio of H2SO4 to REO, 275 °C baking temperature, and 4.3 h baking time.

| Response | Predicted Mean | Standard Derivation | Predicted Interval Bounds |

|---|

| | | | 95% PI Low | Observed | 95% PI High |

|---|

| Yield La | 91.9 | 11.0 | 66.72 | 93.1 | 117.14 |

| Yield Ce | 95.0 | 12.0 | 67.45 | 95.4 | 121.88 |

| Yield Nd | 80.3 | 10.3 | 57.37 | 82.6 | 103.31 |

| Yield Ca | 26.2 | 5.2 | 14.71 | 28.2 | 37.79 |

| Yield Fe | 17.2 | 6.3 | 3.10 | 9.9 | 31.33 |

| Yield P | 34.6 | 11.2 | 8.76 | 60.4 | 60.51 |

| Yield Sr | 11.4 | 4.0 | 2.76 | 8.3 | 20.10 |

| Yield Ti | 2.0 | 1.0 | −0.18 | 1.9 | 4.21 |

| Yield Th | 37.9 | 21.7 | −10.96 | 70.0 | 86.77 |

| Yield Zr | 1.2 | 1.2 | −1.33 | 2.1 | 3.70 |

Table 5.

Optimum process parameters for a selective extraction elements from the monazite concentrate based on DoE and additional experiments.

| Process Settings | Ratio of H2SO4: REO | Baking Temperature | Baking Time |

|---|

| | g/g | °C | h |

| First temperature stage | 6.0 | 275 | 4.3 |

| Second temperature stage | - | 400 | 1 |

Table 6.

Metal ion concentration of a typical leach solution with high impurity content.

| Element | La | Ce | Nd | Al | Ca | Fe | P | Th |

|---|

| Concentration [mg/L] | 3800 | 5800 | 1800 | 20 | 680 | 130 | 1500 | 70 |

Table 7.

Metal ion concentration of a typical leach solution with low impurity content.

| Element | La | Ce | Nd | Al | Ca | Fe | P | Th |

|---|

| Concentration [mg/L] | 3600 | 5500 | 1700 | <1 | 310 | 20 | 10 | <2 |

Table 8.

Composition of the mixed-RE carbonate.

| Element | La | Ce | Nd | Ca | Fe | Mg | P | Sr |

|---|

| Content [%] | 16.71 | 24.3 | 7.81 | 1.16 | 0.02 | 0.002 | 0.009 | 0.26 |