Impact of the LACKS of Fusion Induced by Additive Manufacturing on the Lubrication of a Gear Flank

Abstract

:1. Introduction

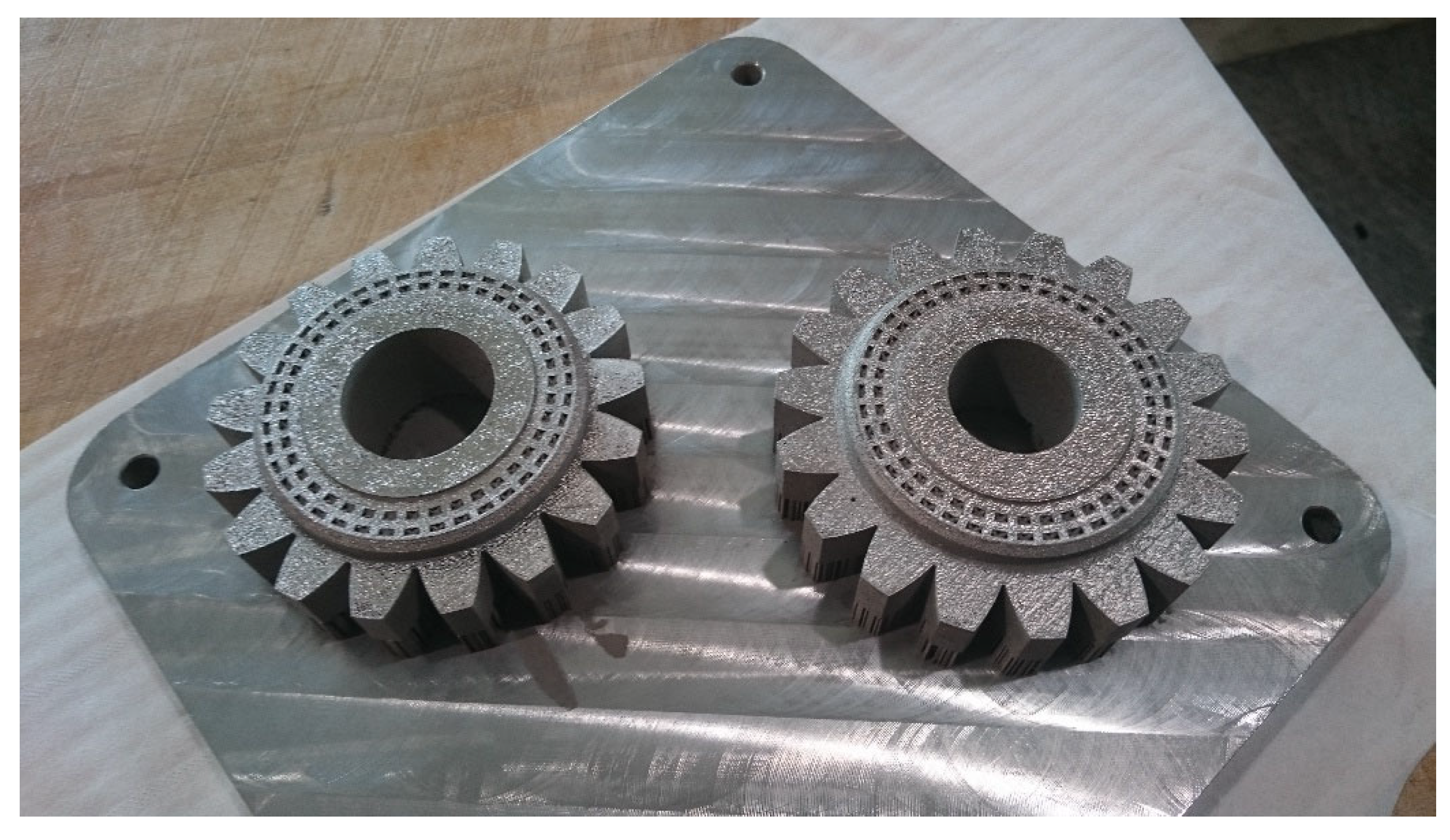

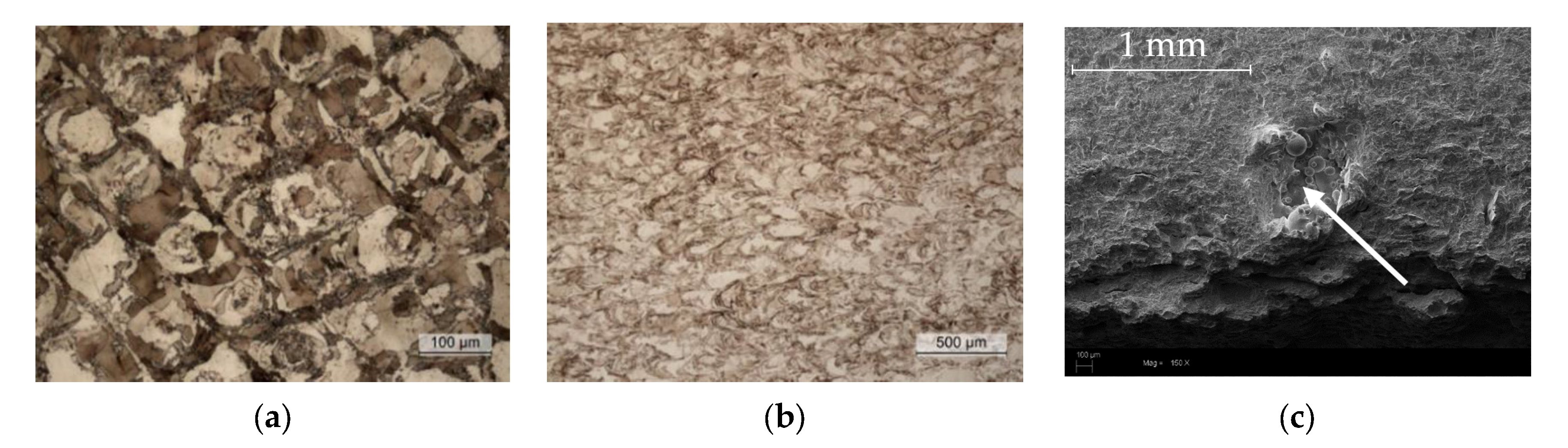

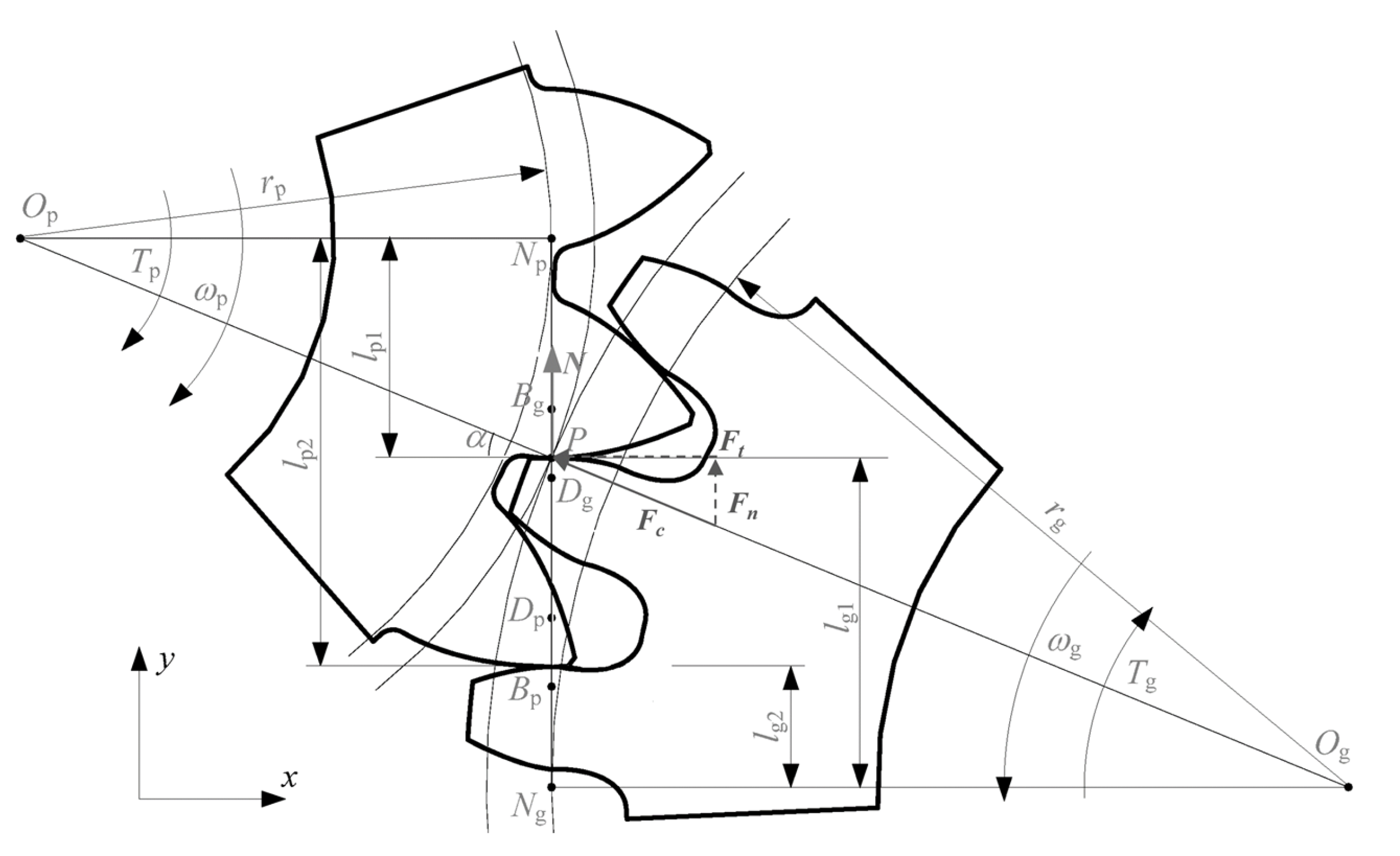

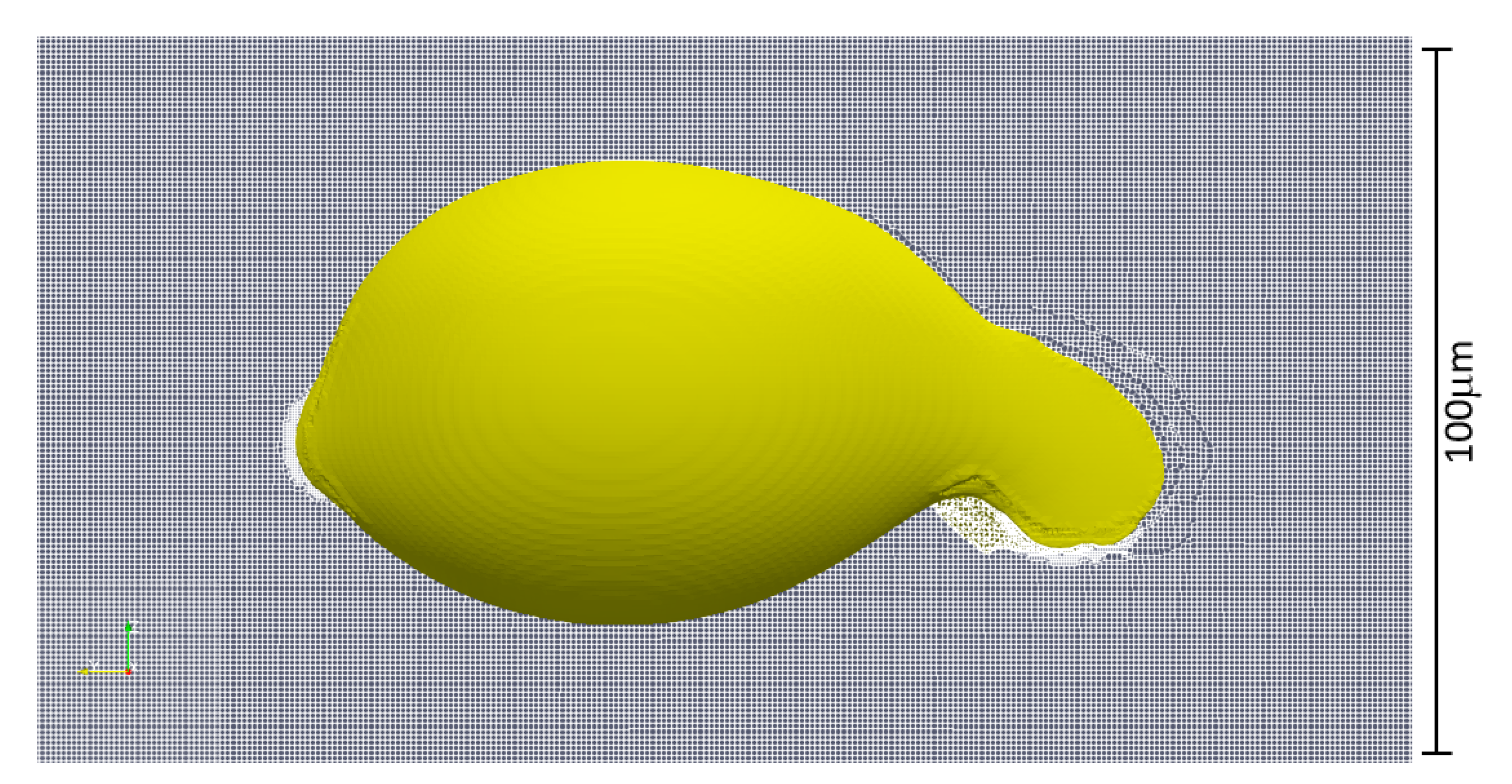

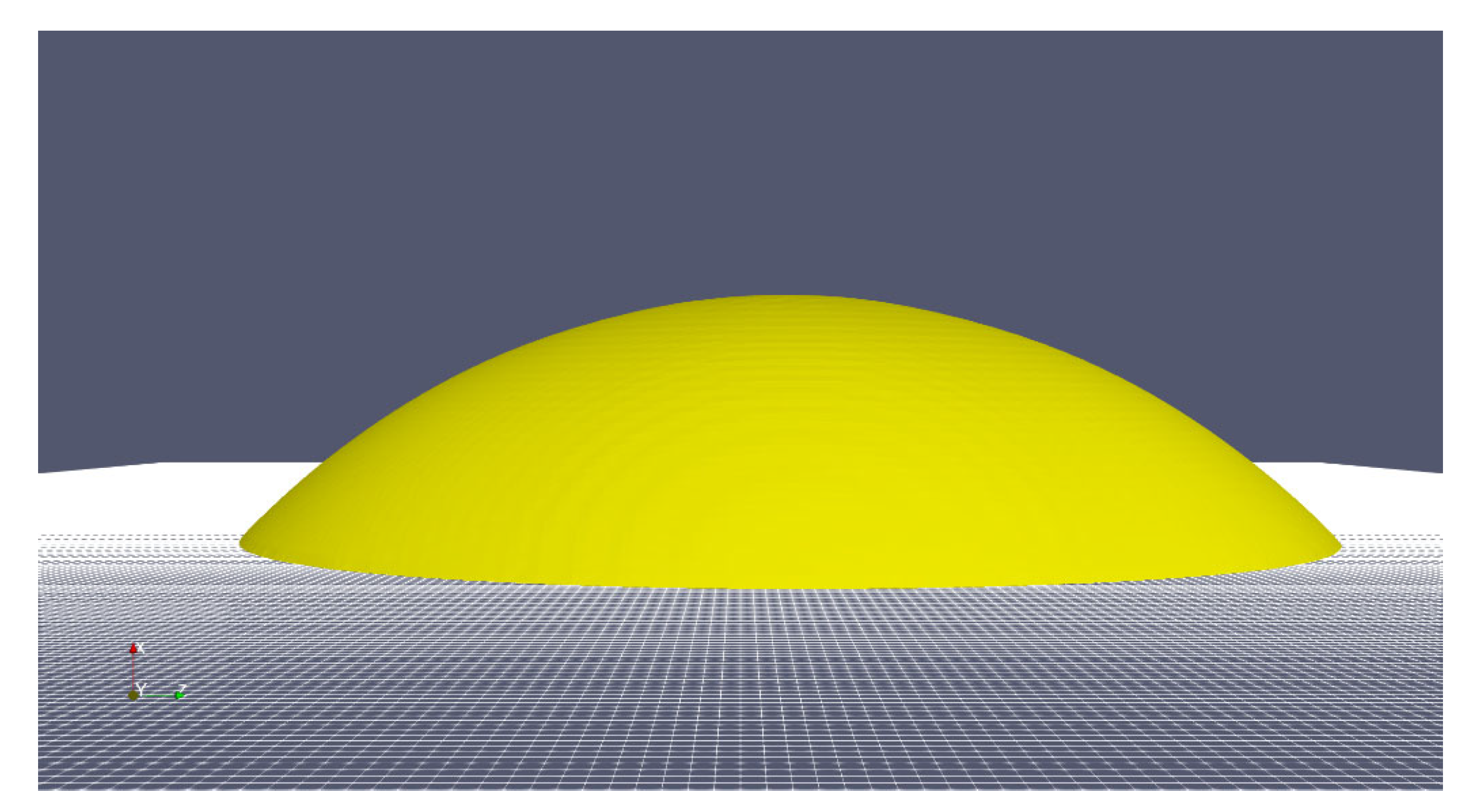

2. Materials

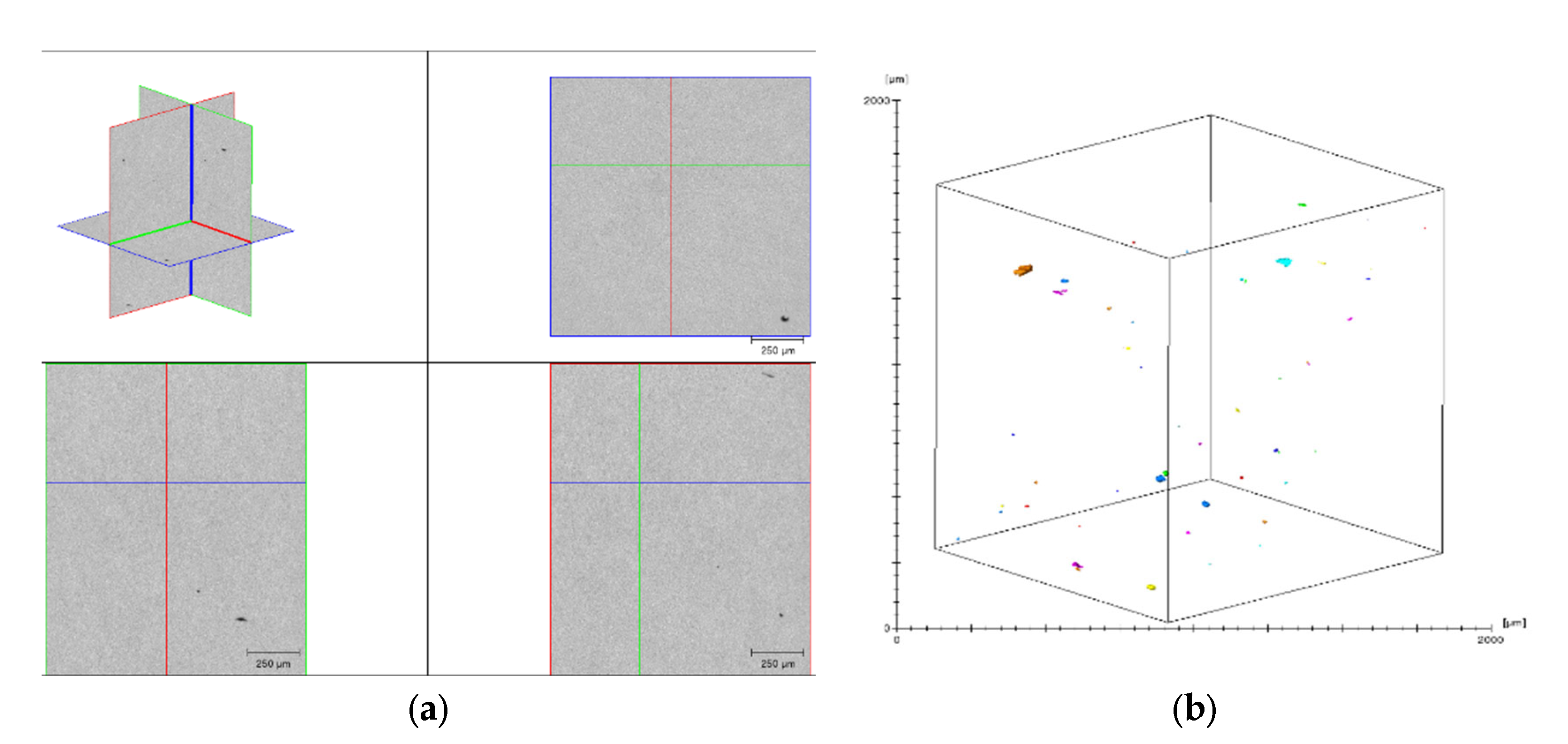

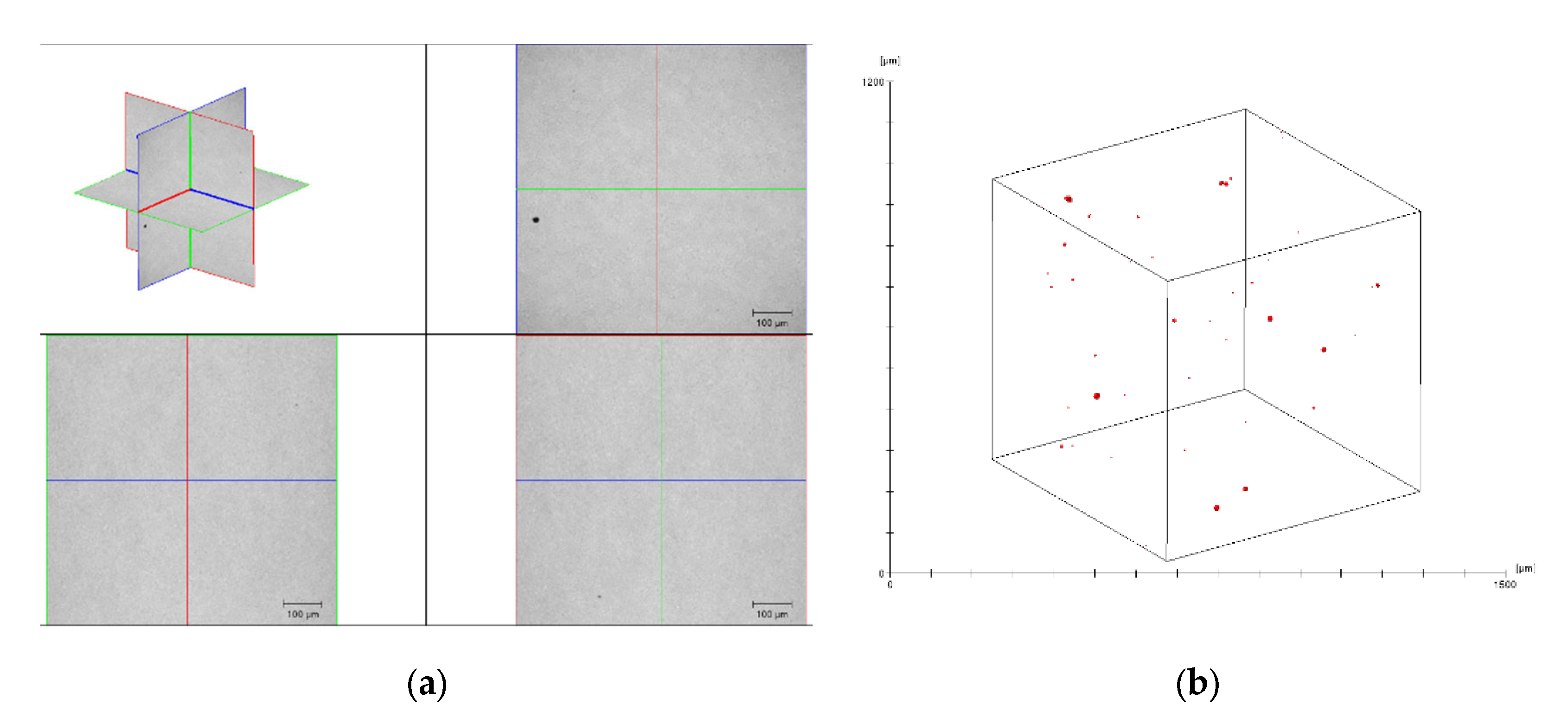

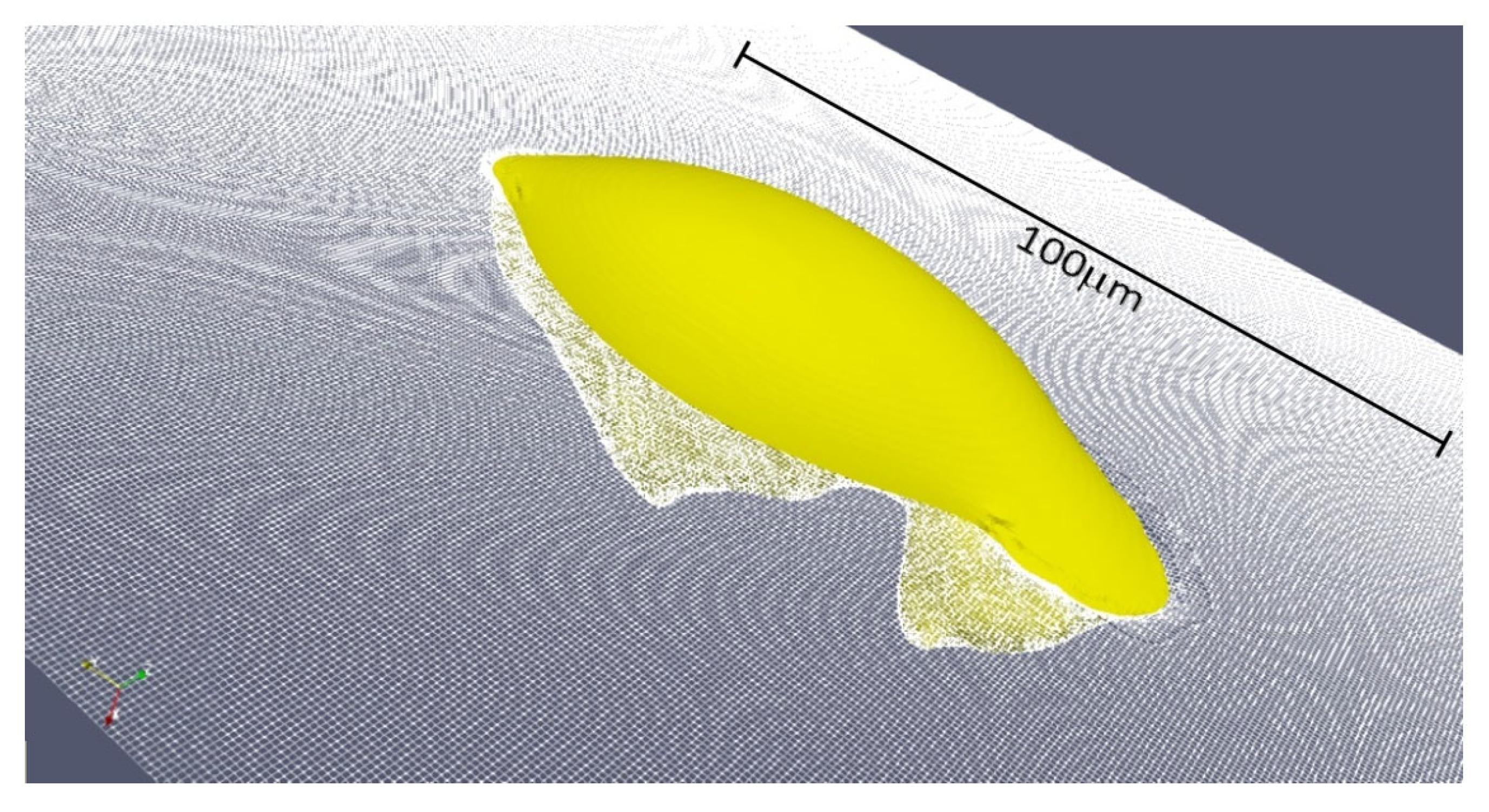

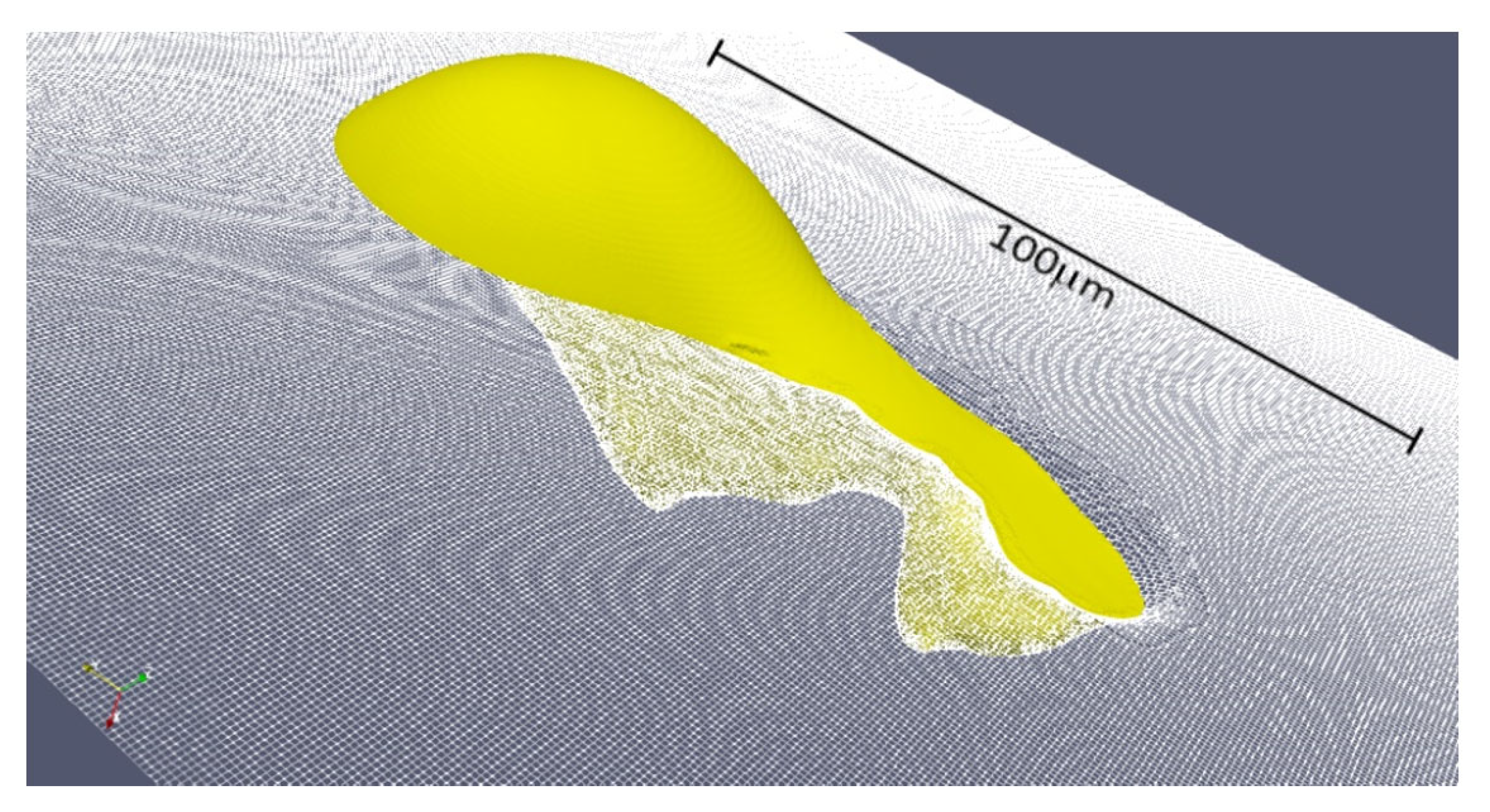

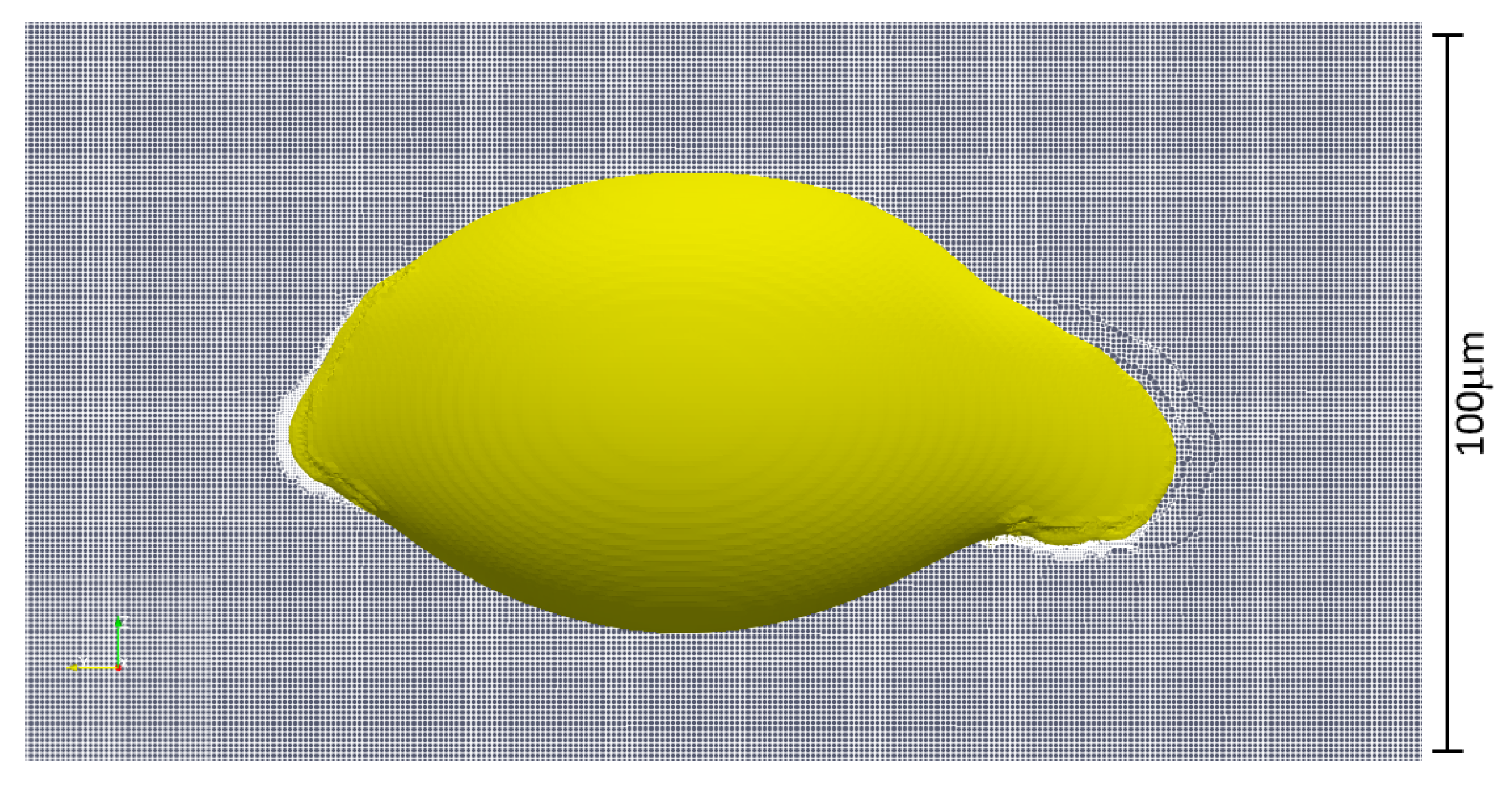

3. Configuration and Simulations

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Munz, O.J. Photo-Glyph Recording. U.S. Patent 2,775,758A, 25 December 1956. [Google Scholar]

- Bourell, D.; Beaman, J.; Leu, M.; Rosen, D. RAPID History of AM and 2009 Roadmap. In Proceedings of the RapidTech 2009 US-TURKEY Workshop on Rapid Technologies, Istanbul, Turkey, 24 September 2009. [Google Scholar]

- Zhai, Y.; Lados, D.A.; Lagoy, J.L. Additive Manufacturing: Making imagination the major Limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef] [Green Version]

- Frazier, E.W. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Maccioni, L.; Fraccaroli, L.; Borgianni, Y.; Concli, F. High-Cycle-Fatigue Characterization of an Additive Manufacturing 17-4 PH Stainless Steel. In Proceedings of the 11th International Conference on Materials and Manufacturing Technologies, Bangkok, Thailand, 24–26 April 2020. MT013. [Google Scholar]

- Maccioni, L.; Rampazzo, E.; Nalli, F.; Borgianni, Y.; Concli, F. Low-Cycle-Fatigue Properties of a 17-4 PH Stainless Steel Manufactured via Selective Laser Melting. In Proceedings of the 11th International Conference on Materials and Manufacturing Technologies, Bangkok, Thailand, 24–26 April 2020. MT012. [Google Scholar]

- Mower, M.J.; Long, T.M. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Cheruvathur, S.; Lass, E.A.; Campbell, C.E. Additive Manufacturing of 17-4 PH Stainless Steel: Post-processing Heat Treatment to Achieve Uniform Reproducible Microstructure. JOM 2016, 68, 930–942. [Google Scholar] [CrossRef]

- Sehrt, G.J.; Witt, T. Dynamic Strength and Fracture Toughness Analysis of Beam Melted Parts. In Proceedings of the 36th International MATADOR Conference, Lancashire, UK, 14–16 July 2010. [Google Scholar]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Mechanical and microstructural properties of selective laser melted 17-4 ph stainless steel. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Houston, TX, USA, 13–19 November 2015. 2A-2015. [Google Scholar]

- Facchini, L.; Vicente, N., Jr.; Lonardelli, I.; Magalini, E.; Robotti, P.; Alberto, M. Metastable austenite in 17-4 precipitation-hardening stainless steel produced by selective laser melting. Adv. Eng. Mater. 2010, 12, 184–188. [Google Scholar] [CrossRef]

- Wu, C.; Lin, J. Tensile and Fatigue Properties of 17-4 PH Stainless Steel at High Temperatures. Met. Mater. Trans. 2002, 33, 1717–1724. [Google Scholar] [CrossRef]

- Gu, H.; Gong, H.; Pal, D.; Rafi, K.; Starr, T.; Stucker, B. Influences of energy density on porosity and microstructure of selective laser melted 17-4PH stainless steel. In Proceedings of the 24th International SFF Symposium-An Additive Manufacturing Conference, SFF, Austin, TX, USA, 2–4 August 2013; pp. 474–489. [Google Scholar]

- Bonaiti, L.; Concli, F.; Gorla, C.; Rosa, F. Bending fatigue behaviour of 17-4 PH gears produced via selective laser melting. Procedia Struct. Integr. 2019, 24, 764–774. [Google Scholar] [CrossRef]

- Gorla, C.; Conrado, E.; Rosa, F.; Concli, F. Contact and bending fatigue behaviour of austempered ductile iron gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 998–1008. [Google Scholar] [CrossRef]

- Concli, F. Austempered Ductile Iron (ADI) for gears: Contact and bending fatigue behavior. Procedia Struct. Integr. 2018, 8, 14–23. [Google Scholar] [CrossRef]

- Concli, F.; Gorla, C.; Torre, A.D.; Montenegro, G. Windage power losses of ordinary gears: Different CFD approaches aimed to the reduction of the computational effort. Lubricants 2014, 4, 162–176. [Google Scholar] [CrossRef]

- Peng, Q.; Zhou, C.; Gui, L.; Fan, Z. Investigation of the lubrication system in a vehicle axle: Optimization and experimental validation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 2096–2107. [Google Scholar] [CrossRef]

- Luke, P.; Olver, A.V. A study of churning losses in dip-lubricated spur gears. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 213, 337–345. [Google Scholar] [CrossRef]

- Seetharaman, S.; Kahraman, A.; Moorhead, M.D.; Petry-Johnson, T.T. Oil churning power losses of a gear pair: Experiments and model validation. J. Tribol. 2009, 131, 0222021–02220210. [Google Scholar] [CrossRef]

- Hill, M.J.; Kunz, R.F.; Medvitz, R.B.; Handschuh, R.F.; Long, L.N.; Noack, R.W.; Morris, P.J. CFD analysis of gear windage losses: Validation and parametric aerodynamic studies. J. Fluids Eng. Trans. ASME 2009, 133, 031103. [Google Scholar] [CrossRef] [Green Version]

- Kodela, C.; Kraetschmer, M.; Basa, S. Churning Loss Estimation for Manual Transmission Gear Box Using CFD. SAE Int. J. Passeng. Cars-Mech. Syst. 2015, 8, 391–397. [Google Scholar] [CrossRef]

- Hamlin, R.J. Microstructural Evolution and Mechanical Properties of Simulated Heat Affected Zones in Cast Precipitation Hardened Stainless Steels 17-4 and 13-8 + Mo. Metal. Mater. Trans. 2017, 48, 246–264. [Google Scholar] [CrossRef]

- Concli, F.; Gorla, C.; Stahl, K.; Höhn, B.-R.; Miachaelis, K.; Schultheiss, H. Stemplinger Load independent power losses of ordinary gears: Numerical and experimental analysis. In Proceedings of the 5th World Tribology Congress, WTC2013, Torino, Italy, 8–13 September 2013; Volume 2, pp. 1243–1246. [Google Scholar]

- Concli, F.; Gorla, C.; Rosa, F.; Conrado, E. Effect of the static pressure on the power dissipation of gearboxes. Lubr. Sci. 2019, 31, 347–355. [Google Scholar] [CrossRef]

- Höhn, B.-R.; Michaelis, K.; Otto, H.-P. Influence on no-load gear losses. In Proceedings of the ECOTRIB 2011: 3rd European Conference on Tribology in Tandem with Viennano ’11-4th Vienna International Conference on Nano-Technology, Wien, Austria, 7–9 June 2011; pp. 639–644. [Google Scholar]

- Concli, F.; Gorla, C. CFD simulation of power losses and lubricant flows in gearboxes. In Proceedings of the American Gear Manufacturers Association Fall Technical Meeting, Alexandria, VA, USA, 27 June 2017. [Google Scholar]

- Lilienfeld, S.O.; Arkowitz, H. Lunacy and the Full Moon. Sci. Am. Mind 2009, 20, 64–65. [Google Scholar] [CrossRef]

- Bugatti. Available online: https://assets.bugatti.com/ (accessed on 15 July 2019).

- Dennis, J.R. Space Shuttle: Developing an Icon–1972–2013; Specialty Press: Forest Lake, MN, USA, 2016. [Google Scholar]

- FORMULA 1. Available online: www.f1.com (accessed on 15 July 2019).

- FIA. Available online: www.fia.com (accessed on 15 July 2019).

- AUTO123. Available online: www.auto123.com (accessed on 15 July 2019).

- Lechome. Available online: www.lechom.com (accessed on 15 July 2019).

- Concli, F. Thermal and efficiency characterization of a low-backlash planetary gearbox: An integrated numerical-analytical prediction model and its experimental validation. Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 2016, 230, 996–1005. [Google Scholar] [CrossRef]

- OpenFOAM. Available online: www.openfoam.com (accessed on 15 July 2019).

- Concli, F.; Schaefer, T.C.; Bohnert, C. Innovative Meshing Strategies for Bearing Lubrication Simulations. Lubricants 2020, 8, 46. [Google Scholar] [CrossRef] [Green Version]

- Linux Containers. Available online: https://linuxcontainers.org (accessed on 28 August 2019).

- Cisco. Available online: https://www.cisco.com/c/dam/en/us/products/collateral/servers-unified-computing/ucs-b-series-blade-servers/B200M3_SpecSheet.pdf (accessed on 30 August 2019).

- Ceph. Available online: https://ceph.com (accessed on 2 October 2019).

| C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.036 | 0.78 | 0.33 | 0.009 | 0.004 | 16.2 | 4.02 | 0.002 |

| Co | V | Ti | Cu | W | Sn | Al | Nb |

| 0.012 | 0.018 | 0.002 | 0.372 | 0.009 | 0.004 | 0.001 | 0.29 |

| Value [g] | |

|---|---|

| Gravity on the moon [29] | 0.165 |

| Gravity on the Earth | 1.000 |

| Bugatti Veyron 0 to 100 km/h [30] | 1.550 |

| Space Shuttle take off [31] | 3.000 |

| F1 car—hard breaking [32] | 6.300 |

| Car crash—maximum acceleration human body can withstand [33] | 100.0 |

| F1—acceleration of the piston [34] | 8600 |

| Military guns—bullet acceleration [35] | 15500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Concli, F.; Della Torre, A. Impact of the LACKS of Fusion Induced by Additive Manufacturing on the Lubrication of a Gear Flank. Lubricants 2021, 9, 83. https://doi.org/10.3390/lubricants9080083

Concli F, Della Torre A. Impact of the LACKS of Fusion Induced by Additive Manufacturing on the Lubrication of a Gear Flank. Lubricants. 2021; 9(8):83. https://doi.org/10.3390/lubricants9080083

Chicago/Turabian StyleConcli, Franco, and Augusto Della Torre. 2021. "Impact of the LACKS of Fusion Induced by Additive Manufacturing on the Lubrication of a Gear Flank" Lubricants 9, no. 8: 83. https://doi.org/10.3390/lubricants9080083

APA StyleConcli, F., & Della Torre, A. (2021). Impact of the LACKS of Fusion Induced by Additive Manufacturing on the Lubrication of a Gear Flank. Lubricants, 9(8), 83. https://doi.org/10.3390/lubricants9080083