An Identification Method for Orifice-Type Restrictors Based on the Closed-Form Solution of Reynolds Equation

Abstract

1. Introduction

2. Materials and Methods

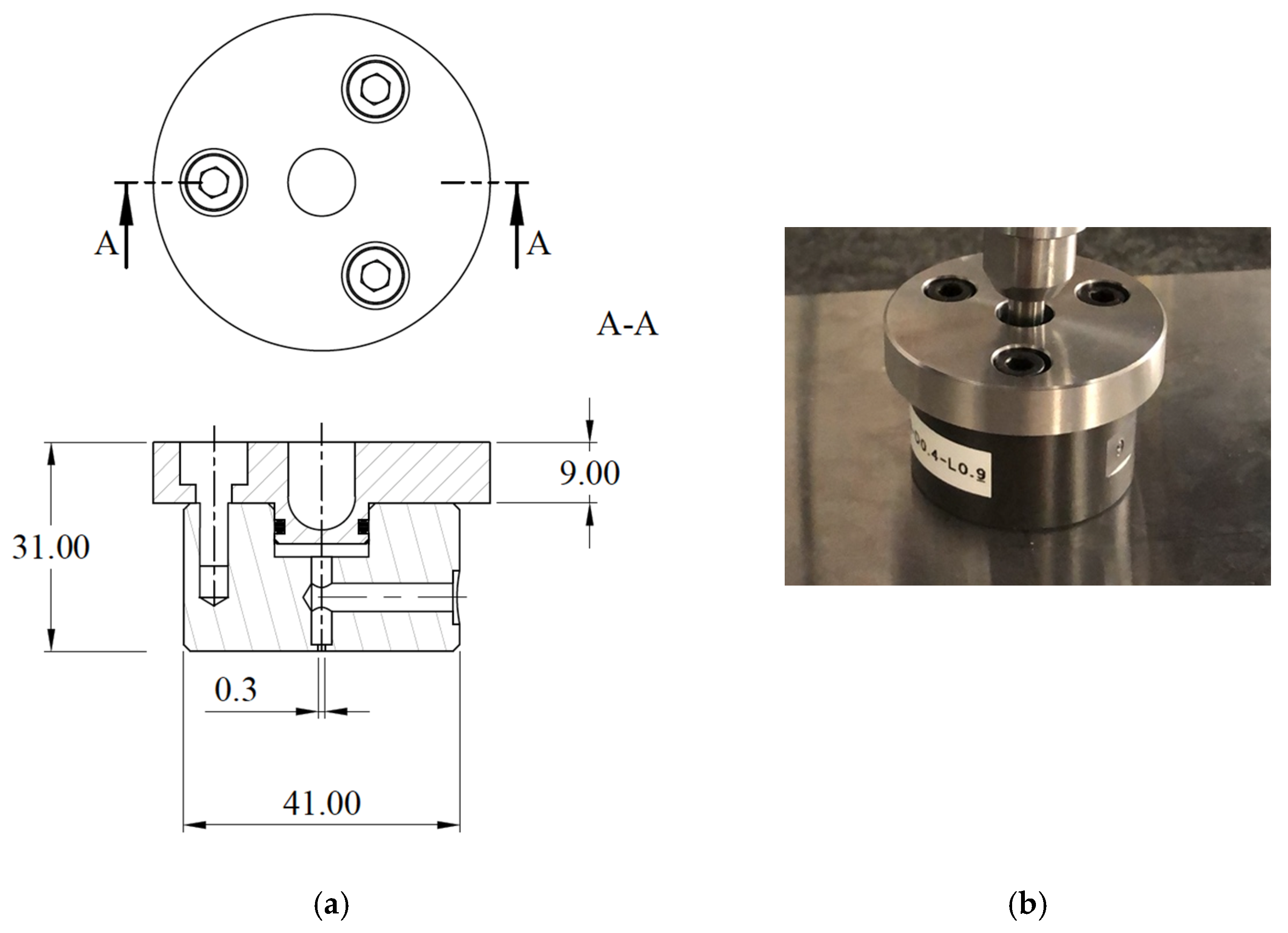

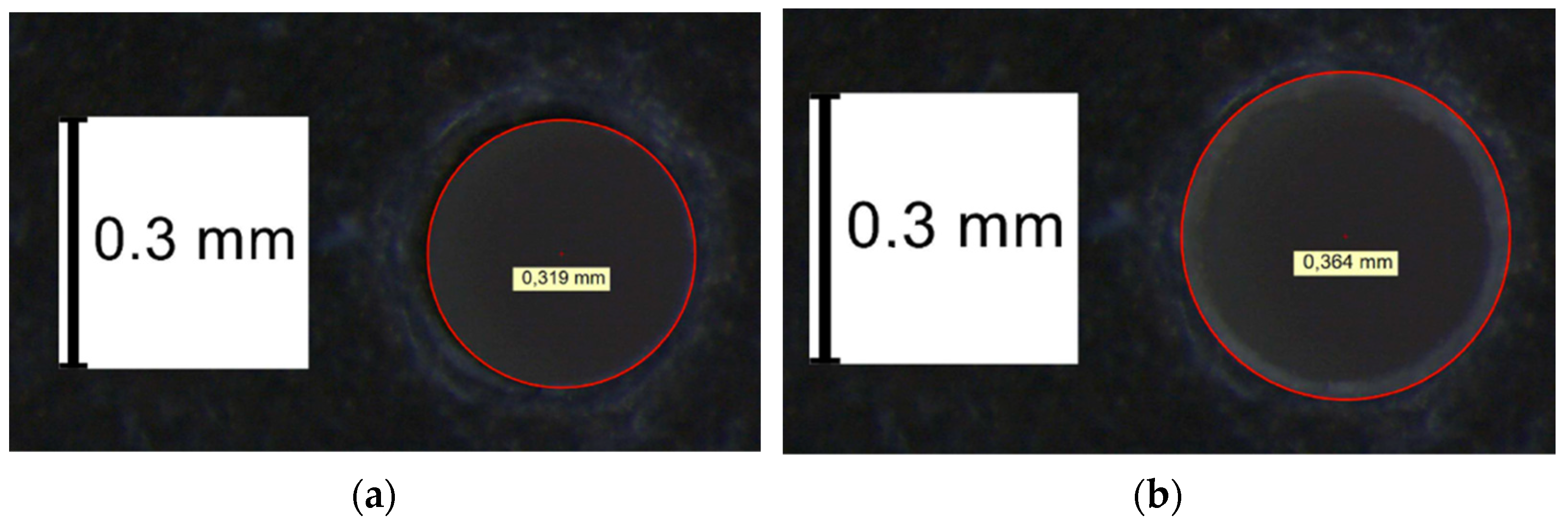

2.1. Pad Geometry

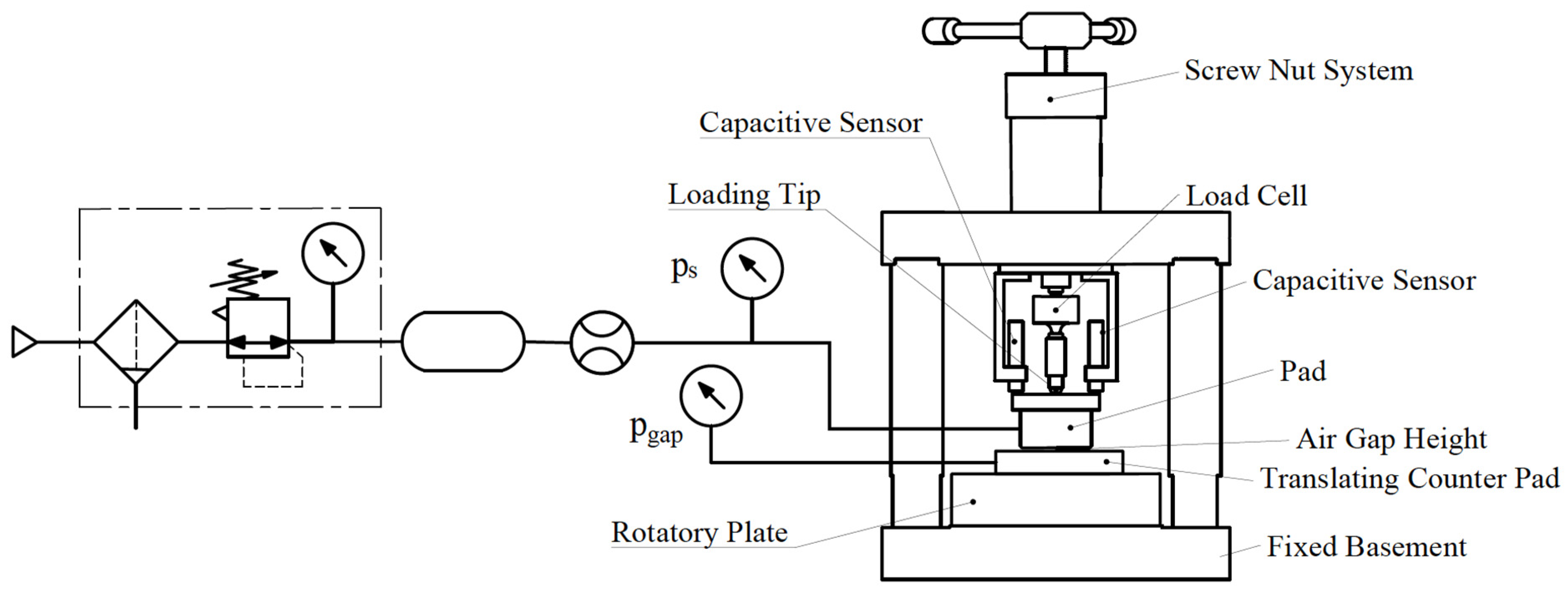

2.2. Test Bench

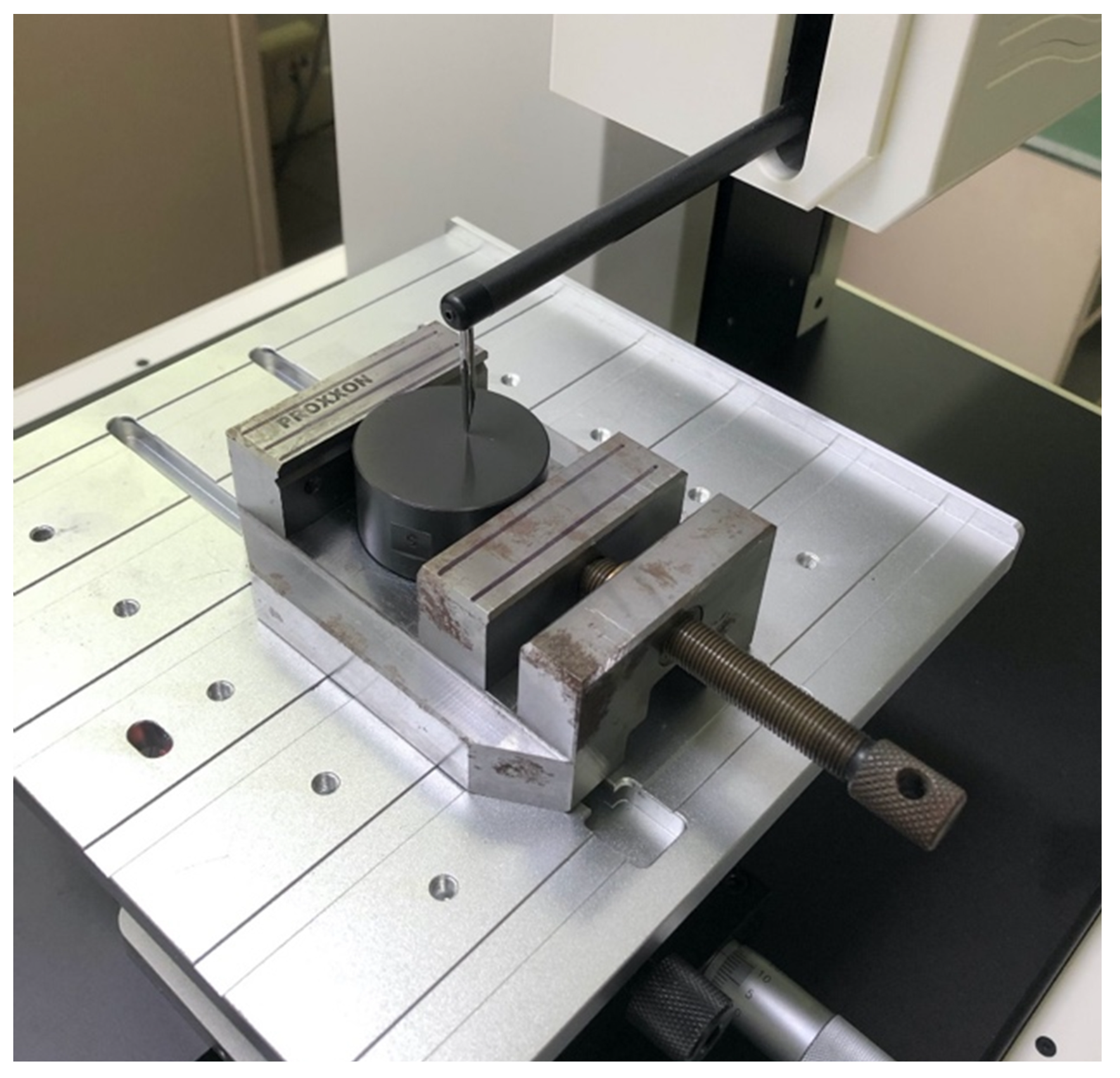

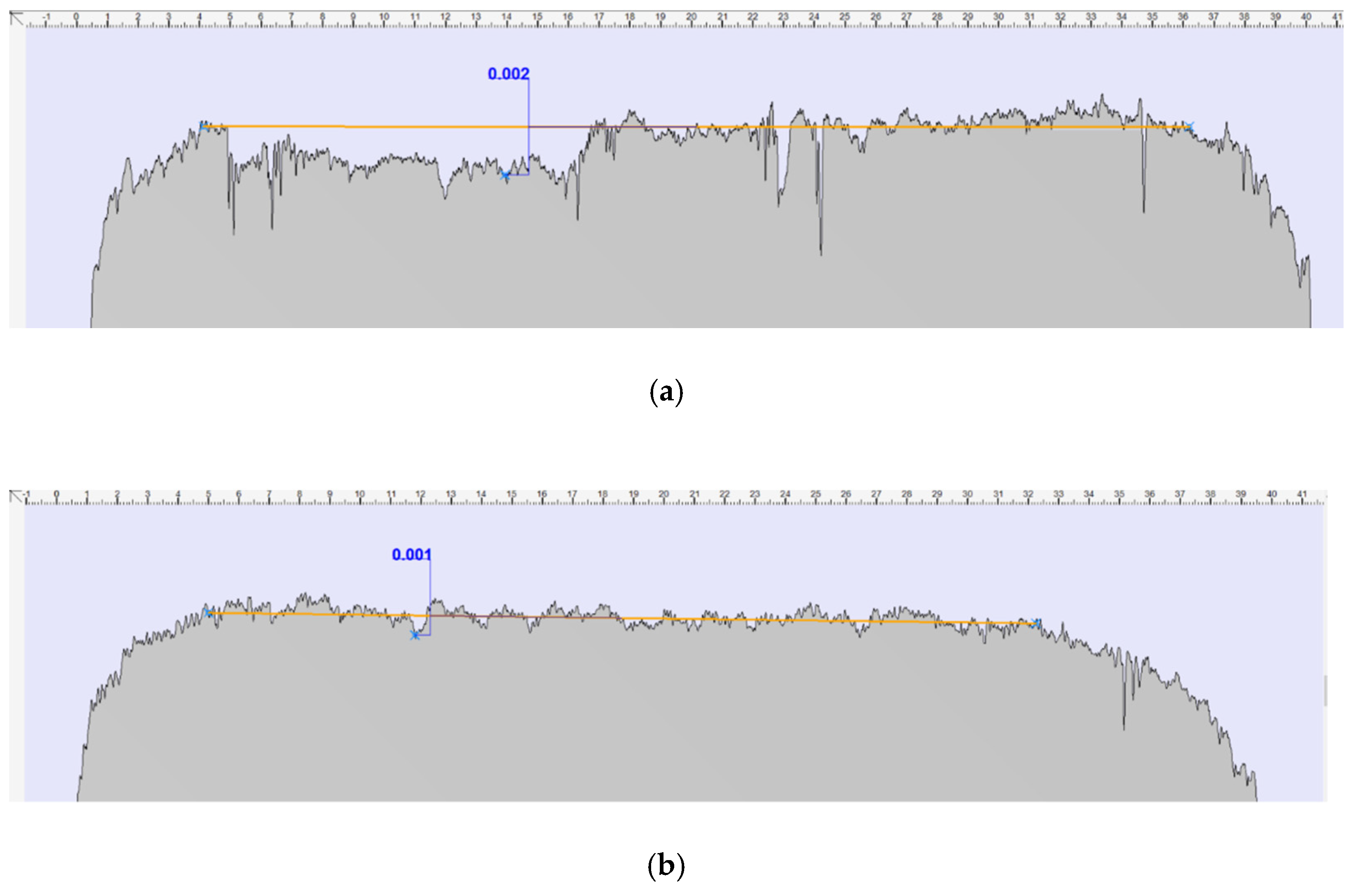

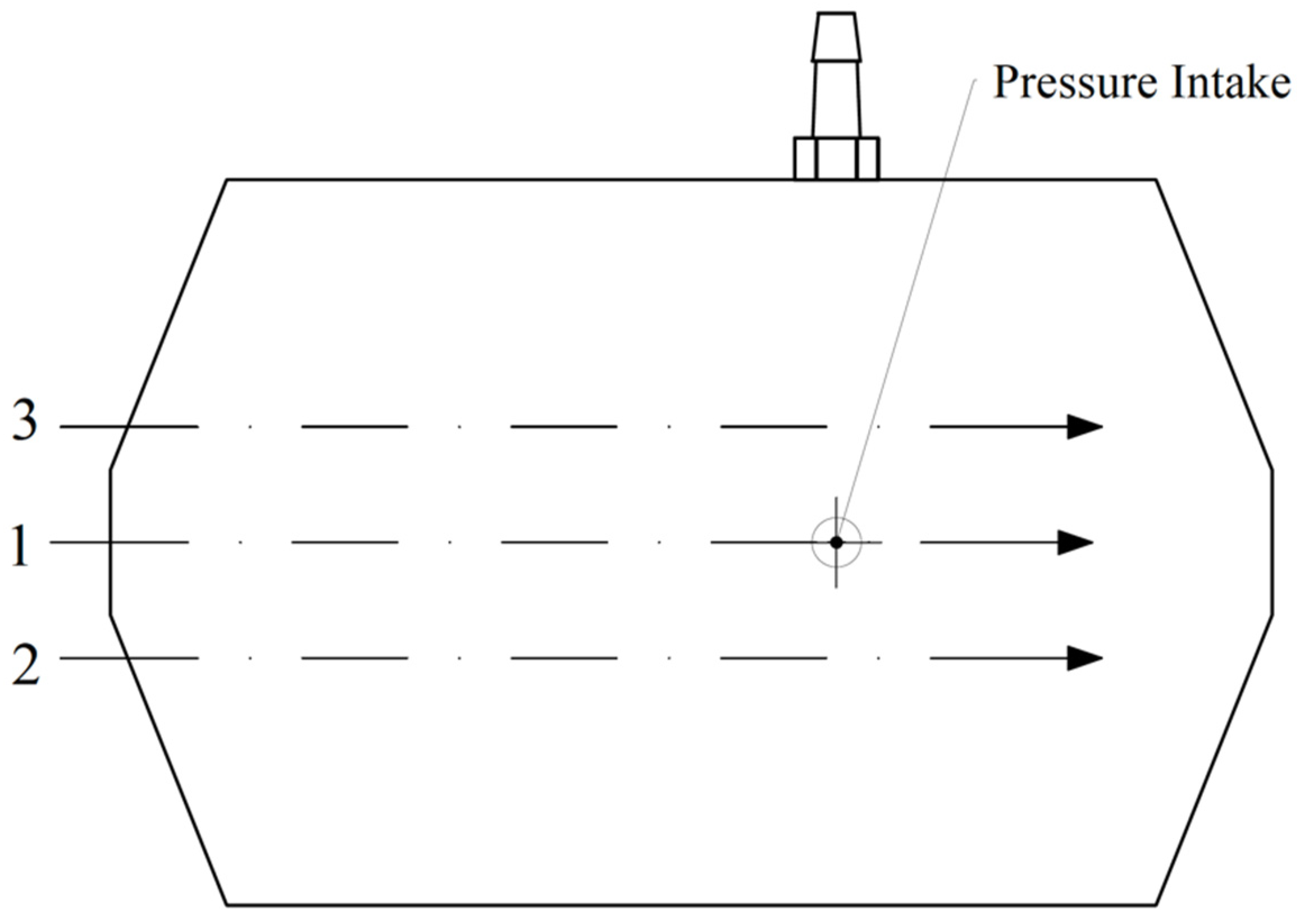

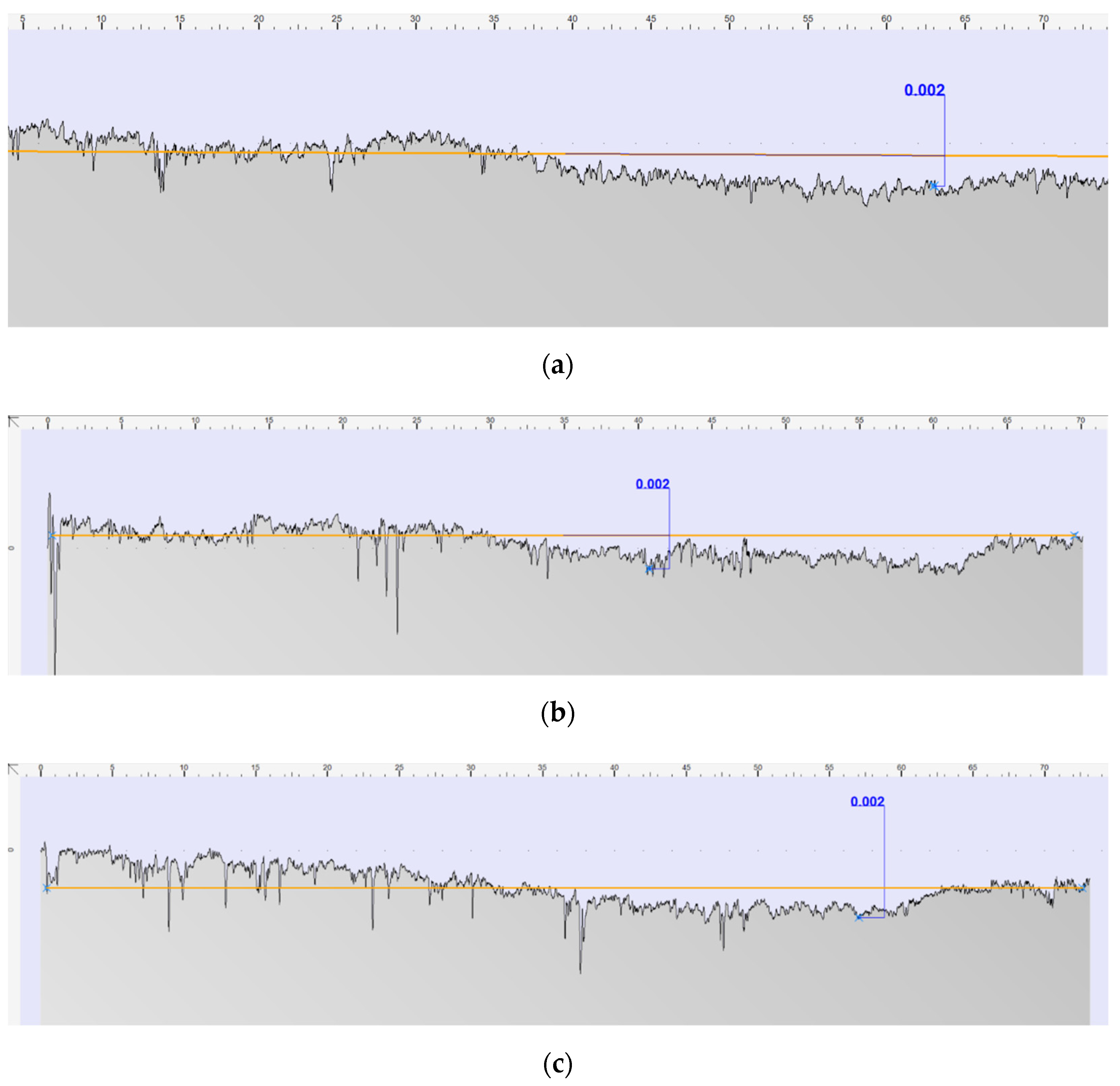

2.3. Pressure Profile Measurements

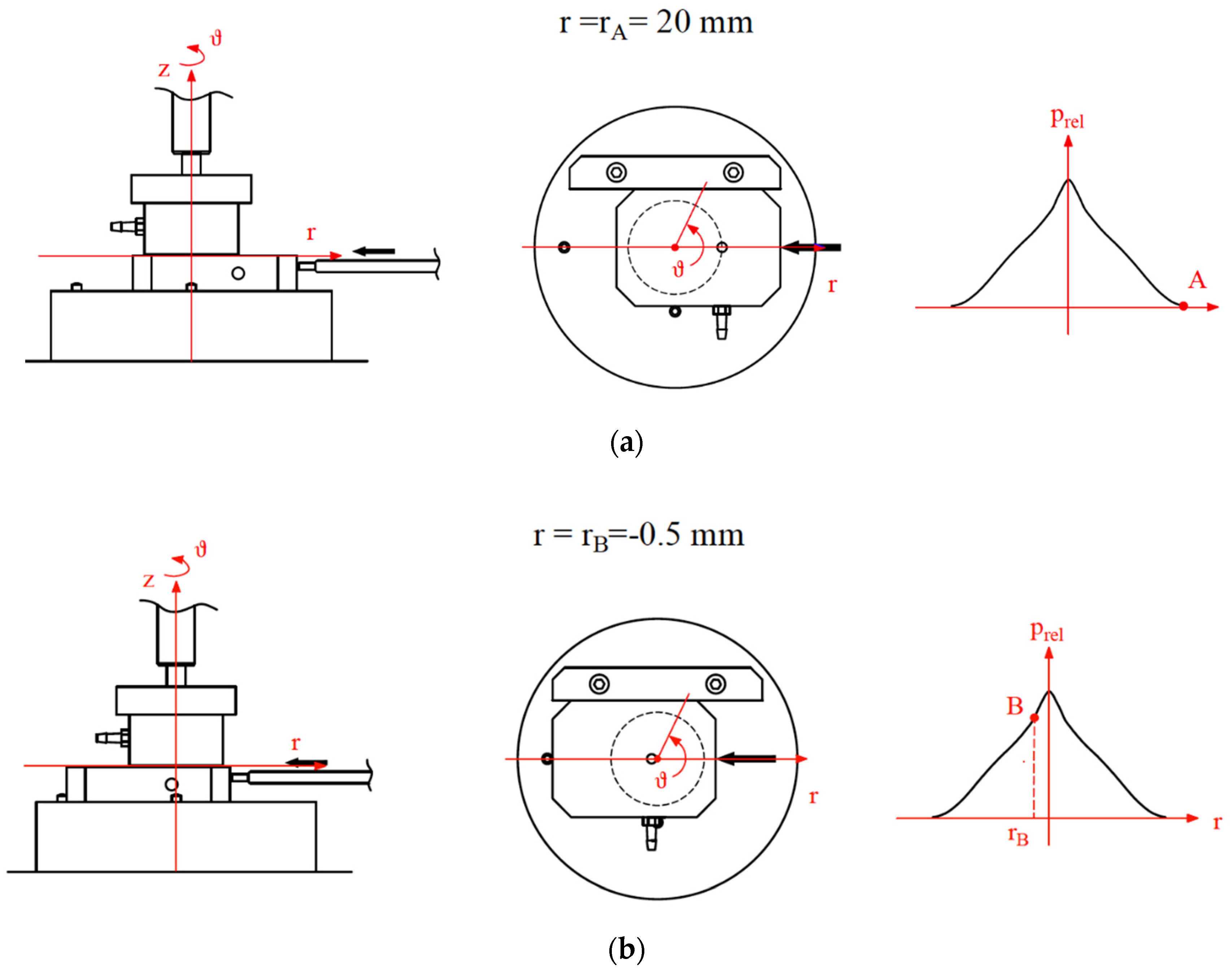

2.4. Static Characterization Procedure

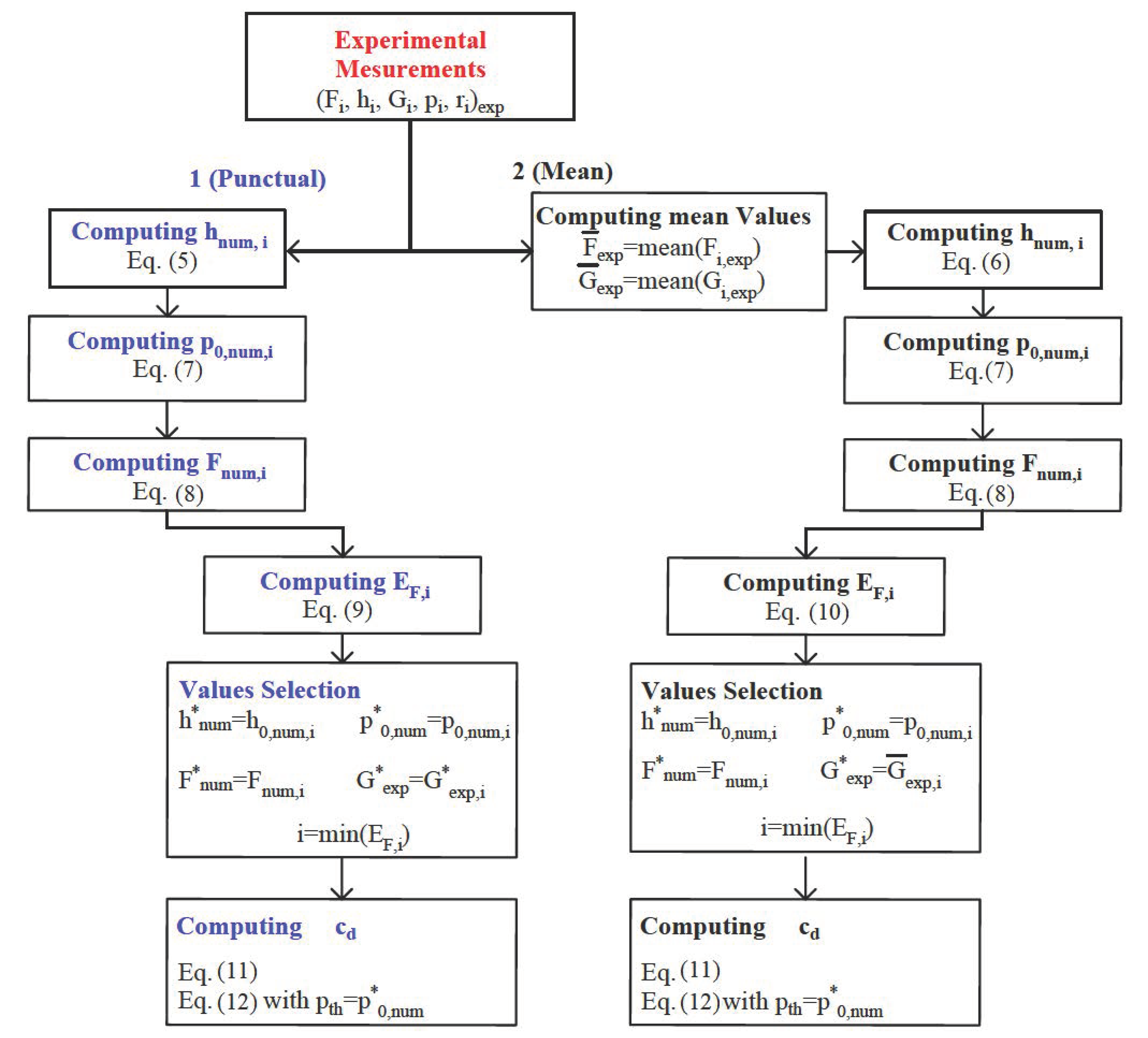

2.5. Identification of the Discharge Coefficients

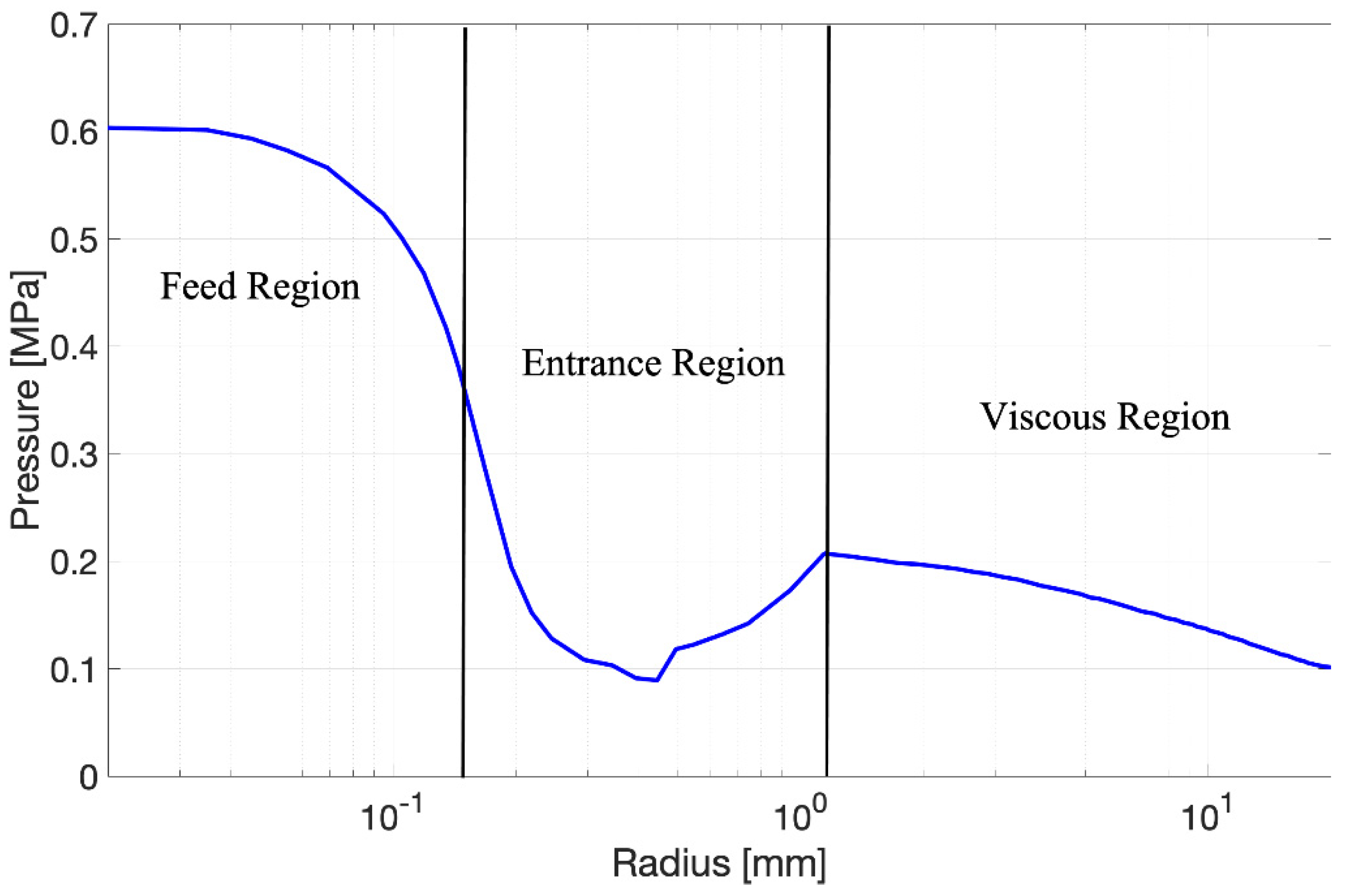

- It is well known that, in aerostatic bearings, the viscous region is by far the largest of the three regions.

- It has been proven numerous times that isothermal and laminar flow models provide accurate predictions in the viscous region [19].

3. Results

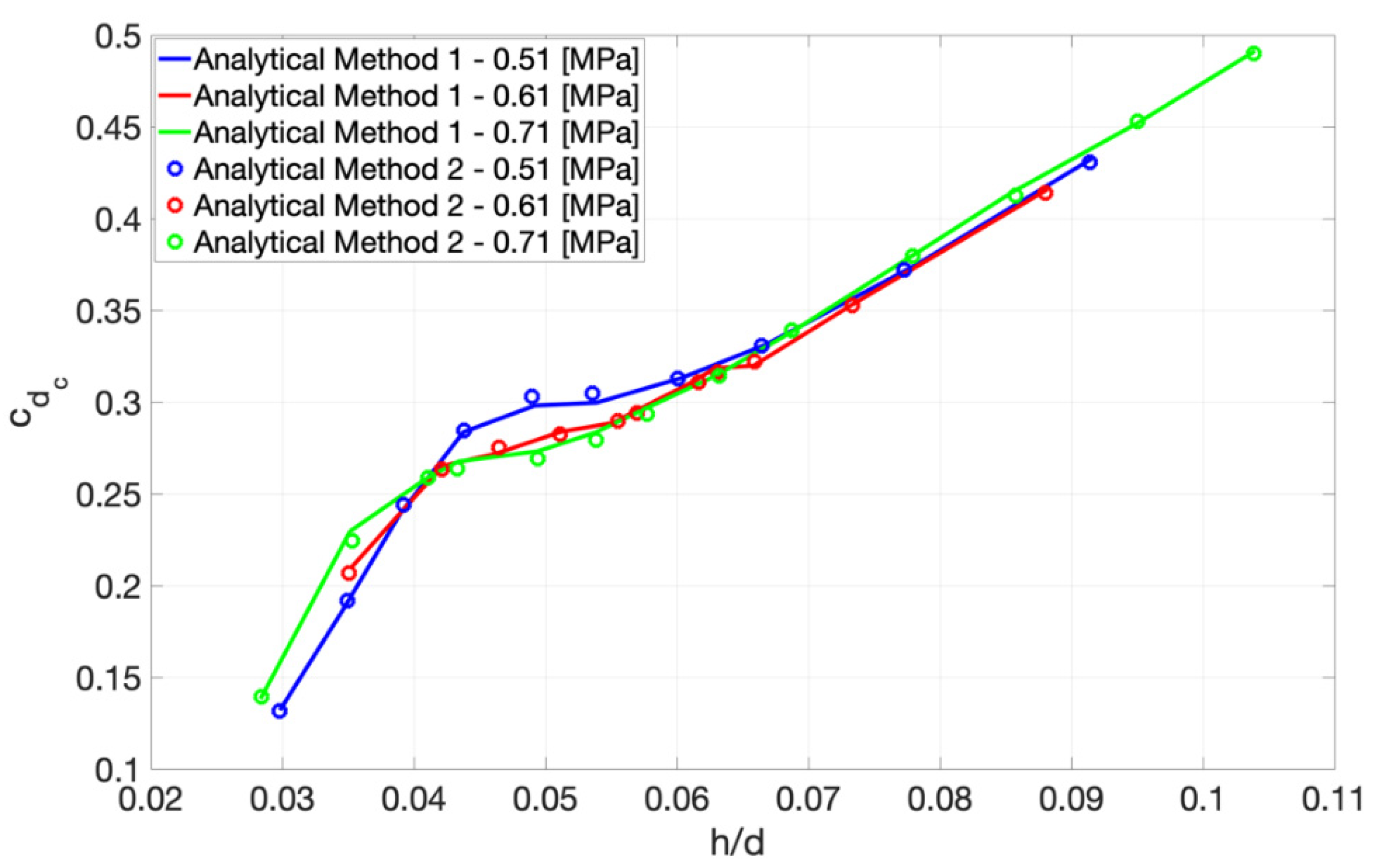

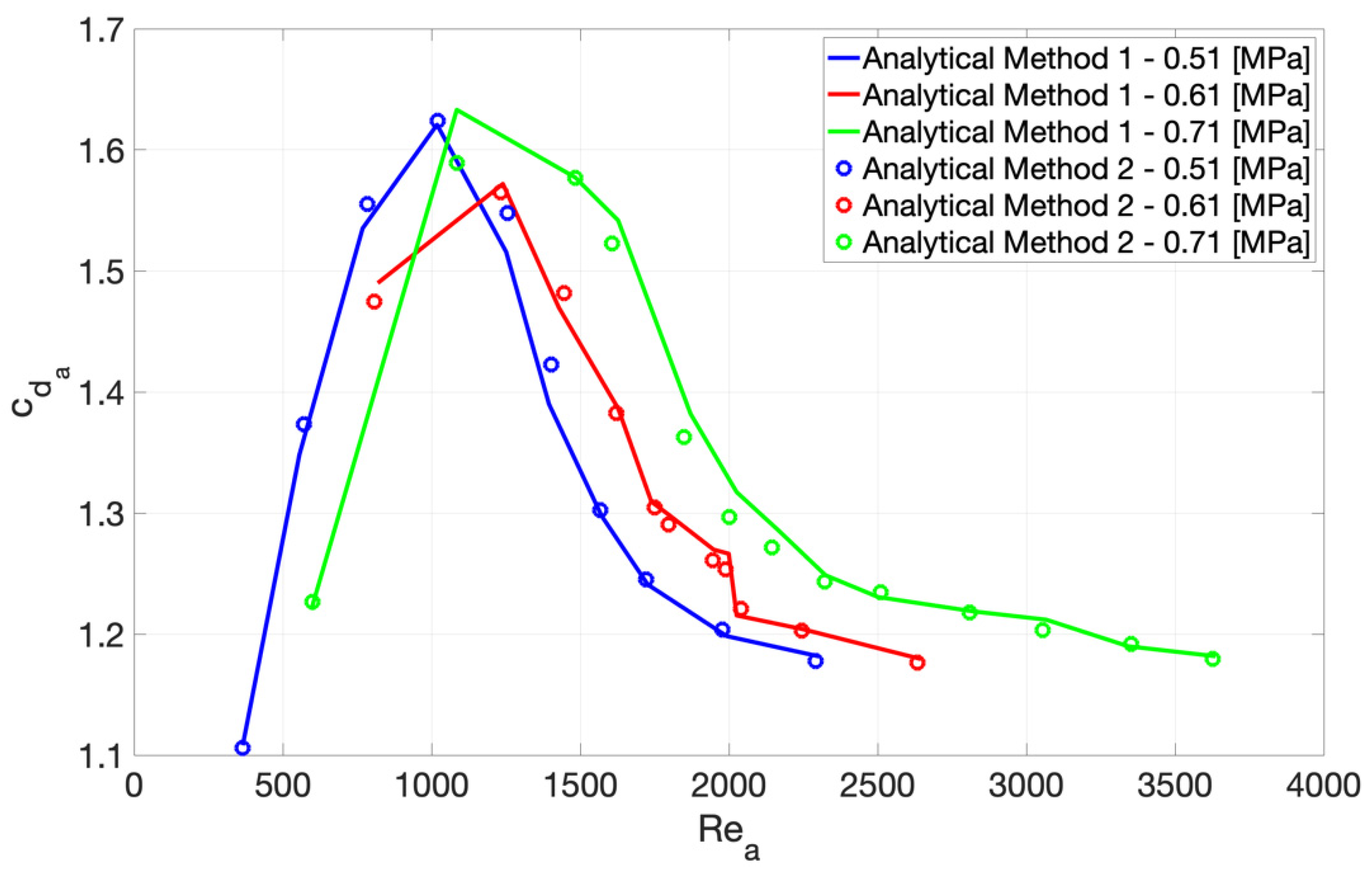

3.1. Discharge Coefficient Identification

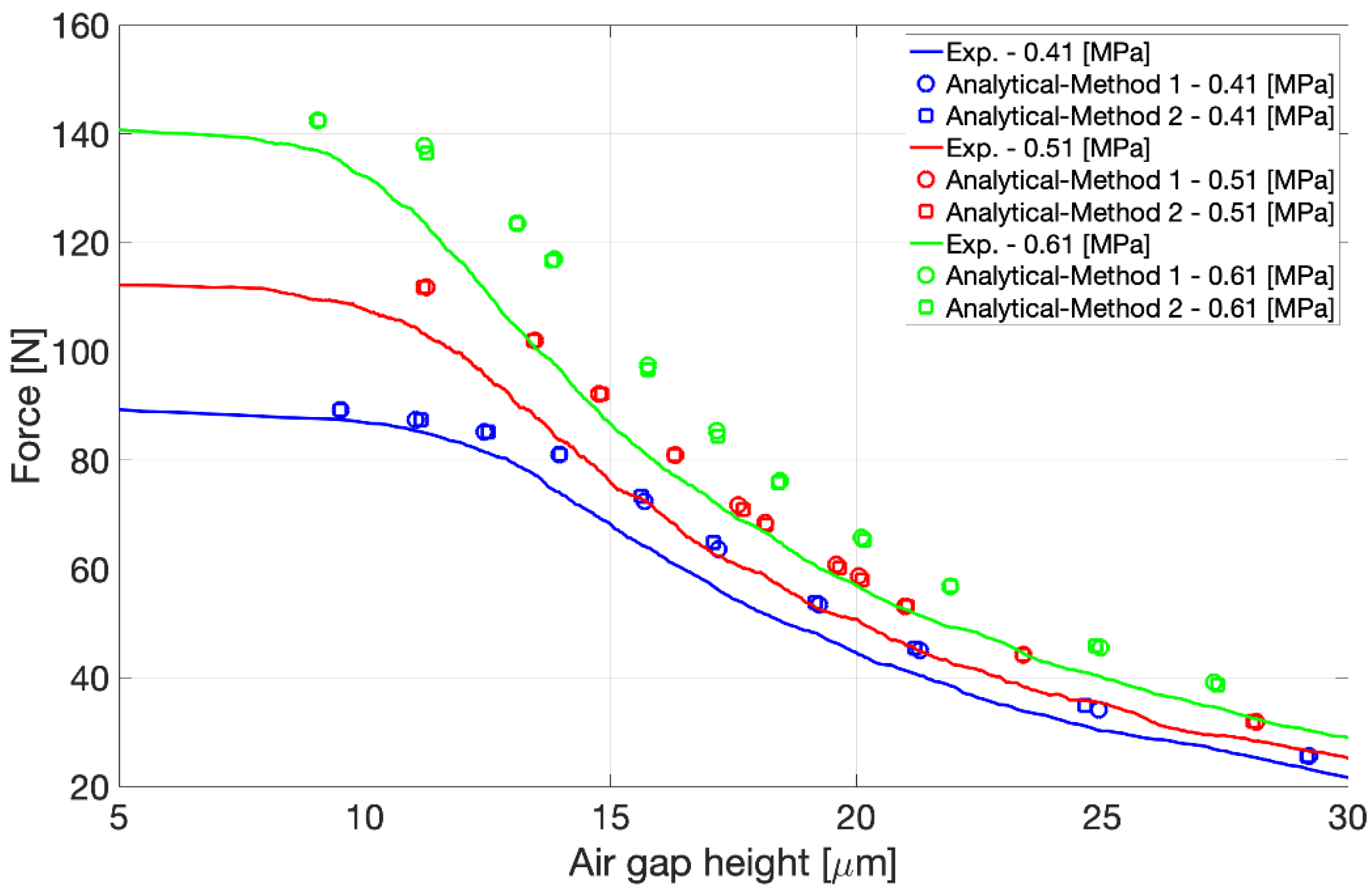

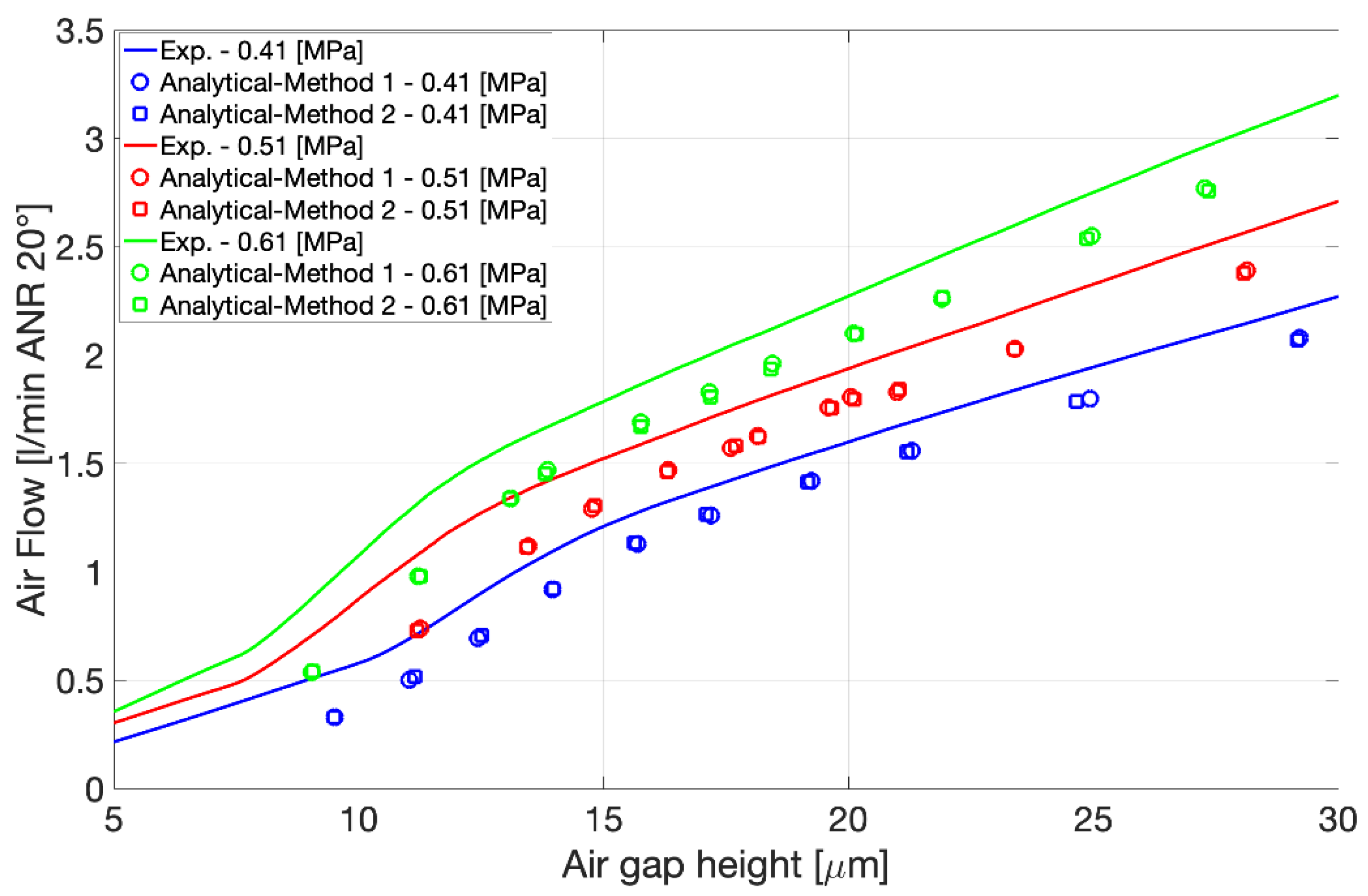

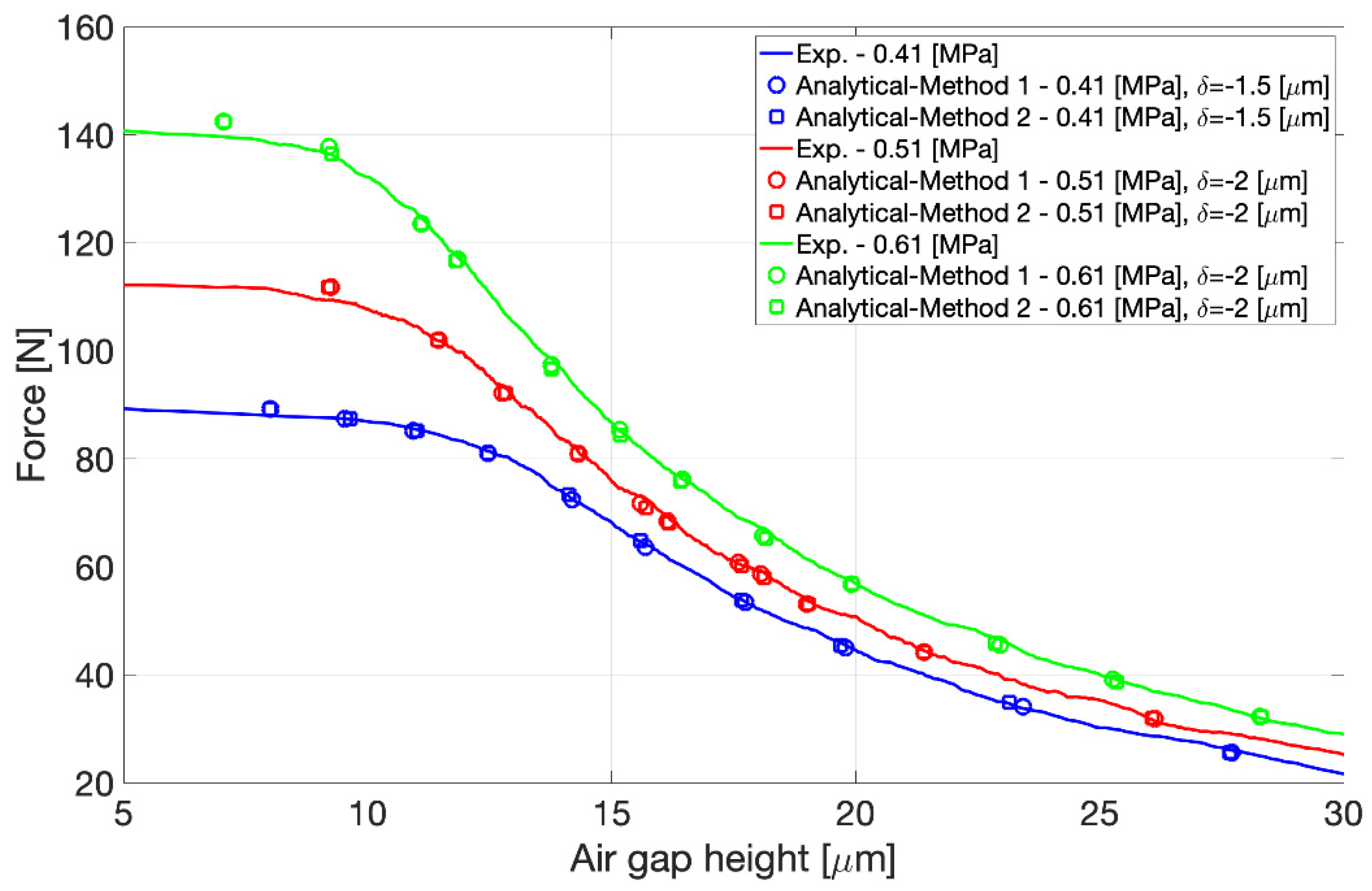

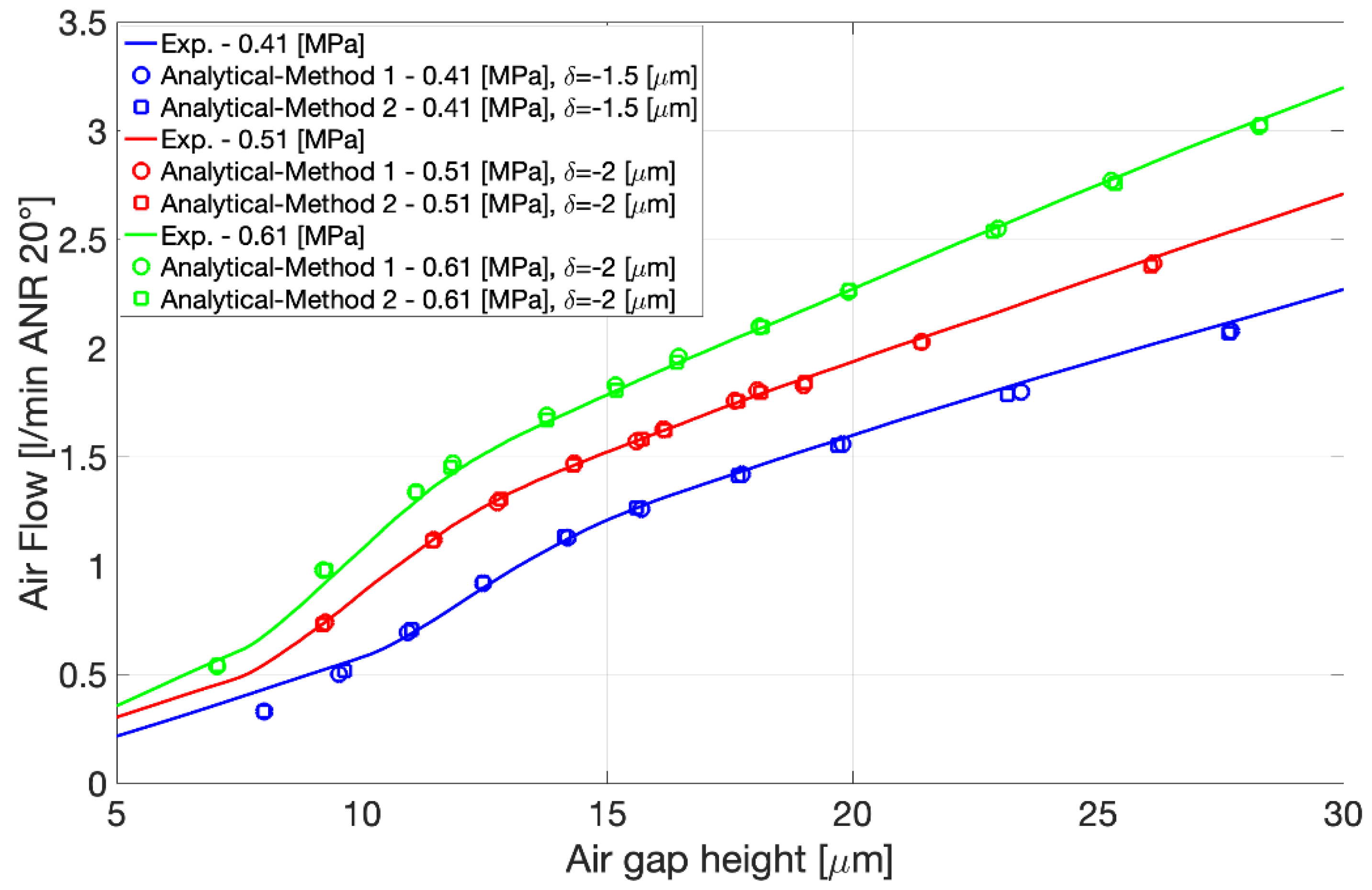

3.2. Comparison with Static Characterisation Results

4. Discussion and Conclusions

- Reduce the data scattering thanks to the use of a mathematical framework (closed-form solution).

- Overcome the difficulties related to the evaluation of the air gap height during the acquisition of the pressure profile.

- Minimize the error on the numerical air flow and load capacity.

Author Contributions

Funding

Conflicts of Interest

Appendix A

- isothermal laminar and isoviscous flow

- negligible body forces

- negligible velocity gradients along and

- Newtonian fluid

- constant pressure along the and direction (Due to the axisymmetry of the problem and the small thickness of the air gap.)

- stationary conditions

References

- Lentini, L.; Moradi, M.; Colombo, F. A Historical Review of Gas Lubrication: From Reynolds to Active Compensations. Tribol. Ind. 2018, 40, 165–182. [Google Scholar] [CrossRef][Green Version]

- Gao, Q.; Chen, W.; Lu, L.; Huo, D.; Cheng, K. Aerostatic bearings design and analysis with the application to precision engineering: State-of-the-art and future perspectives. Tribol. Int. 2019, 135, 1–17. [Google Scholar] [CrossRef]

- Waumans, T.; Al-Bender, F.; Reynaerts, D. A semi-analytical method for the solution of entrance flow effects in inherently restricted aerostatic bearings. In Turbo Expo: Power for Land, Sea, and Air; ASME: Berlin, Germany, 2008; Volume 43154, pp. 1047–1057. [Google Scholar]

- Mori, H.; Miyamatsu, Y. Theoretical flow-models for externally pressurized gas bearings. J. Lubr. Technol. 1969, 91, 181–193. [Google Scholar] [CrossRef]

- Gao, S.; Cheng, K.; Chen, S.; Ding, H.; Fu, H. CFD based investigation on influence of orifice chamber shapes for the design of aerostatic thrust bearings at ultra-high speed spindles. Tribol. Int. 2015, 92, 211–221. [Google Scholar] [CrossRef]

- Zhang, J.; Zou, D.; Ta, N.; Rao, Z. Numerical research of pressure depression in aerostatic thrust bearing with inherent orifice. Tribol. Int. 2018, 123, 385–396. [Google Scholar] [CrossRef]

- Helene, M.; Arghir, M.; Frene, J. Numerical three-dimensional pressure patterns in a recess of a turbulent and compressible hybrid journal bearing. J. Trib. 2003, 125, 301–308. [Google Scholar] [CrossRef]

- Mori, H. A theoretical investigation of pressure depression in externally pressurized gas-lubricated circular thrust bearings. J. Basic Eng. 1961, 83, 201–208. [Google Scholar] [CrossRef]

- Chang, S.H.; Chan, C.W.; Jeng, Y.R. Numerical analysis of discharge coefficients in aerostatic bearings with orifice-type restrictors. Tribol. Int. 2015, 90, 157–163. [Google Scholar] [CrossRef]

- Chang, S.H.; Chan, C.W.; Jeng, Y.-R. Discharge coefficients in aerostatic bearings with inherent orifice-type restrictors. J. Tribol. 2015, 137. [Google Scholar] [CrossRef]

- Miyatake, M.; Yoshimoto, S. Numerical investigation of static and dynamic characteristics of aerostatic thrust bearings with small feed holes. Tribol. Int. 2010, 43, 1353–1359. [Google Scholar] [CrossRef]

- Nishio, U.; Somaya, K.; Yoshimoto, S. Numerical calculation and experimental verification of static and dynamic characteristics of aerostatic thrust bearings with small feedholes. Tribol. Int. 2011, 44, 1790–1795. [Google Scholar] [CrossRef]

- Renn, J.-C.; Hsiao, C.-H. Experimental and CFD study on the mass flow-rate characteristic of gas through orifice-type restrictor in aerostatic bearings. Tribol. Int. 2004, 37, 309–315. [Google Scholar] [CrossRef]

- Al-Bender, F.; Van Brussel, H. A method of “separation of variables” for the solution of laminar boundary-layer equations of narrow-channel flows. J. Tribol. 1992. [Google Scholar] [CrossRef]

- Zhang, J.; Zou, D.; Ta, N.; Rao, Z.; Ding, B. A numerical method for solution of the discharge coefficients in externally pressurized gas bearings with inherent orifice restrictors. Tribol. Int. 2018, 125, 156–168. [Google Scholar] [CrossRef]

- Belforte, G.; Raparelli, T.; Viktorov, V.; Trivella, A. Discharge coefficients of orifice-type restrictor for aerostatic bearings. Tribol. Int. 2007, 40, 512–521. [Google Scholar] [CrossRef]

- Belforte, G.; Colombo, F.; Raparelli, T.; Trivella, A.; Viktorov, V. A new identification method of the supply hole discharge coefficient of gas bearings. Tribol. Des. WIT Trans. Eng. Sci. 2010, 66, 95–105. [Google Scholar]

- Colombo, F.; Lentini, L.; Raparelli, T.; Trivella, A.; Viktorov, V. Dynamic Characterisation of Rectangular Aerostatic Pads with Multiple Inherent Orifices. Tribol. Lett. 2018, 66. [Google Scholar] [CrossRef]

- Belforte, G.; Raparelli, T.; Trivella, A.; Viktorov, V.; Visconte, C. CFD analysis of a simple orifice-type feeding system for aerostatic bearings. Tribol. Lett. 2015, 58, 25. [Google Scholar] [CrossRef]

- Colombo, F.; Lentini, L.; Raparelli, T.; Viktorov, V.; Trivella, A. On the Static Performance of Concave Aerostatic Pads. In IFToMM World Congress on Mechanism and Machine Science; Springer: Cham, Switzerland, 2019; pp. 3919–3928. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colombo, F.; Lentini, L.; Raparelli, T.; Trivella, A.; Viktorov, V. An Identification Method for Orifice-Type Restrictors Based on the Closed-Form Solution of Reynolds Equation. Lubricants 2021, 9, 55. https://doi.org/10.3390/lubricants9050055

Colombo F, Lentini L, Raparelli T, Trivella A, Viktorov V. An Identification Method for Orifice-Type Restrictors Based on the Closed-Form Solution of Reynolds Equation. Lubricants. 2021; 9(5):55. https://doi.org/10.3390/lubricants9050055

Chicago/Turabian StyleColombo, Federico, Luigi Lentini, Terenziano Raparelli, Andrea Trivella, and Vladimir Viktorov. 2021. "An Identification Method for Orifice-Type Restrictors Based on the Closed-Form Solution of Reynolds Equation" Lubricants 9, no. 5: 55. https://doi.org/10.3390/lubricants9050055

APA StyleColombo, F., Lentini, L., Raparelli, T., Trivella, A., & Viktorov, V. (2021). An Identification Method for Orifice-Type Restrictors Based on the Closed-Form Solution of Reynolds Equation. Lubricants, 9(5), 55. https://doi.org/10.3390/lubricants9050055