Rapid Fleet Condition Analysis through Correlating Basic Vehicle Tracking Data with Engine Oil FT-IR Spectra

Abstract

1. Introduction

- Accumulation of contaminants, such as soot, water, or fuel,

- Oxidation and nitration through thermo-oxidative degradation and

- Additive depletion, e.g., antioxidant (AO) and antiwear (AW) additive reduction.

2. Materials and Methods

2.1. Field Test and Selected Vehicles

- SUV-S: standard size suburban utility vehicle

- SUV-C: a compact suburban utility vehicle

- SW-E: executive size station wagon

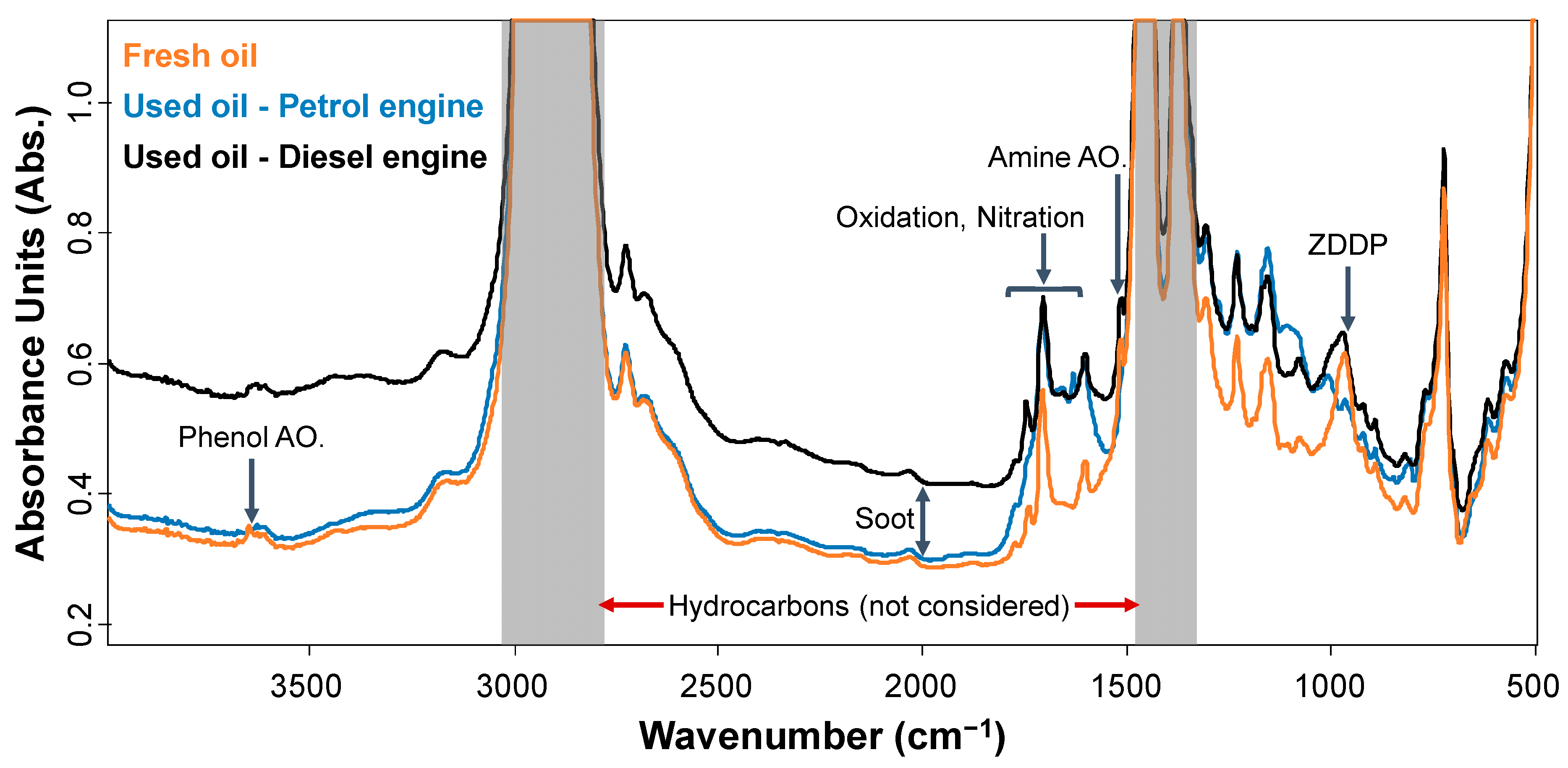

2.2. Oil Condition Monitoring

2.3. Multivariate Data Analysis

3. Results and Discussion

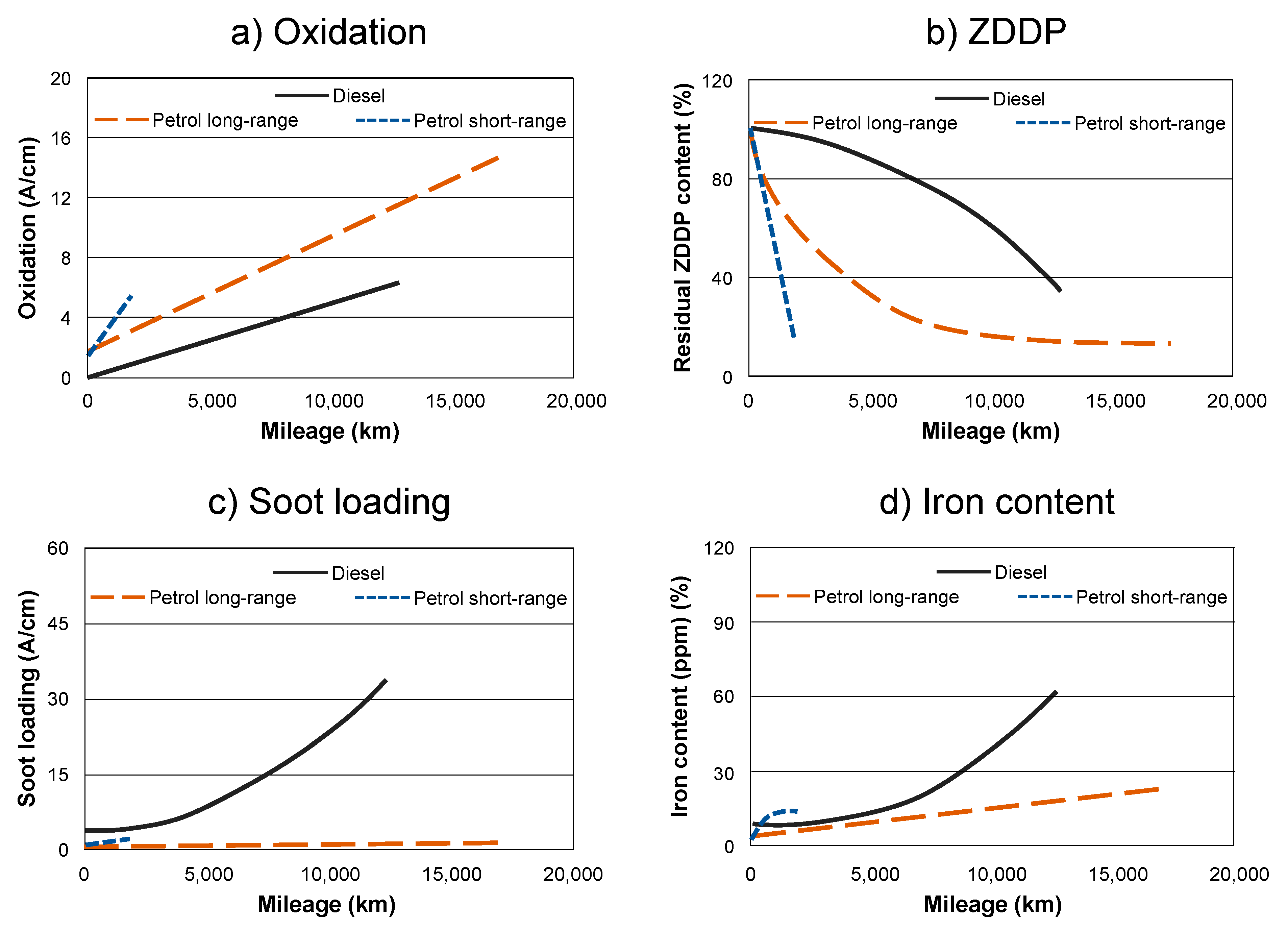

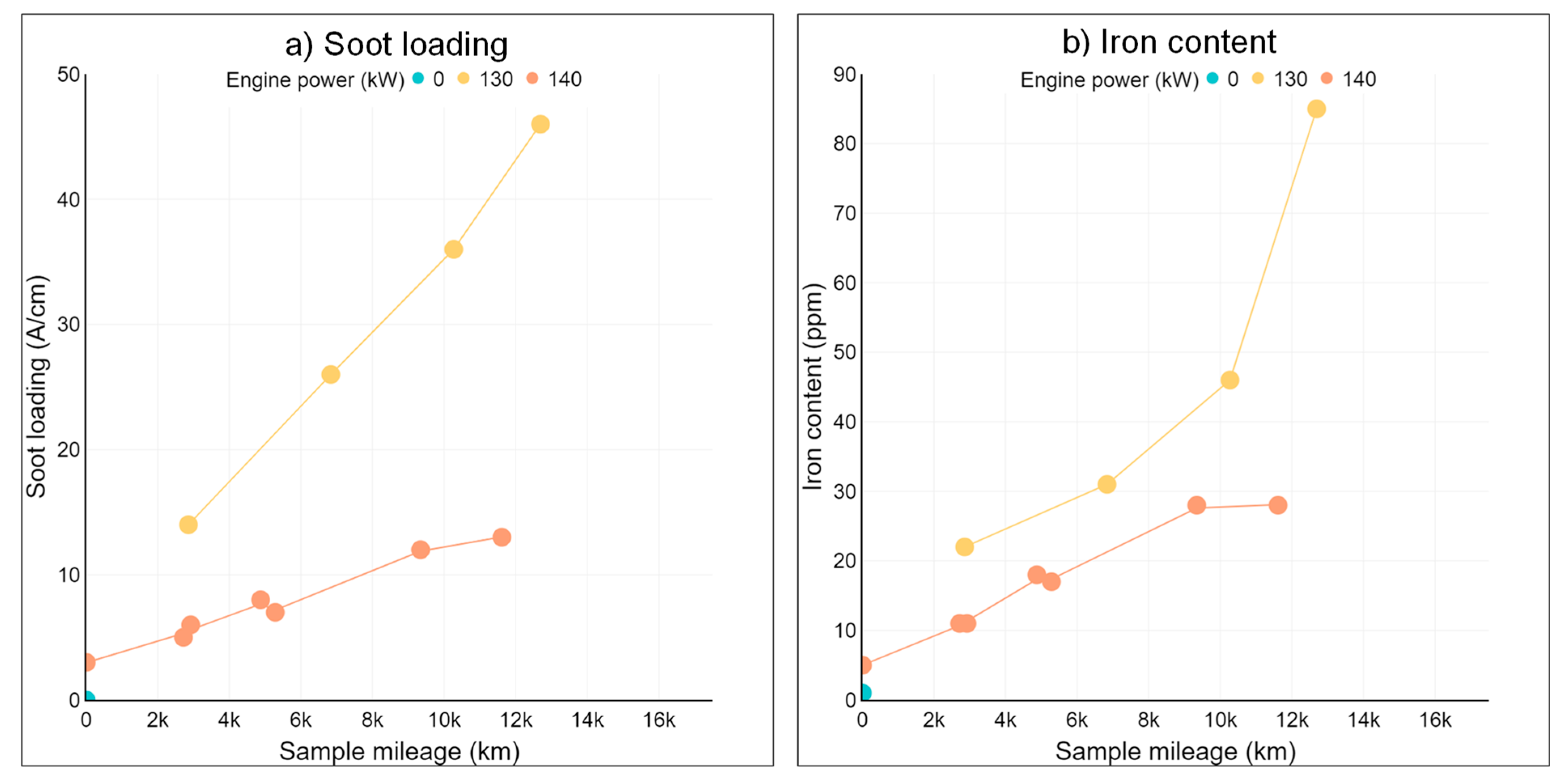

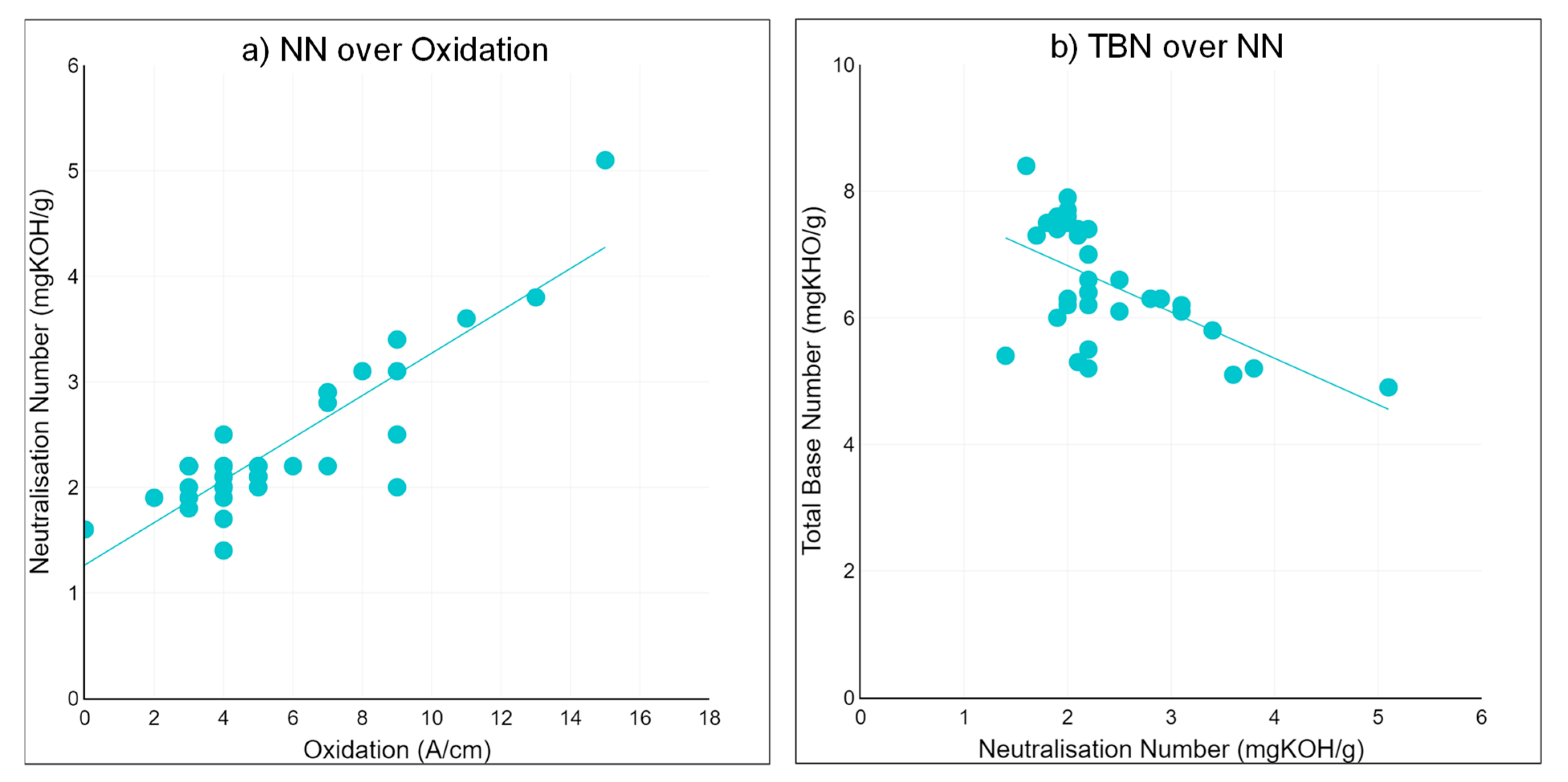

3.1. Summary of the Chemical Parameters

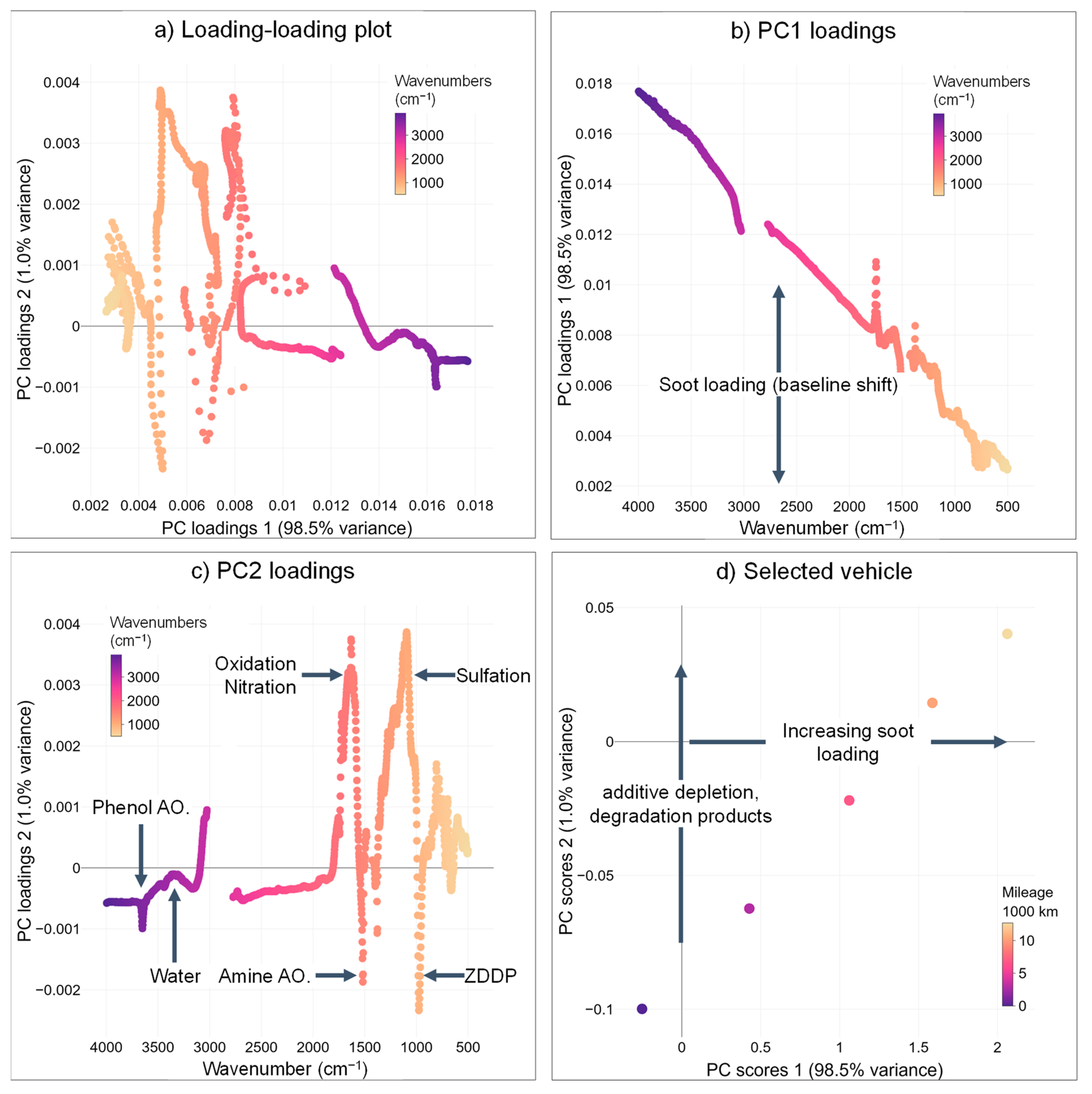

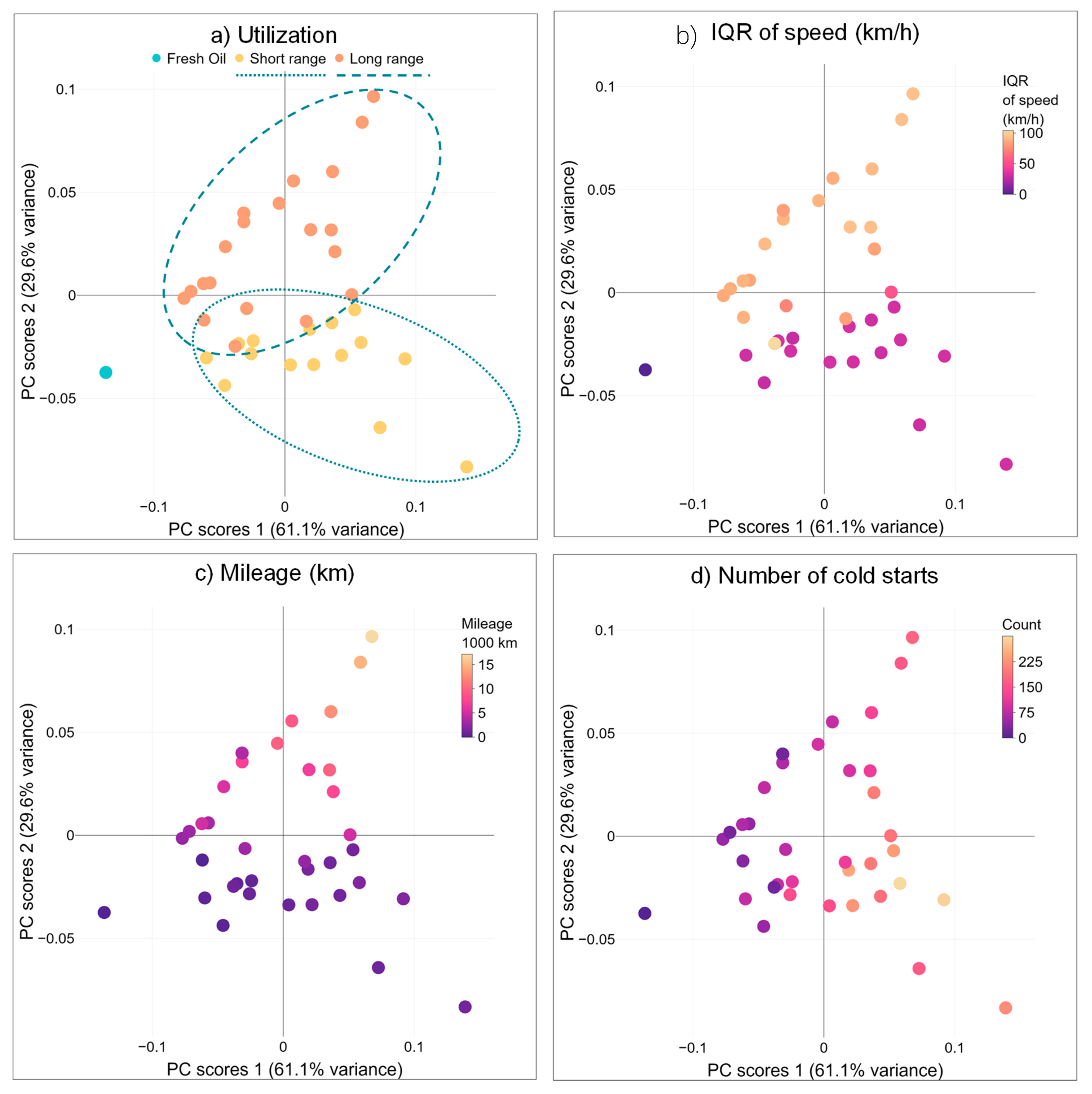

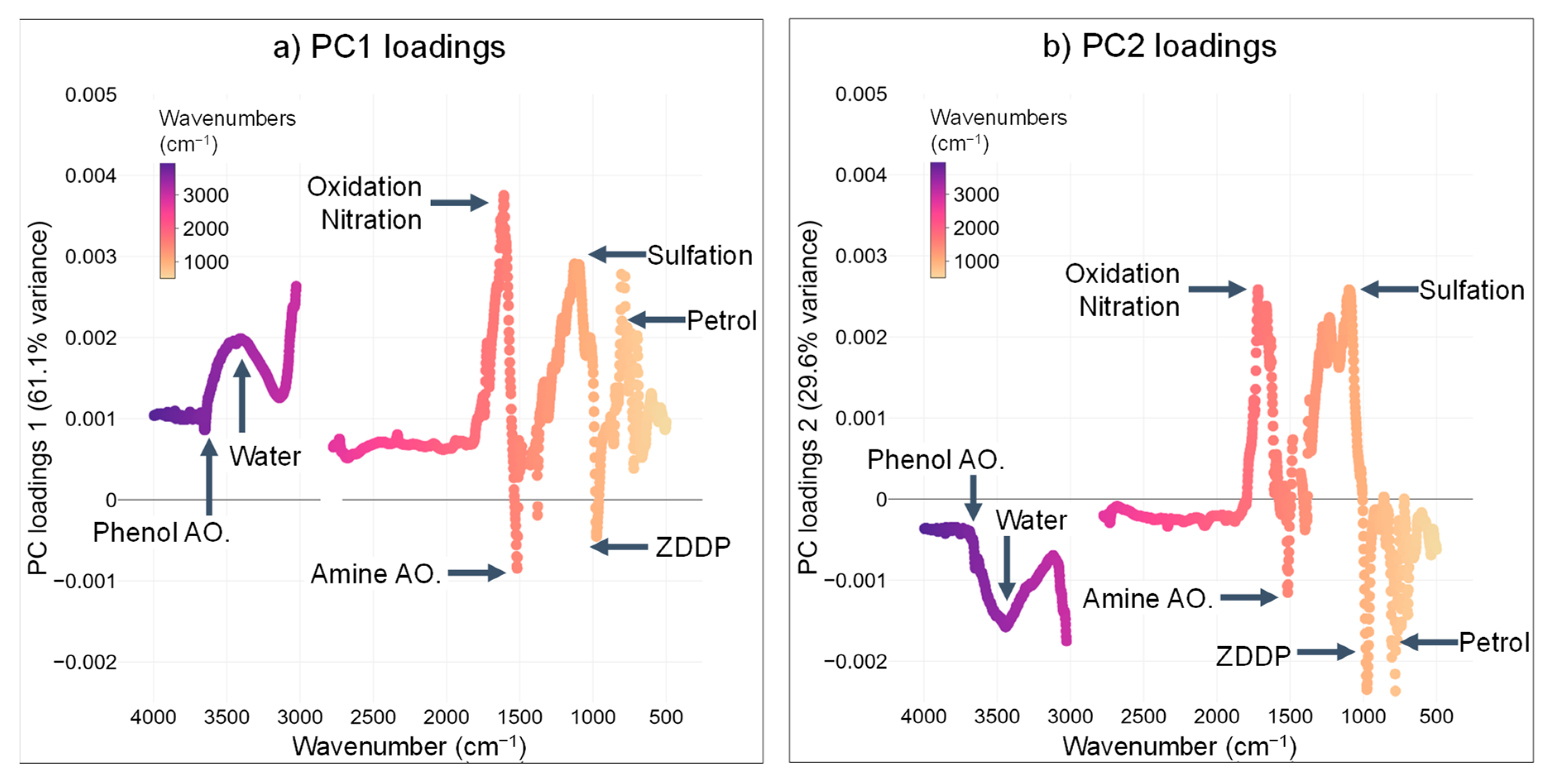

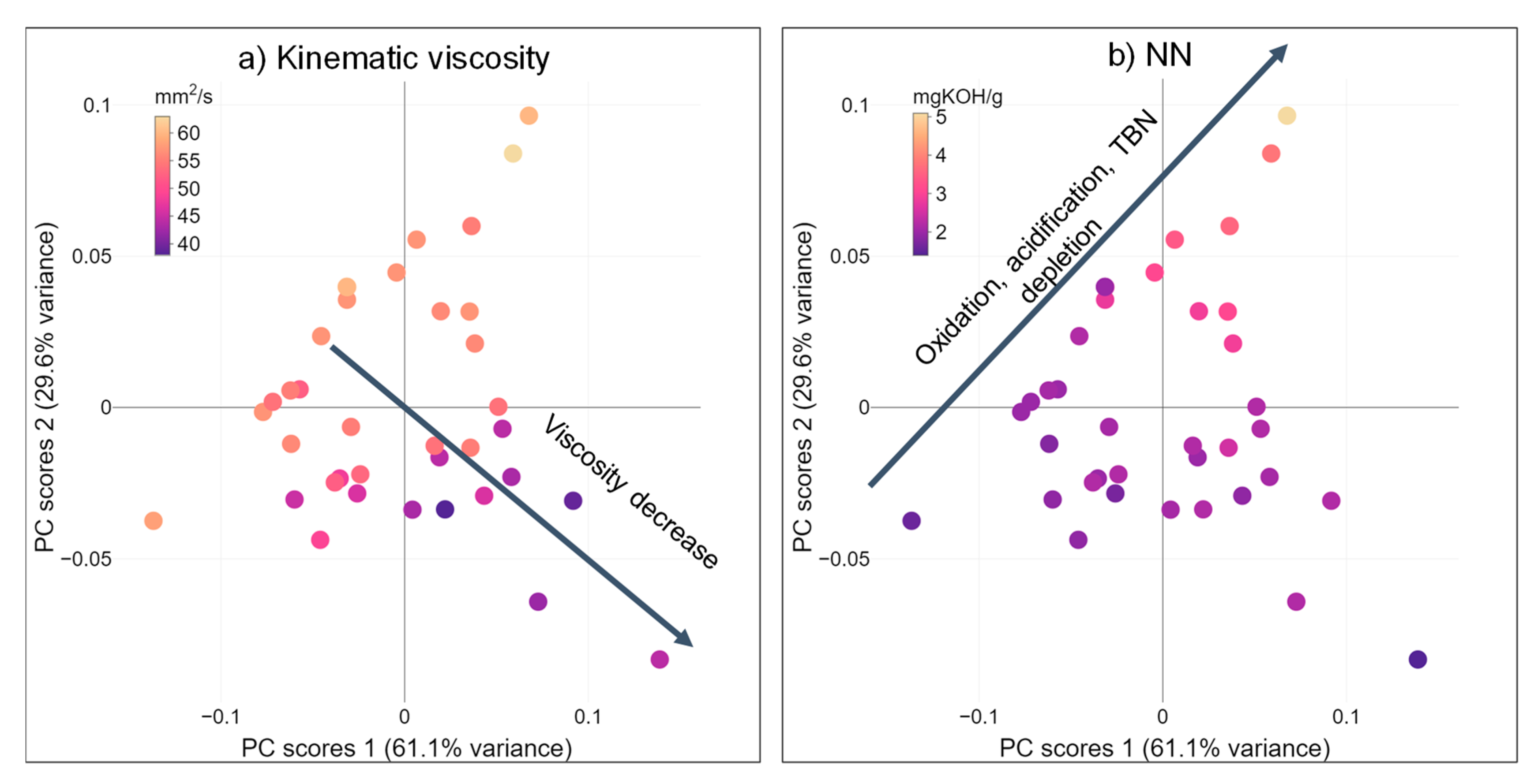

3.2. Principal Component Analysis (PCA)—All Vehicles

3.3. Principal Component Analysis (PCA)—Petrol Vehicles Only

4. Merits of the PCA Approach

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Commission Launches the Fit for 55% Package. Available online: https://www.interregeurope.eu/policylearning/news/12610/commission-launches-the-fit-for-55-package/?no_cache=1&cHash=a371af17736f1f2f09030ee45e7dd6f2 (accessed on 30 August 2021).

- Cui, H.; Hall, D.; Lutsey, N. Update on the Global Transition to Electric Vehicles through 2019; International Council on Clean Transportation: Beijing, China; Berlin, Germany, 2020; Available online: https://theicct.org/publications/update-global-ev-transition-2019 (accessed on 30 August 2021).

- Baldwin, R. Toyota Is Finally Making an Electric Vehicle, Plans More. Available online: https://www.caranddriver.com/news/a34896309/toyota-electric-cars-plans-revealed/ (accessed on 30 August 2021).

- Blanco, S. Honda, VW Making Wildly Different Bets on Our Electric Future. Available online: https://www.caranddriver.com/news/a30350065/honda-vw-electric-cars-future/ (accessed on 30 August 2021).

- Reuters BMW Aims for 20% of Its Vehicles to Be Electric by 2023 -Paper. Available online: https://www.reuters.com/article/bmw-electric-idUSKBN2910GV (accessed on 30 August 2021).

- Toyota Mirai Breaks World Record for Distance Driven with One Fill of Hydrogen. Available online: https://newsroom.toyota.eu/toyota-mirai-breaks-world-record-for-distance-driven-with-one-fill-of-hydrogen/ (accessed on 30 August 2021).

- BMW Starts European Road Tests of Hydrogen Fuel Cell Cars. Available online: https://www.cnbc.com/2021/06/17/bmw-starts-european-road-tests-of-hydrogen-fuel-cell-cars.html (accessed on 30 August 2021).

- Volkswagen Investiert in Batterie-Standort Salzgitter. Available online: https://www.volkswagenag.com/de/news/2020/05/Volkswagen_invests_in_battery_operations_at_Salzgitter.html# (accessed on 30 August 2021).

- “Automotive Cells Company”: Groupe PSA und Total schaffen Joint Venture zur Produktion von Batterien in Europa. Available online: https://media.stellantis.de/de/Automotive-Cells-Company-Groupe-PSA-und-Total-schaffen-Joint-Venture-zur-Produktion-von-Batterien-in-Europa_03092020 (accessed on 30 August 2021).

- H2—Key Player in the Maritime Energy Transition. Available online: https://www.man-es.com/marine/strategic-expertise/future-fuels/hydrogen (accessed on 30 August 2021).

- Cummins Begins Testing of Hydrogen Fueled Internal Combustion Engine. Available online: https://www.cummins.com/news/releases/2021/07/13/cummins-begins-testing-hydrogen-fueled-internal-combustion-engine (accessed on 30 August 2021).

- Toyota Developing Hydrogen Engine Technologies Through Motorsports. Available online: https://global.toyota/en/newsroom/corporate/35209996.html (accessed on 30 August 2021).

- Fuel Types of New Passenger Cars in the, EU. Available online: https://www.acea.auto/figure/fuel-types-of-new-passenger-cars-in-eu/ (accessed on 30 August 2021).

- Qian, Y.; Zhu, L.; Wang, Y.; Lu, X. Recent progress in the development of biofuel 2,5-dimethylfuran. Renew. Sustain. Energy Rev. 2015, 41, 633–646. [Google Scholar] [CrossRef]

- Omari, A.; Heuser, B.; Pischinger, S. Potential of oxymethylenether-diesel blends for ultra-low emission engines. Fuel 2017, 209, 232–237. [Google Scholar] [CrossRef]

- Aakko-Saksa, P.; Koponen, P.; Roslund, P.; Laurikko, J.; Nylund, N.-O.; Karjalainen, P.; Rönkkö, T.; Timonen, H. Comprehensive emission characterisation of exhaust from alternative fuelled cars. Atmos. Environ. 2020, 236, 117643. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, J.; Han, B.; Zhang, P.; Hua, H.; Chen, H.; Su, X. Emissions of automobiles fueled with alternative fuels based on engine technology: A review. J. Traffic Transp. Eng. 2018, 5, 318–334. [Google Scholar] [CrossRef]

- Niethammer, B.; Wodarz, S.; Betz, M.; Haltenort, P.; Oestreich, D.; Hackbarth, K.; Arnold, U.; Otto, T.; Sauer, J. Alternative Liquid Fuels from Renewable Resources. Chem. Ing. Tech. 2018, 90, 99–112. [Google Scholar] [CrossRef]

- Semelsberger, T.A.; Borup, R.L.; Greene, H.L. Dimethyl ether (DME) as an alternative fuel. J. Power Sources 2006, 156, 497–511. [Google Scholar] [CrossRef]

- Costa, H.L.; Spikes, H. Effects of Ethanol Contamination on Friction and Elastohydrodynamic Film Thickness of Engine Oils. Tribol. Trans. 2015, 58, 158–168. [Google Scholar] [CrossRef][Green Version]

- Nagy, A.L.; Singer, A. The impact of RME biodiesel on base oil aging—A friction and wear study. In Proceedings of the 7th European Conference on Tribology, Vienna, Austria, 12–14 June 2019; pp. 55–56. [Google Scholar]

- Nagy, A.L.; Knaup, J.; Zsoldos, I. A friction and wear study of laboratory aged engine oil in the presence of diesel fuel and oxymethylene ether. Tribol. Mater. Surfaces Interfaces 2019, 13, 20–30. [Google Scholar] [CrossRef]

- Nagy, A.L.; Rohde-Brandenburger, J.; Zsoldos, I. Artificial Aging Experiments of Neat and Contaminated Engine Oil Samples. Lubricants 2021, 9, 63. [Google Scholar] [CrossRef]

- Dörr, N.; Agocs, A.; Besser, C.; Ristić, A.; Frauscher, M. Engine Oils in the Field: A Comprehensive Chemical Assessment of Engine Oil Degradation in a Passenger Car. Tribol. Lett. 2019, 67, 68. [Google Scholar] [CrossRef]

- Rudnick, L.R. Lubricant Additives, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781315120621. [Google Scholar]

- Diaby, M.; Sablier, M.; Le Negrate, A.; El Fassi, M.; Bocquet, J. Understanding carbonaceous deposit formation resulting from engine oil degradation. Carbon N. Y. 2009, 47, 355–366. [Google Scholar] [CrossRef]

- Khuong, L.S.; Zulkifli, N.W.M.; Masjuki, H.H.; Mohamad, E.N.; Arslan, A.; Mosarof, M.H.; Azham, A. A review on the effect of bioethanol dilution on the properties and performance of automotive lubricants in gasoline engines. RSC Adv. 2016, 6, 66847–66869. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dörr, N. Comprehensive assessment of oil degradation patterns in petrol and diesel engines observed in a field test with passenger cars—Conventional oil analysis and fuel dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Besser, C.; Agocs, A.; Ronai, B.; Ristic, A.; Repka, M.; Jankes, E.; McAleese, C.; Dörr, N. Generation of engine oils with defined degree of degradation by means of a large scale artificial alteration method. Tribol. Int. 2019, 132, 39–49. [Google Scholar] [CrossRef]

- Agocs, A.; Budnyk, S.; Frauscher, M.; Ronai, B.; Besser, C.; Dörr, N. Comparing oil condition in diesel and gasoline engines. Ind. Lubr. Tribol. 2020, 72, 1033–1039. [Google Scholar] [CrossRef]

- Agocs, A.; Budnyk, S.; Besser, C.; Ristic, A.; Frauscher, M.; Ronai, B.; Dörr, N. Production of Used Engine Oils with Defined Degree of Degradation in a Large-scale Device: Correlation of Artificially Altered Oils with Field Samples. Acta Tech. Jaurinensis 2020, 13, 131–150. [Google Scholar] [CrossRef]

- Besser, C.; Schneidhofer, C.; Dörr, N.; Novotny-Farkas, F.; Allmaier, G. Investigation of long-term engine oil performance using lab-based artificial ageing illustrated by the impact of ethanol as fuel component. Tribol. Int. 2012, 46, 174–182. [Google Scholar] [CrossRef]

- Besser, C.; Dörr, N.; Novotny-Farkas, F.; Varmuza, K.; Allmaier, G. Comparison of engine oil degradation observed in laboratory alteration and in the engine by chemometric data evaluation. Tribol. Int. 2013, 65, 37–47. [Google Scholar] [CrossRef]

- Besser, C.; Steinschütz, K.; Dörr, N.; Novotny-Farkas, F.; Allmaier, G. Impact of engine oil degradation on wear and corrosion caused by acetic acid evaluated by chassis dynamometer bench tests. Wear 2014, 317, 64–76. [Google Scholar] [CrossRef]

- Wei, L.; Duan, H.; Jin, Y.; Jia, D.; Cheng, B.; Liu, J.; Li, J. Motor oil degradation during urban cycle road tests. Friction 2020, 9, 1002–1011. [Google Scholar] [CrossRef]

- Dörr, N.; Brenner, J.; Ristic, A.; Ronai, B.; Besser, C.; Pejaković, V.; Frauscher, M. Correlation Between Engine Oil Degradation, Tribochemistry, and Tribological Behavior with Focus on ZDDP Deterioration. Tribol. Lett. 2019, 67. [Google Scholar] [CrossRef]

- Barnes, A.M.; Bartle, K.D.; Thibon, V.R.A. A review of zinc dialkyldithiophosphates (ZDDPS): Characterisation and role in the lubricating oil. Tribol. Int. 2001, 34, 389–395. [Google Scholar] [CrossRef]

- Cen, H.; Morina, A.; Neville, A. Effect of lubricant ageing on lubricant physical and chemical properties and tribological performance. Part I: Effect of lubricant chemistry. Ind. Lubr. Tribol. 2018, 70, 385–392. [Google Scholar] [CrossRef]

- Fuller, M.L.S.; Kasrai, M.; Bancroft, G.M.; Fyfe, K.N.; Tan, K.H. Solution decomposition of zinc dialkyl dithiophosphate and its effect on antiwear and thermal film formation studied by X-ray absorption spectroscopy. Tribol. Int. 1998, 31, 627–644. [Google Scholar] [CrossRef]

- Uy, D.; Simko, S.J.; Carter, R.O.; Jensen, R.K.; Gangopadhyay, A.K. Characterization of anti-wear films formed from fresh and aged engine oils. Wear 2007, 263, 1165–1174. [Google Scholar] [CrossRef]

- Macián, V.; Tormos, B.; García-Barberá, A.; Tsolakis, A. Applying chemometric procedures for correlation the FTIR spectroscopy with the new thermometric evaluation of Total Acid Number and Total Basic Number in engine oils. Chemom. Intell. Lab. Syst. 2021, 208, 104215. [Google Scholar] [CrossRef]

- Gracia, N.; Thomas, S.; Bazin, P.; Duponchel, L.; Thibault-Starzyk, F.; Lerasle, O. Combination of mid-infrared spectroscopy and chemometric factorization tools to study the oxidation of lubricating base oils. Catal. Today 2010, 155, 255–260. [Google Scholar] [CrossRef]

- Wolak, A.; Molenda, J.; Zając, G.; Janocha, P. Identifying and modelling changes in chemical properties of engine oils by use of infrared spectroscopy. Measurement 2021, 186, 110141. [Google Scholar] [CrossRef]

- Bassbasi, M.; Hafid, A.; Platikanov, S.; Tauler, R.; Oussama, A. Study of motor oil adulteration by infrared spectroscopy and chemometrics methods. Fuel 2013, 104, 798–804. [Google Scholar] [CrossRef]

- Srata, L.; Farres, S.; Fethi, F. Engine oil authentication using near infrared spectroscopy and chemometrics methods. Vib. Spectrosc. 2019, 100, 99–106. [Google Scholar] [CrossRef]

- O’Kelly, M.; Niedzielski, M. Efficient spatial interaction: Attainable reductions in metropolitan average trip length. J. Transp. Geogr. 2008, 16, 313–323. [Google Scholar] [CrossRef]

- Studie: Das Verkehrstempo in Großstädten Sinkt. Available online: https://www.focus.de/auto/news/studie-das-verkehrstempo-in-grossstaedten-sinkt-duesseldorfer-fahren-am-langsamsten_id_11269331.html (accessed on 14 September 2021).

- ISO 3833:1977 Road Vehicles—Types—Terms and Definitions; International Organization for Standardization: Geneva, Switzerland, 1977.

- ASTM E2412-10(2018). Standard Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Varmuza, K.; Filzmoser, P. Introduction to Multivariate Statistical Analysis in Chemometrics, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9780429145049. [Google Scholar]

- Brereton, R.G. Chemometrics; John Wiley & Sons, Ltd.: Chichester, UK, 2003; ISBN 0471489778. [Google Scholar]

| Vehicle | 1 | 2 | 3 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|

| Engine power (kW) | 130 | 140 | 140 | 155 | 155 | 155 |

| Engine type | Diesel | Diesel | Diesel | Petrol | Petrol | Petrol |

| Transmission | MT | AT | AT | AT | AT | AT |

| Drivetrain | AWD | AWD | FWD | AWD | AWD | FWD |

| Model year | 2014 | 2017 | 2016 | 2013 | 2012 | 2011 |

| Curb weight (kg) | 1755 | 1770 | 1660 | 1565 | 1565 | 1565 |

| Chassis type | SUV-S | SUV-S | E | SUV-C | SUV-C | SUV-C |

| Oil change ODO (km) | 120,122 | 123,567 | 71,025 | 62,745 | 48,354 | 106,838 |

| Mileage (km) | 12,700 | 11,700 | 1300 | 1700 | 1100 | 1800 |

| Range | Long | Long | Long | Short | Short | Short |

| Vehicle | 5 | 6 | 7 | 4 | 8 | 9 |

|---|---|---|---|---|---|---|

| Engine power (kW) | 185 | 185 | 185 | 221 | 221 | 221 |

| Engine type | Petrol | Petrol | Petrol | Petrol | Petrol | Petrol |

| Transmission | AT | AT | AT | AT | AT | AT |

| Drivetrain | AWD | AWD | AWD | AWD | AWD | AWD |

| Model year | 2018 | 2018 | 2018 | 2014 | 2014 | 2016 |

| Curb weight (kg) | 1725 | 1725 | 1725 | 1620 | 1445 | 1450 |

| Chassis type | SW-E | SW-E | SW-E | C | C | C |

| Oil change ODO (km) | 65,842 | 63,384 | 68,171 | 69,102 | 73,341 | 73,726 |

| Mileage (km) | 14,700 | 17,100 | 9200 | 8000 | 5100 | 7500 |

| Range | Long | Long | Long | Long | Long | Long |

| Parameter | Wavenumber (1/cm) | Measured Spectral Characteristics | Reporting |

|---|---|---|---|

| Phenol AO. | 3650 | Peak height | Comparative to the fresh oil |

| Soot | 2000 | Peak height | Absorption/cm |

| Oxdation | 1720 | Peak height | Absorption/cm |

| Nitration | 1630 | Peak height | Absorption/cm |

| Amin AO. | 1515 | Peak height | Comparative to the fresh oil |

| Sulfation | 1150 | Peak height | Absorption/cm |

| ZDDP | 1020–920 | Maximum peak height in range | Comparative to the fresh oil |

| Water | 3500–3150 | Area | Absorption/cm |

| Petrol | 755–745 | Area | Absorption/cm |

| Diesel | 817–804 | Area | Absorption/cm |

| Parameter | Changes | Diesel Long-Range | Petrol Long-Range | Petrol Short-Range |

|---|---|---|---|---|

| Oxidation | Increasing |  |  |  |

| Nitration | Increasing |  |  |  |

| Sulfation | Increasing |  |  |  |

| Phenolic antioxidant content | Decreasing |  |  |  |

| Aminic antioxidant content | Decreasing |  |  |  |

| ZDDP antiwear content | Decreasing |  |  |  |

| NN | Increasing |  |  |  |

| TBN | Decreasing |  |  |  |

| Soot loading | Increasing |  |  |  |

| Boron content | Decreasing |  |  |  |

| Calcium content | Insignificant | Insignificant changes | ||

| Phosphorus content | Decreasing |  |  |  |

| Sulfur content | Decreasing |  |  |  |

| Zinc content | Insignificant | Insignificant changes | ||

| Iron content (Engine wear) | Increasing |  |  |  |

| Fuel dilution | Increasing |  |  |  |

| Kinematic viscosity | Decreasing | Insignificant changes |  | |

| Population 1. | Population 2 | Parameter | Test Type | T Value | Critical T Value (One-Tail) | Means Different? |

|---|---|---|---|---|---|---|

| Diesel 130 kW | Diesel 140 kW | Average trip length (km) | Equal variances | 11.635 | 1.729 | No |

| Average speed (km/h) | Unequal variances | 18.827 | 1.725 | No | ||

| Petrol 155 kW (short range) | Petrol 185 kW and 221 kW (long range) | Average trip length (km) | Unequal variances | −0.582 | 1.833 | Yes |

| Average speed (km/h) | Unequal variances | −1.653 | 1.860 | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagy, A.L.; Agocs, A.; Ronai, B.; Raffai, P.; Rohde-Brandenburger, J.; Besser, C.; Dörr, N. Rapid Fleet Condition Analysis through Correlating Basic Vehicle Tracking Data with Engine Oil FT-IR Spectra. Lubricants 2021, 9, 114. https://doi.org/10.3390/lubricants9120114

Nagy AL, Agocs A, Ronai B, Raffai P, Rohde-Brandenburger J, Besser C, Dörr N. Rapid Fleet Condition Analysis through Correlating Basic Vehicle Tracking Data with Engine Oil FT-IR Spectra. Lubricants. 2021; 9(12):114. https://doi.org/10.3390/lubricants9120114

Chicago/Turabian StyleNagy, András Lajos, Adam Agocs, Bettina Ronai, Péter Raffai, Jan Rohde-Brandenburger, Charlotte Besser, and Nicole Dörr. 2021. "Rapid Fleet Condition Analysis through Correlating Basic Vehicle Tracking Data with Engine Oil FT-IR Spectra" Lubricants 9, no. 12: 114. https://doi.org/10.3390/lubricants9120114

APA StyleNagy, A. L., Agocs, A., Ronai, B., Raffai, P., Rohde-Brandenburger, J., Besser, C., & Dörr, N. (2021). Rapid Fleet Condition Analysis through Correlating Basic Vehicle Tracking Data with Engine Oil FT-IR Spectra. Lubricants, 9(12), 114. https://doi.org/10.3390/lubricants9120114