Friction and Tribo-Chemical Behavior of SPD-Processed CNT-Reinforced Composites

Abstract

1. Introduction

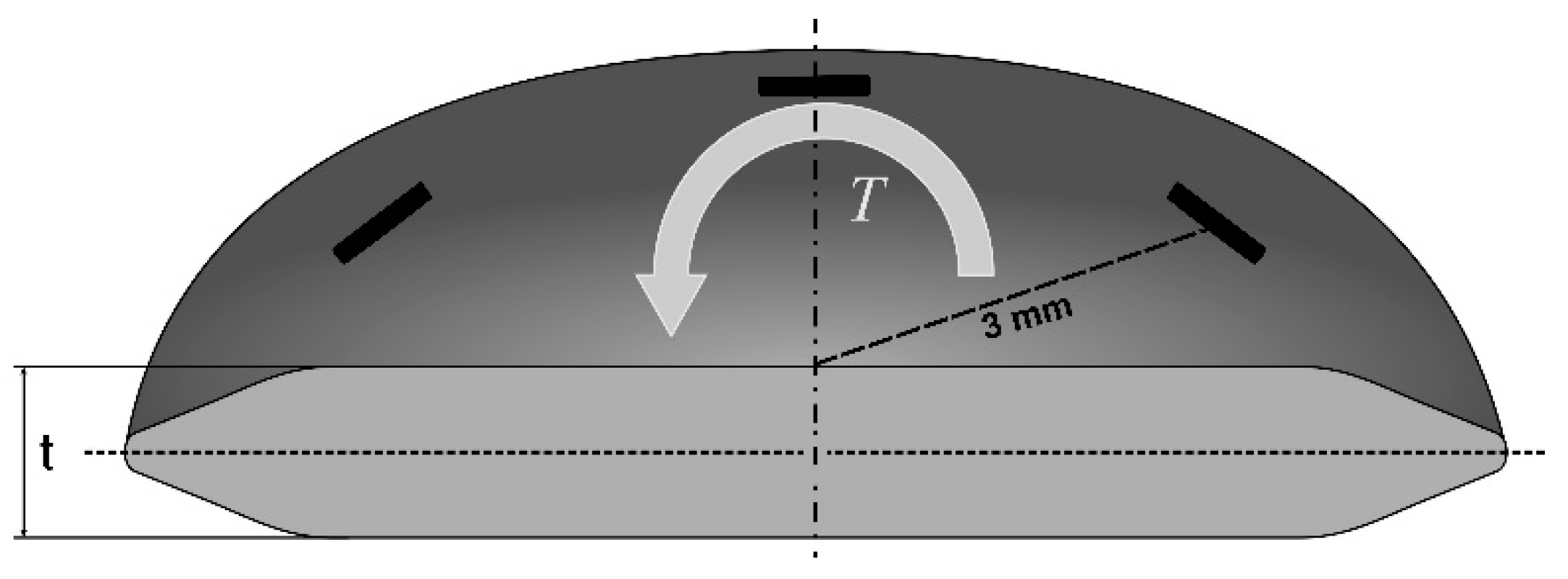

2. Materials and Methods

3. Results and Discussion

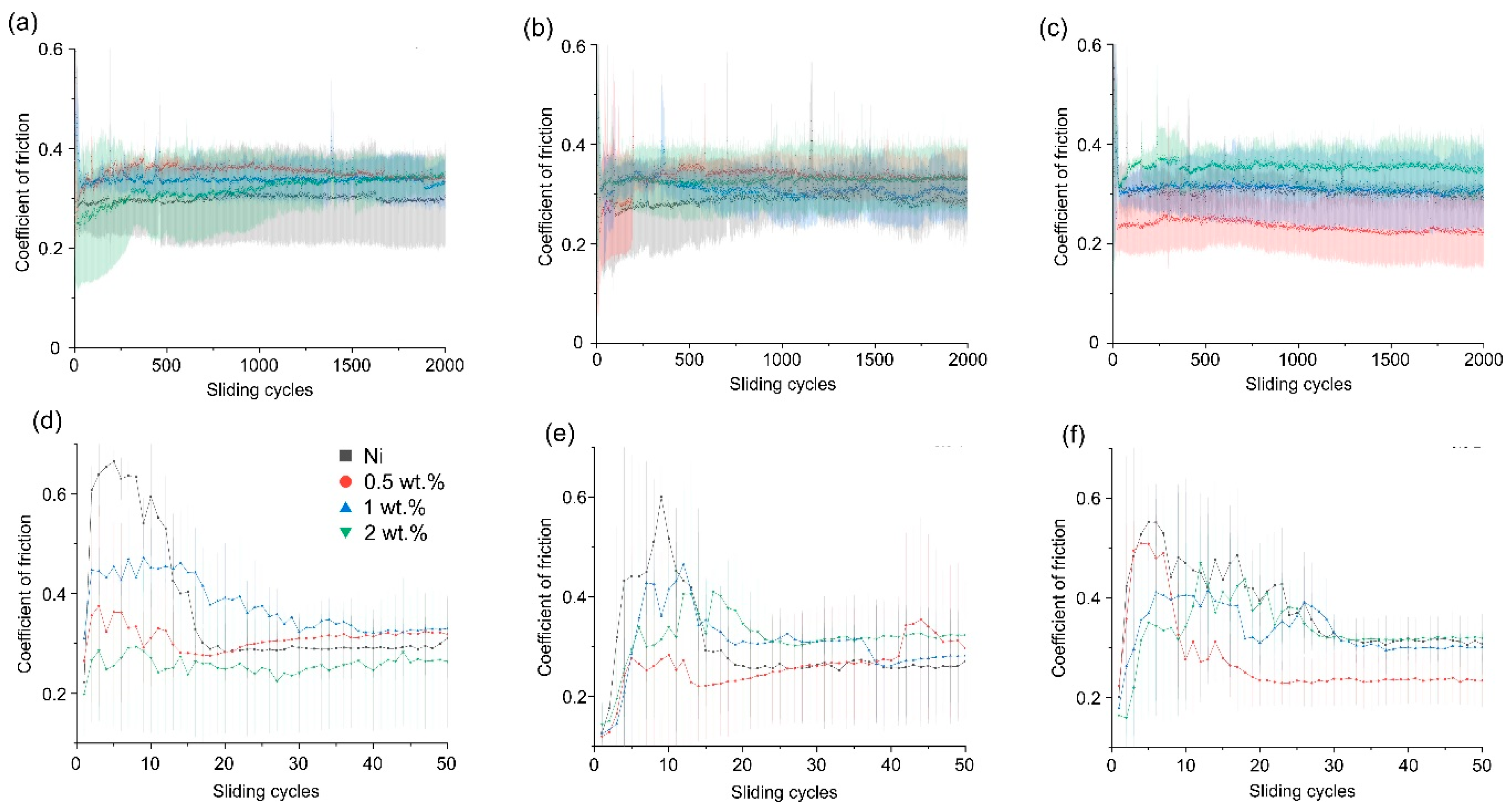

3.1. Friction Analysis

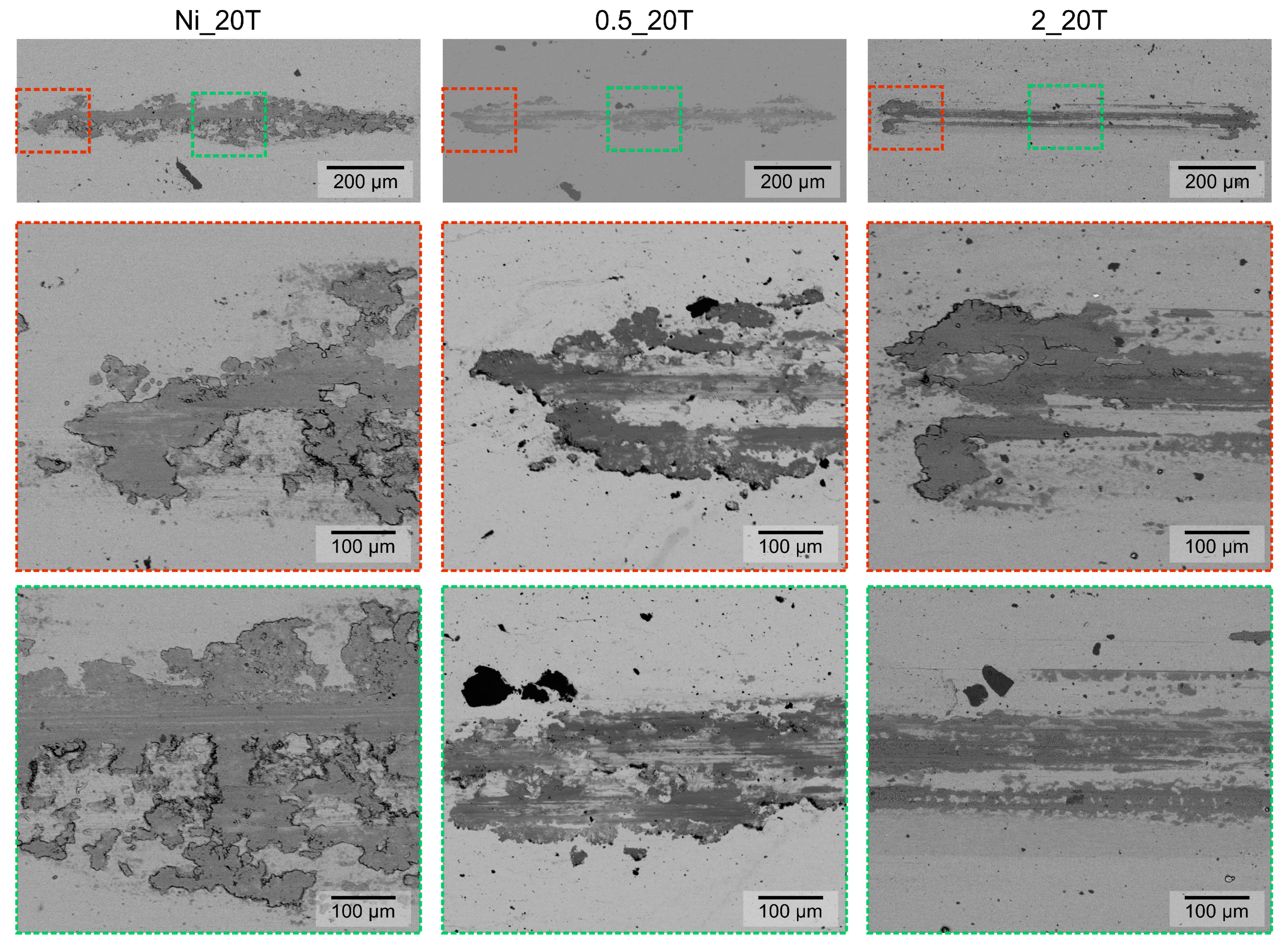

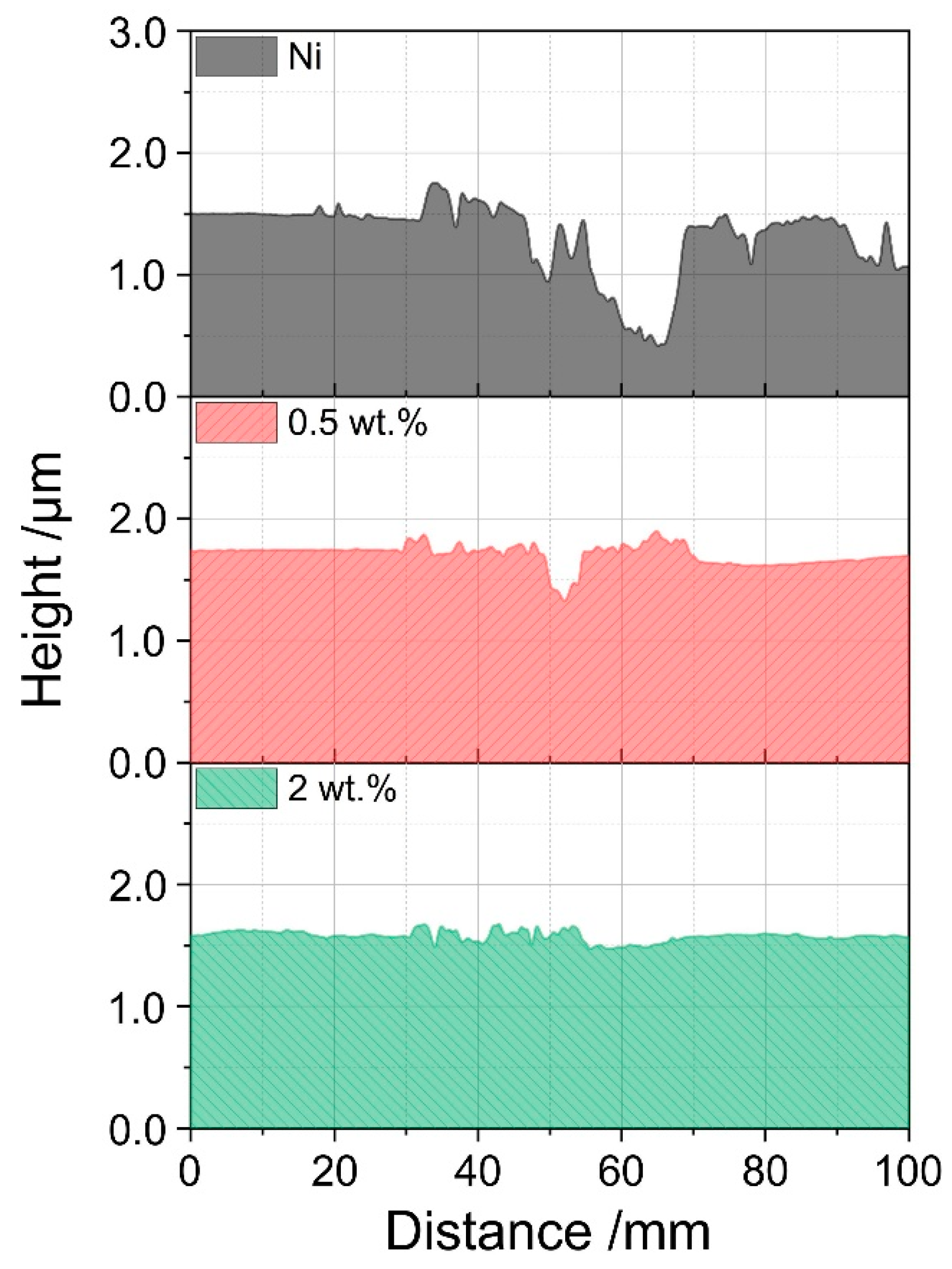

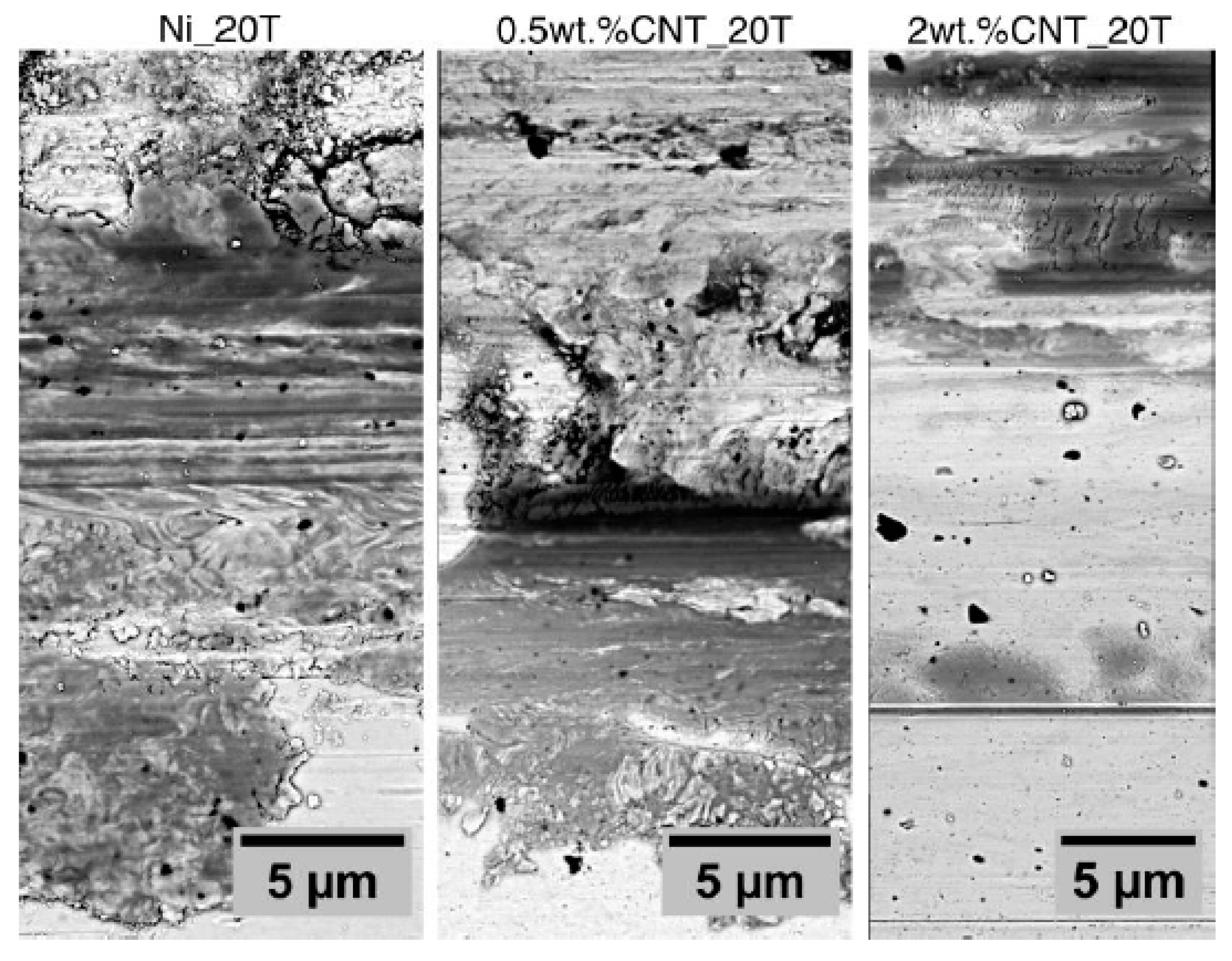

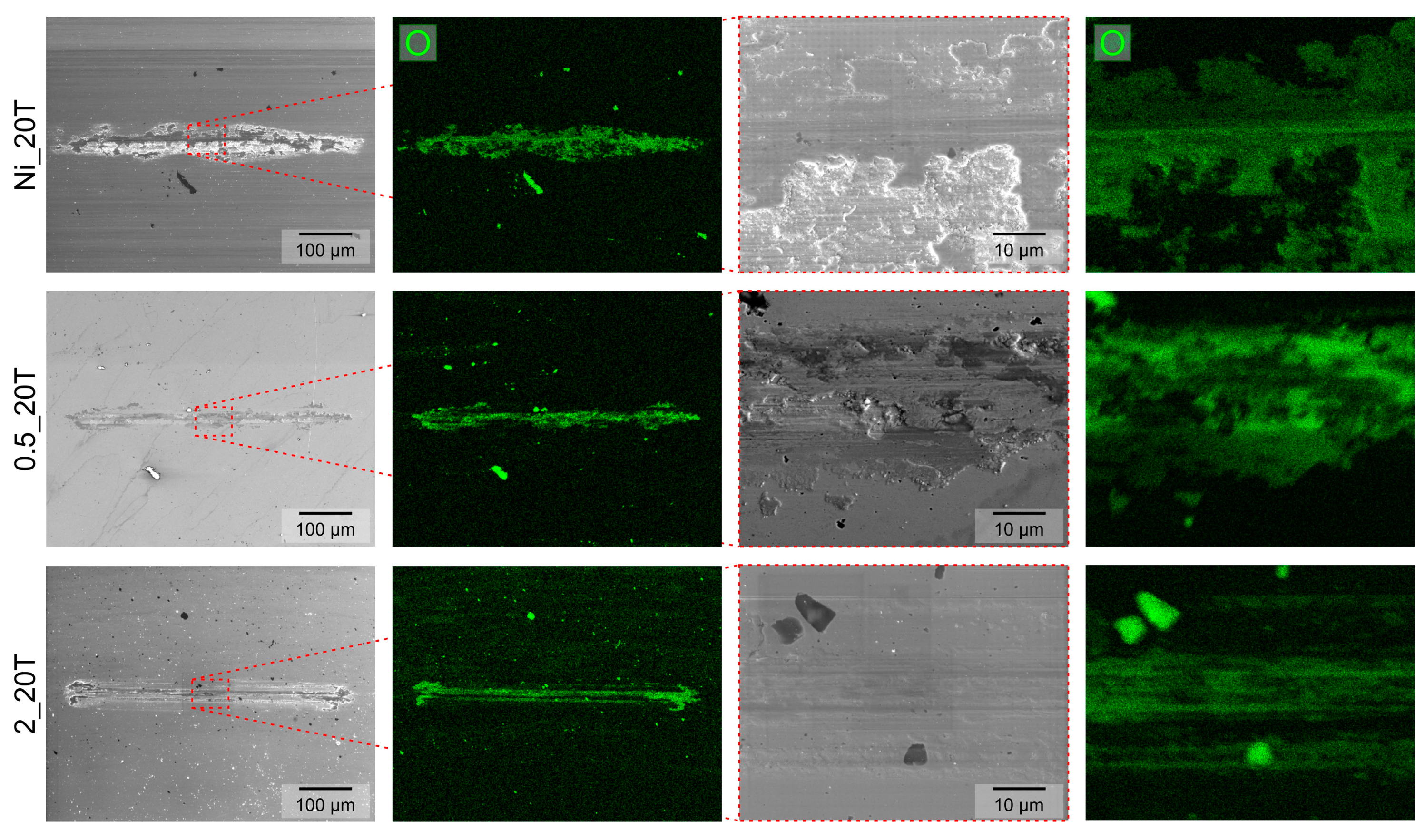

3.2. Wear Track Morphology and Tribo-Chemical Mechanisms

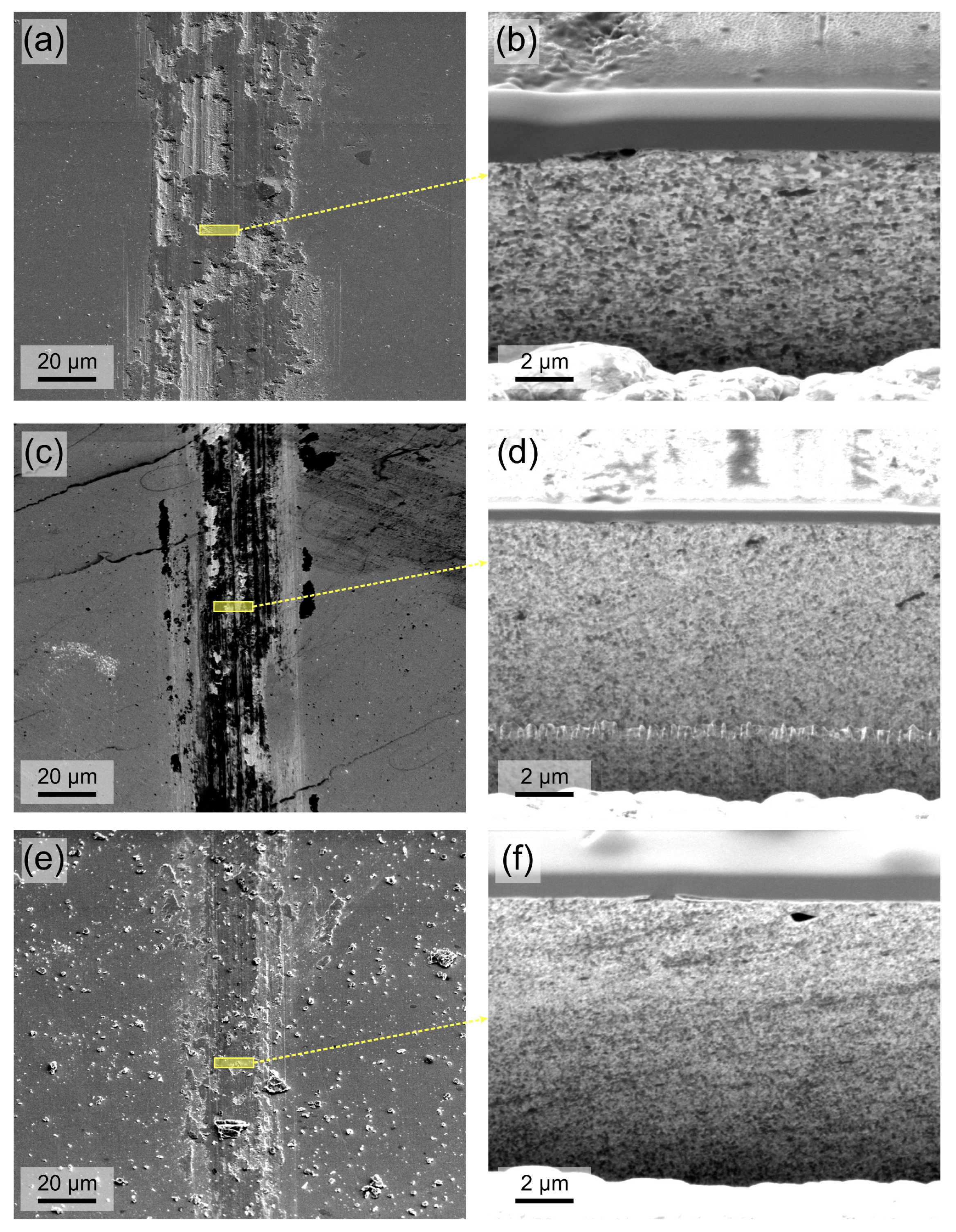

3.3. Microstructure under the Wear Scar

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Influence of surface preparation on roughness parameters, friction and wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Meine, K.; Schneider, T.; Spaltmann, D.; Santner, E. The influence of roughness on friction Part I: The influence of a single step. Wear 2002, 253, 725–732. [Google Scholar] [CrossRef]

- Meine, K.; Schneider, T.; Spaltmann, D.; Santner, E. The influence of roughness on friction: Part II. The influence of multiple steps. Wear 2002, 253, 733–738. [Google Scholar] [CrossRef]

- Reinert, L.; Schütz, S.; Suárez, S.; Mücklich, F. Influence of surface roughness on the lubrication effect of carbon nanoparticle-coated steel surfaces. Tribol. Lett. 2018, 66, 45. [Google Scholar] [CrossRef]

- Mishra, R.; Basu, B.; Balasubramaniam, R. Effect of grain size on the tribological behavior of nanocrystalline nickel. Mater. Sci. Eng. A 2004, 373, 370–373. [Google Scholar] [CrossRef]

- Argibay, N.; Chandross, M.; Cheng, S.; Michael, J.R. Linking microstructural evolution and macro-scale friction behavior in metals. J. Mater. Sci. 2017, 52, 2780–2799. [Google Scholar]

- Grützmacher, P.G.; Rammacher, S.; Rathmann, D.; Motz, C.; Mücklich, F.; Suarez, S. Interplay between microstructural evolution and tribo-chemistry during dry sliding of metals. Friction 2019. [Google Scholar] [CrossRef]

- Hutchings, I. Tribology: Friction and Wear of Engineering Materials, 2nd ed.; Elsevier: Oxford, UK, 2017. [Google Scholar]

- Rigney, D.A.; Fu, X.Y.; Hammerberg, J.E.; Holian, B.L.; Falk, M.L. Examples of structural evolution during sliding and shear of ductile materials. Scr. Mater. 2003, 49, 977–983. [Google Scholar] [CrossRef]

- Prasad, S.V.; Battaile, C.C.; Kotula, P.G. Friction transitions in nanocrystalline nickel. Scr. Mater. 2011, 64, 729–732. [Google Scholar] [CrossRef]

- Wasekar, N.P.; Haridoss, P.; Seshadri, S.K.; Sundararajan, G. Sliding wear behavior of nanocrystalline nickel coatings: Influence of grain size. Wear 2012, 296, 536–546. [Google Scholar] [CrossRef]

- Gao, N.; Wang, C.T.; Wood, R.J.K.; Langdon, T.G. Tribological properties of ultrafine-grained materials processed by severe plastic deformation. J. Mater. Sci. 2012, 47, 4779–4797. [Google Scholar] [CrossRef]

- Darmiani, E.; Danaee, I.; Golozar, M.A.; Toroghinejad, M.R.; Ashrafi, A.; Ahmadi, A. Reciprocating wear resistance of Al-SiC nano-composite fabricated by accumulative roll bonding process. Mater. Des. 2013, 50, 497–502. [Google Scholar] [CrossRef]

- Edalati, K.; Ashida, M.; Horita, Z.; Matsui, T.; Kato, H. Wear resistance and tribological features of pure aluminum and Al-Al2O3 composites consolidated by high-pressure torsion. Wear 2014, 310, 83–89. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Tribological studies on microwave sintered copper-carbon nanotube composites. Wear 2011, 270, 613–621. [Google Scholar] [CrossRef]

- Bastwros, M.M.H.; Esawi, A.M.K.; Wifi, A. Friction and wear behavior of Al-CNT composites. Wear 2013, 307, 164–173. [Google Scholar] [CrossRef]

- Abdullahi, U.; Maleque, M.A.; Nirmal, U. Wear mechanisms map of CNT-Al nano-composite. Procedia Eng. 2013, 68, 736–742. [Google Scholar] [CrossRef]

- Dorri Moghadam, A.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Reinert, L.; Suárez, S.; Rosenkranz, A. Tribo-Mechanisms of Carbon Nanotubes: Friction and Wear Behavior of CNT-Reinforced Nickel Matrix Composites and CNT-Coated Bulk Nickel. Lubricants 2016, 4, 11. [Google Scholar] [CrossRef]

- Reinert, L.; Lasserre, F.; Gachot, C.; Grützmacher, P.; Maclucas, T.; Souza, N.; Mücklich, F.; Suarez, S. Long-lasting solid lubrication by CNT-coated patterned surfaces. Sci. Rep. 2017, 7, 42873. [Google Scholar] [CrossRef] [PubMed]

- Aristizabal, K.; Suárez, S.; Katzensteiner, A.; Bachmaier, A.; Mücklich, F. Evolution of the microstructure in carbon nanotube reinforced Nickel matrix composites processed by high-pressure torsion. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bristol, UK, 2017; Volume 258, No. 1. p. 012008. [Google Scholar]

- Aristizabal, K.; Katzensteiner, A.; Bachmaier, A.; Mücklich, F.; Suárez, S. On the reinforcement homogenization in CNT/metal matrix composites during severe plastic deformation. Mater. Charact. 2018, 136, 375–381. [Google Scholar] [CrossRef]

- Katzensteiner, A.; Aristizabal, K.; Suarez, S.; Pippan, R.; Bachmaier, A. Temperature dependent structural evolution in nickel/carbon nanotube composites processed by high-pressure torsion. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bristol, UK, 2017; Volume 194, No. 1. p. 01201. [Google Scholar]

- Aristizabal, K.; Katzensteiner, A.; Leoni, M.; Mücklich, F.; Suárez, S. Evolution of the lattice defects and crystalline domain size in carbon nanotube metal matrix composites processed by severe plastic deformation. Mater. Charact. 2019, 154, 344–352. [Google Scholar] [CrossRef]

- Katzensteiner, A.; Müller, T.; Kormout, K.; Aristizabal, K.; Suarez, S.; Pippan, R.; Bachmaier, A. Influence of Processing Parameters on the Mechanical Properties of HPT-Deformed Nickel/Carbon Nanotube Composites. Adv. Eng. Mater. 2019, 21, 1800422. [Google Scholar] [CrossRef]

- Stüwe, H.P. Equivalent strains in severe plastic deformation. Adv. Eng. Mater. 2003, 5, 291–295. [Google Scholar] [CrossRef]

- Reinert, L.; Zeiger, M.; Suárez, S.; Presser, V.; Mücklich, F. Dispersion analysis of carbon nanotubes, carbon onions, and nanodiamonds for their application as reinforcement phase in nickel metal matrix composites. RSC Adv. 2015, 5, 95149–95159. [Google Scholar] [CrossRef]

- La, P.; Ma, J.; Zhu, Y.T.; Yang, J.; Liu, W.; Xue, Q.; Valiev, R.Z. Dry-sliding tribological properties of ultrafine-grained Ti prepared by severe plastic deformation. Acta Mater. 2005, 53, 5167–5173. [Google Scholar] [CrossRef]

- Blau, P.J. On the nature of running-in. Tribol. Int. 2005, 38, 1007–1012. [Google Scholar] [CrossRef]

- Blau, P.J. Running-in: Art or engineering? J. Mater. Eng. 1991, 13, 47–53. [Google Scholar] [CrossRef]

- Wilson, S.; Alpas, A.T. Thermal effects on mild wear transitions in dry sliding of an aluminum. Wear 1999, 225, 440–449. [Google Scholar] [CrossRef]

- Stachowiak, G. Wear—Materials, Mechanisms and Practice, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Scharf, T.W.; Neira, A.; Hwang, J.Y.; Tiley, J.; Banerjee, R. Self-lubricating carbon nanotube reinforced nickel matrix composites. J. Appl. Phys. 2009, 106, 013508. [Google Scholar] [CrossRef]

- Aristizabal, K.; Katzensteiner, A.; Bachmaier, A.; Mücklich, F.; Suarez, S. Study of the structural defects on carbon nanotubes in metal matrix composites processed by severe plastic deformation. Carbon 2017, 125, 156–161. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Temperature | °C | 25 |

| Relative humidity | % | 3.8 |

| Load FN | N | 0.1 |

| Sliding velocity v | mm/s | 1 |

| Stroke length | Mm | 0.6 |

| Sample | Tested Equivalent Strain | Hardness/GPa |

|---|---|---|

| Ni_1T | 14.51 ± 0.75 | 4.56 ± 0.09 |

| Ni_10T | 146.47 ± 4.54 | 4.78 ± 0.04 |

| Ni_20T | 310.67 ± 8.68 | 4.85 ± 0.10 |

| 0.5_1T | 15.1 ± 0.65 | 3.92 ± 0.02 |

| 0.5_10T | 134.94 ± 8.18 | 5.56 ± 0.05 |

| 0.5_20T | 282.44 ± 25.89 | 6.44 ± 0.14 |

| 1_1T | 15.76 ± 0.73 | 3.63 ± 0.02 |

| 1_10T | 135.71 ± 3.48 | 6.33 ± 0.03 |

| 1_20T | 281.86 ± 0 | 7.58 ± 0.41 |

| 2_1T | 14.73 ± 1.09 | 3.58 ± 0.08 |

| 2_10T | 149.57 ± 2.59 | 7.62 ± 0.03 |

| 2_20T | 298.74 ± 14.23 | 8.01 ± 0.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aristizabal, K.; Tayrac, A.; Katzensteiner, A.; Bachmaier, A.; Suarez, S. Friction and Tribo-Chemical Behavior of SPD-Processed CNT-Reinforced Composites. Lubricants 2019, 7, 75. https://doi.org/10.3390/lubricants7090075

Aristizabal K, Tayrac A, Katzensteiner A, Bachmaier A, Suarez S. Friction and Tribo-Chemical Behavior of SPD-Processed CNT-Reinforced Composites. Lubricants. 2019; 7(9):75. https://doi.org/10.3390/lubricants7090075

Chicago/Turabian StyleAristizabal, Katherine, Alexandra Tayrac, Andreas Katzensteiner, Andrea Bachmaier, and Sebastian Suarez. 2019. "Friction and Tribo-Chemical Behavior of SPD-Processed CNT-Reinforced Composites" Lubricants 7, no. 9: 75. https://doi.org/10.3390/lubricants7090075

APA StyleAristizabal, K., Tayrac, A., Katzensteiner, A., Bachmaier, A., & Suarez, S. (2019). Friction and Tribo-Chemical Behavior of SPD-Processed CNT-Reinforced Composites. Lubricants, 7(9), 75. https://doi.org/10.3390/lubricants7090075