1. Introduction

Tribology, a multi-disciplinary field across mechanical and materials engineering, has been under ongoing exploration to ensure the maximum usage of potential materials where friction and wear are unavoidable. Among different material classes, high-performance polymers (HPPs) and their composites are being investigated by various researchers [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13] for such applications, owing to their high strength/density ratio as well as the structural integrity. A number of the applications, such as seals and bearings, are mainly focused on the tribological performance of HPPs and their composites, especially in non-lubricated, sliding conditions [

2,

3,

4,

5,

6]. For instance, the exceptional wear behavior of HPPs (commonly against metallic counterparts) without the requirement of lubricants is desirable in a number of applications, such as the textile and food industries, to avoid contamination problems. Further, HPPs have the ability to dampen shock and vibration with excellent corrosion resistance, making them excellent candidates for aerospace, chemical, and offshore applications.

Up to now, different kinds of polymers, including both thermoplastics and thermosets, are frequently used for various tribological applications [

8]. For example, epoxy is a common example of a thermoset, commonly withstanding its fragile and sensitive nature towards microfracture. On the contrary, high performance epoxies, which are normally prepared with high cross-link density, may have high Young’s modulus, greater strength, durable bond ability, and outstanding chemical constancy [

2,

3,

4,

5]. In particular, the mechanical properties, as well as the wear resistance of thermoset composites, can be significantly improved by filling with continuous fibers at high volume contents (> 50 vol %), e.g., using the conventional autoclave moulding technique. Nevertheless, the production time that is required for thermoset-based composites is rather long, due to the curing process. It has been envisioned that thermoplastics will be increasingly used, owing to the more cost-effective injection moulding with particulate and/or short fiber fillers. As noted, neat polymers are commonly ‘blended’ with different types of fillers to achieve desirable tribological/mechanical properties and other functions. It is important to state that to modify the properties of polymers using fillers, the right term should be “blended” instead of “reinforced”. This has been frequently overlooked in the literature. For instance, polytetrafluoroethylene (PTFE) is often employed as a solid lubricant to improve the friction performance, but it does not have an effect on improving (reinforcing) the mechanical properties. Towards that, Hunke et al. [

14,

15] recently indicated the benefits of surface functionalized PTFE powders for better reinforcement capabilities in HPPs. Also, the philosophy of incorporating fillers in the polymer matrix resembles that of metal matrix filled with inorganic oxide/carbide/nitride particles [

16]. The type, form, and compatibility of fillers all have major roles in overall material performance.

In the literature, polymer composites with various types of fiber-like fillers have been well documented [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26]. Diverse matrix and fiber materials endow composites with exceptional properties for various applications where the retention of the mechanical properties of materials is of prime concern. However, compared to injection-mouldable neat polymers or particle-blended polymers, a drawback of such fiber-reinforced composites is that components fabricated from these materials generally require relatively lengthy fabrication times and a complex dispersing process to maintain the high length/diameter ratio of the fibers. Moreover, the alignment and orientation of fibers in fiber-blended composites are vital, but not in particle-blended polymers. Rasheva et al. [

27] pointed out the advantages of nanoparticle addition in polymer matrices over a short carbon fiber (SCF)-type filler blend, as the orientation of the fiber-type filler significantly influenced the wear behavior of the composites and directional loading during sliding. It is also worthwhile indicating that fiber-like fillers may not be easily used for novel additive manufacturing, such as the selective laser sinter (SLS) three-dimensional (3D) printer.

Over the last few decades, the tribological behavior of nanoparticle-blended HPPs has received more and more attention in the research community [

16,

17,

18,

19,

20,

21]. The strong mechanical properties of HPPs and their composites have led to the expectation of good wear resistance, even at high temperatures. Indeed, HPPs are presently being applied in sliding machinery components or as tribo-pairs in various fields where low friction and wear are required [

28,

29,

30,

31]. However, the involved wear mechanisms are not been fully understood, particularly due to the complex physical and chemical interactions in the wear process. During the wear, material removal occurs due to complex thermo-mechanical reactions that are dependent on the polymeric chain structure, the types of polymers or co-polymers (thermoplastic/thermoset), the polymeric functional groups, the tactility, molecular weight, and curing/setting behavior of polymer chains. [

28]. Moreover, because of the relatively low cohesive energy of polymers when compared to their pairing materials, such as metals and ceramics, polymers are capable of transmitting and distributing the load effectively across the matrix and blended particles, which results in significant reduction in wear and friction [

32,

33,

34,

35]. With the additional nanofillers, more complicated tribo-chemical reactions might take place in tribo-contact areas, which yield characteristic transfer layers (TLs). Incorporation of nanoparticles into the polymer matrix makes these TLs more stable and resilient, which may significantly decrease friction and wear. The structure and properties of such TLs differ from system to system and their in-depth understanding is required to understand the fundamental aspects of the tribology of HPPs and their composites. For example, such TLs may offer a boundary lubricant effect in tribo-contact, which allows such HPP composites to be used under high

pv (contact pressure,

p times sliding velocity,

v) conditions in unlubricated sliding. It is noted that both the terms, TFL and TL, have been used interchangeably in the literature. However, there is a distinction between them, as pointed out by Bahadur et al. [

18]. The term TFL is not appropriate when referring to material being transferred from a soft polymer interface to a harder metal counterpart. In fact, TFL is most appropriately used for continuous and uniform materials, while TL is attributed to either uniform or irregular materials along the wear patch or track. To develop high wear-resistant HPPs, it is important to understand the formation mechanism of TLs, as well as their dependence on the properties of polymer matrix, the type of fillers, and service conditions, such as temperature and lubrication.

Another important aspect of friction and wear is that they are not only dependent on material properties, but also on the tribo-system where the materials are being used, and are termed as “system responses” [

36]. Thus, the environmental conditions, such as lubricant medium, temperature, humidity, vibration, etc. also play big roles towards the overall performance of the system. For example, in liquid medium or at high temperatures, the abovementioned TLs might be partly dissolved or melted and become unstable, which sometimes severely outweighs the benefits that are required for dry sliding conditions. Moreover, liquids, such as water, may be absorbed by the polymers, which interrupt their molecular structures and thus deteriorate their tribological properties. Such ‘system responses’ of tribology makes it difficult to study the wear behavior of HPPs in isolation without considering their application environments, and an integrated approach is required to get the complete picture. Although it is necessary, a complete description of the tribological behavior of HPPs considering the material system and environment is not yet available. There are gaps in the knowledge related to the effects of environment on the tribological performance of such HPPs, and a fundamental understanding that is related to the role of TLs is absent. Additionally, the most recent progress in this field is not well interconnected in terms of the mechanical properties of HPPs and their tribological aspects. To tackle these concerns, the wear mechanisms of HPPs and the effects of diverse system variables, such as sliding speed, vibration, load, and environment temperature, on friction and wear development were examined based on the evidence offered in the literature. Understanding these will enable the design and selection of tribo-materials for specific applications.

Thus, the aim of this review is to get an overall picture of the tribological performance of HPPs and their composites, in terms of their respective mechanical properties, wear debris, and TLs formation, as well as the effect of the service environment.

2. Recent Developments of the Tribological Aspects of HPPs

Having a high heat distortion temperature (also known as heat deflection temperature under load, HDT) is a key feature of HPPs. In practice, HPPs are expected to retain their structural integrity over their continuous service temperature (CST), which is commonly higher than 150 °C by definition [

18]. In contrast, commonly used polymers, such as polyethylene terephthalate (PET), usually get deformed below 100 °C, which substantially limits their applications under dry sliding conditions, since the contact temperature can be significantly higher [

16]. High performance thermoplastics, such as polyamides, can be melted into complex shapes with high physical-mechanical and thermal properties. In fact, polyamides are the most widely used structural thermoplastics and they are characterized by high impact resistance and resistance to fluctuating loads, gasoline, and oils [

1,

2,

3,

4,

5,

6,

7,

8,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49]. On the other hand, heat-resistant engineering thermoplastics for specific purposes include fluoroplastics (polyfluoroolefins, fluoropolymers), some of which suffer from poor mechanical properties [

16,

20]. Fluoroplastics cannot be used as structural plastics, since their physical and mechanical properties are considerably inferior to other plastics, such as polyamides. The typical tensile strength of fluoroplastics does not exceed 30–40 MPa, with a modulus of elasticity of about 0.4 GPa. Since tribological properties are products of the entire system, to develop HPPs and their composites as potential tribo-materials, their properties, such as chemical resistance, mechanical properties, cohesive strength, and the retention of strength and structural integrity at service temperature, should be taken into consideration, according to the sliding conditions of the system in which these materials are intended to function.

2.1. Processing Characteristics of HPP Materials

The high thermal stability, as characterized by HDT, of HPPs normally makes their processing difficult and special instruments are often required. Most HPPs are made based on their heat stability, which makes them moderately expensive [

29,

33]. HPPs are thus about three to 20 times more expensive than common polymers/plastics [

18,

35]. Among the various HPPs that are reported in the literature, the followings are some that are commonly used in structural applications: Polyamides (PA), Polysulfone (PSU), Polyethersulfone (PES), Polyphthalamide (PPA), Poly(

p-vinylidene) fluoride (PVDF), Polyetherimide (PEI), Poly(

p-phenylene) sulphide (PPS), Polyether ether ketone (PEEK), Styrene-butadiene copolymers (SBC), Polyketone (PK), Poly(ether ketones) (PEK), Poly(para-phenylene) (PPP), and Polybenzimidazole (PBI). Like normal polymers, HPPs are also made up of repeating units of macromolecules that give rise to long polymeric chain structures in three dimensions.

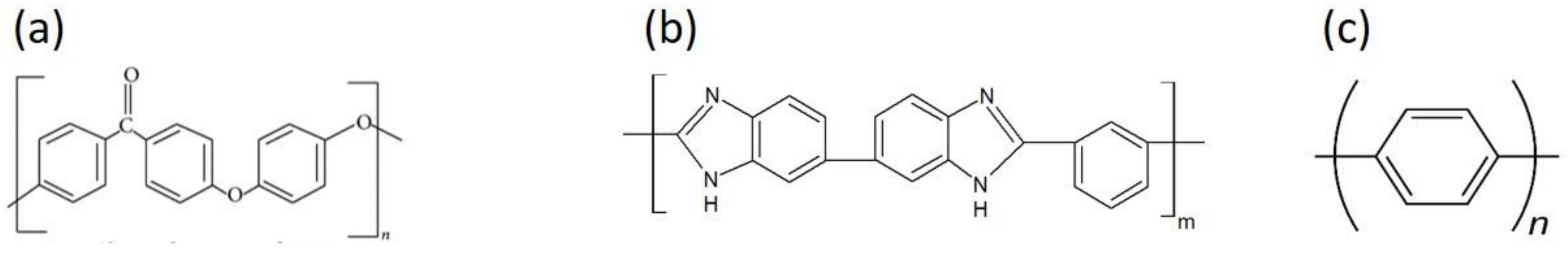

Figure 1 shows the reiterating units of PEEK, PPP, and PBI that build up their respective polymer structures.

Based on the microstructure of polymers, two approaches are usually taken to further enhance their mechanical and thermal performances: (i) the addition of inorganic nanofillers in the form of blends and (ii) co-polymerization by the addition of organic macromolecules. In the latter case, organic macromolecules also serve as “cross-linking” agents. Such macromolecules sometimes incorporate aromatics rings, which, during sliding, offer enhanced resistance against polymer chain movement, even under high contact temperature, and thus retain strong mechanical properties [

51]. Other commonly used cross-linking agents include SO

2 and CO. By mixing these different compounds, diverse HPPs have been created with different characteristics [

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28]. According to the literature [

52,

53,

54,

55,

56], a maximum temperature resistance of about 260 °C can be achieved with fluoropolymers, although their wear resistance may not be favorable. Mixture of co-polymers gives rise to amorphous and semi-crystalline polymers: PSU, PES, and PEI are examples of amorphous structures, whereas PPS, PEEK, PBI, and PPP are semi-crystalline. Semi-crystalline polymers can be used even above their glass transition temperature (

Tg), another added advantage against chemical constancy [

54]. Various inorganic nanofillers blends, e.g., silicon nitride (Si

3N

4) [

45], silicon dioxide (SiO

2) [

49], goethite (α-FeOOH) [

19], zirconium dioxide (ZrO

2) [

21,

32,

47], and titanium dioxide (TiO

2) [

32,

45,

48], have been proved to not only contribute towards enhancing mechanical properties, but also to lowering the friction coefficient and the rate of wear under various sliding circumstances [

57,

58,

59]. In particular, PEEK, PPS, and PTFE are the most widely studied polymers for different tribological applications and they are often blended with TiO

2, SiC, Si

3N

4, and carbon fiber fillers. Nevertheless, it is also noted that there are no single or combined polymers or fillers that provide the best tribological performance in all conditions. Being a result of “system responses”, friction and wear always depend on both the intrinsic material properties and the external environmental conditions.

2.2. Tribological Characteristics of HPP Materials and Their Dependence on PV Factor

In general, the wear of HPPs under sliding is subjective to certain contact circumstances, depending on the bulk mechanical behavior and surface profile of HPPs, as well as TLs. The effect of lubricants and the atmosphere on the wear of a polymer is described by the chemical interactions when it experiences with its contacts. The wear resistance of HPPs can be effectively improved with blended fillers (either nanoparticles or traditional fiber fillers). To predict the wear life and rank the wear resistance of materials, time-related depth of wear rate (

Wt) is commonly used, which is defined according to Equation (1) [

4]:

where

k* is the wear constant,

p is pressure,

v is sliding speed,

t is the duration of the test, and Δ

h is the loss of height of the specimen. The wear constant

k* is theoretically a material variable that is equivalent to the adjustment of the product of

p and

v. According to Equation (1),

pv might be assumed as a tribological measure of the load-carrying ability of materials, which leads to two evaluation variables [

28]: (i) basic wear constant

k*, which remains unchanged in a specific limit of

pv and (ii) limiting

pv, beyond which the rise of wear rate is excessively fast to be meaningfully used in practical applications. Diminishing the basic wear factor

k* and boost limiting the

pv value are the common goals in designing wear-resistant HPP materials.

In practice, for the convenience of material selection, it is commonly assumed that when the limiting

pv value is not exceeded the specific wear rate,

k* and the friction coefficient are material parameters and are independent of the

pv factor. Nevertheless, to develop new engineering tribo-materials, it is important to systematically evaluate their wear behavior under different

pv conditions and to understand the effect of

pv, as well as the load-carry capacity of the material under the given environmental conditions [

60,

61,

62,

63,

64,

65]. Pei et al. [

1] observed that, with the rise of

pv parameters, a general trend of increasing temperature occurred, and it thus concluded that the temperature constancy of polymers would the focus in situations where wear and friction are vital matters. According to Briscoe et al. [

66], during the sliding process, polymeric materials can experience very high temperatures that are mainly concentrated at the interface region (within depth of around 100 nm). However, the rest of the material, except the contact region, are at testing temperature. This high temperature in the contact region is significant for the tribological features of polymers, as structural failure of the components often starts from this region.

Research has shown that the increase of velocity mostly affects the tribological properties of polymers by increasing the contact temperature, whereas higher-pressure conditions may change the wear mechanism in different ways, depending on the thermal-mechanical properties of the polymers. In general, with the increasing pressure, the friction coefficient tends to decrease, which can be explained by the thermal/stress softening effect on polymers. On the other hand, the polymer surface could be plasticized under high pressure conditions, which assists in the separation of the surface materials and contributes to acute wear. Zhang et al. [

60] noted that, under higher applied pressure, the wear properties of amorphous PEEK might be closely associated with its viscoelastic behavior, which is absent in low load conditions. However, it is worth indicating that such a correlation between wear and intrinsic material properties remains challenging. Based on studies of PBI, Friedrich et al. [

28] concluded that the comparative action of hardness or modulus vs. impact toughness or ductility stays vague and more work is required to achieve a good understanding.

For HPP composites blended with different fillers, some work showed that the wear rate could be less dependent as a function of the normal load until a critical value was reached [

67].

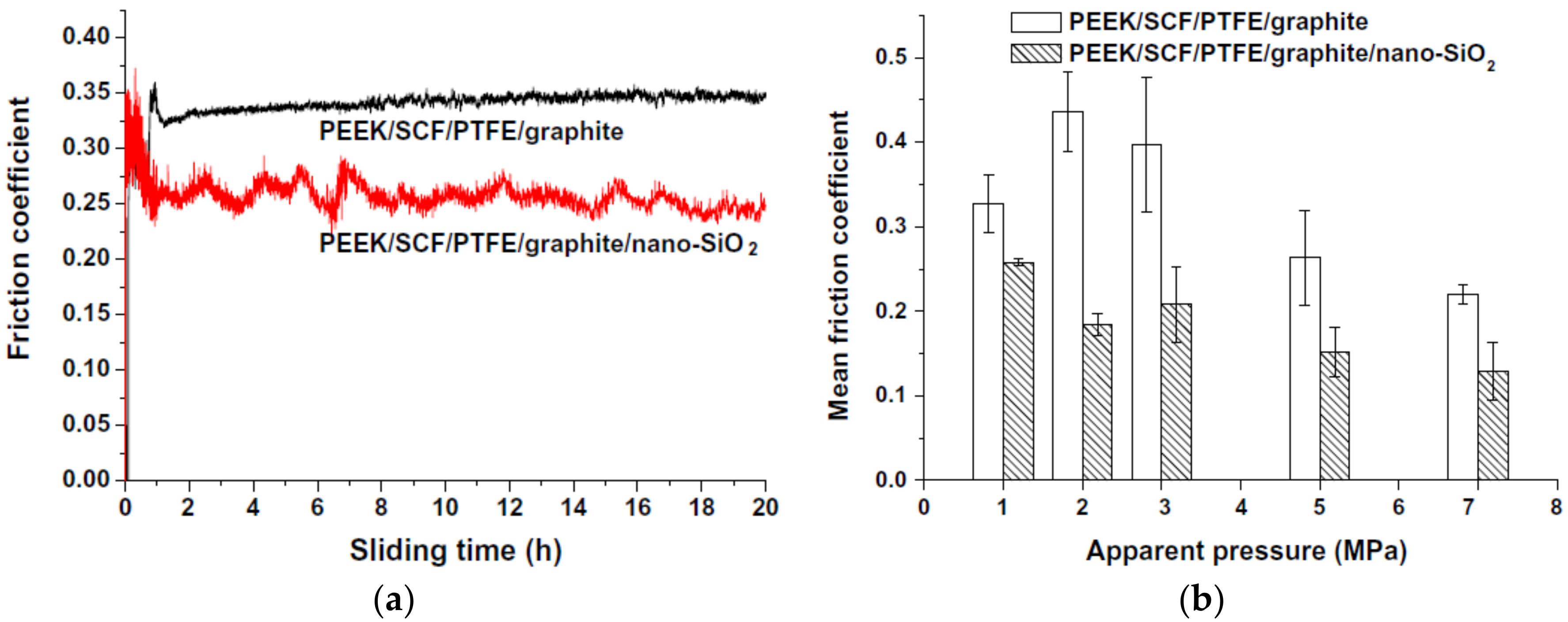

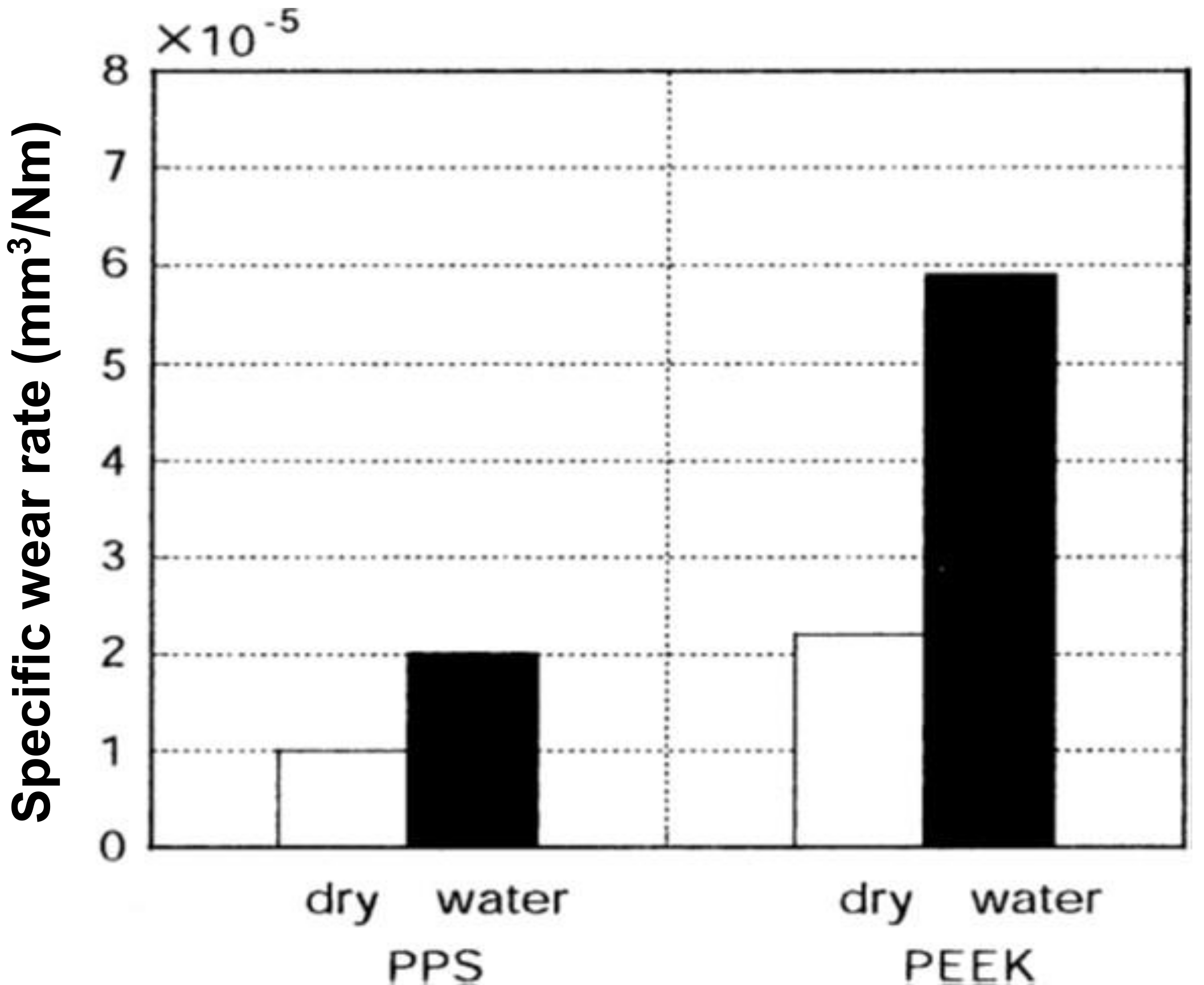

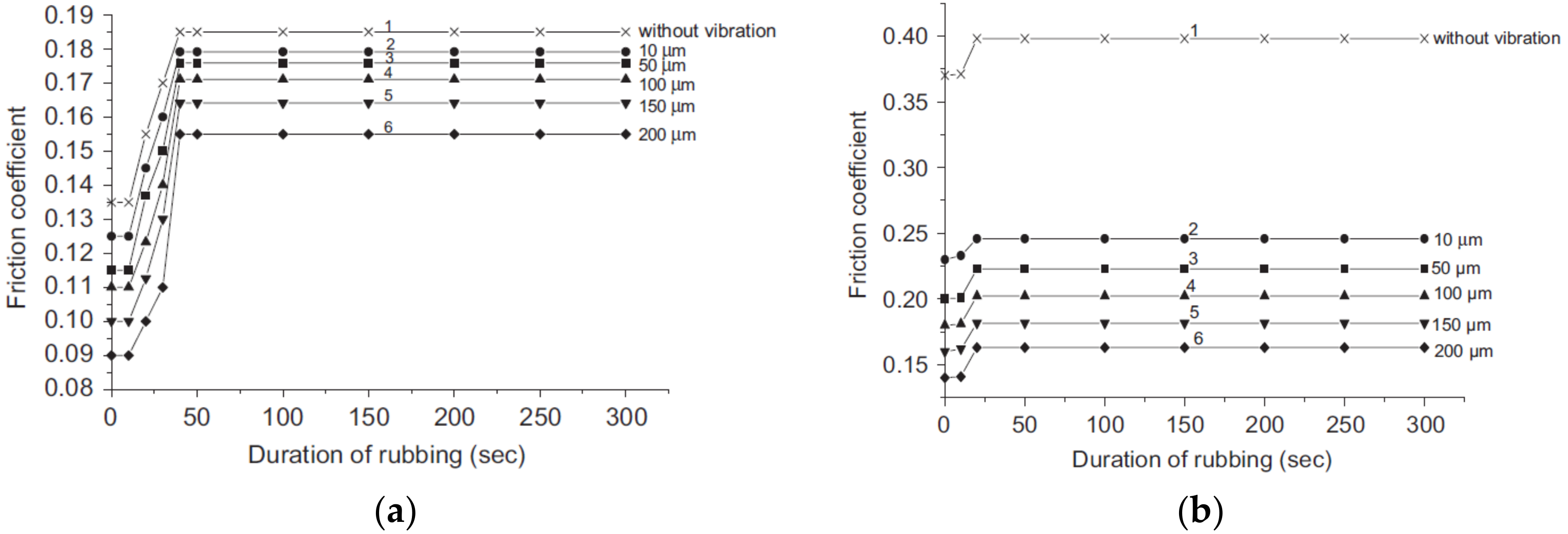

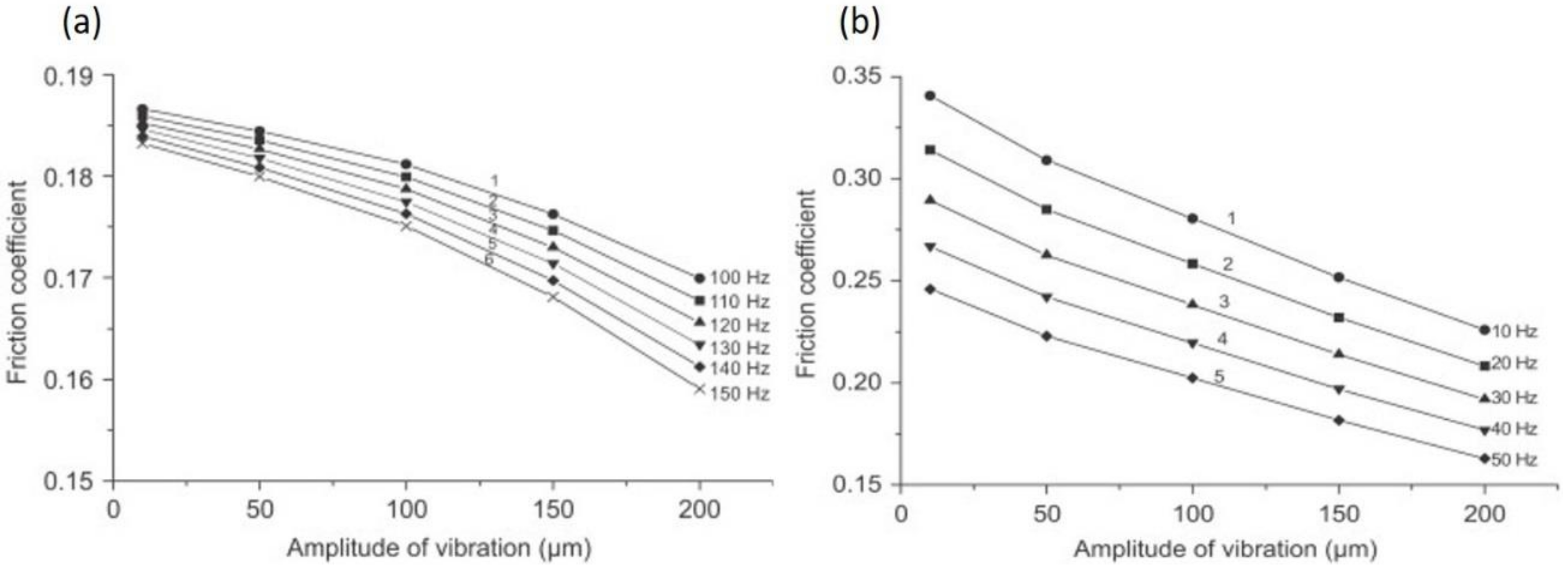

Figure 2 shows the effect of nanofiller (SiO

2)-incorporated PEEK composite as a function of pressure and sliding speed [

67]. As given in (

Figure 2a), under 1 MPa applied pressure, the friction coefficient reaches the stable state rapidly in the case of nanofiller-incorporated composites. After that, there are fluctuations in the evolution of the coefficient of friction, which is absent in case of neat PEEK. This implies the effect of wear debris on the friction coefficient. In all cases (

Figure 2b), the mean friction coefficient is almost half of the neat sample.

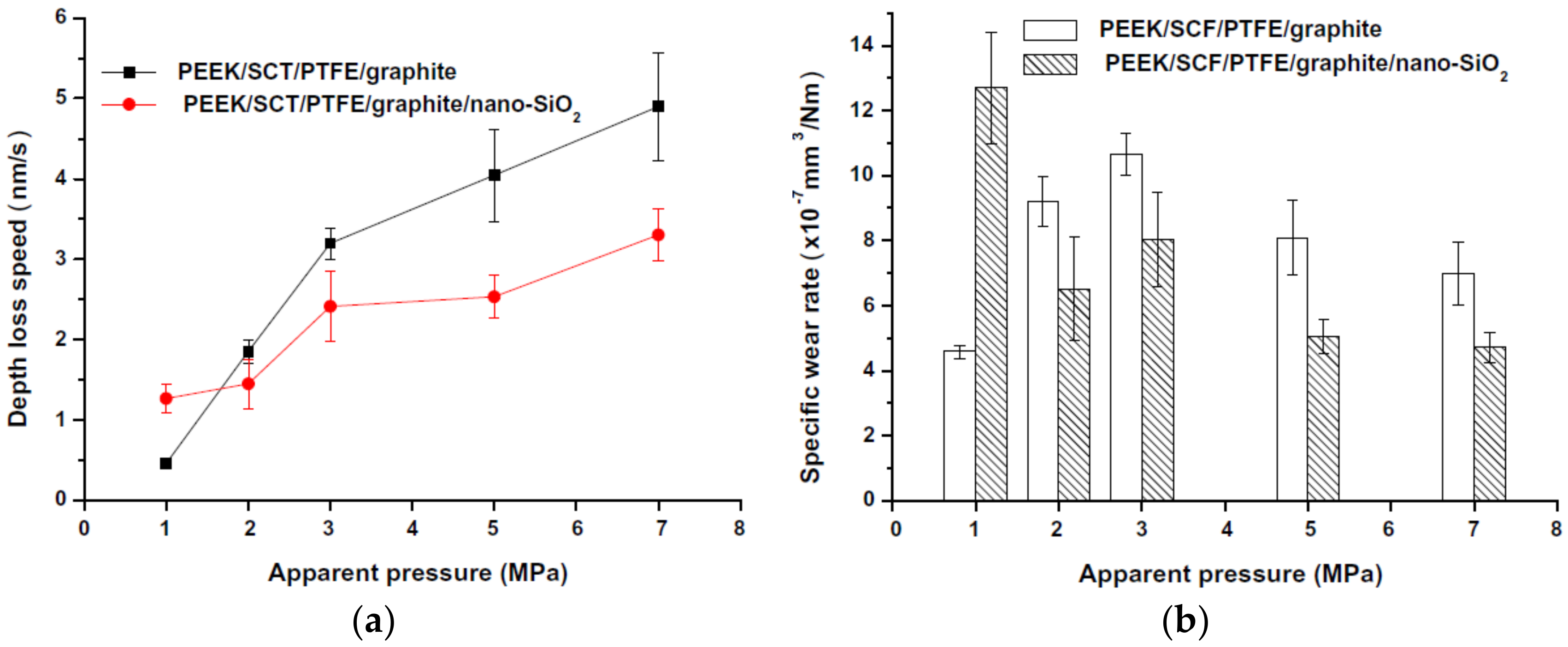

The wear behavior of PEEK composites, as shown in

Figure 3, shows mixed behavior. Under high pressure and sliding speed, de-bonding of fillers from the matrix takes place, which increases the wear rate. In addition, detached fillers can graze the matrix material and lead to further removal of materials as sliding continues. The grazing effect of broken fillers was reported in [

67] as a dominant failure mechanism, and deeper scratch marks were produced by cracked fillers on worn surfaces. The separation of filler/polymer matrix is understood because of interfacial exhaustion happening in several regions where fillers carry extreme loads [

5,

61]. Stress transfer and stress concentration at the filler–matrix interface could also lead to significant deformation along the direction of rubbing. Owing to repetitive high stress and strain, specific zones lose their load carrying capability and filler pull-out takes place.

This higher stress also generates cracks in the filler when the highest stress level of fillers ultimately suppresses its strength [

5]. Furthermore, the impact that is applied to fillers at protruding areas may also cause filler breakdown when the stress cannot be effectively transmitted to the relatively soft/ductile matrix material. Particularly, this might occur after detachment of the filler/matrix. When the pressure exceeds the critical value, agglomerated nanofillers flatten and no longer play their impingement role effectively. Nevertheless, it was noticed that a change in the speed or dispersion situation of nanofillers might alter the limiting pressure level. In addition, the increase in sliding velocity might be associated with greater contact temperature, with colliding dynamics being applied by protruding areas on the substrate. The rise in contact temperature reduces the matrix stiffness and thus initiates acute stress concentration. Greater contact temperature also reduces the shear strength of the matrix and it could result in an increased wear rate [

67]. The worn surface turns out to be smoother at faster sliding speeds, which may reduce the coefficient of friction, as crushed filler agglomerates alter their movement from sliding to rolling [

58]. These two aspects can lessen ploughing and cutting influences on pulled-out nanofiller and thus reduce further wear. Throughout the sliding procedure, stress transformation takes place from the matrix to nanofiller in the frictional layer, and consequently the stress concentration on the nanofillers decreases. This morphology is shaped owing to plastic flow of the surface layer because of the lower stiffness and higher ductility of the polymer matrix [

6]. Plastic flow of the PEEK matrix is considerably abridged when nanofillers are integrated into it. Additionally, the improved stiffness of PEEK can diminish the deformation of nanofillers under tension. In general, this is the wear mechanism of nanofiller-incorporated polymer matrix composites, regardless of filler and matrix type and composition.

2.3. Development High Wear Resistant Polymer Materials with Incorporated Particles

In literature, a variety of fillers in different forms, such as shape, size, and nature, have been added to the neat polymers with the objective of enhancing their wear resistance [

32,

33,

45,

47,

48,

61,

62,

63]. Kurdi et al. [

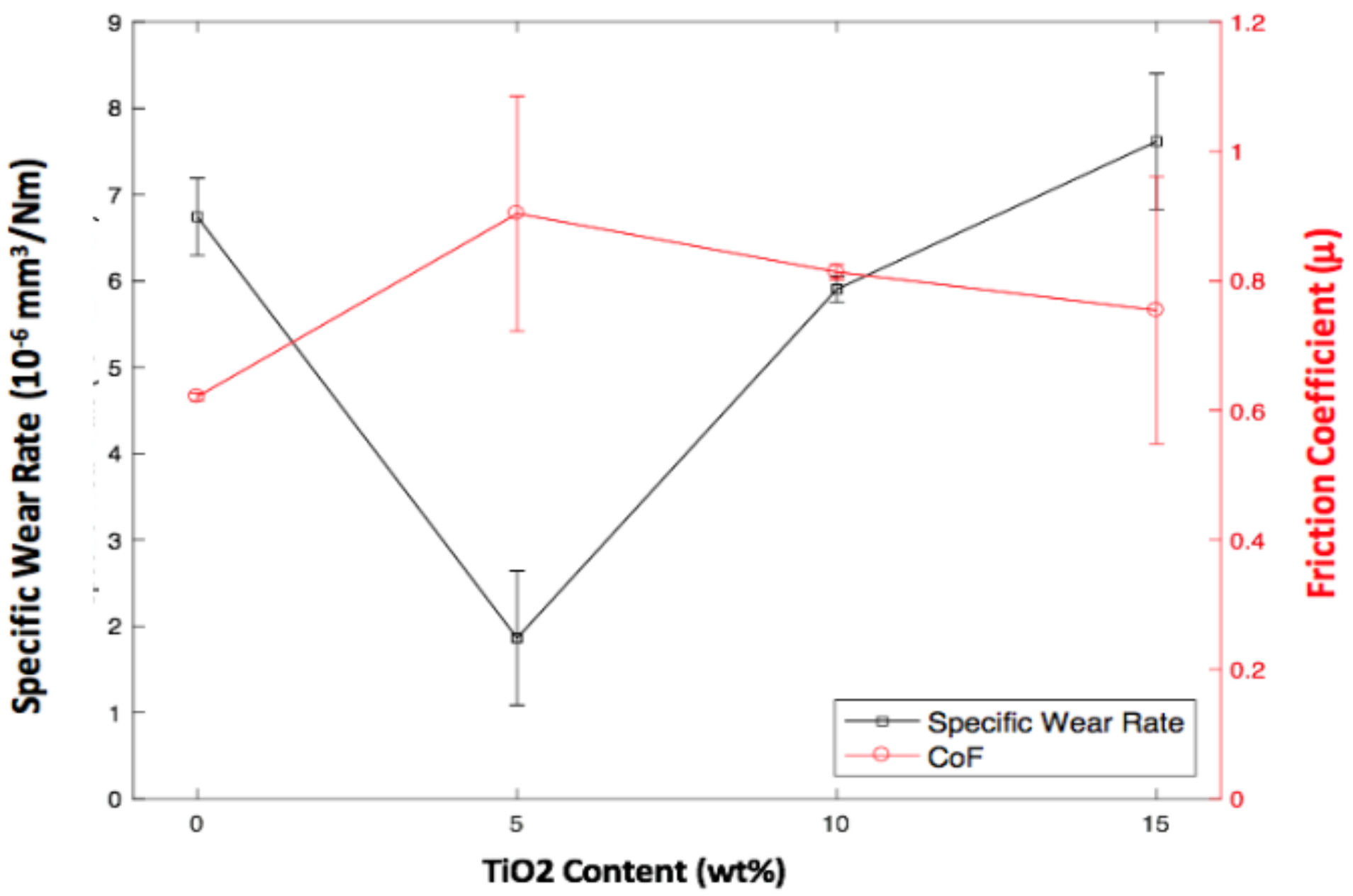

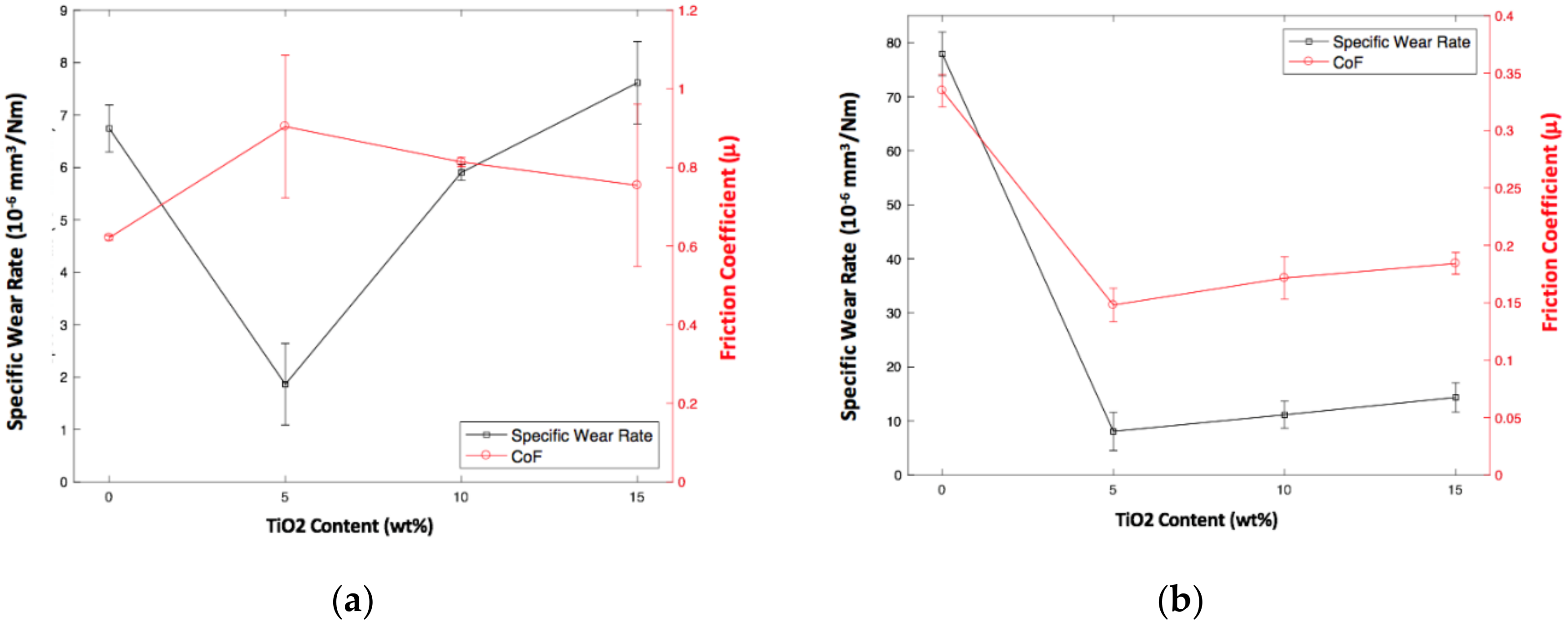

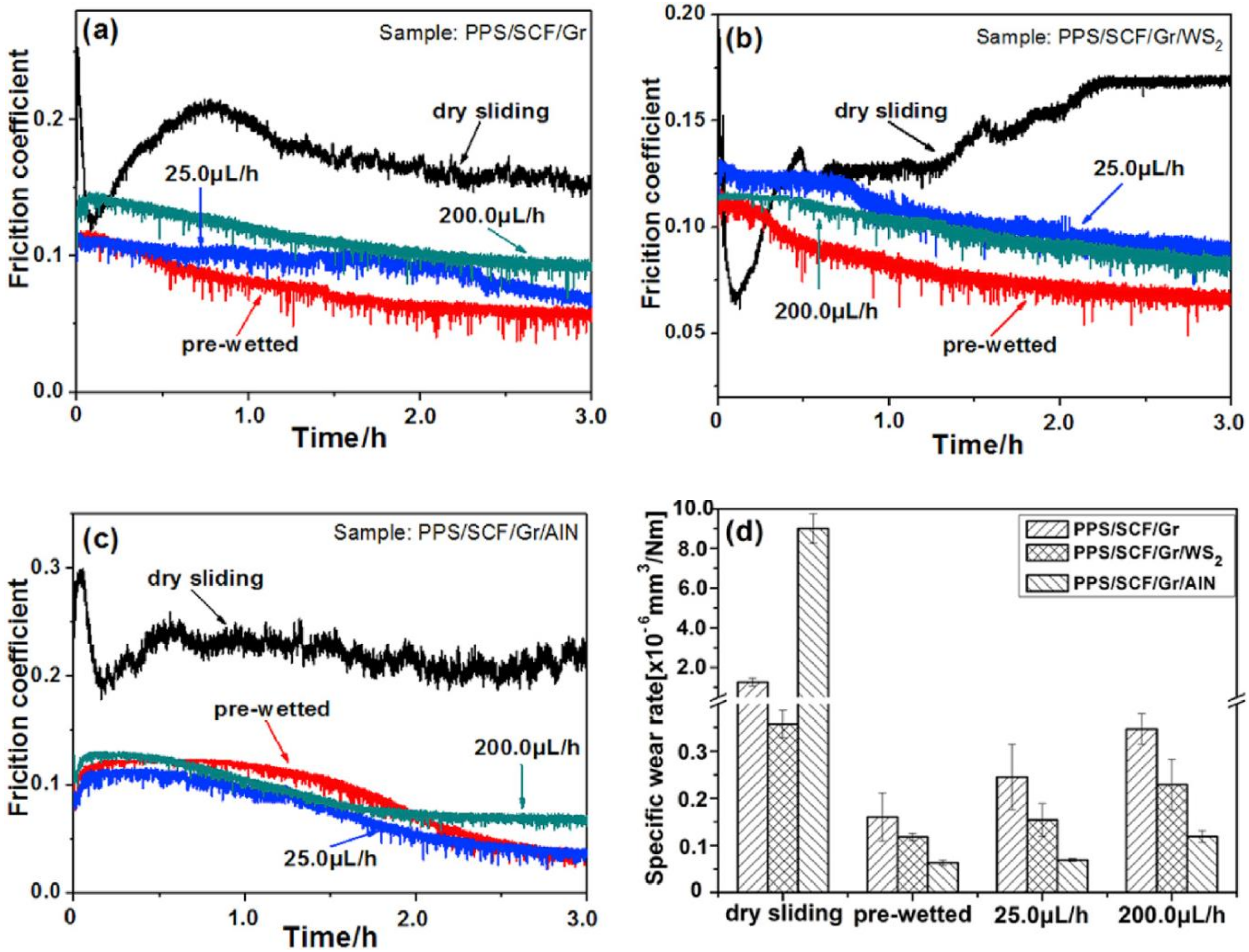

32] reported the effect of nanofiller contents on wear and friction behavior of TiO

2-incorporated PEEK polymer, as shown in

Figure 4. Up to 5% addition of TiO

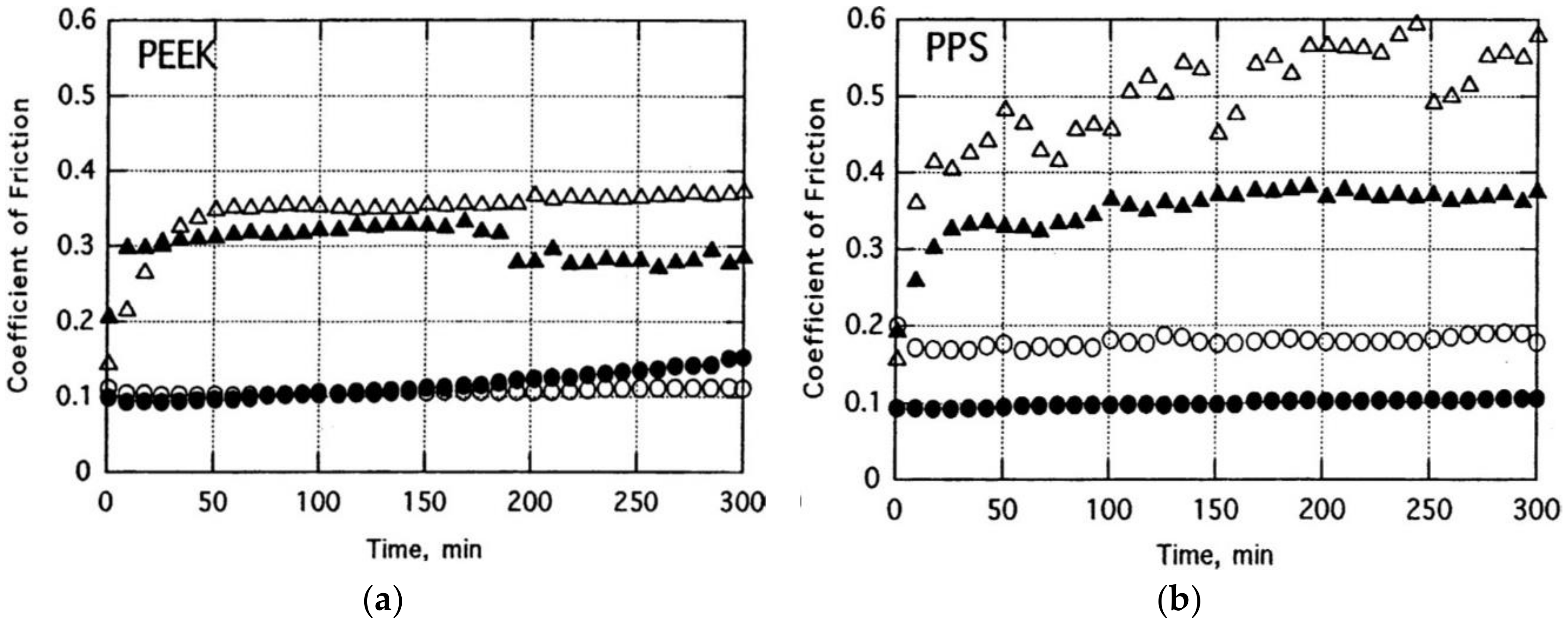

2 nanoparticles in PEEK reduced the wear rate most effectively, as compared to pure PEEK, although beyond that, a rise in wear rate was noted. This offers an understanding of the critical nanofiller amount in PEEK. This is because of the formation of the effective lubricating TLs in the tribo-contact zone in dry conditions, whereas the contribution of nanofillers to friction is negligible.

Further, a theory was proposed by Zhang et al. [

33], correlating the tribological property of PEEK to its viscoelastic property, the effect of interface temperature, and strain rate of the surface layers (TLs)—all of which are associated with the friction procedure. Beyond the critical level, nanofillers protrude through thin TLs and they act as third bodies to increase the friction coefficient. For wear resistance, the addition of TiO

2 nanofiller was useful, as an escalation of the friction coefficient might occur related to the reduction of the specific wear rate, which might be explained by the generation of TLs and will be further discussed in later sections.

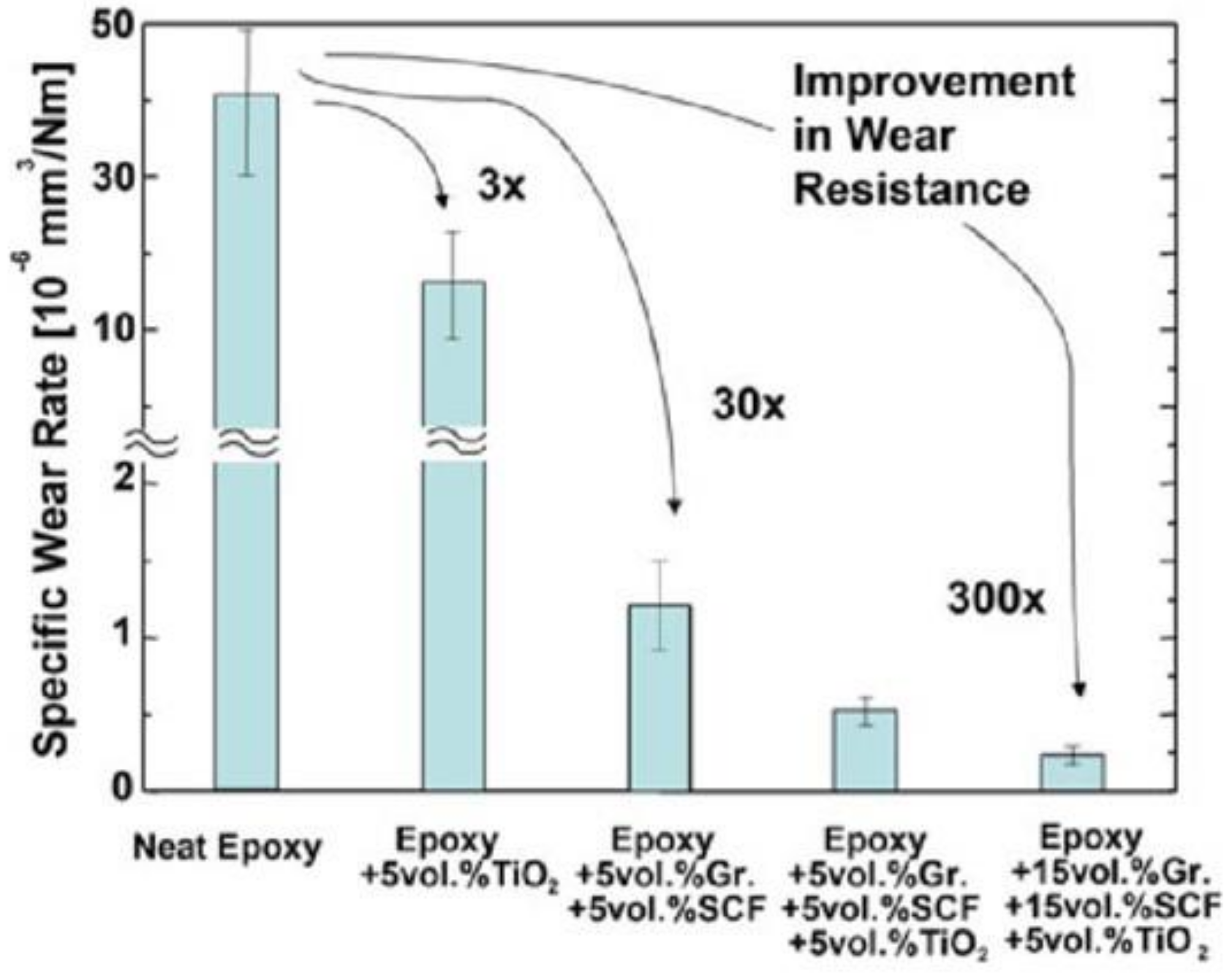

However, in reality, some fillers improve wear but deteriorate friction behavior, and trends in the opposite direction have been reported in literature. With the increase of nanofiller content, there is a high possibility of particle agglomeration in the polymer matrix and the effectiveness of nanofiller addition is suspended. A possible solution is using a combination of fillers in the neat polymer matrix instead of a single one. Such combinations, like a blend of fiber- and particle-type fillers, is more effective when compared to a single filler of similar content, as reported by Friedrich et al. [

4]. As given in

Figure 5, there is about a 300-fold increase of wear resistance of neat epoxy as a result of incorporation of a combination of nanofillers and traditional micro-sized fillers. During the wear process, there is a synergistic effect between short fibers and nanoparticles, which can resist the exfoliation of the surface and accommodate fine wear debris forming effective and durable TLs. As will be presented in later sections, an effective and durable TL not only keeps the coefficient of friction at a manageable scale, but it also reduces the wear rate by altering the wear mechanism to a greater extent. Österle et al. [

64] evaluated the outstanding tribological behavior of a polymer composite incorporated with an amalgamation of micron-sized carbon fibers and nanosized silica particles. Silica-based tribo-films firstly prevent severe oxidational wear, followed by preventing pull-out and rupture of carbon fibers in the composite by offering a cushioning effect. Xie et al. [

1] reported that carbon fiber and potassium titanite whiskers (PTW) also function synergistically to boost the wear resistance of hybrid PEEK composites. Furthermore, the carbon fiber transferred the main loads between the contact surfaces and shielded the matrix from additional austere abrasion from the counterpart. Zhang [

35,

65] reported that adding up of 20 wt. % nanosilica particles boosted the modulus and hardness by 78% and 130%, respectively, as compared to that of pure epoxy. In addition, they also emphasized that the size of the wear debris on TL formation was influenced by the quantity of nanoparticle fillers.

Based on the discussions mentioned above, it can be summarized that a variety of fillers are being used in HPPs to enhance their wear resistance. In general, hybrid type fillers, such as a combination of fiber and particles, are more effective than single fillers. Studies also showed that nanometer-sized particle fillers are more effective than micron-sized ones, though their cost-effectiveness is still uncertain.

2.4. Wear Mechanisms of HPPs in Dry Sliding

2.4.1. Transfer Layers

The importance of a TF for the tribological performance of polymers has long been realized and widely studied [

68,

69,

70,

71,

72,

73,

74,

75,

76,

77,

78,

79,

80,

81,

82,

83,

84,

85,

86,

87,

88,

89,

90,

91,

92,

93,

94,

95]. Recently, efforts have been directed to quantitatively characterize TLs and thus to establish more accurate correlations between TLs and the involved wear mechanisms. Chang et al. [

54] studied TL formation for different polymer-based hybrid composites by applying nanoindentation with in-situ AFM examination. Based on wear results and indentation analysis, it was noted that the hybrid nanocomposites that were incorporated with both nanoparticles and conventional tribo-fillers were useful for forming long-lasting TLs, particularly in severe sliding circumstances, and subsequently reduced the friction coefficient and wear rate. A synergistic action between nanoparticles and TLs is presented that might be the key mechanism for the enhanced wear characteristics of polymeric hybrid nanocomposites. Generally, a reduction of the coefficient of friction and wear rate takes place with increased TL thickness and even coverage. In most tribological uses, the TL controls load transmission and the wear mechanism. Therefore, trustworthy material data for TLs is advantageous [

6,

31]. TL behavior is often treated as a signature for different combinations of polymer/incorporated particles. Some blends affect the progression of TLs, whereas others do not, and consequently increase wear rather than reducing it [

31]. It was stated that when polymeric composites are incorporated with conventional fillers, the composites were more useful for forming durable TLs on a sliding steel surface, regarding their tribological characteristics [

7]. It was also proposed that the brittle–ductile transition of polymers plays a vital role in controlling the development of TLs when temperature increases [

14].

The effect of nanofillers on enhanced TFL generation is generally considered to be more effective than that of micro/macrofiller, as established in the literature [

15,

32,

33,

34,

47,

48]. This was commonly attributed to the higher surface-to-volume ratio of nanofillers, which provides the more interfacial areas at the same volume fractions compared to microfiller-incorporated blends. Also, wear debris is comparatively bigger in size and shape for micro/macrofiller-incorporated composites, which does not favor the formation of continuous, uniform TLs. In fact, TLs form as compacted wear remains and are greatly associated with the use of nanofiller-incorporated blends. TLs that are generated in the polymer-on-metal sliding process are dissimilar to traditional lubrication films. Gao et al. [

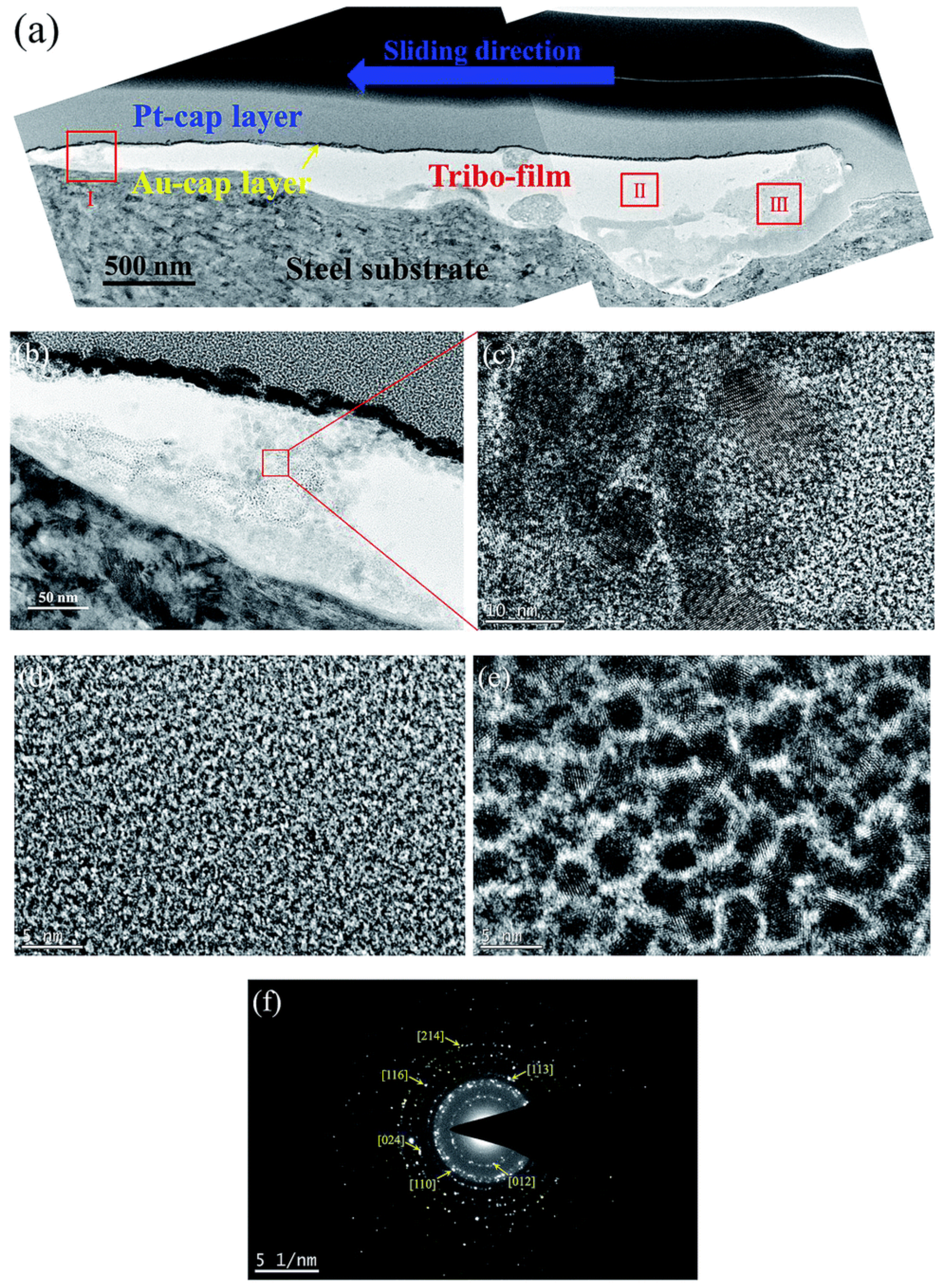

19,

46] carried out a detailed investigation on the nature of TLs that form on steel during sliding against PEEK composites with the help of focused ion beam and scanning electron microscopes (FIB-SEM) and Transmission electron microscopy (TEM), as shown in

Figure 6. It was evident that the accumulation of TLs on steel is uneven in nature. Moreover, the diffraction pattern of the selected area contains both hollow rings and dots, which represent the amorphous and crystalline nature of the TLs.

The thickness of TLs can be also determined by nanoindentation based on a relatively simple model, as described by Bahadur et al. [

95,

96] and Chang et al. [

37], where composite hardness,

Hc of the film/substrate arrangement while indenting through the film onto the substrate can be defined from the portion of contact areas [

37,

95,

96]:

where

At is total projected contact area of indentation,

As and

Af are the projected contact areas of the substrate and film, respectively, and

Hf and

Hs are intrinsic harnesses of film and substrate, respectively. Since

At =

Af +

As, Equation (2) can be rearranged as:

For sharper indenters, for example, the Berkovich, indenter contact area is proportionate to the square of indention depth, i.e.,

A =

k·h2 and thus, Equation (4) can be rearranged as:

where

ht is total indentation depth,

hf is TLs thickness, and

hs is indentation depth in the substrate. The hardness of TLs,

Hf, was considered to be similar to the neat polymer matrix hardness. In addition, the variation of hardness between the steel counterpart and neat polymers varies largely. Therefore, the minor deviances in

Hf due to the presence of harder minor pieces in soft TL might be overlooked. It is noteworthy that a strong variation in hardness along the wear trails was commonly observed, which implies the nonuniform allocation of TLs along the wear track. On the other hand, a thicker TL corresponds to lower magnitudes of

Hc. A soft TL is usually pushed out from the indentation region, generating a “pile-up” of material nearby the indentation due to the confinement of plastic flow of polymer TLs by the hard substrate beneath [

37]. With the estimation of film thickness, the transferal film efficiency factor (λ) can be defined by applying Equation (4) [

37]:

where

t = (

hf) is the average TL thickness established by nanoindentation and

Ra is the surface roughness of the steel surface. Further reading on the equation’s development and the concept of TLs can be found in the literature [

37].

With the transferal film efficiency factor, the tribo-effects TLs can be further described, showing the similarity to well-established Stribeck curvatures [

39]. Santer et al. [

97] extended this in wear systems as a function of relevant factors [

97]. Lately, Krudi et al. [

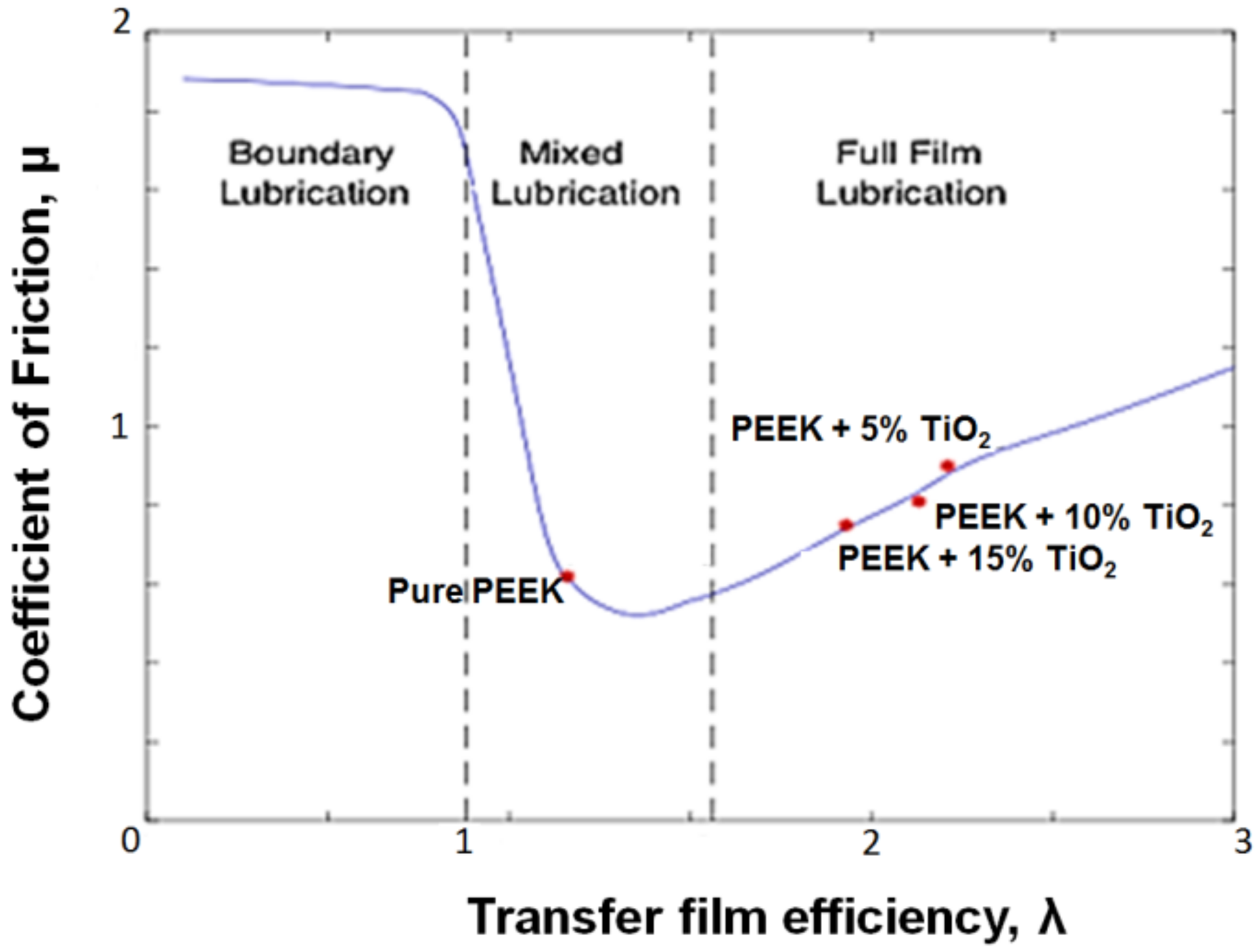

32] also reported a similar effect of TLs on the coefficient of friction of various TiO

2-incorporated PEEK composites, as shown in

Figure 7. TLs share the similar physical meaning of those conventionally applied variables [

32], i.e., a higher magnitude of the parameter points out that the characteristics of TLs further control the frictional property of the sliding pairs. Despite the desirable wear performance that is achieved by the presence of TLs, it was also observed that the spreading of TLs was uneven, as mentioned earlier. Therefore, during nanoindentation, in order to find the thickness of TLs, a sufficient number of tests should be performed along the wear track for the statistical purpose. Though the magnitudes of hardness might be varied broadly between the hardness of virgin steel counterpart and that of the polymer matrix, the average magnitude of hardness exhibited decent replicability with an adequate number of indentation tests (e.g. 100 times) over certain length (e.g. 1 mm) and the curves displayed comparable trends. Since the film was discontinuous, such average magnitudes would not be assumed as the general characteristic of a comparable film. The ‘mean thickness’ is considered as a quantifiable guide of the total amount of TLs covered on the counterpart. The unevenness of TLs on substrate restricts the accuracy of the calculated thickness. Additional shortcomings arise due to other parameters, for example, indenter tip sharpness, the surface finish of sample, pile-up, etc., which induce uncertainties in defining the actual contact area during nanoindentations. Nonetheless, the investigation offers a practical technique to define and compare the TLs generated on a range of materials in various sliding circumstances. Regardless of ‘

pv’ factor, the common tendency was that the composites incorporated with nanoparticles experienced thicker TLs, as compared to those without nanofillers. The literature indicated that TLs generated by neat polymers has the tendency to form thicker TLs at faster speeds but thinner ones at larger pressures [

8,

60]. As pointed by Bahadur et al. [

95,

96], wear is also dependent on the cohesion strength of TLs on counterpart. Friedrich et al. [

34], however, emphasized more on the thickness of TLs. According to SEM observation, it was proposed that when the TL is thinner than substrate’s roughness the effect of TLs is less dominant, and breakage of TLs is more likely. In the case of the higher surface roughness of mating pairs, more debris is required to fill up the valleys, associated with a high abrasive wear in running-stage. After filling the valleys with wear debris and forming semi-continuous TLs, however, the detachment of large chunk of TLs could still occur, leading to a high-wear process, even after the running-in stage.

2.4.2. Wear Mechanism in the “Steady State” of Sliding Wear

As aforementioned, the TLs would be gradually developed on the metallic counterpart, during the initial running-in phase. Subsequently, the overall friction and wear of the tribo-system become rather steady. In the steady state, with the presence of the TLs, the mode of tribo-contact changes from the initial hard (metal)—on—soft (polymer) to one or more of the subsequent contact couples, depending on the thickness, distribution, and components of TLs, namely, (a) hard-on-hard (rigid fillers against asperities of steel surface), (b) hard-on-soft (rigid fillers against polymeric TLs), and (c) soft-on-soft (polymer against polymeric TLs). Thus, the contact mode relies on the spreading and quantity of TLs in actual contact area.

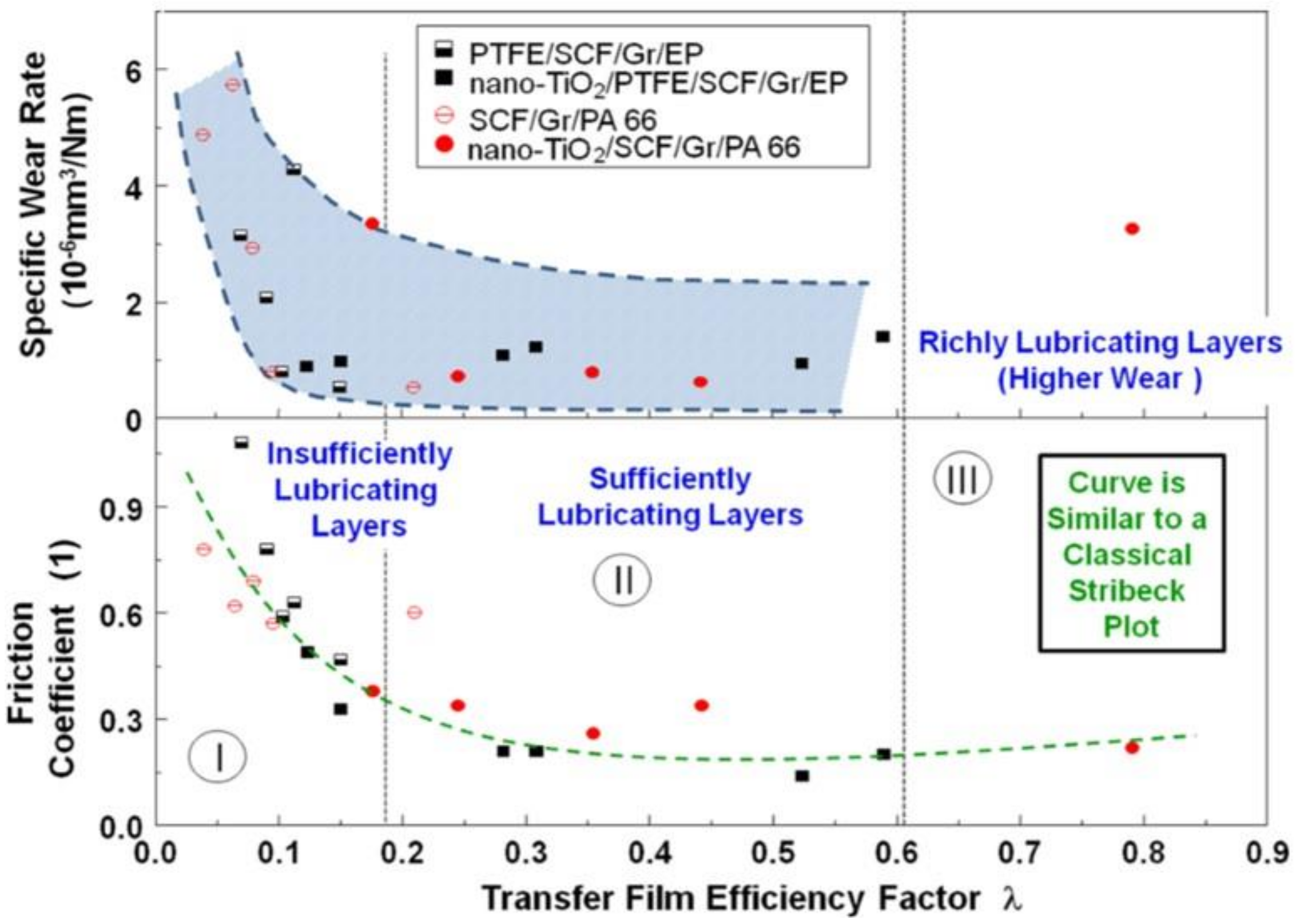

In respect of the values of λ, three different wear- and friction-regimes might be identified, as shown in

Figure 8 by Chang et al. [

37] who have investigated the tribological aspect of HPPs-based composites filled with various fillers. When the magnitude of λ is comparatively low (< 0.2), the contact is considered as insufficiently lubricated, as there is not enough TLs to completely cover the steel counter-face. In this situation, wear behavior greatly depends on sliding circumstances, such as “

pv” factors, as described in

Section 2.1. When the product of “

pv” is small, it is likely to shield the surface efficiently, even with thin TLs, because of a small actual contact area. Polymer composites might attain decent wear characteristics with a relatively smoother worn surface. However, under greater “

pv” values, the actual contact area rises, and additional fillers, such as fibers, are exposed to steel counter surface with insufficient shielding from TLs. The contact type would be in the form of “hard-on-hard”, resulting in a high coefficient of friction. In addition, fillers are more probable to break down and pull out rapidly. The wear procedure could be further intensified by the thermal assisted mechanical failure of polymer matrix, particularly in the interfacial area. Therefore, polymer composites risk acute wear loss at severing sliding circumstances with thin TLs. This has somewhat resembled boundary lubrication situations. With rising magnitudes of λ, TLs can be considered as adequately lubricated layers where they are capable of shielding most of the fillers from direct contact with steel counter-face, for both high and low “

pv” factors. Wear behavior is determined by a combination of two contact modes: (a) contact of the polymer against TLs (soft-on-soft) and (b) contact of hard incorporated fillers against TLs (hard-on-soft). Due to the shielding of TLs, severe fillers pull-out might be evaded, even at high “

pv” conditions. Nevertheless, if the quantity of TLs is very high, this might be also related to the high wear loss. In this case, TLs can break down in the form of the large chuck of wear debris as relatively thick TLs could act as thermal insulators on steel surfaces. Hence, localized contact temperature in that thick TLs area might be high and may cause strong adhesion between polymers and TLs. On the other hand, high contact temperature may decrease the viscosity of polymeric TLs, which sequentially results in a small coefficient of friction. In view of that, there is no such a direct correlation between the coefficient of friction and wear of material, even when taking consideration of the role of TLs. However, it should be stated that, at greater quantities of λ, the tribological behavior of sliding system is mostly controlled by the characteristics of TLs. Therefore, under such circumstances, the wear behavior of HPPs displays less dependency on sliding circumstances. Though the TLs showed the resembling lubrication influence to that of conventional lubrication films, there are more complex interactions between tribological characteristics of TLs and polymers. One example is that TLs are formed directly by the wear debris of sliding pairs while the traditional lubrication films are normally formed by external lubricants. Additionally, the rise of temperature in solid contact due to sliding might significantly affect the characteristics of TLs, which, in turn, influences the tribological behavior of the sliding pairs [

98]. For example, a small coefficient of friction was attained for PA66 matrix composite with no nanoparticles, at the expense of surface melting due to high contact temperature. As the thermal conductivity of steel counter surface (around 58 Wm

−1 K

−1 [

99]) is considerably greater than that of polymers (about 0.25 Wm

−1 K

−1 for PA66 [

99]), a thicker TL may also work as a thermal shield, as mentioned before. In case the thickness of TLs is greater than the surface roughness of the steel counter surface, the effect became more significant. The pulped TLs might contribute to a small coefficient of friction due to the lubrication effect. However, the melted polymer in the contact region cannot effectively carry the load and sometime failed to protect filler pull-out, associated with high wear loss. Henceforth, tribological effects of TLs always require being considered cautiously, on the basis of a good knowledge of the wear/contact mechanisms of the system in the given sliding condition.

The experimental data have shown that more durable TLs could be expected by adding more than one type of tribo-fillers in neat polymers. According to Kurdi et al. [

32], the use of sole TiO

2 nanoparticles is not as effective as the combination of such nanoparticles with short fibers, solid lubrications, etc. [

27,

36]. The outcomes suggested that the lower friction characteristic of nanofiller-incorporated composites resulted from the mechanical interactions among supplementary nanofillers, polymeric nature of TLs, and contact surfaces [

29,

36]. Nanofillers can contribute to a lower coefficient of friction, because of their ‘spacer’ effect, as well as its capability of rolling [

36]. These effects of nanofillers would also favor the formation of durable TLs. The existence of nanofillers may also reduce the adhesion between TLs and polymers by decreasing the real contact area. At the same time, nanofillers could be entrenched into soft TLs, instead of being pushed away from the compressed surfaces. Thus, TLs partly cover the nanofillers and minimalize their abrasion effect. Such a synergistic effect between TLs and nanofillers is useful for an improved wear characteristic of polymeric composites, particularly under acute sliding circumstances.

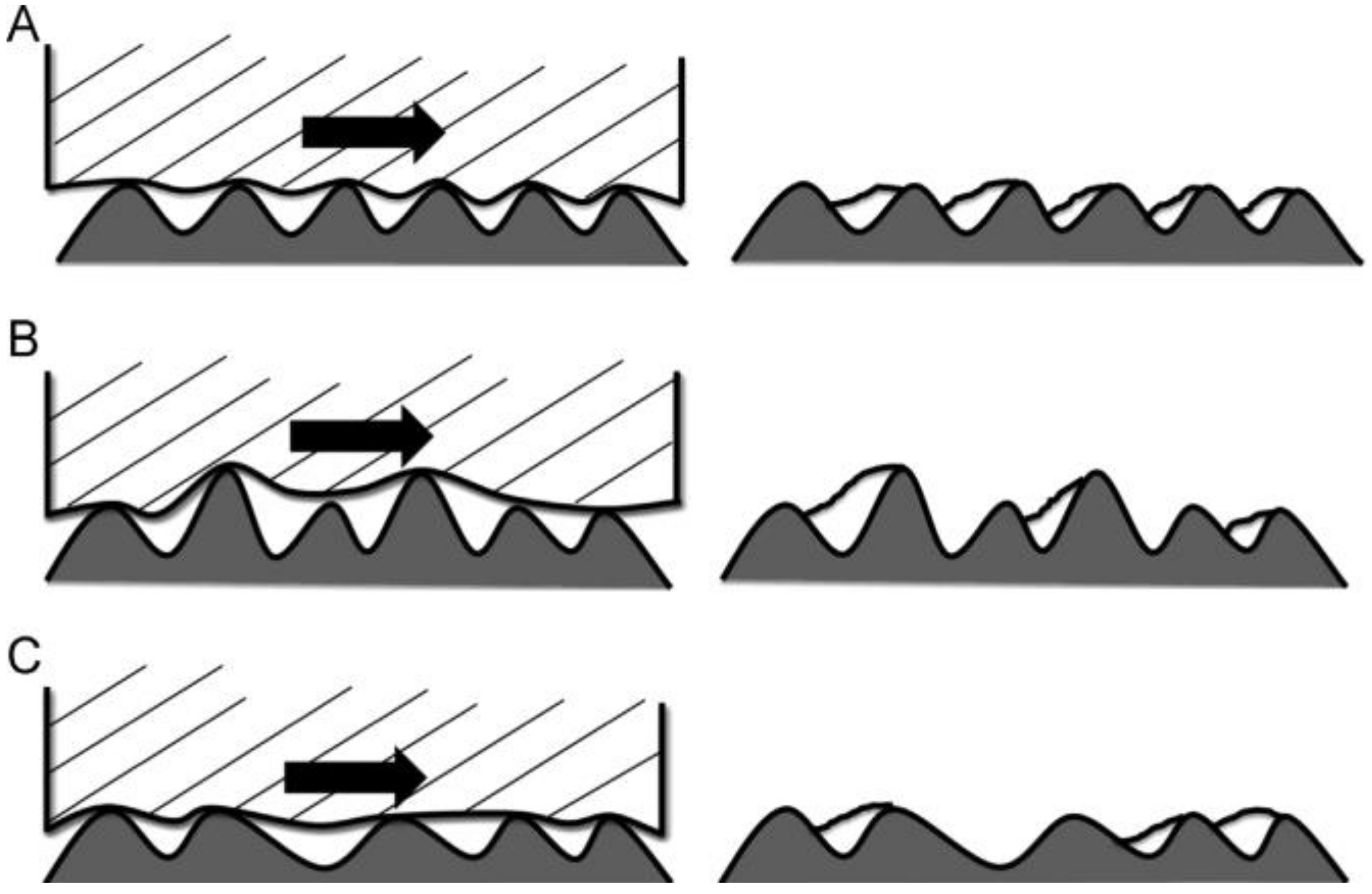

As discussed in the literature [

9], at the microscopic level the contact between mating surfaces during sliding can be resolved as a summation of a number of asperities contact. The nature of continuous/semi-continuous transfer film can be explained in view of such asperities contact, as schematically shown in

Figure 9. As the pin (test coupon) travels on the hard counter surface, the front edge of asperities cut the bulk material from the pin, and the removed materials can be accumulated by front flanks. In the course of that, the tail edges of the asperities keep exposed, as they do not contact the bulk material. This phenomenon gives rise to the characteristic, ‘rippler’ like appearance of the counter surfaces, as stated in the literature [

9]. As the process continues, the space between asperities get filled up with wear debris, forming the TL. With the development of a stable TL, the wear process enters the “steady-state”, where both the coefficient of friction and wear rate dropped, as compared to the “running-in” phase. From this point onward, the governing wear mechanism, as well as the wear rate of the specimen is dictated by the retention ability of the TL. Nevertheless, it is worth indicating that additional tribo-fillers in the neat polymers do not always yield positive effect on TL formation, as presented by Bahadur et al. [

15]. The beneficial effects of tribo-fillers are normally associated with the improved adhesion of the transfer layer on the counter surface, depending on fillers’ compatibility and chemical nature.

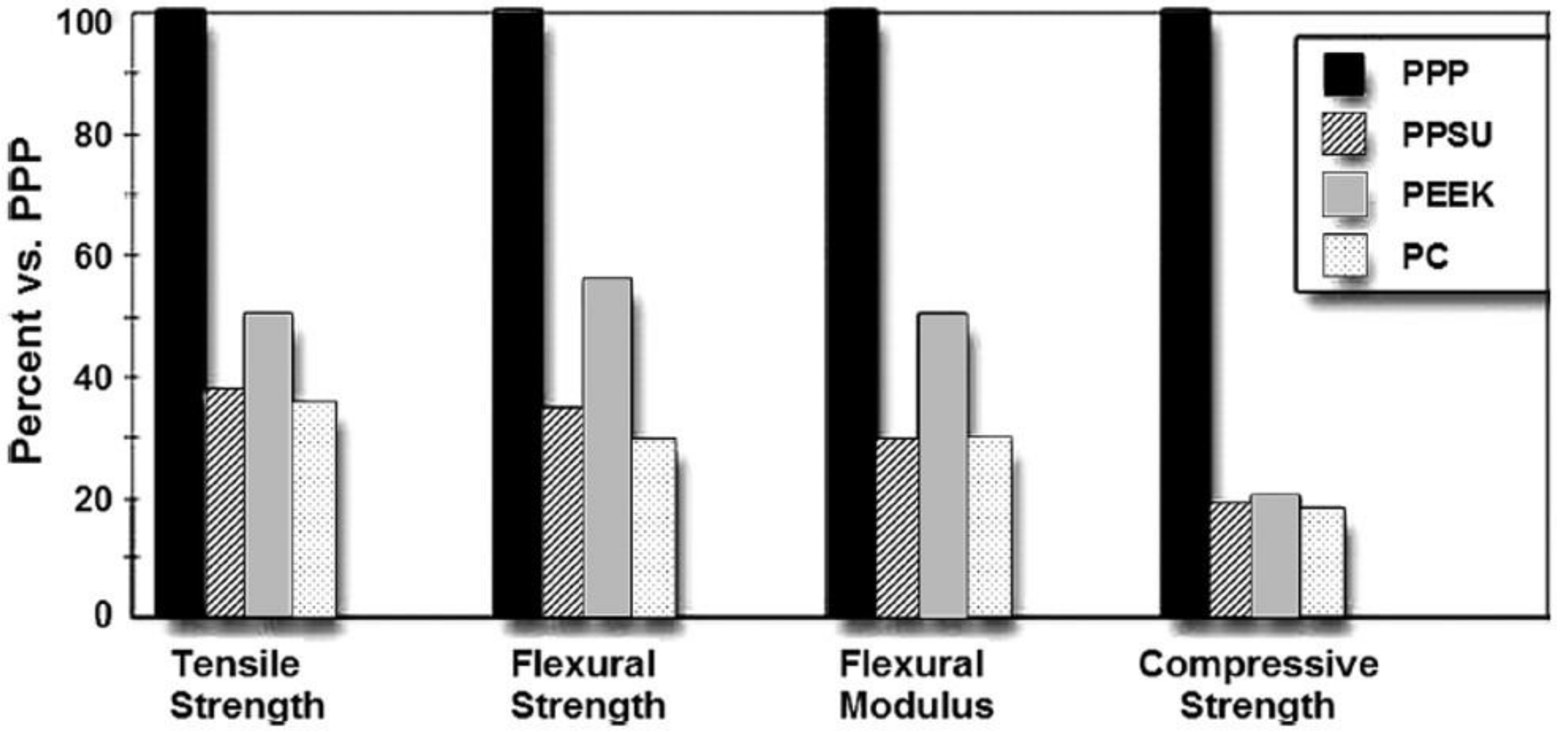

4. Correlation between Mechanical and Tribological Properties

Although there is no a simple relationship between the basic mechanical properties and tribological performance, it is important for materials engineers and scientists to understand the dependence of the friction and wear behavior on intrinsic material parameters, such as the type of fillers and basic mechanical properties. Such an understanding is critical for industries to select and design new, high-performance polymeric materials. According to commercial manufacturers (Ensinger, Germany; Solvay Advanced Polymers, USA), HPPs, such as PEEK and PPP, possess quite extraordinary mechanical properties, as compared to other commonly used polymers (

Figure 20). Both modulus and strength are much higher than that of thermosetting polyimide (PI). Particularly, in case of compressive characteristics, the strength of PPP under compression surpasses other polymers (PEEK, PC, PPSU) by a factor of 5. At room temperature, PPP provides a significant possibility when other high performing thermosets and thermoplastics stretch to their mechanical properties’ boundaries. However, by considering the effect of the service environments, such as temperature, this is not the case in all ways. Recently, Kurdi et al. [

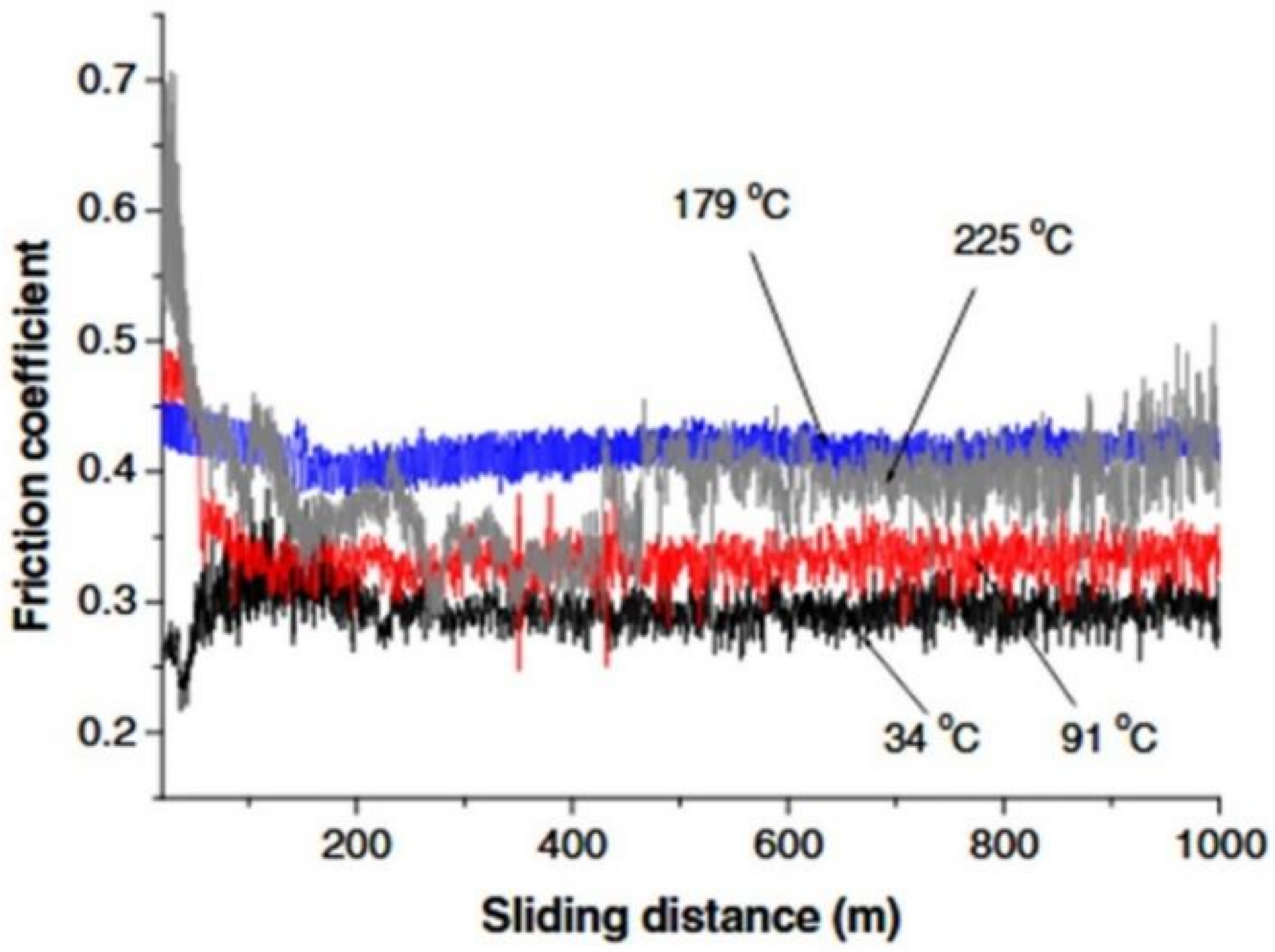

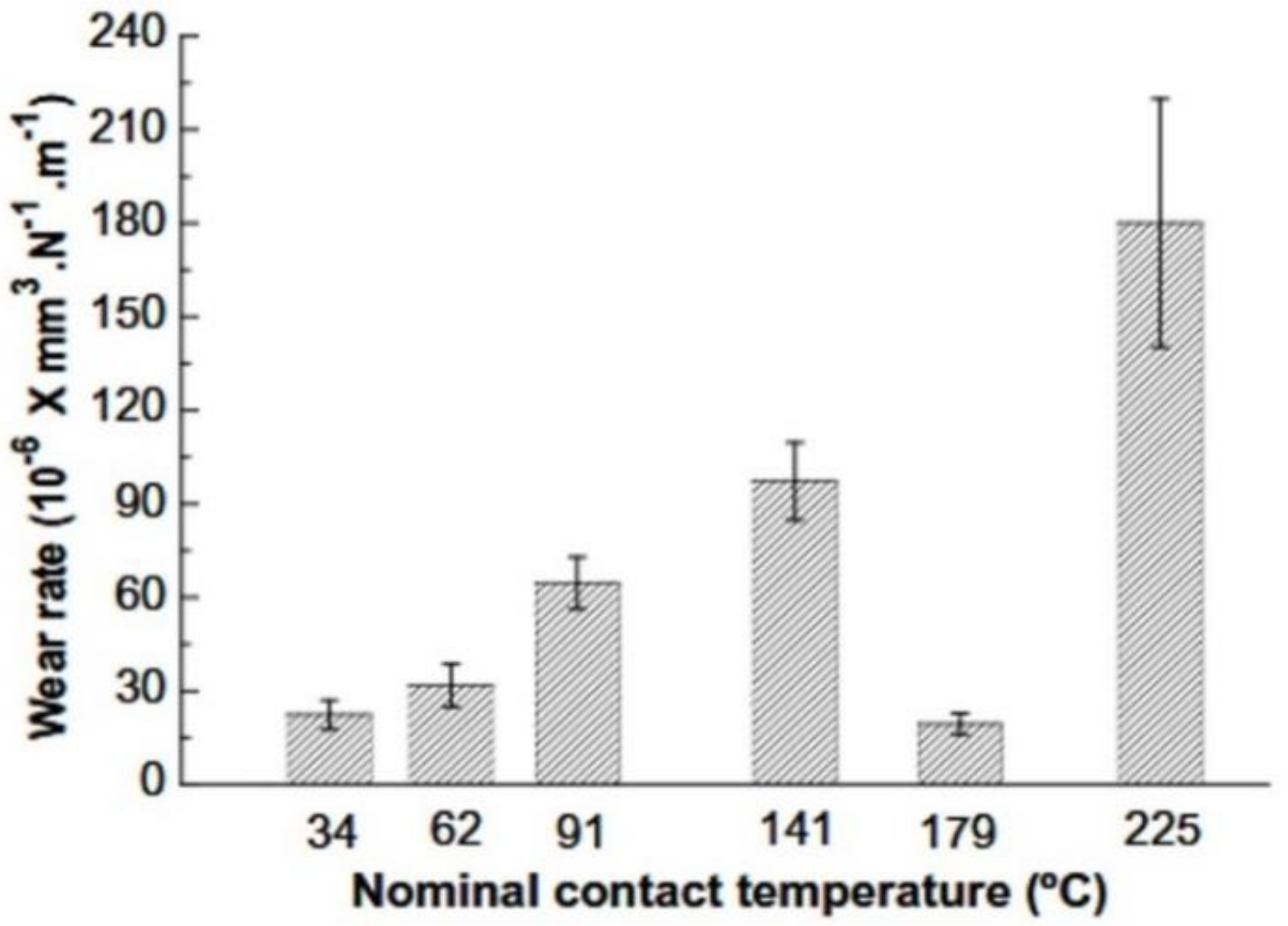

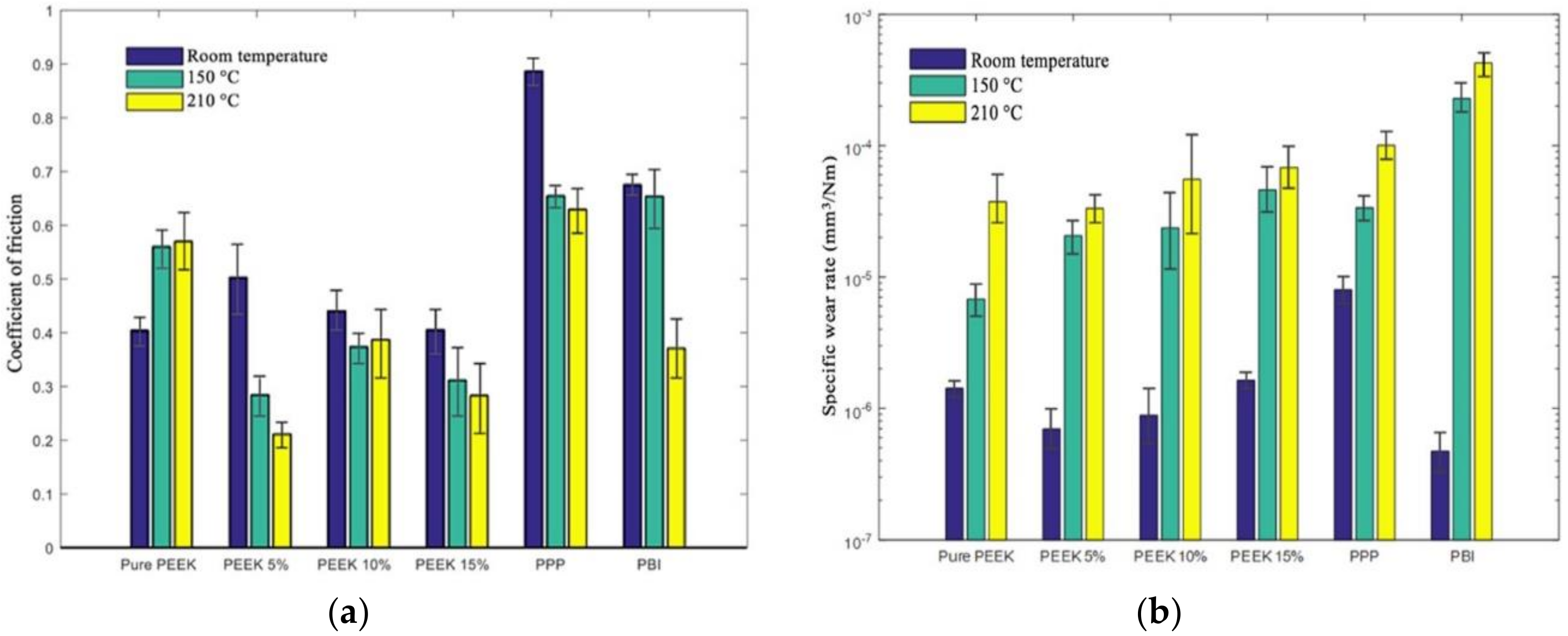

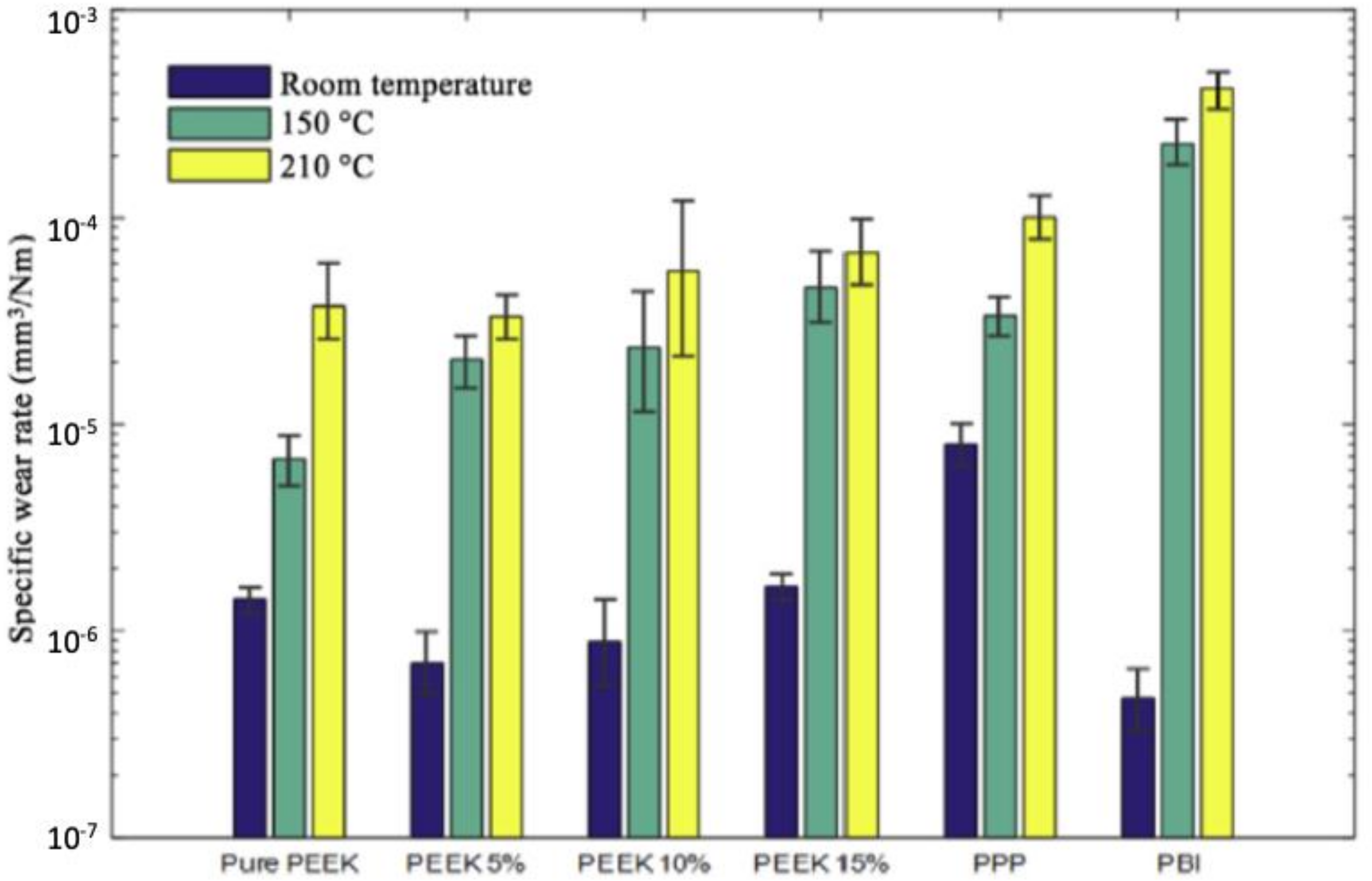

98] reported that, though the tribological behaviors of PPP at room temperature are promising, its high-temperature aspect is questionable, as shown in

Figure 21. The wear resistance of all the tested polymeric samples decreased with the increase of environment temperature. Nevertheless, it was the worst in the case of PPP. This may be due to the integral nature of PPP, as indicated by K. Friedrich et al. [

28], in view of their amorphous nature through TGA-DSC analysis. PPP shows a broad temperature assisted swelling rather than a sharp melting point which is mostly true for all thermoplastics [

101,

102,

103,

104]. Therefore, when the material is subjected to friction, generated heat at contact soften the amorphous polymer. The wear debris would come off in layer by layer (instead of fragmented particles) with a high wear rate. Thus, PPP, a mechanically sound and superior polymer, fails to retain its tribo-response at high temperature. In general, the better the mechanical characteristics (such as hardness) of the materials, the lower is the rate of wear, as materials with the higher mechanical property will show more resistance against wear debris formation. However, there is no one-to-one relationship between the hardness of the material and its wear rate, as wear is a system response rather than material property. This observation also holds in the present case, as PPP is the hardest material among the common polymers (

Figure 21).

Nevertheless, continuing efforts have been made to understand the dependence of wear on other mechanical properties, e.g. for the design of wear resistant polymer composites using various fillers. In general, though the introduction of fillers in a polymer causes the discontinuities of material to some extent, its melting temperature and extent of crystallinity are mostly unchanged, as reported by Friedrich et al. [

34]. Therefore, the thermal behavior of the polymer matrix in the composite appears to vary slightly from the equivalent neat polymer. The incorporated fillers usually increase the mechanical characteristics of the composites, for example, tensile strength, hardness, elongation at break, and flexural modulus. With the enhanced mechanical performance, it is expected that the composite could experience less wear rates, which, however, requires a good understanding of the wear mechanism, associated with the failure mechanics in materials under the given sliding condition. For example, the expression for lubricated circumstances was theoretically formulated from the perceptions of crack progression, damage build-up, and traditional fracture mechanics, as reported by Lhymn et al. [

89]. Accordingly, the rate of wear is inversely proportionate to the product of the elastic modulus (E), hardness (H), and elongation at break (ε), as shown in Equation (7) [

105,

106]:

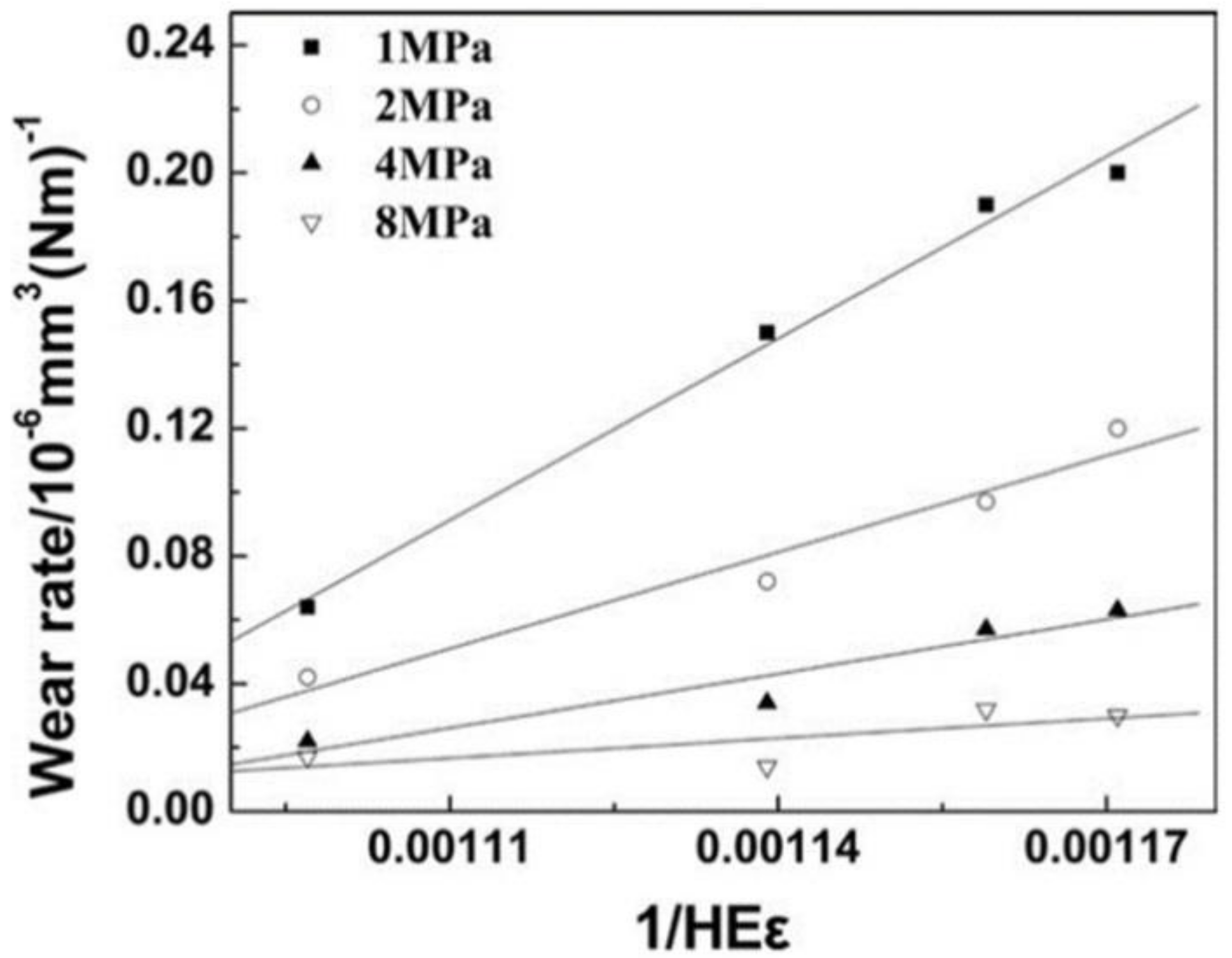

Basak et al [

16] has applied the equation to describe the wear behavior of PEEK composites filled various fillers, as shown in

Figure 22. As the content of nanoparticle ranges 5–20 wt. %, a linear relation to

1/H.E.ε was observed. The wear resistance of the hybrid composites (where both fibre and particle incorporated) tends to increase with the rise of ZrO

2 content in the range from 5 to 15 wt. % Subsequently, it displayed a solid drop-off trend when the content of ZrO

2 was 20 wt. %, which is exceeding the critical incorporate content. A combination of differing types of filler showed different influences on mechanical properties as fiber type fillers could significantly enhance hardness and modulus. However, the tensile strain at break reduced significantly. Therefore,

H.E.ε might be controlled by varying the amounts of different fillers of hybrid composites to achieve the highest possible values of

H.E.ε [

16]. Additional research must be dedicated to find further details on how the mechanical characteristics influence the wear behaviors when a combination of different types of fillers are in use. Further, the external sliding condition may also affect such a relation between wear and mechanical properties.

Recently, Hakami et al. [

107] investigated the influence of the various size of abrasive particles on the wear characteristics of different polymer samples. By comparing the effect of mechanical properties on wear rate subjected to abrasive particles with different sizes, it was observed that, with a small particle size (125 µm), the wear is more influenced elongation at break and tensile strength more. In contrast, bigger abrasive particles (425 µm) could cause larger penetration and result in a higher wear rate. Moreover, the generated wear particles of polymers with lower hardness tend to clog abrasive’s surface and increase the real contact area, leading to a further increase in wear rate [

39,

108]. In view of that, polymers’ hardness and tear strength are dominant mechanical properties under such conditions.

5. Conclusions and Future Directions

The present work discusses the aspects of tribological properties of HPPs and their composites. The wear performance of materials highly depends on the engineering system, where it should be used. With the intention of understanding the sliding wear mechanisms of HPPs and their composites, two factors should be taken into account: (i) materials and (ii) system parameters, such as environment temperature, vibration, and lubrication conditions.

In practice, HPPs are commonly used by incorporating with different types of micro/nanofillers, as well as their combinations. The fillers such as inorganic particles can improve the wear resistance either due to enhanced mechanical characteristics (such as hardness, modulus, and stiffness) or by forming durable and resilience transfer film layer between contact materials. However, the addition of fillers may also cause discontinuities in the polymer matrix and be susceptible to generate wear debris. The latter can also act as the third body, which sometimes tends to increase wear of the system. In that respect, there is a critical filler content beyond which the addition of filler actually degrades the wear resistance of the materials. The critical filler content varies from material to material, however roughly in the range of 5–15 vol. %, as reported in literature. A topographic smoothening and a probable rolling action of the nanoparticles are possible explanations for their improvement on the wear and friction performance. There is also a trend of using a mixture of particle and fibre type fillers together to improve the performance of the polymer composites. In that case, wear mechanism can be more complex.

In summary, the applications of polymer composites in tribological fields are broad and growing in the quest of increasing efficiency and lowering operating cost. In the last few years, particular attention has been paid to HPPs and their composites for engineering fields under extreme conditions, where lower friction and lower wear ought to be achieved. Additional encouraging impacts on the accomplishment of structural tribo-components should be anticipated from the advancement of functionally gradient materials and the hybrid polymer composites with various fillers. For designing future HPP composites, the following factors should be considered: (i) the compatibility of the fillers with the matrix, (ii) a blend of fibers and particulate fillers, and (iii) a positive synergic of the fillers with counter surfaces. The main intention will be forming and maintaining effective TLs during the sliding. There is still sufficient space for the future growths of HPPs and their composites as pointed out hereafter:

The recent trend towards the development of HPPs is to use the combination of particle and fibre type reinforcements. This technique offers the possibility to increase both strength and toughness of HPPs, though makes the scenario more complex in terms of wear mechanism and wear-debris formation. In that respect, a more fundamental investigation is needed in terms of their interactions and the overall effect on friction and wear behavior.

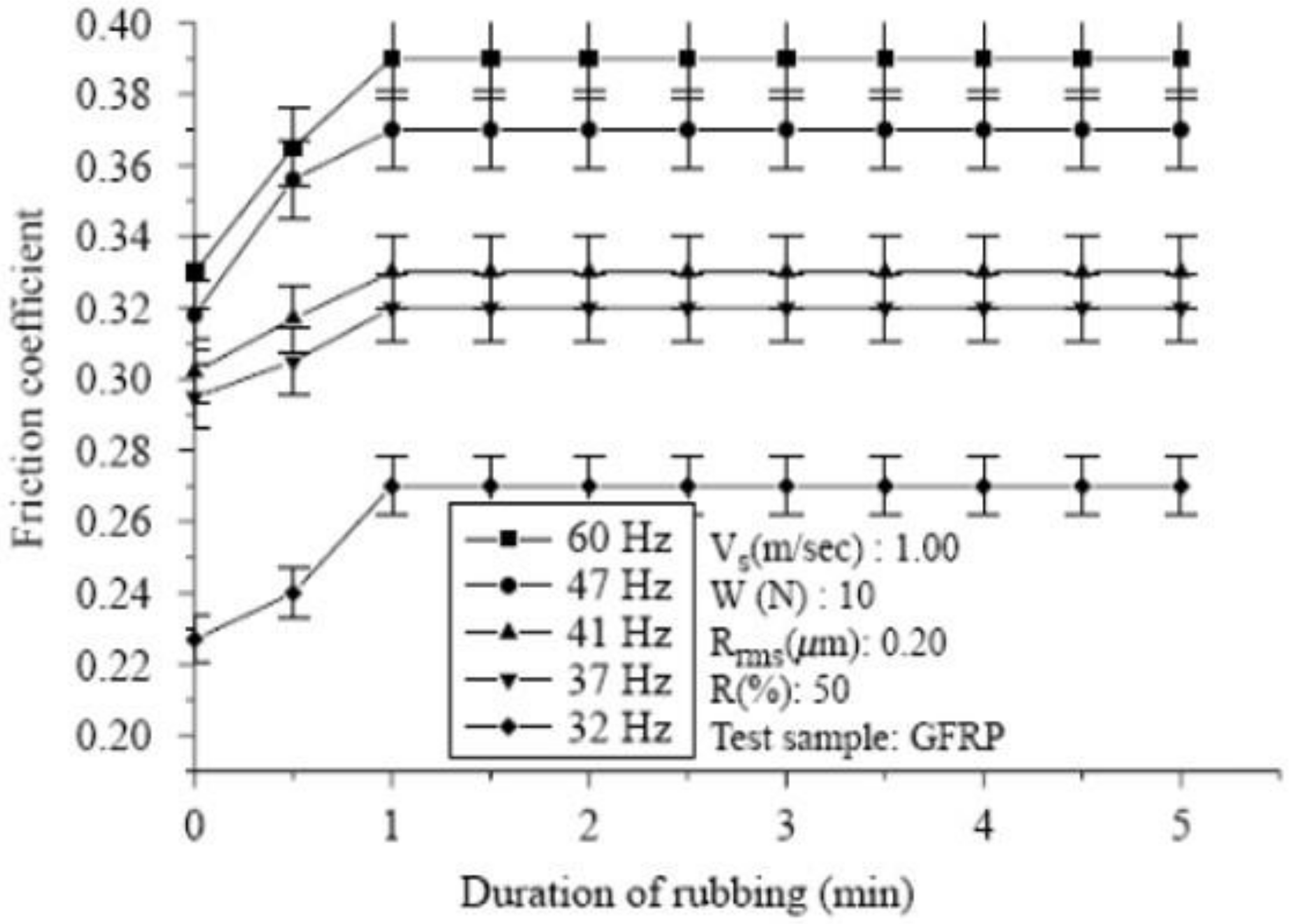

Effects of vibration, both natural and system generated, is another under-research area in this field. Vibration may change the contact mode in the mating materials and accelerate/decelerate friction and wear accordingly. Proper care should be taken in that respect, which has been often overlooked.

There are some contradictions in understandings regarding high-temperature tribological aspects of HPPs and their composite, as some authors reported that the incorporation of particles does not necessarily increase the wear performance of HPPs composite, particularly at high temperature. In addition to that, consideration will be taken regarding the cost of nanofiller and their relatively weighted advantages.