Abstract

Contact friction between moving components leads to severe wear and failure of engineering parts, resulting in large economic losses. The lubricating ability of the protic ionic liquid, tri-[bis(2-hydroxyethylammonium)] citrate (DCi), was studied as a neat lubricant and as an additive in a mineral oil (MO) at various sliding velocities and constant load on an aluminum–steel contact using a pin-on-disk tribometer. Tribological tests were also performed at different concentrations of DCi. When DCi was used as an additive in MO, friction coefficient and wear volume were reduced for each sliding velocity, with a maximum friction and wear reduction of 16% and 40%, respectively, when 2 wt % DCi was added to MO at a sliding velocity of 0.15 m/s. Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) were also applied to analyze the wear mechanism of the interface lubricated by MO and DCi as additive.

1. Introduction

Aluminum is widely used in different industries due to its beneficial chemical and physical properties [1]. Its high strength-to-weight ratio makes it very useful in automobile and aerospace industries [1,2]. When used in these types of applications, aluminum is often subjected to different sliding velocities with different materials. When it is in contact with different materials, due to its poor tribological properties, the system is very difficult to lubricate [3,4].

Appropriate lubricants in steady operation can improve the lifespan of engineering systems [5]. Recently, different types of additives were used in lubricants to reduce friction and wear. These additives offer intrinsic properties like anti-wear agents, resistance to rust and corrosion, and improvement in viscosity [6]. Among them, ionic liquids (ILs) gained more attention as they possess good properties like high thermal stability, non-flammability, negligible volatility, and ultra-low vapor pressure [7,8,9,10]. Specifically, a small amount of ILs as additives could enormously enhance the performance of a system [11]. ILs are synthetic salts in a molten state below 100 °C, and some ILs are liquid at room temperature [12]. They contribute to increasing the service life span of engineering systems by forming ordered layers in a liquid state between the two rubbing surfaces, which increases the load carrying capacity of the lubricant and helps lower the friction coefficient [13,14]. Research studies were done on various contact surfaces like steel–steel using tetraalkylphosphonium-based [11] and choline chloride ILs, titanium–steel using imidazolium- [12] and ammonium-based ILs [15], and aluminum–steel using imidazolium- [3], ammonium- [13], and phosphonium-based ILs [16,17].

Protic ionic liquids (PILs) are formed via the combination of a Brønsted acid and a Brønsted base [18]. PILs possess a wide range of properties, such as high thermal and electronic conductivity, non-flammability, and low toxicity [19]. They can be tailored by changing the cation and anion structures to satisfy specific requirements [13]. Due to the easy synthetic route, and low cost and toxicity, PILs can be a suitable alternative to aprotic ionic liquids (AILs), which are another subset of ILs and have no acidic protons as cations [20]. The transference of protons in PILs from the acid to the base creates proton-donor and proton-acceptor sites, leading to the formation of hydrogen bonds [21]. Most PILs that were studied until now always contained fluorine or sulfur in their compositions [11,19,22]. Tri-[bis(2-hydroxyethylammonium)] citrate (DCi) is made up of an ammonium cation and a carboxylate anion, which just contain carbon, hydrogen, nitrogen, and oxygen, and can be considered as an environmentally friendly ionic liquid.

In this study, the lubricating ability of tri-[bis(2-hydroxyethylammonium)] citrate (DCi) as an additive in a mineral oil and as a neat lubricant was tested at different sliding velocities and a constant load. Effects of these parameters on the loss of wear volume and the coefficient of friction for an aluminum–steel contact were studied using a pin-on-disk tribometer.

2. Materials and Methods

In this study, tri-[bis(2-hydroxyethylammonium)] citrate (DCi) was used as an additive to a mineral oil. DCi was synthesized in our laboratory with diethanolamine (≥98.0) and citric acid (≥99.5%) that were purchased from Sigma Aldrich (St. Louis, MO, USA). Citric acid and diethanolamine were dissolved in ethanol; then, the two solutions were mixed together using a magnetic stirrer at room temperature in an argon atmosphere. After the heat evaporation of the ethanol in the argon atmosphere, the viscous liquid was dried under a vacuum line. The molecular structure and empirical formula of DCi are shown in Table 1. The proton nuclear magnetic resonance (1H NMR) spectrum was done using a Bruker Ultrashield 300 MHz spectrometer (Billerica, MA, USA) with DMSO-d6 as solvent and TMS as internal standard. The viscosity of DCi was measured on a BROOKFIELD Viscometer DV2T-LV (Middleboro, MA, USA) in the range of 25 °C to 100 °C. The thermogravimetric analysis was conducted using a TA Q500 (New Castle, DE, USA) in air atmosphere in the range of 10 °C to 600 °C with a heating rate of 10 °C/min. The base mineral oil (MO), Base Oil VG46, was kindly provided by REPSOL (Madrid, Spain), and had a density of 868 kg/m3 at room temperature.

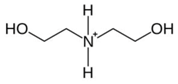

Table 1.

Molecular structure and empirical formula of tri-[bis(2-hydroxyethylammonium)] citrate (DCi).

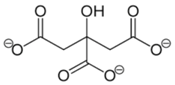

Aluminum 6061 (0.80 wt % Si, 0.70 wt % Fe, 0.40 wt % Cu, 0.15 wt % Mn, 1.20 wt % Mg, 0.35 wt % Cr, 0.25 wt % Zn, and 0.15 wt % Ti) discs (31.70 mm in diameter and 9.525 mm in thickness) were kept in sliding contact with AISI52100 steel balls of 1.5 mm in diameter using a custom-designed pin-on-disk tribometer, as shown in Figure 1. Table 2 shows the modulus of elasticity and Poisson’s ratio for the materials used in this study.

Figure 1.

Pin-on-disk tribometer.

Table 2.

Properties of aluminum disc and steel ball.

DCi was added to MO with concentrations of 1 wt % and 2 wt %. A magnetic stirrer was used for 6 h at room temperature until the DCi was completely dissolved in the base mineral oil. After this process, the lubricants were ultrasonicated for one hour to obtain two homogenous mixtures with clear and transparent appearances. Neat MO was also used for comparison purposes. Tribological tests were conducted for sliding velocities of 0.10 m/s, 0.15 m/s, and 0.20 m/s, using neat MO and MO with 1 wt % DCi, to observe the effect of velocity on friction and wear volume. For the sliding velocity of 0.15 m/s, tribological tests were performed with an additional mixture (2 wt % of DCi in MO).

Each tribological test was conducted under a constant normal load of 2.94 N, which corresponds to a mean effective Hertz contact pressure of 1.00 GPa, a sliding distance of 850 m, and a wear-track radius of 10 mm at room temperature. At least three tests were performed under identical conditions for each lubricant, and the lubricant amount was set as 1 mL with no more lubricant added during each test. The friction coefficient along with the sliding distance was constantly recorded for each test.

Wear-track widths for each sample were measured using a BX60M Olympus optical microscope (Center Valley, PA, USA). At least 24 values of wear-track width were measured along the wear track to get an average value. The loss of wear volume for each sample was measured according to an ASTM G99 standard [23], following Equation (1), after doing at least two tests under the same experimental conditions with standard deviations lower than 5%.

where R is the wear-track radius, d is the wear-track width, and r is the steel ball’s radius.

Disc volume loss = 2πR(r2 sin−1(d/2r) − (d/4)(4r2 − d2)1/2)

Before and after each tribological test, the sample disc was cleaned with isopropyl alcohol (99.5%) in an ultrasonic cleaner, before being dried in air. A Nanovea ST400 profilometer (Irvine, CA, USA) was applied to get the three-dimensional (3D) and profile images of the wear tracks. After that, a Tescan Mira3 (Warrendale, PA, USA) scanning electron microscope (SEM) and energy-dispersive X-ray spectroscopy (EDX) were used to analyze the wear mechanism and surface interaction.

3. Results

3.1. NMR Characterization, and Viscosity and Thermagravimetric Analysis of DCi

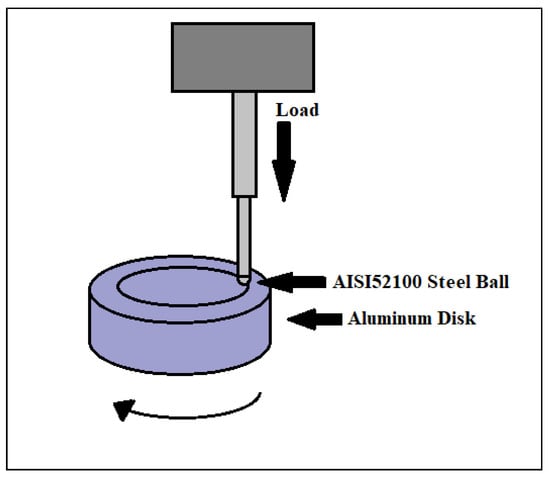

1H NMR spectroscopy was performed to confirm the ionic structure of DCi, and the results are shown in Figure 2. When δ = 4.46, it corresponded to the hydrogen of OH and NH from the cations. The peaks for δ = 3.55–3.60 corresponded to the hydrogens of methylene in the cations. When δ = 2.77–2.85, the peaks were related to the H of CH2, whose carbon atom is connected to the nitrogen of the cations. Furthermore, the fourth peak is the characteristic peak of H in DMSO-d6 (δ = 2.5). The subsequent peaks were related to the H in C–OH of the anions.

Figure 2.

NMR spectrum of tri-[bis(2-hydroxyethylammonium)] citrate (DCi).

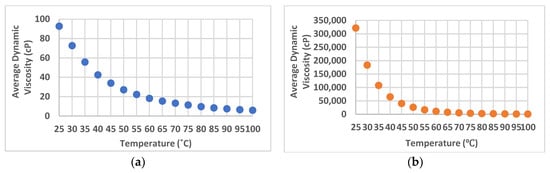

The average dynamic viscosity values as a function of temperature of MO and neat DCi are shown in Figure 3. The viscosity of both MO and DCi decreased as the temperature increased. This increase was particularly noticeable for DCi, where, at 25 °C, the viscosity was 321,671.4 cP, and, at 100 °C, the viscosity decreased to 941.2 cP.

Figure 3.

Viscosity of (a) mineral oil (MO) and (b) DCi.

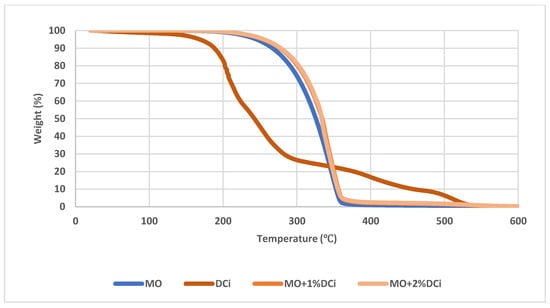

The thermal stability of MO and DCi were examined using thermogravimetric analysis (TGA), and the results are summarized in Figure 4 and Table 3. MO showed higher thermal stability than DCi, with onset decomposition temperatures of 291.2 °C and 191.2 °C, respectively. When 1 wt % DCi and 2 wt % DCi were added to MO, the mixtures exhibited even better thermal stabilities than MO.

Figure 4.

Experimental thermogravimetric analysis (TGA) for MO and DCi.

Table 3.

The thermal stability of mineral oil (MO) and DCi.

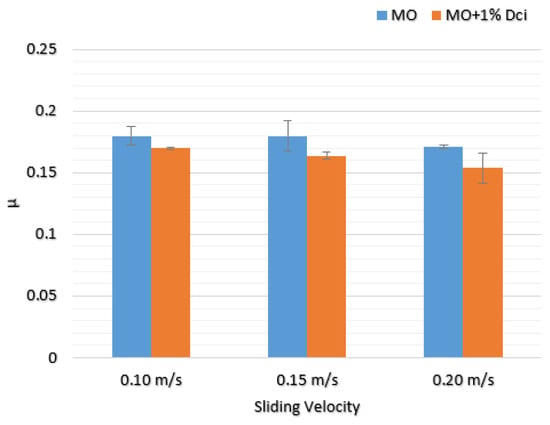

3.2. Effect of Sliding Velocity

Three sliding velocities (0.10, 0.15, and 0.20 m/s) were used under a constant normal load of 2.94 N. Figure 5 shows the average value of the friction coefficient for the different velocities using MO and MO + 1% DCi as lubricants. From the figure, the addition of 1 wt % DCi to MO slightly reduced the friction coefficient at all velocities with a maximum friction reduction of 10% at 0.20 m/s.

Figure 5.

Average friction coefficients as a function of sliding velocity.

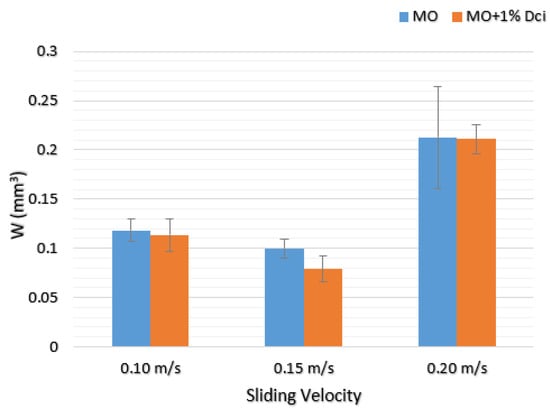

The average values of the wear volume of the aluminum discs as a function of sliding velocity are shown in Figure 6. It is important to mention that no wear on the steel balls was observed under the conditions studied. For both lubricants, wear volume was reduced when the sliding velocity increased from 0.10 m/s to 0.15 m/s, and increased again from 0.15 m/s to 0.20 m/s. A velocity of 0.15 m/s may be optimal for the molecules of the lubricant to form an ordered layer that separates the surfaces in contact [24]. Higher temperatures due to higher speeds may have a negative effect on the formation of this layer. Wear volumes on the aluminum discs were always smaller when the PIL was added to the mixture, with a maximum wear reduction of 20% with respect to MO at 0.15 m/s.

Figure 6.

Wear volume on aluminum discs as a function of the sliding velocity.

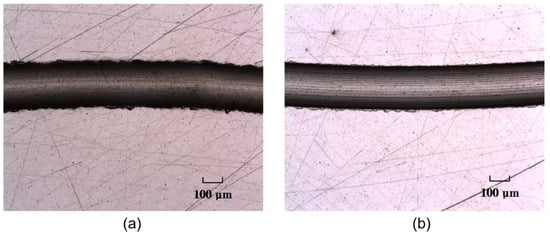

Figure 7 shows the optical images of the aluminum worn surfaces after tests of samples lubricated with MO and MO + 1% DCi at 0.10 m/s. The wear-track width decreased to 8% when IL was used as additive, which resulted in a reduction in wear volume. For both lubricants at this velocity, the wear mechanism was mainly abrasive with a component of plastic deformation at the borders of the wear tracks. The amount of plastically deformed materials was reduced with the presence of DCi in the MO (Figure 7d).

Figure 7.

Wear tracks on aluminum discs for a sliding velocity of 0.10 m/s: (a,c) MO; (b,d) MO + 1% DCi. (a,b) Images are displayed with 50× magnification; (c,d) images are displayed with 200× magnification.

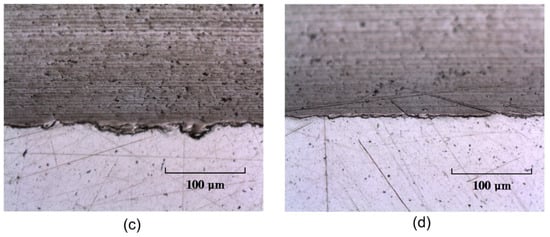

As mentioned previously, the wear volume of steel discs reached a minimum at 0.15 m/s (Figure 6). As can be seen in the optical micrographs of the worn surfaces of Figure 8, at this velocity, the addition of 0.1 wt % DCi to the MO reduced the wear-track width on the aluminum discs, as well as the plastic deformation component of wear. A strong plowing effect was still present for both lubricants (Figure 8c,d).

Figure 8.

Wear tracks on aluminum discs for a sliding velocity of 0.15 m/s: (a,c) MO; (b,d) MO + 1% DCi. (a,b) Images are displayed with 50× magnification; (c,d) images are displayed with 200× magnification.

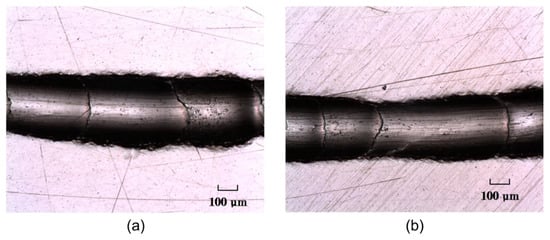

Increasing the sliding velocity from 0.10 m/s to 0.15 m/s reduced the wear volume of the steel disc by up to 6.5% and increased the amount of plastically deformed material at the border of the wear scars, particularly for MO + 1% DCi. From 0.15 m/s to 20 m/s (Figure 8 and Figure 9), a transition from mainly abrasive to mostly adhesive wear was observed for both lubricants.

Figure 9.

Wear tracks for a sliding velocity of 0.20 m/s: (a) MO; (b) MO + 1% DCi. Images are displayed with 50× magnification.

3.3. Effect of Ionic Liquid

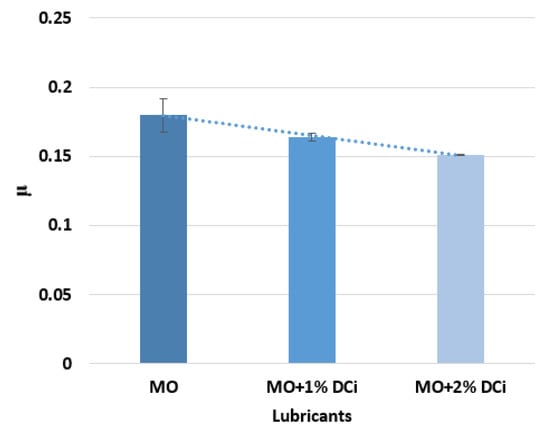

Figure 10 shows the average value of the friction coefficient at a sliding velocity of 0.15 m/s with different lubricants. When DCi was used as an additive in MO, a slight reduction in friction coefficient was obtained. The highest friction reduction was obtained when MO + 2% DCi was used (nearly 16% reduction compared to MO).

Figure 10.

Average friction coefficient for a sliding velocity of 0.15 m/s.

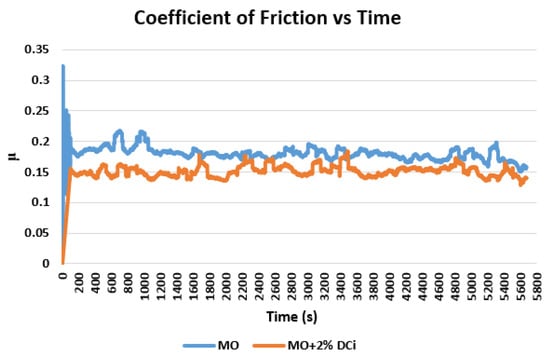

The graphs of friction variation with time for MO and MO + 2% DCi are shown in Figure 11. When MO was used, high values of friction were obtained during the first three minutes of the test, before the friction coefficient remained relatively constant until the end. For MO + 2% DCi, the friction coefficient was maintained around 0.15 from the beginning until the end of the test.

Figure 11.

Friction coefficient vs. time when MO and MO + 2% DCi were used.

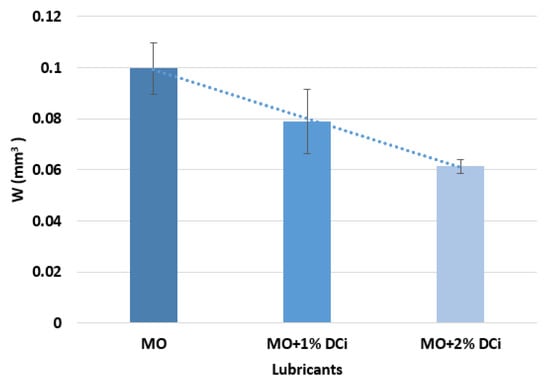

Figure 12 summarizes the average wear volume on steel discs for MO, MO + 1% DCi, and MO + 2% DCi at a sliding velocity of 0.15 m/s. From the figure, as the concentration of DCi increased in the MO, the wear volume decreased. When MO + 1% DCi was used, a reduction of almost 20% was obtained compared to MO. The addition of 2% DCi to the MO reduced wear volume by almost 40%.

Figure 12.

Loss of wear volume for different concentrations of ionic liquid at 0.15 m/s.

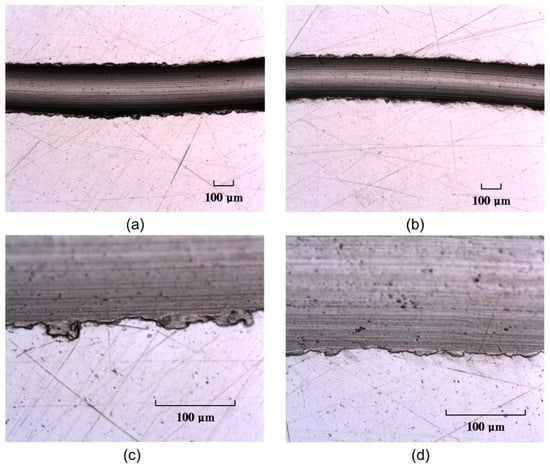

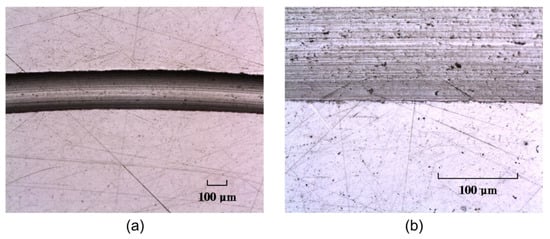

The optical images of the worn surfaces are summarized in Figure 13. When MO was used as a lubricant, the wear mechanism was mainly abrasion with a component of plastic deformation at the edges of the wear tracks. As the concentration of PIL increased in the mixture, a smaller amount of plastically deformed material was observed.

Figure 13.

Wear track for a sliding velocity of 0.15 m/s: (a) MO + 2% DCi (50× magnification); (b) MO + 2% DCi (200× magnification).

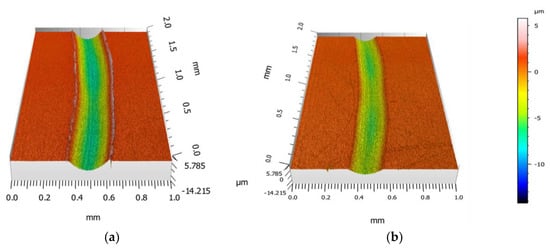

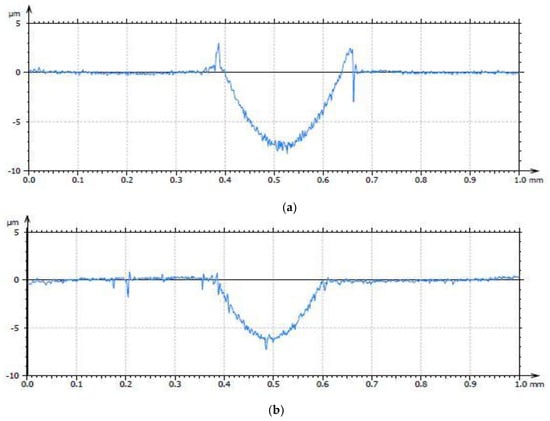

The wear reduction on the aluminum discs when 2 wt % DCi was added to the MO is clearly seen in the 3D images (Figure 14) and two-dimensional (2D) profiles (Figure 15) of the worn surfaces. The wear tracks after tests lubricated with MO + 2% DCi were not only narrower, but also shallower (see Figure 14 and Figure 15) compared to those obtained after tests lubricated with MO. It is important to note that the amount of plastically deformed material at the edges of the wear path was negligible (Figure 15) when the IL was present in the lubricant.

Figure 14.

Three-dimensional (3D) profilometer images of wear tracks in tests with (a) MO, and (b) MO + 2% DCi.

Figure 15.

Two-dimensional (2D) profiles of wear tracks in tests with (a) MO, and (b) MO + 2% DCi.

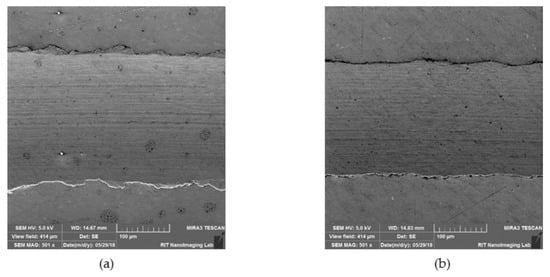

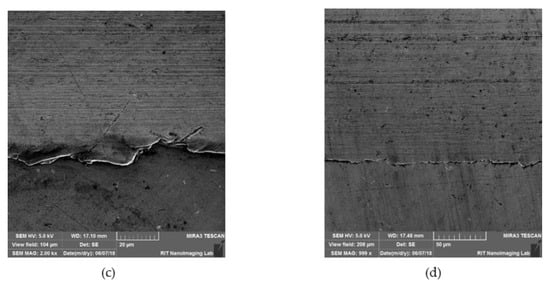

For the sliding velocity of 0.15 m/s, SEM and EDS were performed to analyze the wear mechanism. Figure 16 shows the wear-track images obtained under SEM for tests with MO and MO + 2% DCi. An abrasive wear mechanism was confirmed for both lubricants. However, the abrasion marks were deeper (Figure 16a,c) when the aluminum surface was lubricated with MO. The accumulation of plastically deformed material at the edges of the wear tracks are again evident in Figure 16c.

Figure 16.

SEM micrographs for a sliding velocity of 0.15 m/s: (a,c) MO; (b,d) MO + 2% DCi.

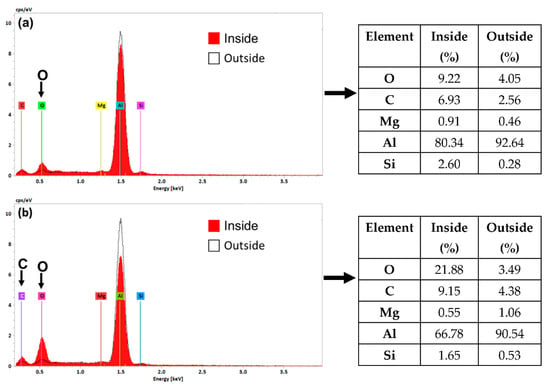

Figure 17 shows a comparison of the EDX analysis obtained for both the inside and the outside of the wear track using MO and MO + 2% DCi. A slightly higher amount of O and C was found inside the wear track compared to the outside when the surface was lubricated with MO. When 2 wt % DCi was added to the lubricant, a much higher amount of O and C was observed inside the wear track compared to the outside. The formation of a tribolayer rich in O and C [25,26] may be responsible for the reductions in friction and wear.

Figure 17.

Energy-dispersive X-ray (EDX) spectrum of the inside and outside of the wear track with tables summarizing element percentages after tests lubricated with (a) MO, and (b) MO + 2% DCi.

4. Conclusions

In this work, the lubricating ability of a protic ionic liquid was studied as an additive to an MO for an aluminum–steel contact at different sliding velocities and concentrations. When 1 wt % DCi was used as an additive in MO, friction and wear were reduced compared to that seen with the neat MO at all velocities studied. Increasing the IL concentration from 1 wt % to 2 wt % reduced friction and wear, with a maximum reduction of 16% for friction and 40% for wear compared to MO.

Optical and SEM images of the worn surfaces showed that the wear mechanism was mainly abrasion with a component of plastic deformation at the edges of the wear tracks. As the concentration of PIL increased in the lubricant mixture, a smaller amount of plastically deformed material was observed. EDX analysis confirmed the presence of a higher amount of O and C inside the wear track when DCi was present. This tribolayer may be responsible for the reductions in friction and wear.

Author Contributions

Conceptualization, P.I. and A.P. Methodology, P.I. Validation, P.I. Formal analysis, A.P. and H.G. Investigation, P.I. Resources, P.I. Data curation, A.P. and H.G. Writing—original draft preparation, A.P., H.G., and P.I. Writing—review and editing, A.P., H.G., and P.I. Supervision, P.I. Project administration, P.I.

Funding

This research received no external funding.

Acknowledgments

The authors wish to thank the financial support of the Mechanical Engineering Department at the Kate Gleason College of Engineering at the Rochester Institute of Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qu, J.; Blau, P.J.; Dai, S.; Luo, H.; Meyer, H.M.; Truhan, J.J. Tribological characteristics of aluminum alloys sliding against steel lubricated by ammonium and imidazolium ionic liquids. Wear 2009, 267, 1226–1231. [Google Scholar] [CrossRef]

- Singh, K.K.; Singh, S.; Shrivastava, A.K. Study of Tribological Behavior of Silicon Carbide Based Aluminum Metal Matrix Composites under Dry and Lubricated Environment. Adv. Mater. Sci. Eng. 2016, 2016, 3813412. [Google Scholar] [CrossRef]

- Mu, Z.; Zhou, F.; Zhang, S.; Liang, Y.; Liu, W. Effect of the functional groups in ionic liquid molecules on the friction and wear behavior of aluminum alloy in lubricated aluminum-on-steel contact. Tribol. Int. 2005, 38, 725–731. [Google Scholar] [CrossRef]

- Iglesias, P.; Bermúdez, M.D.; Carrión, F.J.; Martínez-Nicolás, G. Friction and wear of aluminium-steel contacts lubricated with ordered fluids-neutral and ionic liquid crystals as oil additives. Wear 2004, 256, 386–392. [Google Scholar] [CrossRef]

- Mohammad, A.; Inamuddin, D. (Eds.) Green Solvents II: Properties and Applications of Ionic Liquids; Springer Science & Business Media: Dordrecht, The Netherlands, 2012; ISBN 9789400728912. [Google Scholar]

- Nicholls, M.A.; Do, T.; Norton, P.R.; Kasrai, M.; Bancroft, G.M. Review of the lubrication of metallic surfaces by zinc dialkyl-dithiophosphates. Tribol. Int. 2005, 38, 15–39. [Google Scholar] [CrossRef]

- Qu, J.; Truhan, J.J.; Dai, S.; Luo, H.; Blau, P.J. Ionic liquids with ammonium cations as lubricants or additives. Tribol. Lett. 2006, 22, 207–214. [Google Scholar] [CrossRef]

- Gutierrez, M.; Haselkorn, M.; Iglesias, P. The lubrication ability of ionic liquids as additives for wind turbine gearboxes oils. Lubricants 2016, 4, 14. [Google Scholar] [CrossRef]

- Gren, P. Feasibility of using digital speckle correlation in the study of seal contacts. Lubr. Sci. 2009, 21, 123–134. [Google Scholar] [CrossRef]

- Somers, A.E.; Khemchandani, B.; Howlett, P.C.; Sun, J.; Macfarlane, D.R.; Forsyth, M. Ionic liquids as antiwear additives in base oils: Influence of structure on miscibility and antiwear performance for steel on aluminum. ACS Appl. Mater. Interfaces 2013, 5, 11544–11553. [Google Scholar] [CrossRef] [PubMed]

- Weng, L.J.; Liu, X.Q.; Liang, Y.M.; Xue, Q.J. Effect of tetraalkylphosphonium based ionic liquids as lubricants on the tribological performance of a steel-on-steel system. Tribol. Lett. 2007, 26, 11–17. [Google Scholar] [CrossRef]

- Jiménez, A.E.; Bermúdez, M.D. Ionic liquids as lubricants of titanium-steel contact. Part 3. Ti6Al4V lubricated with imidazolium ionic liquids with different alkyl chain lengths. Tribol. Lett. 2010, 40, 237–246. [Google Scholar] [CrossRef]

- Vega, M.R.O.; Parise, K.; Ramos, L.B.; Boff, U.; Mattedi, S.; Schaeffer, L.; Malfatti, C.F. Protic ionic liquids used as metal-forming green lubricants for aluminum: Effect of anion chain length. Mater. Res. 2017, 20, 675–687. [Google Scholar] [CrossRef]

- Jiménez, A.E.; Bermúdez, M.D.; Iglesias, P.; Carrión, F.J.; Martínez-Nicolás, G. 1-N-alkyl-3-methylimidazolium ionic liquids as neat lubricants and lubricant additives in steel-aluminium contacts. Wear 2006, 260, 766–782. [Google Scholar] [CrossRef]

- Jiménez, A.E.; Bermúdez, M.D. Ionic liquids as lubricants of titanium-steel contact. Tribol. Lett. 2009, 33, 111–126. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, D.; Zhang, L.; Feng, D. Study of tribological performance and mechanism of phosphonate ionic liquids for steel/aluminum contact. Tribol. Int. 2015, 84, 71–80. [Google Scholar] [CrossRef]

- Somers, A.E.; Howlett, P.C.; Sun, J.; MacFarlane, D.R.; Forsyth, M. Phosphonium ionic liquids as lubricants for aluminium-steel. WIT Trans. Eng. Sci. 2010, 66, 273–283. [Google Scholar] [CrossRef]

- Menne, S.; Anouti, M.; Balducci, A. Aprotic and protic ionic liquids in lithium ion batteries: A comparative study. In ECS Meeting Abstract; The Electrochemical Society: San Francisco, CA, USA, 2013. [Google Scholar]

- Kondo, H. Protic Ionic Liquids with Ammonium Salts as Lubricants for Magnetic Thin Film Media. Tribol. Lett. 2008, 31, 211–218. [Google Scholar] [CrossRef]

- Angell, C.A.; Byrne, N.; Belieres, J. Parallel Developments in Aprotic and Protic Ionic Liquids: Physical Chemistry and Applications. Acc. Chem. Res. 2007, 40, 1228–1236. [Google Scholar] [CrossRef] [PubMed]

- Greaves, T.L.; Drummond, C.J. Protic Ionic Liquids: Properties and Applications. Chem. Rev. 2008, 108, 206–237. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Zhao, G.; Zhang, M. Tribological Behavior of Protic Ionic Liquids with Dodecylamine Salts of Dialkyldithiocarbamate as Additives in Lithium Complex Grease. Tribol. Lett. 2012, 48, 133–144. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM G99-05 Standard Test Method for Wear Testing with a Pin-On-Disk Apparatus1; West Conshohocken: Philadelphia, PA, USA, 2005. [Google Scholar]

- Bermúdez, M.-D.; Carrión, F.-J.; Iglesias, P.; Jiménez, A.-E.; Martínez-Nicolás, G.; Sanes, J. Ionic Liquids Interactions with Materials Surfaces Applications in Tribology and Nanotechnology. In Proceedings of the Materials Research Society (MRS) Spring Meeting, San Francisco, CA, USA, 24–28 March 2008. [Google Scholar]

- Cigno, E.; Magagnoli, C.; Pierce, M.; Iglesias, P. Lubricating ability of two phosphonium-based ionic liquids as additives of a bio-oil for use in wind turbines gearboxes. Wear 2017, 376, 756–765. [Google Scholar] [CrossRef]

- Espinosa, T.; Jimenez, M.; Sanes, J.; Jimenez, A.E.; Iglesias, M.; Bermudez, M.D. Ultra-low friction with a protic ionic liquid boundary film at the water-lubricated sapphire-stainless steel interface. Tribol. Lett. 2014, 53, 1–9. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).