A Comparison Study on Wear Behaviors of Mo and Al2O3-Mo Coatings from RT to 300 °C

Abstract

1. Introduction

2. Materials and Experimental Procedure

2.1. Feedstock Powders and Coatings Preparation

2.2. Microstructures Characterization of Coatings

2.3. Mechanical Properties Test

2.4. Friction and Wear Test

3. Results and Discussion

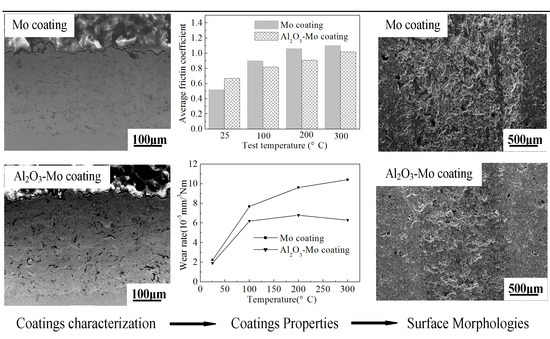

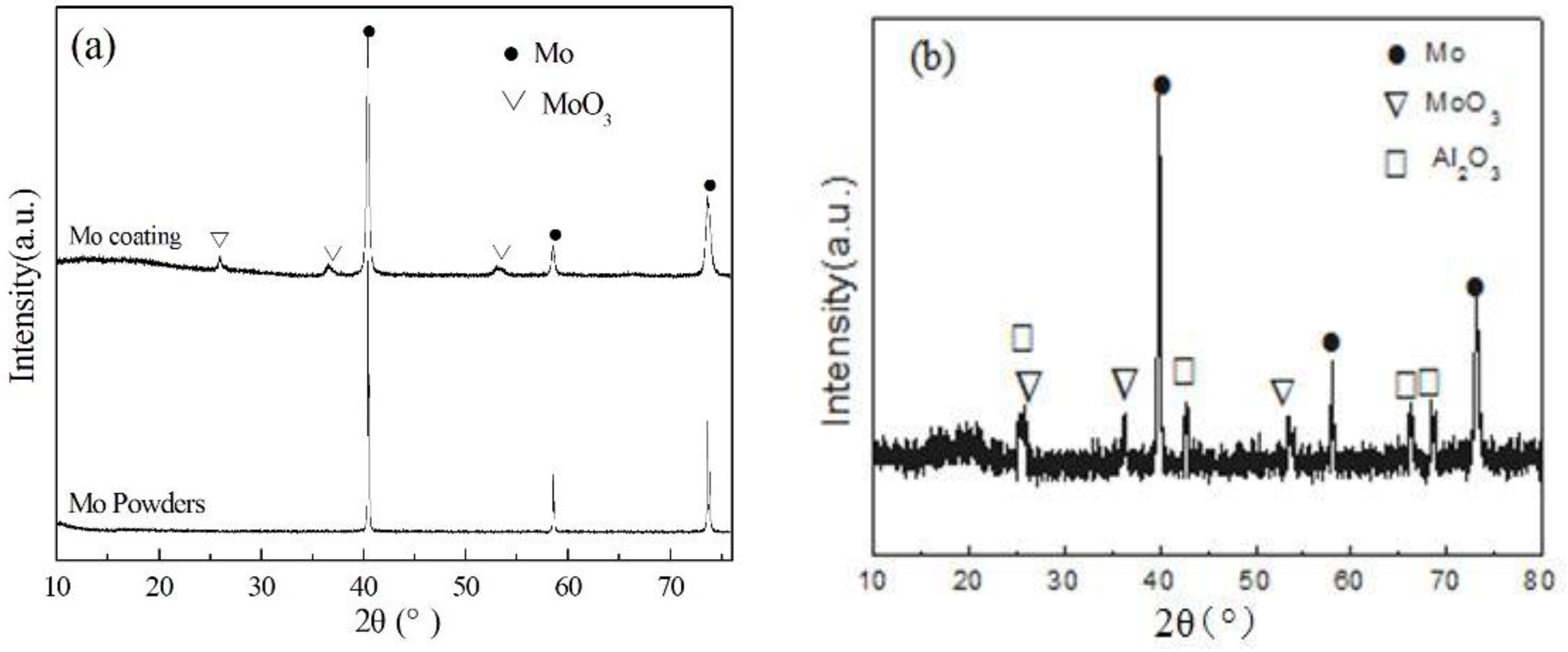

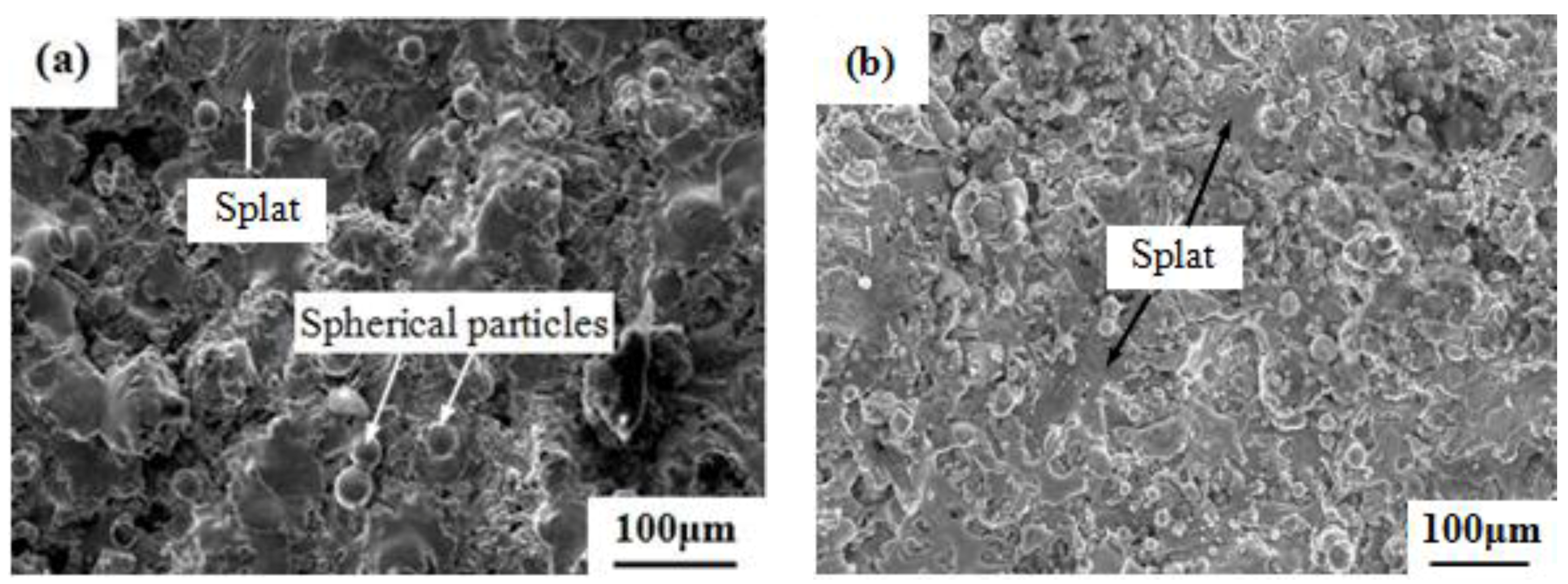

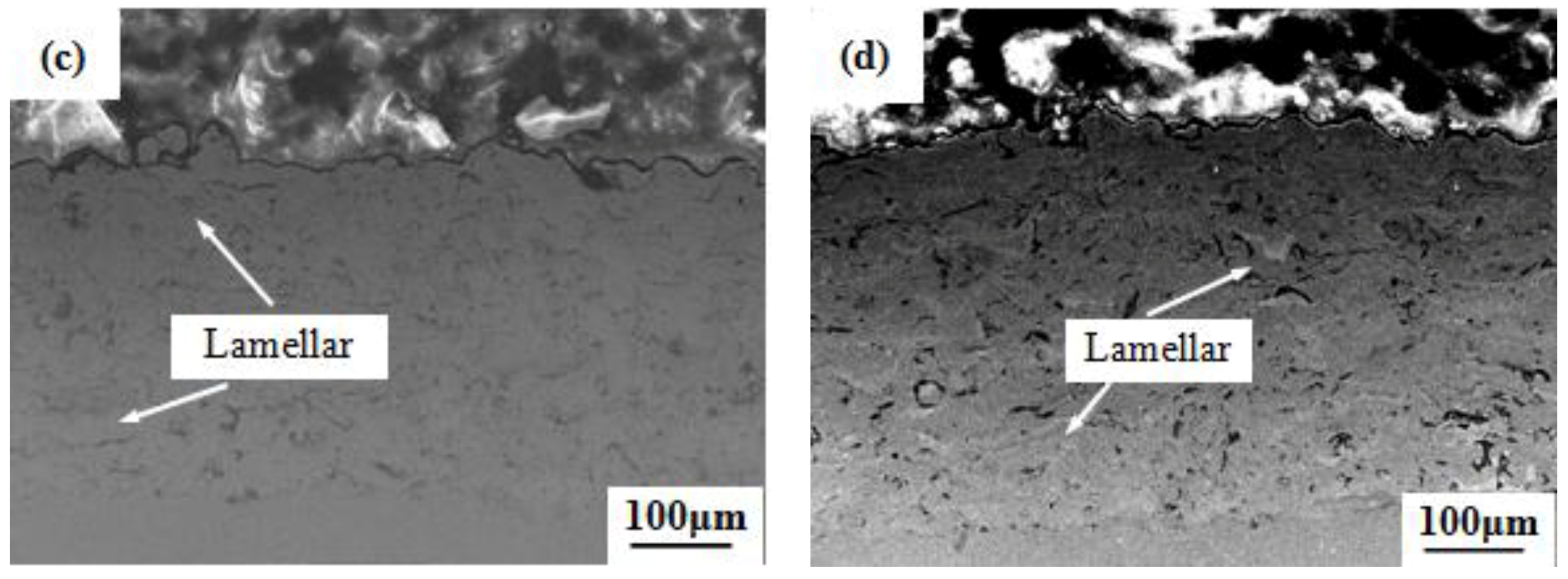

3.1. Microstructure of As-Sprayed Coatings

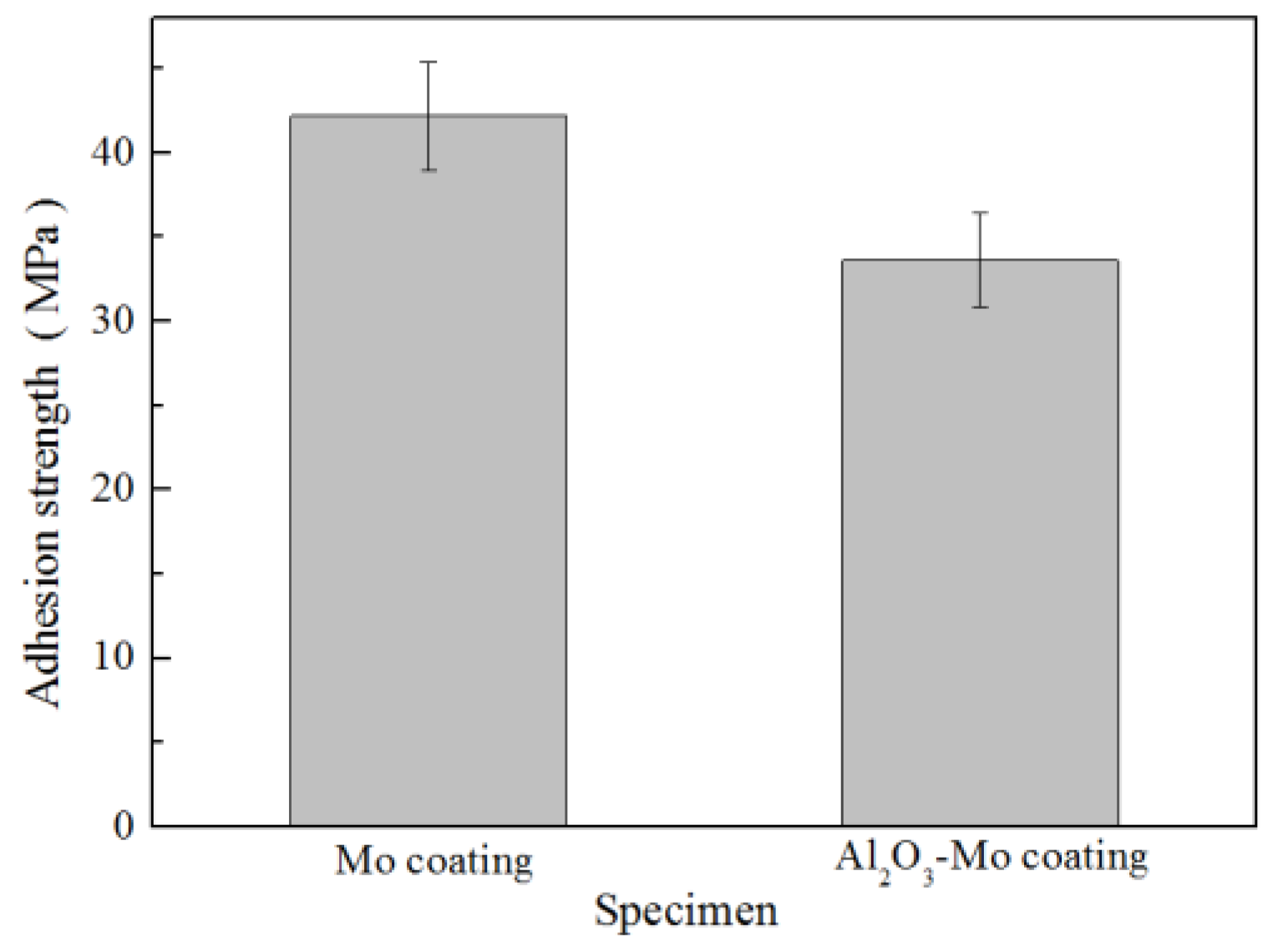

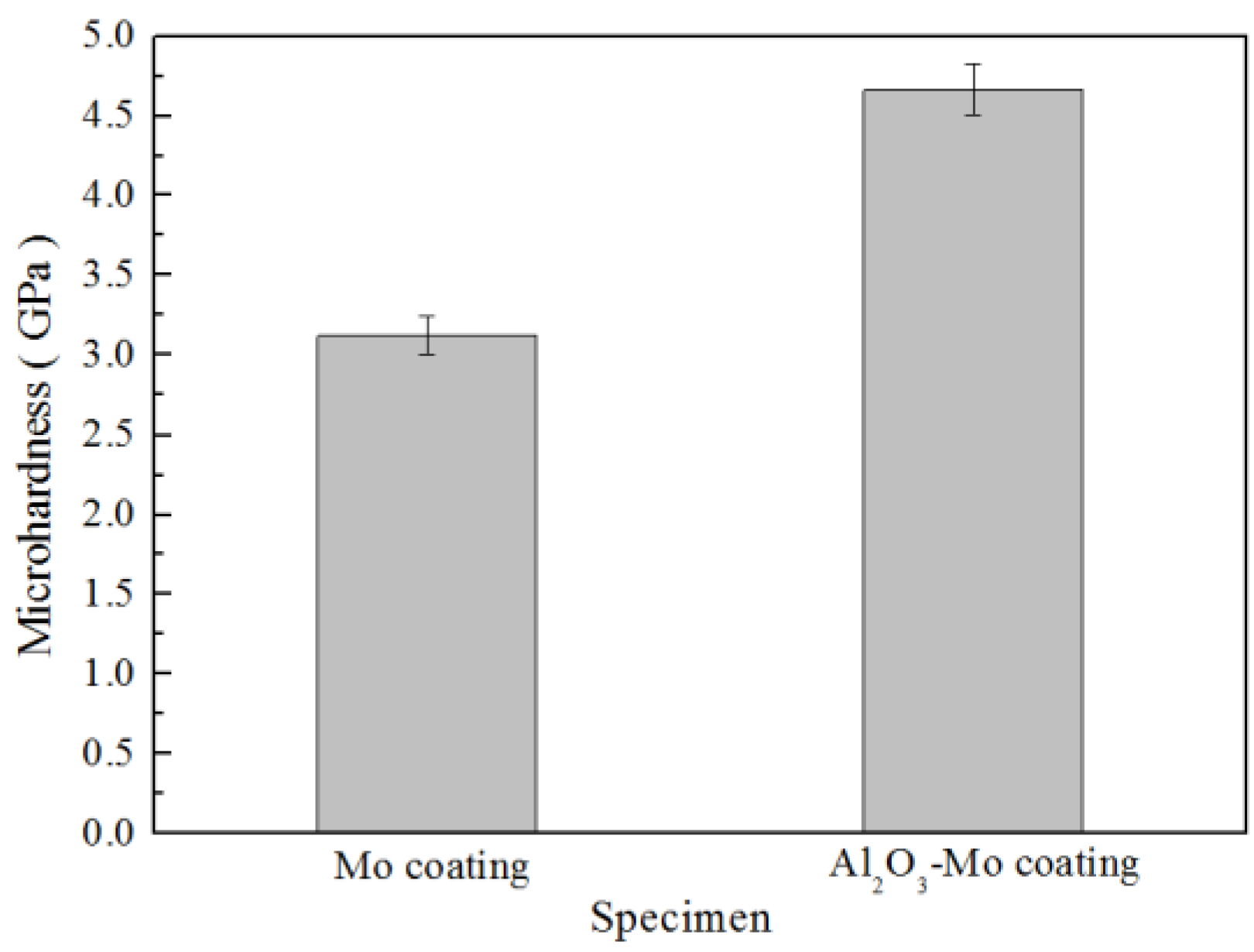

3.2. Adhesion Strength and Micro Hardness of Coatings

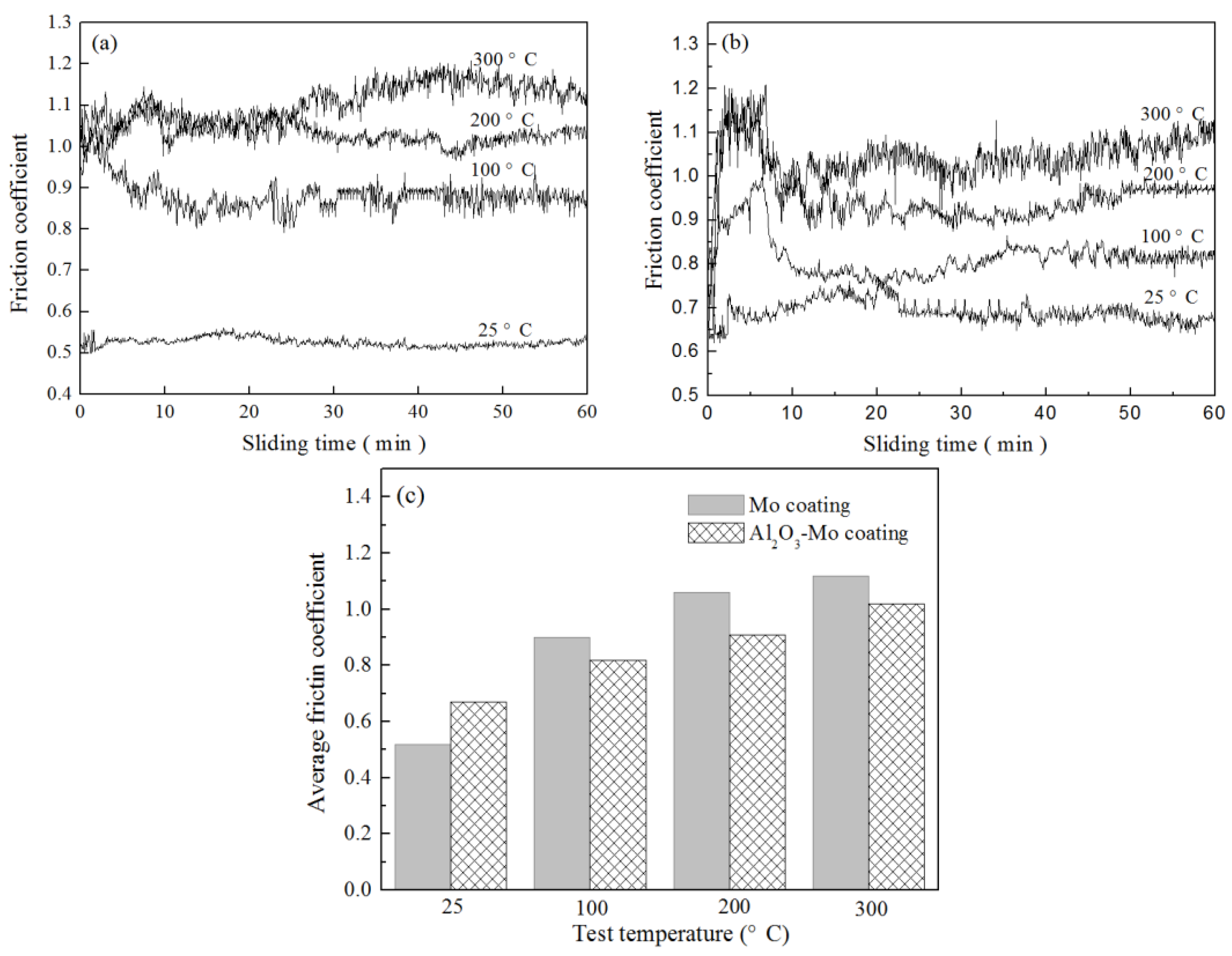

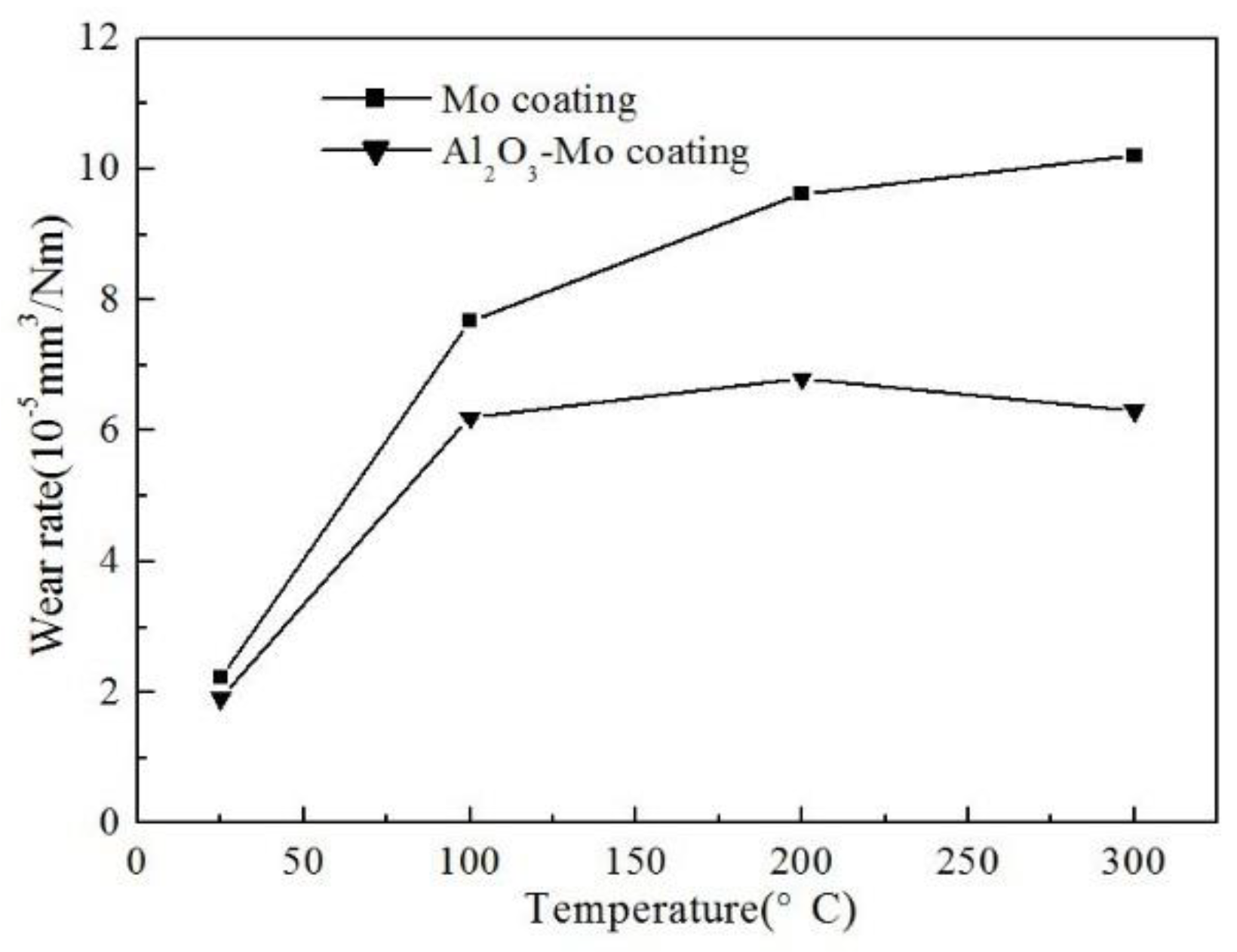

3.3. Friction Coefficient and Wear Rate of Coatings

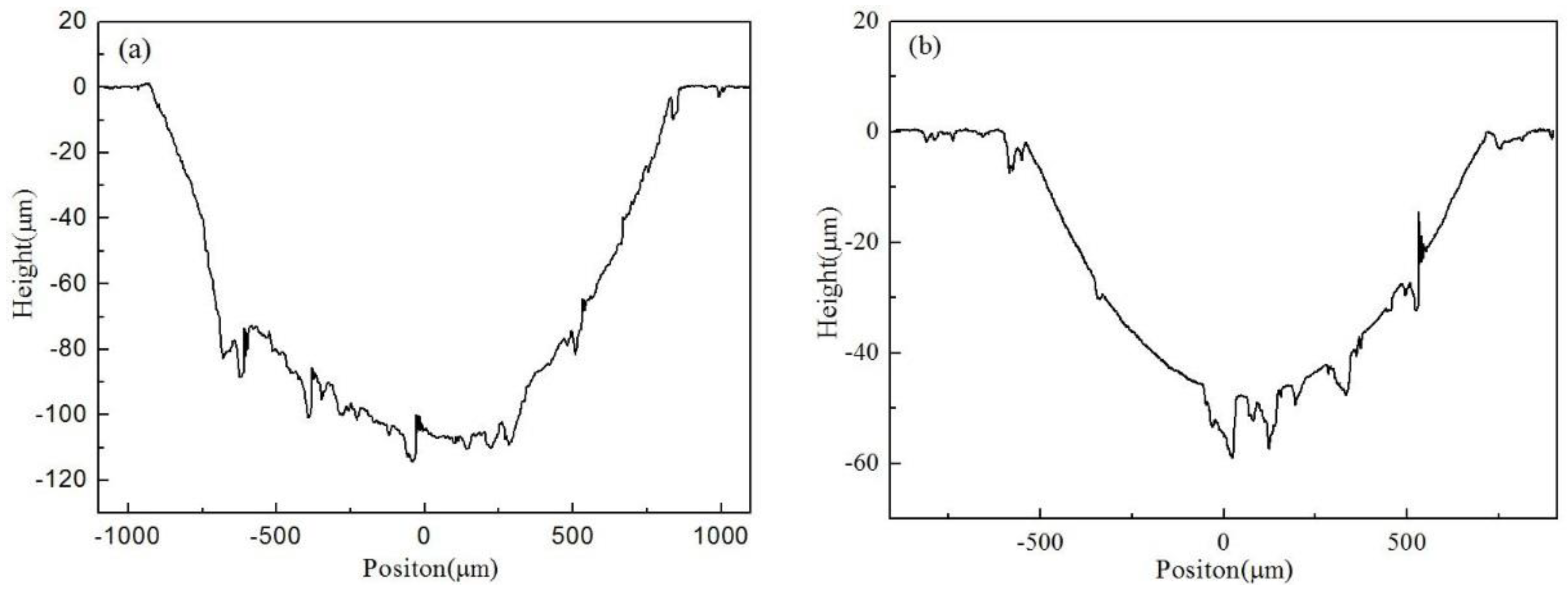

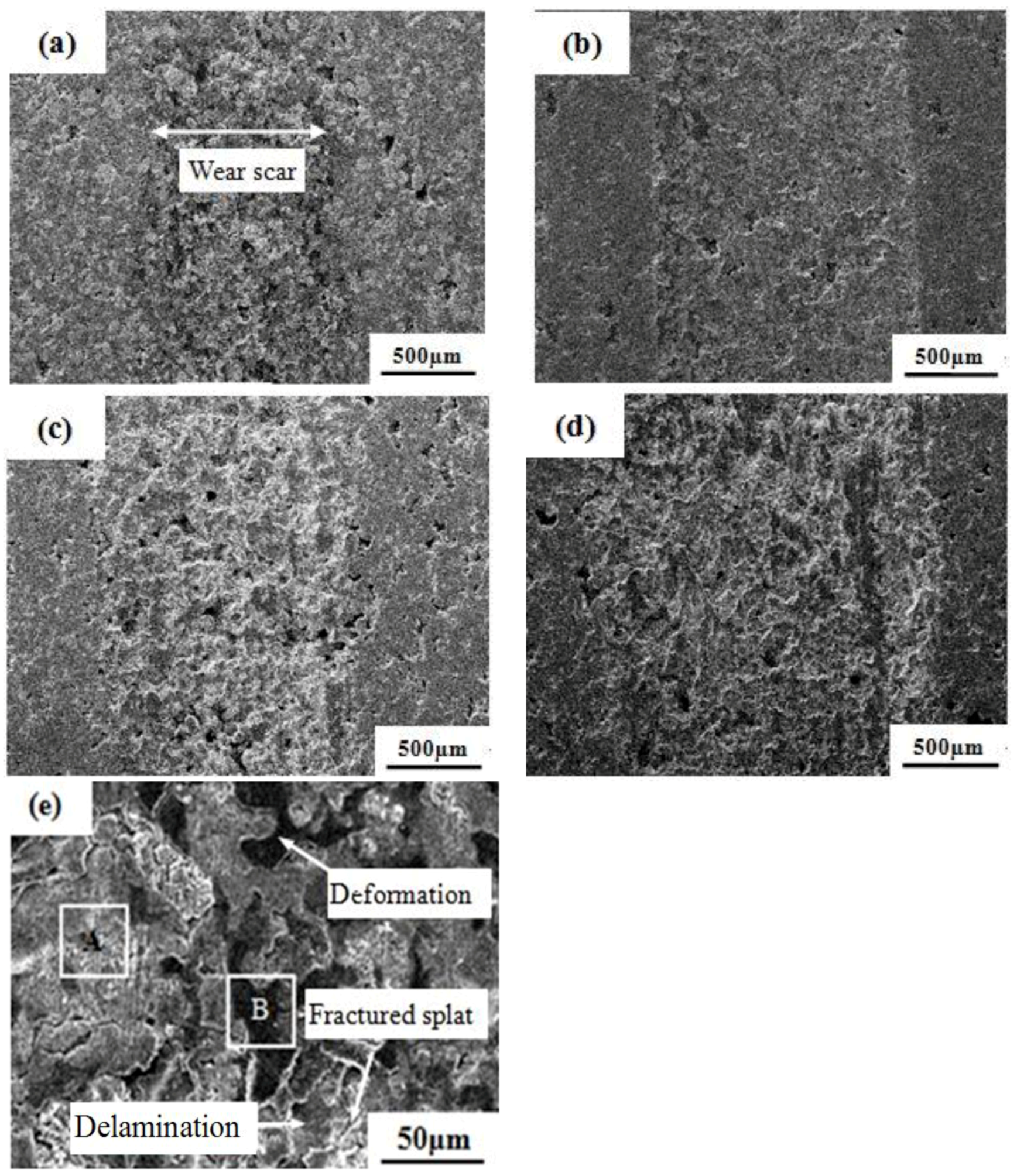

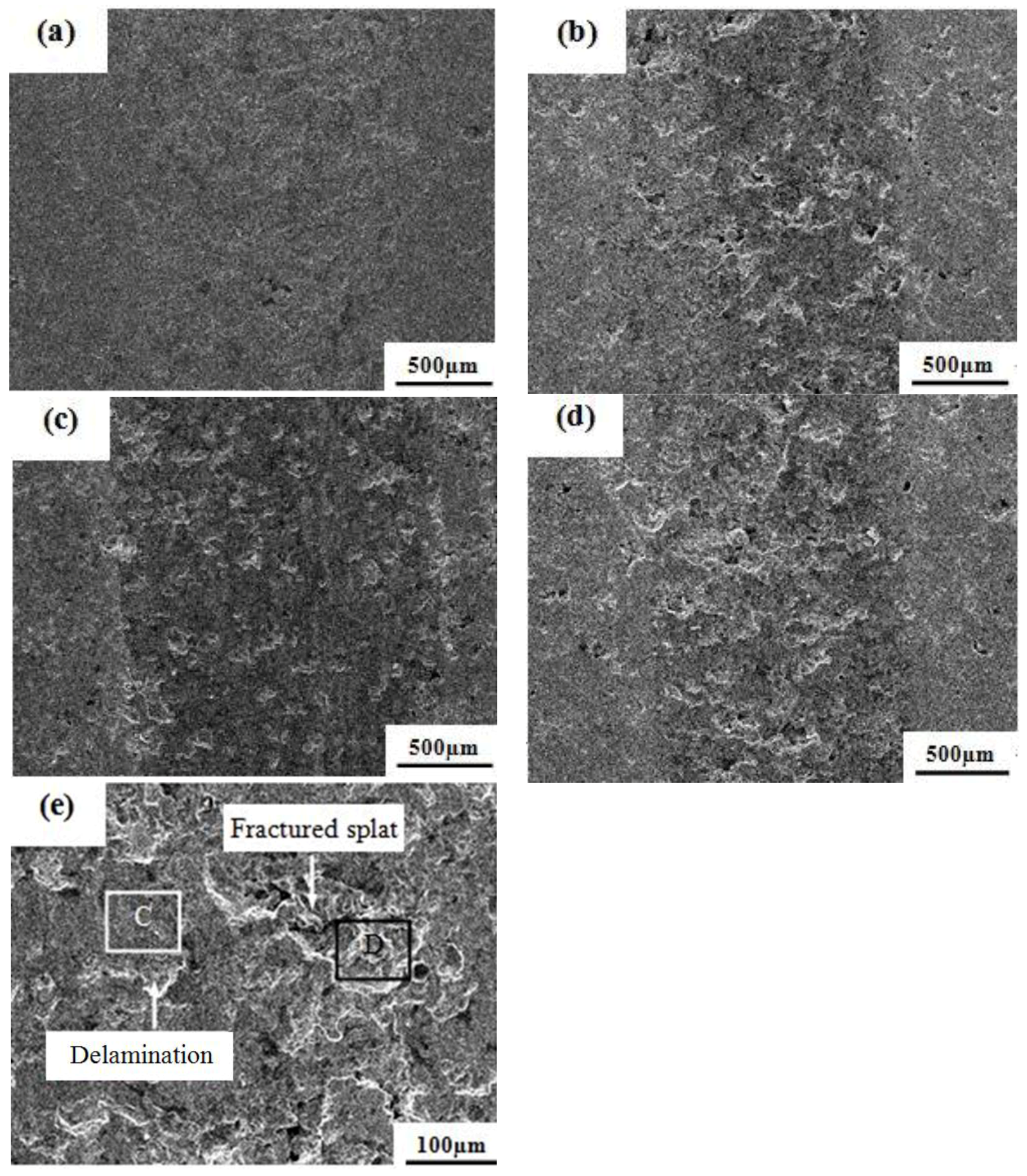

3.4. Wear Mechanisms of Coatings

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Laribi, M.; Vannes, A.B.; Treheux, D. Study of Mechanical Behavior of Molybdenum Coating Using Sliding Wear and Impact Tests. Wear 2007, 262, 1330–1336. [Google Scholar] [CrossRef]

- Farahmand, R.; Sohrabi, B.; Ghaffarinejad, A.; Meymian, M.R.Z. Synergistic effect of molybdenum coating and SDS surfactant on corrosion inhibition of mild steel in presence of 3.5% NaCl. Corros. Sci. 2018, 136, 393–401. [Google Scholar] [CrossRef]

- Osadnik, M.; Wrona, A.; Lis, M.; Kamińska, M.; Bilewska, K.; Czepelak, M.; Czechowska, K.; Moskal, M.; Więcław, G. Plasma-sprayed Mo-Re Coatings for Glass Industry Applications. Surf. Coat. Technol. 2017, 318, 349–354. [Google Scholar] [CrossRef]

- Liu, Z.; Hua, M. Wear Transition and Mechanism in Lubricated Sliding of a Molybdenum Coating. Tribol. Int. 1999, 32, 499–506. [Google Scholar] [CrossRef]

- Hwang, B.; Ahn, J.; Lee, S. Effects of Blending Elements on Wear Resistance of Plasma-Sprayed Molybdenum Blend Coatings Used for Automotive Synchronizer Rings. Surf. Coat. Technol. 2005, 194, 256–264. [Google Scholar] [CrossRef]

- Wang, K.M.; Chang, B.H.; Chen, J.S.; Fu, H.G.; Lin, Y.H.; Lei, Y.P. Effect of Molybdenum on the Microstructures and Properties of Stainless Steel Coatings by Laser Cladding. Appl. Sci. 2017, 7, 1065. [Google Scholar] [CrossRef]

- Modi, S.C.; Calla, E. A Study of High-Velocity Combustion Wire Molybdenum Coatings. J. Therm. Spray Technol. 2001, 10, 480–486. [Google Scholar] [CrossRef]

- Sampath, S.; Wayne, S.F. Microstructure and Properties of Plasma-sprayed Mo-Mo2C composites. J. Therm. Spray Technol. 1994, 3, 282–288. [Google Scholar] [CrossRef]

- Yan, J.H.; He, Z.Y.; Wang, Y.; Qiu, J.W.; Wang, Y.M. Microstructure and Wear Resistance of Plasma-sprayed Molybdenum Coating Reinforced by MoSi2 Particles. J. Therm. Spray Technol. 2016, 26, 1322–1329. [Google Scholar] [CrossRef]

- Prchlik, L.; Gutleber, J.; Sampath, S. Deposition and Properties of High-Velocity-Oxygen-Fuel and Plasma-Sprayed Mo-Mo2C Composite Coatings. J. Therm. Spray Technol. 2001, 10, 643–655. [Google Scholar] [CrossRef]

- Debasish, D.; Mantry, S.; Behera, D.; Jha, B.B. Improvement of Microstructural and Mechanical Properties of Plasma Sprayed Mo Coatings Deposited on Al-Si Substrates by Premixing of Mo with TiN Powder. High Temp. 2014, 52, 19–25. [Google Scholar] [CrossRef]

- Matikainen, V.; Niemi, K.; Koivuluoto, H.; Vuoristo, P. Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings. Coatings 2014, 4, 18–36. [Google Scholar] [CrossRef]

- Goel, S.; Björklund, S.; Curry, N. Axial Suspension Plasma Spraying of Al2O3 Coatings for Superior Tribological Properties. Surf. Coat. Technol. 2017, 315, 80–87. [Google Scholar] [CrossRef]

- Deng, W.; Li, S.G.; Hou, G.L.; Liu, X.; Zhao, X.Q.; An, Y.L. Comparative study on wear behavior of plasma sprayed Al2O3 coatings sliding against different counterparts. Ceram. Int. 2017, 43, 6976–6986. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, Y.P.; Hua, X.H.; Yang, Z.H.; Hou, S.Z.; Yu, Z.H. Al2O3/Mo Composite and Its Tribological Behavior Against AISI201Stainless Steel at Elevated Temperatures. Int. J. Refract. Met. Hard Mater. 2014, 43, 263–268. [Google Scholar] [CrossRef]

- Ghasemi, R.; Vakilifard, H. Plasma-sprayed nanostructured YSZ thermal barrier coatings: Thermal insulation capability and adhesion strength. Ceram. Int. 2017, 43, 8556–8563. [Google Scholar] [CrossRef]

- Davis, J.R. Hand Book of Thermal Spray Technology, 1st ed.; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

- Yan, J.H.; Wang, Y.; Liu, L.F.; Wang, Y.M.; Chen, F. Preparation of Protective MoSi2 Coating on Niobium Substrate. J. Therm. Spray Technol. 2015, 24, 1093–1099. [Google Scholar] [CrossRef]

- Planche, M.P.; Liao, H.; Coddet, C. Oxidation Control in Atmospheric Plasma Spraying Coating. Surf. Coat. Technol. 2007, 202, 69–76. [Google Scholar] [CrossRef]

- Gao, P.H.; Yang, G.J.; Cao, S.T.; Li, J.P.; Yang, Z.; Guo, Y.C. Heredity and Variation of Hollow Structure from Powders to Coatings Through Atmospheric Plasma Spraying. Surf. Coat. Technol. 2016, 305, 76–82. [Google Scholar] [CrossRef]

- Wan, D.T.; Zhou, Y.C.; Bao, Y.W. Evaluation of the elastic modulus and strength of unsymmetrical Al2O3 coating on Ti3SiC2 substrate by a modified relative methodology. Mater. Sci. Eng. A 2008, 474, 64–70. [Google Scholar] [CrossRef]

- Cockeram, B.V. The mechanical properties and fracture mechanisms of wrought low carbon arc cast (LCAC), molybdenum-0.5pct titanium-0.1pct zirconium (TZM), and oxide dispersion strengthened (ODS) molybdenum flat products. Mater. Sci. Eng. A 2006, 418, 120–136. [Google Scholar] [CrossRef]

- Fei, X.; Niu, Y.; Ji, H.; Zheng, X.B. A Comparative Study of MoSi2 Coatings Manufactured by Atmospheric and Vacuum Plasma Spray Processes. Ceram. Int. 2011, 37, 813–817. [Google Scholar] [CrossRef]

- Yan, J.H.; Zhang, Z.; Liu, L.F.; Xu, H.M.; Mao, Z.Y. Effect of Nano-ZrO2 on the Microstructure and High Temperature Tribological Properties of Mosi2 Coating. J. Therm. Spray Technol. 2013, 22, 873–881. [Google Scholar] [CrossRef]

- Zha, X.M.; Jiang, F.; Xu, X.P. Investigating the high frequency fatigue failure mechanisms of mono and multilayer PVD coatings by the cyclic impact tests. Surf. Coat. Technol. 2018, 344, 689–701. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, S.; Ahn, J. Correlation of Microstructure and Wear Resistance of Molybdenum Blends Coatings Fabricated by Atmospheric Plasma Spraying. Mater. Sci. Eng. A 2004, 366, 152–163. [Google Scholar] [CrossRef]

| Items | Parameters |

|---|---|

| Ar flow rate | 45 L/min |

| H2 flow rate | 6.5 L/min |

| Arc current | 500 A |

| Powder feeding rate | 60~65 g/min |

| Spraying distance | 110 mm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Guo, Y.; Wang, Y.; Zhou, P.; Qiu, J. A Comparison Study on Wear Behaviors of Mo and Al2O3-Mo Coatings from RT to 300 °C. Lubricants 2018, 6, 48. https://doi.org/10.3390/lubricants6020048

Yan J, Guo Y, Wang Y, Zhou P, Qiu J. A Comparison Study on Wear Behaviors of Mo and Al2O3-Mo Coatings from RT to 300 °C. Lubricants. 2018; 6(2):48. https://doi.org/10.3390/lubricants6020048

Chicago/Turabian StyleYan, Jianhui, Yuanjun Guo, Yi Wang, Peng Zhou, and Jingwen Qiu. 2018. "A Comparison Study on Wear Behaviors of Mo and Al2O3-Mo Coatings from RT to 300 °C" Lubricants 6, no. 2: 48. https://doi.org/10.3390/lubricants6020048

APA StyleYan, J., Guo, Y., Wang, Y., Zhou, P., & Qiu, J. (2018). A Comparison Study on Wear Behaviors of Mo and Al2O3-Mo Coatings from RT to 300 °C. Lubricants, 6(2), 48. https://doi.org/10.3390/lubricants6020048