Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication

Abstract

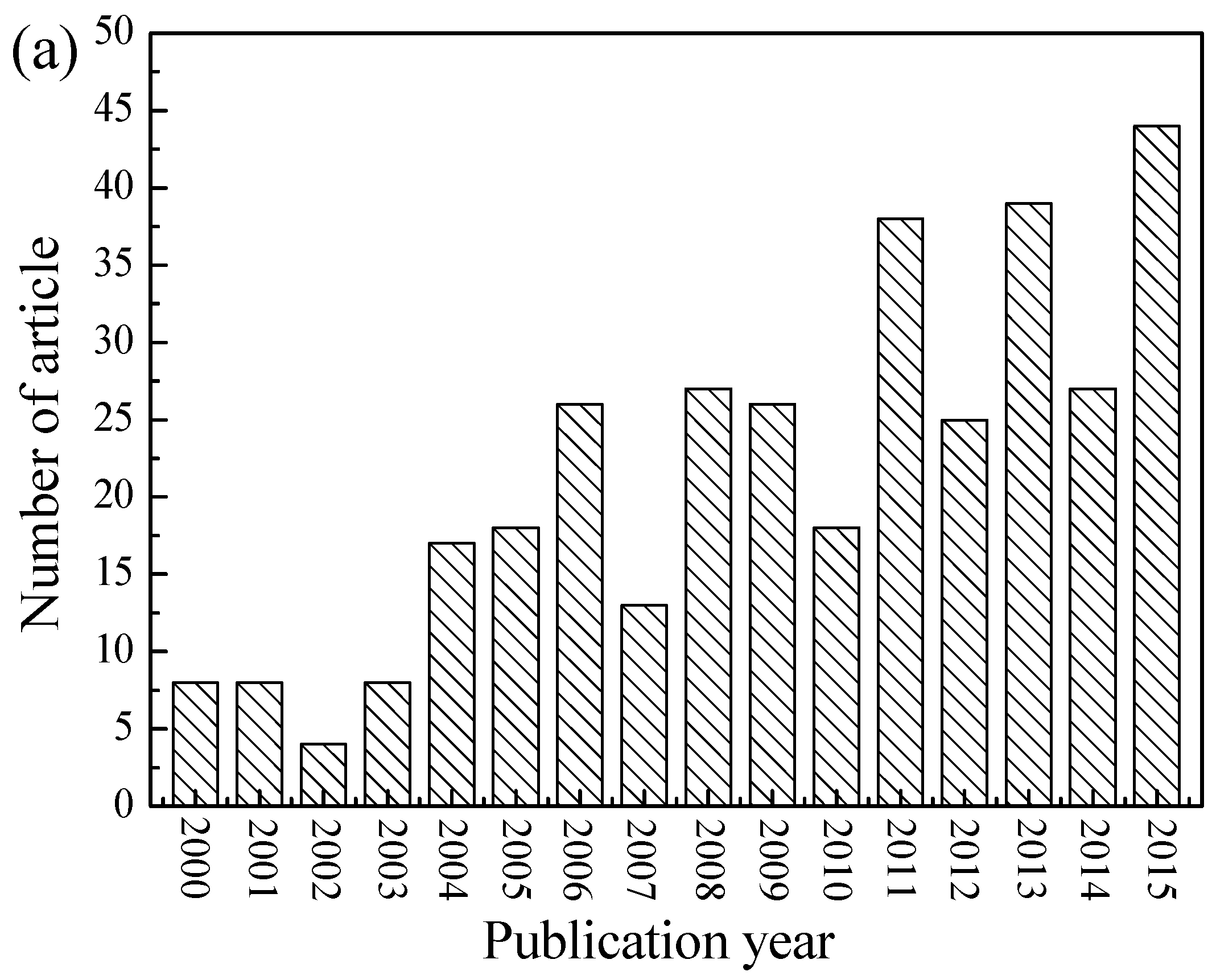

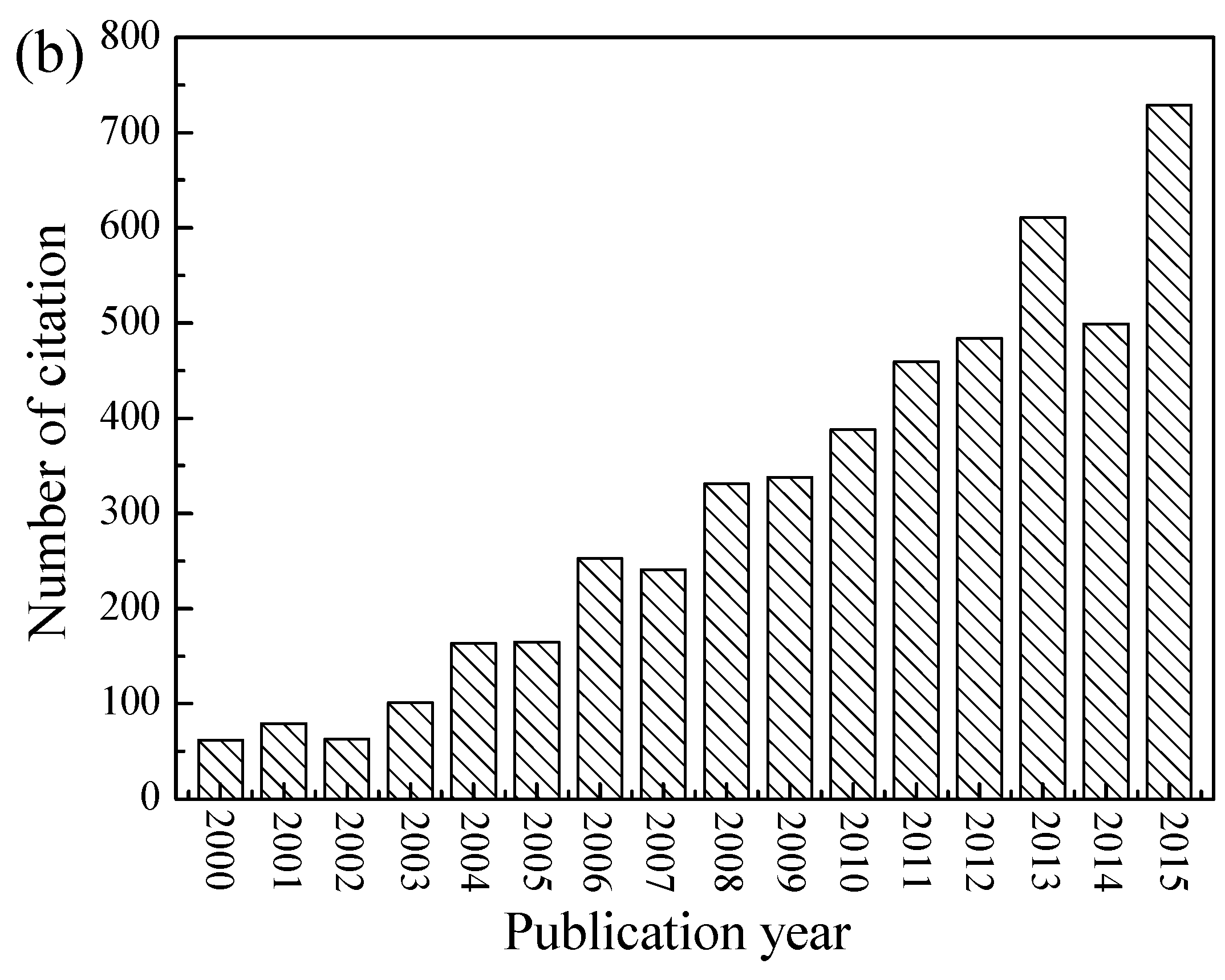

:1. Introduction

2. Tribological Properties of DLC Coatings under Water Lubrication

2.1. Influence of Microstructure

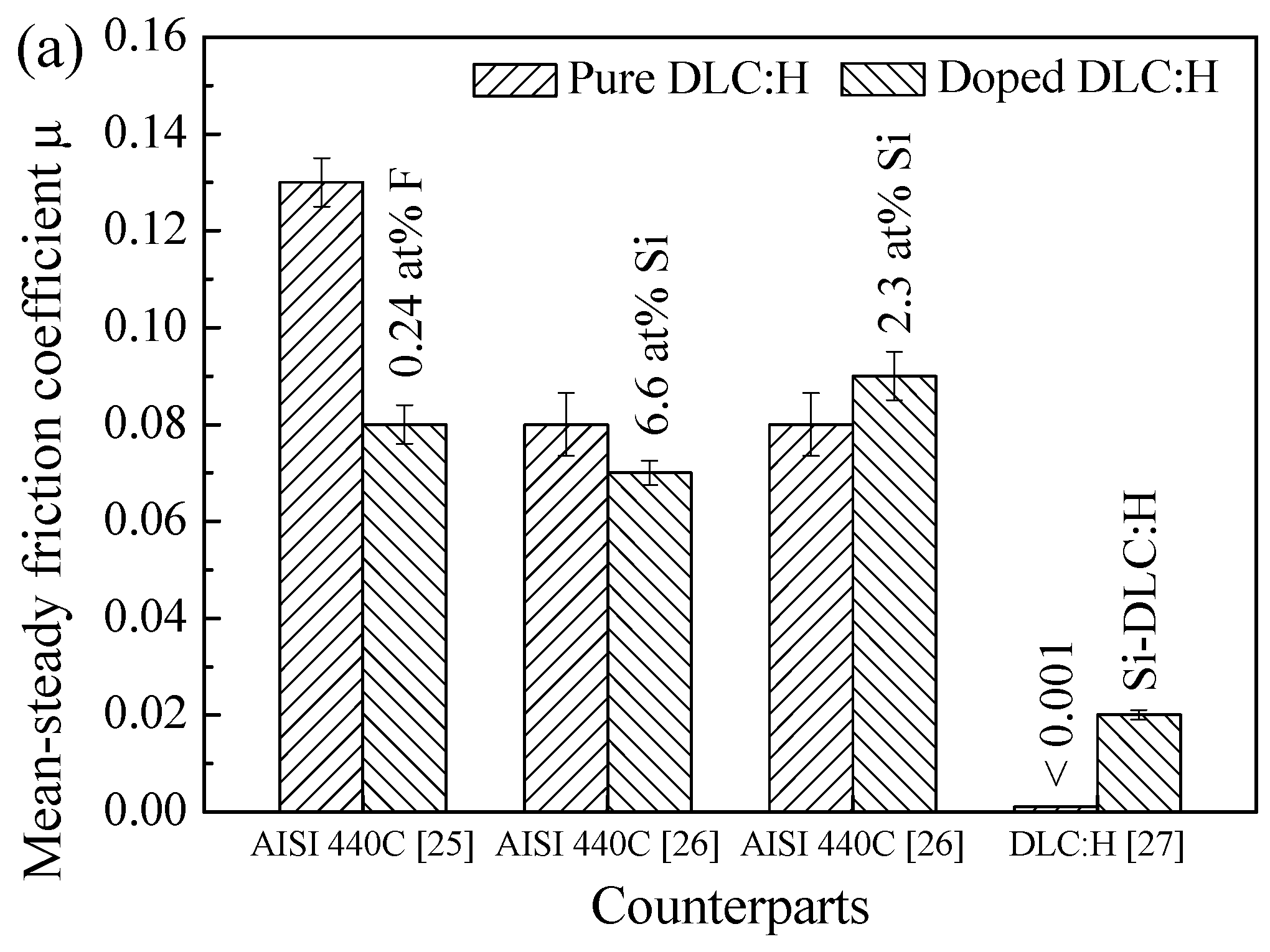

2.1.1. Composition

2.1.2. Architecture

2.2. Influence of Test Conditions

2.2.1. Counterpart

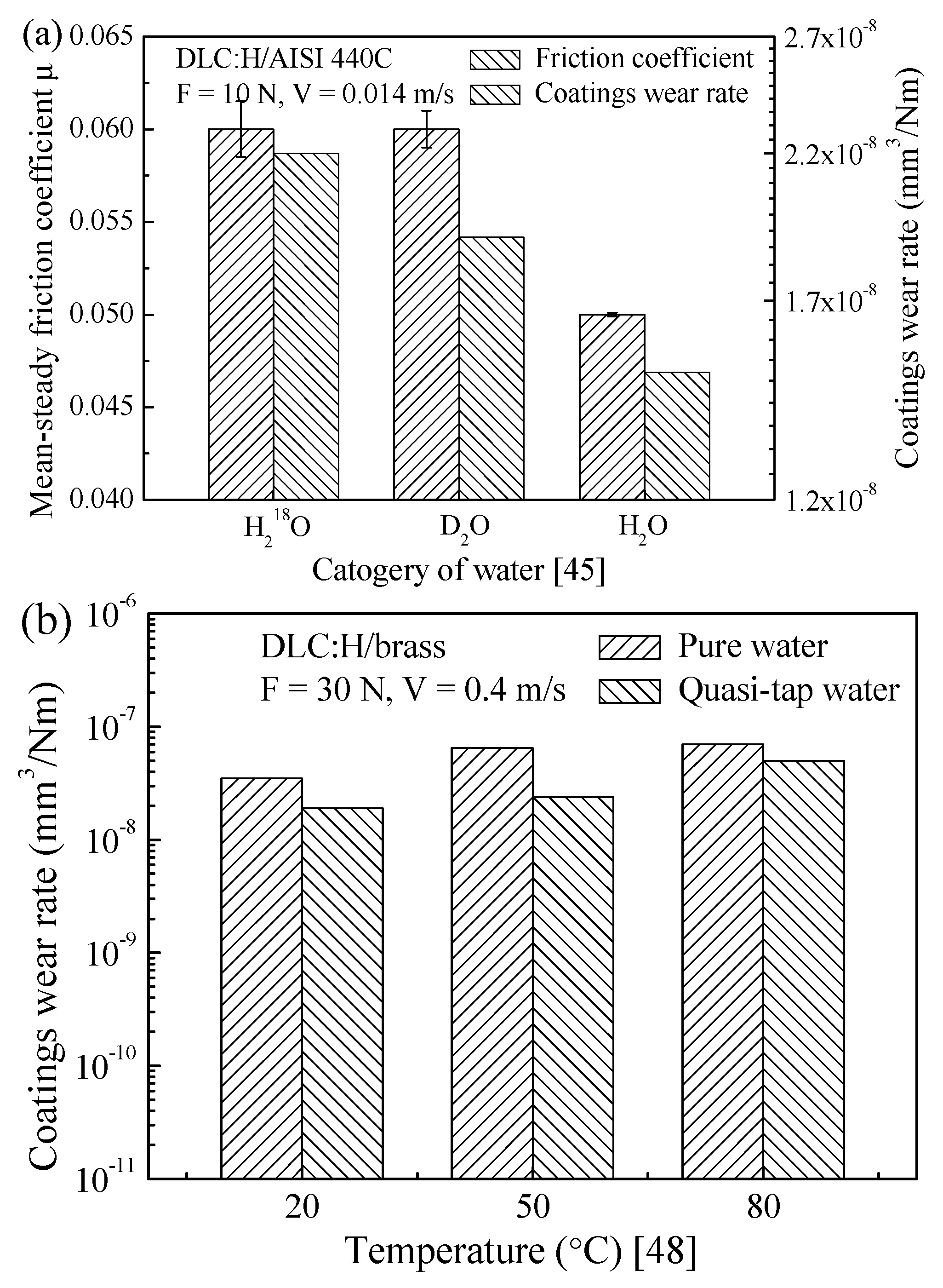

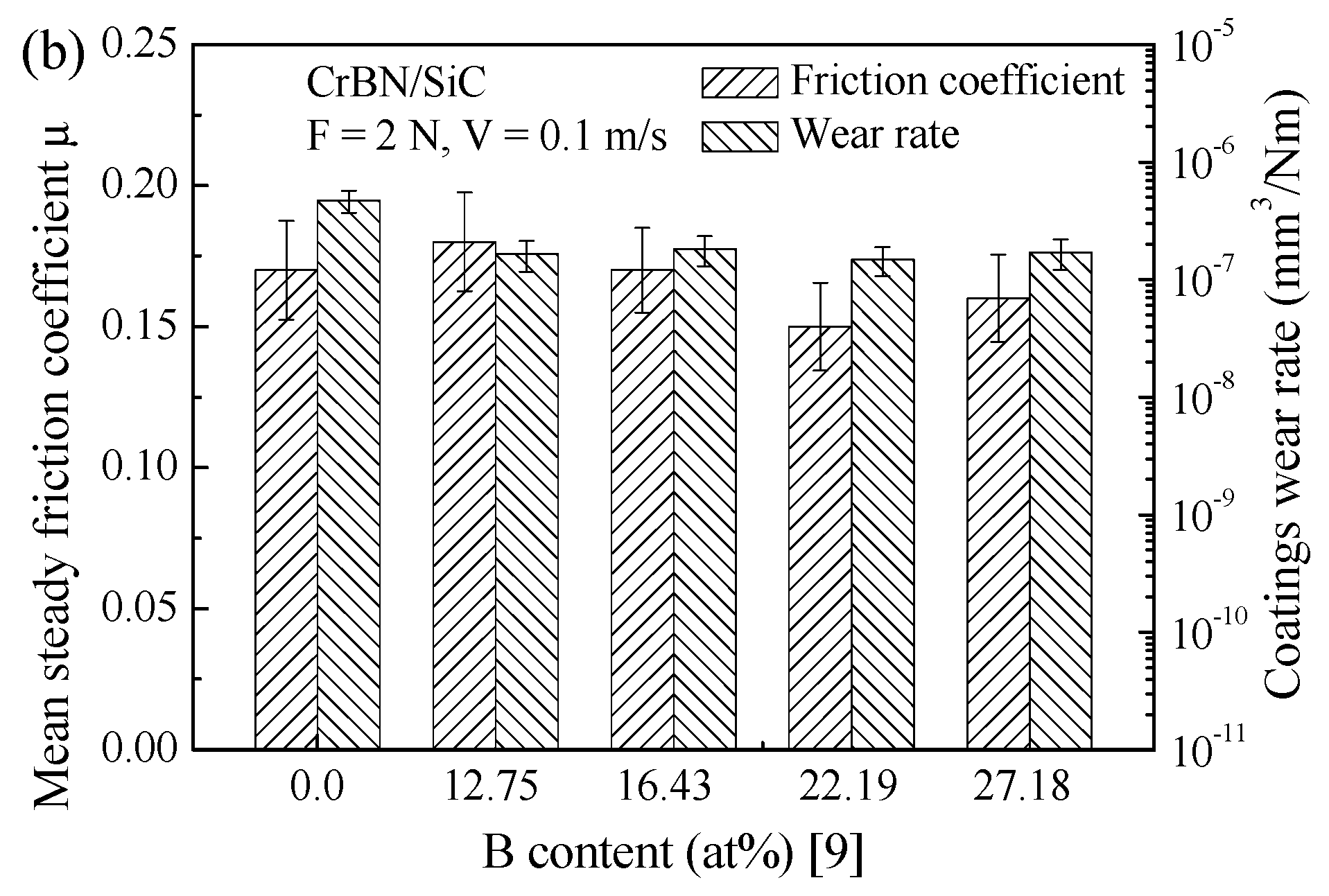

2.2.2. Aqueous Solution

3. Tribological Properties of a-CNx Coatings under Water Lubrication

3.1. Influence of Microstructure

3.2. Influence of Test Conditions

4. Tribological Properties of TiN-Based and CrN-Based Coatings under Water Lubrication

4.1. Influence of Microstructure

4.2. Influence of Test Conditions

5. Summary and Prediction of Nano-Composite Hard Coatings under Water Lubrication

5.1. Summary

5.2. Prediction

Acknowledgments

Conflicts of Interest

References

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Kato, K.; Adachi, K. Wear of advanced ceramics. Wear 2002, 253, 1097–1104. [Google Scholar] [CrossRef]

- Zhang, S. An approach to the developing ways of tribology in China. Tribology 2001, 21, 321–323. (In Chinese) [Google Scholar]

- Wang, Q.; Zhou, F.; Wang, X.; Chen, K.; Wang, M.; Qian, T.; Li, Y. Comparison of tribological properties of CrN, TiCN and TiAlN coatings sliding against SiC balls in water. Appl. Surf. Sci. 2011, 257, 7813–7820. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, Q. Low-friction behavior of hard solid coatings in water environment. In Encyclopedia of Tribology, 1st ed.; Wang, Q.J., Chung, Y.-W., Eds.; Springer: New York, NY, USA, 2013; Volume 1, pp. 2020–2023. [Google Scholar]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B: Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Omrani, E.; Moghadam, A.D.; Menezes, P.L.; Rohatgi, P.K. New emerging self-lubricating metal matrix composites for tribological applications. In Ecotribology; Davim, J.P., Ed.; Springer International Publishing: Basel, Switzerland, 2016; pp. 63–103. [Google Scholar]

- Moghadam, A.D.; Schultz, B.F.; Ferguson, J.B.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional metal matrix composites: Self-lubricating, self-healing, and nanocomposites-an outlook. JOM 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Ma, Q.; Zhou, F.; Gao, S.; Wu, Z.; Wang, Q.; Chen, K.; Zhou, Z.; Li, L. Influence of boron content on the microstructure and tribological properties of Cr-B-N coatings in water lubrication. Appl. Surf. Sci. 2016, 377, 394–405. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, F.; Chen, K.; Wang, Q.; Zhou, Z.; Yan, J.; Li, L. Friction and wear properties of CrSiCN coatings with low carboncontent as sliding against SiC and steel balls in water. Tribol. Int. 2016, 94, 176–186. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, F.; Wang, Q.; Zhou, Z.; Yan, J.; Li, L. Influence of trimethylsilane flow on the microstructure, mechanical and tribological properties of CrSiCN coatings in water lubrication. Appl. Surf. Sci. 2015, 355, 516–530. [Google Scholar] [CrossRef]

- Ma, Q.; Zhou, F.; Wang, Q.; Wu, Z.; Chen, K.; Zhou, Z.; Li, L. Influence of CrB2 target current on themicrostructure, mechanical and tribologicalproperties of Cr-B-C-N coatings in water. RSC Adv. 2016, 6, 47698–47711. [Google Scholar] [CrossRef]

- Wang, Q. Microstructure, Mechanical, Tribological and Corrosion Properties of Carbon/Nitride-Based-Coatings in Aqueous Environment. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2013. [Google Scholar]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Tribological performance of different DLC coatings in water-lubricated conditions. Wear 2001, 249, 267–271. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Friction and wear properties in dry, water- and oil-lubricated DLC against alumina and DLC against steel contacts. Wear 1998, 222, 120–128. [Google Scholar] [CrossRef]

- Stallard, J.; Mercs, D.; Jarratt, M.; Teer, D.; Shipway, P. A study of the tribological behaviour of three carbon-based coatings, tested in air, water and oil environments at high loads. Surf. Coat. Technol. 2004, 177–178, 545–551. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Frictional behavior of diamond-like carbon films in vacuum and under varying water vapor pressure. Surf. Coat. Technol. 2003, 163–164, 535–540. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Friction of diamond-like carbon films in different atmospheres. Wear 2003, 254, 1070–1075. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Wang, Y.; Xue, Q. Tribological performances of non-hydrogenated amorphous carbon coupling with different coating counterparts in ambient air and water. Wear 2013, 300, 20–28. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, L.; Yu, L.; Zhang, P. Synthesis and tribological behaviors of diamond-like carbon films by electrodeposition from solution of acetonitrile and water. Appl. Surf. Sci. 2008, 254, 3896–3901. [Google Scholar] [CrossRef]

- Suzuki, M.; Ohana, T.; Tanaka, A. Tribological properties of DLC films with different hydrogen contents in water environment. Diam. Relat. Mater. 2004, 13, 2216–2220. [Google Scholar] [CrossRef]

- Statuti, R.; Radi, P.; Santos, L.; Trava-Airoldi, V. A tribological study of the hybrid lubrication of DLC films with oil and water. Wear 2009, 267, 1208–1213. [Google Scholar] [CrossRef]

- Yamamoto, K.; Matsukado, K. Effect of hydrogenated DLC coating hardness on the tribological properties in water lubrication. Tribol. Int. 2006, 39, 1609–1614. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Shan, L.; Chen, J.; Xue, Q. Tribological performances of the graphite-like carbon films deposited with different target powers in ambient air and distilled water. Tribol. Int. 2014, 73, 17–24. [Google Scholar] [CrossRef]

- Tanaka, A.; Suzuki, M.; Ohana, T. Friction and wear of various DLC films in water and air environments. Tribol. Lett. 2004, 17, 917–924. [Google Scholar] [CrossRef]

- Wu, X.; Suzuki, M.; Ohana, T.; Tanaka, A. Characteristics and tribological properties in water of Si-DLC coatings. Diam. Relat. Mater. 2008, 17, 7–12. [Google Scholar] [CrossRef]

- Vila, M.; Carrapichano, J.; Gomes, J.; Camargo, S., Jr.; Achete, C.; Silva, R. Ultra-high performance of DLC-coated Si3N4 rings for mechanical seals. Wear 2008, 265, 940–944. [Google Scholar] [CrossRef]

- Suzuki, M.; Tanaka, A.; Ohana, T.; Zhang, W. Frictional behavior of DLC films in a water environment. Diam. Relat. Mater. 2004, 13, 1464–1468. [Google Scholar] [CrossRef]

- Zhao, F.; Li, H.; Ji, L.; Mo, Y.; Quan, W.; Du, W.; Zhou, H.; Chen, J. Superlow friction behavior of Si-doped hydrogenated amorphous carbon film in water environment. Surf. Coat. Technol. 2009, 203, 981–985. [Google Scholar] [CrossRef]

- Ohana, T.; Suzuki, M.; Nakamura, T.; Tanaka, A.; Koga, Y. Low-friction behaviour of diamond-like carbon films in a water environment. Diam. Relat. Mater. 2006, 15, 962–966. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Zhou, Z.; Yang, Y.; Yan, C.; Wang, C.; Zhang, W.; Li, L.; Bello, I.; Lee, S. Influence of Ti content on the structure and tribological properties of Ti-DLC coatings in water lubrication. Diam. Relat. Mater. 2012, 25, 163–175. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Ding, X.; Zhou, Z.; Wang, C.; Zhang, W.; Li, L.; Lee, S. Structure and water-lubricated tribological properties of Cr/a-C coatings with different Cr contents. Tribol. Int. 2013, 67, 104–115. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Ding, X.; Zhou, Z.; Zhang, W.; Li, L.; Lee, S. Influences of ceramic mating balls on the tribological properties of Cr/a-C coatings with low chromium content in water lubrication. Wear 2013, 303, 354–360. [Google Scholar] [CrossRef]

- Ohana, T.; Suzuki, M.; Nakamura, T.; Tanaka, A.; Koga, Y. Friction behaviour of Si-DLC/DLC multi layer films on steel substrate in water environment. Diam. Relat. Mater. 2005, 14, 1089–1093. [Google Scholar] [CrossRef]

- Park, S.; Lee, K.; Ahn, S.; Kim, J. Instability of diamond-like carbon (DLC) films during sliding in aqueous environment. Diam. Relat. Mater. 2008, 17, 247–251. [Google Scholar] [CrossRef]

- Wang, L.; Nie, X.; Lukitsch, M.; Jiang, J.; Cheng, Y. Effect of tribological media on tribological properties of multilayer Cr(N)/C(DLC) coatings. Surf. Coat. Technol. 2006, 201, 4341–4347. [Google Scholar] [CrossRef]

- Ohana, T.; Suzuki, M.; Nakamura, T.; Tanaka, A.; Koga, Y. Tribological properties of DLC films deposited on steel substrate with various surface roughness. Diam. Relat. Mater. 2004, 13, 2211–2215. [Google Scholar] [CrossRef]

- Ohana, T.; Wu, X.; Nakamura, T.; Tanaka, A. Roughness effect of mating ball on friction of diamond-like carbon film and friction mechanism in water and air environment. Diam. Relat. Mater. 2008, 17, 860–863. [Google Scholar] [CrossRef]

- Tokoro, M.; Aiyama, Y.; Masuko, M.; Suzuki, A.; Ito, H.; Yamamoto, K. Improvement of tribological characteristics under water lubrication of DLC-coatings by surface polishing. Wear 2009, 267, 2167–2172. [Google Scholar] [CrossRef]

- Lei, X.; Shen, B.; Chen, S.; Wang, L.; Sun, F. Tribological behavior between micro- and nano-crystalline diamondfilms under dry sliding and water lubrication. Tribol. Int. 2014, 69, 118–127. [Google Scholar] [CrossRef]

- Wang, L.; Guan, X.; Zhang, G. Friction and wear behaviors of carbon-based multilayer coatings sliding against different rubbers in water environment. Tribol. Int. 2013, 64, 69–77. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, F.; Liao, T.; Deng, Q.; Li, S.; Wang, Y.; Leng, Y. Tribological behavior of diamond like carbon film sliding againstCoCrMo or Al2O3 in air and water environment. Tribol. Int. 2016, 95, 456–461. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Li, J.; Chen, J.; Xue, Q. Tribological properties of graphite-like carbon coatings coupling with different metals in ambient air and water. Tribol. Int. 2013, 60, 147–155. [Google Scholar] [CrossRef]

- Ohana, T.; Wu, X.; Nakamura, T.; Tanaka, A. Formation of lubrication film of diamond-like carbon films in water and airenvironments against stainless steel and Cr-plated balls. Diam. Relat. Mater. 2007, 16, 1336–1339. [Google Scholar] [CrossRef]

- Wu, X.; Ohana, T.; Tanaka, A.; Kubo, T.; Nanao, H.; Minami, I.; Mori, S. Tribochemical investigation of DLC coating in water using stable isotopic tracers. Appl. Surf. Sci. 2008, 254, 3397–3402. [Google Scholar] [CrossRef]

- Wu, X.; Ohana, T.; Tanaka, A.; Kubo, T.; Nanao, H.; Minami, I.; Mori, S. Tribochemical investigation of DLC coating tested against steel in water using a stable isotopic tracer. Diam. Relat. Mater. 2007, 16, 1760–1764. [Google Scholar] [CrossRef]

- Wu, X.; Ohana, T.; Tanaka, A.; Kubo, T.; Nanao, H.; Minami, I.; Mori, S. Tribochemical reaction of Si-DLC coating in water studied by stable isotopic tracer. Diam. Relat. Mater. 2008, 17, 147–153. [Google Scholar] [CrossRef]

- Uchidate, M.; Liu H, B.; Iwabuchi, A.; Yamamoto, K. Effects of water environment on tribological properties of DLC rubbed against brass. Wear 2009, 267, 1589–1594. [Google Scholar] [CrossRef]

- Uchidate, M.; Liu, H.; Yamamoto, K.; Iwabuchi, A. Effects of hard water on tribological properties of DLC rubbed against stainless steel and brass. Wear 2013, 308, 79–85. [Google Scholar] [CrossRef]

- Uchidate, M.; Liu, H.; Iwabuchi, A.; Yamamoto, K. Effects of water environment on tribological properties of DLC rubbed against stainless steel. Wear 2007, 263, 1335–1340. [Google Scholar] [CrossRef]

- Liu, A.; Cohen, M. Prediction of new low compressibility solids. Science 1989, 245, 841–842. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Adachi, K.; Kato, K. Sliding friction and wear property of a-C and a-CNxcoatings against SiC ball in water. Thin Solid Films 2006, 514, 231–239. [Google Scholar] [CrossRef]

- Zhou, F.; Kato, K.; Adachi, K. Friction and wear properties of CNx/SiC in water lubrication. Tribol. Lett. 2005, 18, 153–163. [Google Scholar] [CrossRef]

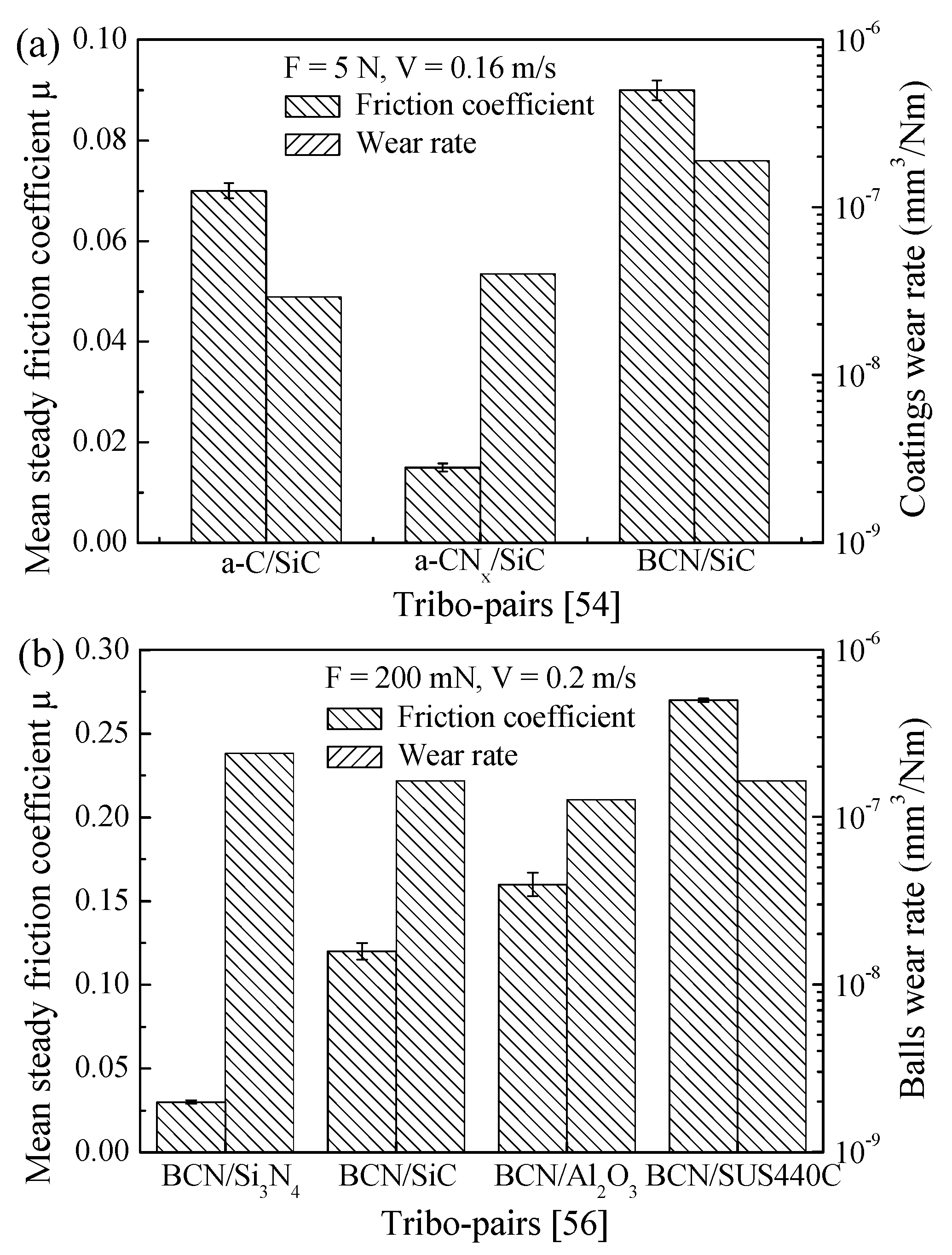

- Zhou, F.; Adachi, K.; Kato, K. Comparisons of tribological properties of a-C, a-CNx and BCN coatings sliding against SiC balls in water. Surf. Coat. Technol. 2006, 200, 4471–4478. [Google Scholar] [CrossRef]

- Carettia, I.; Albella J, M.; Jimenez, I. Friction and wear of amorphous BC4N coatings under different atmospheres. Diam. Relat. Mater. 2007, 16, 1445–1449. [Google Scholar] [CrossRef]

- Zhou, F.; Adachi, K.; Kato, K. Friction and wear behavior of BCN coatings sliding against ceramic and steel balls in various environments. Wear 2006, 261, 301–310. [Google Scholar] [CrossRef]

- Zhou, F.; Yue, B.; Wang, Q.; Wang, X.; Koshi, A.; Kato, K. Tribological properties of a-CNx coatings sliding against SiC ballsin ethylene glycol aqueous solution. Lubrication Sci. 2010, 22, 225–236. [Google Scholar] [CrossRef]

- Zhou, F.; Adachi, K.; Kato, K. Friction and wear properties of a-CNx coatings sliding against ceramic and steel ball in water. Diam. Relat. Mater. 2005, 14, 1711–1720. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Kato, K.; Dai, Z. Friction and wear property of a-CNx coatings sliding against Si3N4 balls in water. Wear 2007, 263, 1253–1258. [Google Scholar] [CrossRef]

- Zhou, F.; Adachi, K.; Kato, K. Wear-mechanism map of amorphous carbon nitride coatings sliding against silicon carbide balls in water. Surf. Coat. Technol. 2006, 200, 4909–4917. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Adachi, K.; Kato, K. Influence of normal load and sliding speed on the tribological property of amorphous carbon nitride coatings sliding against Si3N4 balls in water. Surf. Coat. Technol. 2008, 202, 3519–3528. [Google Scholar] [CrossRef]

- Polcar, T.; Kubart, T.; Novak, R.; Kopecky, L.; Siroky, P. Comparison of tribological behaviour of TiN, TiCN and CrN at elevated temperatures. Surf. Coat. Technol. 2005, 193, 192–199. [Google Scholar] [CrossRef]

- Guruvenket, S.; Li, D.; Klemberg-Sapieha, J.; Martinu, L.; Szpunar, J. Mechanical and tribological properties of duplex treated TiN, nc-TiN/a-SiNx and nc-TiCN/a-SiCN coatings deposited on 410 low alloy stainless steel. Surf. Coat. Technol. 2009, 203, 2905–2911. [Google Scholar] [CrossRef]

- Cheng, Y.; Browne, T.; Heckerman, B.; Meletis, E. Influence of the C content on the mechanical and tribological properties of the TiCN coatings deposited by LAFAD technique. Surf. Coat. Technol. 2011, 205, 4024–4029. [Google Scholar] [CrossRef]

- Zhang, G.; Li, B.; Jiang, B.; Yan, F.; Chen, D. Microstructure and tribological properties of TiN, TiC and Ti(C, N) thin films prepared by closed-field unbalanced magnetron sputtering ion plating. Appl. Surf. Sci. 2009, 255, 8788–8793. [Google Scholar]

- Wang, Q.; Zhou, F.; Chen K, M.; Wang, M.; Qian, T. Friction and wear properties of TiCN coatings sliding against SiC and steel balls in air and water. Thin Solid Films 2011, 519, 4830–4841. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Zhou, Z.; Yang, Y.; Yan, C.; Wang, C.; Zhang, W.; Li, L.; Bello, I.; Lee, S. Influence of carbon content on the microstructure and tribological properties of TiN(C) coatings in water lubrication. Surf. Coat. Technol. 2012, 206, 3777–3787. [Google Scholar] [CrossRef]

- Choi, E.; Kang, M.; Kwon, D.H.; Shin, D.; Kim, K. Comparative studies on microstructure and mechanical properties of CrN, Cr-C-N and Cr-Mo-N coatings. J. Mater. Process. Technol. 2007, 187–188, 566–570. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuklinski, Z.; Myslinski, P. Hard CrCN/CrN multilayer coatings for tribological applications. Surf. Coat. Technol. 2010, 204, 2289–2293. [Google Scholar] [CrossRef]

- Hu, P.; Jiang, B. Study on tribological property of CrCN coating based on magnetron sputtering plating technique. Vacuum 2011, 85, 994–998. [Google Scholar]

- Wang, Q.; Zhou, F.; Ding, X.; Zhou, Z.; Wang, C.; Zhang, W.; Li, L.; Lee, S. Microstructure and water-lubricated friction and wear properties of CrN(C) coatings with different carbon contents. Appl. Surf. Sci. 2013, 268, 579–587. [Google Scholar] [CrossRef]

- Masuko, M.; Suzuki, A.; Sagae, Y.; Tokoro, M.; Yamamoto, K. Friction characteristics of inorganic or organic thin coatings on solid surfaces under water lubrication. Tribol. Int. 2006, 39, 1601–1608. [Google Scholar] [CrossRef]

- Lee, S.; Hong, Y. Effect of CrSiN thin film coating on the improvement of the low-speed torque efficiency of a hydraulic piston pump. Surf. Coat. Technol. 2007, 202, 1129–1134. [Google Scholar] [CrossRef]

- Kim, G.; Kim, B.; Lee, S. High-speed wear behaviors of CrSiN coatings for the industrial applications of water hydraulics. Surf. Coat. Technol. 2005, 200, 1814–1818. [Google Scholar] [CrossRef]

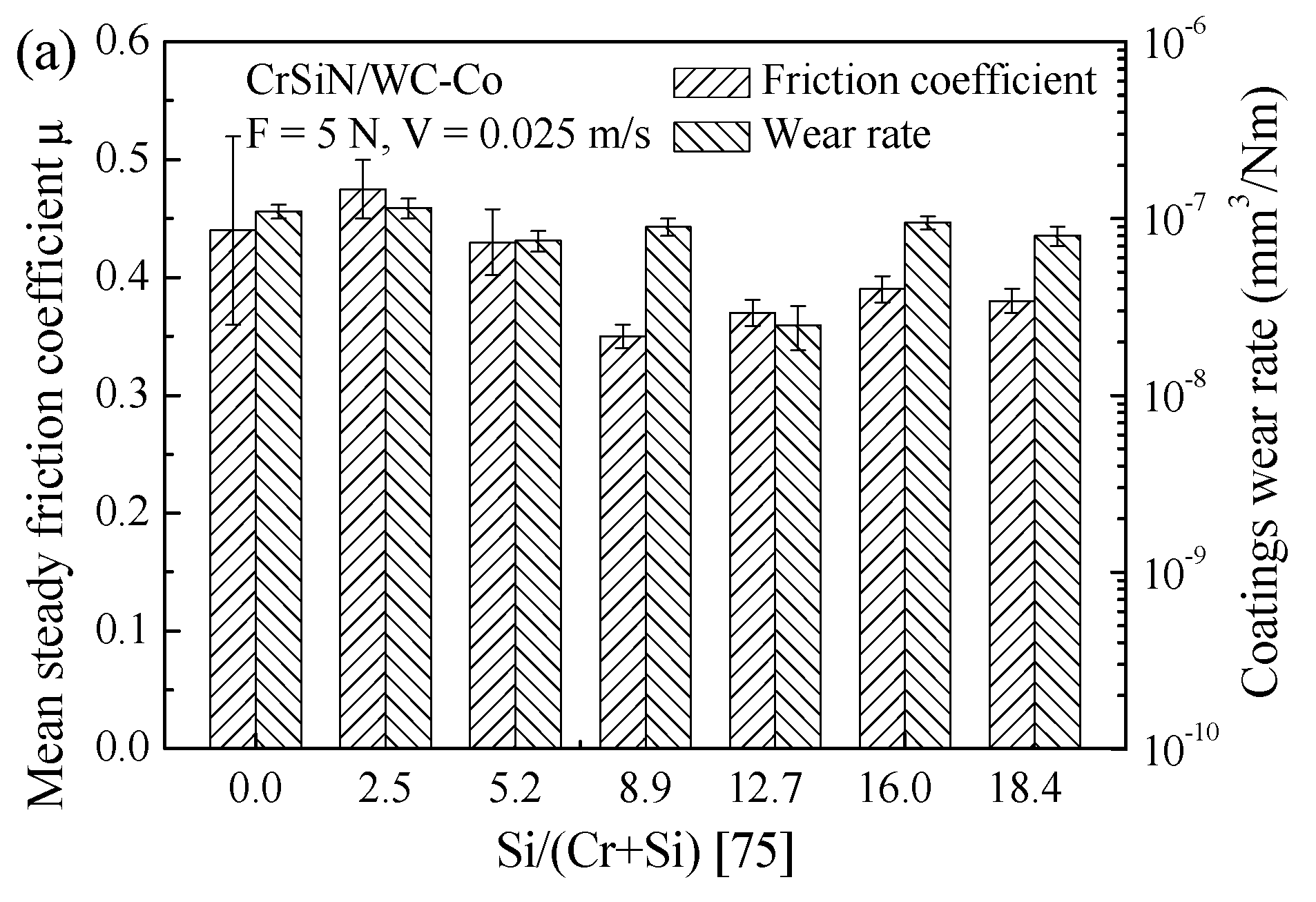

- Geng, Z.; Wang, H.; Wang, C.; Wang, L.; Zhang, G. Effect of Si content on the tribological properties of CrSiN films in air andwater environments. Tribol. Int. 2014, 79, 140–150. [Google Scholar] [CrossRef]

- Yamamoto, K.; Oomoto, S. The effect of Si content and substrate bias on structural and tribological properties of (Cr, Si)N coatings under water lubrication. In Tribol. Interface Eng Ser; Dowson, D., Priest, M., Dalmaz, G., Lubrecht, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 48, pp. 401–407. [Google Scholar]

- Wu, P.; Drees, D.; Stals, L.; Celis, J.P. Comparison of wear and corrosion wear of TiN coatings under uni- and bidirectional sliding. Surf. Coat. Technol. 1999, 113, 251–258. [Google Scholar] [CrossRef]

- Zhou, F.; Chen, K.; Wang, M.; Xu, X.; Meng, H.; Yu, M.; Dai, Z. Friction and wear properties of CrN coatings sliding against Si3N4 balls in water and air. Wear 2008, 265, 1029–1037. [Google Scholar] [CrossRef]

- Wang, Y. Research on Tribological Properties of Alumina Ceramic Coating by Micro-Arc Oxidation (MAO) and Modified Coating on Aluminum Alloy. Master Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2007. [Google Scholar]

- Wang, Y.; Wang, M.; Zhou, F.; Ding, H.; Dai, Z. Tribological properties of ceramic coating prepared by micro-arc oxidation for aluminum alloys in various environments. Trans. Nonferr. Metal Soc. 2007, 17, 1266–1272. (In Chinese) [Google Scholar]

- Zhou, F.; Wang, Y.; Ding, H.; Wang, M.; Yu, M.; Dai, Z. Friction characteristic of micro-arc oxidative Al2O3 coatings sliding against Si3N4 balls in various environments. Surf. Coat. Technol. 2008, 202, 3808–3814. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Y.; Chen, H.; Li, J.; Zhou, S.; Xue, Q. Influences of bias voltage on the microstructures and tribological performances of Cr-C-N coatings in seawater. Surf. Coat. Technol. 2015, 270, 305–313. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Y.; Wang, C.; Li, J.; Yao, Y. An analysis on tribological performance of CrCN coatings with differentcarbon contents in seawater. Tribol. Int. 2015, 91, 131–139. [Google Scholar] [CrossRef]

- Wu, D.; Liu, Y.; Zhao, X.; Li, D.; Ren, X. The tribological behaviors of different mass ratio Al2O3-TiO2coatings in water lubrication sliding against Si3N4. Tribol. Trans. 2016, 59, 352–362. [Google Scholar] [CrossRef]

- Niu, M.; Bi, Q.; Yang, J.; Liu, W. Tribological performances of Ni3Si–Cr7C3 composite coatings under water and acid environments. Tribol. Int. 2012, 48, 216–225. [Google Scholar] [CrossRef]

- Li, X.; Gao, Y.; Yang, Q.; Pan, W.; Li, Y.; Zhong, Z.; Song, L. Evaluation of tribological behavior of B4C-hBN ceramic compositesunder water-lubricated condition. Ceram. Int. 2015, 41, 7387–7393. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, F.; Chen, K.; Wang, Q.; Zhou, Z.; Yan, J.; Li, L. Microstructure, mechanical and tribological properties of CrSiC coatings sliding against SiC and Al2O3 balls in water. Appl. Surf. Sci. 2016, 368, 129–139. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, L.; Wang, Y.; Wang, S.; Hu, L.; Xue, Q. Improved Tribological behavior of DLC films under water lubrication by surface texturing. Tribol. Lett. 2011, 41, 439–449. [Google Scholar] [CrossRef]

- Song, H.; Ji, L.; Li, H.; Liu, X.; Zhou, H.; Liu, L.; Chen, J. Superlow Friction behavior of surface-textured a-C:H film in water environments. Tribol. Trans. 2016, 58, 867–874. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, Y.; Hu, T.; Song, J.; Ding, Q.; Hu, L. Surface composition–lubrication design of Al2O3/Ni laminatedcomposites-Part I: Tribological synergy effect of micro-dimpledtexture and diamond-like carbon films in a water environment. Tribol. Int. 2015, 84, 142–151. [Google Scholar] [CrossRef]

- Fan, H.; Hu, T.; Wan, H.; Zhang, Y.; Song, J.; Hu, L. Surface composition–lubrication design of Al2O3/Ni laminatedcomposites-Part II: Tribological behavior of LaF3-doped MoS2composite coating in a water environment. Tribol. Int. 2016, 96, 258–268. [Google Scholar] [CrossRef]

- Wang, C.; Ye, Y.; Guan, X.; Hu, J.; Wang, Y.; Li, J. An analysis of tribological performance on Cr/GLC film couplingwith Si3N4, SiC, WC, Al2O3 and ZrO2 in seawater. Tribol. Int. 2016, 96, 77–86. [Google Scholar] [CrossRef]

| Refs. | Tribopairs | Water | Load (N) | Velocity (m/s) | Friction Coefficient µ | Coating Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [14] | a-C/α-Al2O3 a-C:H/α-Al2O3 | Distilled | 5 | 0.004 | 0.05 0.69 | Immeasurable wear Worn through |

| [15] | a-C/α-Al2O3 a-C:H/α-Al2O3 | Distilled | 5 | 0.004 | 0.03 -- | Immeasurable wear Worn through |

| [16] | a-C/tungsten carbide WC-6%Co a-C:H/tungsten carbide WC-6%Co | Distilled | 40 | 0.05 | 0.08 -- | 1.1 × 10−8 Worn through |

| [19] | a-C/a-C a-C:H/a-C | Distilled | 5 | 0.05 | 0.03 0.04 | 0.5 × 10−8 1.5 × 10−8 |

| Refs. | Tribopairs | Water | Load (N) | Velocity (m/s) | Friction Coefficient µ | Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [19] | a-C/a-C a-C/a-C:H a-C/CrN a-C/CrSiN | Distilled | 5 | 0.05 | 0.030 0.040 0.041 0.042 | Coatings: 0.5 × 10−8 Coatings: 1.5 × 10−8 Coatings: 3.1 × 10−8 Coatings: 3.9 × 10−8 |

| [40] | Micro-crystalline diamond(MCD)/Nano-crystalline diamond(NCD) MCD/MCD NCD/NCD NCD/MCD | Deionized | 4 | 0.128 | 0.025 0.023 0.023 0.024 | immeasurable immeasurable Coatings: 4.3 × 10−7 Coatings: 9.5 × 10−7 |

| [41] | GLC/rubber EPDM 8370 GLC/rubber FKM 26 GLC/rubber NBR 7201 | Distilled | 100 | 0.6 | 0.06 0.03 0.04 | Counterpart: 0.8 × 10−6 Counterpart: 2.2 × 10−6 Counterpart: 0.3 × 10−5 |

| [42] | DLC/CoCrMo DLC/Al2O3 | Pure | 2 | 0.025 | 0.025 0.038 | Coatings: 70 nm in depth Coatings: 700 nm in depth |

| [43] | GLC/Ti GLC/GCr15 GLC/brass GLC/Al | Distilled | 5 | 0.078 | 0.14 0.11 0.09 0.10 | Coatings: 1.3 × 10−8 Coatings: 2.5 × 10−8 Coatings: 3.1 × 10−8 Coatings: 2.6 × 10−7 |

| [44] | DLC:H/AISI 440C DLC:H/Cr | Deionized | 2 | 0.016 | 0.11 0.09 | Coatings: 2.0 × 10−8 Coatings: 6.0 × 10−8 |

| Refs. | Tribopairs | Load (N) | Velocity (m/s) | Lubrication Regime | Friction Coefficient µ | Specific Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [16] | Graphit-iC/tungsten carbide WC-Co | 10 | 0.05 | BL | 0.10 | 2.3 × 10−8 |

| [22] | DLC/stainless steel 316L | 2 | 0.01 | BL | 0.11 | 6.7 × 10−8 |

| [23] | DLC/17-4PH | 2 | 0.5 | BL | 0.10 | 4.5 × 10−7 |

| [26] | DLC/stainless steel AISI 440C | 4.8 | 0.016 | BL | 0.08 | 3.0 × 10−8 |

| [38] | DLC/stainless steel AISI 440C | 1.9 | 0.016 | BL | 0.08 | -- |

| [19] | a-C/a-C | 5 | 0.05 | ML | 0.03 | 0.5 × 10−8 |

| [24] | GLC/WC | 2 | 0.05 | ML | 0.07 | 1.4 × 10−7 |

| [29] | a-C:H:Si/Si3N4 | 2 | 0.08 | ML | 0.006 | 1.7 × 10−8 |

| [39] | DLC/stainless steel SUS630 | 4.7 | 0.1 | ML | 0.10 | -- |

| [41] | Cr/CrN/GLC/FKM26 | 100 | 0.6 | ML | 0.03 | -- |

| Refs. | Tribopairs | Load (N) | Velocity (m/s) | Friction Coefficient µ | Coating Wear Rate (mm3/Nm) | Wear Mechanism |

|---|---|---|---|---|---|---|

| [60] | a-CNx/SiC | 15 9 6 9 | 0.05 0.1 0.3 0.5 | 0.066 0.041 0.033 0.009 | 8.0 × 10−8 6.5 × 10−8 2.7 × 10−8 2.0 × 10−8 | I:MW II: MW+Partial TW III: TW+Partial MW IV: TW |

| [61] | a-CNx/Si3N4 | 12 6 6 6 | 0.05 0.1 0.3 0.5 | 0.094 0.029 0.008 0.001 | 1.9 × 10−7 9.0 × 10−8 6.7 × 10−8 2.4 × 10−8 | I:MW II: MW+Partial TW III: TW+Partial MW IV: TW |

| Refs. | Tribopairs | Load (N) | Velocity (m/s) | Lubrication Regime | Friction Coefficient µ | Specific Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [57] | a-CNx/SiC | 3 | 0.15 | HL | 0.032 | 8.0 × 10−8 |

| [58] | a-CNx/Si3N4 | 5 | 0.16 | HL | 0.013 | 1.4 × 10−8 |

| [59] | a-CNx/Si3N4 | 5 | 0.16 | HL | 0.007 | 3.9 × 10−8 |

| [53] | a-CNx/SiC | 10 5 | 0.16 0.16 | BL HL | 0.050 0.020 | 3.0 × 10−8 1.1 × 10−8 |

| [60] | a-CNx/SiC | 3 6 9 | 0.05 0.3 0.5 | BL ML HL | 0.085 0.040 0.010 | 1.0 × 10−7 3.0 × 10−8 2.0 × 10−8 |

| [61] | a-CNx/Si3N4 | 12 9 6 | 0.05 0.05 0.5 | BL ML HL | 0.093 0.027 0.001 | 1.9 × 10−7 1.5 × 10−7 2.5 × 10−8 |

| Refs. | Tribopairs | Load (N) | Velocity (m/s) | Friction Coefficient µ | Coating Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|

| [62] | TiN/100Cr6 TiCN/100Cr6 | 5 | 0.04 | Air: 0.78 Air: 0.50 | Air: 6.0×10−7 Air: 3.5×10−6 |

| [63] | TiN/Al2O3 nc-TiCN/a-SiCN/Al2O3 | 2.5 | 0.03 | Air: 0.49 Air: 0.18 | Air: 3μm in depth Air: 0.4μm in depth |

| [64] | TiN/Al2O3 TiCN/Al2O3 (9.3at %C) | 1 | -- | Air: 0.87 Air: 0.21 | Air: 2.5 × 10−6 Air: 5.3 × 10−7 |

| [65] | TiN/WC TiC0.7N0.3/WC | 6 | 0.2 | Air: 0.64 Air: 0.24 | Air: 2.6 × 10−6 Air: 6.0 × 10−7 |

| [66] | TiCN/SiC TiCN/SiC | 3 | 0.3 | Air: 0.28 Water: 0.18 | Air: 2.8 × 10−6 Water: 2.7 × 10−6 |

| [67] | TiCN(2.46 at % C)/SiC | 2 | 0.1 | Water: 0.24 | Water: 3.3 × 10−6 |

| Refs. | Tribopairs | Load (N) | Velocity (m/s) | Friction Coefficient µ | Coating Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|

| [68] | CrN/steel CrCN (39.1 at % C)/steel | 1 | 0.157 | Air: 0.60 Air: 0.50 | -- -- |

| [69] | CrN/high speed steel (HSS) CrCN (7 at % C)/high speed steel (HSS) | 30 | 1.2 | Air: 0.56 Air: 0.45 | Air: 7.6 × 10−7 Air: 2.0 × 10−7 |

| [70] | CrN/GCr15 CrCN (4.72 at % C)/GCr15 CrCN (27.13 at % C)/GCr15 CrCN (46.43 at % C)/GCr15 | 2 | 0.22 | Air: 0.82 Air: 0.69 Air: 0.48 Air: 0.38 | Air: 8.3 × 10−6 Air: 6.9 × 10−6 Air: 5.2 × 10−6 Air: 3.8 × 10−6 |

| [71] | CrCN (15.35 at % C)/Si3N4 CrCN (52.60 at % C)/Si3N4 CrCN (74.97 at % C)/Si3N4 CrCN (79.04 at % C)/Si3N4 | 2 | 0.1 | Water: 0.20 Water: 0.42 Water: 0.44 Water: 0.50 | Water: 2.3 × 10−6 Water: 2.0 × 10−5 Water: 5.2 × 10−5 Water: 3.9 × 10−5 |

| Refs. | Tribopairs | Water | Load (N) | Velocity (m/s) | Friction Coefficient µ | Coating Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [10] | CrCN/SiC CrSiCN (2.05 at % Si)/SiC CrSiCN (3.40 at % Si)/SiC CrSiCN (6.20 at % Si)/SiC CrSiCN (7.00 at % Si)/SiC | Deionized | 2 | 0.1 | 0.16 0.11 0.22 0.26 0.27 | 1.5 × 10−7 8.4 × 10−8 2.0 × 10−6 4.9 × 10−6 8.1 × 10−6 |

| [11] | CrSiCN (2.67 at % Si)/SiC CrSiCN (5.53 at % Si)/SiC CrSiCN (9.86 at % Si)/SiC | Deionized | 2 | 0.1 | 0.14 0.15 0.24 | 2.5 × 10−7 1.5 × 10−6 3.4 × 10−6 |

| [12] | CrCN/SiC CrBCN (24.9 at % B)/SiC CrBCN (25.1 at % B)/SiC CrBCN (27.2 at % B)/SiC | Deionized | 3 | 0.1 | 0.21 0.20 0.16 0.22 | 5.7 × 10−7 4.1 × 10−7 2.1 × 10−7 6.3 × 10−7 |

| Refs. | Tribopairs | Water | Load (N) | Velocity (m/s) | Friction Coefficient µ | Coating Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [77] | TiN/diamond | Demineralized | 5 | 0.2 Bidirectional 0.2 Unidirectional | 0.3 0.6 | 5.0 µm in depth 2.3 µm in depth |

| [78] | CrN/Si3N4 | Distilled | 0.5 1.0 1.5 | 0.04 | 0.42 0.37 0.34 | 6.0 × 10−6 4.2 × 10−6 3.0 × 10−6 |

| [79] | CrN/Si3N4 Al2O3/Si3N4 | Pure | 5.0 7.5 10 | 0.15 | 0.51 0.39 0.36 | 1.7 × 10−5 2.6 × 10−5 3.2 × 10−5 |

| 5.0 7.5 10 | 0.70 0.67 0.65 | 3.8 × 10−5 4.2 × 10−5 4.5 × 10−5 |

| Refs. | Tribopairs | Load (N) | Velocity (m/s) | Lubrication Regime | Friction Coefficient µ | Specific Wear Rate (mm3/Nm) |

|---|---|---|---|---|---|---|

| [66] | TiCN/SiC | 3 | 0.4 | ML | 0.17 | 2.1 × 10−6 |

| [72] | CrSiN/SUS630 | 20 | 1.0 | ML | 0.06 | -- |

| [75] | CrSiN/WC-Co | 5 | 0.025 | ML | 0.36 | 2.0 × 10−6 |

| [78] | CrN/Si3N4 | 0.5 1.5 | 0.01 0.04 | BL ML | 0.55 0.35 | 6.0 × 10−6 3.0 × 10−6 |

| [82] | CrCN/WC | 5 | 0.05 | ML | 0.21 | 6.0 × 10−7 |

| [83] | CrCN/WC | 5 | 0.05 | ML | 0.18 | 7.7 × 10−7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhou, F. Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication. Lubricants 2017, 5, 5. https://doi.org/10.3390/lubricants5010005

Wang Q, Zhou F. Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication. Lubricants. 2017; 5(1):5. https://doi.org/10.3390/lubricants5010005

Chicago/Turabian StyleWang, Qianzhi, and Fei Zhou. 2017. "Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication" Lubricants 5, no. 1: 5. https://doi.org/10.3390/lubricants5010005

APA StyleWang, Q., & Zhou, F. (2017). Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication. Lubricants, 5(1), 5. https://doi.org/10.3390/lubricants5010005