Evaluation of Two Total Hip Bearing Materials for Resistance to Wear Using a Hip Simulator

Abstract

:1. Introduction

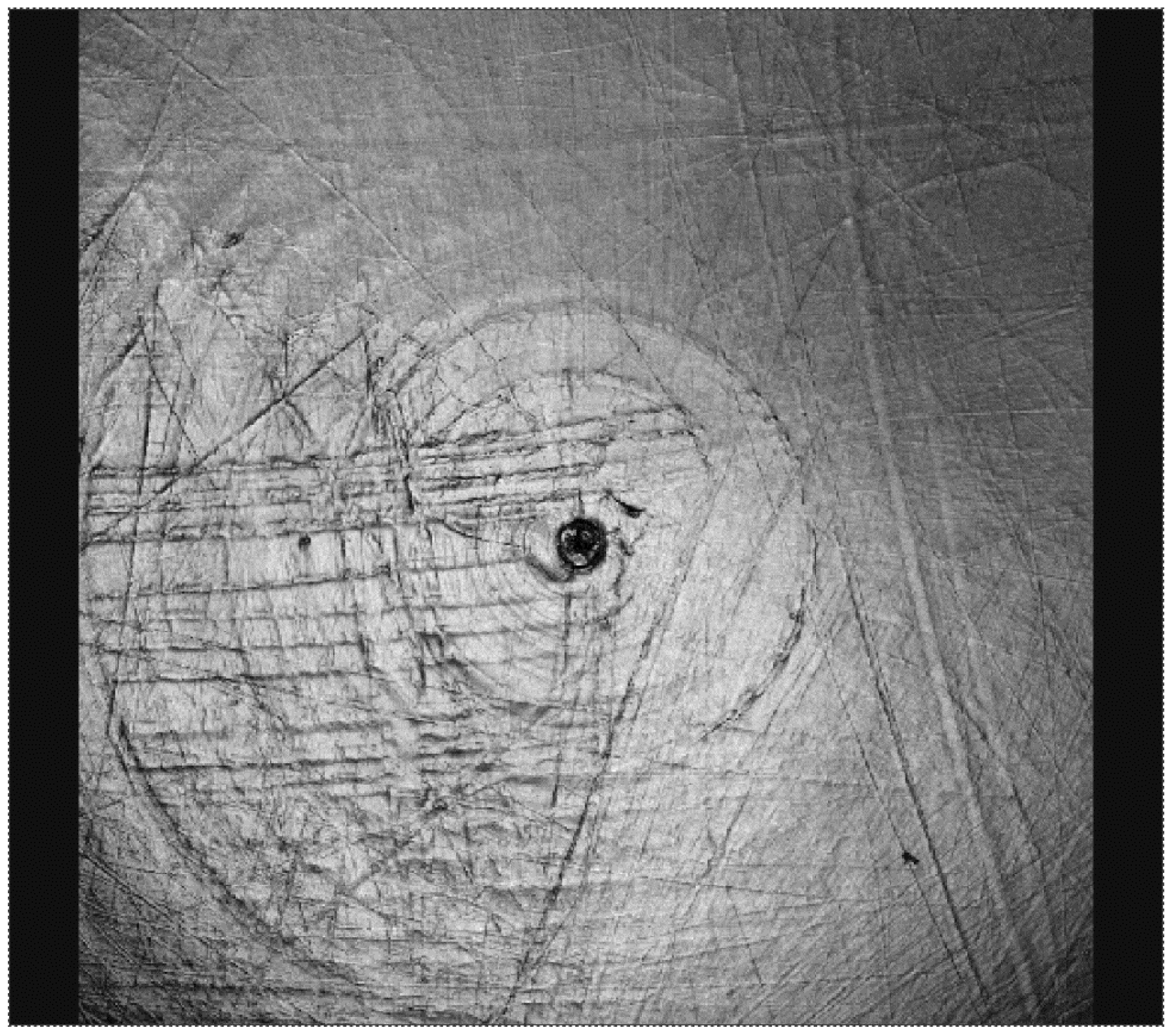

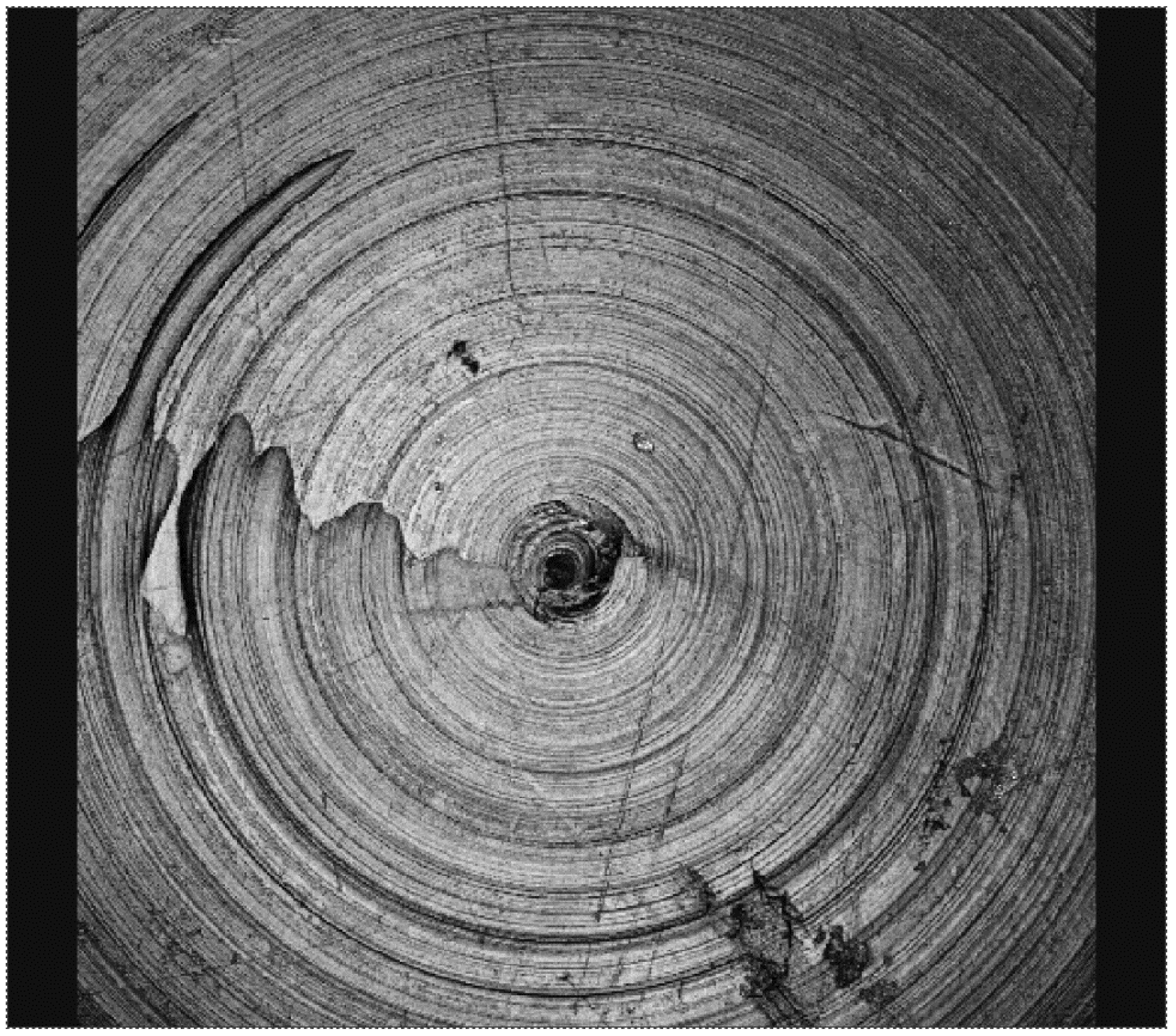

2. Materials and Methods

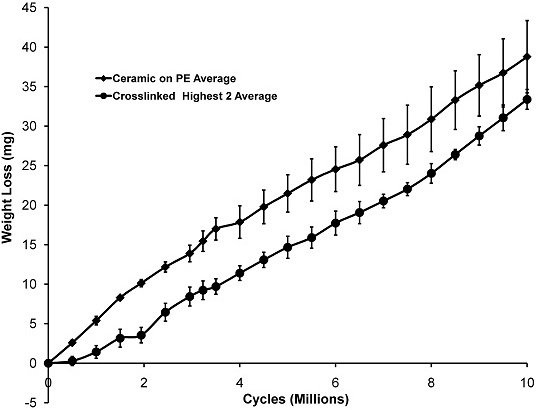

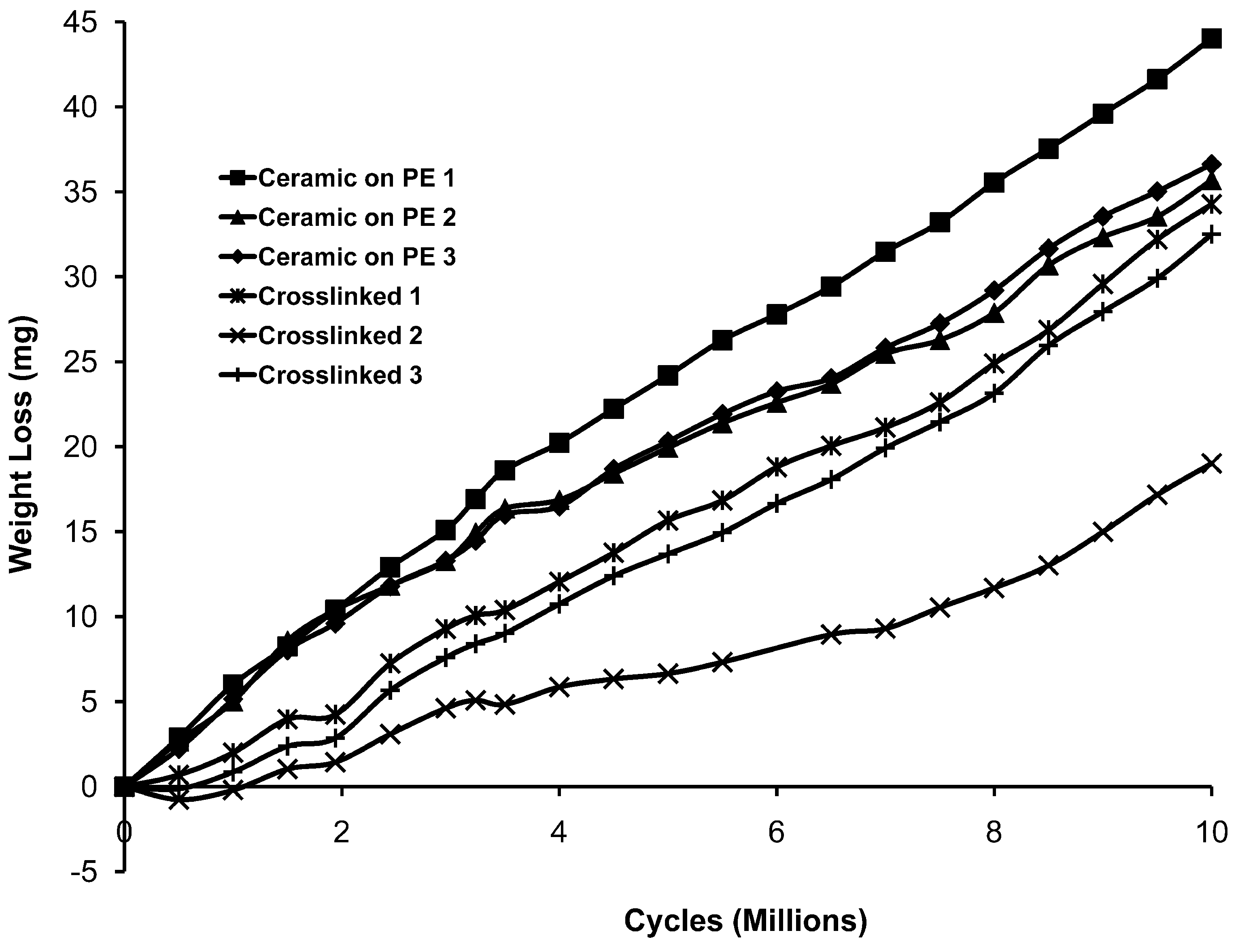

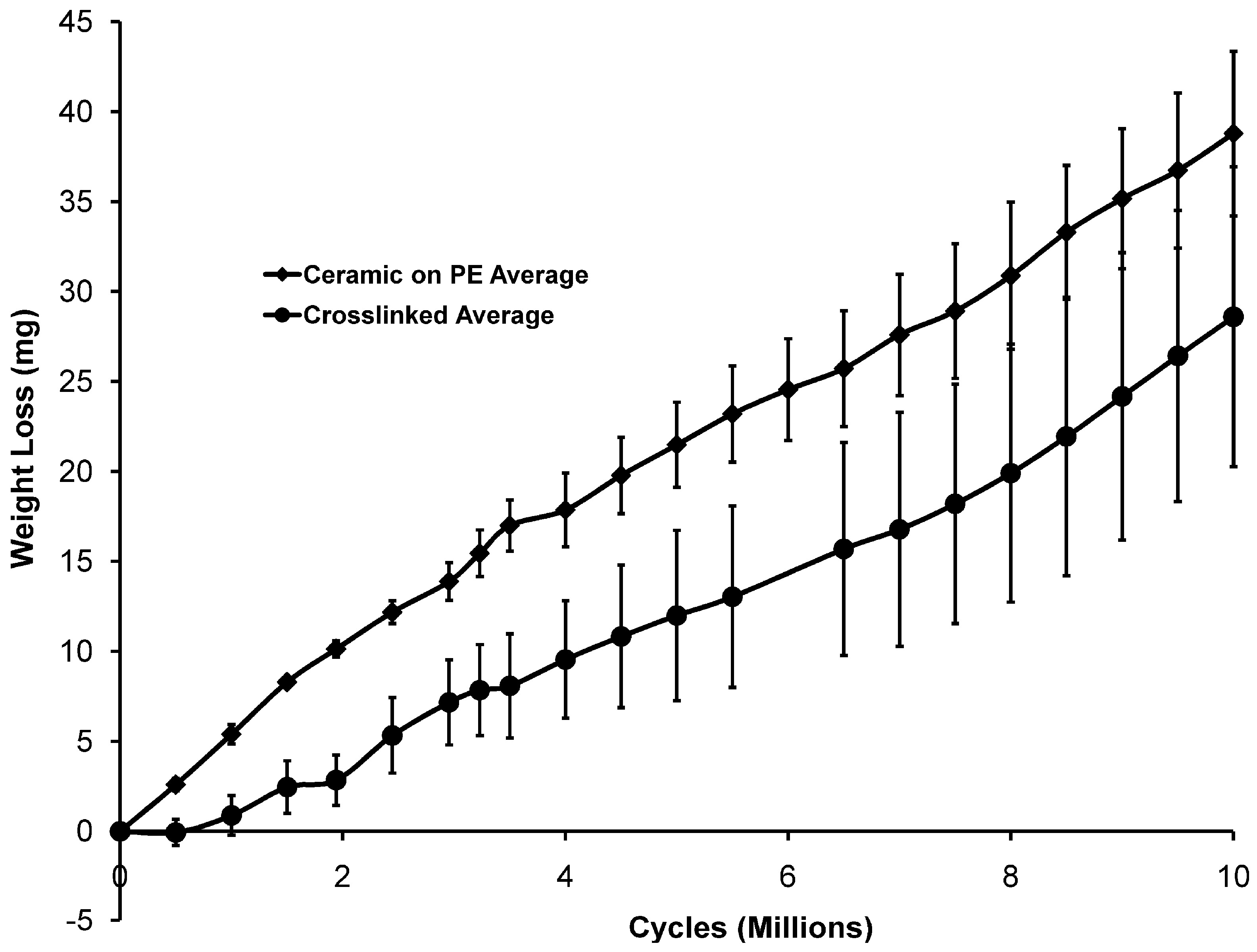

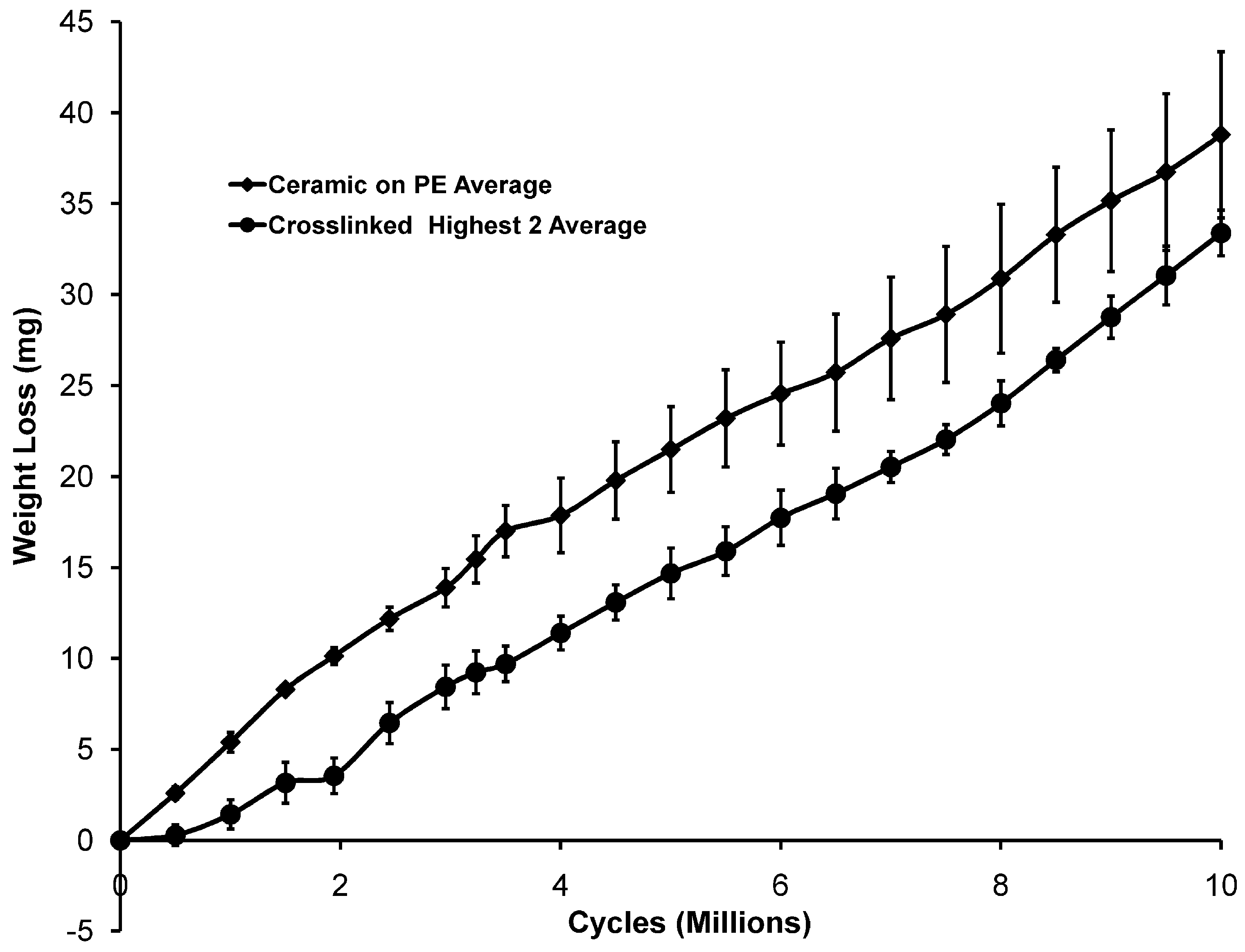

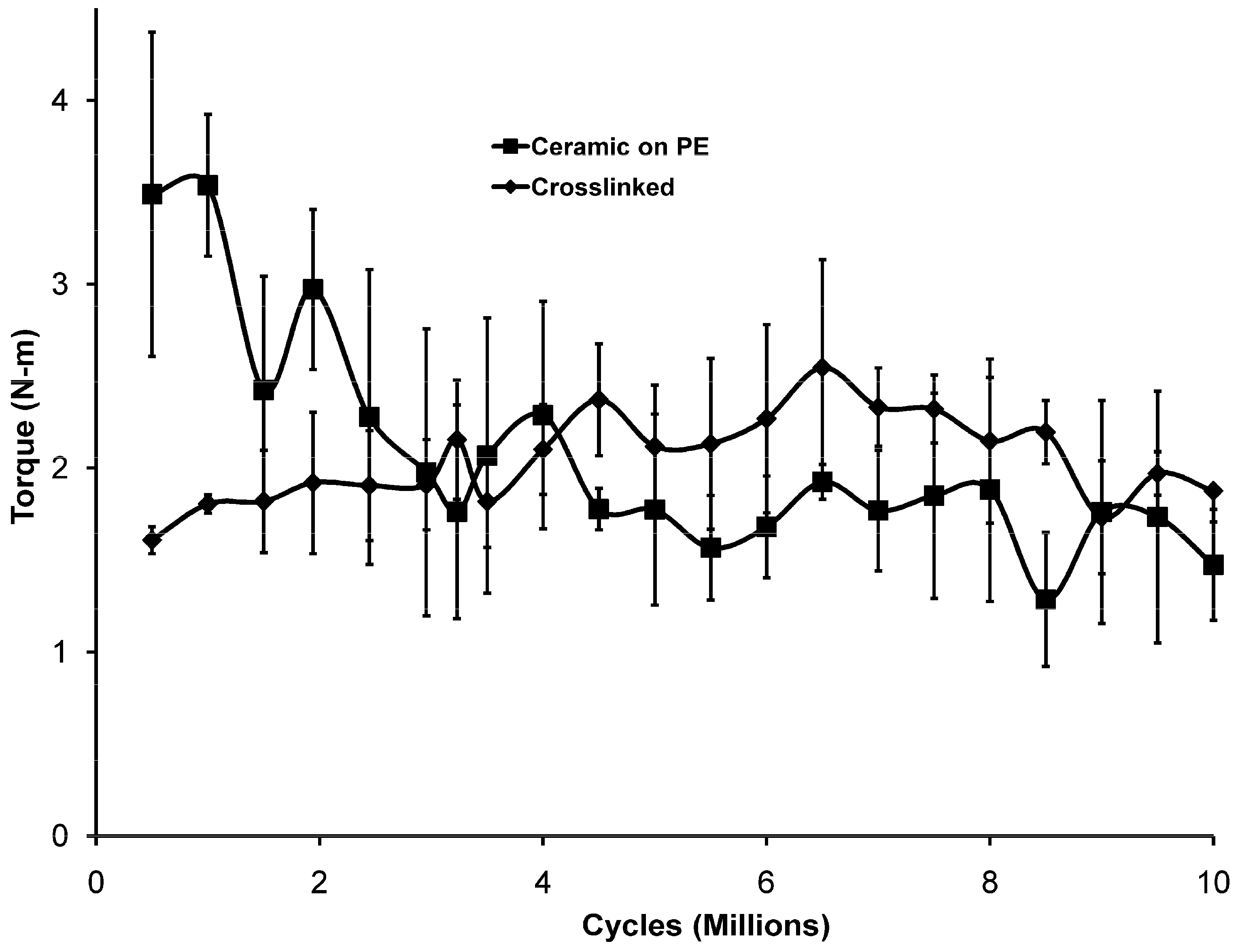

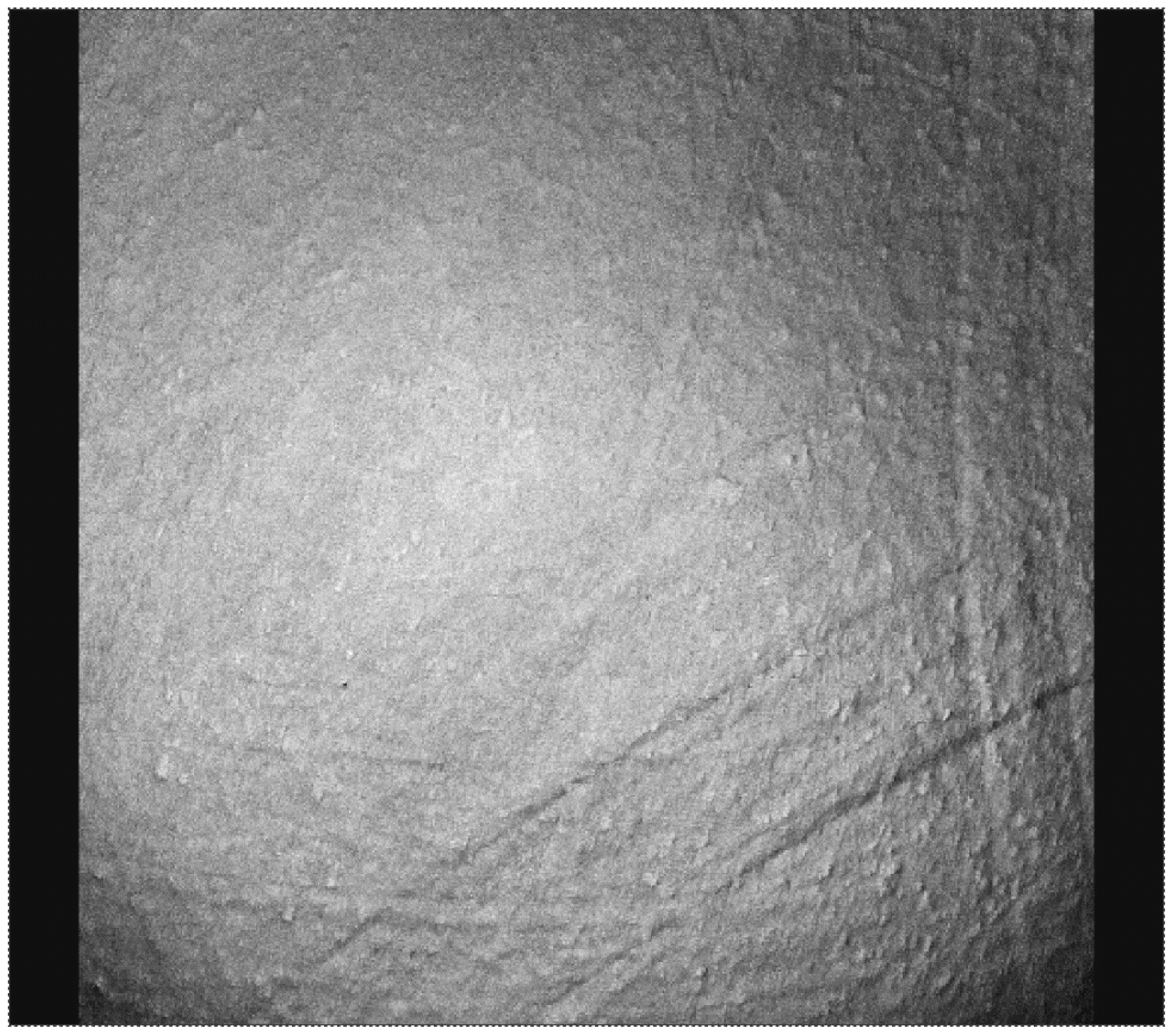

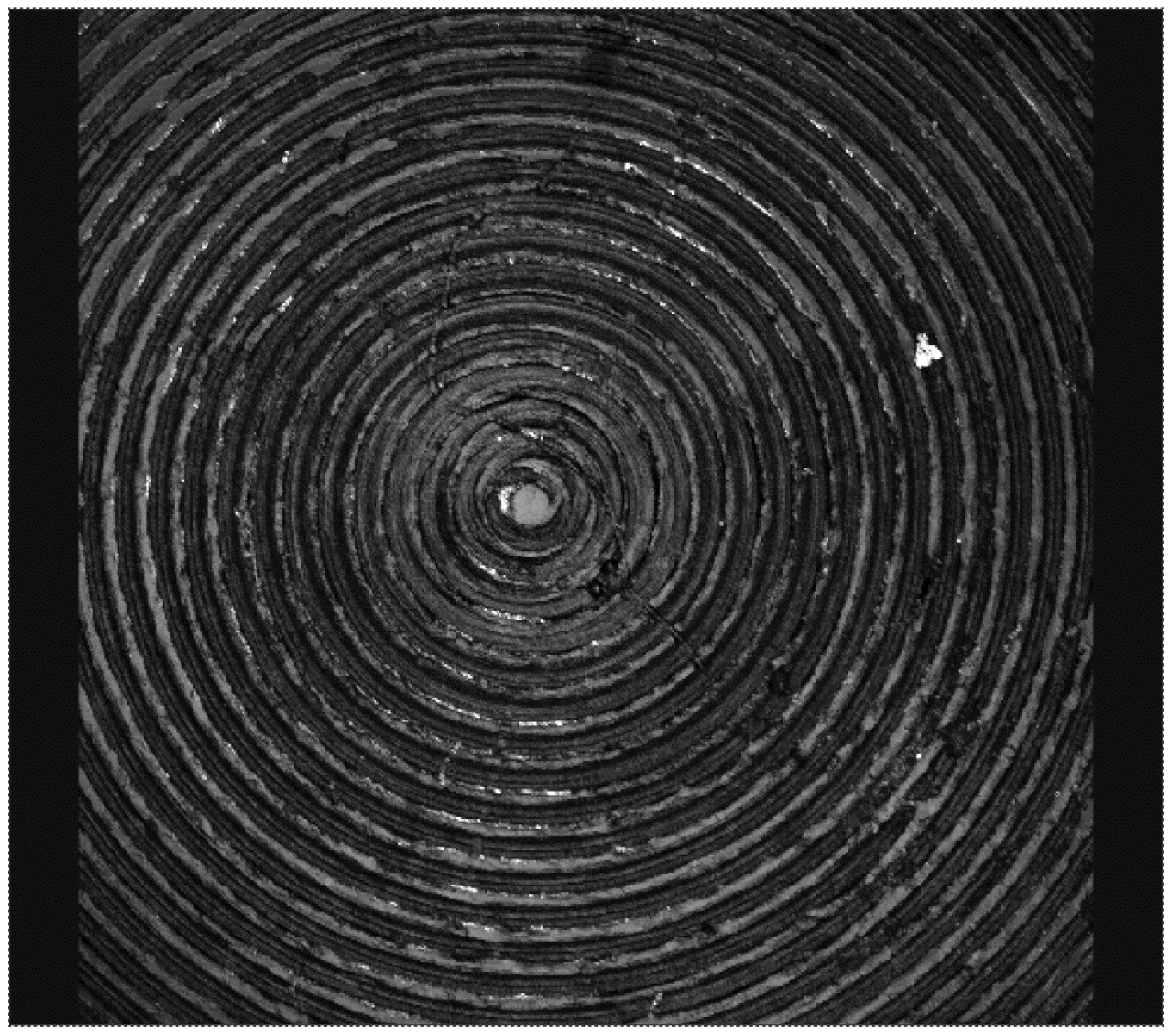

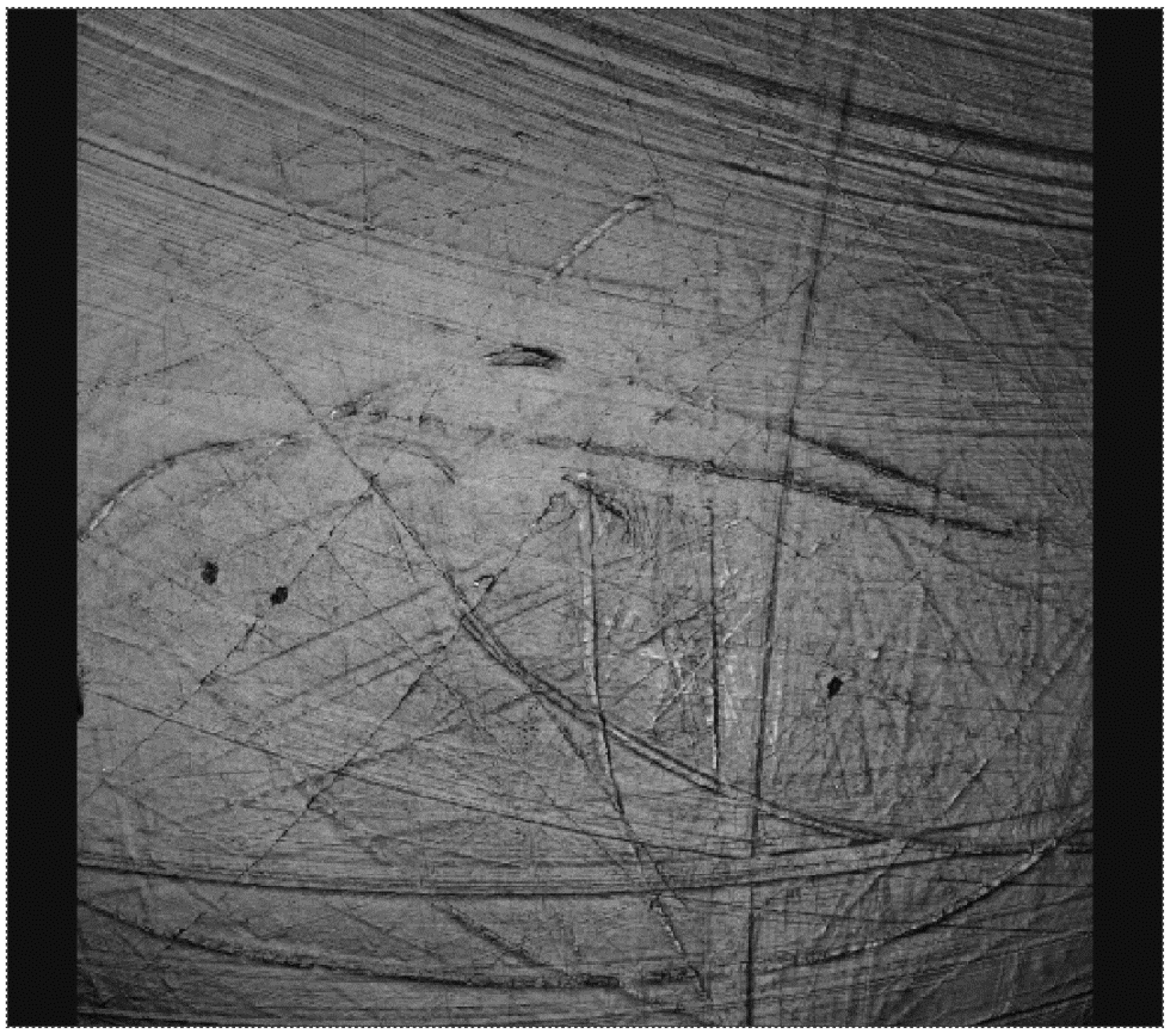

3. Results

| Sample Type | First 1,000,000 | 1,000,000 to 2,000,000 | 2,000,000 to 5,000,000 | 5,000,000 to 10,000,000 | 2,000,000 to 10,000,000 |

|---|---|---|---|---|---|

| Ceramic on Polyethylene | 5.40 ± 0.54 | 5.04 ± 0.59 | 3.71 ± 0.72 | 3.46 ± 0.44 | 3.55 ± 0.55 |

| Crosslinked | 0.89 ± 1.10 | 2.08 ± 0.33 | 2.99 ± 1.12 | 3.32 ± 0.73 | 3.20 ± 0.88 |

| Crosslinked (2 highest) | 1.43 | 2.26 | 3.63 | 3.74 | 3.70 |

4. Discussion

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Cates, H.E. Polyethylene wear in cemented metal-backed actabular cups. J. Bone Joint Surg. Br. 1993, 75, 249–253. [Google Scholar] [PubMed]

- Galante, J.O.; Rostoker, W. Wear in total hip prostheses. ACTA Orthop. Suppl. 1973, 145, 1–46. [Google Scholar]

- Jasty, M.; Goetz, D.D.; Bragdon, C.R.; Lee, K.R.; Hanson, A.E.; Elder, J.R.; Harris, W.H. Wear of polyethylene acetabular components in total hip arthroplasty. J. Bone Joint Surg. Am. 1997, 79, 349–358. [Google Scholar] [PubMed]

- Kabo, J.M. In Vivo Wear of polyethylene acetabular components. J. Bone Joint Surg. Br. 1993, 75, 254–258. [Google Scholar] [PubMed]

- Lewis, G. Polyethylene wear in total hip and knee arthroplasties. J. Biomed. Mater. Res. 1997, 38, 55–75. [Google Scholar] [CrossRef]

- Schmalzried, T.P.; Callaghan, J.J. Wear in total hip and knee replacements. J. Bone Joint Surg. Am. 1999, 81, 115–136. [Google Scholar] [PubMed]

- Edidin, A.A.; Herr, M.P.; Villarraga, M.L.; Muth, J.; Yau, S.S.; Kurtz, S.M. Accelerated aging studies of UHMWPE. I. Effect of resin, processing, and radiation environment on resistance to mechanical degradation. J. Biomed. Mater. Res. 2002, 61, 312–322. [Google Scholar] [CrossRef] [PubMed]

- Elfick, A.P.D. The effect of socket design, materials and liner thickness on the wear of the porous coated anatomic total hip replacement. Proc. Inst. Mech. Eng. 2001, 215, 447–457. [Google Scholar] [CrossRef]

- Liu, C.Z.; Wu, J.Q.; Li, J.Q.; Ren, L.Q.; Tong, J.; Arnell, A.D. Tribological behaviours of PA/UHMWPE blend under dry and lubricating condition. Wear 2006, 260, 109–115. [Google Scholar] [CrossRef]

- McKellop, H.; Shen, F.W.; Lu, B.; Campbell, P.; Salovey, R. Effect of sterilization method and other modifications on the wear resistance of acetabular cups made of ultra-high molecular weight polyethylene. A hip-simulator study. J. Bone Joint Surg. Am. 2000, 82, 1708–1725. [Google Scholar] [PubMed]

- McKellop, H.A.; Shen, F.-W.; Campbell, P.; Ota, T. Effect of molecular weight, calcium stearate, and sterilization methods on the wear of ultra high molecular weight polyethylene acetabular cups in a hip joint simulator. J. Orthop. Res. 1999, 17, 329–339. [Google Scholar] [CrossRef] [PubMed]

- Allen, C.; Bloyce, A.; Bell, T. Sliding wear behaviour of ion implanted ultra high molecular weight polyethylene against a surface modified titanium alloy Ti-6Al-4V. Trib. Int. 1996, 29, 527–534. [Google Scholar] [CrossRef]

- Rostland, T.; Albrektsson, B.; Albrektsson, T.; McKellop, H. Wear of ion-implanted pure titanium against UHMWPE. Biomaterials 1989, 10, 176–181. [Google Scholar] [CrossRef]

- Scholes, S.C. Compliant layer acetabular cups: Friction testing of a range of materials and designs for a new generation of prosthesis that mimics the natural joint. Proc. Inst. Mech. Eng. 2006, 220, 583–596. [Google Scholar] [CrossRef]

- Clarke, I.C.; Gustafson, A. Clinical and hip simulator comparisons of ceremic-on-polyethylene and metal-on-polethylene wear. Clin. Orthop. 2000, 379, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Galvin, A.; Brockett, C.; Williams, S.; Hatto, P.; Burton, A.; Isaac, G.; Stone, M.; Ingham, E.; Fisher, J. Comparison of wear of ultra-high molecular weight polyethylene acetabular cups against surface-engineered femoral heads. Proc. Inst. Mech. Eng. 2008, 222, 1073–1080. [Google Scholar] [CrossRef]

- Goldsmith, A.A.; Dowson, D. A multi-station hip joint simulator study of the performance of 22 mm diameter zirconia-ultra-high molecular weight polyethylene total replacement hip joints. Proc. Inst. Mech. Eng. 1999, 213, 77–90. [Google Scholar] [CrossRef]

- Hernigou, P.; Bahrami, T. Zirconia and alumina ceramics in comparison with stainless-steel heads: Polyethylene wear after a minimum ten-year follow-up. J. Bone Joint Surg. Br. 2003, 85, 504–509. [Google Scholar] [CrossRef] [PubMed]

- Kawanabe, K.; Tanaka, K.; Tamura, J.; Shimizu, M.; Onishi, E.; Iida, H.; Nakamura, T. Effect of alumina femoral head on clinical results in cemented total hip arthroplasty: Old vs. current alumina. J. Orthop. Sci. 2005, 10, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.H. Comparison of polyethylene wear associated with cobalt-chromium and zirconia heads after total hip replacement. A prospective, randomized study. J. Bone Joint Surg. Am. 2005, 87, 1769–1776. [Google Scholar] [CrossRef] [PubMed]

- Saikko, V.; Ahlroos, T.; Calonius, O.; Keranen, J. Wear simulation of total hip prostheses with polyethylene against CoCr, alumina and diamond-like carbon. Biomaterials 2001, 22, 1507–1514. [Google Scholar] [CrossRef]

- Semlitsch, M.; Willert, H.G. Clinical wear behavior of ultra-high molecular weight polyethylene cups paired with metal and ceramic ball heads in comparison to metal-on-metal pairings of hip joint replacements. Proc. Inst. Mech. Eng. 1997, 211, 73–88. [Google Scholar] [CrossRef]

- Smith, S.L.; Unsworth, A. A comparison between gravimetric and volumetric techniques of wear measurement of UHMWPE acetabular cups against zirconia and coblat-chromium-molybdenum femoral heads in a hip simulator. Proc. Inst. Mech. Eng. 1999, 213, 475–483. [Google Scholar] [CrossRef]

- Wroblewski, B.M.; Siney, P.D.; Fleming, P.A. Low-friction arthroplasty of the hip using alumina ceramic and cross-linked polyethylene. J. Bone Joint Surg. Br. 1999, 81, 54–55. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Ferrari, G.; Chevalier, J.; Ruggeri, O.; Toni, A. Surface characterization and debris analysis of ceramic pairings after ten million cycles on a hip joint simulator. Proc. Inst. Mech. Eng. 2002, 216, 419–424. [Google Scholar] [CrossRef]

- Shishido, T.; Clarke, I.C.; Williams, P.; Boehler, M.; Asano, T.; Shoji, H.; Masaoka, T.; Yamamoto, K.; Imakiire, A. Clinical and simulator wear study of alumina ceramic THR to 17 years and beyond. J. Biomed. Mater. Res. 2003, 67, 638–647. [Google Scholar] [CrossRef] [PubMed]

- Stewart, T.D.; Tipper, J.L.; Insley, G.; Streicher, R.M.; Ingham, E.; Fisher, J. Long-term wear of ceramic matrix composite materials for hip prostheses under severe swing phase microseparation. J. Biomed. Mater. Res. 2003, 66, 567–573. [Google Scholar] [CrossRef] [PubMed]

- Yoon, T.R.; Rowe, S.M.; Jung, S.T.; Seon, K.J.; Maloney, W.J. Osteolysis in association with a total hip arthroplasty with ceramic bearing surfaces. J. Bone Joint Surg. Am. 1998, 80, 1459–1468. [Google Scholar] [PubMed]

- Muller, M.E. The benefits of metal-on-metal total hip replacements. Clin. Orthop. 1995, 311, 54–59. [Google Scholar] [PubMed]

- Walker, P.S.; Erkman, M.J. Metal-on-metal lubrication in artificial human joints. Wear 1972, 21, 377–392. [Google Scholar] [CrossRef]

- Chan, F.W.; Bobyn, J.D.; Medley, J.B.; Krygier, J.J.; Tanzer, M. The Otto Aufranc Award. Wear and lubrication of metal-on-metal hip implants. Clin. Orthop. Relat. Res. 1999, 369, 10–24. [Google Scholar] [CrossRef] [PubMed]

- Dorr, L.D.; Wan, Z.; Longjohn, D.B.; Dubois, B.; Murken, R. Total hip arthroplasty with use of the Metasul metal-on-metal articulation. Four to seven-year results. J. Bone Joint Surg. Am. 2000, 82, 789–798. [Google Scholar] [PubMed]

- Fisher, J.; Hu, X.Q.; Stewart, T.D.; Williams, S.; Tipper, J.L.; Ingham, E.; Stone, M.H.; Davies, C.; Hatto, P.; Bolton, J.; et al. Wear of surface engineered metal-on-metal hip prostheses. J. Mater. Sci. Mater. Med. 2004, 15, 225–235. [Google Scholar] [CrossRef] [PubMed]

- Fisher, J.; Hu, X.Q.; Tipper, J.L.; Stewart, T.D.; Williams, S.; Stone, M.H.; Davies, C.; Hatto, P.; Bolton, J.; Riley, M.; et al. An in vitro study of the reduction in wear of metal-on-metal hip prostheses using surface-engineered femoral heads. Proc. Inst. Mech. Eng. 2002, 216, 219–230. [Google Scholar] [CrossRef]

- Goldsmith, A.A.; Dowson, D.; Isaac, G.H.; Lancaster, J.G. A comparative joint simulator study of the wear of metal-on-metal and alternative material combinations in hip replacements. Proc. Inst. Mech. Eng. 2000, 214, 39–47. [Google Scholar] [CrossRef]

- Schmalzried, T.P.; Peters, P.C.; Maurer, B.T.; Bragdon, C.R.; Harris, W.H. Long-duration metal-on-metal total hip arthroplasties with low wear of the articulating surfaces. J. Arthroplast. 1996, 11, 322–331. [Google Scholar] [CrossRef]

- Streicher, R.M.; Semlitsch, M.; Schon, R.; Weber, H.; Rieker, C. Metal-on-metal articulation for artificial hip joints: Laboratory study and clinical results. Proc. Inst. Mech. Eng. 1996, 210, 223–232. [Google Scholar] [CrossRef]

- Willert, H.G.; Buchhorn, G.H.; Gobel, D.; Koster, G.; Schaffner, S.; Schenk, R.; Semlitsch, M. Wear behavior and histopathology of classic cemented metal on metal hip endoprostheses. Clin. Orthop. 1996, 329, S160–S186. [Google Scholar] [CrossRef] [PubMed]

- Livermore, J.; Ilstrup, D.; Morrey, B. Effect of femoral head size on wear of the polyethylene acetabular component. J. Bone Joint Surg. Am. 1990, 72, 518–528. [Google Scholar] [PubMed]

- Clarke, I.C.; Gustafson, A.; Jung, H.; Fujisawa, A. Hip-simulator ranking of polyethylene wear: Comparisons between ceramic heads of different sizes. Acta Orthop. Scand. 1996, 67, 128–132. [Google Scholar] [CrossRef] [PubMed]

- Beaule, P.E.; Schmalzreid, T.P.; Udomkiat, P.; Amstutz, H.C. Jumbo femoral head for the treatment of recurrent dislocation following total hip replacement. J. Bone Joint Surg. Am. 2002, 84, 256–263. [Google Scholar] [PubMed]

- Kluess, D.; Martin, H.; Mittelmeier, W.; Schmitz, K.-P.; Bader, R. Influence of femoral head size on impingement, dislocation and stress distribution in total hip replacement. Med. Eng. Phys. 2007, 29, 465–471. [Google Scholar] [CrossRef] [PubMed]

- Burroughs, B.R.; Hallstrom, B.; Golladay, G.J.; Hoeffel, D.; Harris, W.H. Range of motion and stability in total hip arthroplasty with 28-, 32-, 38-, and 22-mm femoral head sizes. J. Arthroplast. 2005, 20, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Matsushita, A.; Nakashima, Y.; Jingushi, S.; Yamamoto, T.; Kuraoka, A.; Iwamoto, Y. Effects of the femoral offset and the head size on the safe range of motion in total hip arthroplasty. J. Arthroplast. 2009, 24, 646–651. [Google Scholar] [CrossRef] [PubMed]

- D’Lima, D.D.; Hermida, J.C.; Chen, P.C.; Colwell, C.W., Jr. Polyethylene cross-linking by two different methods reduces acetabular liner wear in a hip joint wear simulator. J. Orthop. Res. 2003, 21, 761–766. [Google Scholar] [CrossRef]

- Geerdink, C.H.; Grimm, B.; Ramakrishnan, R.; Ronduis, J.; Verberg, A.J.; Tonino, A.J. Crosslinked polyethylene compared to conventional polyethylene in total hip replacement: Pre-clinical evaluation, in vitro testing and prospective clinical follow-up study. Acta Orthop. 2006, 77, 719–725. [Google Scholar] [CrossRef] [PubMed]

- McKellop, H.; Shen, F.-W.; Lu, B.; Campbell, P.; Salovey, R. Development of an extremely wear-resistant ultra high molecular weight polyethylene for total hip replacements. J. Orthop. Res. 1999, 17, 157–167. [Google Scholar] [CrossRef] [PubMed]

- Muratoglu, O.K.; O’Connor, D.O.; Bragdon, C.R.; Delaney, J.; Jasty, M.; Harris, W.H.; Merrill, E.; Venugopalan, P. Gradient crosslinking of UHMWPE using irradiation in molten state for total joint arthroplasty. Biomaterials 2002, 23, 717–724. [Google Scholar] [CrossRef]

- Muratoglu, O.K.; Wannomae, K.; Christensen, S.; Rubash, H.E.; Harris, W.H. Ex vivo wear of conventional and cross-linked polyethylene acetabular liners. Clin. Orthop. 2005, 438, 158–164. [Google Scholar] [CrossRef] [PubMed]

- Gordon, A.C.; D’Lima, D.D.; Colwell, C.W. Highly cross-linked polyethylene in total hip arthroplasty. J. Am. Acad. Orthop. Surg. 2006, 14, 511–523. [Google Scholar] [PubMed]

- Oonishi, H.; Takayama, Y.; Tsuji, E. The low wear of cross-linked polyethylene socket in total hip prostheses. In Encyclopedic Handbook of Biomaterials and Bioengineering, Part A: Materials; Wise, D.L., Trantolo, D.J., Altobelli, D.F., Yaszemski, M.J., Gresser, J.D., Schwartz, E.R., Eds.; Marcel Dekker: New York, NY, USA, 1995; Volume 1, pp. 1853–1868. [Google Scholar]

- McCalden, R.W.; MacDonald, S.J.; Rorabeck, C.H.; Bourne, R.B.; Chess, D.G.; Charron, K.D. Wear rate of highly cross-linked polyethylene in total hip arthroplasty. A randomized controlled trial. J. Bone Joint Surg. Am. 2009, 91, 773–782. [Google Scholar] [CrossRef] [PubMed]

- Nikolaou, V.S.; Edwards, M.R.; Bogoch, E.; Schemitsch, E.H.; Waddell, J.P. A prospective randomised controlled trial comparing three alternative bearing surfaces in primary total hip replacement. J. Bone Joint Surg. Br. 2012, 94, 459–465. [Google Scholar] [CrossRef] [PubMed]

- Muratoglu, O.K.; Bragdon, C.R.; O’Connor, D.; Perinchief, R.S.; Estok, D.M.; Jasty, M.; Harris, W.H. Larger diameter femoral heads used in conjunction with a highly cross-linked ultra-high molecular weight polyethylene: A new concept. J. Arthroplast. 2001, 16, 24–30. [Google Scholar] [CrossRef]

- Hermida, J.C.; Bergula, A.; Chen, P.; Colwell Jr, C.W.; D’Lima, D.D. Comparison of the wear rates of twenty-eight and thirty-two millimeter femoral heads on cross-linked polyethylene acetabular cups in a wear simulator. J. Bone Joint Surg. Am. 2003, 85, 2325–2331. [Google Scholar] [PubMed]

- Plank, G.R.; Estok, D.M., 2nd; Muratoglu, O.K.; O’Connor, D.O.; Burroughs, B.R.; Harris, W.H. Contact stress assessment of conventional and highly crosslinked ultra high molecular weight polyethylene acetabular liners with finite element analysis and pressure sensitive film. J. Biomed. Mater. Res. B Appl. Biomater. 2007, 80, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Lachiewicz, P.F.; Heckman, D.S.; Soileau, E.S.; Mangla, J.; Martell, J.M. Femoral head size and wear of highly cross-linked polyethylene at 5 to 8 years. Clin. Orthop. 2009, 467, 3290–3296. [Google Scholar] [CrossRef] [PubMed]

- Nakahara, I.; Nakamura, N.; Takao, M.; Sakai, T.; Nishii, T.; Sugano, N. Eight-year wear analysis in Longevity highly cross-linked polyethylene liners comparing 26- and 32-mm heads. Arch. Orthop. Trauma Surg. 2011, 131, 1731–1737. [Google Scholar] [CrossRef] [PubMed]

- Cuckler, J.M.; Bearcroft, J.; Asgian, C.M. Femoral head technologies to reduce polyethylene wear in total hip arthroplasty. Clin. Orthop. 1995, 317, 57–63. [Google Scholar] [PubMed]

- D’Antonio, J.A.; Sutton, K. Ceramic materials as bearing surfaces for total hip arthroplasty. J. Am. Acad. Orthop. Surg. 2009, 17, 63–68. [Google Scholar] [PubMed]

- Galvin, A.L.; Jennings, L.M.; Tipper, J.L.; Ingham, E.; Fisher, J. Wear and creep of highly crosslinked polyethylene against cobalt chrome and ceramic femoral heads. Proc. Inst. Mech. Eng. 2010, 224, 1175–1183. [Google Scholar] [CrossRef]

- Urban, J.A.; Garvin, K.L.; Boese, C.K.; Bryson, L.; Pedersen, D.R.; Callaghan, J.J.; Miller, R.K. Ceramic-on-polyethylene bearing surfaces in total hip arthroplasty. Seventeen to twenty-one year results. J. Bone Joint Surg. Am. 2001, 83, 1688–1694. [Google Scholar] [PubMed]

- Kawate, K.; Omura, T.; Kawahara, I.; Tamai, K.; Ueha, T.; Takemura, K. Differences in highly cross-linked polyethylene wear between zirconia and cobalt-chromium femoral heads in Japanese patients: A prospective, randomized study. J. Arthroplast. 2009, 24, 1221–1224. [Google Scholar] [CrossRef] [PubMed]

- Stilling, M.; Nielsen, K.A.; Soballe, K.; Rahbek, O. Clinical comparison of polyethylene wear with zirconia or cobalt-chromium femoral heads. Clin. Orthop. 2009, 467, 2644–2650. [Google Scholar] [CrossRef] [PubMed]

- Kraay, M.J.; Thomas, R.D.; Rimnac, C.M.; Fitzgerald, S.J.; Goldberg, V.M. Zirconia vs. Co-Cr femoral heads in total hip arthroplasty: Early assessment of wear. Clin. Orthop. 2006, 453, 86–90. [Google Scholar] [CrossRef] [PubMed]

- Meftah, M.; Klingenstein, G.G.; Yun, R.J.; Ranawat, A.S.; Ranawat, C.S. Long-term performance of ceramic and metal femoral heads on conventional polyethylene in young and active patients: A matched-pair analysis. J. Bone Joint Surg. Am. 2013, 95, 1193–1197. [Google Scholar] [CrossRef] [PubMed]

- Laurent, M.P.; Johnson, T.S.; Crowninshield, R.D.; Blanchard, C.R.; Bambri, S.K.; Yao, J.Q. Characterization of a highly cross-linked ultrahigh molecular-weight polyethylene in clinical use in total hip arthroplasty. J. Arthroplast. 2008, 23, 751–761. [Google Scholar] [CrossRef] [PubMed]

- ISO 14242-3-Implants for Surgery—Wear of Total Hip-Joint Prostheses—Part 3: Loading and displacement parameters for orbital bearing type wear testing machines and corresponding environmental conditions for test. International Organization for Standardization: Geneva, Switzerland, 2009.

- F1714–96 (2013)-Standard Guide for Gravimetric Wear Assessment of Prosthetic Hip-Designs in Simulator Devices. ASTM International: West Conshohocken, PA, USA, 2013.

- ISO 14242-2-Implants for Surgery—Wear of Total Hip-Joint Prostheses—Part 2: Methods of measurement. International Organization for Standardization: Geneva, Switzerland, 2000.

- Jasty, M.; Rubash, H.E.; Muratoglu, O.K. Highly crosslinked polyethylene: The debate is over—In the affirmative. J. Arthroplast. 2005, 20, 55–58. [Google Scholar] [CrossRef]

- Bragdon, C.R.; Barrett, S.; Martell, J.M.; Greene, M.E.; Henrik, M.; Harris, W.H. Steady state penetration rates of electron beam-irradiated, highly cross-linked polyethylene at an average of 45-month follow-up. J. Arthroplast. 2006, 21, 935–943. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

St. John, K.R. Evaluation of Two Total Hip Bearing Materials for Resistance to Wear Using a Hip Simulator. Lubricants 2015, 3, 459-474. https://doi.org/10.3390/lubricants3020459

St. John KR. Evaluation of Two Total Hip Bearing Materials for Resistance to Wear Using a Hip Simulator. Lubricants. 2015; 3(2):459-474. https://doi.org/10.3390/lubricants3020459

Chicago/Turabian StyleSt. John, Kenneth R. 2015. "Evaluation of Two Total Hip Bearing Materials for Resistance to Wear Using a Hip Simulator" Lubricants 3, no. 2: 459-474. https://doi.org/10.3390/lubricants3020459

APA StyleSt. John, K. R. (2015). Evaluation of Two Total Hip Bearing Materials for Resistance to Wear Using a Hip Simulator. Lubricants, 3(2), 459-474. https://doi.org/10.3390/lubricants3020459