Abstract

The objective of this study was to develop an advanced-bearing couple for TKA that optimizes the balance between wear resistance and mechanical properties. The mechanical and structural properties of virgin and highly crosslinked, re-melted UHMWPE were evaluated, and tibial inserts manufactured from these UHMWPE materials were tested against either oxidized zirconium (OxZr) or CoCr femoral components on a knee simulator. This study confirmed that the wear resistance of crosslinked UHMWPE improves with increasing radiation dose but is accompanied by a concomitant reduction in mechanical properties. Compared to CoCr, the ceramic surface of OxZr allows the use of a lower irradiation dose to achieve equivalent reductions in wear rates. As a result, a given wear rate can be achieved without sacrificing the mechanical properties to the same extent that is necessary with a CoCr femoral component. The advantage of ceramic counter bearing surfaces extends to both pristine and microabrasive conditions.

1. Introduction

The most common bearing couple used in total hip and knee arthroplasties (THA and TKA, respectively) is ultra-high molecular weight polyethylene (UHMWPE) articulating against a CoCr alloy. This couple has demonstrated excellent clinical results with survivorship greater than 90% at 13 years in THA [1] and greater than 92% at 13 years in TKA [1]. However, UHMWPE wear and subsequent osteolysis have been a primary long-term failure mechanism, which results in decreasing survivorship with increasing time in vivo [2,3,4]. Traditionally, THA and TKA were performed in elderly patients with the intent of reducing pain and providing mobility. However, a number of changes in patient demographics have occurred in the intervening decades, namely: (1) the population has become heavier; (2) patients are receiving THA and TKA at younger ages; and (3) the patients are more likely to continue active lifestyles after surgery [5,6,7]. Therefore, contemporary joint replacements experience greater biomechanical demands than experienced in the past, which create a need for more wear-resistant implants.

This need for improvement was first identified in THA due to the larger number of procedures performed, higher wear rates, and greater incidence of osteolysis. In the late 1990s, crosslinking, which was first used and quizzically abandoned in the 1970s [8], was resurrected as a technique for improved wear resistance of UHMWPE. Today, the formulations of crosslinked UHMWPE that were introduced into the THA marketplace in the late 1990s and early 2000s are showing promising clinical results with up to 12 years of follow-up [9,10,11]. Radiographic wear shows marked improvements, and the incidence of osteolysis secondary to wear shows dramatic reductions compared to conventional UHMWPE.

Historically, highly crosslinked UHMWPE did not see wide-spread use in TKA because crosslinking results in the reduction of particular mechanical properties and contact stresses can be higher in TKA than in THA. However, total knee replacement is now a more prevalent procedure and is predicted to grow at a faster rate than total hip replacement [7]. In addition, Sharkey et al. reported that one of the primary, long-term causes of TKA revision was polyethylene wear, which accounted for 25% of the failures in their retrospective review of 212 consecutive TKA revisions [12]. Ten years later, a follow-up study by Sharkey et al. [13] reported a remarkable decrease in revisions due to polyethylene wear and concluded that this reduction was, in part, likely due to the successful development of materials with improved wear resistance.

Clearly there is a need for further improvements in TKA bearings technology. Encouraged by the clinical success of crosslinked UHMWPE in the hip, there is now greater confidence that the material may also have a compelling application in knees. Engineers and clinicians, however, recognize that the stresses and motions in knees are different from those in hips and that the effects of the reduction in mechanical properties concomitant with crosslinking must be evaluated carefully. As a result, adoption of crosslinked UHMWPE in TKA has proceeded with greater caution.

It is well understood that the degree of crosslinking appropriate for a particular application is a delicate balance between improvements in wear and reduced mechanical properties resulting from increased crosslinking [14]. With that in mind, the crosslinked UHMWPE formulations currently marketed for TKA typically utilize lower crosslink densities than those marketed for THA.

The hypothesis of the present study is that the wear rates of various formulations of UHMWPE can be reduced not only by increasing crosslink density, but additionally by changing the counter bearing surface from the metallic CoCr alloy to a ceramic. Ceramics (typically sintered aluminum or zirconium oxides) are commonly utilized in THA femoral heads for two reasons, namely (1) reduced wear of UHMWPE because of a lower coefficient of friction compared to CoCr; and (2) improved microabrasion resistance because they are harder than CoCr. Both of these properties are singularly attributed to the predominantly covalently bonded molecular structure of ceramics. However, ceramics are brittle (due to the strong covalent bonds) and have found very limited use in the higher stress application of TKA. A solution to this limitation of bulk ceramics is to design a material system in which the component is fully ceramic only at the bearing surface and metallic in its core. Surface oxidized zirconium (OxZr), trademarked as OXINIUM™ (Smith and Nephew, Memphis, TN, USA), is one such material marketed for orthopaedic implants.

The objective of this study was to develop an advanced-bearing couple for TKA that optimizes the balance between wear resistance and mechanical properties. Wear testing was conducted under pristine and tumbled/abraded conditions to examine the performance and durability of the bearing couples under ideal and less-than-ideal conditions. Mechanical and structural characterizations of various UHMWPEs were also conducted as a function of crosslink density to rationalize the balance between wear resistance and mechanical/structural properties.

2. Materials and Methods

2.1. Materials

The UHMWPE materials examined in this study were fabricated from multiple lots of compression-molded GUR1020 UHMWPE rod stock that were obtained from MediTECH Medical Polymers (Fort Wayne, IN, USA). Some of the material was evaluated in the unirradiated state and is denoted as virgin material. Additional rods were crosslinked with nominal gamma-radiation doses of 5.0 Mrad (50 kGy), 7.5 Mrad (75 kGy), or 10.0 Mrad (100 kGy) and subsequently re-melted to stabilize them against oxidation. These highly crosslinked materials are identified as 5-XLPE, 7.5-XLPE and 10-XLPE, respectively. Only the components for wear testing were sterilized by ethylene oxide (EtO) gas. The remainder of the material was evaluated in the unsterilized condition since multiple studies have demonstrated that EtO sterilization does not alter the properties of either virgin or highly crosslinked UHMWPE [15,16,17].

2.2. Mechanical and Physical Characterization

All of the mechanical and physical testing was conducted by MediTECH. Tensile testing (n = 5) was performed according to ASTM F648-07 and ASTM D638-03 with Type IV specimens with thicknesses of 3.0 ± 0.05 mm and displacement rates of 50 mm/min. Izod impact testing (n = 5) was conducted according to ASTM F648-07 and ASTM D256-05 with a 7.5 J hammer, and density (n = 3) was determined according to ASTM D792-00, Method B.

2.3. Thermophysical Analysis

Thermal analysis was conducted according to ASTM F2625-07 using a Netzsch 204 F1 Phoenix differential scanning calorimeter (DSC). Each DSC sample was removed from the core of the rod stock. Samples were cut and weighed to a resolution of 0.01 mg and ranged in mass from approximately 7 to 10 mg. An attempt was made to produce plate-like samples and keep the approximate dimensions consistent in order to minimize dimensional effects on the thermogram variability. The DSC cycle consisted of a 10 min equilibration at 30 °C, followed by heating to 180 °C at 10 °C/min rate, and cooling to 30 °C at 10 °C/min. For all of the thermograms, an empty aluminum crucible was used as the reference. First, an empty aluminum crucible was run as a baseline correction. The samples were crimped into aluminum crucibles and placed in the DSC chamber, which was continuously flushed with research-grade nitrogen gas at a flow rate of approximately 30 mL/min. Five samples (n = 5) were run per material condition with this heating profile. The resultant thermograms were analyzed to determine the extrapolated onset (TOM) and peak melting (TPM) temperatures and the heats of fusion (ΔHm). For the determination of ΔHm, the integration limits were systematically placed at 50 °C and 160 °C. The percent crystallinity (%X) was estimated as:

where 291 J/g is the enthalpy associated with the melting of 100% crystalline polyethylene.

2.4. Molecular Network Parameters

The molecular network parameters were evaluated by Cambridge Polymer Group (Boston, MA, USA). Three cubes (n = 3) with nominal dimensions of 5 × 5 × 5 mm were prepared from each lot of material by Cambridge Polymer. It should be noted that the orientations of the samples relative to the compression axes can affect the results [18] but were unknown in this study. The virgin samples were evaluated according to ASTM D2765-01. The highly crosslinked samples were evaluated according to ASTM F2214-02, and the swell ratio (qs) and crosslink density (νd) were reported. Two lots of virgin UHMWPE, 7 lots of 5-XLPE, 6 lots of 7.5-XLPE, and 3 lots of 10-XLPE were evaluated. The repeat measurements were averaged for each lot of material, and the replicate measurements for each lot were averaged for each level of crosslinking. Briefly, the initial heights (Ho) of the cube specimens were first measured using a digital micrometer with a resolution of 1 µm. The specimens were then immersed in o-xylene with 0.1 wt % Irganox™ antioxidant, and the specimen height was monitored with a lightweight, ceramic dilatometer probe until steady-state conditions were achieved (Hf = final height). As specified in the standard, the swell ratio was calculated according to Equation (2):

Once qs was determined, the crosslink density and molecular weight between crosslinks were calculated for all materials according to the following equations delineated in ASTM F2214:

Where:

- χ1 = Heat of mixing for the polymer-solvent system (Flory interaction parameter) = 0.33 + 0.55qs−1

- Φ1 = Molar volume of the solvent = 136 cm3/mol

- = Specific volume of the polymer = 920 g/dm3

2.5. Wear Resistance

The wear resistances of the virgin, 5-XLPE and 7.5-XLPE materials were evaluated on a knee simulator against pristine (i.e., new) CoCr (ASTM F75) and OxZr [19] (ASTM F2384) femoral components. Per standard processing, the cast CoCr femorals were hot isostatic pressed (HIPed) followed by solution heat treating. In addition, testing was conducted with CoCr and OxZr femoral components that were subjected to a tumbling protocol to simulate the effects of microabrasion by third-body debris in vivo [20]. This protocol involved tumbling the femoral components in a centrifugal barrel mass-finisher for approximately 30 s in a 25 µm alumina powder and plastic cone media. These tumbled femoral components were then tested on a knee simulator against the various UHMWPE materials to evaluate the effect of the microabrasion on UHMWPE wear.

Genesis II™ (Smith and Nephew, Memphis, TN, USA) cruciate-retaining (CR) knee components (n = 3) were tested on a 6-station, displacement-controlled, knee simulator (AMTI, Watertown, MA, USA) and rotated weekly to minimize the effect of station variability. Unloaded soak controls (n = 3) were utilized to account for fluid uptake by the UHMWPE tibial inserts. The lubricant was alpha calf fraction (Hyclone Labs, Logan, UT) with 20 mM EDTA and 0.2% sodium azide, which was diluted to 50% with deionized water to achieve an average protein concentration of approximately 20 g/L. These tests were run for approximately 5 million cycles (Mc) each. The lubricant was replaced and the tibial inserts were weighed about every 0.5 Mc. The load/motion profiles were the “high kinematics” inputs described by Barnett et al. [21], which was based on a gait-lab study of young, healthy males by Lafortune [22]. In this study, the total A/P translation was 11 mm, which is slightly greater than that used by Barnett et al. The slope of the least squares best-fit line of cumulative volume loss vs. cycles was determined for each liner, averaged for each bearing combination and defined as the wear rate.

2.6. Roughness Measurements

Roughness measurements of the femoral components were made using a contact profilometer (Surfcom 1800D, Carl Zeiss, Brighton, MI, USA) with a 2 μm radius stylus tip, a 0.25 mm cut-off length and a 4.0 mm evaluation length. Roughness measurements (n = 10) were made systematically in the medial-lateral axis from 0° to 45° of flexion on each condyle of each femoral component before wear-simulator testing for both the pristine and tumbled components. Roughness was characterized using five parameters: Ra, the average surface displacement (of peaks and valleys) from the mean surface line; Rpm, the average peak height above the mean surface line; Rp, the maximum peak height above the mean surface line; Rpk, the average peak height above the mean surface line; and Rsk, the skewness, or asymmetry of the profile about the mean surface line.

2.7. Electron Spin Resonance

Evaluation of the residual free-radical concentrations in these materials was conducted to verify the effectiveness of the post-irradiation re-melting process in reducing the free radicals. Samples (n = 5) for electron spin resonance (ESR) with diameters of 3 mm and lengths of 10 mm were punched from the center of the rod stock for each material. A 7.5 Mrad gamma-irradiated material without any subsequent heat treatment was utilized as a positive control in this experiment.

The free-radical concentration (FRC) in each material was determined with an X-band ESR spectrometer (Bruker EMX300, University of Memphis) operating at a microwave frequency of approximately 9.8 GHz and employing a high-sensitivity universal X-band resonator cavity. ESR test parameters were constant for all measurements at 1 mW microwave power, 5 Gauss amplitude modulation, 200 G sweep width, 3500 center field, and a relatively high gain and Q-value. The absolute magnitude of the free-radical concentration was analyzed and computed with WinEPR analysis software. The area under the absorption curve of a test specimen was compared to that of the National Institute of Standards and Technology (NIST) intensity standard SRM-2601, and these results were normalized to the specimen’s weight.

2.8. Delamination Evaluation

A unidirectional, reciprocating pin-on-disk wear test was conducted to evaluate the susceptibility of the 7.5-XLPE material to delaminate under worst-case conditions. Virgin, unirradiated UHMWPE was used as a negative control in this test because delamination in virgin polyethylene has not been observed clinically. Samples that were gamma sterilized in air were used as a positive control due to the well-known history of in vivo delamination for that material [16]. Three replicate samples (n = 3) were evaluated per material treatment. Prior to delamination testing, these samples were subjected to accelerated aging according to ASTM F2003-02 for 21 days.

Delamination testing was conducted on a multidirectional pin-on-disk device (OrthoPOD, AMTI, Watertown, MA, USA) with CoCr pins articulating against UHMWPE disks. The CoCr pins were fabricated with a tip radius of 19.81 mm (0.78 in) and polished to a fine, mirror-like finish. A load of 444.8 N (100 lbf) was applied to each pin to produce an initial, maximum Herztian contact stress of 60.4 MPa, which is at the upper limit of contact stresses reported for TKA in vivo [23]. The stroke length was approximately 19 mm. These tests were conducted with reciprocating motion at a frequency of 1.24 Hz for a total of 3 million cycles in 100% alpha calf fraction serum (HyClone, Logan, UT, USA) that was changed at approximately every 500,000 cycles. At those times, the UHMWPE samples were rinsed and examined for signs of delamination with the naked eye. In the case of one gamma-air sample, delamination caused complete wear-through of the UHMWPE and resulted in the removal of this specific sample at less than 3 Mc.

Upon completion of 3 Mc, the samples were removed and any signs of delamination were noted. The samples were then sectioned along the long axis of the wear track, cut with a microtome to produce a relatively smooth cross-section, sputter-coated with gold, and examined with a scanning electron microscope (SEM) in secondary electron mode. Both the wear surface and the sub-surface were examined for any signs of cracking or delamination.

2.9. Statistical Analyses

Statistical analyses of the results were performed with Minitab 16 (Minitab, Inc., State College, PA, USA). The homogeneity of variances within the various data sets was evaluated with Levene’s test. If the variances were homogeneous, either the Student’s t-test with pooled variances or analysis of variance (ANOVA) with Tukey’s post hoc test was conducted to determine statistically significant differences in the properties. If the variances were not homogeneous, either the Student’s t-test with separate variances or Welch analysis of variance (ANOVA) with a Tukey’s post hoc test was conducted to determine statistically significant differences in the properties. The level of significance (α) was 0.05.

3. Results and Discussion

3.1. Mechanical and Physical Characterization

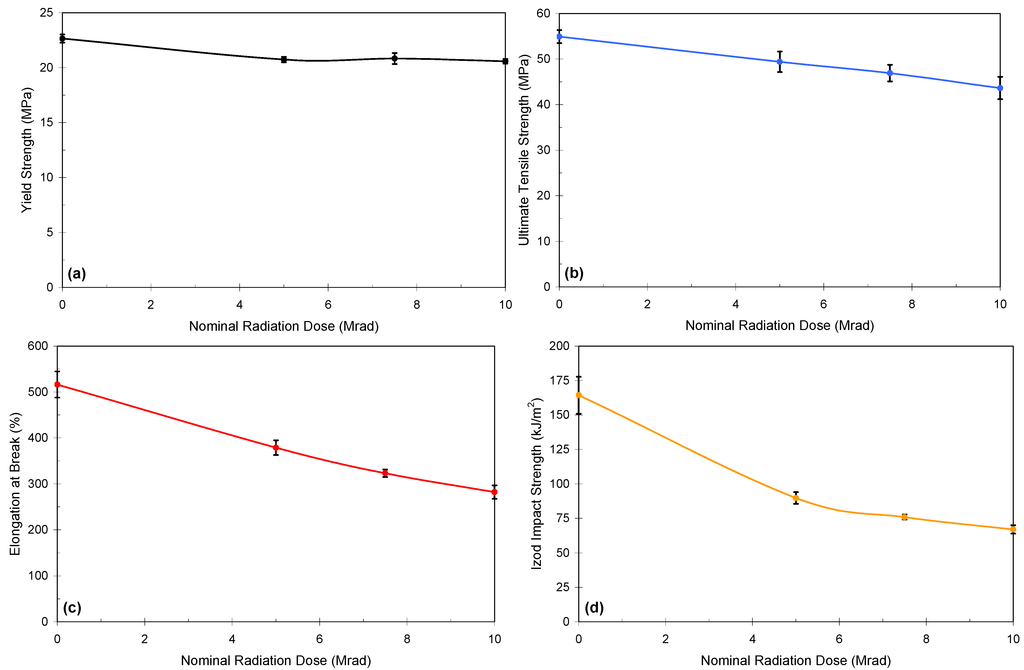

While the yield strength (YS) exhibited small, but significant decreases (p < 0.001) of approximately 8%–9% upon irradiation to any dose (Table 1), the ultimate tensile strength (UTS) and elongation at break decreased linearly with increasing radiation dose with statistically significant differences between each dose (Figure 1). Compared to virgin, the UTS decreased 10%–21% (p < 0.001) and elongation decreased 27%–45% (p < 0.001) depending upon the selected irradiation dose (Figure 1b,c). Likewise, the impact strength decreased approximately 45%–59% upon crosslinking with statistically significant differences (p < 0.001) between each dose (Figure 1d).

Table 1.

Summary of the mean (±standard deviations) properties evaluated in this study for compression-molded GUR1020 UHMWPE in the virgin and highly crosslinked, re-melted conditions.

| Material Property | Nominal Radiation Dose (Mrad) | |||

|---|---|---|---|---|

| 0.0 | 5.0 | 7.5 | 10.0 | |

| Yield Strength, YS (MPa) | 22.6 ± 0.4 | 20.7 ± 0.3 | 20.8 ± 0.5 | 20.6 ± 0.2 |

| Ultimate Tensile Strength, UTS (MPa) | 54.9 ± 1.4 | 49.4 ± 2.3 | 46.9 ± 1.8 | 43.6 ± 2.5 |

| Elongation at Break, EL (%) | 516 ± 29 | 379 ± 16 | 323 ± 8 | 282 ± 15 |

| Izod Impact Strength (kJ/m2) | 164 ± 13 | 90 ± 4 | 76 ± 2 | 67 ± 3 |

| Density (g/cm3) | 0.936 ± 0.001 | 0.932 ± 0.001 | 0.932 ± 0.001 | 0.932 ± 0.002 |

| Onset Melting Temperature, TOM (°C) | 125.9 ± 0.5 | 123.6 ± 0.4 | 122.2 ± 0.6 | 120.9 ± 1.0 |

| Peak Melting Temperature, TPM (°C) | 140.8 ± 0.6 | 139.8 ± 0.4 | 141.2 ± 0.7 | 141.6 ± 0.4 |

| Crystallinity (%) | 55.9 ± 0.8 | 50.6 ± 0.6 | 50.7 ± 1.2 | 50.7 ± 0.9 |

| Swell Ratio, q | 17.57 ± 0.26 | 3.57 ± 0.10 | 3.08 ± 0.10 | 2.82 ± 0.17 |

| Extract (%) | 18.5 ± 3.5 | -- | -- | -- |

| Crosslink Density, νd (mol/dm3) | 0.011 ± 0.003 | 0.151 ± 0.008 | 0.204 ± 0.024 | 0.237 ± 0.018 |

| Molecular Weight Between Crosslinks, Mc (103 g/mol) | 90.55 ± 16.39 | 6.11 ± 0.31 | 4.62 ± 0.54 | 3.94 ± 0.30 |

| Free-Radical Concentration, FRC (spins/g) | Not Detectable | Not Detectable | Not Detectable | Not Detectable |

| Maximum Oxidation Index, OImax | 0.02 ± 0.00 | 0.02 ± 0.01 | 0.01 ± 0.00 | -- |

Figure 1.

Plots of the (a) yield strength; (b) ultimate tensile strength; (c) elongation at break; and (d) Izod impact strength for GUR1020 UHMWPE irradiated with various gamma-radiation doses and subsequently re-melted.

3.2. Thermophysical Analysis

As demonstrated in Table 1, the TOM was found to decrease by up to 4% in the crosslinked materials compared to the virgin materials with statistically significant differences (p < 0.001) for virgin compared to 7.5-XLPE and 10-XLPE and for 5-XLPE compared to 10-XLPE. The TPM changed by ±1% or less in the crosslinked materials, relative to the virgin material, and some of these differences were statistically significant (p < 0.001). Finally, the %X decreased by approximately 10%, compared to virgin, upon irradiation to any of the irradiation doses examined in this study (p < 0.001).

3.3. Molecular Network Parameters

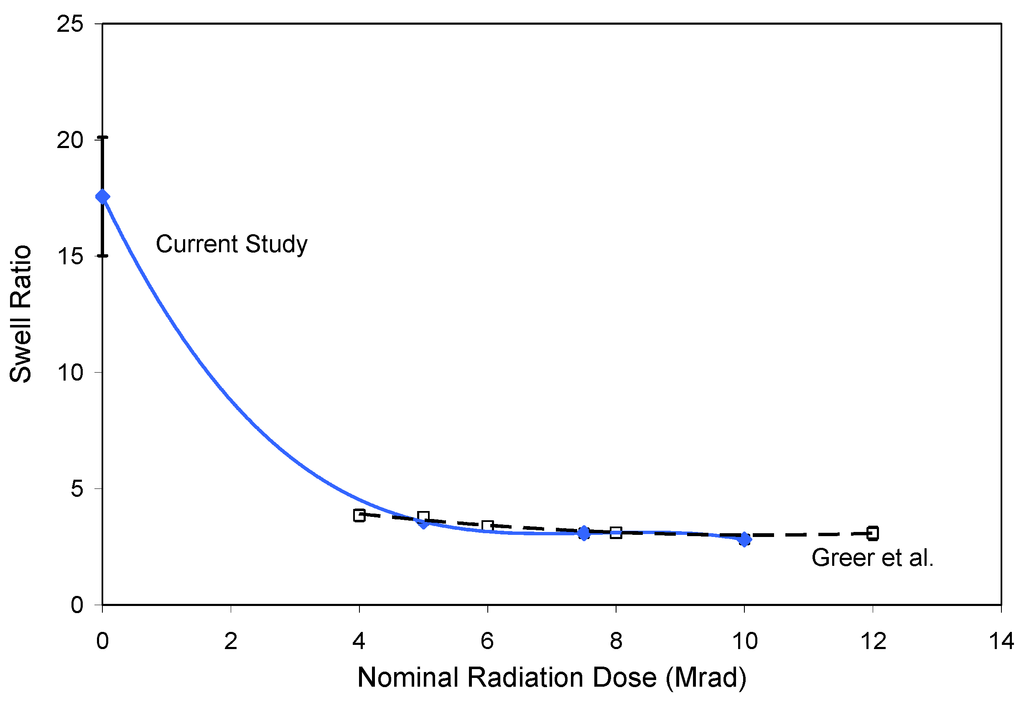

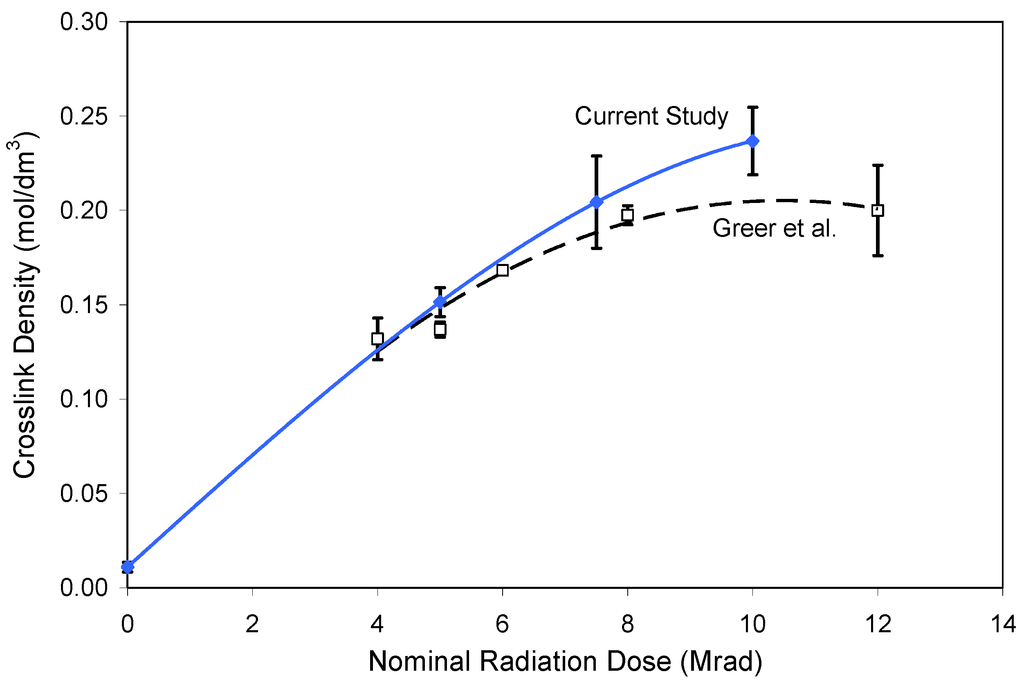

The mean swell ratio, percent extract, crosslink density, and molecular weight between crosslinks for the virgin and highly crosslinked materials are summarized in Table 1. The swell ratio (Figure 2) and molecular weight between crosslinks decreased with increasing radiation dose, and the crosslink density (Figure 3) increased with increasing radiation dose. The changes in all of these metrics were statistically significant (p < 0.001) as the dose increased to 7.5 Mrad. The differences in these metrics between the 7.5-XLPE and 10-XLPE materials was not significant at the levels evaluated in this study. Within the dose range examined, these values were similar to those reported by Greer and co-authors [24] as demonstrated in Figure 2 and Figure 3.

Figure 2.

Plot of swell ratio for compression-molded GUR1020 UHMWPE in the virgin state and gamma-irradiated to various doses and re-melted. The results reported by Greer et al. [24] are also plotted for comparison. The error bars represent the standard deviations.

Figure 3.

Plot of crosslink density for compression-molded GUR1020 UHMWPE in the virgin state and gamma-irradiated to various doses and re-melted. The results reported by Greer et al. [24] are also plotted for comparison. The error bars represent the standard deviations.

3.4. Roughness Measurements

The mean roughness parameters in the pristine conditions met the applicable quality specifications and standards for both femoral materials (Table 2 and Table 3). After the CoCr femoral components were subjected to the tumbling protocol, all of the roughness parameters evaluated in this study increased (p ≤ 0.016, Table 2). For the OxZr femorals (Table 3), all of the roughness parameters except for Ra (p = 0.062) and Rsk increased by statistically significant amounts (p ≤ 0.031) after tumbling. In contrast, Rsk decreased significantly (p < 0.001) after tumbling. Comparing the materials in the tumbled conditions, all of the roughness parameters were significantly higher for CoCr relative to OxZr (p < 0.001).

Table 2.

Summary of the mean (± standard deviations) roughness parameters for the CoCr femoral components in the pristine and roughened conditions. The levels of significance (p) for the differences between the pristine and roughened components are also reported.

| Roughness Parameter | Pristine CoCr | Roughened CoCr | p |

|---|---|---|---|

| Ra (µm) | 0.035 ± 0.004 | 0.077 ± 0.009 | <0.001 |

| Rpm (µm) | 0.140 ± 0.013 | 0.510 ± 0.057 | <0.001 |

| Rp (µm) | 0.216 ± 0.028 | 1.658 ± 0.160 | <0.001 |

| Rpk (µm) | 0.066 ± 0.008 | 0.253 ± 0.022 | <0.001 |

| Rsk | 0.618 ± 0.115 | 2.008 ± 1.363 | 0.016 |

Table 3.

Summary of the mean (± standard deviations) roughness parameters for the OxZr femoral components in the pristine and roughened conditions. The levels of significance (p) for the differences between the pristine and roughened components are also reported.

| Roughness Parameter | Pristine OxZr | Roughened OxZr | p |

|---|---|---|---|

| Ra (µm) | 0.044 ± 0.007 | 0.050 ± 0.002 | 0.062 |

| Rpm (µm) | 0.152 ± 0.027 | 0.179 ± 0.011 | 0.001 |

| Rp (µm) | 0.248 ± 0.088 | 0.397 ± 0.066 | 0.019 |

| Rpk (µm) | 0.052 ± 0.009 | 0.072 ± 0.006 | <0.001 |

| Rsk | −1.443 ± 0.683 | −2.801 ± 0.557 | <0.001 |

3.5. Wear Resistance

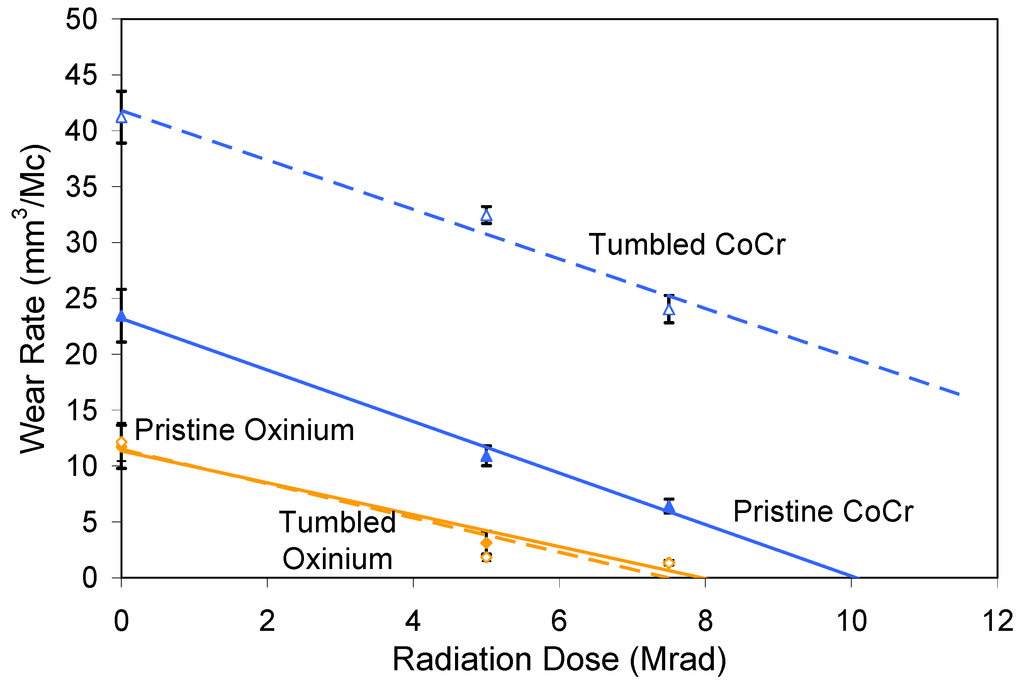

Wear testing of pristine CoCr femoral components against virgin and highly crosslinked UHMWPE tibial inserts reflected documented trends in the literature [14] in that the mean wear rate decreased significantly (p < 0.001) with each increase in the radiation dose examined in this study (Figure 4). The mean wear rates (± standard deviations) of the virgin, 5-XLPE, and 7.5-XLPE tibial inserts were 23.4 ± 2.4 mm3/Mc, 10.9 ± 0.9 mm3/Mc, and 6.4 ± 0.6 mm3/Mc, respectively. As a result, 5-XLPE produced a 53% reduction in wear while the use of 7.5-XLPE resulted in a 73% reduction in wear compared to virgin UHMWPE. Based on this trend with pristine CoCr femoral components, it is estimated that a nominal radiation dose of about 10 Mrad is necessary to produce a wear rate that is not measurable by the gravimetric technique.

Knee simulator wear testing of pristine OxZr femoral components against virgin, 5-XLPE, and 7.5-XLPE tibial inserts yielded wear rates of 11.7 ± 1.9 mm3/Mc, 3.1 ± 1.0 mm3/Mc, and 1.4 ± 0.2 mm3/Mc, respectively. As a result, 5-XLPE produced a 73% reduction in wear while the use of 7.5-XLPE resulted in an 88% reduction in wear compared to virgin UHMWPE against pristine OxZr femoral components. Statistical analysis demonstrated that the wear rates for the highly crosslinked materials were significantly lower than that of the virgin material (p < 0.001), but there was insufficient evidence of differences between the 5-XLPE and 7.5-XLPE at the levels tested in this study. This data suggests that an estimated, nominal radiation dose of about 8 Mrad is necessary to produce a wear rate that is not measurable by the gravimetric technique when paired with pristine OxZr (Figure 4). More importantly, pristine OxZr femoral components alone reduced wear by 50% to 79% (p ≤ 0.001) compared to pristine CoCr femoral components tested against the same UHMWPE materials.

Figure 4.

Plot of the mean wear rates (±standard deviations) in a knee simulator for UHMWPE crosslinked to various doses against either CoCr or OxZr femoral components in pristine (solid symbols and lines) and tumbled (open symbols and dashed lines) conditions. The regression lines have been extrapolated to radiation doses greater than 7.5 Mrad.

When the CoCr femoral components were tumbled to simulate in vivo microabrasion of the surfaces due to third-body debris, the wear rates for each material increased by statistically significant amounts (p ≤ 0.001) compared to those calculated against pristine CoCr femoral components (Figure 4). In these tests, the mean wear rates (± standard deviations) of virgin, 5-XLPE, and 7.5-XLPE tibial inserts were 41.2 ± 2.3 mm3/Mc, 32.5 ± 0.7 mm3/Mc, and 24.0 ± 1.2 mm3/Mc, respectively. This data demonstrates that, although the trend between radiation dose and wear rate is similar, the dramatic improvements in wear resistance for highly crosslinked materials are degraded by abrasion of the CoCr femoral components.

In contrast, no statistically significant changes in wear rates (p ≥ 0.113) were observed, relative to pristine OxZr, when each material was tested against OxZr femoral components that were exposed to the same microabrasive challenge (Figure 4). For these simulator tests, the mean wear rates (±standard deviations) of virgin, 5-XLPE, and 7.5-XLPE tibial inserts were 12.2 ± 1.7 mm3/Mc, 1.8 ± 0.4 mm3/Mc, and 1.3 ± 0.1 mm3/Mc, respectively. Under these microabrasive conditions, the wear rates against tumbled OxZr remained 49% to 83% lower (p ≤ 0.003) than the wear rates observed for pristine CoCr femoral components tested against the same UHMWPE materials.

3.6. Electron Spin Resonance

The virgin, 5-XLPE, 7.5-XLPE, and 10-XLPE specimens did not show detectable ESR signals, indicating that the free-radical concentration (Table 1) was below the sensitivity of the instrument, which is approximately 1 × 1013 spins/g. In contrast, the 7.5 Mrad irradiated, unannealed material (positive control) exhibited a high mean FRC (±SD) of 2.36 × 1016 ± 0.36 × 1016 spins/g, which is 3 orders of magnitude greater than the instrument sensitivity.

3.7. Delamination Study

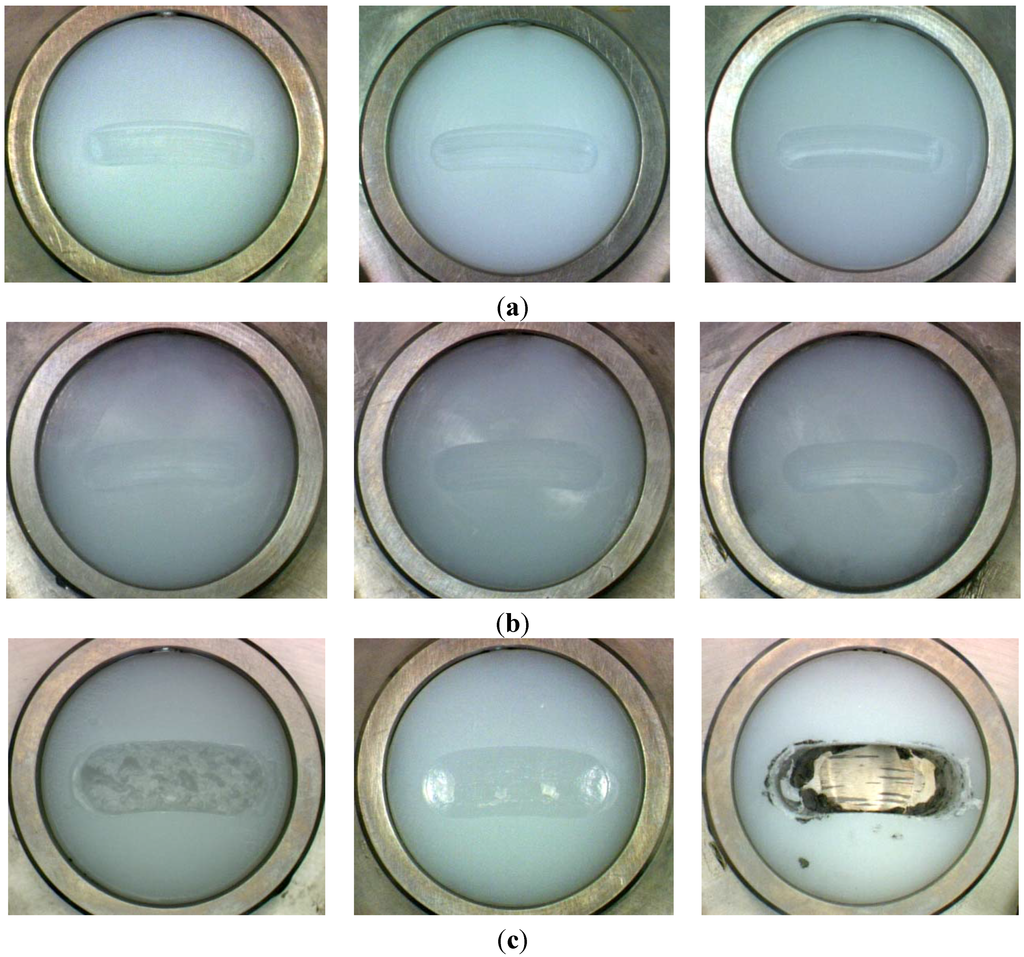

The virgin and highly crosslinked samples endured 3 Mc of testing without any evidence of cracking or delamination on the wear surfaces (Figure 5a,b) or on the longitudinal cross-sections of the wear tracks in the post-test examinations. In contrast, all of the gamma-air-sterilized samples (Figure 5c) exhibited the onset of delamination prior to the completion of the full 3 Mc test protocol.

Figure 5.

Photomacrographs of the (a) virgin; (b) 7.5-XLPE; and (c) gamma-air-sterilized samples after 3 million cycles of reciprocating pin-on-disk testing. Although wear tracks are visible on the virgin and 7.5-XLPE samples, no cracking or delamination was observed.

In this pin-on-disk study, the highly crosslinked UHMWPE materials did not exhibit a propensity for delamination under worst-case testing conditions. In addition, this particular test protocol was validated by the absence of delamination in the negative control and mild to extensive delamination in the positive controls, which replicated the damage observed in clinical retrievals. The resistance of highly crosslinked and re-melted UHMWPE to delamination has been similarly demonstrated by others in both pin-on-disk [25] and knee simulator testing [26].

4. Discussion

This study confirmed that increasing crosslink density (i.e., increasing the radiation dose) results in significant reductions in wear rates. This trend was independent of the femoral bearing material. When the femoral component was pristine CoCr alloy, the wear rate versus radiation dose trend suggests that a crosslink dose of 10 Mrad would result in wear rates that are not measurable by the gravimetric technique. This does not mean that the wear rate is zero, rather that the wear rate is low enough that gravimetric measurement errors cannot distinguish it from zero as has been previously reported for hip simulator testing on 10 Mrad irradiated and re-melted UHMWPE [27].

This study also confirmed that the ceramic bearing surface of oxidized zirconium resulted in greater reductions in wear of crosslinked UHMWPE than a pristine CoCr bearing surface. When the relationships between wear rate and radiation dose for pristine CoCr and ceramic oxidized zirconium are compared, it was found that oxidized zirconium was more effective in reducing the wear of UHMWPE at a given radiation dose. This finding was expected considering the widely documented advantage of ceramic bearing materials when tested against UHMWPE in both THA [28,29] and TKA [30,31,32]. Subsequent knee-simulator testing has demonstrated that the low wear provided by OxZr femorals paired with 7.5-XLPE tibial inserts is maintained for an unprecedented 45 Mc of simulator testing [33,34].

The factorial (or percent) differences in UHMWPE wear rates between CoCr and OxZr increase as the crosslinking dose increases; 50% for virgin UHMWPE and 79% for 7.5 Mrad UHMWPE. However, the absolute difference in wear rates between CoCr and OxZr diminishes as the crosslink dose increases; 11.7 mm3/Mc for virgin vs. 5 mm3/Mc for 7.5 Mrad UHMWPE. The ramification of these trends is that a lower crosslinking dose can be used with OxZr than with CoCr to achieve a given wear reduction. For instance, in order to achieve a wear rate of approximately 3 mm3/Mc, one would need to use a crosslinking dose of about 6 Mrad with OxZr vs. approximately 9 Mrad with CoCr. This additional 3 Mrad of radiation has consequences to the mechanical and structural properties of UHMWPE, as will be discussed later.

The discussion thus far has focused on knee simulator wear testing of femoral components in the pristine condition. When the femoral components were subjected to a microabrasive tumbling protocol, as expected the metallic, CoCr surfaces roughen to a greater extent than the harder [35], ceramic surfaces of OxZr. After tumbling, the roughness metrics measured on the CoCr components were well within the range reported previously for clinical retrievals [36]. Because the ceramic surface of OxZr is twice as hard as CoCr (12.1 GPa and 5.5 GPa, respectively, based on nanoindentation per the Oliver-Pharr method [35]), it was expected to roughen to a lesser degree than CoCr. However, the finding that the wear rates of UHMWPE against OxZr were unaffected by the tumbling protocol was unexpected, because OxZr did, indeed, exhibit increases in the roughness parameters. Understanding this observation requires a more detailed review of the roughness data.

The tumbling of CoCr and OxZr resulted in increases in the average surface roughness (Ra) for both materials. However, the increase in Ra was greater for CoCr (+122%, p < 0.001) than for OxZr (+12%, p = 0.062) relative to the respective pristine materials. Similar trends were observed for Rp, Rpm, and Rpk. The surface skewness (Rsk) exhibited a different behavior and illustrates the primary difference between metallic and ceramic counterfaces. CoCr femorals almost always exhibited positive values of Rsk, which means that there were more peaks than valleys on the bearing surface. After the CoCr femorals were subjected to the tumbling protocol, the scratches resulted in a greater quantity of larger peaks due to pile-up on the sides of the scratches, and the Rsk generally increased to greater positive values (+225%, p = 0.016). In contrast, the OxZr femorals always exhibited negative values of Rsk, which means that there are more valleys than peaks. After the tumbling protocol, Rsk decreased (−94%, p < 0.001) to more negative values due to scratching of the surface (i.e., valleys) with little pile-up (i.e., peaks), which is characteristic of ceramic bearing surfaces [37].

The wear rates of each of the UHMWPE formulations increased when CoCr was roughened compared to the corresponding wear rates under pristine conditions. During articulation of these components, the hard peaks on the CoCr femorals plow into the softer UHMWPE tibial inserts and generate greater amounts of wear. When UHMWPE was tested against OxZr subjected to the same microabrasive challenge, the resulting knee simulator wear rates were not elevated compared to the corresponding wear rates under pristine conditions. This lack of increase in wear after tumbling is primarily due to the smoother counterface with negative skewness. In other words, the tumbled OxZr femorals do not have many peaks that can plow into the UHMWPE tibial inserts and generate wear debris. As a result, wear does not increase even after a microabrasive challenge.

When these tumbled components were tested in a knee simulator against virgin and the various formulations of highly crosslinked UHMWPEs, the trends in wear rates were similar to those noted above for pristine femoral components. Increasing the crosslink dose resulted in improved wear resistance against both femoral materials. However, the wear rates increased when CoCr was abraded, while they did not change when OxZr was tumbled. If one wanted to achieve a wear rate of approximately 3 mm3/Mc with tumbled OxZr as the counter bearing surface, a crosslink dose of about 6 Mrad would be required. To achieve that same 3 mm3/Mc wear rate with abraded CoCr as the counter bearing surface, a predicted crosslink dose of approximately 18 Mrad would be required. Such a high crosslink dose is unlikely to be useful clinically because of the attendant loss of mechanical properties.

The wear-test results discussed above have highlighted the following trends: (1) the wear rates decrease with increasing radiation dose (crosslink density); (2) this trend is similar for both of the femoral bearing materials evaluated; (3) this trend is independent of the surface roughness of the counter bearing surface; (4) ceramic bearing surfaces result in lower UHMWPE wear rates than CoCr alloy bearing surfaces independent of the crosslinking dose; (5) wear rates of all formulations of UHMWPE increase markedly when CoCr counter bearing surfaces are abraded; and (6) wear rates of all formulations of UHMWPE are unaffected when OxZr ceramic counter bearing surfaces are subjected to a microabrasive challenge.

This study also confirmed previous studies [24,38,39] that showed that mechanical properties are affected by radiation crosslinking, particularly ultimate tensile strength (UTS), elongation at break, and impact strength. It stands to reason that the mechanically strongest material would be the ideal choice for use in orthopaedic implants. However, the mechanically strongest material (virgin, non-crosslinked UHMWPE) is also the least resistant to wear. Therefore, a balance between wear resistance and mechanical properties needs to be achieved and should also take into account the design of the orthopaedic implant. As discussed above, the ability to use a ceramic counter bearing surface affords greater reduction in wear rates with a given level of crosslinking as compared to CoCr surfaces. This study demonstrated that ceramic surfaces provide reductions in wear that are equivalent to an additional 3–5 Mrad crosslinking dose compared to pristine CoCr. When CoCr is roughened, this advantage of ceramics is elevated by an estimated 12 Mrad of crosslinking dose.

The crosslinked UHMWPE materials tested in this study were all re-melted after irradiation, and did not undergo any further irradiation. Because of this thermal treatment, all crosslinked formulations were found to have no measurable free radicals, which improves the resistance to oxidation [40]. However, it should be noted that UHMWPE that is prone to oxidation is also prone to in vivo degradation, particularly subsurface delamination wear [16]. This study confirmed that virgin (non-irradiated) and crosslinked, re-melted UHMWPEs are resistant to delamination wear after accelerated aging. Under identical conditions, the UHMWPE material that was irradiated in air, and subsequently aged showed copious delamination as has been documented clinically.

In summary, this study confirmed that crosslinking of UHMWPE for improved wear resistance comes at the expense of reduced mechanical properties. For applications in TKA, a majority of the research to-date has focused on striking the right balance between wear resistance and mechanical properties through selection of the irradiation dose alone. This study, however, showed that the counter bearing surface can have a profound effect on the wear rates of UHMWPEs. Compared to CoCr, the ceramic surface of OxZr allows the use of a lower irradiation dose to achieve equivalent reductions in wear rates. As a result, a given wear rate can be achieved without sacrificing the mechanical properties to the same extent that is necessary if a CoCr femoral component is used. The advantage of ceramic counter bearing surfaces extends to both pristine and microabrasive conditions.

5. Conclusions

This study confirmed that the wear resistance of crosslinked UHMWPE in TKA improves with increasing irradiation dose. However, along with this advantage is the concomitant reduction in key mechanical properties in highly crosslinked UHMWPE. When CoCr is used as the counter bearing surface, the appropriate balance between the wear resistance and the mechanical properties of crosslinked UHMWPE can be controlled only by the choice of the irradiation dose within a narrow range. On the other hand, when a ceramic counter bearing surface (e.g., oxidized zirconium) is used in the bearing couple under ideal, pristine conditions, the resultant improvement in wear resistance is equivalent to an additional 3–5 Mrad of radiation without sacrificing additional UHMWPE mechanical properties. This improvement in wear resistance is expanded even further to the equivalent of an approximate dose of 12 Mrad under microabrasive conditions.

The oxidized zirconium ceramic bearing surface articulating against UHMWPE crosslinked to a dose of 7.5 Mrad can provide a wear resistance that is similar to pristine CoCr articulating against approximately 10 Mrad crosslinked UHMWPE. If microabrasion of the CoCr femoral occurs in vivo, this difference in wear resistance grows even greater. Furthermore, the mechanical properties of the UHMWPE are preserved due to the lower irradiation dose that is necessary to achieve a given wear rate against oxidized zirconium.

Finally, re-melting of the radiation crosslinked UHMWPE results in elimination of all measurable free radicals and imparts oxidative stability to the material and attendant resistance to delamination wear.

Acknowledgments

Gary Hines and Carolyn Weaver are gratefully acknowledged for their assistance in this study.

Author Contributions

Mark Morrison, Shilesh Jani and Amit Parikh conceived and designed the experiments; Mark Morrison and Amit Parikh performed the experiments and analyzed the data; Mark Morrison, Shilesh Jani and Amit Parikh wrote the paper.

Conflicts of Interest

All of the authors were employees of Smith and Nephew at the time of this study.

References

- Australian Orthopaedic Association National Joint Replacement Registry. Annual Report; Australian Orthopaedic Association: Adelaide, Australia, 2014. [Google Scholar]

- Archibeck, M.J.; Jacobs, J.J.; Roebuck, K.A.; Glant, T.T. The basic science of periprosthetic osteolysis. J. Bone Jt. Surg. Am. 2001, 82, 1478–1489. [Google Scholar]

- Harris, W.H. Wear and periprosthetic osteolysis: The problem. Clin. Orthop. Relat. Res. 2001, 393, 66–70. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.K.; Chu, A.; Ranawat, A.S.; Slamin, J.; Ranawat, C.S. Review article: Osteolysis after total knee arthroplasty. J. Arthroplast. 2007, 22, 787–799. [Google Scholar] [CrossRef] [PubMed]

- D’Apuzzo, M.R.; Hernandez-Polo, V.H.; Sierra, R.J. National Trends in Primary Total Knee Arthroplasty: A Population-Based Study; American Academy of Orthopaedic Surgeons: New Orleans, LA, USA, 2010; p. 681. [Google Scholar]

- Dahl, A.W.; Robertsson, O.; Lidgren, L. Surgical Treatment for Knee OA in Younger Patients; American Academy of Orthopaedic Surgeons: New Orleans, LA, USA, 2010; p. 126. [Google Scholar]

- Crowninshield, R.D.; Rosenberg, A.G.; Sporer, S.M. Changing demographics of patients with total joint replacement. Clin. Orthop. Relat. Res. 2006, 443, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Ong, K. Contemporary total hip arthroplasty: Hard-on-hard bearings and highly crosslinked UHMWPE. In UHMWPE Biomaterials Handbook, 2nd ed.; Kurtz, S.M., Ed.; Academic Press: Burlington, MA, USA, 2009; pp. 55–79. [Google Scholar]

- Epinette, J.A.; Manley, M.T. No differences found in bearing related hip survivorship at 10–12 years follow-up between patients with ceramic on highly cross-linked polyethylene bearings compared to patients with ceramic on ceramic bearings. J. Arthroplast. 2014, 29, 1369–1372. [Google Scholar] [CrossRef] [PubMed]

- Glyn-Jones, S.; Thomas, G.E.R.; Garfjeld-Roberts, P.; Gundle, R.; Taylor, A.; McLardy-Smith, P.; Murray, D.W. The John Charnley award: Highly crosslinked polyethylene in total hip arthroplasty decreases long-term wear: A double-blind randomized trial. Clin. Orthop. Relat. Res. 2015, 473, 432–438. [Google Scholar] [CrossRef] [PubMed]

- Engh, C.A., Jr.; Hopper, R.H., Jr.; Huynh, C.; Ho, H.; Sritulanondha, S.; Engh, C.A., Sr. A prospective, randomized study of cross-linked and non–cross-linked polyethylene for total hip arthroplasty at 10-year follow-up. J. Arthroplast. 2012, 27, 2–7. [Google Scholar] [CrossRef] [PubMed]

- Sharkey, P.F.; Hozack, W.J.; Rothman, R.H.; Shastri, S.; Jacoby, S.M. Insall award paper. Why are total knee arthroplasties failing today? Clin. Orthop. Relat. Res. 2002, 404, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Sharkey, P.F.; Lichstein, P.M.; Shen, C.; Tokarski, A.T.; Parvizi, J. Why are total knee arthroplasties failing today—Has anything changed after 10 years? J. Arthroplast. 2014, 29, 1774–1778. [Google Scholar] [CrossRef] [PubMed]

- Asano, T.; Akagi, M.; Clarke, I.C.; Masuda, S.; Ishii, T.; Nakamura, T. Dose effects of cross-linking polyethylene for total knee arthroplasty on wear performance and mechanical properties. J. Biomed. Mater. Res. B 2007, 83, 615–622. [Google Scholar] [CrossRef] [PubMed]

- Muratoglu, O.K.; Merrill, E.W.; Bragdon, C.R.; O’Connor, D.; Hoeffel, D.; Burroughs, B.; Jasty, M.; Harris, W.H. Effect of radiation, heat, and aging on in vitro wear resistance of polyethylene. Clin. Orthop. Relat. Res. 2003, 417, 253–262. [Google Scholar] [PubMed]

- Williams, I.R.; Mayor, M.B.; Collier, J.P. The impact of sterilization method on wear in knee arthroplasty. Clin. Orthop. Relat. Res. 1998, 356, 170–180. [Google Scholar] [CrossRef] [PubMed]

- Goldman, M.; Lee, M.; Pruitt, L.; Gronsky, R. A Comparison of Sterilization Techniques on the Structure and Morphology of Medical Grade UHMWPE; Society for Biomaterials: Toronto, ON, Canada, 1996; p. 189. [Google Scholar]

- Terrill, L.; Liao, C.W.; Lin, S.; DeAzevedo, M.; Sun, D.C. Effects of Anisotropy in UHMWPE on Crosslinked Density Testing; Orthopaedic Research Society: San Francisco, CA, USA, 2008; p. 1674. [Google Scholar]

- Sheth, N.P.; Lementowski, P.; Hunter, G.; Garino, J.P. Clinical applications of oxidized zirconium. J. Surg. Orthop. Adv. 2008, 17, 17–26. [Google Scholar] [PubMed]

- Widding, K.; Hines, G.; Hunter, G.; Salehi, A. Knee Simulator Protocol for Testing of Oxidized Zirconium and Cobalt Chrome Femoral Components under Abrasive Conditions; Orthopaedic Research Society: Dallas, TX, USA, 2002; p. 1009. [Google Scholar]

- Barnett, P.I.; Fisher, J.; Auger, D.D.; Stone, M.H.; Ingham, E. Comparison of wear in a total knee replacement under different kinematic conditions. J. Mater. Sci. Mater. Med. 2001, 12, 1039–1042. [Google Scholar] [CrossRef] [PubMed]

- Lafortune, M.A.; Cavanagh, P.R.; Sommer, H.J., III; Kalenak, A. Three-dimensional kinematics of the human knee during walking. J. Biomech. 1992, 25, 347–357. [Google Scholar] [CrossRef]

- Bartel, D.L.; Rawlinson, J.J.; Burstein, A.H.; Ranawat, C.S.; Flynn, W.F., Jr. Stresses in polyethylene components of contemporary total knee replacements. Clin. Orthop. Relat. Res. 1995, 317, 76–82. [Google Scholar] [PubMed]

- Greer, K.W.; King, R.S.; Chan, F.W. The effects of raw material, irradiation dose, and irradiation source on crosslinking of UHMWPE. In Crosslinked and Thermally Treated Ultra-High Molecular Weight Polyethylene for Joint Replacements, ASTM STP 1445; Kurtz, S.M., Gsell, R., Martell, J., Eds.; ASTM International: West Conshohocken, PA, USA, 2003; pp. 209–220. [Google Scholar]

- Burroughs, B.; Muratoglu, O.K.; O’Connor, D.O.; Bragdon, C.R.; Harris, W.H. Development of a Pitting/Delamination Pin on Disc Wear Model to Simulate the Failure Modes Often Seen in UHMWPE Tibial Knee Inserts; Orthopaedic Research Society: Orlando, FL, USA, 2000; p. 0552. [Google Scholar]

- Deluzio, K.J.; Muratoglu, O.K.; O’Connor, D.O.; Bragdon, C.R.; O’Flynn, H.; Rubash, H.; Jasty, M.; Wyss, U.P.; Harris, W.H. Development of an in vitro Knee Delamination Model in a Knee Simulator with Physiologic Load and Motion; World Biomater Cong: Kamuela, HI, USA, 2000; p. 842. [Google Scholar]

- Good, V.; Ries, M.; Barrack, R.L.; Widding, K.; Hunter, G.; Heuer, D. Reduced wear with oxidized zirconium femoral heads. J. Bone Jt. Surg. Am. 2003, 85A, 105–110. [Google Scholar]

- Dahl, J.; Nivbrant, B.; Soderlund, P.; Nordsletten, L.; Rohrl, S.M. Less wear with aluminumoxide heads against conventional polyethylene—A 10 year follow-up radiostereometry (RSA). J. Bone Jt. Surg. Br. 2010, 92, 392–397. [Google Scholar]

- Wroblewski, B.M.; Siney, P.D.; Dowson, D.; Collins, S.N. Prospective clinical and joint simulator studies of a new total hip arthroplasty using alumina ceramic heads and cross-linked polyethylene cups. J. Bone Jt. Surg. Br. 1996, 78, 280–285. [Google Scholar]

- Kaddick, C.; Streicher, R. Ceramic total knee replacements: Do they produce less wear? Bone Jt. J. 2013, 95, 94–97. [Google Scholar]

- Oonishi, H.; Ueno, M.; Kim, S.C.; Oonishi, H.; Iwamoto, M.; Kyomoto, M. Ceramic vs. cobalt-chrome femoral components; wear of polyethylene insert in total knee prosthesis. J. Arthroplast. 2009, 24, 374–382. [Google Scholar] [CrossRef] [PubMed]

- Zietz, C.; Bergschmidt, P.; Lange, R.; Mittelmeier, W.; Bader, R. Third-body abrasive wear of tibial polyethylene inserts combined with metallic and ceramic femoral components in a knee simulator study. Int. J. Artif. Org. 2013, 36, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Papannagari, R.; Hines, G.; Sprague, J.; Morrison, M. Long-Term Wear Performance of an Advanced Bearing Knee Technology; ISTA: Dubai, UAE, 2010; pp. A12–A13. [Google Scholar]

- Papannagari, R.; Hines, G.; Morrison, M.; Sprague, J. Long-Term Wear Performance of an Advanced Bearing Technology for TKA; Orthopaedic Research Society: Long Beach, CA, USA, 2011; p. 1141. [Google Scholar]

- Long, M.; Riester, L.; Hunter, G. Nano-Hardness Measurements of Oxidized Zr-2.5Nb and Various Orthopaedic Materials; Society Biomater: San Diego, CA, USA, 1998; p. 528. [Google Scholar]

- Levesque, M.; Livingston, B.J.; Jones, W.M.; Spector, M. Scratches on Condyles in Normal Functioning Total Knee Arthroplasty; Orthopaedic Research Society: New Orleans, LA, USA, 1998; pp. 241–247. [Google Scholar]

- Cooper, J.R.; Dowson, D.; Fisher, J.; Jobbins, B. Ceramic bearing surfaces in total artificial joints: Resistance to third body wear damage from bone cement particles. J. Med. Eng. Technol. 1991, 15, 63–67. [Google Scholar] [CrossRef] [PubMed]

- Pruitt, L.A. Deformation, yielding, fracture and fatigue behavior of conventional and highly cross-linked ultra high molecular weight polyethylene. Biomaterials 2005, 26, 905–915. [Google Scholar] [CrossRef] [PubMed]

- Oral, E.; Malhi, A.S.; Muratoglu, O.K. Mechanisms of decrease in fatigue crack propagation resistance in irradiated and melted UHMWPE. Biomaterials 2006, 27, 917–925. [Google Scholar] [CrossRef] [PubMed]

- Muratoglu, O.K. Highly crosslinked and melted UHMWPE. In UHMWPE Biomaterials Handbook, 2nd ed.; Kurtz, S.M., Ed.; Academic Press: Burlington, MA, USA, 2009; pp. 197–204. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).