1. Introduction

Nowadays, environmental issues are of great importance. Current lubricants are formulated from mineral oil and frequently different types of additives are used that are not environmentally friendly [

1], and their production process produces some environmentally hazardous chemical components. Therefore, the scientific world is now looking for alternative lubricants that are more environmentally friendly. Some bio-based lubricants have attracted attention due to their good friction and wear characteristics. On the other side, ecotribology deals with energy consumption minimization as well as environmental effects of the specific lubricant that will be used to minimize energy consumption [

2]. Additives in commercial lube oils contain sulfur and phosphorous-based components, which are dangerous to the environment.

Therefore, research has been done in order to produce mixed molybdenum-based sulfur-free and phosphorus-free additives for use in a commercial lubricant [

3].

There has been an enormous amount of research conducted on using vegetable oil as a lubricant [

4,

5,

6,

7]. Vegetable oil has a positive impact in use as a lubricant and has high viscosity index, a high flash point, high biodegradability, and a reduced friction coefficient.

In addition, the fluctuations and uncertainty in the crude oil market, increasing crude oil prices, and issues related to environment make bio-based lubricants more valuable. However, vegetable oil has some drawbacks, such as low oxidation stability, low thermal stability, and a comparatively high wear rate. Bowden and Tabor [

8] stated that the wear rate is high due to chemical attack on the surface by the fatty acids present in bio-based lubricants. Biodegradability is the main concern in ecotribology, because 40% of the lubricant can be lost to the environment [

9].

Various techniques have been carried out to overcome the potential problems produced by vegetable oil, such as blending with other diluents such as polyalphaolefin [

10,

11] and oleates; chemical modification such as esterification and transesterification [

5].

While the problem of torque measurement has been extensively examined in the case of hydrodynamic bearings [

12,

13,

14] the case of journal bearings using biolubricants has not been yet covered. Furthermore less work has been done in the use of environmental lubricants in the tribology of machine elements and few are the comparisons between the mineral, synthetic and bio-based lubricants.

The experimental work presented here is divided into three sections. In the pretest section, a comparison of bulk properties such as density and viscosity of different lubricant base oils is presented. In the tribological test section, the performance of these lubricants was evaluated in a journal bearing apparatus at 21 °C–32 °C. In the last section, the main conclusions are summarized and discussed.

2. Experimental Setup

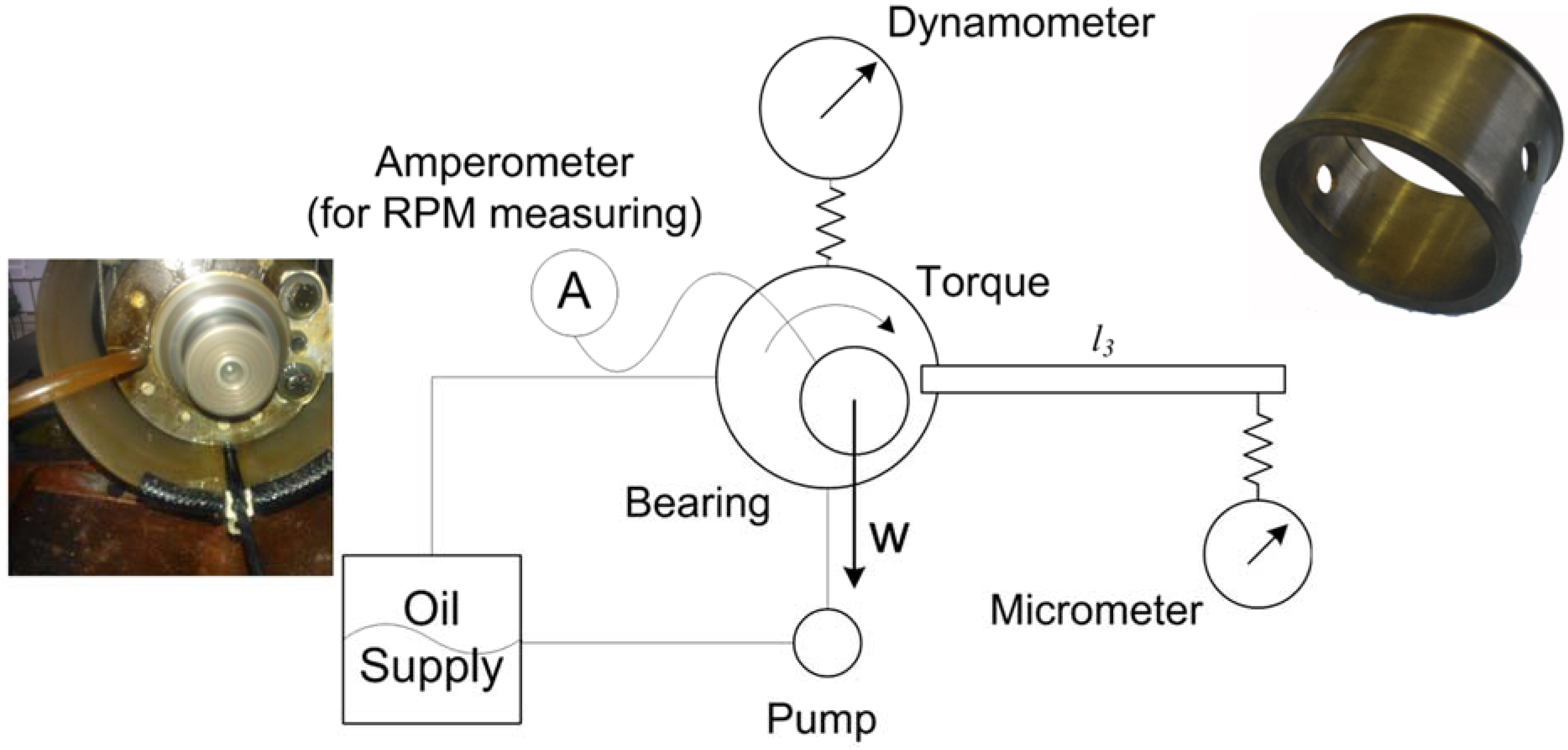

A journal bearing system (see

Figure 1), with rotor and bearing diameters

D = 52.9 mm and

D = 53.1 mm respectively and radial clearance

C = 150 μm was used in order to test the prepared mixture. The bearing length was 30 mm. The rotor could be rotated from 0 to 2590 rounds per minute (rpm) driven by a 5 hp AC electric motor with mechanically variable belt transmission. The lubricants are pumped to the journal bearing by a gear oil pump. The bearing is made of bronze and is loaded with a static load (

W) using the mechanism shown in

Figure 1.

Figure 1.

The experimental setup.

Figure 1.

The experimental setup.

For the purposes of the experiments three different lubricants were used. One AWS 100 biolubricant, an SAE-10W40 synthetic oil and an SAE-30 lubricant. The temperatures of operation in all cases were between 32 °C and 21 °C. The properties of the lubricants used are listed in

Table 1.

The biolubricant complies with DIN 51524 part 2 and 3, while the SAE-10W40 complies with API SL/CF, ACEA A3-02B, B4-04, B3-03.

Table 1.

The properties of the lubricants used in the experiments.

Table 1.

The properties of the lubricants used in the experiments.

| Properties | AWS-100 | SAE-10W40 | SAE-30 |

|---|

| Density (kg/m3) @40 C | 850 | 865 | 878 |

| Viscosity (Pa s) @40 C | 0.085 | 0.079 | 0.075 |

| Flash Point (°C) | 220 | 230 | 229 |

4. Measurements

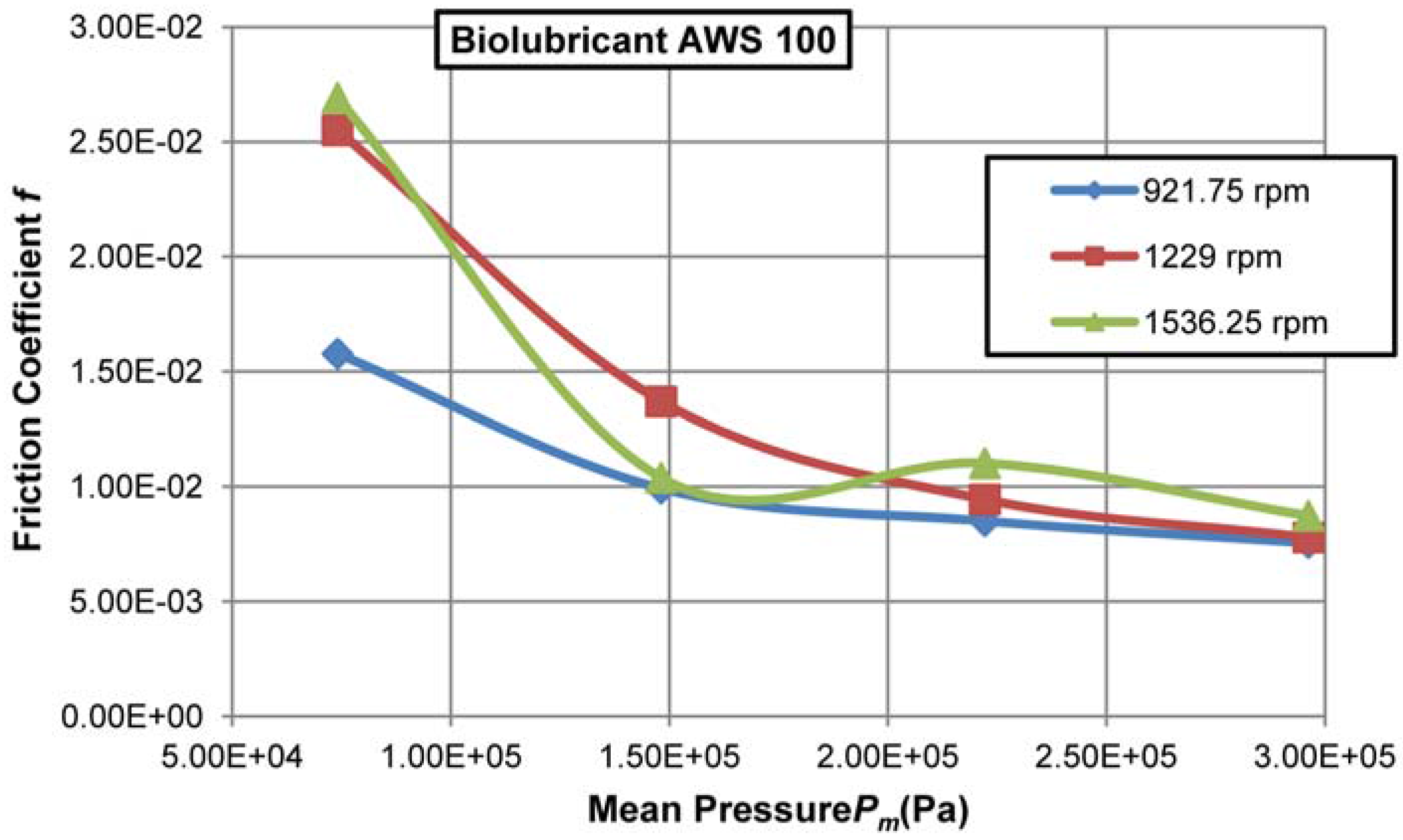

The results of the experiments for the friction coefficient as a function of the developed pressure in the bearing shows significant differences between the three lubricants used in these experiments. The friction produced when the biolubricant is used is shown in

Figure 2 as a function of the mean pressure on the bearing.

Figure 2.

The friction coefficient as a function of mean pressure on the bearing in the biolubricant case for 921, 1229 and 1536 rpm.

Figure 2.

The friction coefficient as a function of mean pressure on the bearing in the biolubricant case for 921, 1229 and 1536 rpm.

It is evident that the friction coefficient drops at higher values of mean pressure, i.e., in higher loads. Considering the effect of the rotational velocity on the produced friction, the three cases examined show some differentiation especially between 921 and 1229 rpm. The most effective case is found at 921 rpm with the maximum applied load on the bearing. The role of the journal velocity is more pronounced in lower loads where an increase of 41% is observed in the higher speed setting.

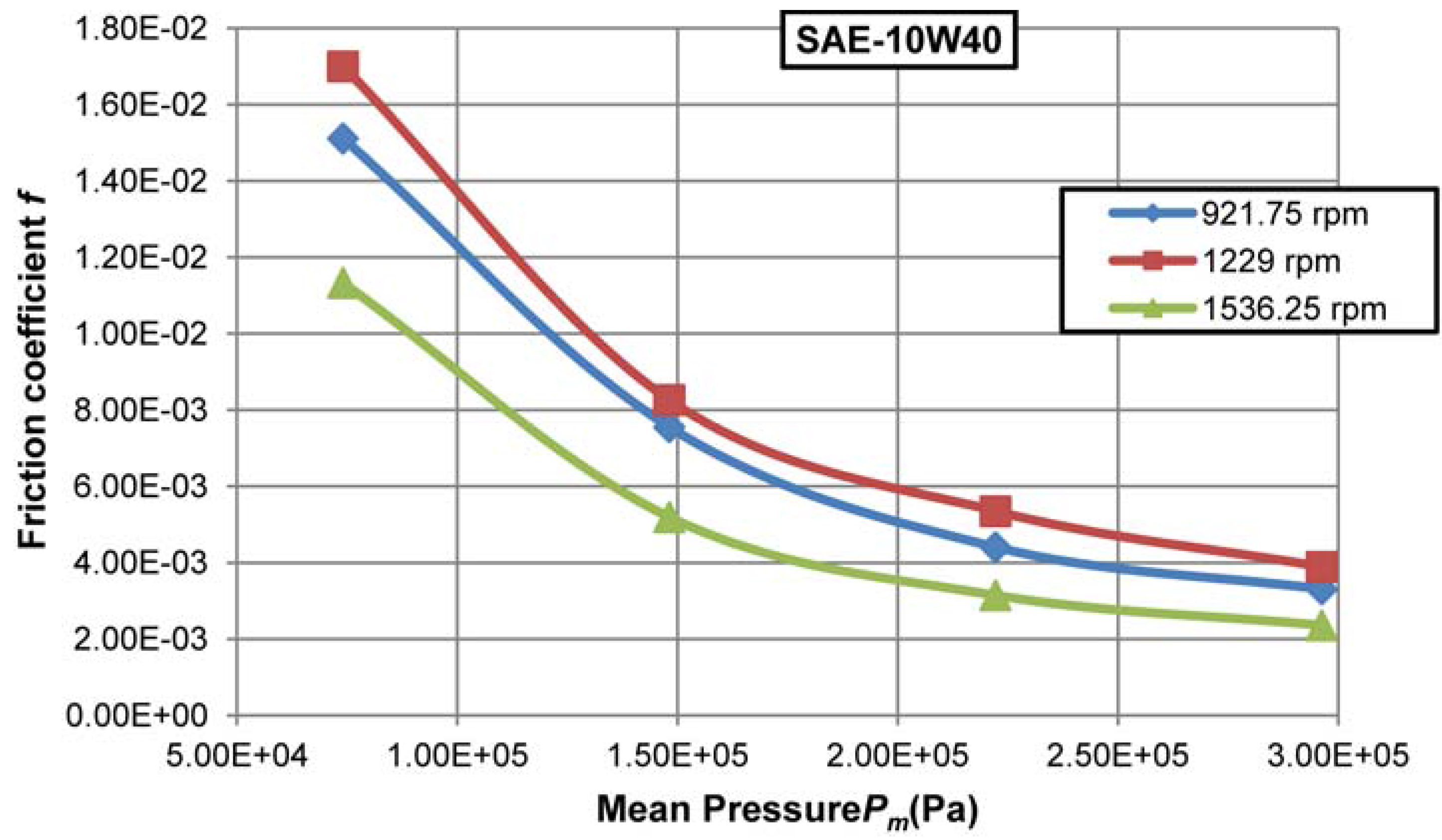

In the case of the SAE-10W40 there is improvement of the measured friction coefficient as shown in

Figure 3. The most pronounced difference between the three cases of rotational velocity values is seen between the 1536 and 1229 rpm. In the latter case the friction coefficient is increased. This observation can be attributed to the role of additives in this specific lubricant as well as the specific geometrical conditions of the bearing. The most pronounced difference is found at the lower load region. The change of viscosity under the influence of temperature is the most probable cause of changes in the behavior of the lubricant. The temperature was monitored and did not exhibit significant rise in the duration of the experiment with a maximum value of 32 °C. Also, some artifact points due to false reading in the measurements procedure could appear. Laboratory experimentation remains the only practical method available for the accurate identification of friction coefficients for arbitrary material pairs. However, accurate and repeatable friction coefficient measurement remains challenging due to the dependence of friction coefficients on the material, surface, environment, and measuring equipment. When reporting friction coefficients, as with any measured quantity, it is also necessary to provide a quantitative statement regarding the quality of the reported value so that those who need to use the data can have an indication of its reliability. The dispersion of values that could reasonably be attributed to the measurement uncertainty [

15] can be calculated as follows:

where

is the combined standard uncertainty of output estimate,

is the estimated variance associated with input estimate

xi that estimates input quantity

,

is the estimated covariance associated with two input estimates

xi and

that estimate input quantities

,

and

is the partial derivative with respect to input quantity

of functional relationship

f between measurement

y and input quantities

on which

y depends.

Figure 3.

The friction coefficient as a function of mean pressure on the bearing in the case of synthetic oil SAE-10W40 for 921, 1229 and 1536 rpm.

Figure 3.

The friction coefficient as a function of mean pressure on the bearing in the case of synthetic oil SAE-10W40 for 921, 1229 and 1536 rpm.

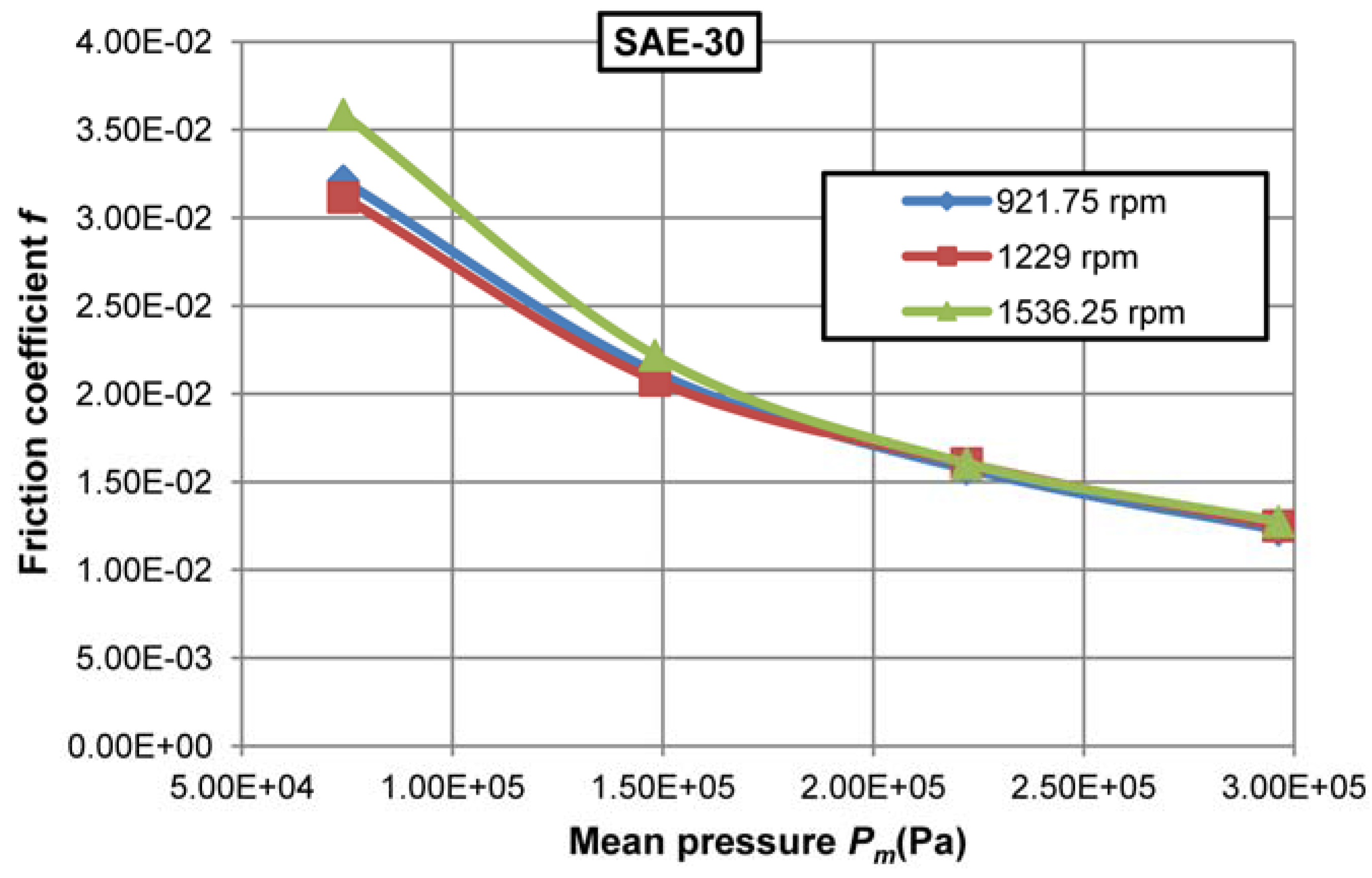

In

Figure 4 the friction coefficient behavior for different loads on the bearing is depicted in the case of the SAE-30 lubricant. The main effect of rotational velocity on the friction coefficient is less pronounced in this case. The best performance is achieved in the higher load region where the friction coefficient is identical for the three cases of rotational velocity examined. The effect of the rotational velocity is seen in the case of lower load where a difference of 15% is observed between the cases of 1229 and 1536 rpm.

Figure 4.

The friction coefficient as a function of mean pressure on the bearing in the case of SAE-30 for 921, 1229 and 1536 rpm.

Figure 4.

The friction coefficient as a function of mean pressure on the bearing in the case of SAE-30 for 921, 1229 and 1536 rpm.

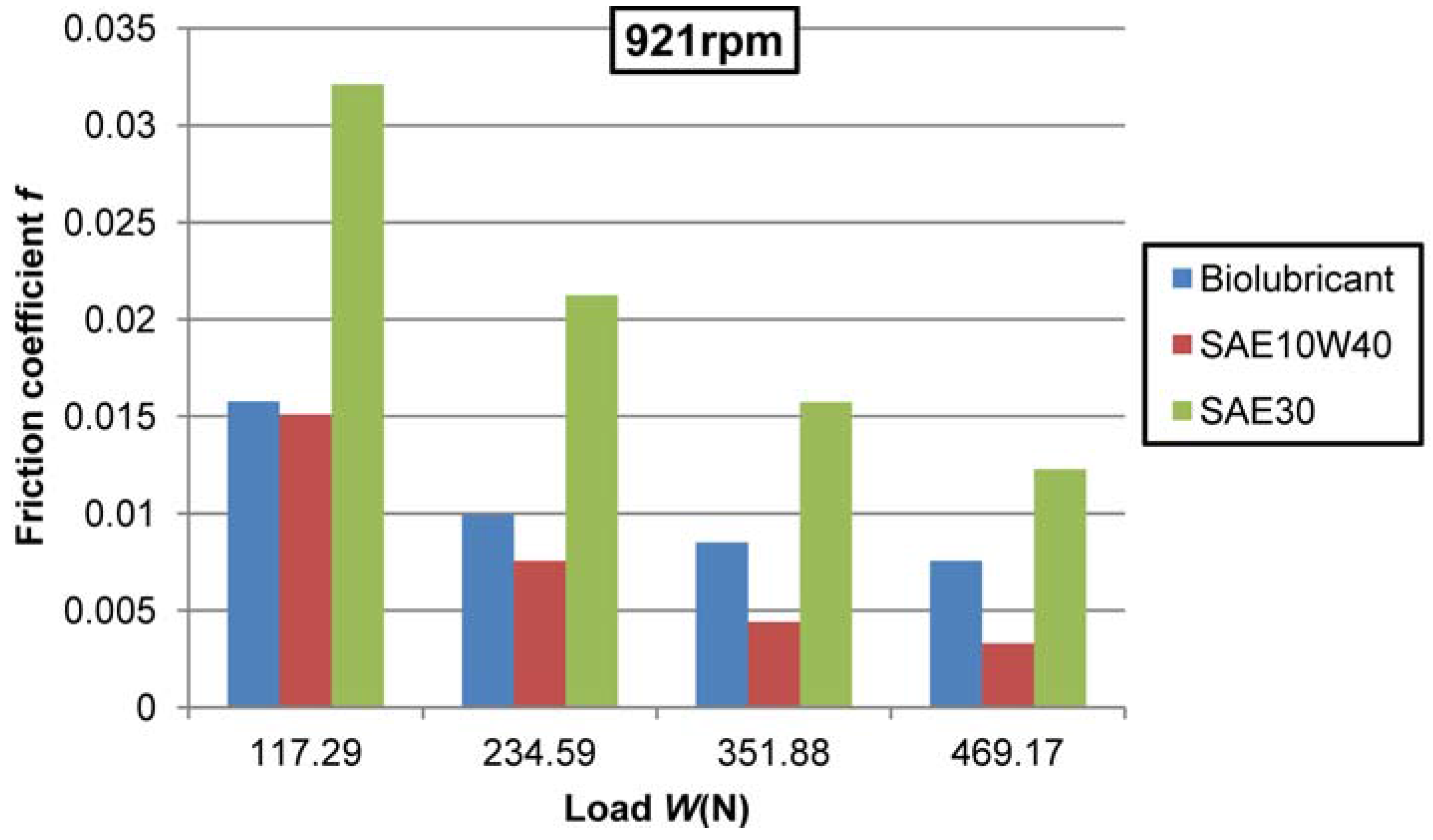

A comparison of the efficiency achieved by the three lubricants is attempted in

Figure 5 where the friction coefficient of the three lubricants is compared for a rotational velocity of 921.75 rpm. It is evident that the synthetic SAE-10W40 offers the best performance in all examined cases but the biolubricant offers considerable improvement. For instance, in the case of

W = 117.29 Nt the biolubricant exhibits a 50% decrease of the friction coefficient in comparison to the friction coefficient achieved when SAE-30 is used.

Figure 5.

The friction coefficient for 921 rpm in all three cases of lubricants.

Figure 5.

The friction coefficient for 921 rpm in all three cases of lubricants.

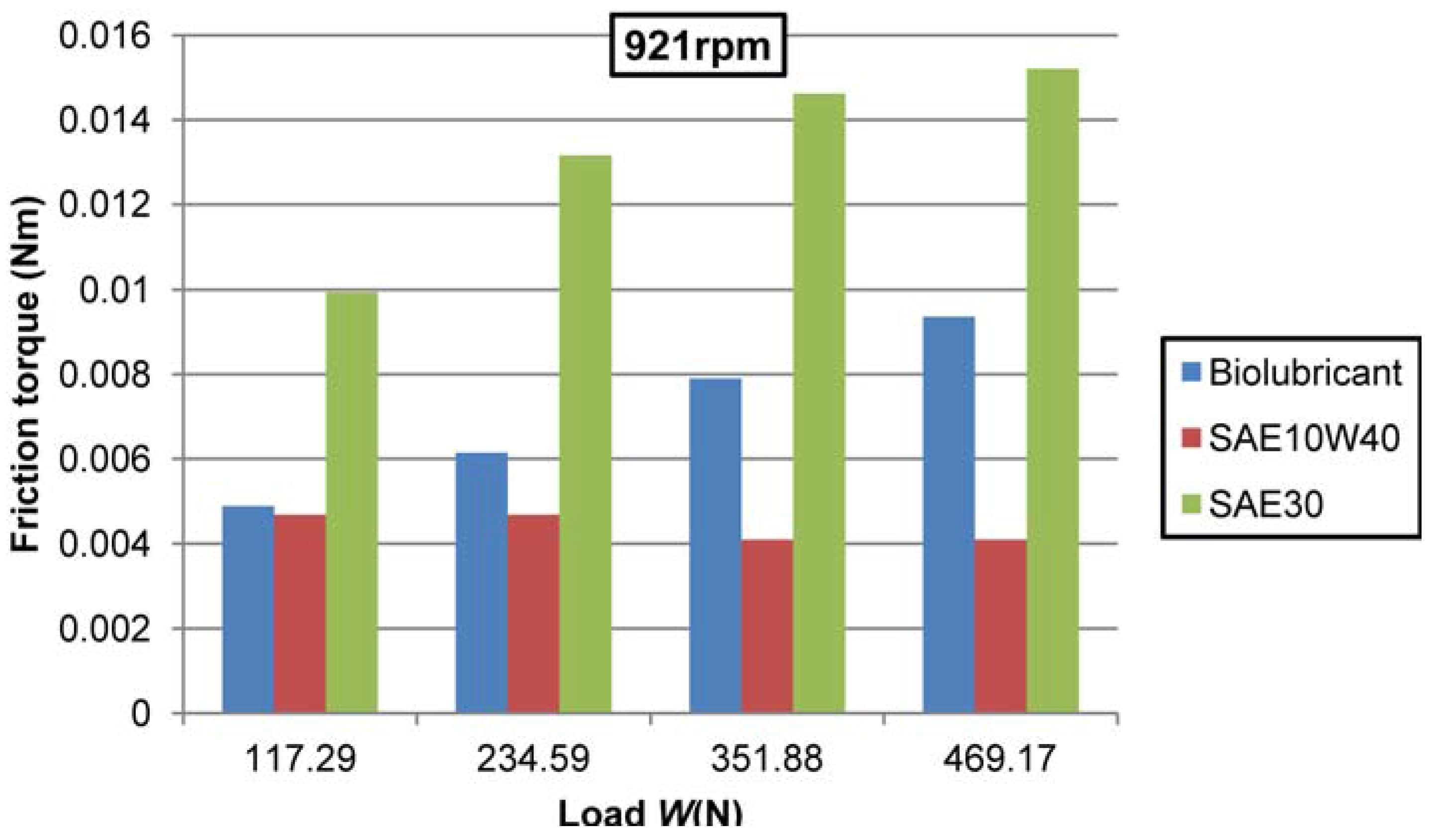

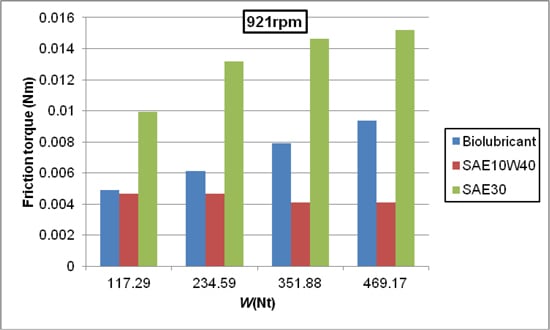

The same trend appears in the way torque varies with the applied load. In

Figure 6 the friction torque measured is presented for journal rotational velocity of 921 rpm. The highest torque is generated by the SAE-30 lubricant in all loads.

Figure 6.

Friction torque comparison at 921 rpm.

Figure 6.

Friction torque comparison at 921 rpm.

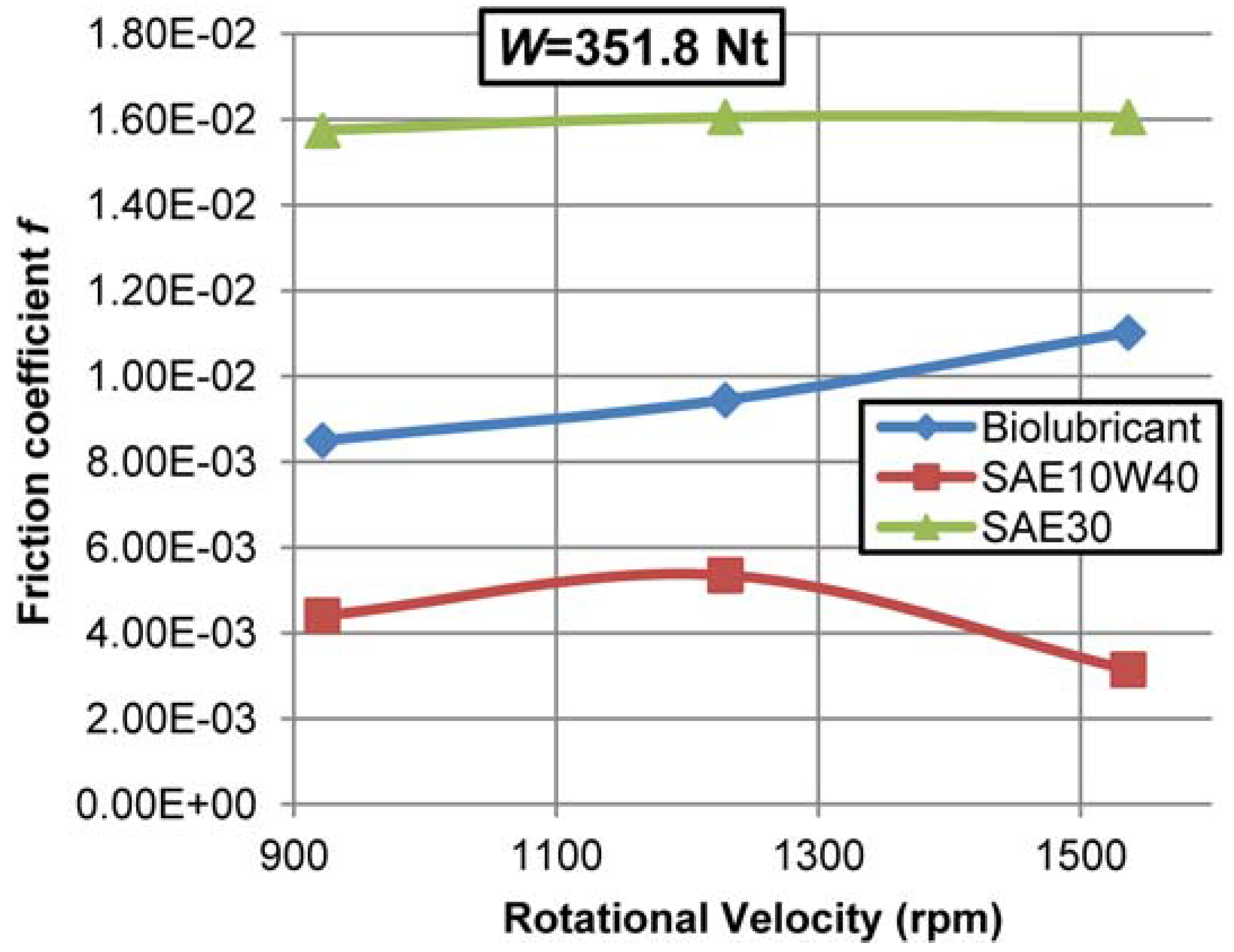

The effect of journal velocity is less pronounced than that of the load in all three cases of lubricant used. In

Figure 7 the friction coefficient is presented for

W = 351.8 Nt for all three lubricants.

Figure 7.

The friction coefficient of the bearing for a load of 351.8 Nt.

Figure 7.

The friction coefficient of the bearing for a load of 351.8 Nt.

As seen in

Figure 7 the rotational velocity of the journal does not seem to change the friction coefficient for the specific load in all three cases of lubricant used in the experiments. The most efficient lubricant is the SAE-10W40 followed by the biolubricant. The smaller difference between the biolubricant and the SAE-10W40 is observed in the case of 921 rpm where the friction coefficient of the biolubricant is 92% higher. The SAE-30 seems to be the least efficient of all three lubricants examined.