Morphological Diversity and Interparticle Interactions of Lubricating Grease Thickeners: Current Insights and Research Approaches

Abstract

1. Phase Characteristics and Dispersed Structure of Lubricating Greases

- Polymorphic thickeners, whose interaction with the dispersing medium increases as they undergo transformation into high-temperature mesomorphic phases. These are thickeners that do not react with the base oil at room temperature and form systems with a high degree of dispersion at elevated temperatures. This group includes, among others, metal soaps.

- Thickeners that do not exhibit polymorphism but melt at relatively low temperatures. Above their melting point, they form homogeneous solutions with the dispersing medium. This group includes solid hydrocarbons.

- High-temperature-resistant organic and inorganic thickeners that are insoluble in the dispersing medium and do not undergo phase transformations with increasing temperature that would enable their interaction with the dispersing medium. These include highly dispersed silica gels, carbon black, pigments, etc.

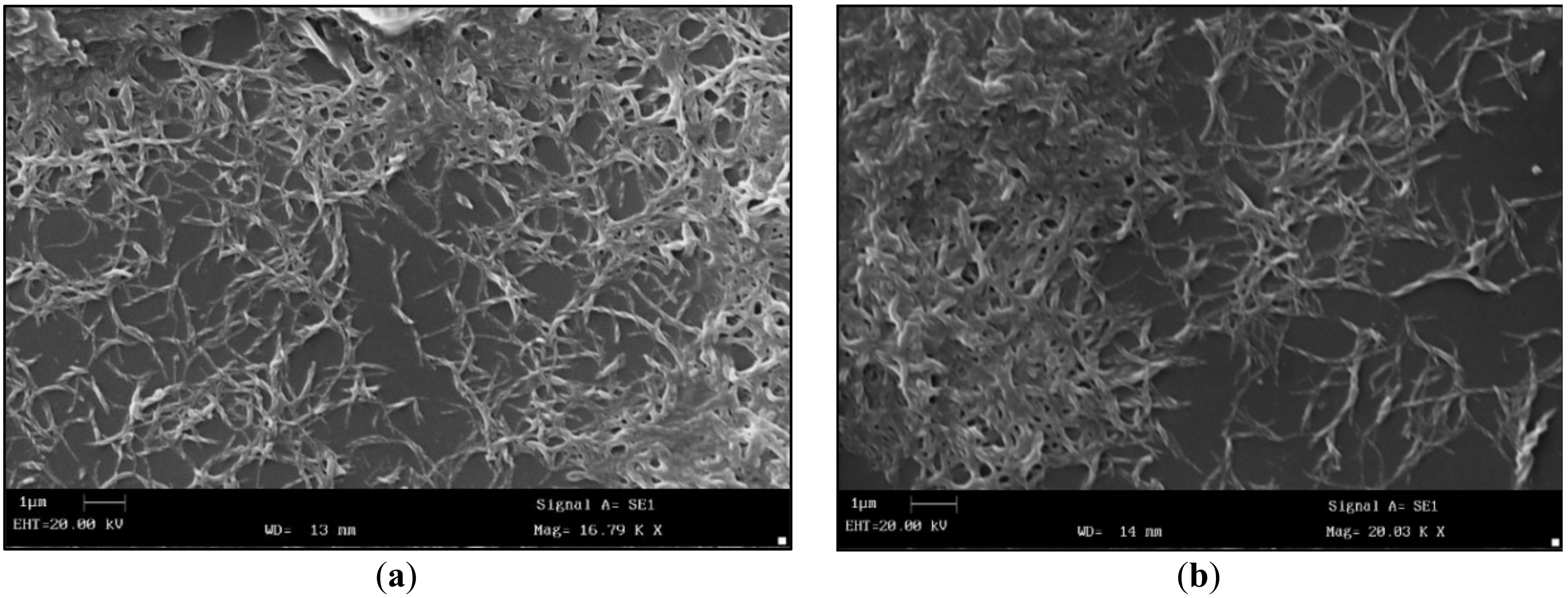

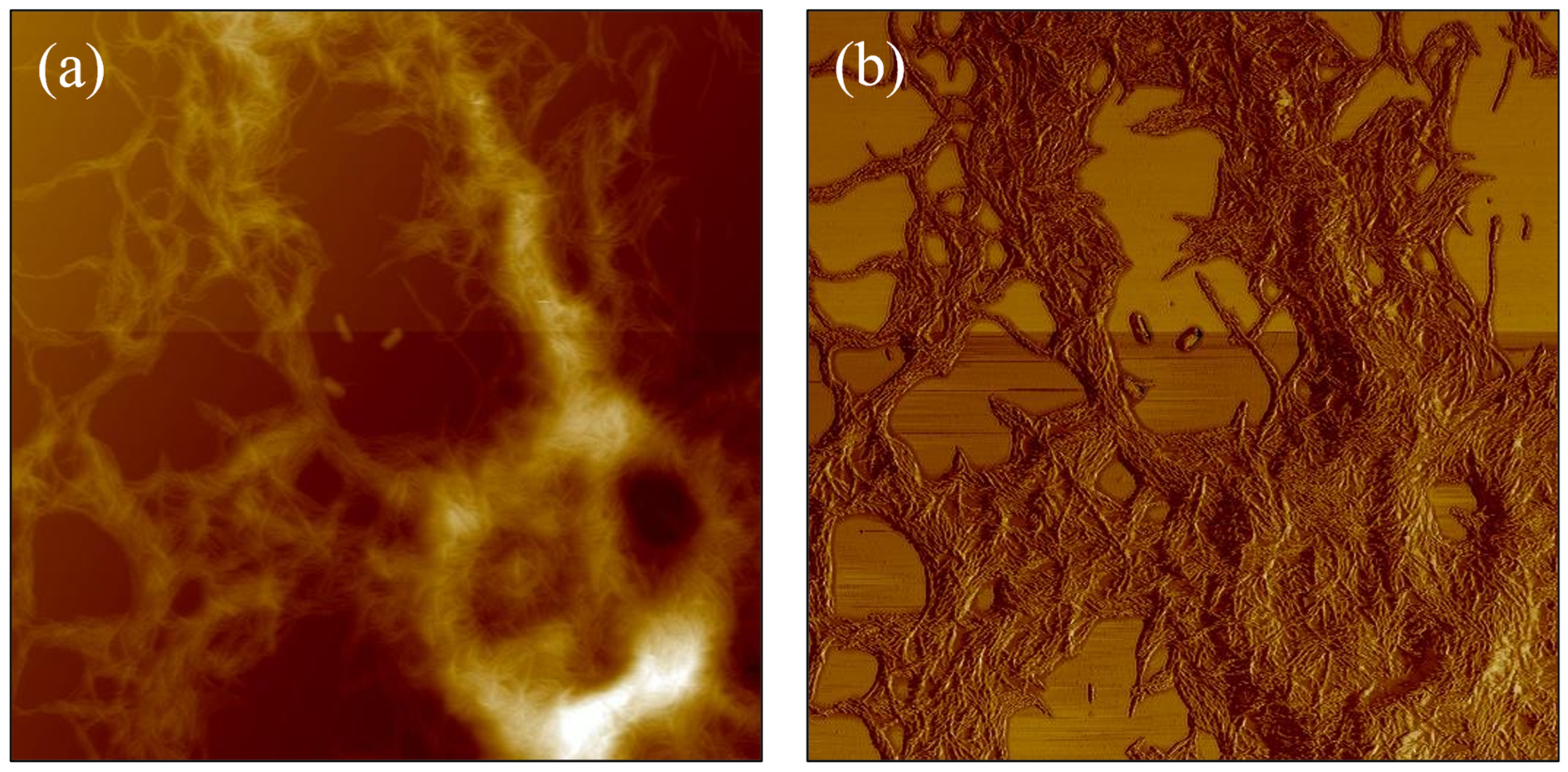

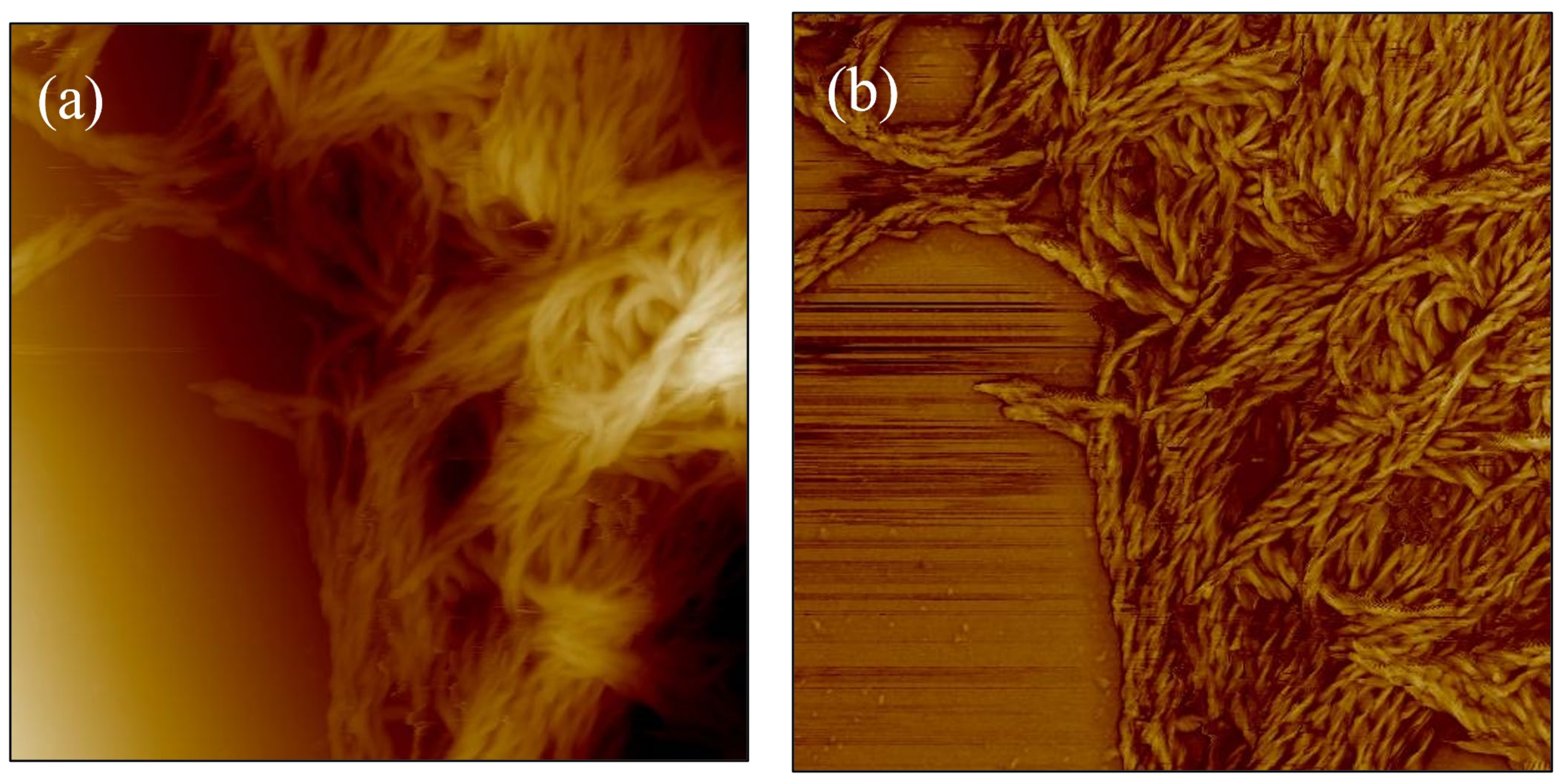

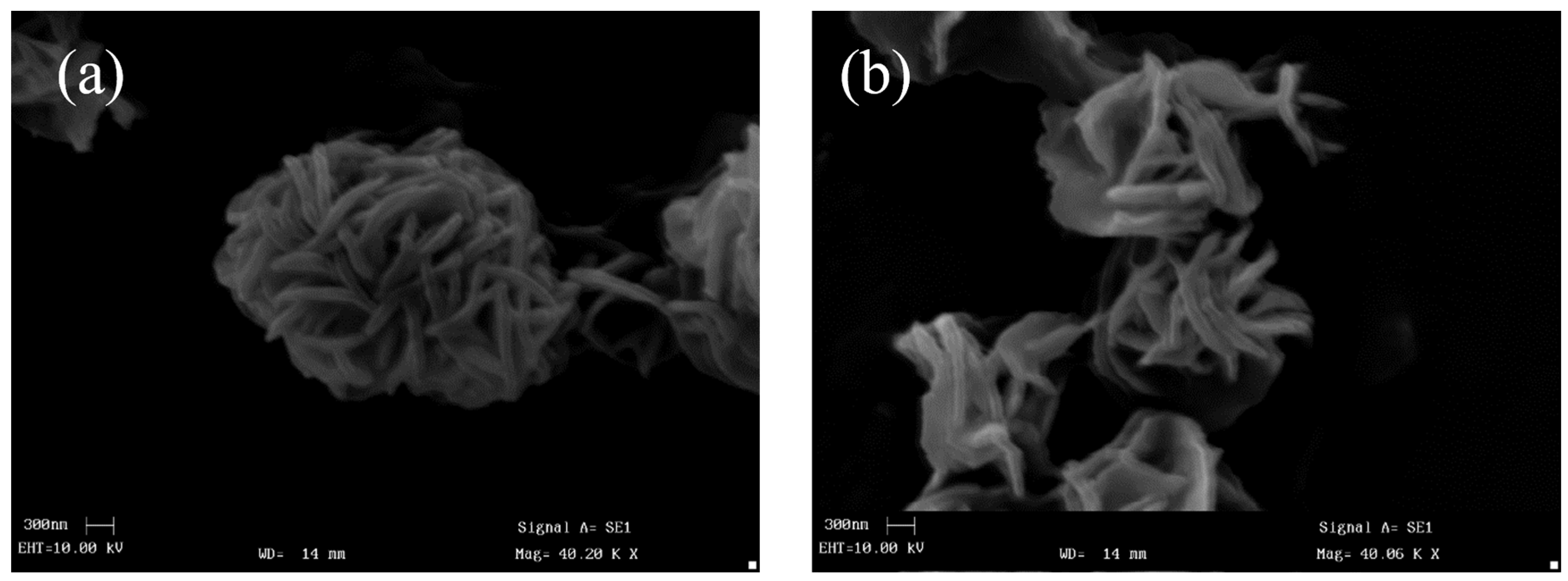

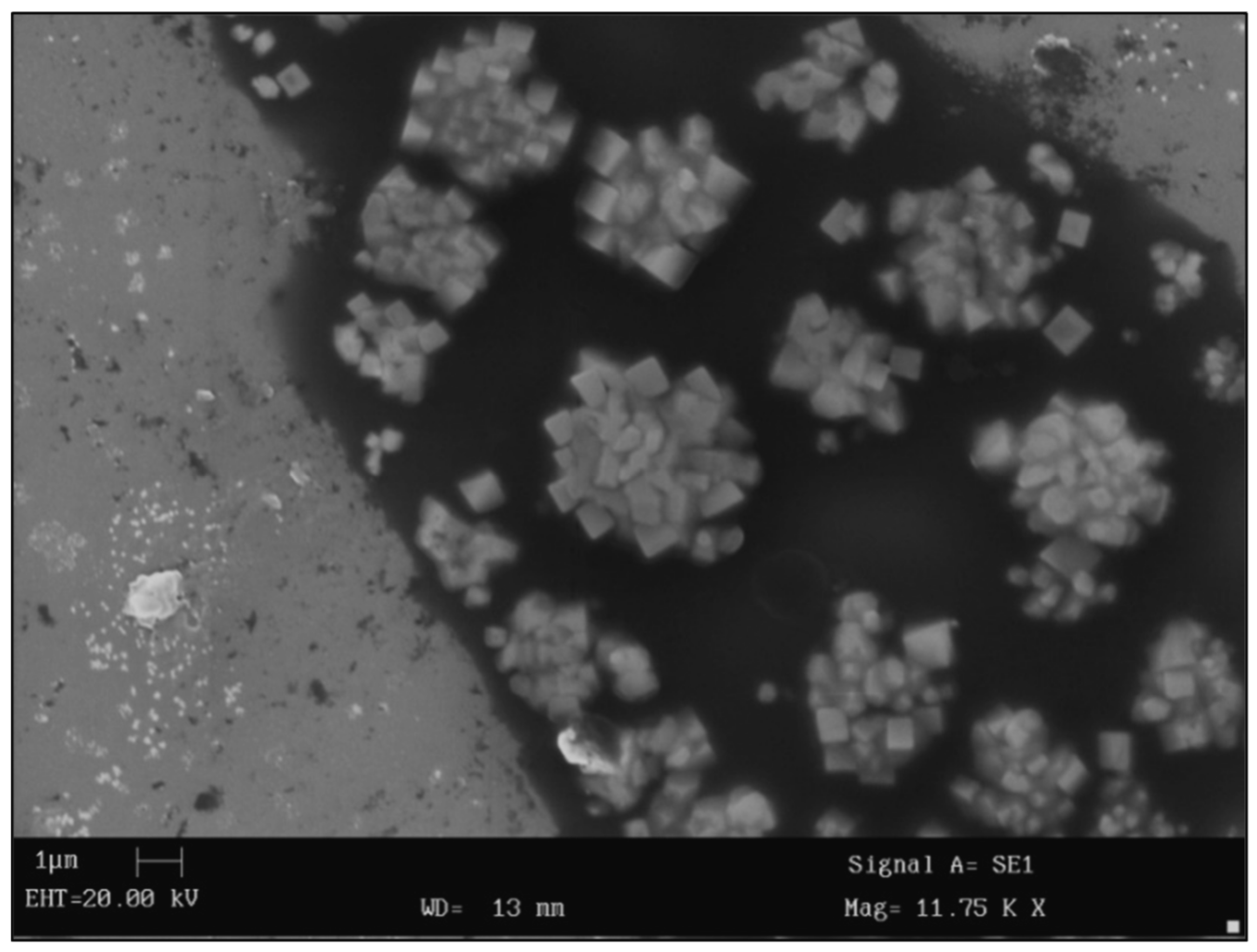

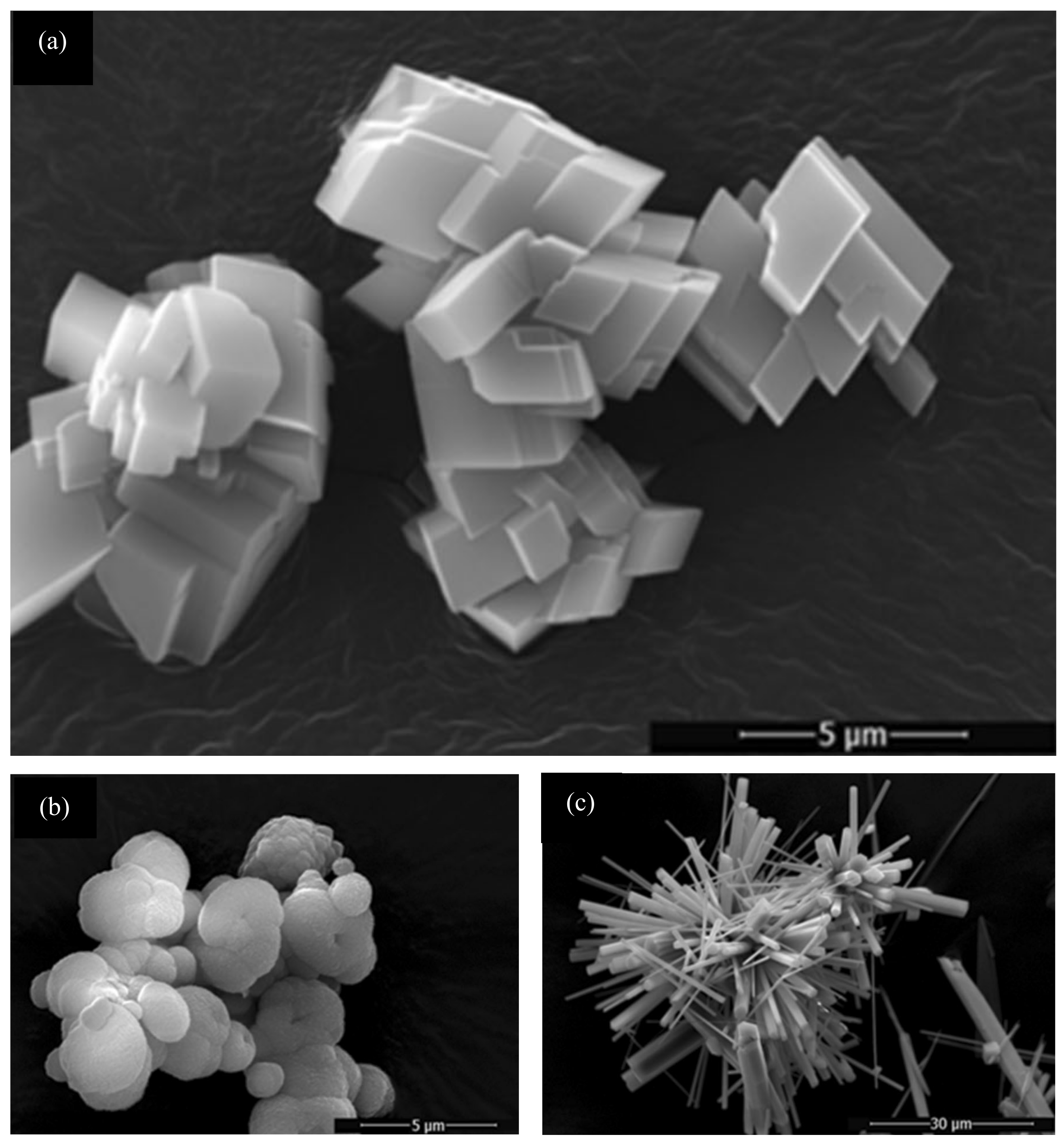

2. Morphology and Particle Size of Selected Soap Thickeners

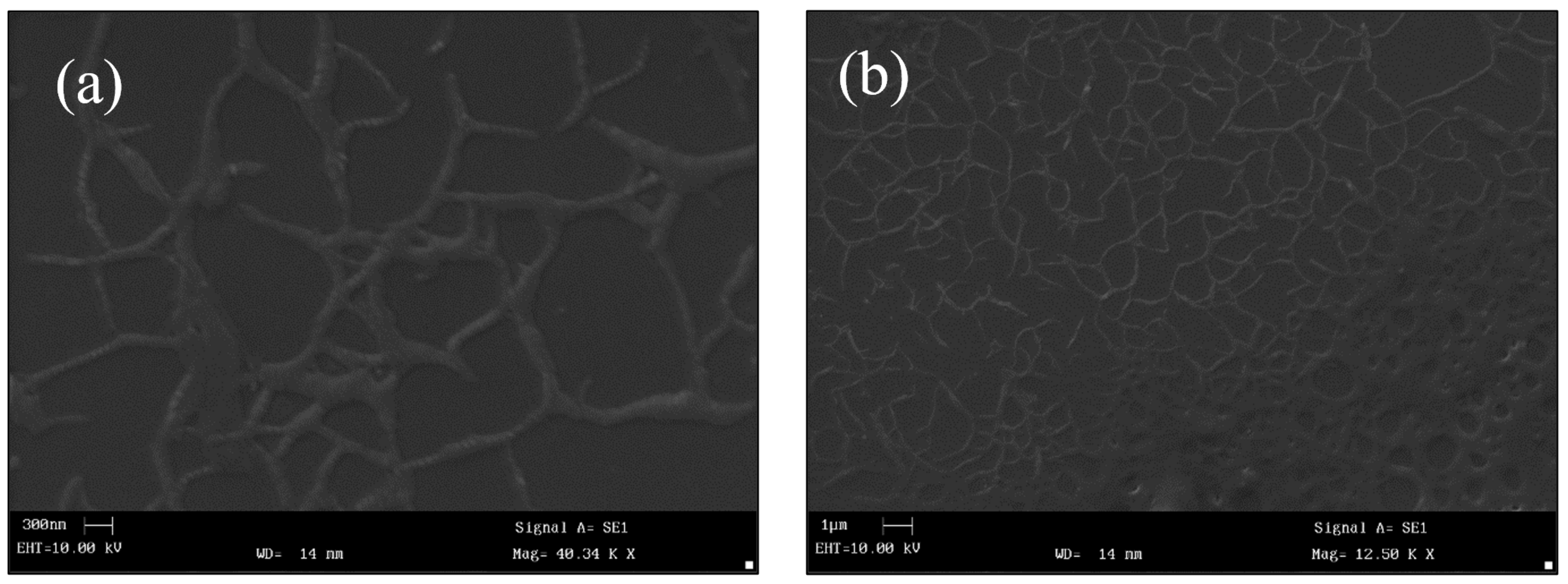

3. Morphology and Particle Size of Selected Non-Soap Thickeners

4. Physicochemical Interactions Responsible for Microstructure Formation and Wall Effects

5. Methods for Imaging the Microstructure of Lubricating Greases

6. Application of Rheometric Measurements to the Evaluation of Lubricating Grease Structure

7. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| µPIV | Micro-Particle Image Velocimetry |

| AFM | Atomic Force Microscopy |

| ATR-FTIR | Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy |

| cryo-TEM | Cryogenic Transmission Electron Microscopy |

| DLS | Dynamic Light Scattering |

| DWS | Diffusing-Wave Spectroscopy |

| EHL | Elastohydrodynamic Lubrication |

| FTIR | Fourier Transform Infrared Spectroscopy |

| IR | Infrared |

| MPT | Multiple Particle Tracking |

| SAOS | Small-Amplitude Oscillatory Shear |

| SAXS | Small-Angle X-ray Scattering |

| SEM | Scanning Electron Microscopy |

| STM | Scanning Tunneling Microscopy |

| TEM | Transmission Electron Microscopy |

| XRD | X-ray Diffraction |

References

- Boner, C.J. Modern Lubricating Greases; Scientific Publications (G.B.) Ltd.: Broseley, UK, 1976. [Google Scholar]

- Velikovsky, D.S.; Poddubny, V.N.; Vainshtok, V.V.; Gotovkin, B.D. Consistent Greases; Khimiya: Moscow, Russia, 1966. [Google Scholar]

- Bańkowski, K.; Bańkowski, Z; Basiński, A.; Biernacka, T.; Bochwic, B.; Böhm, J.; Całus, H.; Ciecierska-Stokłosa, D.; Dorabialska, A.; Dybczyński, R.; et al. Poradnik Fizyko-Chemiczny [Physicochemical Handbook], 2nd ed.; Scientific and Technical Publishing House: Warsaw, Poland, 1974. [Google Scholar]

- Delgado, M.A.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Influence of soap concentration and oil viscosity on the rheology and microstructure of lubricating greases. Ind. Eng. Chem. Res. 2006, 45, 1902–1910. [Google Scholar] [CrossRef]

- Moore, R.J.; Cravath, A.M. Mechanical breakdown of soap-base greases. Ind. Eng. Chem. 1951, 43, 2892–2897. [Google Scholar] [CrossRef]

- Yeong, S.K.; Luckham, P.F.; Tadros, T.F. Steady flow and viscoelastic properties of lubricating grease containing various thickener concentrations. J. Colloid Interface Sci. 2004, 274, 285–293. [Google Scholar] [CrossRef]

- Froishteter, G.B.; Trilsky, K.K.; Ishchuk, Y.L.; Stupak, P.M. Rheological and Thermophysical Properties of Greases; Gordon & Breach: London, UK, 1989. [Google Scholar]

- Varius Authors. Słownik Polskiej Terminologii Chemicznej [Dictionary of Polish Chemical Terminology]; Scientific and Technical Publishing House: Warsaw, Poland, 1975. [Google Scholar]

- Kuhn, E. Description of the energy level of tribologically stressed greases. Wear 1995, 138–139, 41–48. [Google Scholar] [CrossRef]

- Czarny, R. Smary Plastyczne [Greases]; Scientific and Technical Publishing House: Warsaw, Poland, 2004. [Google Scholar]

- Bartz, W.J. (Ed.) Schmierfette: Zusammensetzung, Eigenschaften, Prüfung and Anwendung [Lubricating Greases: Composition, Properties, Testing, and Applications]; Expert: Renningen, Germany, 2000. [Google Scholar]

- Paszkowski, M.; Kowalewski, P.; Leśniewski, T. Badania właściwości reologicznych smarów plastycznych zagęszczanych 12-hydroksystearynianem litu [Study of the Rheological Properties of Lubricating Greases Thickened with Lithium 12-Hydroxystearate in the Linear and Nonlinear Viscoelastic Regime]. Tribologia 2012, 4, 183–194. [Google Scholar]

- Paszkowski, M.; Olsztyńska-Janus, S. Grease thixotropy: Evaluation of grease microstructure change due to shear and relaxation. Ind. Lubr. Tribol. 2014, 66, 223–237. [Google Scholar] [CrossRef]

- Paszkowski, M. Assessment of the effect of temperature, shear rate and thickener content on the thixotropy of lithium lubricating greases. Proc. Inst. Mech. Eng. J 2013, 227, 209–219. [Google Scholar] [CrossRef]

- Paszkowski, M.; Olsztyńska-Janus, S.; Wilk, I. Studies of the kinetics of lithium grease microstructure regeneration by means of dynamic oscillatory rheological tests and FTIR–ATR spectroscopy. Tribol. Lett. 2014, 56, 107–117. [Google Scholar] [CrossRef]

- Samman, N. Chemistry of aluminum complex grease revisited. NLGI Spokesm. 1992, 7, 313–320. [Google Scholar]

- Farrington, B.B.; Davis, W.N. Structure of lubricating greases. Ind. Eng. Chem. 1936, 28, 414–416. [Google Scholar] [CrossRef]

- Rizvi, S.Q.A. A Comprehensive Review of Lubricant Chemistry, Technology, Selection, and Design; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Vold, J.M. Colloidal structure in lithium stearate greases. J. Phys. Chem. 1956, 60, 439–442. [Google Scholar] [CrossRef]

- Irina, R.; Radulescu, A.V.; Florin, V. The structure of lubricating greases by electron microscopy. Tribol. Ind. 2004, 26, 58–64. [Google Scholar]

- Zhang, E.; Li, W.; Zhao, G.; Wang, Z. A study on microstructure, friction and rheology of four lithium greases formulated with different base oils. Tribol. Lett. 2021, 69, 98. [Google Scholar] [CrossRef]

- Czarny, R. Badanie zjawisk związanych z przepływem smarów plastycznych w układach smarowniczych [Investigation of Phenomena Related to the Flow of Lubricating Greases in Lubrication Systems]. In Scientific Papers of the Institute of Machine Design and Operation, Wrocław University of Science and Technology, Series: Monographs; Wrocław University of Science and Technology Publishing House: Wrocław, Poland, 1992. [Google Scholar]

- Farrington, B.B. The fine structure of lubricating greases. Ann. N. Y. Acad. Sci. 1951, 53, 979–986. [Google Scholar] [CrossRef]

- Mas, R.; Magnin, A. Rheology of colloidal suspensions: Case of lubricating greases. J. Rheol. 1994, 38, 889–908. [Google Scholar] [CrossRef]

- Franco, J.M.; Delgado, M.A.; Valencia, C.; Sanchez, M.C.; Gallegos, C. Mixing rheometry for studying manufacture of lubricating greases. Chem. Eng. Sci. 2005, 60, 2409–2418. [Google Scholar] [CrossRef]

- Mewis, J. Thixotropy—A general review. J. Non-Newton. Fluid Mech. 1979, 6, 1–20. [Google Scholar] [CrossRef]

- Luckham, P.F.; Rossi, S. The colloidal and rheological properties of bentonite suspensions. Adv. Colloid Interface Sci. 1999, 82, 43–92. [Google Scholar] [CrossRef]

- Czarny, R.; Paszkowski, M. The influence of graphite solid additives, MoS2 and PTFE on changes in shear stress values in lubricating greases. J. Synth. Lubric. 2007, 24, 19–29. [Google Scholar] [CrossRef]

- Sonntag, H. Lehrbuch der Kolloidwissenschaft; VEB Deutscher Verlag der Wissenschaften: Berlin, Germany, 1977. [Google Scholar]

- Mackwood, W.; Muir, R. Calcium sulfonate grease… one decade later. NLGI Spokesm. 1999, 63, 24–37. [Google Scholar]

- Hone, D.C.; Robinson, B.H.; Steytler, D.C.; Glyde, R.W.; Galsworthy, J.R. Mechanism of acid neutralization by overbased colloidal additives in hydrocarbon media. Langmuir 2000, 16, 340–346. [Google Scholar] [CrossRef]

- Muir, R.J. High performance calcium sulfonate complex lubricating grease. NLGI Spokesm. 1988, 52, 140–146. [Google Scholar]

- Zheng, M.; Ren, G.; Wang, S.; Li, Y.; Xing, M. Investigating the effect of overbased sulfonates on calcium sulfonate complex grease. RSC Adv. 2024, 14, 32992–33006. [Google Scholar] [CrossRef] [PubMed]

- Konopacka-Łyskawa, D. Synthesis methods and favorable conditions for spherical vaterite precipitation: A review. Crystals 2019, 9, 223. [Google Scholar] [CrossRef]

- Makedonsky, O.; Kobylyansky, E.; Ishchuk, Y. Structure and physico-chemical properties of overbased calcium sulfonate complex greases. Eurogrease 2003, 1, 5–23. [Google Scholar]

- Ševčík, R.; Šašek, P.; Viani, A. Physical and nanomechanical properties of the synthetic anhydrous crystalline CaCO3 polymorphs. J. Mater. Sci. 2018, 53, 4022–4033. [Google Scholar] [CrossRef]

- Ni, M.; Ratner, B.D. Surface and interface analysis of calcium carbonate polymorphs. Surf. Interface Anal. 2008, 40, 1356–1361. [Google Scholar] [CrossRef]

- Vagenas, N.V.; Gatsouli, A.; Kontoyannis, C.G. Quantitative analysis of synthetic calcium carbonate polymorphs using FT-IR spectroscopy. Talanta 2003, 59, 831–836. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Aleksanyan, D.R.; Bakunina, Y.N. Calcium carbonate polymorphs in overbased oil additives and greases. Russ. J. Appl. Chem. 2022, 95, 461–471. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, M.; Zhao, G.; Wang, X. Tribological behavior of amorphous and crystalline overbased calcium sulfonate as additives in lithium complex grease. Tribol. Lett. 2012, 45, 265–273. [Google Scholar] [CrossRef]

- Bauer, W.H.; Finkelstein, A.P.; Wiberley, S.E. Flow properties of lithium stearate-oil model greases as a function of soap concentration and temperature. ASLE Trans. 1960, 3, 215–224. [Google Scholar] [CrossRef]

- Zajezierska, A. Stabilność koloidalna smarów plastycznych [Colloidal Stability of Lubricating Greases]. Nafta Gaz 2011, 8, 572–576. [Google Scholar]

- Lugt, P.M. Grease Lubrication in Rolling Bearings; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Olsztyńska-Janus, S.; Paszkowski, M. Behavior of hydrogen bonds in lithium grease during shearing and stress relaxation. In Proceedings of the The 21st International Conference on “Horizons In Hydrogen Bond Research” (HBOND 2015), Wrocław, Poland, 13–18 September 2015. [Google Scholar]

- Czarny, R. Wpływ struktury smaru plastycznego na jego własności reologiczne [Influence of Grease Structure on Its Rheological Properties]. In Scientific Papers of the Institute of Machine Design and Operation; Wrocław University of Science and Technology Publishing House: Wrocław, Poland, 1989. [Google Scholar]

- Donahue, C.J. Lubricating grease: A chemical primer. J. Chem. Educ. 2006, 83, 862–869. [Google Scholar] [CrossRef]

- Freundlich, H. Thixotropie; Hermann: Paris, France, 1935. [Google Scholar]

- Péterfi, T. Die Abhebung der Befruchtungsmembran bei Seeigeleiern: Eine kolloidchemische Analyse. Wilhelm Roux’ Arch. Dev. Mech. Organ. 1927, 112, 660–695. [Google Scholar] [CrossRef]

- Lagaly, G.; Beneke, K.; Kutatádok, H.K.; Anyagtudományi, M.K. Eighty Years of Colloid Science in Hungary and Germany; University Kiel: Kiel, Germany, 2002. [Google Scholar]

- Czarny, R. Effects of changes in grease structure on sliding friction. Ind. Lubr. Tribol. 1995, 47, 3–7. [Google Scholar] [CrossRef]

- Yonggang, M.; Jie, Z. A rheological model for lithium lubricating grease. Tribol. Int. 1998, 31, 619–625. [Google Scholar] [CrossRef]

- Kuhn, E. Some considerations to the energy dissipation of frictionally stressed lubricating greases. Lubricants 2025, 13, 86. [Google Scholar] [CrossRef]

- Czarny, R. A study of Thixotropy Phenomen in Lubricating Greases. In Proceedings of the 5th International Congress on Tribology (Eurotrib 89), Helsinki, Finland, 12–15 June 1989. [Google Scholar]

- Czarny, R. Effect of Temperature on the Thixotropy Phenomenon in Lubricating Greases. In Proceedings of the Japan International Tribology Conference, Nagoya, Japan, 29 October–1 November 1990. [Google Scholar]

- Kozdrach, R. Application of Raman Spectroscopy to Evaluate the Structure Changes of Lubricating Grease Modified with Montmorillonite after Tribological Tests. Processes 2024, 12, 565. [Google Scholar] [CrossRef]

- Bramhall, A.D.; Hutton, J.F. Wall effect in the flow of lubricating greases in plunger viscometers. Br. J. Appl. Phys. 1960, 11, 363–368. [Google Scholar] [CrossRef]

- Vinogradov, G.V.; Froishteter, G.B.; Trilisky, K.K.; Smorodinsky, E.L. The flow of plastic disperse systems in the presence of the wall effect. Rheol. Acta 1975, 14, 765–775. [Google Scholar] [CrossRef]

- Vinogradov, G.V.; Froishteter, G.B.; Trilisky, K.K. Generalized theory of flow of plastic disperse systems with wall effect. Rheol. Acta 1978, 17, 156–165. [Google Scholar] [CrossRef]

- Czarny, R. Influence of surface material and topography on the wall effect of grease. Lubr. Sci. 2002, 14, 255–274. [Google Scholar] [CrossRef]

- Barnes, H.A. A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: Its cause, character, and cure. J. Non-Newton. Fluid Mech. 1995, 56, 221–251. [Google Scholar] [CrossRef]

- Balan, C.; Franco, J.M. Influence of geometry on the transient and steady flow of lubricating greases. Tribol. Trans. 2001, 44, 53–58. [Google Scholar] [CrossRef]

- Biernacki, K. Analiza zjawisk zachodzących w warstwie przyściennej smaru plastycznego [Analysis of Phenomena Occurring in the Wall Layer of Lubricating Grease]. Tribologia 2006, 5, 111–129. [Google Scholar]

- Paszkowski, M.; Wróblewski, R.; Walaszczyk, A. Influence of temperature and surface energy state on wall effects in soap-based greases. Tribol. Lett. 2017, 65, 19. [Google Scholar] [CrossRef]

- Duenas-Dobrowolski, J. Metody wizualizacji ruchu smaru w uszczelnieniach labiryntowych [Methods for Visualization of Grease Flow in Labyrinth Seals]. Zesz. Energetyczne 2014, 1, 1–10. [Google Scholar]

- Duenas-Dobrowolski, J. Określenie profili prędkości smaru w szczelinie uszczelnienia bezstykowego za pomocą mikroanemometrii obrazowej (μPIV) [Determination of Grease Velocity Profiles in a Non-Contact Seal Gap Using Microparticle Image Velocimetry (μPIV)]. Zesz. Energetyczne 2015, 2, 11–20. [Google Scholar]

- Duenas-Dobrowolski, J.; Gawliński, M.; Paszkowski, M.; Westerberg, L.G.; Höglund, E. Experimental study of lubricating grease flow inside the gap of a labyrinth seal. Tribol. Trans. 2018, 61, 31–40. [Google Scholar] [CrossRef]

- Guo, F.; Wong, P.L.; Geng, M.; Kaneta, M. Occurrence of wall slip in EHL contacts. Tribol. Lett. 2009, 34, 103–111. [Google Scholar] [CrossRef]

- Gallay, W.; Puddington, I.E.; Tapp, J.S. Fibre structure in dispersions of soap in mineral oil. Can. J. Res. 1944, 22, 66–75. [Google Scholar] [CrossRef]

- Farrington, B.B.; Birdsall, D.H. Study of lubricating greases by electron microscope. Oil Gas J. 1947, 45, 268–272. [Google Scholar]

- Baart, P.; van der Vorst, B.; Lugt, P.M.; van Ostayen, R.A. Oil-bleeding model for lubricating grease based on viscous flow through a porous microstructure. Tribol. Trans. 2010, 53, 340–348. [Google Scholar] [CrossRef]

- Cyriac, F.; Lugt, P.M.; Bosman, R.; Padberg, C.J.; Venner, C.H. Effect of thickener particle geometry and concentration on grease EHL film thickness. Tribol. Lett. 2016, 61, 18. [Google Scholar] [CrossRef]

- Hurley, A.; Cann, P. Examination of grease structure by SEM and AFM techniques. NLGI Spokesm. 2001, 65, 17–26. [Google Scholar]

- Salomonsson, L.; Stang, G.; Zhmud, B. Oil/thickener interactions and rheology of lubricating greases. Tribol. Trans. 2007, 50, 302–309. [Google Scholar] [CrossRef]

- Sánchez, M.C.; Franco, J.M.; Valencia, C.; Gallegos, C.; Urquiola, F.; Urchegui, R. Atomic force microscopy and thermo-rheological characterization of lubricating greases. Tribol. Lett. 2011, 41, 463–470. [Google Scholar] [CrossRef]

- Lin, C.L.; Meehan, P.A. Microstructure characterization of degraded grease in axle roller bearings. Tribol. Trans. 2019, 62, 667–687. [Google Scholar] [CrossRef]

- Roman, C.; Valencia, C.; Franco, J.M. AFM and SEM assessment of lubricating grease microstructures. Tribol. Lett. 2016, 63, 20. [Google Scholar] [CrossRef]

- Saxena, A.; Kumar, D.; Tandon, N. Development of eco-friendly nano-greases based on vegetable oil. Ind. Crops Prod. 2021, 172, 114033. [Google Scholar] [CrossRef]

- Fan, X.; Li, W.; Li, H.; Zhu, M.; Xia, Y.; Wang, J. Probing the effect of thickener on tribological properties of lubricating greases. Tribol. Int. 2018, 118, 128–139. [Google Scholar] [CrossRef]

- Ahme, L.; Kuhn, E.; Canto, M.Á.D. Optical assessment of structural degradation of rheologically stressed lubricating greases. Tribol. Int. 2023, 187, 108771. [Google Scholar] [CrossRef]

- Sisko, A.W. The flow of lubricating greases. Ind. Eng. Chem. 1958, 50, 1789–1792. [Google Scholar] [CrossRef]

- Forster, E.O.; Kolfenbach, J.J. Viscoelastic behavior of greases. ASLE Trans. 1959, 2, 13–24. [Google Scholar] [CrossRef]

- Criddle, D.W. Typical lubricating greases as linear viscoelastic materials. Trans. Soc. Rheol. 1965, 9, 287–297. [Google Scholar] [CrossRef]

- Hutton, J.F. Grease rheology. In Principles of Lubrication; Cameron, A., Ed.; Longman: London, UK, 1966; Chapter 23. [Google Scholar]

- Barnett, R.S. Review of recent USA publications on lubricating grease. Proc. Inst. Mech. Eng. Conf. Proc. 1969, 184, 87–93. [Google Scholar]

- Czarny, R. Einfluss der Thixotropie auf die rheologischen Eigenschaften der Schmierfette [Influence of Thixotropy on the Rheological Properties of Lubricating Greases]. Tribol. Schmierungstech. 1989, 36, 134–140. [Google Scholar]

- Mas, R.; Magnin, A. Rheological and physical studies of lubricating greases before and after use in bearings. J. Tribol. 1996, 118, 681–686. [Google Scholar] [CrossRef]

- Kuhn, E. Energetics of the time-dependent flow behaviour of greases. Appl. Rheol. 1997, 7, 118–122. [Google Scholar] [CrossRef]

- Kuhn, E. Experimental grease investigations from an energy point of view. Ind. Lubr. Tribol. 1999, 51, 173–180. [Google Scholar] [CrossRef]

- Conrad, A.; Hodapp, A.; Hochstein, B.; Willenbacher, N.; Jacob, K.H. Low-Temperature Rheology and Thermoanalytical Investigation of Lubricating Greases: Influence of Thickener Type and Concentration on Melting, Crystallization and Glass Transition. Lubricants 2021, 10, 1. [Google Scholar] [CrossRef]

- Hodapp, A.; Conrad, A.; Hochstein, B.; Jacob, K.H.; Willenbacher, N. Effect of base oil and thickener on texture and flow of lubricating greases: Insights from bulk rheometry, optical microrheology and electron microscopy. Lubricants 2022, 10, 55. [Google Scholar] [CrossRef]

- Xu, N.; Wang, X.; Ma, R.; Li, W.; Zhang, M. Insights into the rheological behaviors and tribological performances of lubricating grease: Entangled structure of a fiber thickener and functional groups of a base oil. New J. Chem. 2018, 42, 1484–1491. [Google Scholar] [CrossRef]

- Delgado, M.A.; Sánchez, M.C.; Valencia, C.; Franco, J.M.; Gallegos, C. Relationship among microstructure, rheology and processing of lithium lubricating grease. Chem. Eng. Res. Des. 2005, 83, 1085–1092. [Google Scholar] [CrossRef]

- Xu, N.; Li, W.; Zhang, M.; Zhao, G.; Wang, X. New insight into tribology–structure interrelationship of lubricating grease. RSC Adv. 2015, 5, 54202–54210. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, P.; Lin, J.; Gao, X. Rheological and tribological properties of lithium and polyurea greases. Coatings 2022, 12, 527. [Google Scholar] [CrossRef]

- Ren, J.; Cai, H.; Zhao, G.; Xu, Z.; Wang, X. Study of the changes in the microstructures and properties of grease using ball milling to simulate a bearing shear zone on grease. Sci. Rep. 2024, 14, 9734. [Google Scholar] [CrossRef] [PubMed]

- Drabik, J.; Kozdrach, R.; Szczerek, M. Characterization of nano-silica vegetable grease using DWS and Raman spectroscopy. Sci. Rep. 2023, 13, 18989. [Google Scholar] [CrossRef]

- Benois, A.; Echeverri Restrepo, S.; De Laurentis, N.; Hogenberk, F.; Giuntoli, A.; Lugt, P.M. A coarse grained molecular dynamics model for the simulation of lubricating greases. Tribol. Lett. 2024, 72, 78. [Google Scholar] [CrossRef]

| Degree of Dispersion of the Dispersed Phase | ||

|---|---|---|

| Mechanical Dispersion | Colloidal Dispersion | Molecular or Limiting Dispersion |

| Particle size > 0.5 μm | 0.5 μm > Particle size > 1 nm | Particle size < 1 nm |

| Visible under an optical microscope; do not pass through filter paper; do not diffuse and do not undergo dialysis; do not exhibit Brownian motion | Visible under an ultramicroscope; pass through filter paper; do not pass through ultrafilters; do not diffuse and do not undergo dialysis or dialyze very slowly; exhibit Brownian motion | Not visible under an ultramicroscope; pass through ultrafilters; diffuse through semipermeable membranes (dialysis) |

| Thickener | Mean Dimension Diameter × Length [10−6 m] | Description of the Microscopic Image of the Grease |

|---|---|---|

| sodium soap | 1 × 100 | long fiber, strings |

| lithium soap | 0.2 × 25 | long fiber; spiral, mostly double |

| calcium soap | 0.1 × 1 | fine threads, short rings |

| aluminum soap | 0.1 | spheres |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Paszkowski, M.; Kadela, E.; Skibińska, A. Morphological Diversity and Interparticle Interactions of Lubricating Grease Thickeners: Current Insights and Research Approaches. Lubricants 2026, 14, 41. https://doi.org/10.3390/lubricants14010041

Paszkowski M, Kadela E, Skibińska A. Morphological Diversity and Interparticle Interactions of Lubricating Grease Thickeners: Current Insights and Research Approaches. Lubricants. 2026; 14(1):41. https://doi.org/10.3390/lubricants14010041

Chicago/Turabian StylePaszkowski, Maciej, Ewa Kadela, and Agnieszka Skibińska. 2026. "Morphological Diversity and Interparticle Interactions of Lubricating Grease Thickeners: Current Insights and Research Approaches" Lubricants 14, no. 1: 41. https://doi.org/10.3390/lubricants14010041

APA StylePaszkowski, M., Kadela, E., & Skibińska, A. (2026). Morphological Diversity and Interparticle Interactions of Lubricating Grease Thickeners: Current Insights and Research Approaches. Lubricants, 14(1), 41. https://doi.org/10.3390/lubricants14010041