During the braking process of a mine hoist, a stable braking torque is necessary for safety. Therefore, to analyze the friction and wear performance of the YSZ coating on the brake disc, the friction coefficient, wear amount, and variance of the friction coefficient are selected as indexes to evaluate the friction and wear properties of the YSZ thermal barrier coating. Additionally, under the working conditions of a mine hoist, both the pressure force and initial rotational speed can affect the braking effect. Therefore, this study focuses on the friction and wear characteristics under various combinations of pressure force, initial rotational speed, and number of braking cycles.

2.2.1. Influence of Pressure Force on Friction and Wear Properties

The wear amount, friction coefficient, and variance of the friction coefficient are examined at different pressure forces with a constant initial rotational speed of 300 r/min (revolutions per minute).

The wear amount of each sample under these conditions is shown in

Table 2. As shown in the table, the wear amount and pressing force exhibit a positive correlation: as the pressing force increases, the wear amount also increases. The duration of the wear test is set to 5 min.

According to

Table 2, when the pressing force is 100 N, the wear amount of Sample 1 and Sample 2 is the same at 5 × 10

−4 g. Sample 3 and Sample 4 have wear amounts of 24 × 10

−4 g and 7 × 10

−4 g, respectively. In comparison, the wear amount of Sample 4 under a pressing force of 100 N is higher than that of Samples 1 and 2 but much lower than that of Sample 3.

At a pressing force of 200 N, the wear amount of Sample 2 is the lowest at 8 × 10−4 g. The wear amount of Sample 1 is 11 × 10−4 g, which falls between the wear amounts of Sample 2 (8 × 10−4 g) and Sample 4 (15 × 10−4 g). However, Sample 3 has the highest wear amount at 41 × 10−4 g.

When the pressing force is 300 N, the wear amounts of the four samples follow the same trend. Sample 3 has poor wear resistance, with a wear amount much higher than that of Sample 4. Samples 1 and 2 demonstrate superior wear resistance compared to Sample 4, and the wear resistance of Sample 2 is the best among the four samples.

- 2.

Friction coefficient analysis

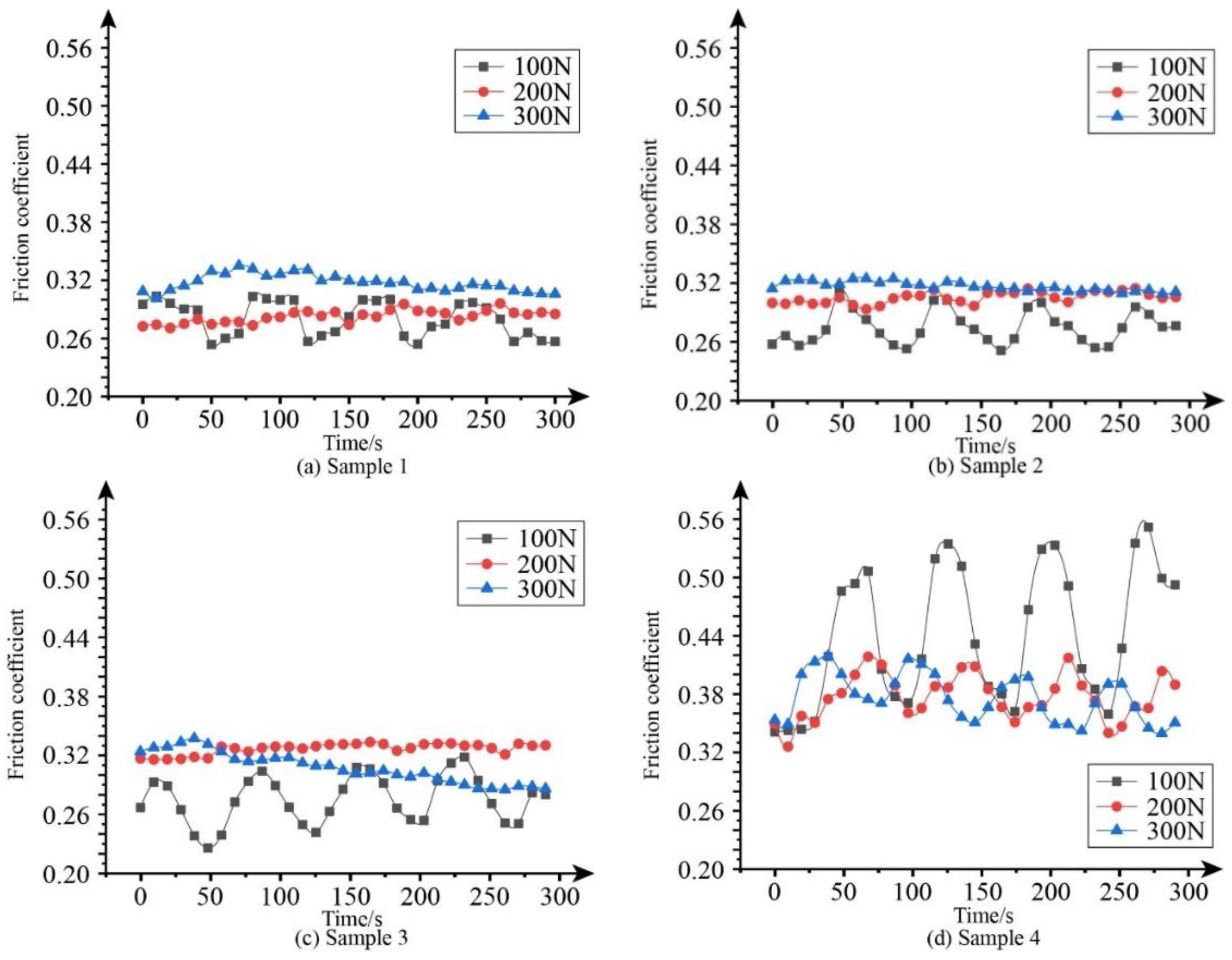

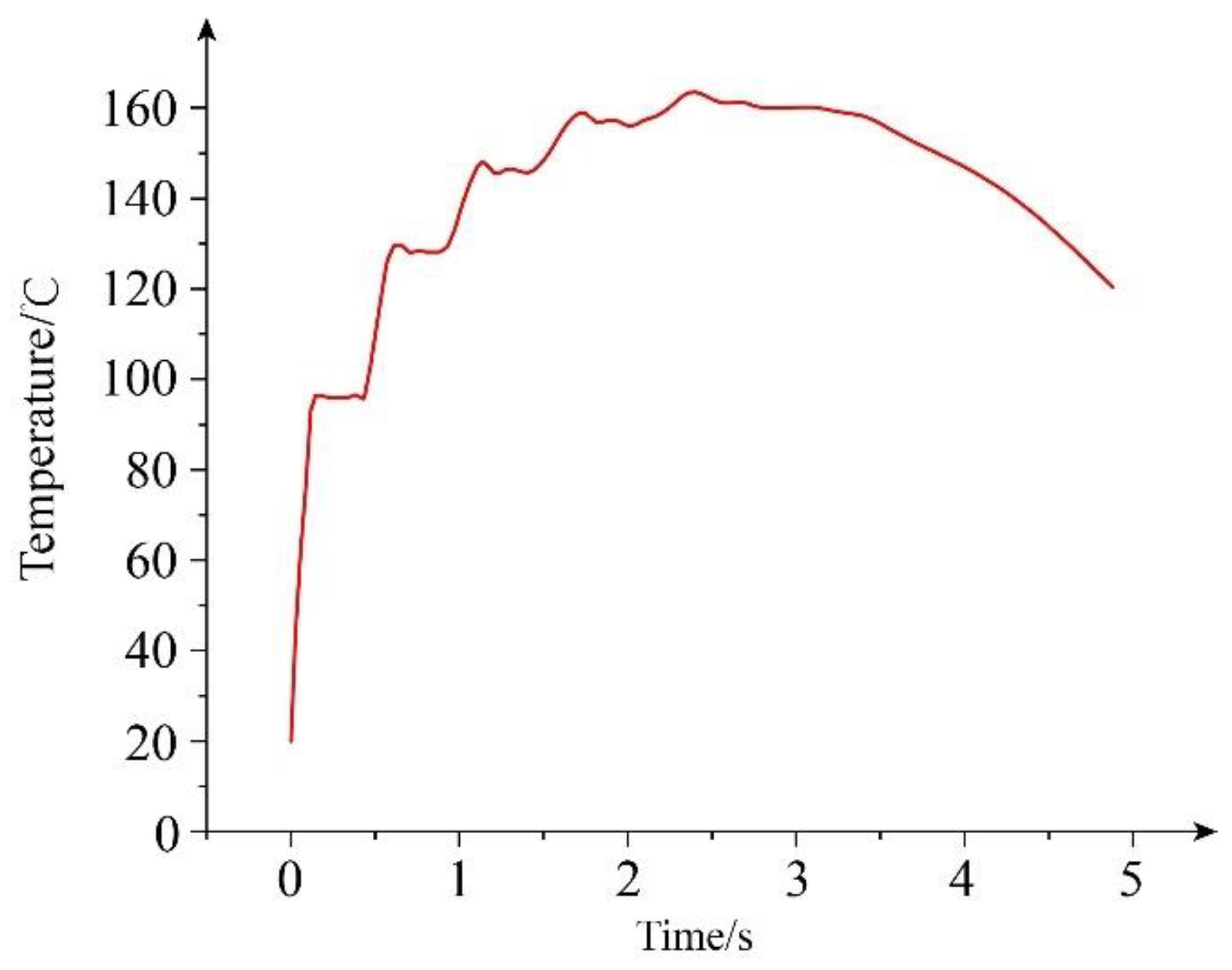

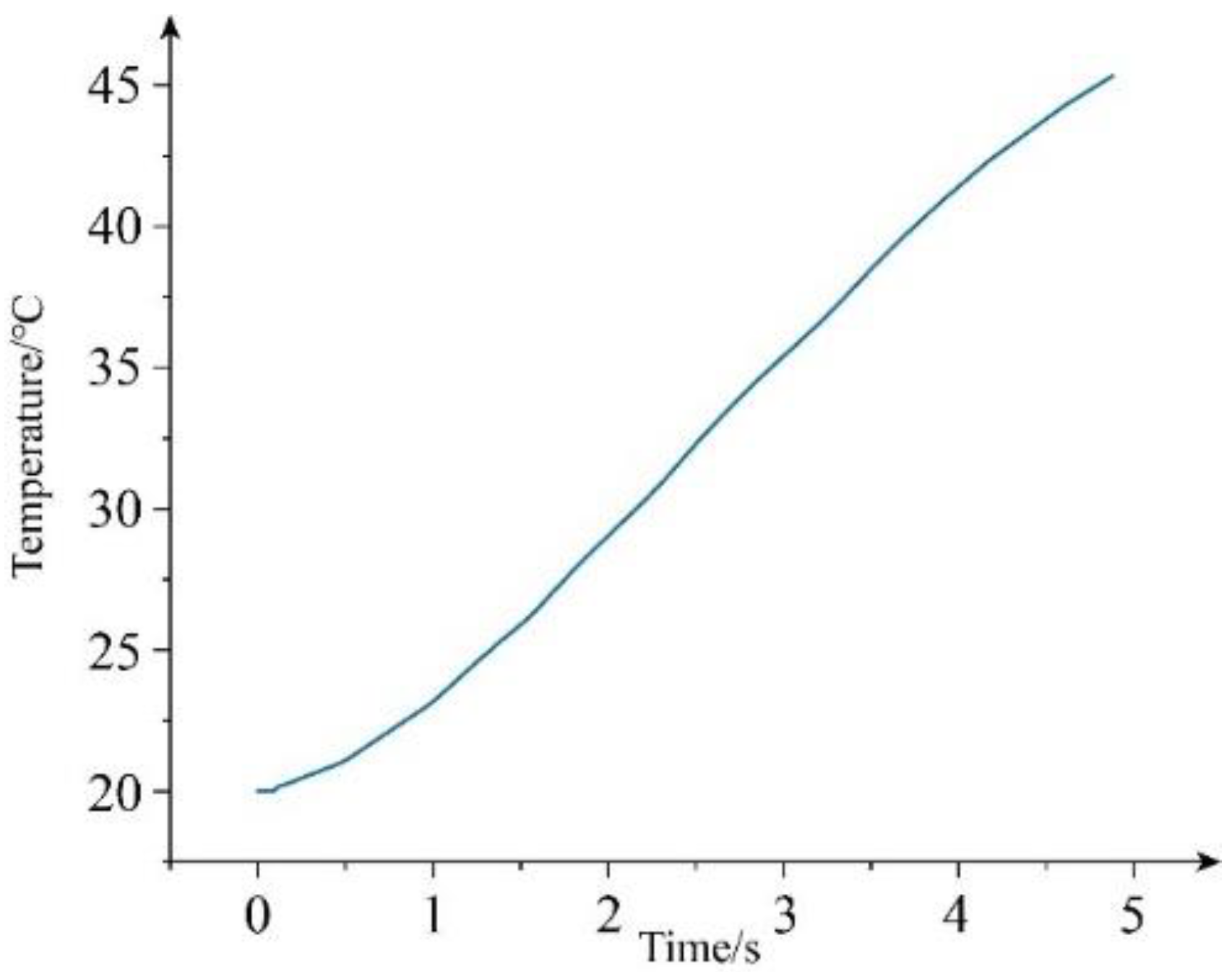

It is worth noting that changes in the friction coefficient can affect the braking torque during the braking process of a hoist, which will affect the effectiveness and safety of braking. As can be seen in

Figure 2, the friction coefficient of each sample under different pressing forces at a rotational speed of 300 r/min is presented. The coefficient of friction is calculated by

μ =

F/P, in which

F represents the measured friction force, and

P represents the measured pressure force.

The friction coefficients of the four samples all show significant fluctuations under a pressing force of 100 N. The fluctuation degrees of the friction coefficients of Samples 1, 2, and 3 are similar, while the friction coefficient of Sample 4 fluctuates dramatically. When the pressing forces are set to 200 N and 300 N, the change in the friction coefficient of Samples 1, 2, and 3 is relatively stable, while that of Sample 4 fluctuates greatly.

In terms of the average friction coefficient, the four samples have values of 0.28, 0.27, 0.27, and 0.44 under a pressing force of 100 N, respectively. When the pressing force is 200 N, the average friction coefficient of the four samples is 0.28, 0.30, 0.32, and 0.37, respectively. When the pressing force is 300 N, the average friction coefficients are 0.31, 0.31, 0.30, and 0.37, respectively.

In conclusion, the friction coefficient of the three coated samples (Samples 1, 2, and 3) is lower than that of the uncoated sample (Sample 4), but the degree of fluctuation in the friction coefficient of the coated samples is lower than that of the uncoated sample. When the pressing force is 300 N, the friction coefficient of both Samples 1 and 3 increases at first and then decreases slightly, while Sample 2 exhibits relatively consistent friction coefficients.

- 3.

Friction coefficient variance analysis

Based on the results of the friction coefficient, the friction coefficient variance is also calculated to quantify the fluctuation degree of the friction coefficient.

The variance of the friction coefficient refers to the variance of the friction coefficient in the braking friction test, which is used to describe the stability of the friction coefficient during the braking process. Its expression is as follows:

where

f1,

f2,…,

fn represent the friction coefficients of each sampling point,

n is the number of sampling points, and

µf is the average value of all sampling points with friction coefficients.

The friction coefficient variance of each sample under different pressing forces is shown in

Table 3. The larger the variance, the more unstable the friction coefficient.

When the pressing force is 100 N, the friction coefficient variance of Sample 1 is the smallest, while that of Sample 2 is slightly higher than that of Sample 1. The friction coefficient variance of Sample 3 is twice that of Sample 2. The friction coefficient variance of Sample 4 is very large and 8.3 times that of Sample 3.

When the pressing force is 200 N, the friction coefficient variance of Samples 1, 2, and 3 is relatively small, while the friction coefficient variance of Sample 4 is relatively large. When the pressing force is 300 N, the friction coefficient variance of Samples 1 and 2 is small, while that of Sample 3 is large. Sample 4 displays twice the variance of the friction coefficients compared to Sample 3.

Additionally, under different pressing forces, the friction coefficient variance of Sample 1 and Sample 2 is relatively small, that of Sample 3 is slightly higher, and that of Sample 4 is much higher. In other words, the friction coefficient stability of coated Sample 1, Sample 2, and Sample 3 is better than that of uncoated Sample 4. Among the coated samples, the friction coefficient stability of Sample 1 and Sample 2 is the best, and the friction coefficient stability of Sample 3 is worse than that of Sample 1 and Sample 2.

2.2.2. Influence of Rotational Speed on Friction and Wear Properties

The impact of different rotational speeds on the friction and wear properties is analyzed at a constant pressing force of 300 N. As before, the wear amount, friction coefficient, and friction coefficient variance are studied.

The wear performance of each sample at different rotational speeds under a pressing force of 300 N is presented in

Table 4.

The wear amount of each sample at the same rotational speed and a pressing force of 300 N is compared, as shown in

Table 4. Obviously, the wear amount increases with the increase in the rotational speed, and the amount of wear is positively correlated with the rotational speed. The wear resistance of Sample 1 is equivalent to that of Sample 4 at relatively lower speeds, while the wear resistance of Sample 1 is slightly better than that of Sample 4 at high speeds. The wear resistance of Sample 2 is the best in the friction test, with the smallest wear amount at both low and high rotational speeds. The wear resistance of Sample 3 is the worst, while that of Sample 4 is the same at 100 r/min, but that of Sample 3 is the highest at 200 r/min and 300 r/min and is much higher than that of Sample 4.

In summary, compared to Sample 4, Sample 2 has the best wear resistance performance, followed by Sample 1, while Sample 3 has the worst performance.

- 2.

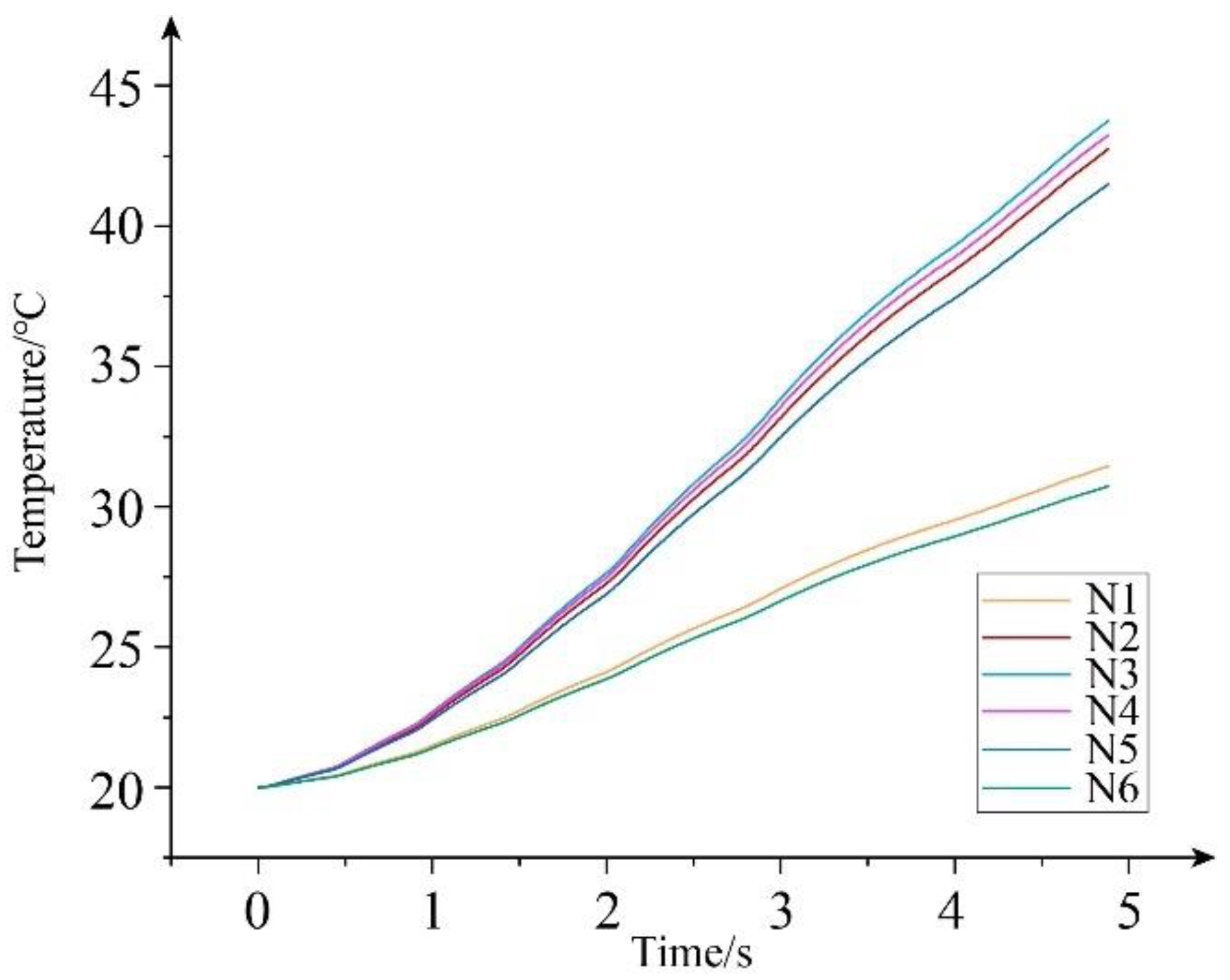

Friction coefficient performance

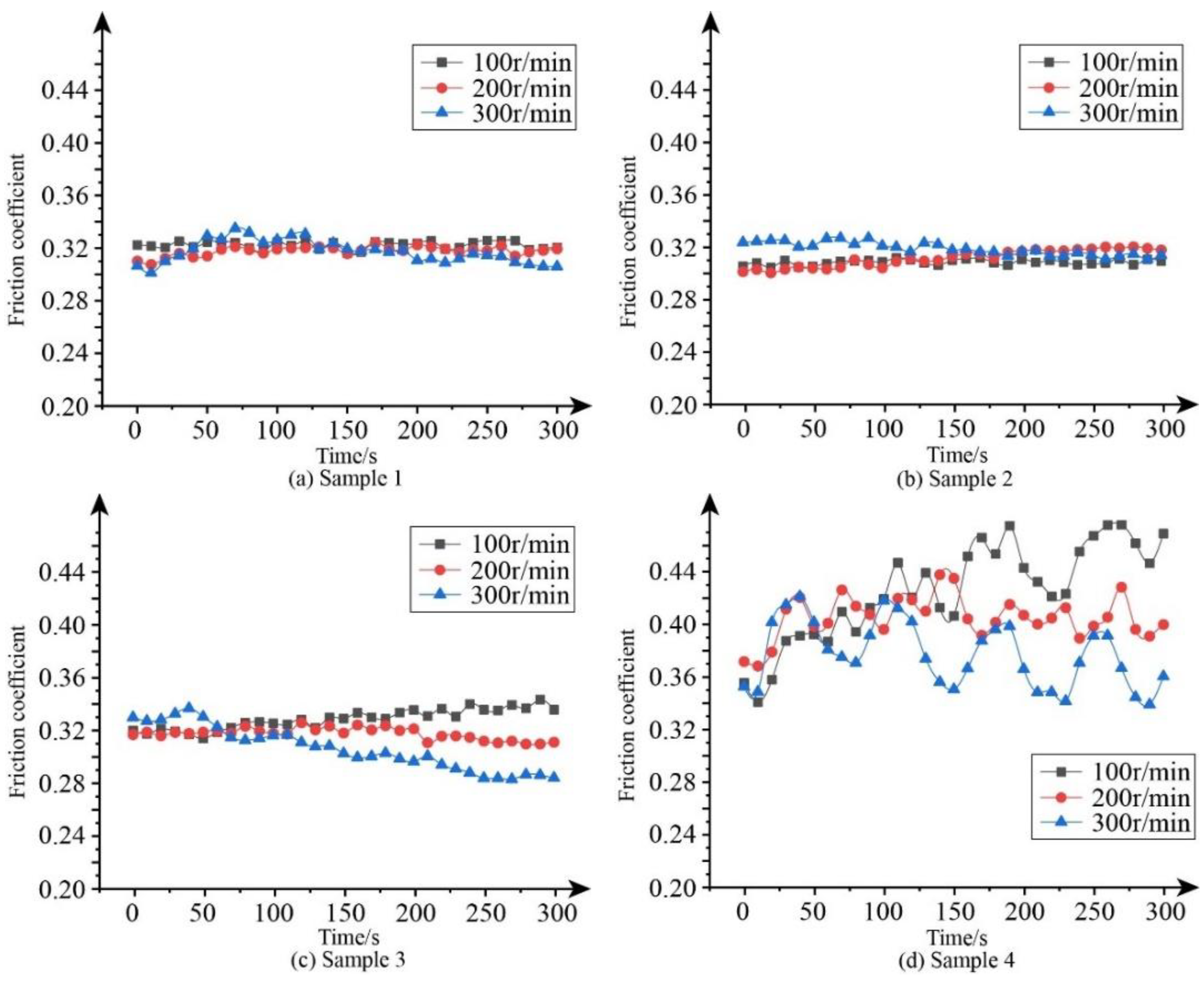

Figure 3 shows the friction coefficient of each sample at different rotational speeds under a pressing force of 300 N. The friction coefficient of Sample 1 and Sample 2 is relatively stable at different rotational speeds. For Sample 3, the friction coefficient increases slightly with time when the rotational speed is 100 r/min. When the rotational speed is 200 r/min, the friction coefficient is relatively stable. When the rotational speed is 300 r/min, the friction coefficient increases slightly at first but then decreases continuously. For Sample 4, the friction coefficient fluctuates greatly at different rotational speeds, and it is significantly higher than that of the other samples.

According to the above analysis, although the coating can slightly reduce the friction coefficient, it can also increase the stability of the friction coefficient. Sample 1 and Sample 2 show the best stability of the friction coefficient, while that of Sample 3 is poorer. Sample 4 has a relatively high friction coefficient, but it fluctuates greatly.

- 3.

Friction coefficient variance analysis

Table 5 shows the friction coefficient variance of each sample at different rotational speeds under a pressing force of 300 N.

Compared to the coated samples, the friction coefficient variance of Sample 4 is the highest at all speeds, while the stability of the friction coefficient of the three coated samples is better than that of the uncoated sample.

When the rotational speed is 100 r/min and 300 r/min, the friction coefficient variance of Sample 2 is the smallest, indicating the best stability of the friction coefficient. The friction coefficient variance of Sample 1 is slightly higher than that of Sample 2. The stability of the friction coefficient of Sample 3 and Sample 4 is poor. When the rotational speed is 200 r/min, the friction coefficient variance of all coated samples is small, indicating a good stability of the friction coefficient.

In terms of friction coefficient stability, that of Sample 1 is the best, followed by that of Sample 2, and that of Sample 3 is poor. The stability of the friction coefficient of the three coated samples is superior to that of the uncoated sample.

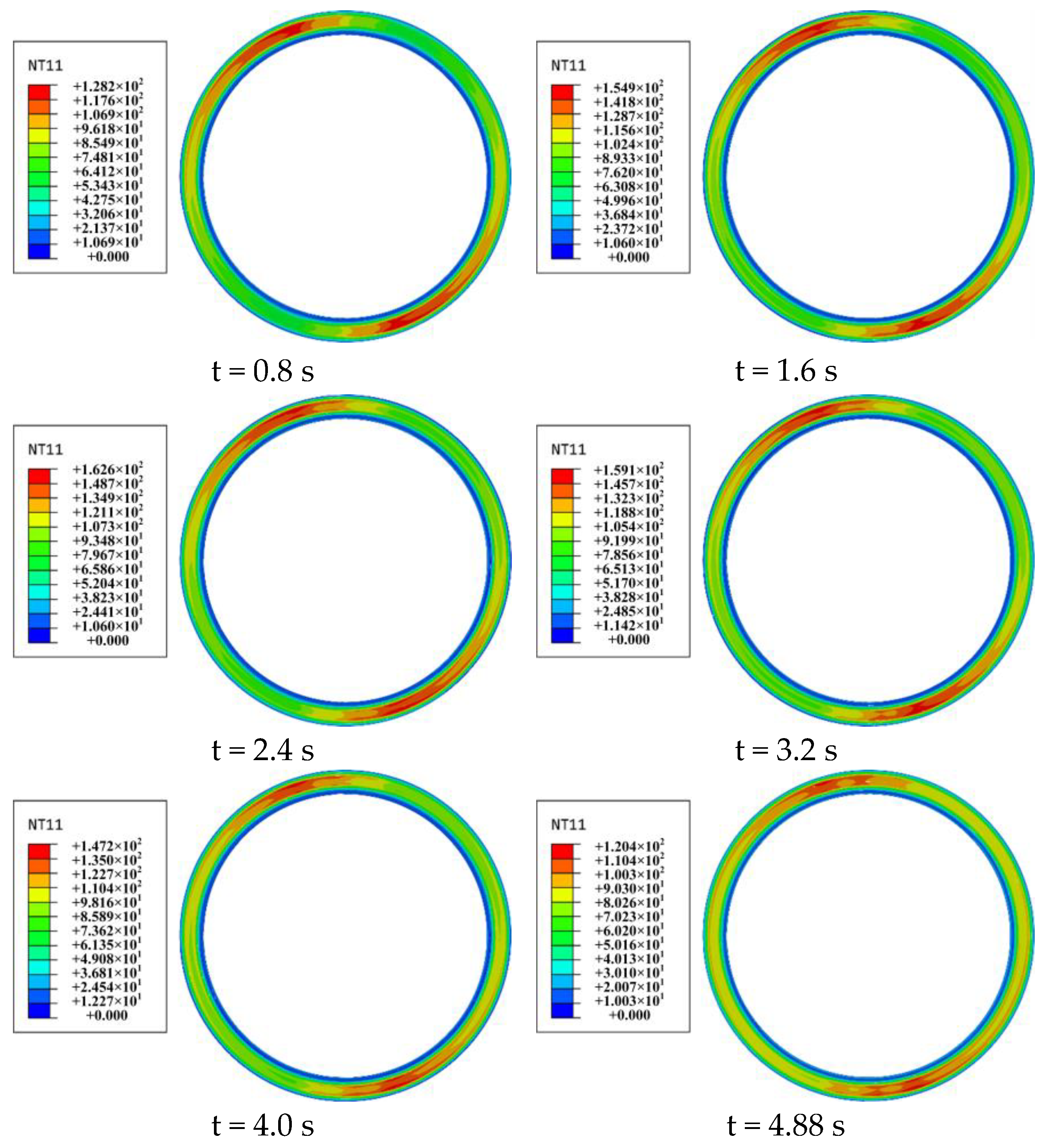

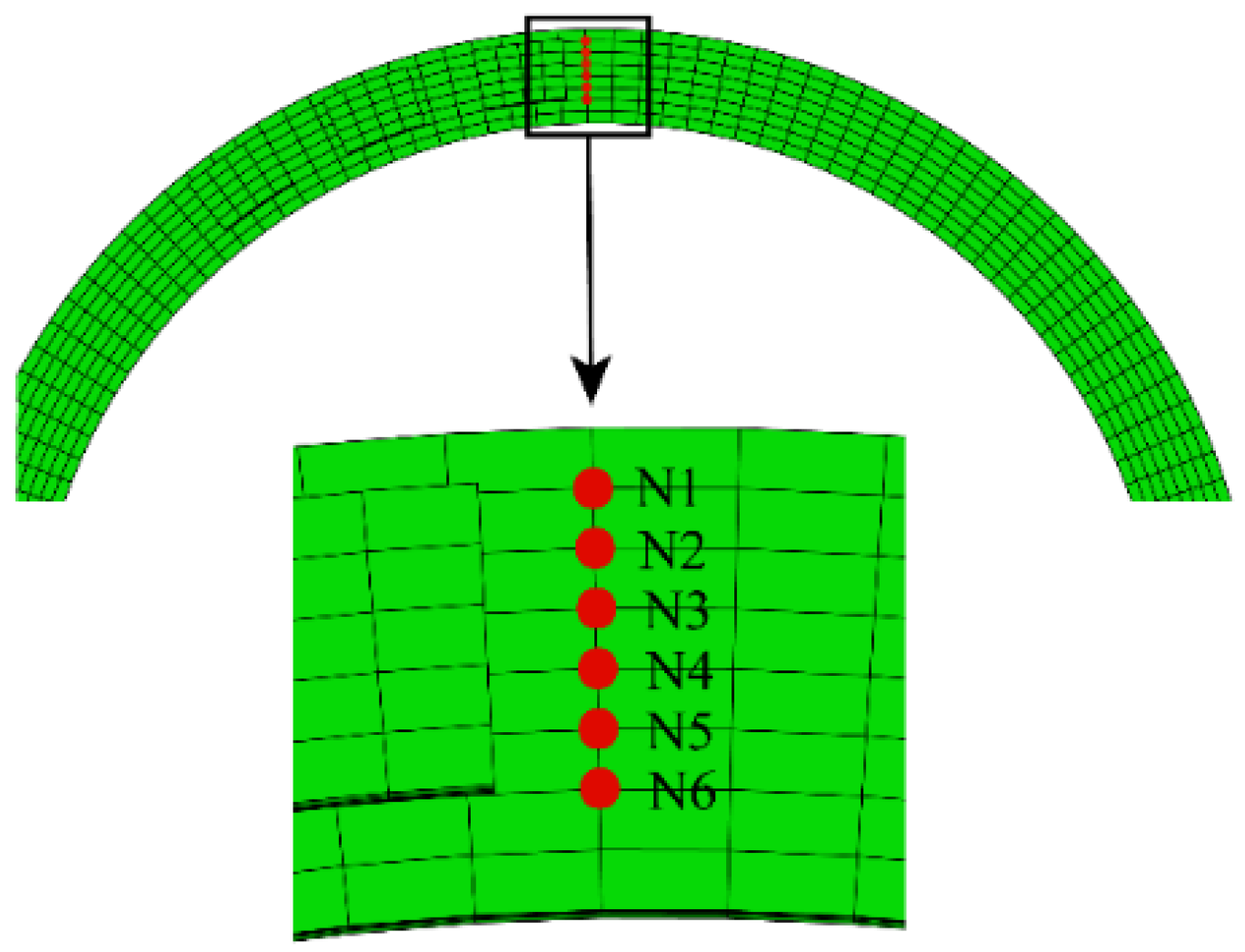

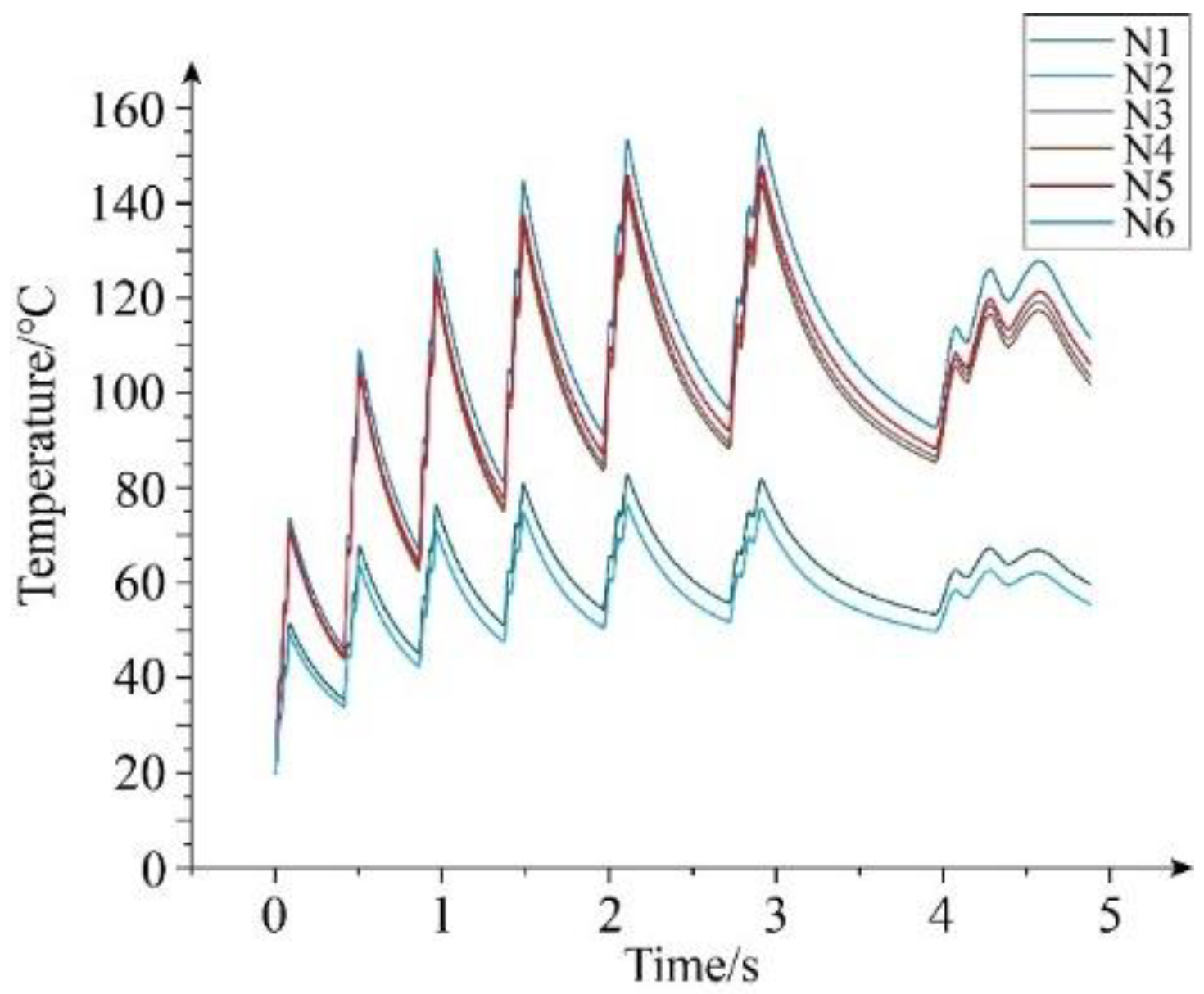

2.2.3. Influence of Braking Times on Friction and Wear Performance

When the pressing force is 300 N and the rotational speed is 300 r/min, the effect of braking times on the friction and wear performance is studied.

Table 6 shows a comparison of the wear amount of each sample under single braking tests and continuous braking tests. It is evident that the wear amount of Sample 2 is the smallest among the four samples in both single and continuous braking, indicating the best wear resistance. The wear resistance performance of Sample 1 is slightly inferior to that of Sample 2 but better than that of uncoated Sample 4. The wear amount of Sample 3 is higher than that of Sample 4, indicating that the wear resistance of Sample 3 is even worse than that of the uncoated sample.

- 2.

Friction coefficient performance

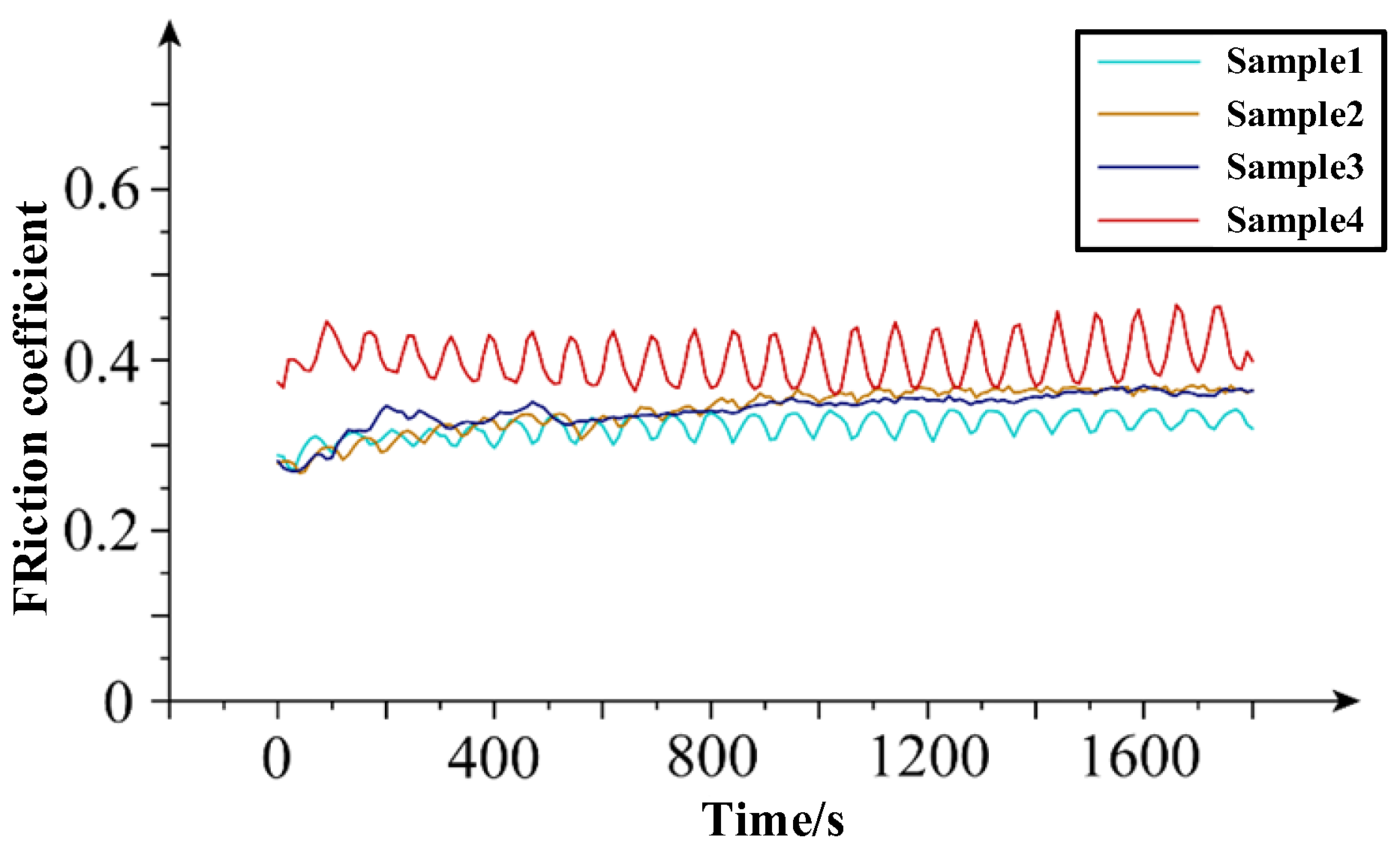

Figure 4 illustrates the variation in the friction coefficient of each sample in the continuous braking tests. It is evident that the friction coefficient of Sample 4 is higher than that of the other three samples throughout the test, and the fluctuation of the friction coefficient is also the largest. The friction coefficient curves of Sample 2 and Sample 3 are close to each other, showing a small upward trend throughout the test process. The friction coefficient curve of Sample 1 is nearly horizontal, but with small fluctuations. When compared with the single friction test, it is apparent that, in the continuous friction test, the value of the friction coefficient does not increase or decrease significantly, but the fluctuation degree of the friction coefficient increases to a certain extent.

- 3.

Friction coefficient variance analysis

Table 7 shows a comparison of the friction coefficient variance between the single braking tests and continuous braking tests for each sample. The friction coefficient variance in the continuous braking tests for all four samples is higher than that in the single braking tests. The stability of the friction coefficient becomes worse with increasing braking times, resulting in greater fluctuations in the friction coefficient.

In the single braking tests, the friction coefficient variance of Sample 2 is the smallest, and its friction coefficient stability is the highest. However, in the continuous braking tests, the stability of the friction coefficient of Sample 2 is comparable to that of Sample 4, indicating that the fluctuation degree of the friction coefficient of Sample 2 increases significantly with increasing braking times.

Furthermore, the friction coefficient variance of Sample 1 in the single braking tests is higher than that of Sample 2 but smaller than that of Sample 3, while the friction coefficient variance of Sample 1 is the smallest in the continuous braking tests. The variation in the friction coefficient of Sample 3 in the single braking tests and continuous braking tests is at a medium level. The variation in the friction coefficient of Sample 4 is the largest in both the single friction tests and continuous braking tests.