Fretting Friction and Wear Characteristics of the Internal Spiral Contact Steel Wires in the Hoisting Wire Rope Under Different Service Conditions

Abstract

1. Introduction

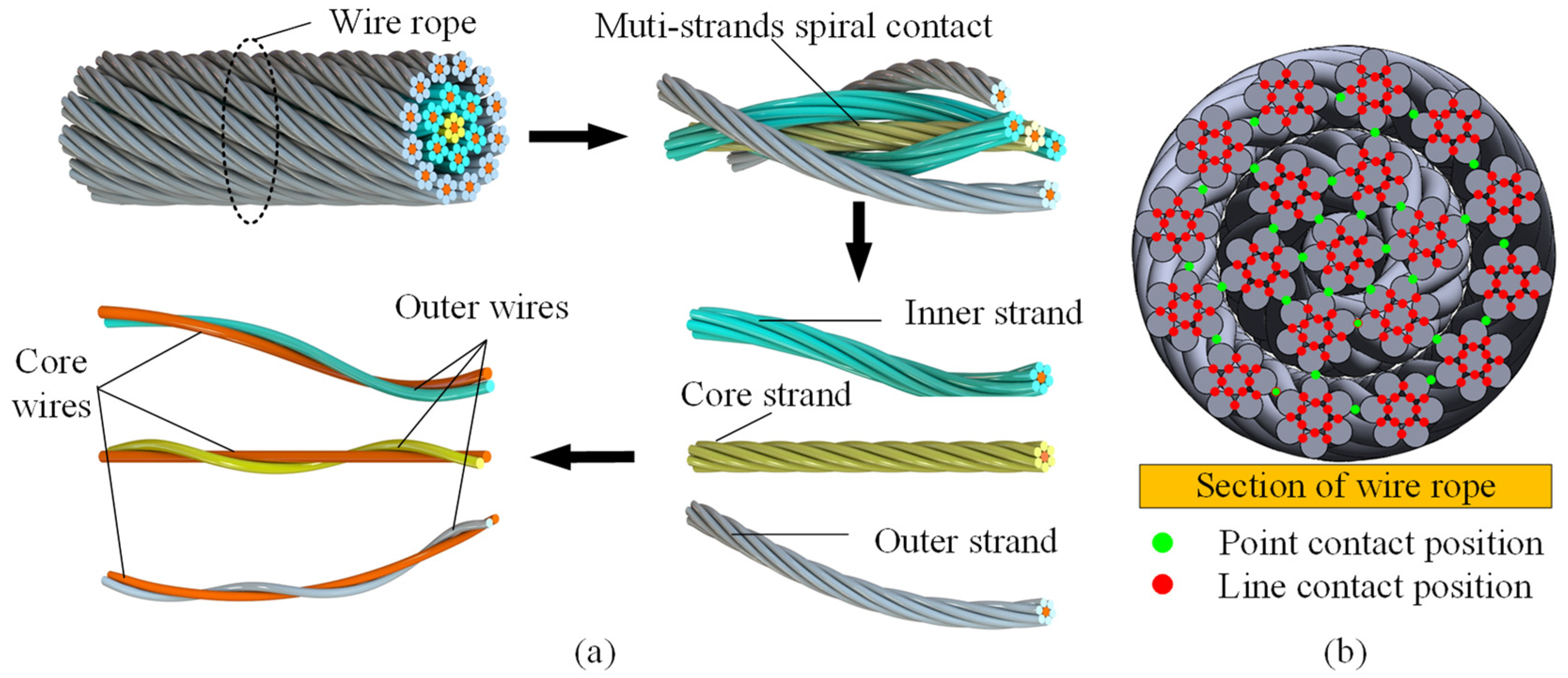

2. Materials and Methods

2.1. Materials

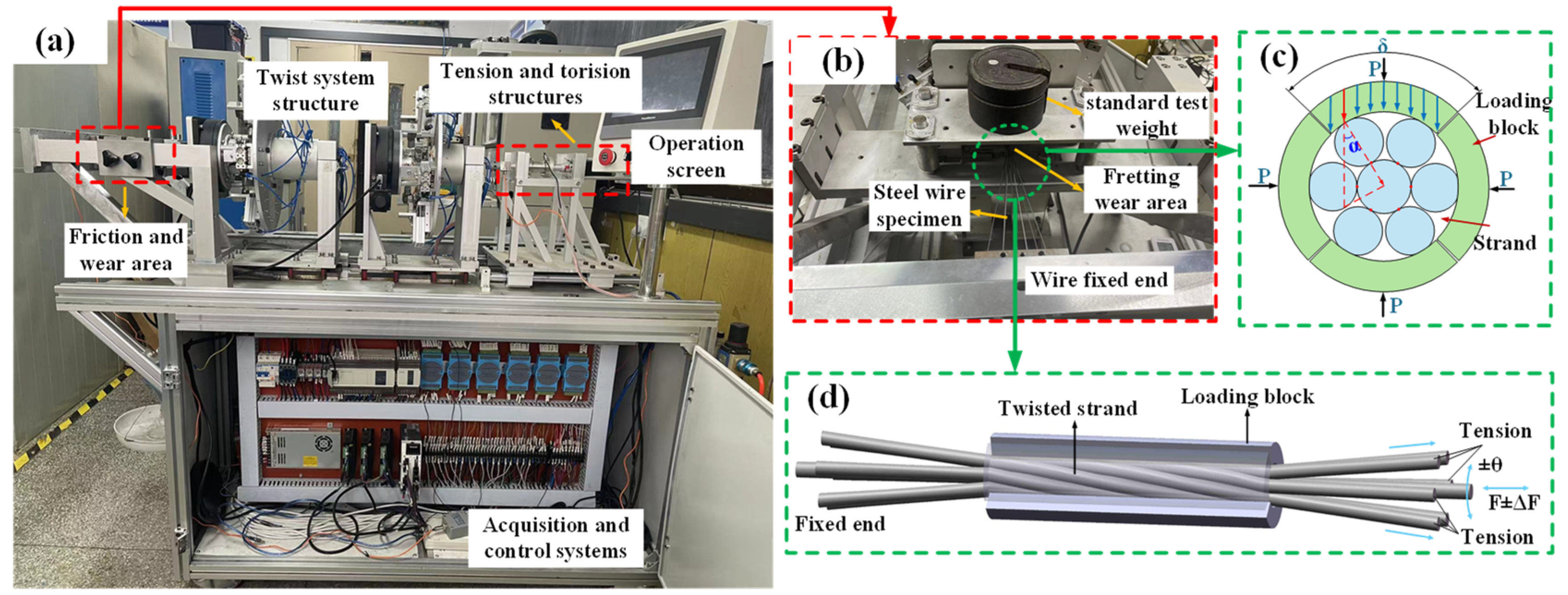

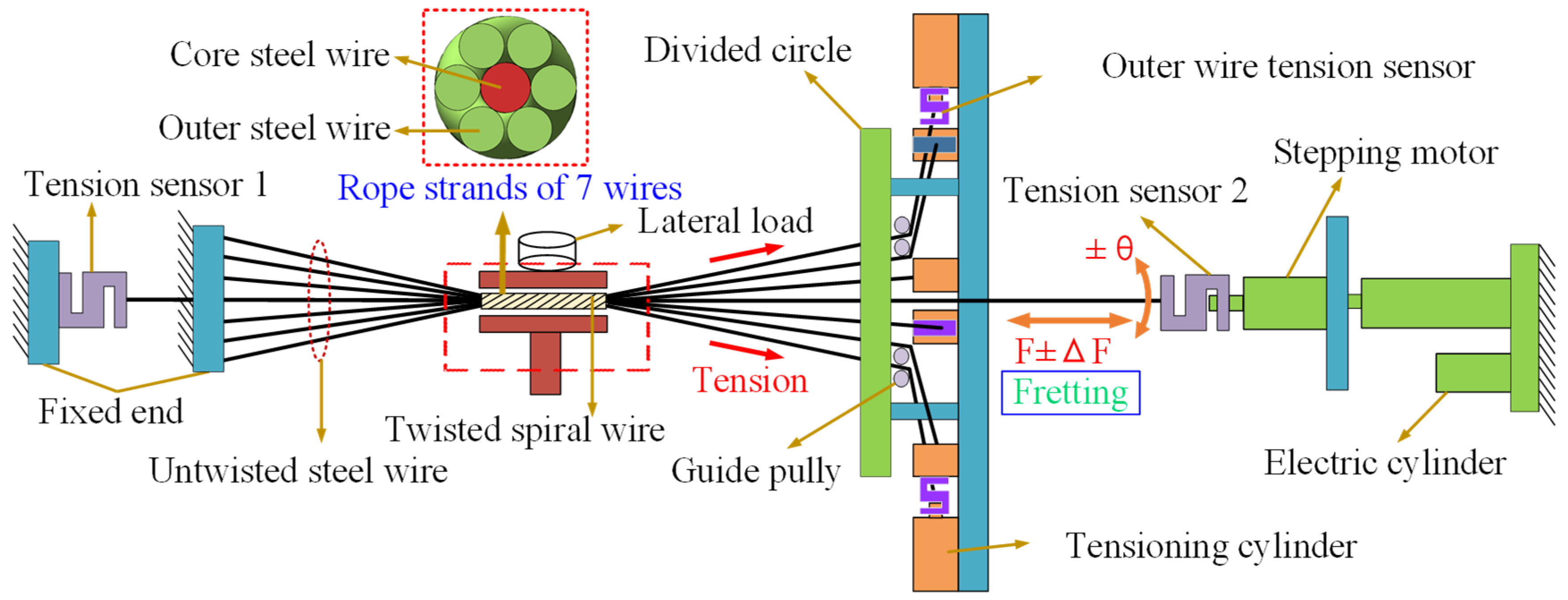

2.2. Testing Apparatus and Procedures

2.3. Analysis Method

3. Results

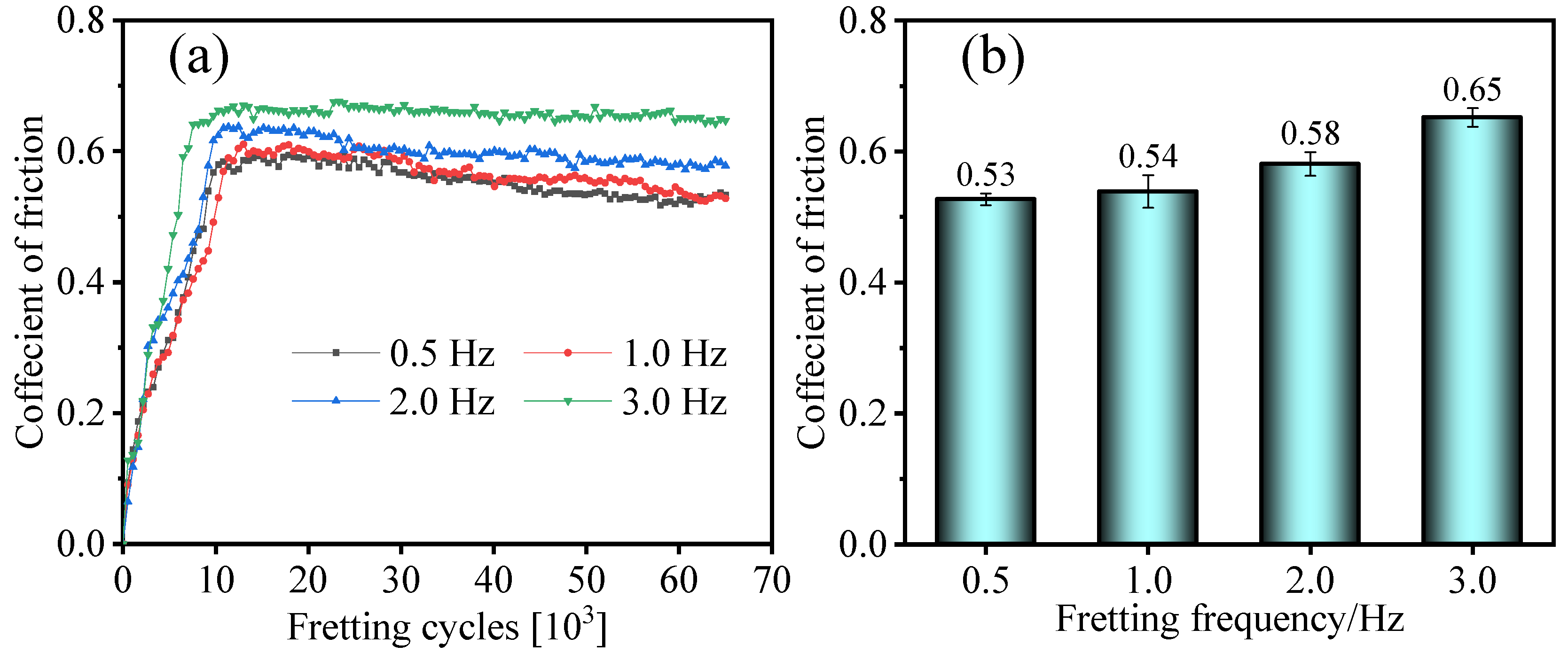

3.1. COF

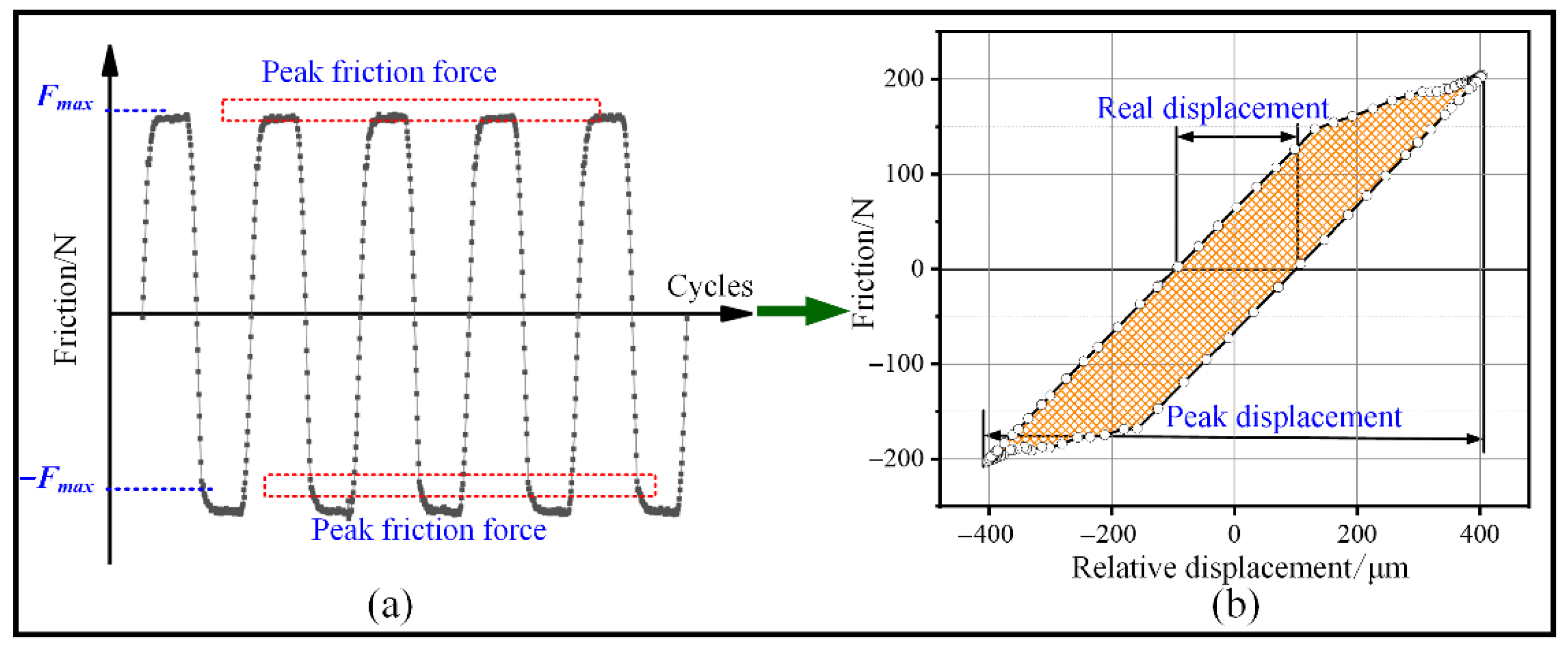

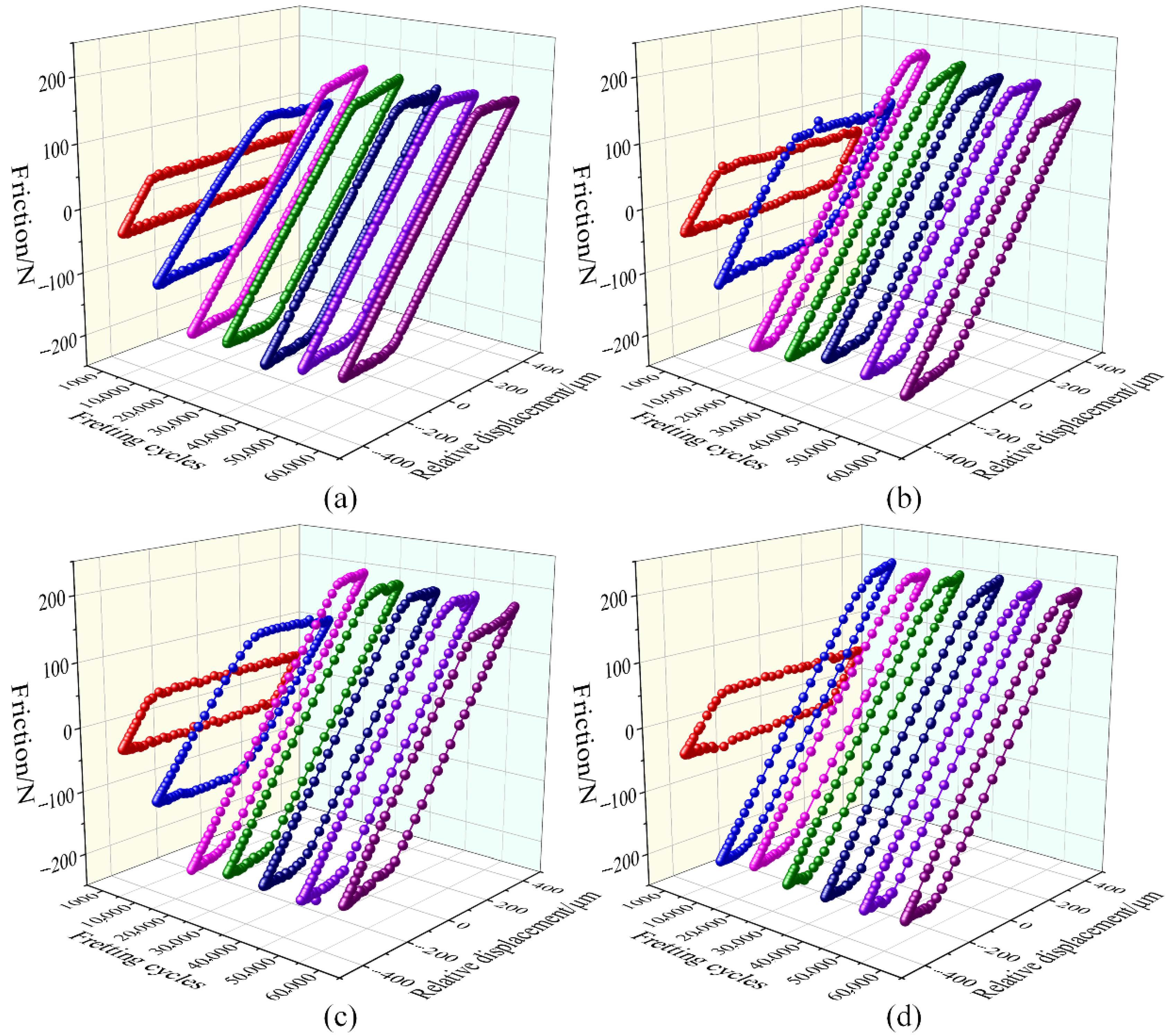

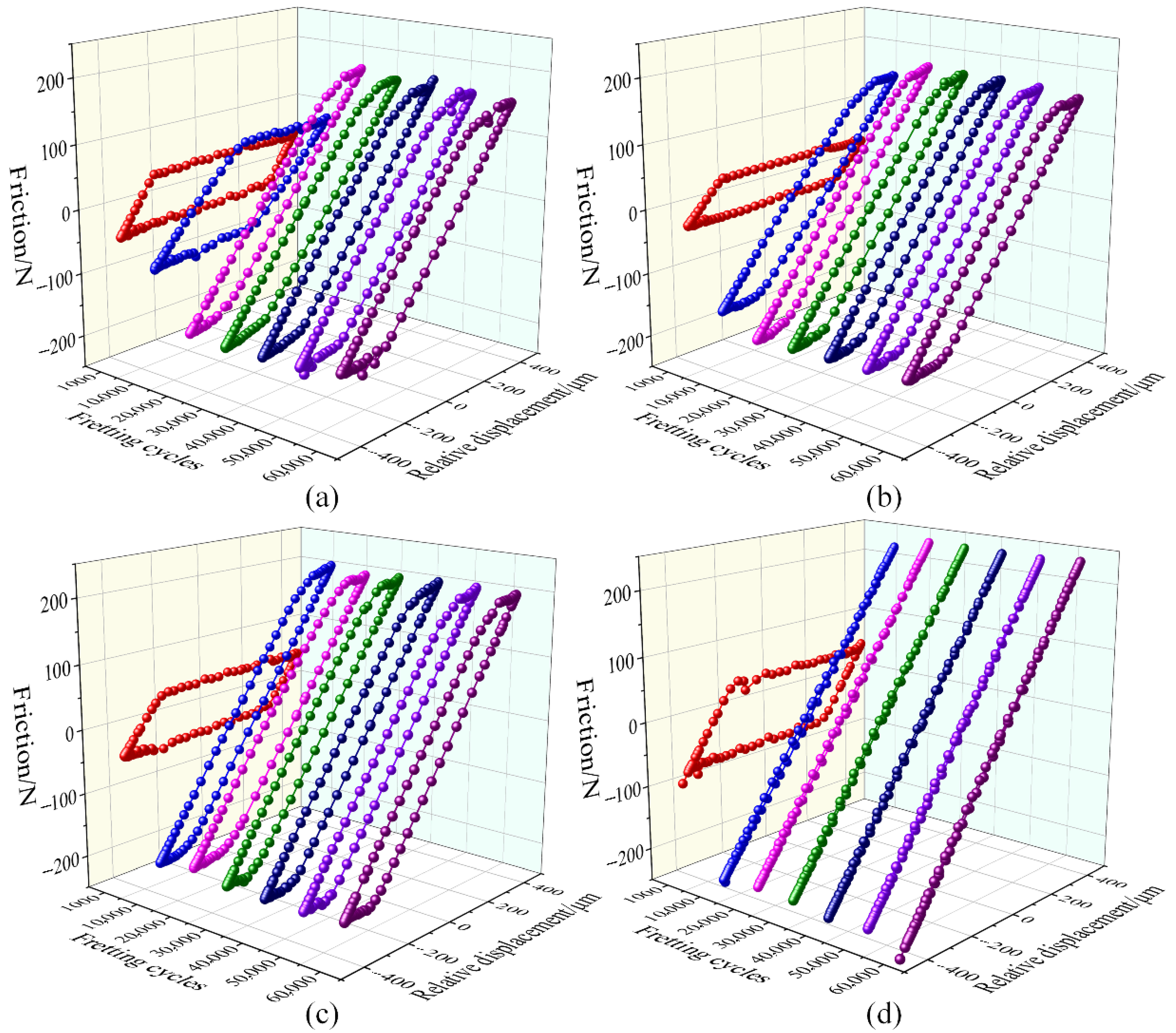

3.2. Hysteretic Characteristics

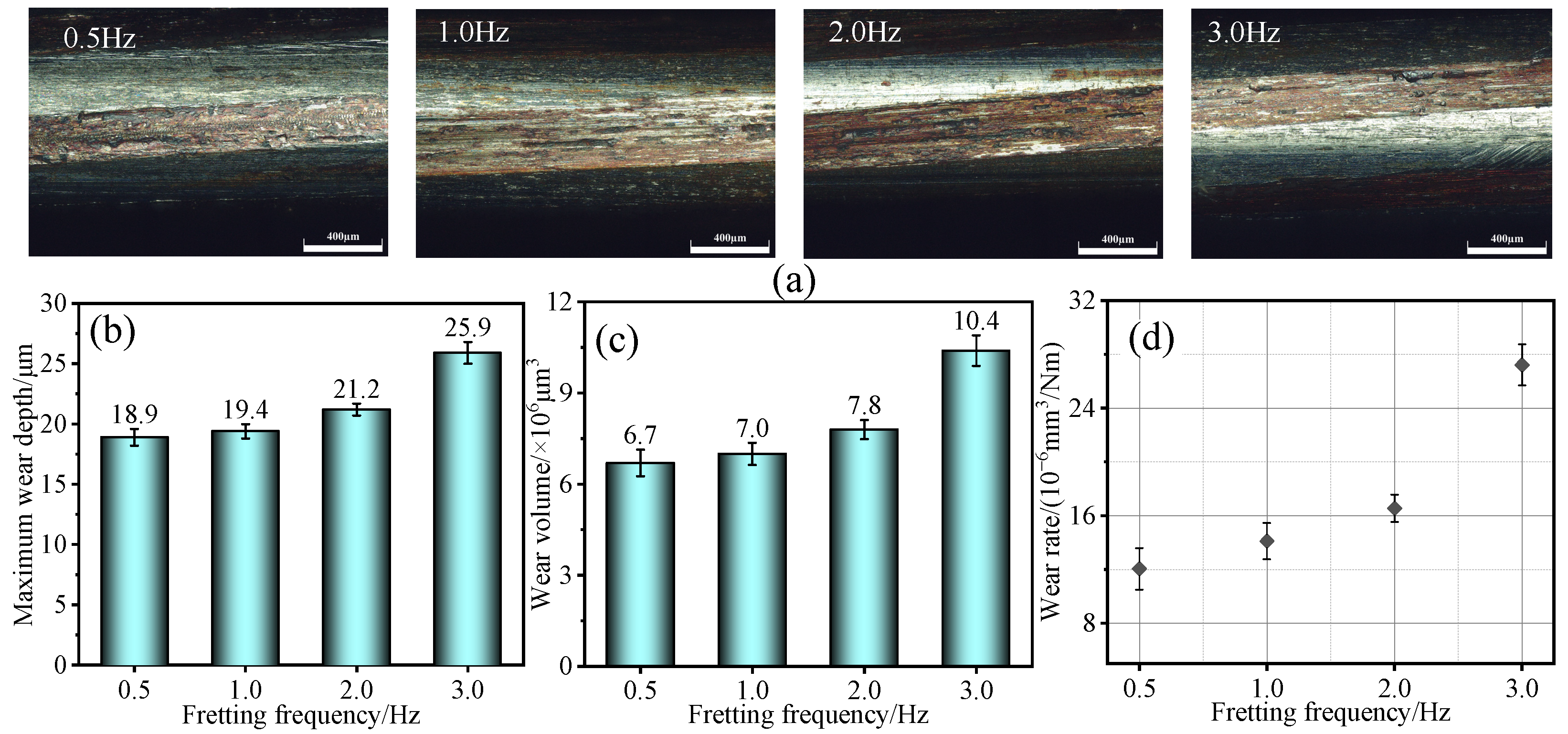

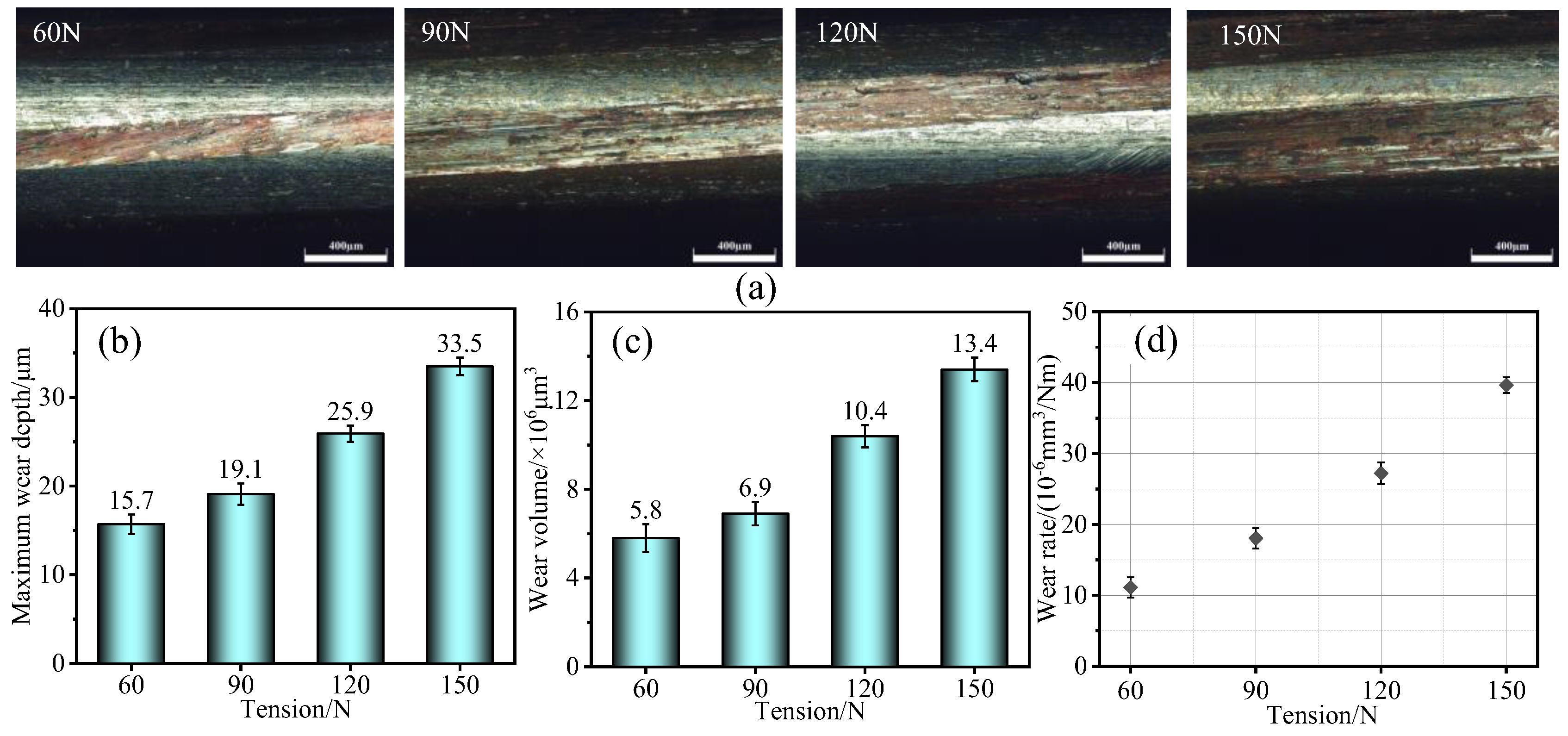

3.3. Wear Characteristics

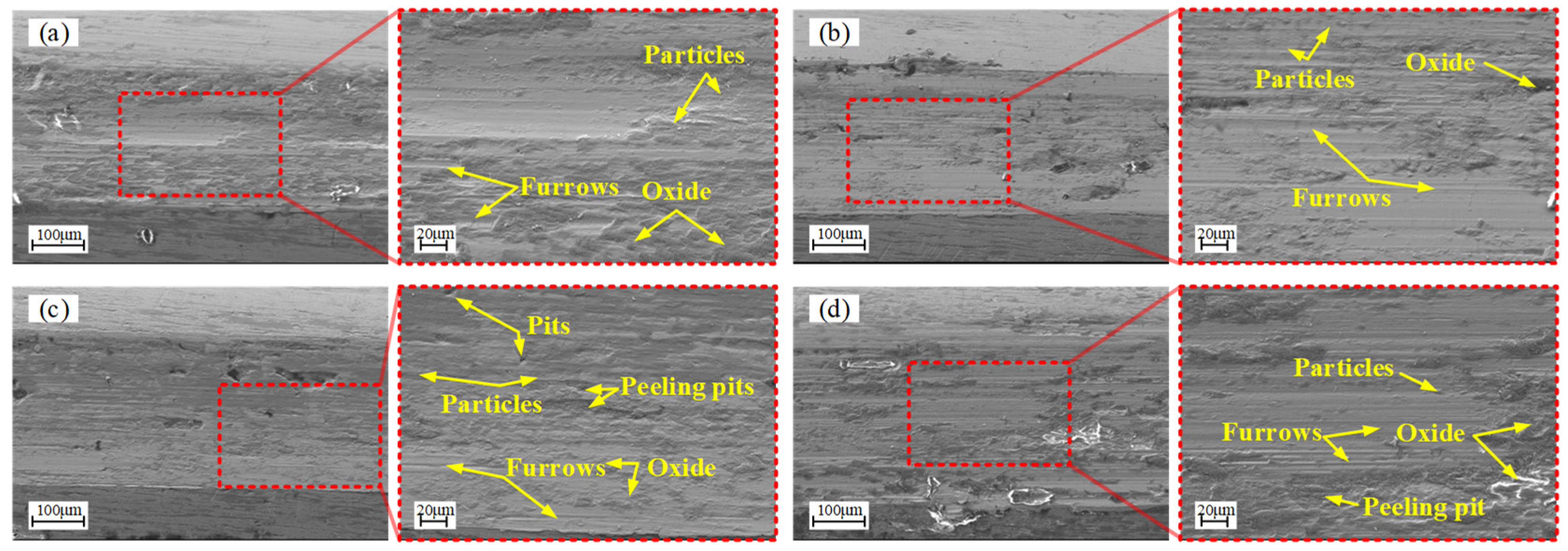

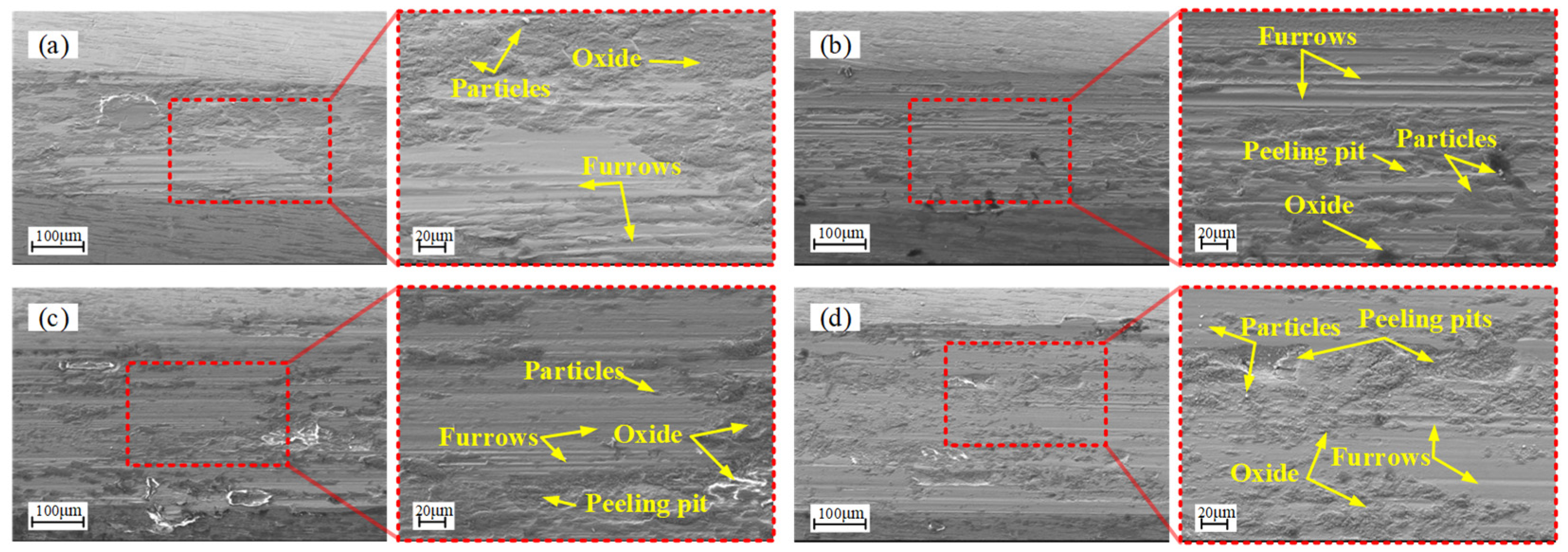

3.4. Wear Mechanism

4. Conclusions

- As the fretting frequency increases from 0.5 Hz to 3.0 Hz, the COF increases from 0.53 to 0.65, and as the wire tension increases from 60 N to 150 N, it decreases from 0.71 to 0.64. Fretting state evolves from gross slip to partial slip with the increase in fretting frequency. When the wire tension is 60 N to 120 N, the fretting state evolves from gross slip to partial slip, and when it increases to 150 N, the fretting regime transitions from an initial state of gross slip, through partial slip, and eventually to adhesion.

- The wear depth, wear volume and wear rate of steel wire increase with the increase in fretting frequency, and increase to 25.9 μm, 10.4 × 106 μm3 and 27.2 × 10−6 mm3/Nm at 3.0 Hz, respectively. With the increase in wire tension from 60 N to 150 N, the wear depth, wear volume and wear rate increased to the maximum of 33.5 μm, 13.4 × 106 μm3 and 39.6 × 10−6 mm3/Nm, respectively.

- The main wear mechanisms with low fretting frequency are abrasive wear and tribochemical reaction, and the main wear mechanisms of steel wire with higher frequency increase surface fatigue; when the tension is high, the two sub-mechanisms of indentation and delamination appear and become more significant with the increase in tension. The wear mechanisms with low tension are mainly abrasive wear and tribochemical reaction. The wear mechanisms with high tension are mainly abrasive wear, surface fatigue and tribochemical reaction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, R.P.; Mallick, M.; Verma, M.K. Studies on the failure behaviour of wire rope used in underground coal mines. Eng. Fail. Anal. 2016, 70, 290–304. [Google Scholar] [CrossRef]

- Hobbs, R.E.; Raoof, M. Mechanism of fretting fatigue in steel cables. Int. J. Fatigue 1994, 16, 273–280. [Google Scholar] [CrossRef]

- Krishnadev, M.; Larouche, M.; Lakshmanan, V.I.; Sridhar, R. Failure Analysis of Failed Wire Rope. J. Fail. Anal. Prev. 2010, 10, 341–348. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Ge, S.R. Effect of terminal mass on fretting and fatigue parameters of a hoisting rope during a lifting cycle in coal mine. Eng. Fail. Anal. 2014, 36, 407–422. [Google Scholar] [CrossRef]

- Kumar, K.; Goyal, D.; Banwait, S.S. Effect of key parameters on fretting behaviour of wire rope: A review. Arch. Comput. Method E 2020, 27, 549–561. [Google Scholar] [CrossRef]

- Chen, Y.P.; Meng, F.M.; Gong, X.S. Full contact analysis of wire rope strand subjected to varying loads based on semi-analytical method. Int. J. Solids Struct. 2017, 117, 51–66. [Google Scholar] [CrossRef]

- Chen, Y.P.; Meng, F.M.; Gong, X.S. Interwire wear and its influence on contact behavior of wire rope strand subjected to cyclic bending load. Wear 2016, 368, 470–484. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, E.Y.; Jia, F.Y. Mechanical and wear behavior of steel wires in typical contact area under tension-tension fatigue. Tribol. Trans. 2022, 65, 282–295. [Google Scholar]

- Urchegui, M.A.; Tato, W.; Gómez, X. A method for evaluating fretting wear scars in thin steel roping wires based on confocal imaging profilometry. J. Test. Eval. 2007, 35, 357–363. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, Y.X.; Zhu, Z.C.; Chang, X.D.; Lu, H.; Zhou, Z.; Cao, G.H.; Tang, W.; Chen, G.A. Influence of longitudinal vibration on the friction and wear characteristics of multi-layer winding hoisting wire rope. Wear 2022, 492–493, 204211. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, Y.X.; Zhu, Z.C.; Chang, X.D.; Lu, H.; Zhou, Z.; Jiang, F.; Tang, W.; Chen, G.A. Tribo-failure characteristics of the multilayer winding hoisting wire ropes with two different structures under vibration. Eng. Fail. Anal. 2022, 140, 106538. [Google Scholar] [CrossRef]

- Ma, W.; Lubrecht, A.A. Temperature of a sliding contact between wire rope and friction lining. Tribol. Int. 2018, 120, 140–148. [Google Scholar] [CrossRef]

- Peng, Y.X.; Wang, G.F.; Zhu, Z.C.; Chang, X.D.; Lu, H.; Tang, W.; Jiang, F.; Chen, G.A. Effect of low temperature on tribological characteristics and wear mechanism of wire rope. Tribol. Int. 2021, 164, 107231. [Google Scholar] [CrossRef]

- Harris, S.J.; Waterhouse, R.B.; Mccoll, I.R. Fretting damage in locked coil steel ropes. Wear 1993, 170, 63–70. [Google Scholar] [CrossRef]

- Waterhouse, R.B.; Mccoll, I.R.; Harris, S.J.; Tsujikawa, M. Fretting wear of a high strength heavily work-hardened eutectoid steel. Wear 1994, 175, 51–57. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R.; Urchegui, M.A.; Gómez, X. Fretting wear of thin steel wires. Part 1: Influence of contact pressure. Wear 2010, 268, 1409–1416. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R.; Urchegui, M.A.; Gómez, X. Fretting wear of thin steel wires. Part 2: Influence of crossing angle. Wear 2011, 273, 60–69. [Google Scholar] [CrossRef]

- Cruzado, A.; Urchegui, M.A.; Gómeza, X. Finite element modelling and experimental validation of fretting wear scars in thin steel wires. Wear 2012, 289, 26–38. [Google Scholar] [CrossRef]

- Cruzado, A.; Urchegui, M.A.; Gómeza, X. Finite element modelling of fretting wear scars in the thin steel wires: Application in crossed cylinder arrangements. Wear 2014, 318, 98–105. [Google Scholar] [CrossRef]

- Cruzado, A.; Leen, S.B.; Urchegui, M.A.; Gómez, X. Finite element simulation of fretting wear and fatigue in thin steel wires. Int. J. Fatigue 2013, 55, 7–21. [Google Scholar] [CrossRef]

- Zhang, D.K.; Yang, X.H.; Chen, K.; Zhang, Z.F. Fretting fatigue behavior of steel wires contact interface under different crossing angles. Wear 2018, 400, 52–61. [Google Scholar] [CrossRef]

- Zhang, D.K.; Geng, H.; Zhang, Z.F.; Wang, D.G.; Wang, S.Q.; Ge, S.R. Investigation on the fretting fatigue behaviors of steel wires under different strain ratios. Wear 2013, 303, 334–342. [Google Scholar] [CrossRef]

- Zhang, D.K.; Shen, Y.; Xu, L.M.; Ge, S.R. Fretting wear behaviours of steel wires in coal mine under different corrosive mediums. Wear 2011, 271, 866–874. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Ge, S.R. Finite element analysis of fretting fatigue behaviour of steel wires and crack initiation characteristics. Eng. Fail. Anal. 2013, 28, 47–62. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Ge, S.R. Fretting-fatigue behaviour of steel wires in low cycle fatigue. Mater. Des. 2011, 32, 4986–4993. [Google Scholar] [CrossRef]

- Torkar, M.; Arzensek, B. Failure of crane wire rope. Eng. Fail. Anal. 2002, 9, 227–233. [Google Scholar] [CrossRef]

- Moradi, S.; Ranjbar, K.; Makvandi, H. Failure Analysis of a Drilling Wire Rope. J. Fail. Anal. Prev. 2012, 12, 558–566. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, T.M.; Chang, W.F. Strength decay of wire ropes by corrosion and wear at different surface conditions. Mater. Test. 2022, 64, 809–819. [Google Scholar] [CrossRef]

- Shi, Z.D.; Chen, H.Y.; Wang, X.Y. Experimental study of mechanical properties on rusting steel wires. In Proceedings of the ISTM/2009: 8TH International Symposium on Test and Measurement, Chongqing, China, 23–26 August 2009; Volumes 1–6, pp. 2140–2142. [Google Scholar]

- Vukelic, G.; Vizentin, G. Damage-induced stresses and remaining service life predictions of wire ropes. Appl. Sci. 2017, 7, 107. [Google Scholar] [CrossRef]

- Tijani, A.; Meknassi, M.; Chaffoui, H. Effect of broken rope components and corrosion on damage evolution through its lifetime. J. Mater. Civil. Eng. 2017, 29, 04017035. [Google Scholar] [CrossRef]

- Slesarev, D.A.; Vorontsov, A.N. The probabilistic characteristics of estimation of the residual strength and operation lifetime of steel wire rope based on the results of non-destructive testing. Russ. J. Nondestruct. Test. 2016, 52, 95–101. [Google Scholar] [CrossRef]

- GB_T33955-2017; Steel Wire Rope for Mine Hoisting. China Standards Press: Beijing, China, 2017.

- JB/T11174-2011; High-Speed Intelligent Tubular Twisting Machine. China Machine Press: Beijing, China, 2011.

- Fouvry, S.; Kapsa, P.; Vincent, L. Analysis of sliding behaviour for fretting loadings: Determination of transition criteria. Wear 1995, 185, 35–46. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Ge, S.R. Effect of displacement amplitude on fretting fatigue behavior of hoisting rope wires in low cycle fatigue. Tribol. Int. 2012, 52, 178–189. [Google Scholar] [CrossRef]

- Afferrante, L.; Putignano, C.; Menga, N.; Carbone, G. Friction in rough contacts of linear viscoelastic surfaces with anisotropic statistical properties. Eur. Phys. J. E 2019, 42, 80. [Google Scholar] [CrossRef] [PubMed]

- Müller, C.; Müser, M.H.; Carbone, G.; Menga, N. Significance of Elastic Coupling for Stresses and Leakage in Frictional Contacts. Phys. Rev. Lett. 2023, 131, 156201. [Google Scholar] [CrossRef] [PubMed]

| Component | Fe | C | Mn | Ni | Si | P | S |

|---|---|---|---|---|---|---|---|

| Percentage/wt.% | 98.53 | 0.70 | 0.55 | 0.01 | 0.19 | 0.012 | 0.008 |

| Diameter/mm | Tensile Strength/MPa | Modulus of Elasticity/GPa | Yield Strength/MPa |

|---|---|---|---|

| 1/1.1 | 2060 | 209 | 1570 |

| Fretting Wear Test Parameters | Value |

|---|---|

| Lay angle/° | 11.6 |

| Lay length/mm | 32.6 |

| Side wire tension/N | 120 |

| Initial stroke/μm | ±400 |

| Loading/N | 160 |

| Frequency | 0.5, 1.0, 2.0, 3.0 |

| Cycles (103) | 65 |

| Lubricating method | Dry friction |

| Temperature/°C | 15 ± 5 |

| Relative humidity/% | 65 ± 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Li, G.; Chang, X.; Zhou, Z.; Peng, Y.; Deng, R. Fretting Friction and Wear Characteristics of the Internal Spiral Contact Steel Wires in the Hoisting Wire Rope Under Different Service Conditions. Lubricants 2025, 13, 453. https://doi.org/10.3390/lubricants13100453

Huang K, Li G, Chang X, Zhou Z, Peng Y, Deng R. Fretting Friction and Wear Characteristics of the Internal Spiral Contact Steel Wires in the Hoisting Wire Rope Under Different Service Conditions. Lubricants. 2025; 13(10):453. https://doi.org/10.3390/lubricants13100453

Chicago/Turabian StyleHuang, Kun, Gongning Li, Xiangdong Chang, Zhou Zhou, Yuxing Peng, and Ran Deng. 2025. "Fretting Friction and Wear Characteristics of the Internal Spiral Contact Steel Wires in the Hoisting Wire Rope Under Different Service Conditions" Lubricants 13, no. 10: 453. https://doi.org/10.3390/lubricants13100453

APA StyleHuang, K., Li, G., Chang, X., Zhou, Z., Peng, Y., & Deng, R. (2025). Fretting Friction and Wear Characteristics of the Internal Spiral Contact Steel Wires in the Hoisting Wire Rope Under Different Service Conditions. Lubricants, 13(10), 453. https://doi.org/10.3390/lubricants13100453