An Optimal Preprocessing Method for Predicting the Acid Number of Lubricating Oil Based on PLSR and Infrared Spectroscopy

Abstract

1. Introduction

2. Methods

2.1. Acid Number

2.2. Mid-Infrared Spectroscopy

2.3. PLSR

2.4. Kennard–Stone Algorithm

| Algorithm 1 Knenard-Stone Sample Selection Algorithm |

| : Data matrix with n samples and m features |

| ) |

| : Indices of selected training samples |

| where: |

| 2: Initialize: |

| 3: Find pair |

| 4: |

| 5: |

| 6: while |

| 10: end for 11: Select |

| 12: Update sets: |

| 15: end while 16: return |

2.5. Principle of Oil Aging Monitoring

3. Experiment Techniques

3.1. Infrared Spectrum Collection

3.2. Acid Number Data Determination

3.3. Data Processing

4. Results and Discussion

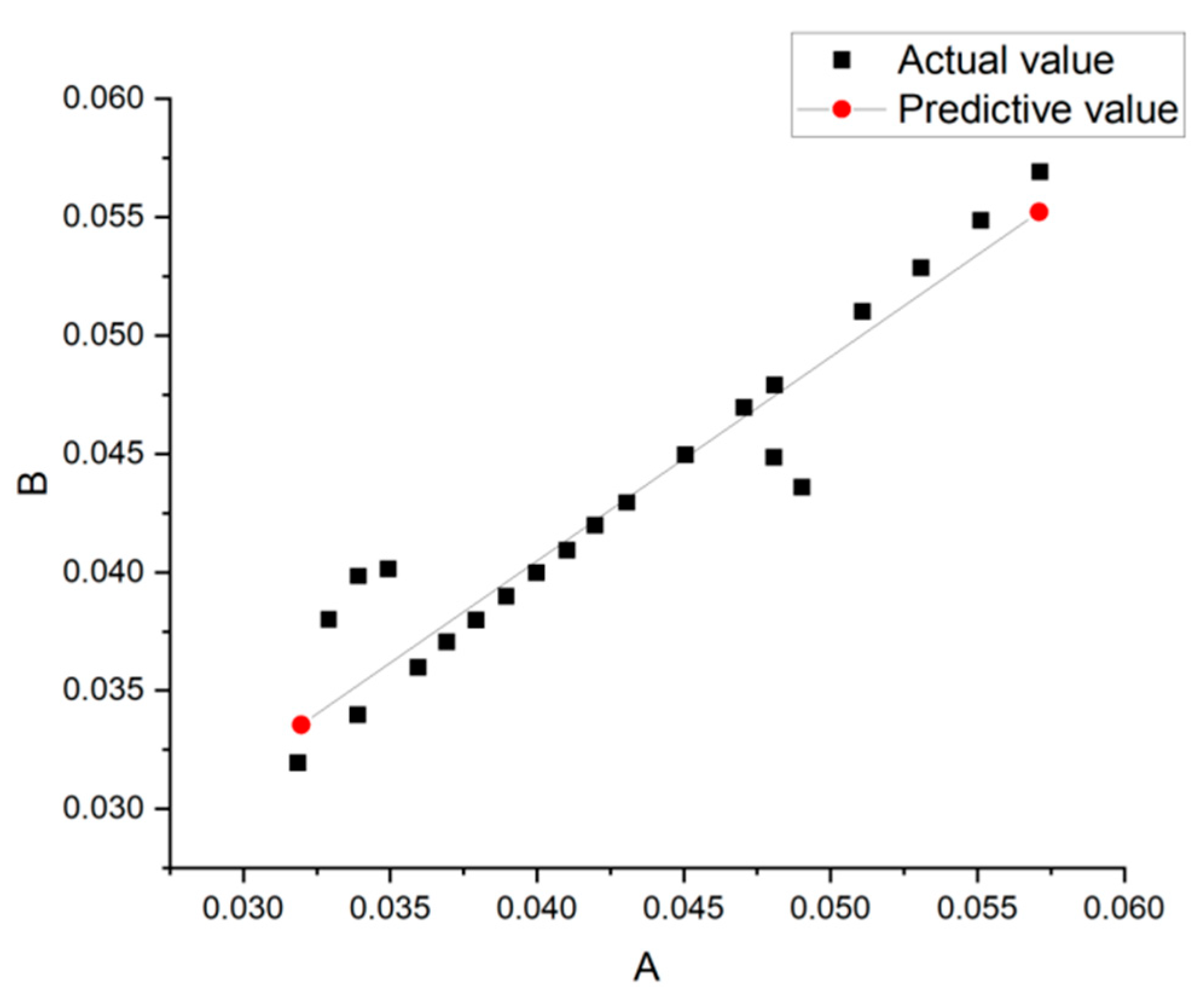

4.1. Data Division

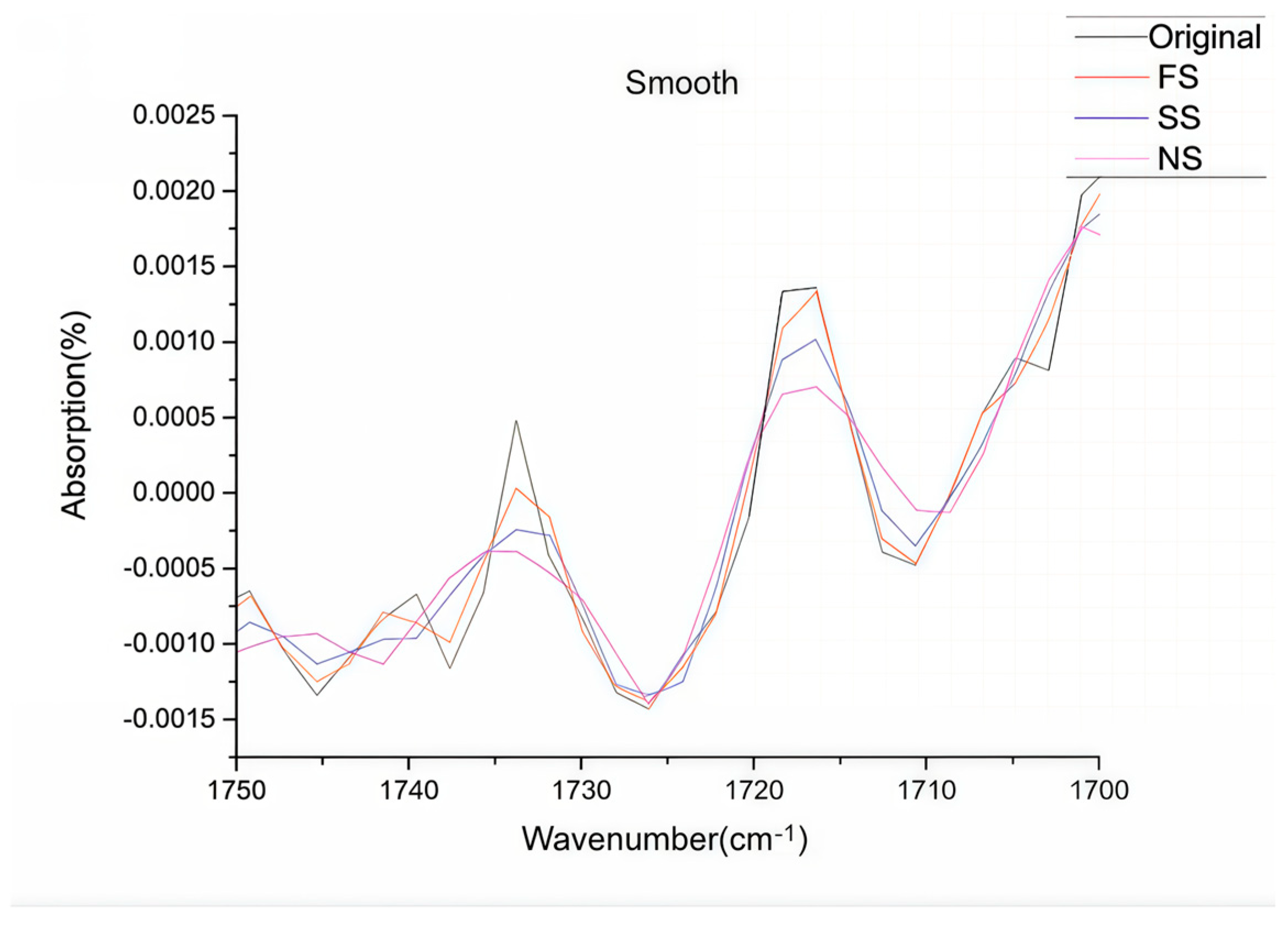

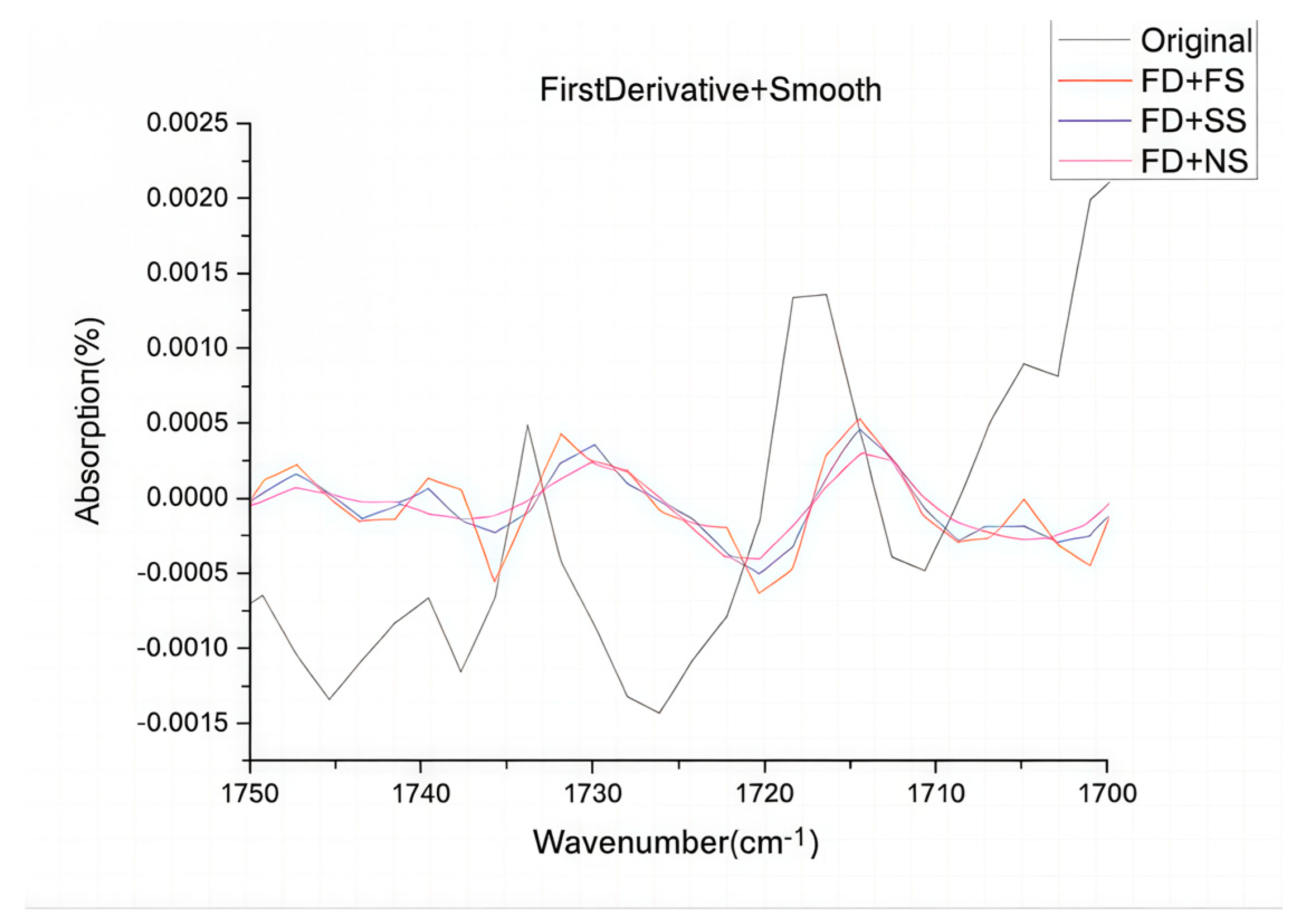

4.2. Data Processing

4.3. Model Establishment and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Murthy, A.A.; Norris, S.; Subiantoro, A. Effects of Lubricating oil on the performance of a Four-Intersecting-Vane Rotary Expander. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1180, 32–41. [Google Scholar] [CrossRef]

- Zheng, N.; Tong, B.; Zhang, G.; Hu, X.; Liang, H.; Wang, W.; Liu, K. Heat transfer characteristics of successive oil droplet impingement under minimum quantity lubrication. Phys. Fluids 2021, 33, 033318. [Google Scholar] [CrossRef]

- Jia, C.; Pang, X.; Song, Y. The mechanism of unconventional hydrocarbon formation: Hydrocarbon self-sealing and intermolecular forces. Pet. Explor. Dev. Engl. Ed. 2021, 48, 20. [Google Scholar] [CrossRef]

- Stpień, Z. Premature Degradation of Lubricating Oil during the Service Life of the Positive-Ignition Engine. Tribol. Online 2021, 16, 31–37. [Google Scholar] [CrossRef]

- Tanwar, M.; Raghavan, N. Lubricating Oil Remaining Useful Life Prediction using Multi-Output Gaussian Process Regression. IEEE Access 2020, 8, 128897. [Google Scholar] [CrossRef]

- Chakravarthy, R.; Naik, G.N.; Savalia, A.; Sridharan, U.; Saravanan, C.; Das, A.K.; Gudasi, K.B. Determination of Naphthenic Acid Number in Petroleum Crude Oils and Their Fractions by Mid-FTIR Spectroscopy. Energy Fuels 2016, 30, 8579–8586. [Google Scholar] [CrossRef]

- Guan, L.; Feng, X.; Xiong, G.; Xie, J. Application of dielectric spectroscopy for engine lubricating oil degradation monitoring. Sens. Actuators A Phys. 2011, 168, 22–29. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, F.; Fu, X.; Jin, P.; Hou, J. Determination of fatty acid content in mixed oil by Raman spectroscopy based on ABC-SV R algorithm. Spectrosc. Spectr. Anal. 2019, 39, 2147–2152. [Google Scholar]

- van de Voort, F.R.; Sedman, J.; Yaylayan, V.; Saint Laurent, C. Determination of acid number and base number in lubricants by Fourier transform infrared spectroscopy. Appl. Spectrosc. 2003, 57, 1425–1431. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Duan, H.; Wei, L.; Chen, S.; Qian, X.; Jia, D.; Li, J. Online infrared spectra detection of lubricating oil during friction process at high temperature. Ind. Lubr. Tribol. 2018, 70, 1294–1302. [Google Scholar] [CrossRef]

- Adams, M.J.; Romeo, M.J.; Rawson, P. FTIR analysis and monitoring of synthetic aviation engine oils. Talanta 2007, 73, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, K.; Han, X. Rapid Determination of Oleic Acid in Diesel Engine using Random forest-correlation Vector Machine algorithm combined with Mid-infrared Spectroscopy. Phys. Chem. Test. Chem. Vol. 2019, 55, 26–30. [Google Scholar]

- Shi, L.; Qu, J.; Xing, Z. Determination of oleic acid number by least square support vector machine combined with infrared spectroscopy. Phys. Chem. Test. Chem. Vol. 2018, 54, 200–203. [Google Scholar]

- Caneca, A.R.; Pimentel, M.F.; Galvão, R.K.H.; da Matta, C.E.; de Carvalho, F.R.; Raimundo, I.M., Jr.; Pasquini, C.; Rohwedder, J.J.R. Assessment of infrared spectroscopy and multivariate techniques for monitoring the service condition of diesel-engine lubricating oils. Talanta 2006, 70, 344–352. [Google Scholar] [CrossRef] [PubMed]

- Dong, J. Quantitative Condition Monitoring of Lubricating Oils by Fourier Transform Infrared (FTIR) Spectroscopy. Ph.D. Thesis, McGill University, Montreal, QC, Canada, 2000. [Google Scholar]

- Rahman, H.; Shahriar, S.; Menezes, P.L. Recent progress of machine learning algorithms for the oil and lubricant industry. Lubricants 2023, 11, 289. [Google Scholar] [CrossRef]

- Zhou, Q.; Guo, Y.; Xu, K.; Chai, B.; Li, G.; Wang, K.; Dong, Y. Research on the prediction algorithm of aero engine lubricating oil consumption based on multi-feature information fusion. Appl. Intell. 2024, 54, 11845–11875. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Yang, S.; Yi, C.; Liu, T.; Zhang, R.; Jia, D.; Peng, S.; Yang, Q. Prediction of lubrication performances of vegetable oils by genetic functional approximation algorithm. Lubricants 2024, 12, 226. [Google Scholar] [CrossRef]

- Park, L.K.-E.; Liu, J.; Yiacoumi, S.; Borole, A.P.; Tsouris, C. Contribution of acidic components to the total acid number (TAN) of bio-oil. Fuel 2017, 200, 171–181. [Google Scholar] [CrossRef]

- Haas, J.; Mizaikoff, B. Advances in mid-infrared spectroscopy for chemical analysis. Annu. Rev. Anal. Chem. 2016, 9, 45–68. [Google Scholar] [CrossRef] [PubMed]

- Abdi, H.; Williams, L.J. Partial least squares methods: Partial least squares correlation and partial least square regression. In Computational Toxicology: Volume II; Humana Press: Totowa, NJ, USA, 2012; pp. 549–579. [Google Scholar]

- Morais, C.L.M.; Santos, M.C.D.; Lima, K.M.G.; Martin, F.L. Improving data splitting for classification applications in spectrochemical analyses employing a random-mutation Kennard-Stone algorithm approach. Bioinformatics 2019, 35, 5257–5263. [Google Scholar] [CrossRef] [PubMed]

- GB/T 7304; Petroleum Products—Determination of Acid Number—Potentiometric Titration Method. National Standard of the People’s Republic of China: Beijing, China, 2014.

| Property | Value | Property | Value |

|---|---|---|---|

| Saturated Hydrocarbons % | >90 | Pour Point (°C) | −20~12 |

| Viscosity Index | 80~120 | Aniline Point (°C) | 80~112 |

| Sulfur Content % | <0.03 | Acid Number (mgKOH/g) | 0.015~0.03 |

| Density (20 °C, g/cm3) | 0.84 | Aromatics (CA) Content % | <10 |

| Flash Point (°C) | 140 | Naphthenes (CN) Content % | 35± |

| Number | Heating Time | Acid Number mgKOH/g | Number | Heating Time | Acid Number mgKOH/g | Number | Heating Time | Acid Number mgKOH/g |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 0.032 | 14 | 28 | 0.043 | 27 | 54 | 0.043 |

| 2 | 4 | 0.035 | 15 | 30 | 0.046 | 28 | 56 | 0.046 |

| 3 | 6 | 0.036 | 16 | 32 | 0.036 | 29 | 58 | 0.048 |

| 4 | 8 | 0.034 | 17 | 34 | 0.038 | 30 | 60 | 0.047 |

| 5 | 10 | 0.036 | 18 | 36 | 0.04 | 31 | 62 | 0.049 |

| 6 | 12 | 0.038 | 19 | 38 | 0.038 | 32 | 64 | 0.046 |

| 7 | 14 | 0.033 | 20 | 40 | 0.038 | 33 | 66 | 0.048 |

| 8 | 16 | 0.037 | 21 | 42 | 0.041 | 34 | 68 | 0.049 |

| 9 | 18 | 0.042 | 22 | 44 | 0.045 | 35 | 70 | 0.05 |

| 10 | 20 | 0.039 | 23 | 46 | 0.042 | 36 | 72 | 0.051 |

| 11 | 22 | 0.035 | 24 | 48 | 0.047 | 37 | 74 | 0.053 |

| 12 | 24 | 0.045 | 25 | 50 | 0.04 | |||

| 13 | 26 | 0.042 | 26 | 52 | 0.042 |

| Number | Spectral Preprocessing Methods | Abbreviation |

|---|---|---|

| 1 | Five-point smoothing | FS |

| 2 | Seven-point smoothing | SS |

| 3 | Nine-point smoothing | NS |

| 4 | First derivative | FD |

| 5 | Second derivative | SD |

| 6 | Five-point smoothing + first derivative | FD+FS |

| 7 | Seven-point smoothing + first derivative | FD+SS |

| 8 | Nine-point smoothing + first derivative | FD+NS |

| 9 | Nine-point smoothing + second derivative | SD+FS |

| 10 | Nine-point smoothing + second derivative | SD+SS |

| 11 | Nine-point smoothing + second derivative | SD+NS |

| Spectral Preprocessing Methods | Best Principal Component | Training Set | Prediction Set |

|---|---|---|---|

| RMSECV | RMSEP | ||

| FS | 2 | 0.00793 | 0.00954 |

| SS | 2 | 0.00794 | 0.00955 |

| NS | 2 | 0.00793 | 0.00957 |

| FD | 2 | 0.00640 | 0.00779 |

| SD | 6 | 0.00615 | 0.00738 |

| FD+FS | 2 | 0.00637 | 0.00763 |

| FD+SS | 2 | 0.00578 | 0.00684 |

| FD+NS | 2 | 0.00565 | 0.00674 |

| SD+FS | 11 | 0.00586 | 0.00703 |

| SD+SS | 2 | 0.00505 | 0.00602 |

| SD+NS | 2 | 0.00541 | 0.00651 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, F.; Shen, J.; Li, X.; Yang, K.; Wang, L. An Optimal Preprocessing Method for Predicting the Acid Number of Lubricating Oil Based on PLSR and Infrared Spectroscopy. Lubricants 2025, 13, 355. https://doi.org/10.3390/lubricants13080355

Zhou F, Shen J, Li X, Yang K, Wang L. An Optimal Preprocessing Method for Predicting the Acid Number of Lubricating Oil Based on PLSR and Infrared Spectroscopy. Lubricants. 2025; 13(8):355. https://doi.org/10.3390/lubricants13080355

Chicago/Turabian StyleZhou, Fanhao, Jie Shen, Xiaojun Li, Kun Yang, and Ling Wang. 2025. "An Optimal Preprocessing Method for Predicting the Acid Number of Lubricating Oil Based on PLSR and Infrared Spectroscopy" Lubricants 13, no. 8: 355. https://doi.org/10.3390/lubricants13080355

APA StyleZhou, F., Shen, J., Li, X., Yang, K., & Wang, L. (2025). An Optimal Preprocessing Method for Predicting the Acid Number of Lubricating Oil Based on PLSR and Infrared Spectroscopy. Lubricants, 13(8), 355. https://doi.org/10.3390/lubricants13080355