Smart Oil Management with Green Sensors for Industry 4.0

Abstract

1. Introduction

1.1. The Importance of Lubricating Oils and Their Degradation Mechanisms

1.2. Current Oil Monitoring Methods and Limitations

1.3. Literature Review of Advanced Techniques

1.4. Identifying the Research Gap

1.5. Objectives of the Current Study

2. Materials and Methods

2.1. Materials

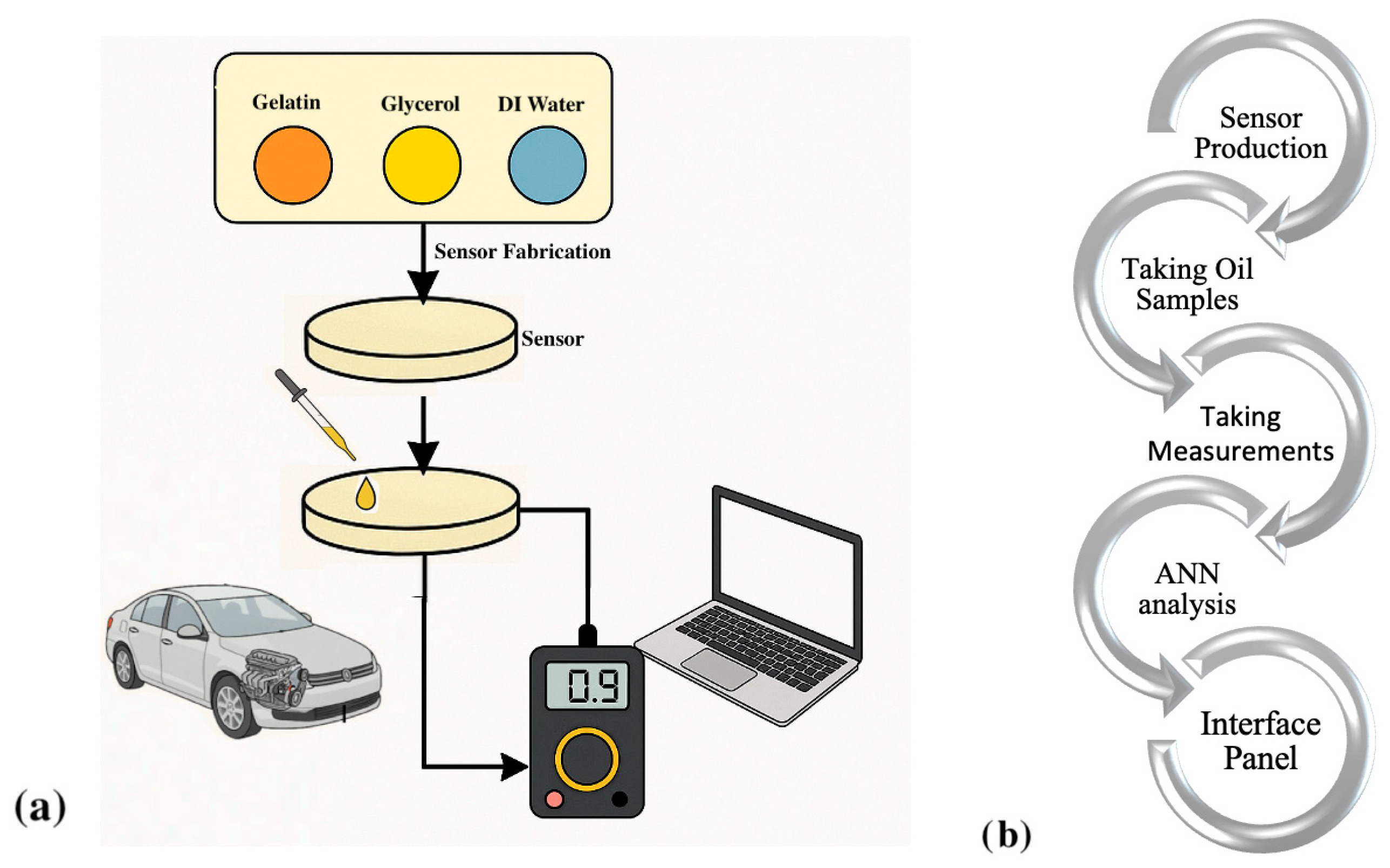

2.2. Sensor Fabrication and Experimental Setup

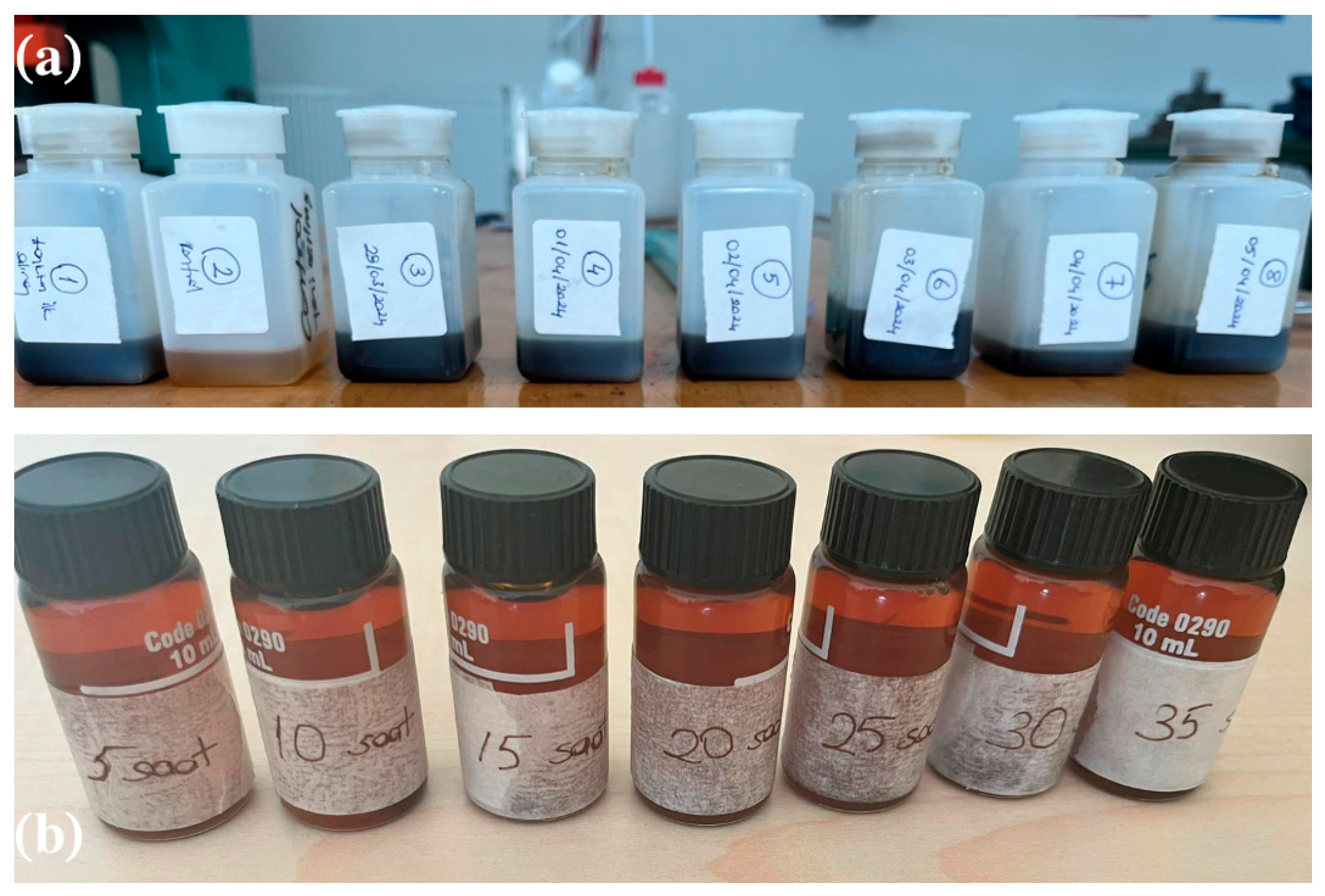

2.3. Oil Sampling and Characterisation

2.4. Resistance and Impedance Measurement

2.5. The Effect of Sensor Thickness on Resistance

2.6. Effect of Temperature Change on Resistance

2.7. Classification and Modelling with Artificial Intelligence

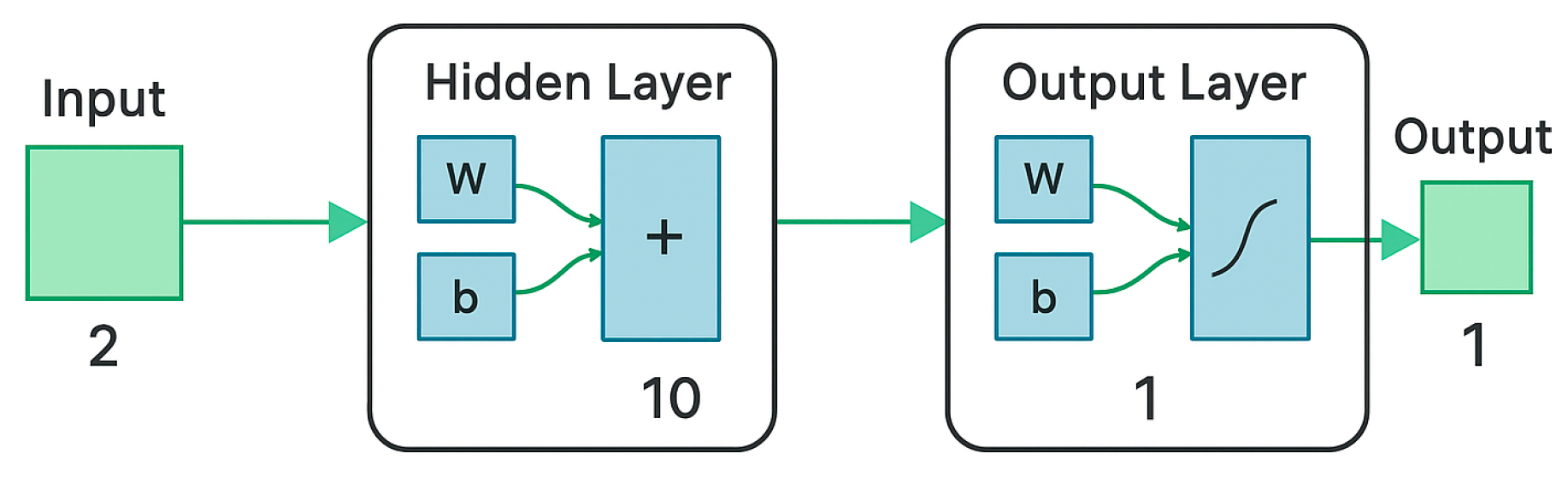

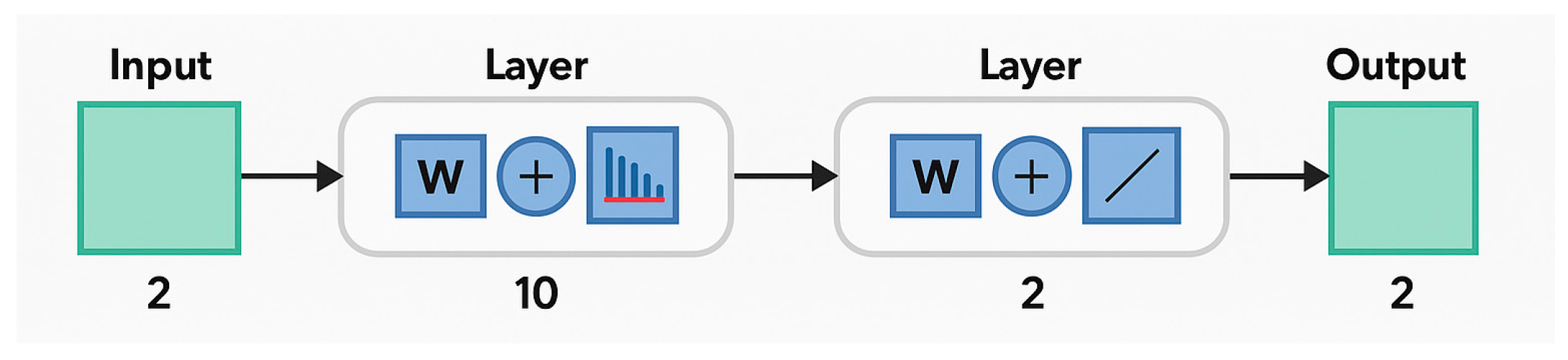

2.8. Multilayer Perceptron (MLP) Structure

2.9. Linear Vector Quantisation (LVQ) Structure

2.10. Statistical Analysis

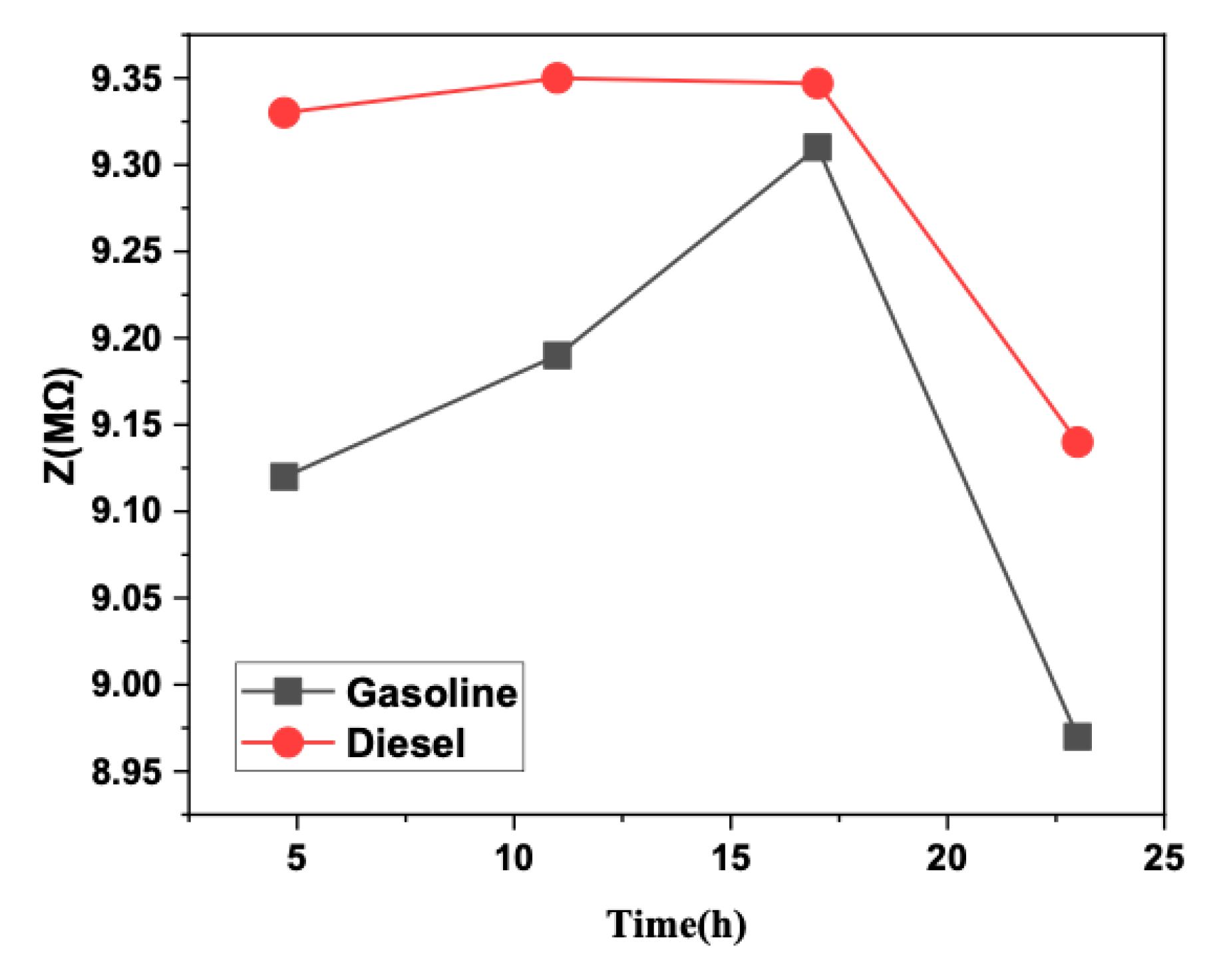

2.11. Interface Design

3. Results

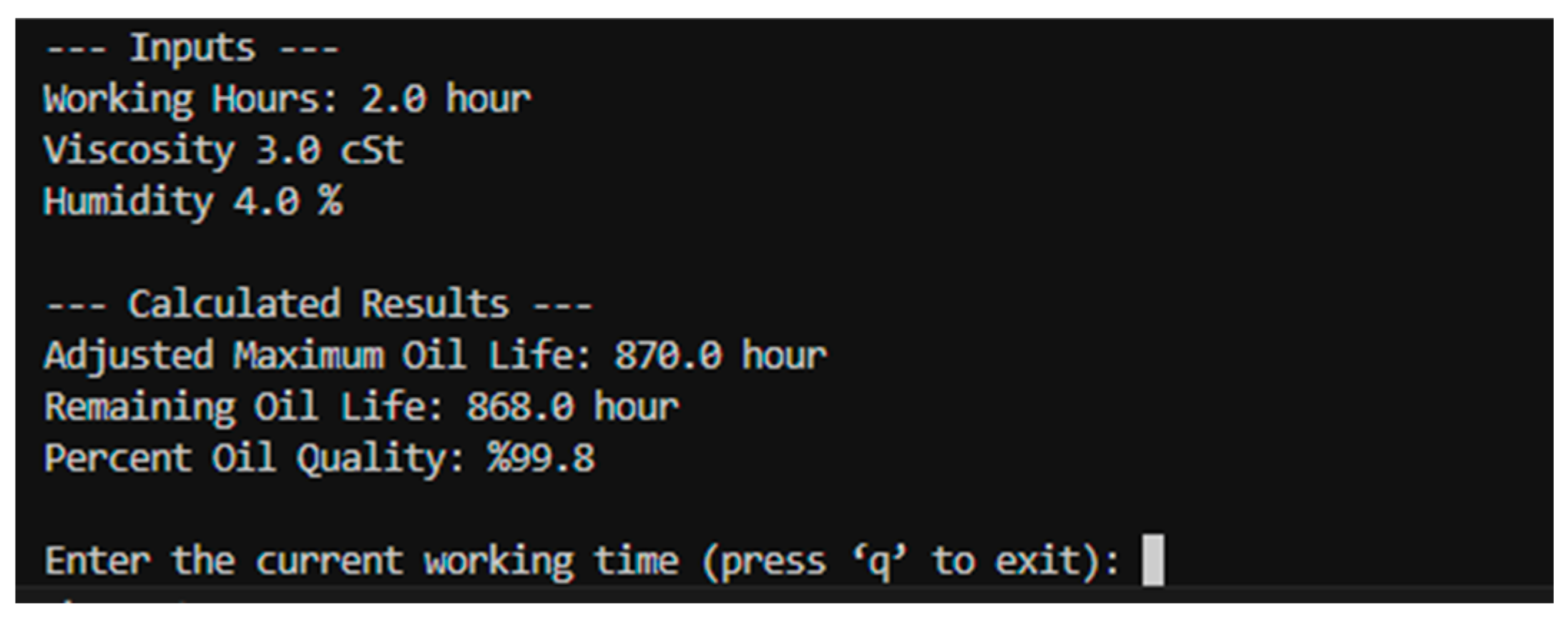

3.1. Resistance and Impedance Changes

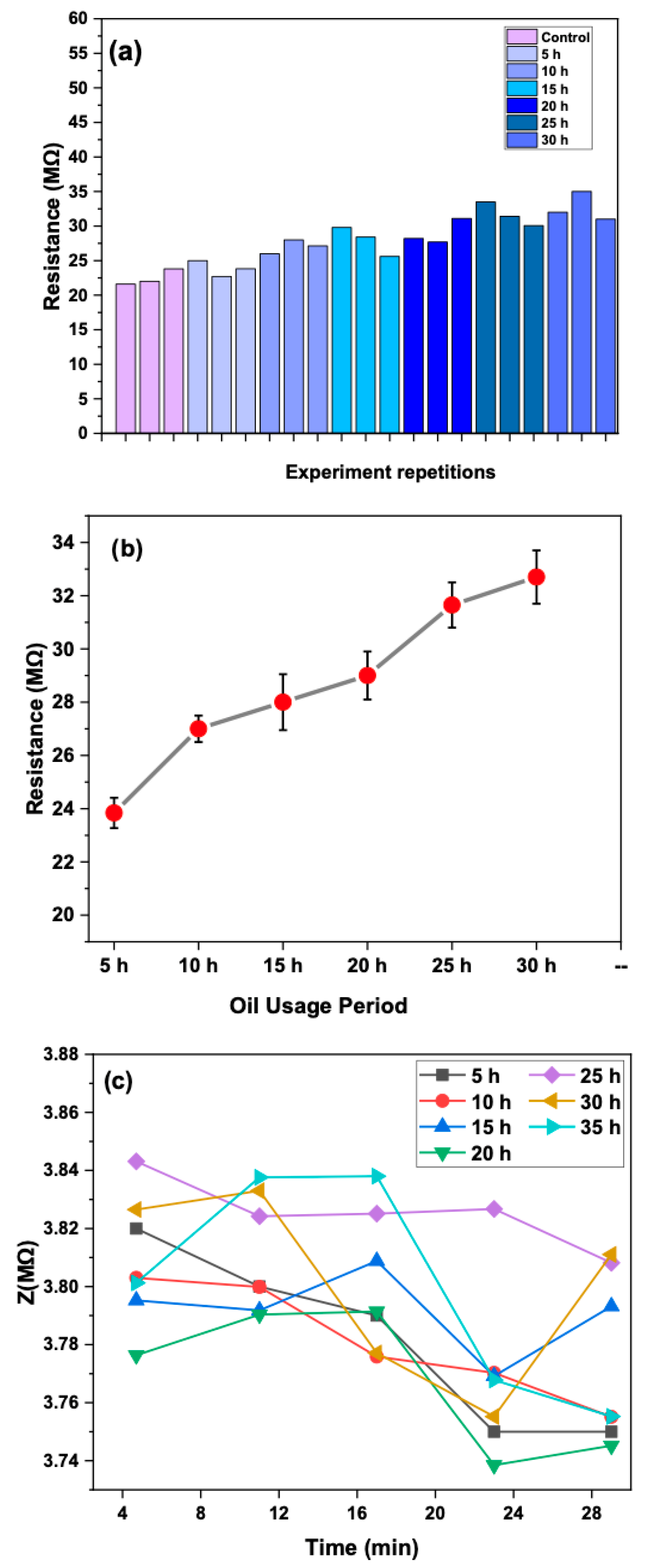

3.2. Comparison Between Oil Types

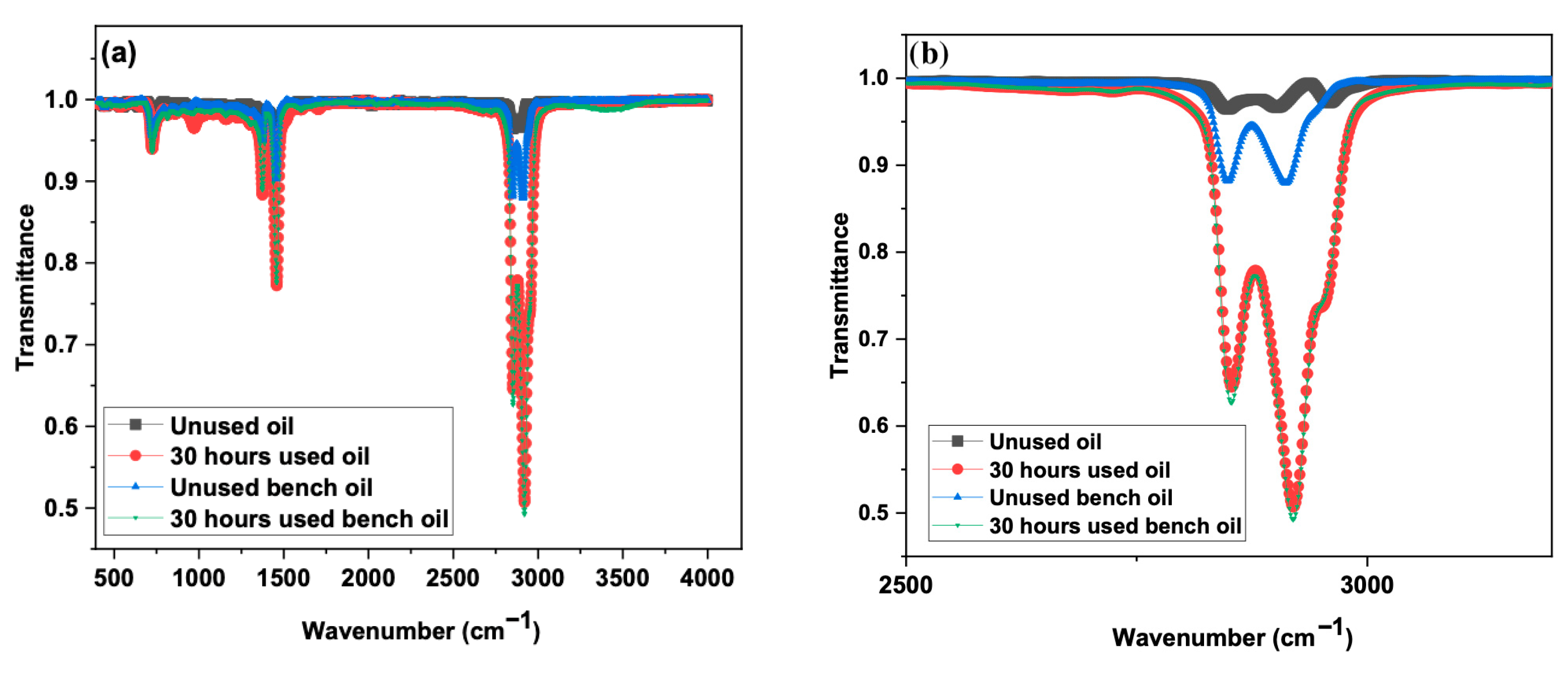

3.3. FTIR Analysis

3.4. Sensor Thickness Effect

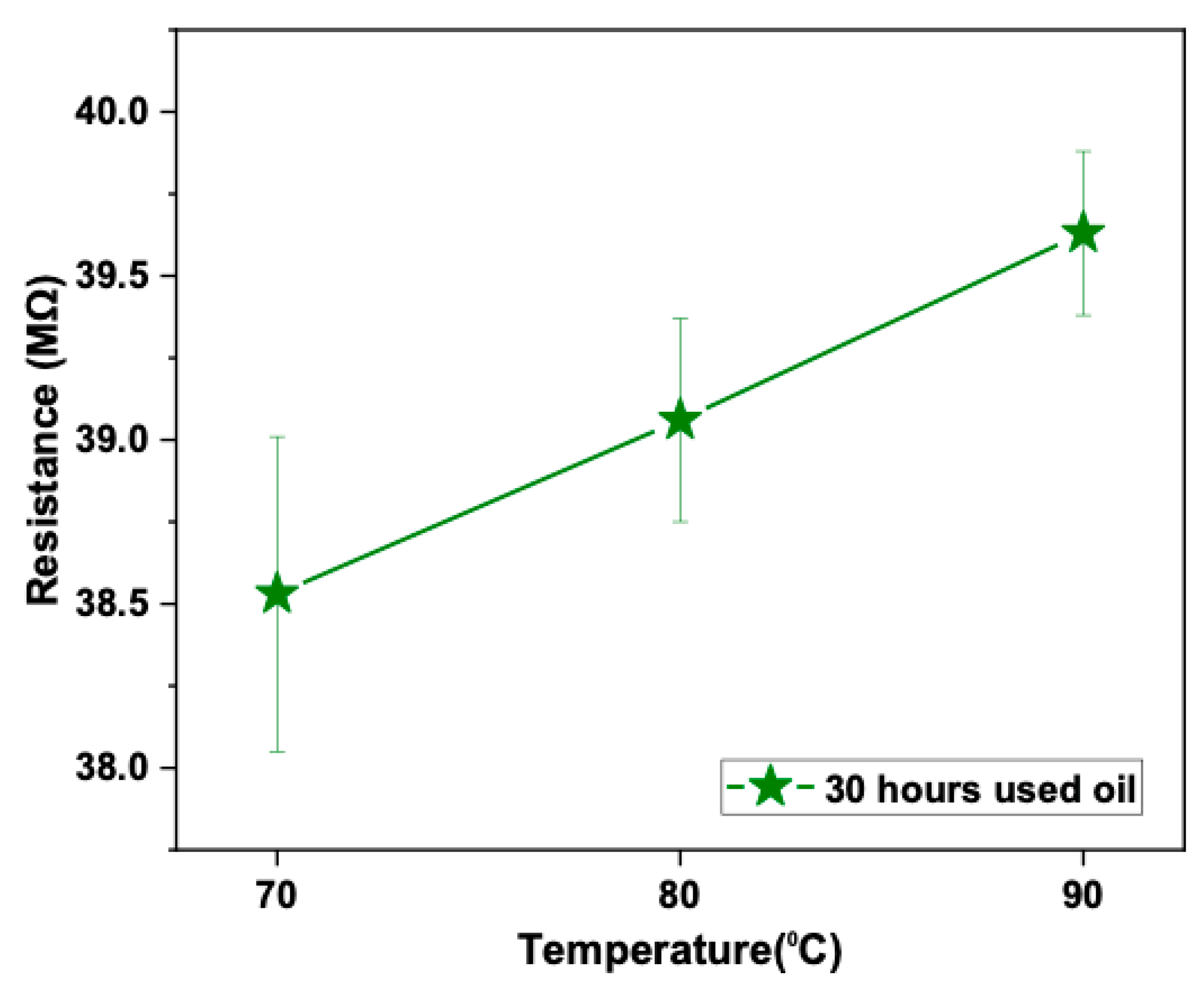

3.5. Temperature Effect

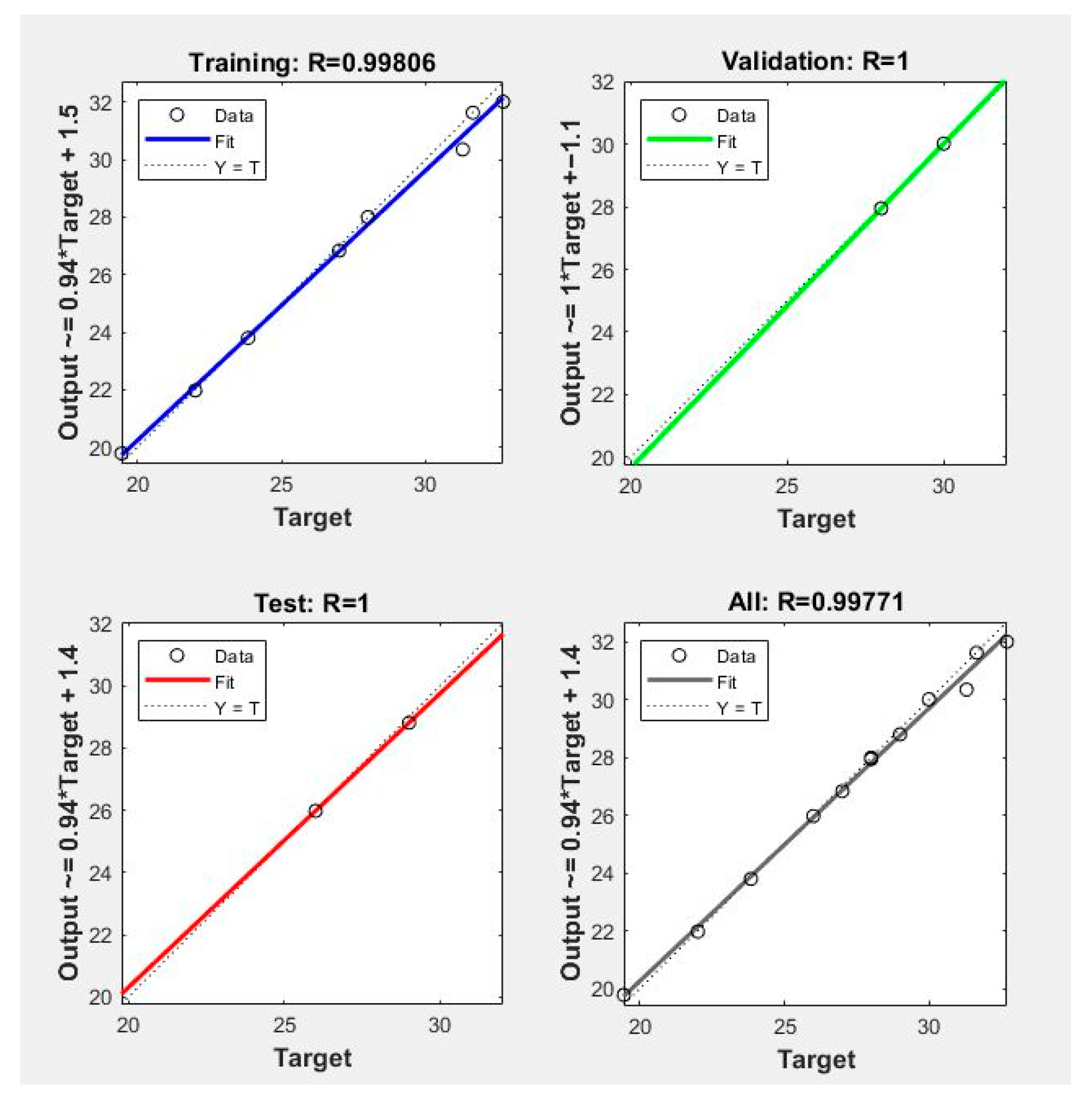

3.6. Artificial Intelligence Model Results

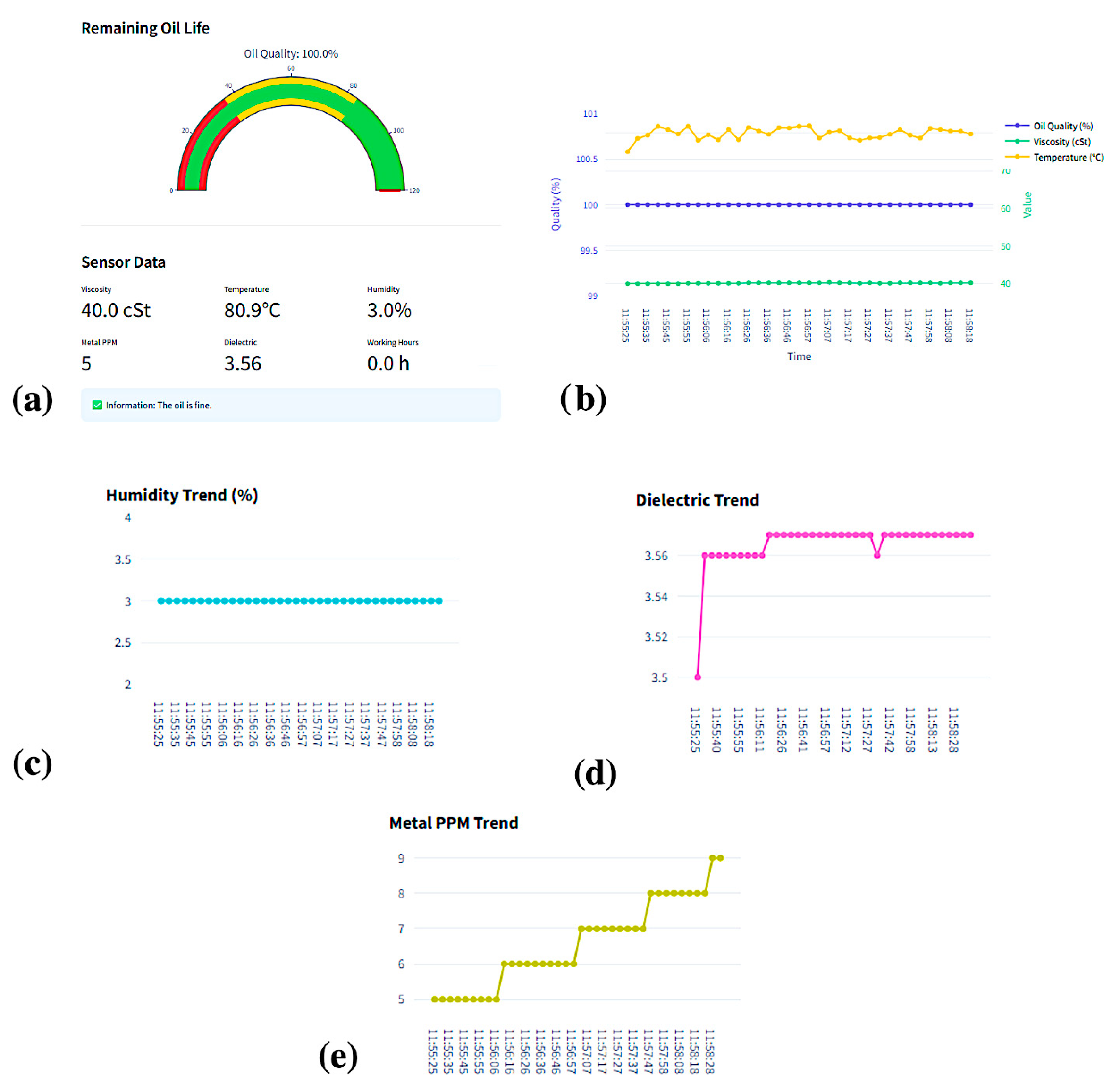

3.7. Interface Design

4. Conclusions

5. Patents

Funding

Data Availability Statement

Conflicts of Interest

References

- Oladimeji, T.E.; Oguntuashe, K.M.; Emetere, M.E.; Efeovbokhan, V.E.; Odunlami, O.A.; Obanla, O.R. Industrial- and Automotive-Used Lubricating Oils Recycling Cum Acidic Sludge Treatment. Int. J. Adv. Manuf. Technol. 2020, 106, 4157–4167. [Google Scholar] [CrossRef]

- Adewole, B.Z.; Olojede, J.O.; Owolabi, H.A.; Obisesan, O.R. Characterization and Suitability of Reclaimed Automotive Lubricating Oils Reprocessed by Solvent Extraction Technology. Recycling 2019, 4, 31. [Google Scholar] [CrossRef]

- International Environmental Technology Centre. Policy Brief on Waste Oil: What, Why and How. 2013. Available online: https://www.unep.org/ietc/ (accessed on 20 August 2025).

- Lnoue, K.; Yarnanaka, Y. Change in Performance of Engine Oils with Degradation. In Proceedings of the International Fuels and Lubricants Meeting and Exposition, Tulsa, OK, USA, 1990; Available online: https://www.sae.org/publications/technical-papers/content/902122/#:~:text=The%20degradation%20leads%20to%20the,%2C%20lowered%20antiwear%20performance%2C%20etc (accessed on 20 August 2025).

- Sejkorová, M.; Hurtová, I.; Jilek, P.; Novák, M.; Voltr, O. Study of the Effect of Physicochemical Degradation and Contamination of Motor Oils on Their Lubricity. Coatings 2021, 11, 60. [Google Scholar] [CrossRef]

- Wei, L.; Duan, H.; Jin, Y.; Jia, D.; Cheng, B.; Liu, J.; Li, J. Motor Oil Degradation during Urban Cycle Road Tests. Friction 2021, 9, 1002–1011. [Google Scholar] [CrossRef]

- Hameed, D.K. Deterioration in Physical Engine Oil Properties after Different Trip Length. Kurd. J. Appl. Res. 2021, 6, 13–20. [Google Scholar] [CrossRef]

- Smigins, R.; Amatnieks, K.; Birkavs, A.; Górski, K.; Kryshtopa, S. Studies on Engine Oil Degradation Characteristics in a Field Test with Passenger Cars. Energies 2023, 16, 7955. [Google Scholar] [CrossRef]

- Shinde, H.; Bewoor, A. Capacitive Sensor for Engine Oil Deterioration Measurement. AIP Conf. Proc. 2018, 1943, 020099. [Google Scholar] [CrossRef]

- Ibrahim, D.; Stapah, M.; Ruslan, M.A.A.; Yaakob, Y.; Budin, S.; Maideen, N.C.; Yusoff, H. Predicting the next Oil Change for Automotive Engine Oil. Proc. J. Phys. Conf. Ser. 2019, 1349, 012018. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Tokarev, I.; Go, S.; Ottikkutti, P.; Kuzhiyil, N.; Mihok, J.; Anzini, C.; Shartzer, S. Multivariable Electrical Resonant Sensors for Independent Quantitation of Aging and External Contaminants in Lubricating Oils. IEEE Sens. J. 2019, 19, 1542–1553. [Google Scholar] [CrossRef]

- Sosnowski, K.; Loh, A.; Zubler, A.V.; Shir, H.; Ha, S.Y.; Yim, U.H.; Yoon, J.Y. Machine Learning Techniques for Chemical and Type Analysis of Ocean Oil Samples via Handheld Spectrophotometer Device. Biosens. Bioelectron. X 2022, 10, 100128. [Google Scholar] [CrossRef]

- Karluk, A.A.; Ekim, S.D.; Baytekin, B.; Tarik Baytekin, H. Online Lubricant Degradation Monitoring Using Contact Charging of Polymers. Appl. Surf. Sci. 2022, 584, 152593. [Google Scholar] [CrossRef]

- TR201910799A2. Available online: https://www.patentguru.com/assignee/hasan-tarik-baytek%C4%B0n (accessed on 20 August 2025).

- Xiaodong, Z.; Kefeng, C.; Jie, Y.; Guangfeng, X.; Jie, S.; Haitao, T. Analysis of Effect of Oil and S2− Impurities on Corrosion Behavior of 16Mn Steel for Storage Tanks by Electrochemical Method. RSC Adv. 2018, 8, 38118–38123. [Google Scholar] [CrossRef]

- Engmarksgaard, M.E. Electrical Impedance Spectroscopy for Use in Oil Quality Assessment. Master’s Thesis, University of Southern Denmark, Odense, Denmark, 2021. [Google Scholar] [CrossRef]

- Kupareva, A.; Mäki-Arvela, P.; Grénman, H.; Eränen, K.; Sjöholm, R.; Reunanen, M.; Murzin, D.Y. Chemical Characterization of Lube Oils. Energy Fuels 2013, 27, 27–34. [Google Scholar] [CrossRef]

- Wolak, A.; Krasodomski, W.; Zając, G. FTIR Analysis and Monitoring of Used Synthetic Oils Operated under Similar Driving Conditions. Friction 2020, 8, 995–1006. [Google Scholar] [CrossRef]

- Zhang, J.; Leung, M.C.Y.; Wong, J.S.S.; Spikes, H. Lubricant Inerting. Tribol. Trans. 2025, 68, 180–193. [Google Scholar] [CrossRef]

- Heredia-Cancino, J.A.; Carrillo-Torres, R.C.; Félix-Domínguez, F.; Álvarez-Ramos, M.E. Experimental Characterization of Chemical Properties of Engine Oil Using Localized Surface Plasmon Resonance Sensing. Appl. Sci. 2021, 11, 8518. [Google Scholar] [CrossRef]

- Hu, K.; Murphy, M.; Van De Voort, F.R.; Pinchuk, D.; Zou, X. A New FTIR Technique for Monitoring the Conditions of Lubricants Used in Pulp and Paper Mills. J. Soc. Tribol. Lubr. Eng. 2012, 3, 23–29. [Google Scholar]

- Keser, K.; Soylu, M.Ç. Dimerkaprol İle Zenginleştirilmiş Jelatin Temelli Katı Elektrolitli İmpedimetrik Elektrokimyasal Sensör İle İçme Sularında Arsenik Tespiti. Ph.D. Thesis, Erciyes Üniversitesi, Fen Bilimleri Enstitüsü Biyomedikal Mühendisliği Anabilim Dalı, Kayseri, Turkey, 2023. [Google Scholar]

- Keser, K.; Soylu, M.Ç. Simple, Specific, and Ultra-Sensitive Arsenic Detection in Real Drinking Water Samples Using an Impedimetric Green Sensor with Dimercaprol-Doped Solid Electrolyte. Electroanalysis 2025, 37, e202400253. [Google Scholar] [CrossRef]

- Keser, K.; Soylu, M.Ç. Detection of Phenylarsine Oxide in Drinking Water Using an Impedimetric Electrochemical Sensor with Gelatin-Based Solid Electrolyte Enriched with Mercaptoethanol: A Novel Prospective Green Biosensor Methodology. ACS Omega 2022, 7, 43111–43121. [Google Scholar] [CrossRef] [PubMed]

- Nabi, M.N.; Rasul, M.; Gudimetla, P. Modelling and Simulation of Performance and Combustion Characteristics of Diesel Engine. In Energy Procedia, Proceedings of the 6th International Conference on Power and Energy Systems Engineering, Okinawa, Japan, 20–23 September 2019; Elsevier Ltd.: Amsterdam, The Netherland, 2019; Volume 160, pp. 662–669. [Google Scholar]

- Abu-Zaid, M. Performance of Single Cylinder, Direct Injection Diesel Engine Using Water Fuel Emulsions. Energy Convers. Manag. 2004, 45, 697–705. [Google Scholar] [CrossRef]

- Frigione, M.; Rodríguez-Prieto, A. Can Accelerated Aging Procedures Predict the Long Term Behavior of Polymers Exposed to Different Environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, R.; Fang, Y.; Lin, Y. Insulation Degradation Analysis Due to Thermo-Mechanical Stress in Deep-Sea Oil-Filled Motors. Energies 2022, 15, 3963. [Google Scholar] [CrossRef]

- Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.W.; Neuber, C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers 2023, 15, 2291. [Google Scholar] [CrossRef]

- Arias-Nava, E.H.; Valles-Rosales, D.J.; Sullivan, B.P. Biopolymer Non-Parametric Analysis: A Degradation Study under Accelerated Destructive Tests. Polymers 2023, 15, 620. [Google Scholar] [CrossRef]

- Hoess, A.J.; Ziviani, D.; Groll, E.A.; Braun, J.E. Development and Application of Accelerated Life Test Cycles for Performance Degradation Study on Water-Cooled Variable speed Screw Compressor Chillers. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 10–14 July 2022. [Google Scholar]

- Demuth, H.; De Jesús, B. Neural Network Design, 2nd ed. Available online: https://hagan.okstate.edu/NNDesign.pdf (accessed on 20 August 2025).

- Popovicheva, O.B.; Kireeva, E.D.; Shonija, N.K.; Vojtisek-Lom, M.; Schwarz, J. FTIR Analysis of Surface Functionalities on Particulate Matter Produced by Off-Road Diesel Engines Operating on Diesel and Biofuel. Environ. Sci. Pollut. Res. 2015, 22, 4534–4544. [Google Scholar] [CrossRef] [PubMed]

- Ulusoy, Y. Investigation of Particulate Matter by FTIR, TEM and Elemental Analyses in a Diesel Engine Operating on Diesel and Waste Cooking Oil-Biodiesel. Environ. Sci. Pollut. Res. 2020, 27, 500–509. [Google Scholar] [CrossRef] [PubMed]

- van de Voort, F.R.; Ghetler, A.; García-González, D.L.; Li, Y.D. Perspectives on Quantitative Mid-FTIR Spectroscopy in Relation to Edible Oil and Lubricant Analysis: Evolution and Integration of Analytical Methodologies. Food Anal. Methods 2008, 1, 153–163. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dörr, N. Comprehensive Assessment of Oil Degradation Patterns in Petrol and Diesel Engines Observed in a Field Test with Passenger Cars—Conventional Oil Analysis and Fuel Dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Gołębiowski, W.; Krakowski, R.; Zając, G. Degradation of Anti-Wear Additives and Tribological Properties of Engine Oils at Extended Oil Change Intervals in City Buses. Sci. Rep. 2025, 15, 27238. [Google Scholar] [CrossRef]

- Adams, M.J.; Romeo, M.J.; Rawson, P. FTIR Analysis and Monitoring of Synthetic Aviation Engine Oils. Talanta 2007, 73, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Yousefinejad, S.; Aalizadeh, L.; Honarasa, F. Application of ATR-FTIR Spectroscopy and Chemometrics for the Discrimination of Furnace Oil, Gas Oil and Mazut Oil. Anal. Methods 2016, 8, 4640–4647. [Google Scholar] [CrossRef]

- Dong, X.; Li, Z.; Ding, B.; Dou, H.; Zhang, X. Electrolyte and Electrode–Electrolyte Interface for Proton Batteries: Insights and Challenges. ChemElectroChem 2024, 11, e202300569. [Google Scholar] [CrossRef]

- Murru, C.; Badía-Laíño, R.; Díaz-García, M.E. Oxidative Stability of Vegetal Oil-Based Lubricants. ACS Sustain. Chem. Eng. 2021, 9, 1459–1476. [Google Scholar] [CrossRef]

- Latif, U.; Dickert, F.L. Conductometric Sensors for Monitoring Degradation of Automotive Engine Oil. Sensors 2011, 11, 8611–8625. [Google Scholar] [CrossRef]

- Zhou, F.; Yang, K.; Wang, L. The Effect of Water Content on Engine Oil Monitoring Based on Physical and Chemical Indicators. Sensors 2024, 24, 1289. [Google Scholar] [CrossRef]

- Soleimani, M.; Sophocleous, M.; Wang, L.; Atkinson, J.; Hosier, I.L.; Vaughan, A.S.; Taylor, R.I.; Wood, R.J.K. Base Oil Oxidation Detection Using Novel Chemical Sensors and Impedance Spectroscopy Measurements. Sens. Actuators B Chem. 2014, 199, 247–258. [Google Scholar] [CrossRef]

- Vadhva, P.; Hu, J.; Johnson, M.J.; Stocker, R.; Braglia, M.; Brett, D.J.L.; Rettie, A.J.E. Electrochemical Impedance Spectroscopy for All-Solid-State Batteries: Theory, Methods and Future Outlook. ChemElectroChem 2021, 8, 1930–1947. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 1988; Available online: https://utstat.utoronto.ca/brunner/oldclass/378f16/readings/CohenPower.pdf (accessed on 20 August 2025).

- Lakens, D. Calculating and Reporting Effect Sizes to Facilitate Cumulative Science: A Practical Primer for t-Tests and ANOVAs. Front. Psychol. 2013, 4, 863. [Google Scholar] [CrossRef]

- Lajos Nagy, A.; Rohde-Brandenburger, J.; Zsoldos, I. Artificial Aging Experiments of Neat and Contaminated Engine Oil Samples. Lubricants 2021, 9, 63. [Google Scholar] [CrossRef]

- Wierzbicka, N.; Szadkowska, D.; Patalas, A.; Talar, R.; Łabudzki, R.; Zawadzki, P. Evaluation of Deterioration of Engine Oil Properties in the Function of Mileage. J. Phys. Conf. Ser. 2020, 1426, 012004. [Google Scholar] [CrossRef]

- Han, Z.; Wang, Y.; Qing, X. Characteristics Study of In-Situ Capacitive Sensor for Monitoring Lubrication Oil Debris. Sensors 2017, 17, 2851. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, T.; Wu, D.; Zhu, L.; Qing, X.; Xue, W. A New In Situ Coaxial Capacitive Sensor Network for Debris Monitoring of Lubricating Oil. Sensors 2022, 22, 1777. [Google Scholar] [CrossRef] [PubMed]

- Lvovich, V.F.; Smiechowski, M.F. Impedance Characterization of Industrial Lubricants. Electrochim. Acta 2006, 51, 1487–1496. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Zhang, F.; Liu, Y.; Chen, B.; Wang, Z.L.; Pan, J.; Larsson, R.; Shi, Y. Real-Time and Online Lubricating Oil Condition Monitoring Enabled by Triboelectric Nanogenerator. ACS Nano 2021, 15, 11869–11879. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, D.; Zhang, F.; Pan, J.; Claesson, P.; Larsson, R.; Shi, Y. Self-Powered, Long-Durable, and Highly Selective Oil–Solid Triboelectric Nanogenerator for Energy Harvesting and Intelligent Monitoring. Nanomicro Lett. 2022, 14, 160. [Google Scholar] [CrossRef]

- Wolak, A.; Żywica, R. Electrical Properties of Engine Oils—Comparison of Electrical Parameters with Physicochemical Characteristics. Energies 2025, 18, 2776. [Google Scholar] [CrossRef]

| Criteria | Existing Literature | This Study | Comparison | Ref. |

|---|---|---|---|---|

| Parameter Tracking | Usually, physical parameters (viscosity, acidity, TBN) are used. | Physical and chemical degradation was monitored over time. | While chemical degradation signals were detected with FTIR, physical changes such as viscosity were also monitored, and the oil change process was evaluated multidimensionally. | [5,17] |

| Use of Spectroscopic Methods | Mainly, FTIR is used, but usually at a single time (e.g., used vs. unused oil comparison). | The FTIR spectrum shows the change trend with time and duration of use. | Using FTIR reveals the gradual progression of oxidation and additive depletion in oil molecules. This allows for more accurate maintenance scheduling decisions. | [18] |

| Oil Type Separation | Most studies are limited to automotive oil or reference oil only. | Both diesel oil and bench oil were analysed. | Different formulations (different types of oil) have highly different oxidation dynamics. | [19] |

| Monitoring Time | Instant measurements or analysis after a short period of use are common. | Data covering up to 30 h of use are presented. | The early stages of the oil cycle are observed in short-term data, but longer-term molecular degradation processes may be overlooked. In this study, the full degradation curves are more clearly defined. | [18] |

| Depth of Analysis | Based on a physical parameter, it may not be supported at the molecular level. | Physical data and FTIR spectral data were correlated. | Molecular degradation data can signal physical change before it occurs, providing critical data for predictive maintenance. | [20] |

| Data Presentation | Usually single-axis graphs. | Time-series graph + IR spectrum were used together. | Multidimensional data presentation allows users to more easily visualise trends and critical thresholds, accelerating decision-making for engineers. | [21] |

| Predictive Potential | Predictive change over time is recommended. | The data infrastructure is suitable for artificial intelligence models since the change trend and structural deterioration are given together. | Prediction models are often fed only with physical data; in this study, prediction accuracy can be increased by adding molecular-level data. | [17,18] |

| Oil Type | Experimental Results (MΩ) | MLP Results (MΩ) | LVQ Results (MΩ) |

|---|---|---|---|

| Diesel | 23.84 ± 0.57 | 23.79 | 23.84 |

| 27 ± 0.5 | 26.84 | 27 | |

| 28 ± 1.05 | 27.95 | 28 | |

| 29 ± 0.9 | 28.81 | 29 | |

| 31.65 ± 0.85 | 31.63 | 31.65 | |

| 32.7 ± 1 | 32.01 | 32.7 | |

| Bench Oil | 19.44 ± 0.06 | 19.78 | 19.44 |

| 22 ± 0.8 | 21.97 | 22 | |

| 26 ± 0.5 | 25.98 | 26 | |

| 28 ± 0.2 | 28 | 28 | |

| 30 ± 0.2 | 30.02 | 30 | |

| 31.3 ± 0.3 | 30.35 | 31.3 |

| (a) | |||||

| Subject of the Study | Oil Type/Engine | Parameters Measured | Test Duration/ Kilometres | Main Results | Ref. |

| Effect of travel length on engine oil properties | 10W-30 Delta NL (API SL) | Viscosity (40 °C, 100 °C), flash point, fire point | 10,000 km road test | Viscosity decreased by 23–26%; flash point decreased by 15.6%, fire point decreased by 14.2% | [7] |

| Determination of oil change intervals | 0W30, 5W30, 5W40 | Concentration of metal particles, additives | 12,000–15,000 km field test | Iron, silicon, and nickel increased; molybdenum and calcium additives decreased; oil change recommended beyond 12,000 km | [8] |

| Laboratory-based ageing of full synthetic oil | SAE 0W-30 full synthetic oil | ZDDP additive, wear performance | 180 °C, 96 h artificial ageing | Oil performance decreased with ZDDP depletion | [48] |

| Evaluation of the deterioration of engine oil properties as a function of mileage | Synthetic and semi-synthetic oils (SAE 5W-40, 5W-30, 10W-40); collected from various passenger car engines | Dynamic viscosity at different temperatures (5 °C to 100 °C) using a Brookfield rotational viscometer | New oils vs. used oils at 12,000; 15,000; 15,500; 17,000; 25,000 km | Viscosity decreased with usage but remained within acceptable limits At 100 °C, relative change in viscosity never exceeded ±25% No oil required replacement based on viscosity alone, even after 25,000 km Most change occurred between 0 and 40 °C | [49] |

| Monitoring lubrication oil debris | Lubricating oil in laboratory cycle and water for comparison | Relationship between capacitance change and debris amount; temperature and flow rate effects | - | Capacitance increases linearly with the amount of debris. Temperature and flow effects have a linear trend; the proposed method is applicable. | [50] |

| Lubricating oil debris monitoring with a capacitive sensor network | Simulated lubricating oil in a laboratory environment | Capacitance change | - | The effects of different sizes and numbers of metal particles on capacitance were investigated, and it was found that the design of the sensor structure increased the detection sensitivity | [51] |

| Impedance characterisation of industrial lubricants | Industrial oils (in a laboratory setting; no actual engine) | Responses from bulk solution, adsorption of surface active additives, R, C, CPE parameters related to diffusion and charge transfer | - | It was shown that oil’s chemical composition and degradation processes can be evaluated with EIS by creating equivalent circuit models containing R, C, and CPE in multiple frequency ranges | [52] |

| Real-time and online oil condition monitoring by triboelectrification of oil-solid contact | Pure base oils and formulated motor oil | Direct measurement of electrical signals; indirect measurement of fat-related parameters. | - | It provides real-time, online, and high-precision monitoring of engine and machine oils. The sensor detects low contamination levels and requires no external power | [53] |

| Monitoring the degradation status of automotive engine oils with conductive sensors | Used engine oils | Conductivity change, especially the effect of carbonic acids | - | The APTES MIP layer demonstrated good sensitivity to engine oil ageing. The composite containing carbon nanotubes provided a significant difference in conductivity between fresh and used oil. The conductivity of the composite is enhanced by the electron-withdrawing effect of carbonic acids | [42] |

| (b) | |||||

| Sensor Type | Sensitivity | Cost | Response Time | Field Applicability | Ref. |

| Conductometric Sensor (Polyurethane-CNT & APTES imprinted polymers) | Clear discrimination against derivative deformations | Requires laboratory infrastructure and LCR meters | Rise and recovery times are fast; based on surface interaction | Safe in a laboratory environment; apparatus and temperature control may be required for field use | [42] |

| Triboelectric Nanogenerator (O–S TENG) | Detection of particles ≥ 1 mg/mL and water ≥ 0.01 wt% Enhanced versions have particles ≥ 0.01 wt% and water ≥ 100 ppm | Self-powered; no additional power supply required. Simple materials (PTFE, LDPE, copper) and surface treatments are sufficient | Signals are instantaneous; they depend on triboelectric contact-separation processes | The tank interior can be applied to a real vehicle and is durable | [53,54] |

| Electrical Parameter Measuring Sensors | Good repeatability in the 1 kHz–10 kHz range; correlation with viscosity and IR spectrum | Can be implemented with a relatively simple electronic measurement system | Speed depends on frequency scan time but can approach real time | Simple sensor structure; can be integrated into industrial systems, sensitive to environmental parameters | [55] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keser, K. Smart Oil Management with Green Sensors for Industry 4.0. Lubricants 2025, 13, 389. https://doi.org/10.3390/lubricants13090389

Keser K. Smart Oil Management with Green Sensors for Industry 4.0. Lubricants. 2025; 13(9):389. https://doi.org/10.3390/lubricants13090389

Chicago/Turabian StyleKeser, Kübra. 2025. "Smart Oil Management with Green Sensors for Industry 4.0" Lubricants 13, no. 9: 389. https://doi.org/10.3390/lubricants13090389

APA StyleKeser, K. (2025). Smart Oil Management with Green Sensors for Industry 4.0. Lubricants, 13(9), 389. https://doi.org/10.3390/lubricants13090389