Abstract

To elucidate the key material parameters governing the tribological performance of ceramic composites under dry sliding against steel, this study presents a comprehensive comparative assessment of the microstructural characteristics, mechanical performance, and tribological behavior of two alumina–zirconia (Al2O3–ZrO2) ceramic composites, each reinforced with a 42 vol.% carbide phase: zirconium carbide (ZrC) and tungsten carbide (WC). Specifically, tungsten carbide (WC) was selected for its exceptional bulk mechanical properties, while zirconium carbide (ZrC) was chosen to contrast its potentially different interfacial reactivity against a steel counterface. ZrC and WC were selected as reinforcing phases due to their high hardness and distinct chemical and interfacial properties, which were expected to critically affect the wear and friction behavior of the composites under demanding conditions. Specimens were consolidated via spark plasma sintering (SPS). The investigation encompassed macro- and nanoscale hardness measurements (Vickers hardness HV1, HV10; nanoindentation hardness H), elastic modulus (E), fracture toughness (KIC), coefficient of friction (COF), and specific wear rate (Ws) under unlubricated reciprocating sliding against 100Cr6 steel at normal loads of 10 N and 25 N. The Al2O3–ZrO2–WC composite exhibited an ultrafine-grained microstructure and markedly enhanced mechanical properties (HV10 ≈ 20.9 GPa; H ≈ 33.6 GPa; KIC ≈ 4.7 MPa·m½) relative to the coarse-grained Al2O3–ZrO2–ZrC counterpart (HV10 ≈ 16.6 GPa; H ≈ 27.0 GPa; KIC ≈ 3.2 MPa·m½). Paradoxically, the ZrC-reinforced composite demonstrated superior tribological performance, with a low and load-independent specific wear rate (Ws ≈ 1.2 × 10−9 mm3/Nm) and a stable steady-state COF of approximately 0.46. Conversely, the WC-reinforced system exhibited significantly elevated wear volumes—particularly under the 25 N regime—and a higher, more fluctuating COF. Scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM–EDX) of the wear tracks revealed the formation of a continuous, iron-enriched tribofilm on the ZrC composite, derived from counterface material transfer, whereas the WC composite surface displayed only sparse tribofilm development. These findings underscore that, in steel-paired tribological applications of Al2O3–ZrO2–based composites, the efficacy of interfacial tribolayer generation can supersede intrinsic bulk mechanical attributes as the dominant factor governing wear resistance.

1. Introduction

Ceramic materials, especially ceramic matrix composites (CMCs), represent a class of advanced materials with a unique combination of high hardness, chemical and thermal stability, and excellent wear resistance, leading to their increasing use in the aerospace, automotive, military, and electronic industries [1,2,3,4]. Their main advantages include high hardness and compressive strength, outstanding mechanical integrity even at elevated temperatures, and high resistance to corrosion and oxidation. These properties, together with relatively low density, make CMCs attractive for demanding applications, where performance and weight savings are critical, including in engine parts, cutting tools, brake disks, bearings, or biomedical implants [2,3,4,5]. However, these materials are inherently brittle and susceptible to crack formation, especially under impact or thermal shock. Even with the addition of zirconia or carbide phases, their toughness remains lower compared to metals or polymers. Furthermore, CMC manufacturing is complex and costly, requiring strict control of microstructure, phase distribution, sintering, and final machining, which often requires diamond tools. Despite these challenges, their unique properties secure an important role in advanced and specialized applications [4].

Alumina-based ceramics (Al2O3) rank among the most widely employed advanced ceramic materials across diverse industrial sectors—from cutting tools to high-performance bearing components—due to their outstanding hardness, thermal stability, and resistance to both corrosion and wear [1,2,3]. However, alumina-based cutting inserts frequently exhibit limited toughness, leading to premature tool failure via chipping or catastrophic fracture [6]. Although considerable progress has been made in enhancing the toughness of ceramics, their inherent brittleness still constrains broader application [5,7].

A well-established strategy to augment fracture toughness is the development of zirconia-toughened alumina (ZTA) composites, in which Al2O3 is reinforced with ZrO2 particles [8,9,10,11]. In ZTA systems, the stress-induced phase transformation of tetragonal ZrO2 to its monoclinic form entails a substantial volume expansion; this generates compressive stresses around advancing cracks, thereby impeding crack propagation and elevating fracture toughness [8]. Despite the improved toughness of ZTA ceramics relative to monolithic Al2O3, their fracture toughness still falls short of the demands posed by the most severe service conditions.

Therefore, as an additional approach to mitigate this limitation, hard carbide particulates—such as tungsten carbide (WC) or zirconium carbide (ZrC)—are frequently incorporated into the ZTA matrix to further enhance its physical and mechanical performance [5,12,13]. Such Al2O3–ZrO2 composites reinforced with carbide phases are anticipated to demonstrate superior tribological characteristics. In wear and tribology contexts, hardness is often regarded as the primary predictor of a material’s wear resistance, with the conventional assumption that higher hardness and fracture toughness correlate with reduced wear. However, the interplay between these bulk mechanical properties and tribological performance—particularly under dry sliding against metallic counterfaces like steel—can be complex and non-linear.

The current challenge lies in elucidating how the nature of the carbide reinforcement influences not only the intrinsic mechanical attributes of the composite but also its interfacial tribological behavior, including the development of tribolayers at the sliding interface. Tungsten carbide (WC) is distinguished by its exceptional hardness and modulus, whereas zirconium carbide (ZrC), though comparably hard, may exhibit differing chemical reactivity and adhesion characteristics with the steel counterface [12,13]. A systematic, side-by-side comparison of WC and ZrC reinforcements within an identical Al2O3–ZrO2 matrix—processed under the same spark plasma sintering (SPS) conditions—can yield critical insights into prevailing wear mechanisms.

In order to systematically compare the influence of two distinct carbide-reinforcing phases on the comprehensive mechanical and tribological properties, either tungsten carbide (WC) or zirconium carbide (ZrC) was incorporated into an identical Al2O3–ZrO2 matrix. The selection of WC is justified by its exceptionally high hardness, elastic modulus, and fracture toughness, attributes that are known to substantially enhance abrasion resistance and mechanical robustness in ceramic composites, which are beneficial especially for cutting tools and components subjected to cyclic or high mechanical loads [12,13]. On the other hand, ZrC provides not only high hardness and thermal stability, but also excellent chemical inertness and a unique ability to interact with metallic counterfaces (e.g., steel), thereby promoting the formation of continuous tribological films (tribofilms) under dry contact. This characteristic can result in a reduced coefficient of friction, stabilized wear behavior, and extended service life of components operating in unlubricated environments [4,12].

Although the available literature clearly demonstrates the beneficial effect of carbide-reinforcing phases such as WC and ZrC on the enhancement of mechanical and tribological properties of Al2O3 and ZrO2-based ceramic composites [14,15,16], prior research has predominantly focused on individual systems, i.e., either Al2O3–ZrO2–WC or Al2O3–ZrC, and often involves differing methodological approaches to powder processing, sintering, or testing. To the best of our knowledge, the literature lacks a direct comparative study that evaluates the effect of WC and ZrC reinforcement within an identical Al2O3–ZrO2 matrix under the same technological and testing conditions. No systematic analysis is available that would allow for a differentiated assessment of the impact of WC-to-ZrC (or vice versa) substitution on the resulting microstructure, mechanical properties, and tribological response of the composite under dry sliding contact with a steel counterbody.

The present work addresses this research gap by providing the first direct, experimentally comparable evaluation of Al2O3–ZrO2 composites reinforced with either 42 vol.% WC or ZrC. Both material variants were fabricated using identical protocols, including consolidation via spark plasma sintering (SPS), to isolate the influence of the carbide phase. The study aims to determine how the anticipated stark contrasts in microstructure—an ultrafine-grained WC composite versus a coarse-grained ZrC composite—and their associated mechanical properties manifest in tribological performance. To this end, the materials were tested under dry reciprocating sliding against a 100Cr6 steel counterbody at loads of 10 N and 25 N. Particular emphasis is placed on wear track analysis and tribolayer characterization to identify dominant wear mechanisms and to clarify the often-observed decorrelation between bulk mechanical properties and actual wear resistance [5,17,18]. A thorough understanding of these relationships is imperative for the rational design of ceramic composites for cutting tools and other high-performance tribological applications.

2. Experimental Methods

This section addresses the Al2O3–ZrO2–ZrC and Al2O3–ZrO2–WC composites. The powder preparation and characterization methods were identical for both material systems.

The following starting powders were employed: α-Al2O3 (dₚ ≈ 150 nm, TAIMICRON TM-DAR, TAIMEI CHEMICALS CO., Tokyo, Japan), tetragonal ZrO2 stabilized with 3 mol.% Y2O3 (30–60 nm, Inframat Corporation, Manchester, CT, USA), WC powder (1–1.5 µm, STD 120, HÖGANÄS AB, Höganäs, Sweden), and ZrC powder (3–5 µm, type B, HÖGANÄS AB). Powders were weighed to yield mixtures of 46 vol.% Al2O3 + 12 vol.% ZrO2 + 42 vol.% of the respective carbide phase (WC or ZrC), with a precision of ±10 mg. The original assumption was that the composites would contain only Al2O3 as the oxide phase with equal proportions of oxide and carbide phases. This assumption was later refined after observing that zirconium oxide can further improve composite properties [19]. Additionally, maintaining a slight predominance of oxide phases facilitates sintering at lower temperatures and enhances overall sinterability, given that pure carbides like WC require temperatures above 2000 °C for SPS, while oxides sinter around 1300 °C. Based on a balance between achieving high hardness from the carbide phase and ensuring good sinterability via the oxide matrix, a composition of 46 vol.% Al2O3, 12 vol.% ZrO2, and 42 vol.% carbide was selected as a representative system for this comparative study. Similar compositions have been explored in related material optimization studies Nishi et al. [14].

The powder mixtures were dispersed in isopropanol (≈40 vol.%) and subjected to planetary milling using a PULVERISETTE 6 (FRITSCH, Idar-Oberstein, Germany) for 2 h at 200 rpm. Milling was conducted in a ZrO2 jar with 10 mm ZrO2 grinding balls at a ball-to-powder weight ratio of 10:1, with rotation direction reversed every 30 min. The resulting slurry was evaporated under reduced pressure in a rotary evaporator, and the dried powder was sieved through a 200 µm mesh before storage in a desiccator.

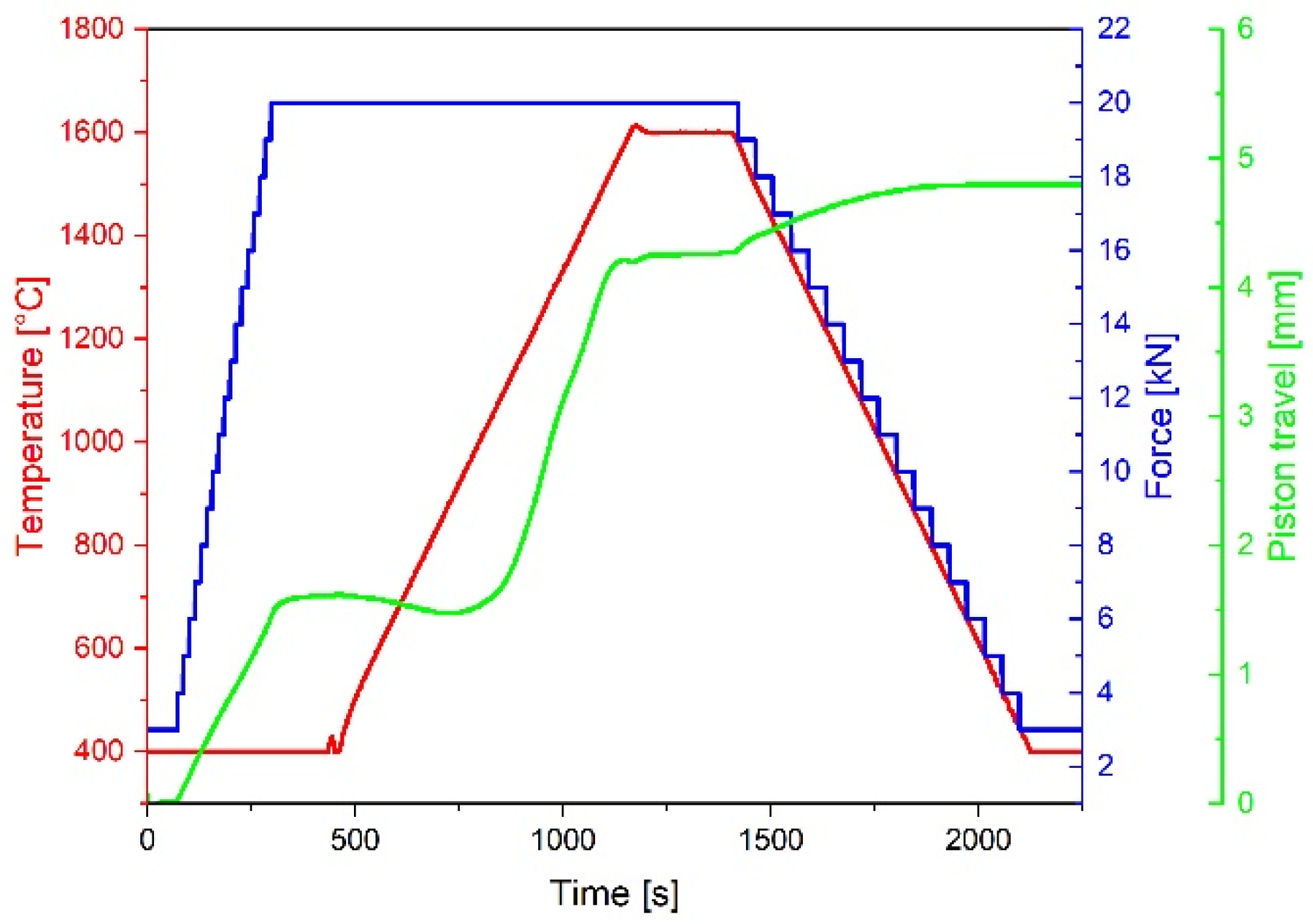

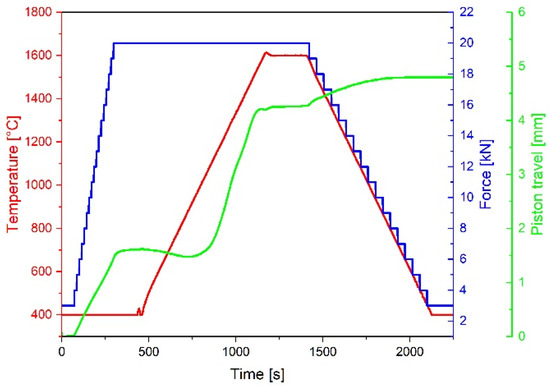

Both composites were sintered in an identical cycle on an HP D 5 (FCT Systeme, Effelder-Rauenstein, Germany) apparatus in a 20 mm-diameter graphite die (lined with graphite foil) in an argon atmosphere (≈500 Pa after evacuation to ≈5 Pa). A representative sintering-cycle record is shown in Figure 1. The cycle included preheating (to 400 °C, dwell ≈ 5 min), main heating (ramp to 1600 °C over 720 s, ≈100 °C min−1), isothermal dwell (4 min at 1600 °C), and controlled cooling (to 400 °C over 720 s, ≈100 °C min−1). The uniaxial force was ramped to 20 kN (≈63 MPa) and maintained during heating and dwell. The bulk density of the sintered samples was measured using the Archimedes method in distilled water, in accordance with the standard [20]. The theoretical density (ρ_th) of each composite was subsequently calculated using the rule of mixtures, based on the volume fractions and theoretical densities of the constituent phases: α-Al2O3 (3.98 g/cm3), 3Y-TZP (6.05 g/cm3), WC (15.7 g/cm3), and ZrC (6.73 g/cm3). Finally, the relative density was determined as the ratio of the measured bulk density to the calculated theoretical density. The resulting specimens exhibited a high degree of densification. Specifically, the Al2O3–ZrO2–WC composite achieved a relative density of ≥99%, while the Al2O3–ZrO2–ZrC composite showed a slightly lower relative density of ≥97.5%, which is consistent with the localized porosity observed in its microstructure. The total porosity (P) of the sintered samples was subsequently determined as the complement to the relative density (P = 100% − ρ_rel).

Figure 1.

Graphical record of the SPS data, representative of both materials.

Specimens were ground sequentially with SiC papers (320 → 1200 grit) and polished on a TEGRAMIN 30 (Struers, Copenhagen, Denmark) using diamond suspensions (9, 3, 1 µm). Final polishing with colloidal SiO2 (0.05 µm) yielded a surface roughness Ra ≈ 0.063 µm (Sensofar PLu Neox, Sensofar Metrology, Barcelona, Spain). This highly polished surface was prepared to minimize the influence of initial topography on the tribological behavior and to provide a standardized, uniform substrate for studying tribofilm formation, thereby ensuring a direct and reliable comparison of the materials’ intrinsic response.

The microstructure was examined using a SEM/FIB–CrossBeam ZEISS AURIGA Compact (Carl Zeiss, Oberkochen, Germany) operated in backscattered electron (BSE) mode. Vickers macrohardness (HV1 and HV10) was measured on a 432SVD hardness tester (Wolpert Wilson Instruments, Norwood, MA, USA) (minimum of five indents per load). Fracture toughness (KIC) was calculated from the radial crack lengths produced under a load of 98.1 N, following the Anstis method [21] a widely used technique for such evaluations in brittle solids [22,23]. Nanomechanical properties—hardness (H) and Young’s modulus (E)—were determined via nanoindentation using an Agilent G200 NanoIndenter (Keysight Technologies, Santa Rosa, CA, USA) (Berkovich tip, CSM mode, hmax = 200 nm, strain rate = 0.05 s−1, 100 indents arranged in a 10 × 10 matrix with 6 µm spacing) and analyzed by the Oliver–Pharr method after calibration on fused SiO2 [24]. Nanoindentation tests were performed using a constant maximum indentation depth of 200 nm to ensure consistent near-surface mechanical property evaluation and to minimize substrate and surface roughness effects. The corresponding maximum indentation loads varied between approximately 17 mN for the ZrC composite and 22 mN for the WC composite, reflecting their differing hardness. This approach enables a reliable comparison of the mechanical response of both composites.

The sliding friction and wear tests were conducted in general accordance with the standard [25]. Sliding tests were conducted on a Bruker UMT-3 tribometer (Bruker, Bremen, Germany) (ball-on-flat) against a 100Cr6 steel ball (Ø 6 mm, HRC 60–66, cleaned in acetone in an ultrasonic bath). Tests were performed under dry conditions (22 ± 1 °C; relative humidity: RH 40 ± 5%) with a reciprocating stroke (amplitude 5 mm, frequency 10 Hz, mean sliding speed 0.1 m s−1). Normal loads of 10 N and 25 N were applied over a total sliding distance of 500 m. The coefficient of friction (COF) was recorded continuously. The tribological contact geometry was a ball-on-flat configuration, using an ideally spherical 6 mm diameter 100Cr6 steel ball as the counterbody. Hertzian contact analysis was performed for both applied loads. For Al2O3–ZrO2–ZrC, the reduced modulus E* was 147 GPa, with calculated contact radii of 53 μm (10 N) and 73 μm (25 N), and maximum Hertzian contact pressures of ~1.67 and ~2.27 GPa, respectively. For Al2O3–ZrO2–WC, E* was 165 GPa, with contact radii of 51 μm (10 N) and 70 μm (25 N), and maximum Hertzian pressures of ~1.80 and ~2.44 GPa. For each combination of material and testing condition (i.e., each material–load pair), three independent experiments were systematically conducted to assess the variability of the results and enable a robust evaluation of reproducibility. Given the sample size (n = 3), formal statistical tests were not performed; the significance of the observed differences is therefore evaluated through a direct comparison of the mean values and their standard deviations. Alumina-zirconia-based composites are frequently developed for high-performance applications where they come into direct contact with steel components. These include cutting tool inserts, machining steel workpieces, bearings with steel races, mechanical seals, and valve components. Testing against a standard, widely used hardened bearing steel like 100Cr6 directly simulates the contact conditions found in these critical industrial applications, making our results directly relevant for material selection and design. Beyond its industrial relevance, the steel counter-body was specifically chosen for a key scientific reason: to serve as an essential source of iron (Fe) for the potential in situ formation of a protective tribolayer. This experimental design allowed for the direct investigation of our central hypothesis that the different carbide phases (WC vs. ZrC) would exhibit distinct chemical affinities and thus profoundly different capacities for generating such a film.

Wear volume (V) was determined from 3D profilometry of the wear tracks (Sensofar PLu Neox). The specific wear rate (Ws) was calculated based on the volume loss (V) per sliding distance (L) and applied load (Fₚ), using Equation (1) [25]:

Track morphology and tribolayer formation were characterized by FIB-SEM on a ZEISS Auriga Compact Oxford Instruments, Oxford, UK (SE, BSE modes) and by energy-dispersive X-ray spectroscopy (EDX).

All comparative mechanical and tribological tests were performed in parallel for both composite types under strictly identical experimental conditions. Specimen preparation, processing, and testing were carried out within the same experimental batches to ensure maximum consistency, reproducibility, and reliability of the results.

To provide molecular-level insight into the phase composition of the pristine composites and the tribo-chemical transformations within the wear tracks, Raman spectroscopy was performed. The spectra were acquired using a spectrometer (XploRA, Horiba Jobin Yvon, Palaiseau, France) equipped with a 532 nm laser excitation source. Data were collected from 100 to 2000 cm−1 using a 100× objective, with an acquisition time of 10 s and 3 accumulations to ensure a high signal-to-noise ratio. The measurements were performed at a laser beam energy density of 12 mW on the sample.

This technique was selected for its high sensitivity to carbonaceous phases and metal oxides, providing chemical information complementary to the elemental data from EDX.

A Philips X’Pert Pro laboratory X-ray in a Bragg-Brentano arrangement was used for phase analysis of the sintered samples. The analysis was performed in the 2 Θ range from 30° to 80°.

3. Results

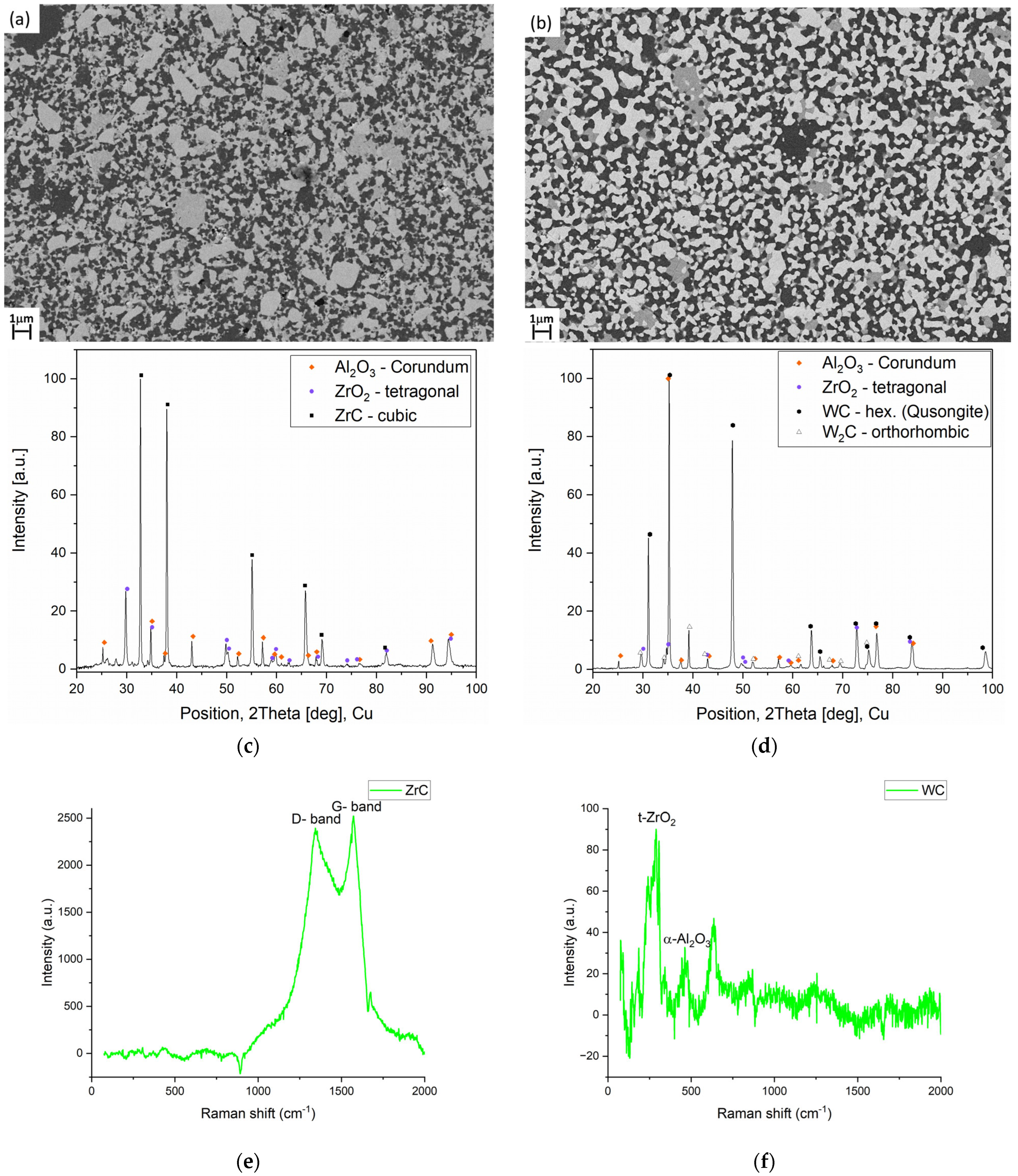

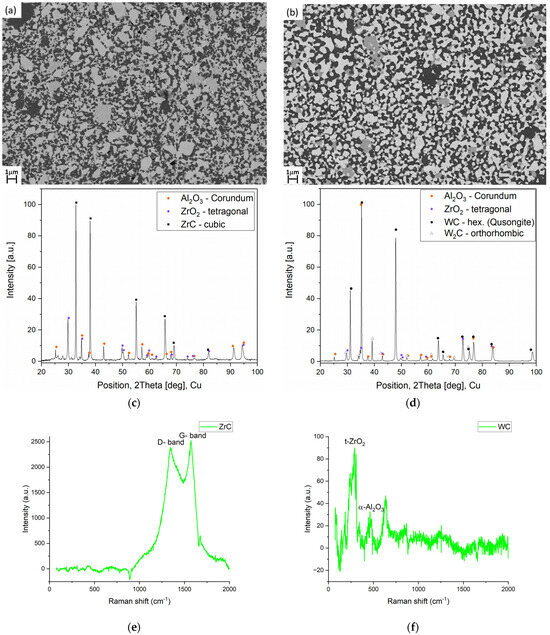

Figure 2a,b SEM-BSE micrographs showing the microstructures of the Al2O3–ZrO2–ZrC and Al2O3–ZrO2–WC composites, respectively. (Figure 2c,d) Corresponding XRD patterns confirm the phase composition. (Figure 2e,f) Raman spectra revealing the presence of disordered graphitic carbon in the ZrC composite (Figure 2e) and its absence in the WC composite (Figure 2f).

Figure 2.

SEM micrographs of the microstructures of the ZrC composite (a) and the WC composite (b) with corresponding phase composition of ZrC (c) and WC (d) and Raman spectra of ZrC (e) and WC (f).

The ZrC composite (Figure 2a) exhibits a markedly coarser-grained microstructure. ZrC carbide particles are significantly larger (2–8 µm) and display a predominantly rounded morphology. This specimen also showed localized regions of slightly elevated porosity.

In contrast, the WC composite (Figure 2b) reveals an ultrafine-grained, highly homogeneous microstructure. WC particles are predominantly submicron in size (<1 µm) and are uniformly distributed within the Al2O3–ZrO2 matrix.

The phase compositions of the sintered composites were determined by XRD analysis, with the resulting patterns shown in Figure 2c,d.

In the case of the Al2O3–ZrO2–ZrC composite, the XRD pattern confirmed the presence of α-alumina, tetragonal zirconia, and cubic zirconium carbide (ZrC) as the main constituent phases. The SEM image of this composite (Figure 2a) shows dark alumina, medium gray tetragonal zirconia, and bright ZrC grains, consistent with the phase composition identified by XRD.

For the Al2O3–ZrO2–WC composite, the primary crystalline phases were identified as α-alumina (corundum, Al2O3), tetragonal zirconia (t-ZrO2), and hexagonal tungsten carbide (WC). Additionally, minor peaks corresponding to the orthorhombic W2C phase were detected, indicating a slight decomposition or reaction of WC, which is sometimes observed under high-temperature SPS conditions. Correspondingly, the SEM microstructure (Figure 2b) reveals the darkest alumina grains, medium gray tetragonal zirconia, and the brightest phase carbide grains corresponding to WC and W2C phases.

For both material systems, the XRD analysis confirms that no significant undesirable reactions occurred during sintering, and the intended primary oxide and carbide phases were successfully retained in the final microstructure. This confirms the successful fabrication of the intended composites, providing a solid baseline for the subsequent mechanical and tribological evaluation. To complement the bulk phase analysis from XRD, EDX point analysis was performed to investigate the local chemical composition of the as-sintered composites, followed by a detailed surface analysis using Raman spectroscopy.

In the Al2O3–ZrO2–ZrC composite, the EDX analysis confirmed the distinct multiphase structure. Point analyses performed on large, bright grains revealed a composition consistent with zirconium carbide (approx. 68 wt.% Zr, 24 wt.% C), including a small amount of hafnium (Hf), a common impurity in Zr. In contrast, analyses of the dark matrix regions showed elemental compositions corresponding to alumina (approx. 45 wt.% Al, 46 wt.% O), while intermediate gray areas were identified as zirconia-rich regions within the alumina matrix.

Similarly, for the Al2O3–ZrO2–WC composite, EDX confirmed the presence of the intended phases. The brightest grains were identified as tungsten carbide (approx. 79 wt.% W, 15 wt.% C). The surrounding matrix and interface areas showed a complex mixture of all constituent elements (Al, Zr, W, O, C), confirming the fine, intermixed nature of the microstructure observed in the SEM images.

Overall, the EDX results are in full agreement with the XRD data, confirming the successful retention of the primary oxide and carbide phases and providing a solid baseline for the subsequent mechanical and tribological evaluation.

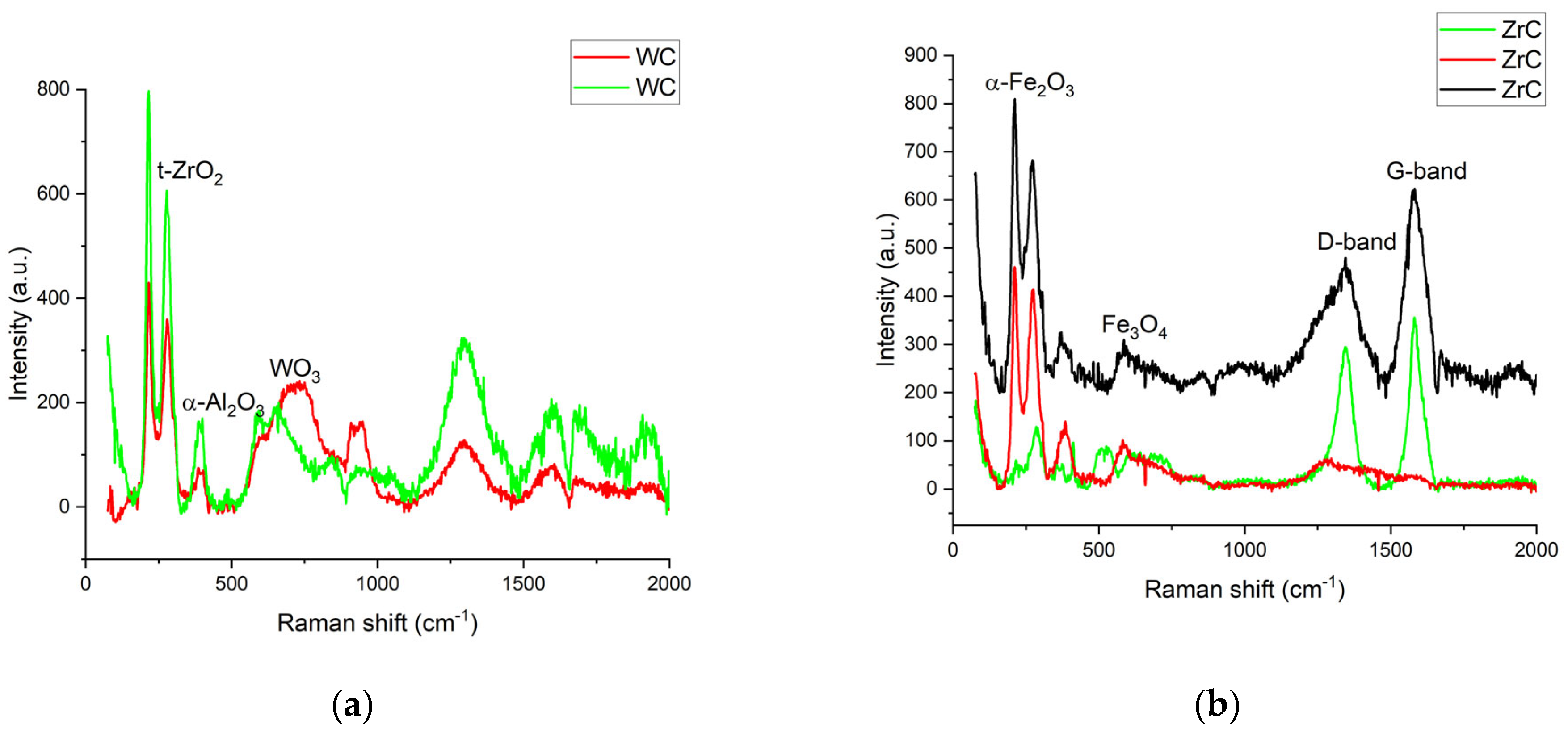

Raman spectroscopy (Figure 2e,f) provided further critical insights into the intrinsic chemical differences between the two systems. The Al2O3–ZrO2–WC composite (Figure 2f) displayed a clean spectrum characteristic of its constituent ceramic phases, with clearly resolved peaks for α-Al2O3, t-ZrO2, and WC. Crucially, the absence of any signal in the 1300–1600 cm−1 region confirmed the lack of a free, Raman-active carbon phase. In stark contrast, the spectrum of the Al2O3–ZrO2–ZrC composite (Figure 2e) was overwhelmingly dominated by two intense bands at ~1355 cm−1 (D-band) and ~1590 cm−1 (G-band). This is the unambiguous signature of disordered graphitic carbon, not the ZrC phase itself [26]. This finding provides definitive evidence that the ZrC composite, unlike its WC counterpart, possesses a “built-in” solid lubricant phase, likely segregated at grain boundaries, which pre-conditions it for a unique tribological response.

The mechanical properties parameters for the ZrC composite and the WC composite are summarized in Table 1 (macrohardness and KIC) and Table 2 (nanomechanical properties).

Table 1.

Vickers macrohardness (HV1, HV10) and fracture toughness (KIC) determined by the Anstis method [21] for the ZrC composite and the WC composite.

Table 2.

Nanoindentation hardness (H) and Young’s modulus (E) for the ZrC composite and the WC composite.

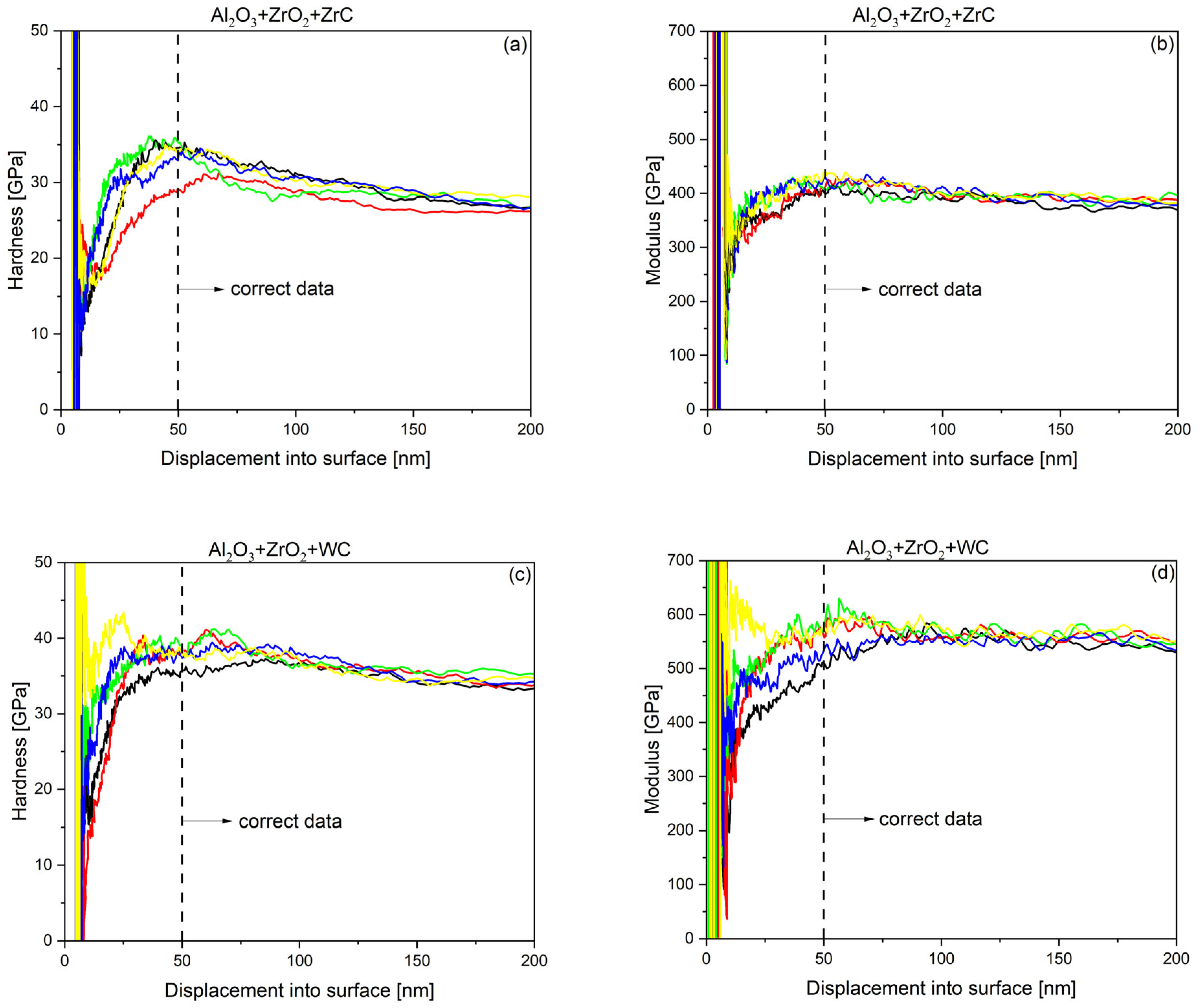

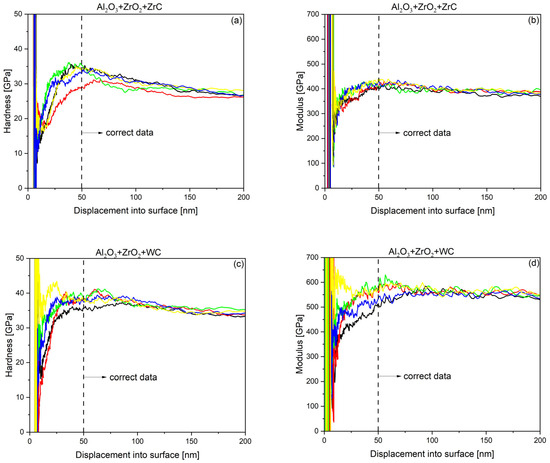

The data clearly indicate that the WC-reinforced composite surpasses the ZrC-reinforced variant in every measured mechanical parameter (HV1, HV10, KIC, H, and E). Both composites display a notable indentation size effect (ISE) [27,28,29,30]. Representative load–displacement traces from the nanoindentation experiments are provided in Figure 3.

Figure 3.

Representative results of nanoindentation measurements: hardness (H) and Young’s modulus (E) as a function of indentation depth: (a) hardness and (b) modulus for the ZrC composite; (c) hardness and (d) modulus for the WC composite.

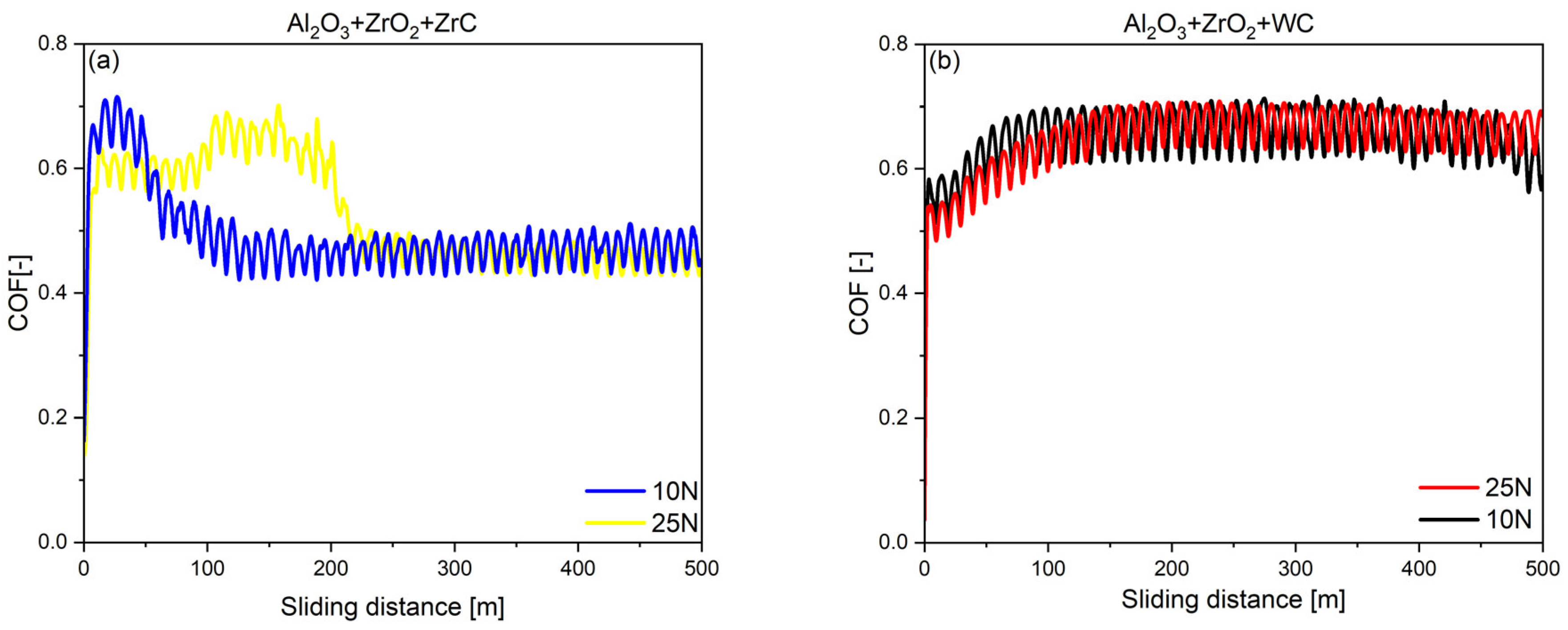

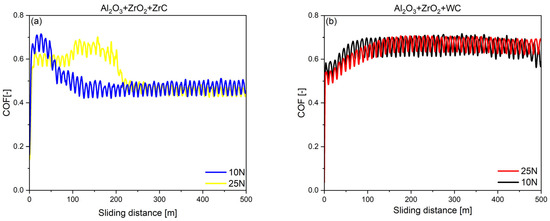

In terms of tribological properties, differences between the individual composites can be observed. Figure 4 plots the COF versus sliding distance for both composites at 10 N and 25 N loads. The ZrC-reinforced composite (Figure 4a) achieves a low and stable steady-state COF of approximately 0.46. Notably, under the 25 N load, it shows a brief friction spike between 100 m and 200 m, which likely corresponds to the initial nucleation and densification of the protective tribofilm, before settling into a stable friction regime. Conversely, the WC-reinforced composite (Figure 4b) exhibits significantly higher and more fluctuating friction, with a steady-state COF of around 0.67. Notably, under a 25 N load, it shows a brief friction spike between 100 m and 200 m before settling into a stable friction regime.

Figure 4.

COF vs. sliding distance for the ZrC composite (a) and the WC composite (b).

As detailed in Table 3, the mean COF over the final 200 m substantiates the frictional behaviors described above.

Table 3.

Steady-state COF (mean over the last 200 m ± SD) for the ZrC composite and the WC composite under applied normal loads 10 N and 25 N.

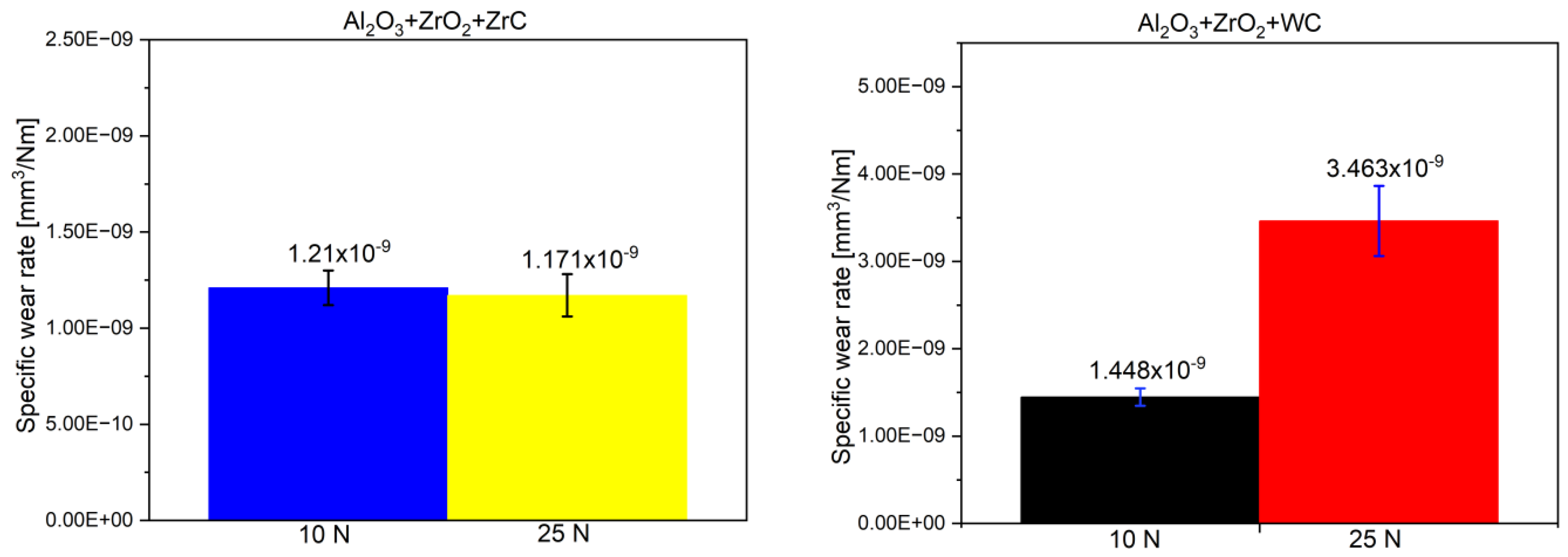

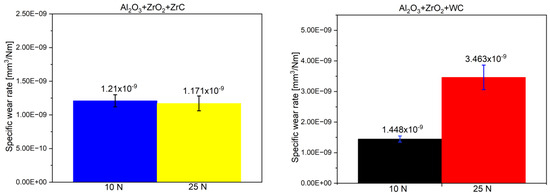

The specific wear rates for the ZrC- and WC-reinforced composites are compiled in Table 4 and plotted in Figure 5. The ZrC composite exhibits the lowest Ws values, with minimal sensitivity to the applied load. In contrast, the WC composite displays a modest WS under the 10 N load but experiences a more than two-fold increase when the load is raised to 25 N.

Table 4.

Specific wear rate (Ws) for the ZrC composite and the WC composite under applied normal loads 10 N and 25 N.

Figure 5.

Bar chart of the specific wear rate (Ws) for the ZrC composite and the WC composite.

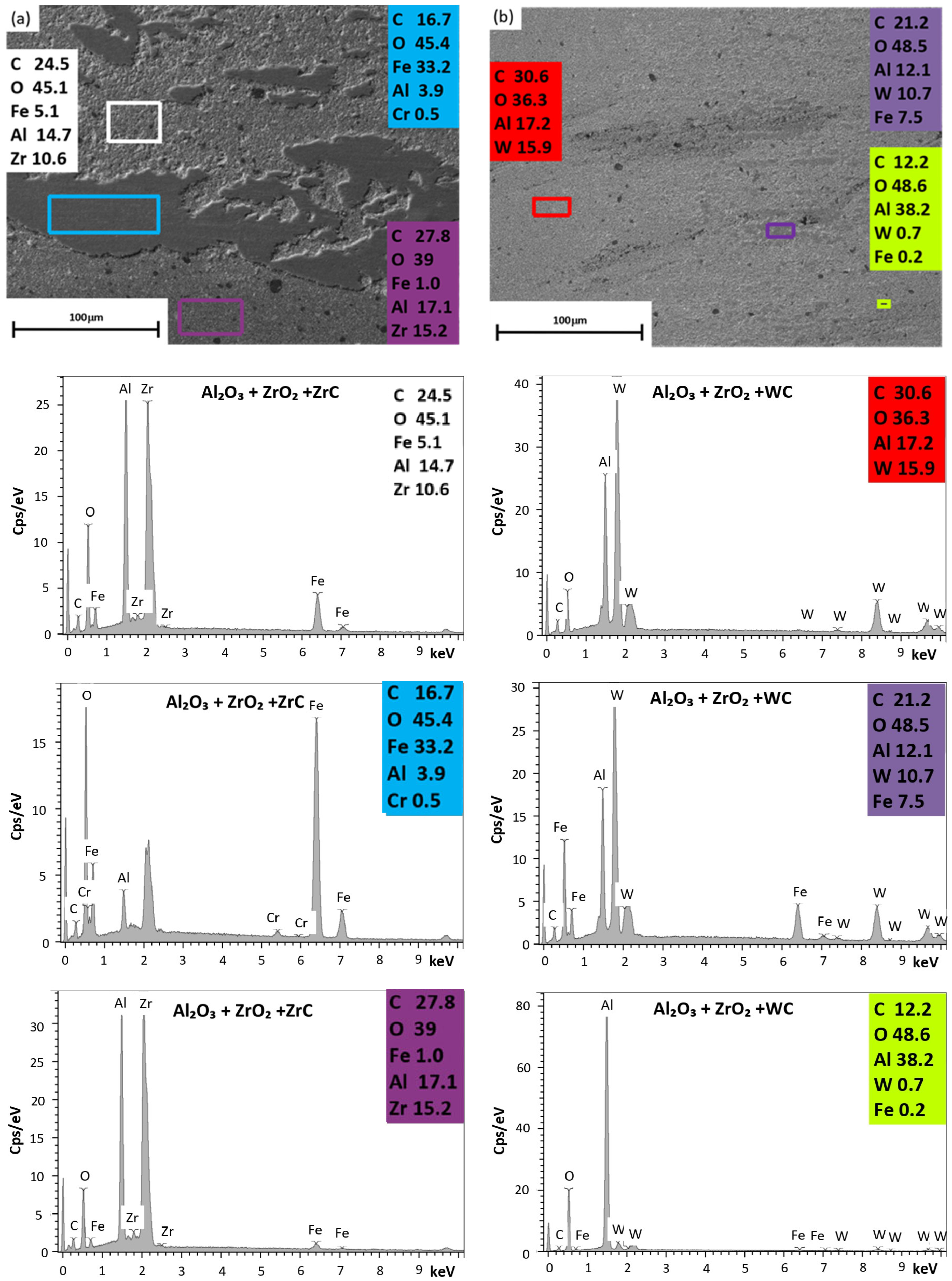

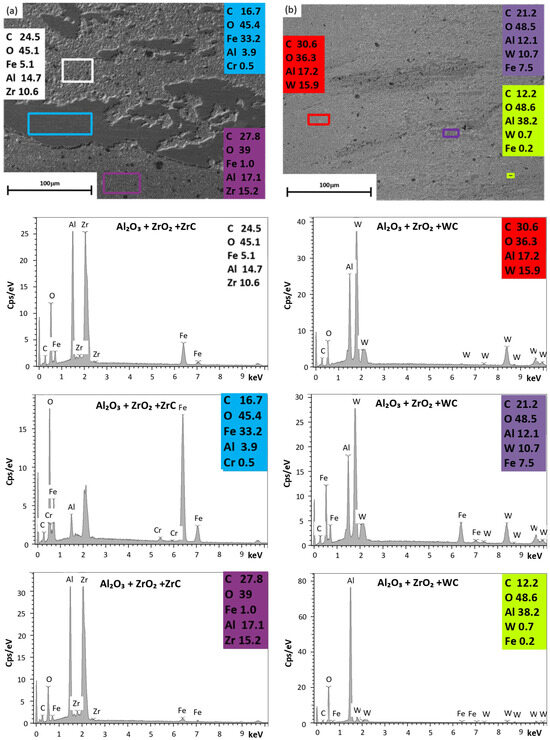

A definitive explanation for the divergent tribological behavior of the two composites is found in the micro-chemical analysis of the wear tracks. SEM imaging coupled with spatially resolved quantitative EDS analysis revealed fundamentally different interfacial phenomena, which directly govern the wear mechanisms (Figure 6).

Figure 6.

SEM images of the wear tracks on the tested ZrC composite (a) and the WC composite (b) after the wear test under 25 N with EDX spectra analysis.

The superior performance of the Al2O3–ZrO2–ZrC composite (Figure 6a) is unequivocally attributed to its capacity to generate a thick, continuous, and chemically robust tribofilm. In tribofilm-rich regions (blue spectrum), EDS analysis revealed a composition dominated by high contents of iron (33.2 at.%) and oxygen (45.7 at.%), along with significant carbon (16.7 at.%). Critically, the detection of chromium (0.5 at.%) provided an unambiguous tracer for material transfer from the 100Cr6 steel counterbody. In stark contrast, analysis of the underlying composite matrix (purple spectrum) showed a composition closely resembling the bulk material (Al: 17.1 at.%, Zr: 15.2 at.%, C: 27.8 at.%, O: 39.0 at.%) with only trace levels of iron (1.0 at.%) detected. This sharp chemical gradient provides direct evidence of a highly effective protective mechanism.

In stark contrast, the Al2O3–ZrO2–WC composite (Figure 6b) failed to establish such a stable protective layer, and its wear track presented as a chemically heterogeneous mosaic. EDS analysis revealed that even the most Fe-enriched patches (purple spectrum) contained a mere 7.5 at.% of iron, accompanied by elevated oxygen (48.5 at.%) and reduced matrix elements (Al: 12.1 at.%, W: 10.7 at.%, C: 21.2 at.%). Other regions were either virtually devoid of iron, corresponding to the exposed composite matrix (red spectrum), or showed a composition indicative of preferential WC phase pull-out, being highly enriched in Al (38.2 at.%) and O (48.6 at.%) with negligible W content (0.7 at.%). This chemical heterogeneity confirms the lack of a continuous, well-adhered film, leaving the surface vulnerable.

The estimated uncertainty for the main elements in all EDS measurements is approximately ±2 at.%, while for minor constituents such as Fe, Cr, and W, it is around ±1 at.%. These spatially resolved analyses clearly demonstrate that, whereas the WC composite shows sparse and discontinuous tribofilm formation, the ZrC composite consistently develops a thick, continuous tribofilm highly enriched in Fe and Cr. The observed chemical gradients correlate directly with the measured tribological performance: the robust, iron- and oxide-rich tribofilm in the ZrC composite acts as a highly effective protective barrier, underpinning its low wear rate and stable friction. In contrast, the WC composite’s lack of such a tribolayer results in greater direct substrate exposure and less effective wear protection. These findings highlight the critical importance of interfacial tribochemistry, far beyond what can be predicted by bulk mechanical properties alone.

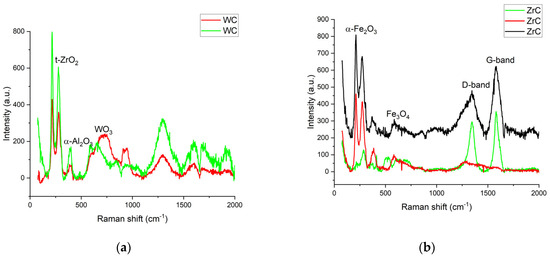

To provide a definitive, molecular-level elucidation of the divergent tribo-chemical pathways, Raman spectroscopy was performed directly inside the wear tracks. The resulting spectra (Figure 7), which are the direct result of these in situ measurements on the authors’ samples, provide a compelling narrative of successful tribofilm synthesis versus catastrophic chemical failure.

Figure 7.

Representative Raman spectra from the wear tracks of (a) the Al2O3–ZrO2–WC composite and (b) the Al2O3–ZrO2–ZrC composite.

The spectrum from the wear track of the Al2O3–ZrO2–ZrC composite (Figure 7b) is a testament to the formation of a synergistic, multifunctional composite tribolayer. The complete attenuation of any spectral features from the underlying Al2O3-ZrO2-ZrC substrate is immediate and powerful evidence of a thick, uniform film that provides full protective coverage. The spectrum itself is dominated by well-resolved phonon modes of crystalline iron oxides. Specifically, the sharp peaks at ~225 and 498 cm−1 (A1g modes) and ~293, 412, and 613 cm−1 (Eg modes) are the unambiguous fingerprints of hematite (α-Fe2O3), while a strong, defining peak at ~670 cm−1 is assigned to the A1g mode of magnetite (Fe3O4). These hard, load-bearing oxide crystallites form a robust scaffold. Critically, this inorganic framework is embedded within a carbonaceous matrix, as confirmed by the two prominent bands characteristic of disordered carbon: the D-band at ~1355 cm−1, arising from A1g symmetry breathing modes of six-atom rings activated by defects, and the G-band at ~1590 cm−1, corresponding to the E2g stretching mode of sp2-bonded carbon atoms. The high intensity ratio of these bands (I_D/I_G > 1) indicates a high degree of disorder and nanocrystallinity within the graphitic phase, a structure ideal for providing low-shear-strength interfaces. This composite film structure—a hard oxide scaffold within a lubricating carbon matrix—is the archetypal “easy shear” protective layer, perfectly explaining the observed low friction and wear.

In diametric opposition, the spectrum from the Al2O3–ZrO2–WC composite’s wear track (Figure 7a) tells a story of chemical instability and interface degradation. The prominent, sharp peaks corresponding to the underlying Al2O3 and t-ZrO2 phases are not minor features; they dominate parts of the spectrum. This is irrefutable evidence of a catastrophically failed tribofilm, leaving large areas of the substrate directly exposed to severe contact stresses. The most damning evidence, however, is the emergence of broad, poorly defined bands spanning the 700–820 cm−1 region. These are the characteristic vibrational modes of tungsten trioxide (WO3). Their broad nature, lacking sharp crystalline peaks, suggests the formation of a disordered or amorphous WO3 phase, which is known to be mechanically brittle and possess poor adhesion. This confirms that the primary reinforcing phase, WC, is not inert but is actively consumed via tribo-oxidation to form a deleterious product. This establishes a destructive feedback loop: initial abrasive contact promotes oxidation of WC to brittle WO3, which then likely acts as a third-body abrasive, accelerating further wear and substrate fracture.

4. Discussion

The findings of this study elucidate the intricate interplay between microstructure, mechanical properties, and tribological performance of Al2O3–ZrO2 composites. The most striking observation is the clear decorrelation between conventional bulk mechanical metrics and wear resistance. Before delving into the tribological paradox, it is pertinent to address the mechanical properties themselves. The observed discrepancy between the hardness values obtained from nanoindentation (H) and Vickers macroindentation (HV10) is a direct manifestation of the well-documented Indentation Size Effect (ISE) [27,28,29]. At the nanoscale, where deformation is highly localized, a greater stress is required to initiate plastic flow via dislocation motion, leading to higher apparent hardness. In contrast, macroindentation probes a larger volume, and the resulting hardness is more representative of the bulk material’s response, which is often influenced by pre-existing microstructural features and crack propagation. Although the ultrafine-grained WC composite demonstrated markedly superior bulk properties—including macrohardness (HV10 ≈ 20.9 GPa vs. 16.6 GPa) and fracture toughness (KIC ≈ 4.7 MPa·m½ vs. 3.2 MPa·m½)—it was the mechanically inferior ZrC composite that exhibited profoundly better tribological behavior. This paradox, characterized by the ZrC composite’s low, stable coefficient of friction (COF ≈ 0.46) and minimal, load-independent wear rate (Ws ≈ 1.2 × 10−9 mm3/Nm), highlights that the governing wear mechanism is not dictated by bulk mechanical strength. The superior stability of this system is further underscored by the high reproducibility and low standard deviation of the wear rate measurements, especially compared to the larger data scatter for the WC composite, which is characteristic of its less predictable, fracture-driven wear mechanism. Instead, it is controlled by the distinct tribo-chemical pathways at the sliding interface, a principle previously established by key researchers such as Kato & Adachi [5] and Rainforth [12].

The definitive explanation for this behavior lies in the intrinsic chemical differences between the two carbide reinforcements, as unequivocally revealed by Raman spectroscopy. The ZrC composite’s superior performance is rooted in its unique initial chemistry. As shown in Figure 2e, it is the only material possessing an inherent, free-carbon phase. This “built-in” solid lubricant acted as a precursor, facilitating the rapid in situ synthesis of a robust, multifunctional composite tribofilm during sliding (Figure 7b). This layer, composed of hard iron oxides (hematite, magnetite) within a lubricating graphitic matrix, effectively shielded the substrate. Conversely, the WC composite failed due to its chemical instability. Lacking an intrinsic lubricating phase (Figure 2f), it was unable to form a stable protective layer and instead underwent deleterious tribo-oxidation to WO3 (Figure 7a). This chemical degradation, combined with high interfacial stresses, promoted the fracture-driven wear observed in SEM, explaining its poor tribological performance.

These divergent tribo-chemical pathways directly manifested in the nature of the interfacial layers observed via SEM-EDX (Figure 6 and Figure 7). The stable, self-lubricating tribofilm on the ZrC composite effectively blanketed the substrate, precluding direct, high-friction contact and dissipating wear energy. This explains not only the low and stable COF but also the film’s resilience, which prevented a transition to a severe wear regime even at a higher load. In stark contrast, the failure to form a protective layer on the WC composite resulted in direct, severe contact between hard WC grains and the steel ball. This triggered a transition to a fracture-dominated wear mechanism (micro-chipping), perfectly aligning with the classic wear transition mechanisms described by Wang and Hsu [18] and explaining the catastrophic, non-linear increase in its wear rate.

It is crucial to emphasize that this dramatic difference in tribological behavior is a genuine chemo-mechanical phenomenon and not an artifact of material quality. The measured mechanical properties of our composites are, in fact, highly representative of this class of materials, with the nanomechanical profile being consistent with values reported for similar Al2O3–ZrO2 systems [31]. The Al2O3-ZrO2-WC composite’s high hardness (HV10 ≈ 20.9 GPa) and fracture toughness (KIC ≈ 4.7 MPa·m½) are comparable to, or even exceed, values reported for similar systems [15]. Similarly, the mechanical profile of the ZrC-reinforced composite falls squarely within the documented range [14]. This validation confirms that the observed tribological discrepancy arises directly from the distinct interfacial chemistry of WC and ZrC reinforcements.

Our results support the assertion that microstructural features, particularly grain size, may also play a secondary role. It is plausible that the coarser-grained microstructure of the ZrC composite, while less favorable for conventional mechanical metrics, promoted the “capture” and integration of material transferred from the counterface, facilitating the formation of a mechanically robust tribolayer. Conversely, the ultra-fine WC particles may have been more readily dislodged from the matrix under high tangential stresses.

The implications for materials design are significant. These results imply that, for applications demanding high wear resistance under dry sliding against steel, a strategy focused solely on maximizing hardness and toughness may not be optimal. Instead, emphasis should also be placed on a material’s ability to generate a favorable tribological interface. The ZrC composite, despite lower bulk mechanical properties, emerges as a more promising candidate for such applications owing to its capacity to develop an effective protective tribolayer. Conversely, the high hardness of the WC composite may be better exploited in lubricated environments, where deleterious tribo-chemical reactions are suppressed and its inherent abrasion resistance can dominate. To further validate these findings, future work should focus on cross-sectional characterization of the tribological interface using Focused Ion Beam (FIB) milling.

5. Conclusions

This comparative study demonstrated a clear decorrelation between the bulk mechanical properties and the dry sliding tribological performance of Al2O3–ZrO2 composites. The WC-reinforced composite, despite its superior hardness (HV10 ≈ 20.9 GPa) and fracture toughness (KIC ≈ 4.7 MPa·m½), exhibited high friction (COF ≈ 0.67) and a load-sensitive wear rate. Conversely, the mechanically inferior ZrC-reinforced composite (HV10 ≈ 16.6 GPa, KIC ≈ 3.2 MPa·m½) achieved excellent tribological performance, characterized by low, stable friction (COF ≈ 0.46) and a minimal, load-independent wear rate (Ws ≈ 1.2 × 10−9 mm3·N−1·m−1).

This paradoxical behavior is governed by distinct tribo-chemical pathways. The superior performance of the ZrC composite is attributed to its intrinsic free-carbon phase, which facilitated the in situ formation of a continuous, protective tribofilm composed of iron oxides within a graphitic matrix. In contrast, the WC composite failed due to its inability to form a stable film, instead undergoing deleterious tribo-oxidation to brittle WO3, which led to abrasive wear and micro-chipping.

These findings carry significant implications for materials design, proving that a strategy focused solely on maximizing hardness and toughness can be counterproductive for dry sliding applications. The results provide a robust basis for a more rational selection of advanced ceramics:

The Al2O3–ZrO2–ZrC system is a highly promising candidate for unlubricated applications that require long-term stability, such as self-lubricating bearings, mechanical seals, or sliding valves.

The Al2O3–ZrO2–WC system, with its outstanding bulk properties, is better suited for applications dominated by high-stress abrasion, particularly where lubrication can mitigate deleterious tribo-chemical wear, such as in cutting tools or certain engine components.

In summary, this work provides a robust basis for the rational selection of advanced ceramic composites. By moving beyond a singular focus on bulk mechanical properties and considering the crucial role of interfacial phenomena, engineers can make more informed design choices. This approach enables the targeted deployment of materials for specific conditions. The Al2O3–ZrO2–ZrC system, for instance, emerges as a highly promising candidate for unlubricated applications requiring long-term stability, including self-lubricating bearings, mechanical seals, or sliding valves. In contrast, the Al2O3–ZrO2–WC system, with its outstanding bulk properties, is better suited for applications dominated by high-stress abrasion, particularly where lubrication can mitigate deleterious tribo-chemical wear, including in cutting tools and certain engine components.

Future work will proceed along several key directions. The immediate next steps involve advanced interface characterization using Focused Ion Beam (FIB) milling to provide direct evidence of the proposed tribofilm mechanisms. Subsequently, research will focus on optimizing the promising ZrC-based system for targeted applications, including performance evaluation in real-world machining tests. Finally, investigating the tribological behavior under lubricated conditions represents a logical future step, where the superior bulk mechanical properties of the WC-reinforced composite might prove advantageous.

Author Contributions

Conceptualization, J.A. and D.M.; Methodology, J.A. and D.M.; Validation, J.A., D.M. and R.S.; Formal analysis, J.A. and D.M.; Investigation, J.A., D.M., M.V., R.S., P.K. and J.D.; Data curation, J.A.; Writing—original draft, J.A. and D.M.; Writing—review & editing, J.A. and R.S.; Visualization, J.A. and D.M.; Supervision, D.M.; Project administration, D.M.; Funding acquisition, D.M. and J.D. All authors have read and agreed to the published version of the manuscript.

Funding

The work was funded by the EU NextGenerationEU through the Recovery and Resilience Plan for Slovakia under the project No. 09I03-03-V04-00260. This work was carried out within the framework of the DuplexCER project, entitled “High performance duplex ceramics for efficient machining of nickel superalloys”, co-founded by The Slovak Academy of Sciences within the framework of the M-ERA.NET programme (Agreement No. M-ERA.NET3/2021/295/DuplexCER) and The Polish National Centre for Research and Development within the framework of the M-ERA.NET programme (Agreement No. M-ERA.NET3/2021/82/DuplexCER/2022).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors have no conflicts of interest to declare. The funding sources had no involvement in the study design; in the collection, analysis, or interpretation of data; in the writing of the report; or in the decision to publish the results.

References

- Dörre, E.; Hübner, H. Alumina: Processing, Properties and Applications; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Morrell, R. Handbook of Properties of Technical & Engineering Ceramics. Part 2. Data Reviews, Section 1. In High-Alumina Ceramics; The Stationery Office Books: London, UK, 1987. [Google Scholar]

- Krell, A.; Blank, P.; Ma, H.; Hutzler, T.; van Bruggen, M.P.B.; Apetz, R. Transparent sintered corundum with high hardness and strength. J. Am. Ceram. Soc. 2003, 86, 12–18. [Google Scholar] [CrossRef]

- Stojanovic, B.; Glisovic, J. Application of Ceramic Matrix Composite in Automotive Industry. Encycl. Mater. Compos. 2021, 2, 275–292. [Google Scholar]

- Kato, K.; Adachi, K. Wear of advanced ceramics. Wear 2002, 253, 1097–1104. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Processes for Engineering Materials, 4th ed.; Pearson Education: London, UK, 2003; p. 449. [Google Scholar]

- Smuk, B.; Szutkowska, M.; Walter, J. Alumina ceramics with partially stabilized zirconia for cutting tools. J. Mater. Process. Technol. 2003, 133, 195–198. [Google Scholar] [CrossRef]

- Evans, A.G.; Cannon, R.M. Toughening of brittle solids by martensitic transformations. Acta Metall. 1986, 34, 761–800. [Google Scholar] [CrossRef]

- Claussen, N. Fracture Toughness of Al2O3 with an Unstabilized ZrO2 Dispersed Phase. J. Am. Ceram. Soc. 1976, 59, 49–51. [Google Scholar] [CrossRef]

- de Aza, A.H.; Chevalier, J.; Fantozzi, G.; Schehl, M.; Torrecillas, R. Slow-crack-growth behavior of zirconia-toughened alumina ceramics processed by different methods. J. Am. Ceram. Soc. 2003, 86, 115–120. [Google Scholar] [CrossRef]

- Fan, K.; Pastor, J.Y.; Ruiz-Hervias, J.; Gurauskis, J.; Baudin, C. Determination of mechanical properties of Al2O3/Y-TZP ceramic composites: Influence of testing method and residual stresses. Ceram. Int. 2016, 42, 18700–18710. [Google Scholar] [CrossRef]

- Rainforth, W.M. The wear behaviour of oxide ceramics-A Review. J. Mater. Sci. 2004, 39, 6705–6721. [Google Scholar] [CrossRef]

- Kameo, K.; Friedrich, K.; Bartolomé, J.F.; Díaz, M.; López-Esteban, S.; Moya, J.S. Sliding wear of ceramics and cermets against steel. J. Eur. Ceram. Soc. 2003, 23, 2867–2877. [Google Scholar] [CrossRef]

- Nishi, T.; Matsunaga, K.; Mitsuoka, T.; Okimura, Y.; Katsu, Y. Advanced superhard composite materials with extremely improved mechanical strength by interfacial segregation of dilute dopants. Sci. Rep. 2020, 10, 21008. [Google Scholar] [CrossRef] [PubMed]

- Landfried, R.; Kern, F.; Burger, W.; Leonhardt, W.; Gadow, R. Development of Electrical Discharge Machinable ZTA Ceramics with 24 vol% of TiC,TiN,TiCN,TiB2 and WC as Electrically Conductive Phase. Int. J. Cer. Tech. 2013, 10, 509–518. [Google Scholar] [CrossRef]

- Huang, C.; Xu, C.; Ai, X. Toughening and strengthening of advanced ceramics with rare earth additives. Cer. Int. 2006, 32, 423–429. [Google Scholar]

- Akhtar, S.S.; Waqar, T.; Hakeem, A.S.; Arif, A.F.M.; Al-Athel, K.S. Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions, Mechanical Behavior of Composite. Materials 2019, 12, 2378. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hsu, S.M. Wear and wear transition mechanisms of ceramics. Wear 1996, 195, 112–122. [Google Scholar] [CrossRef]

- Wang, J.; Stevens, R. Toughening mechanisms in duplex alumina-zirconia ceramics. J. Mat. Sci. 1988, 23, 804–808. [Google Scholar] [CrossRef]

- ISO 18754:2020; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Density and Apparent Porosity. International Organization for Standardization: Geneva, Switzerland, 2020.

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A critical evaluation of indentation techniques for measuring fracture toughness: I, Direct crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Niihara, K.; Morena, R.; Hasselman, D.P.H. Evaluation of KIC of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1982, 1, 13–16. [Google Scholar] [CrossRef]

- JIS R 1607:1995; Testing Methods for Fracture Toughness of Fine Ceramics. Japan Industrial Standards Committee: Tokyo, Japan, 2010.

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- ASTM G133-95; ASTM International. Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM International: West Conshohocken, PA, USA, 2015.

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. 2000, 61, 14095. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids. 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Li, H.; Bradt, R.C. The indentation load/size effect in ceramics: Where is the physics? J. Hard. Mater. 1992, 3, 403–419. [Google Scholar]

- Sangwal, K. On the reverse indentation size effect and microhardness measurement of solids. Mater. Chem. Phys. 2000, 63, 145–157. [Google Scholar] [CrossRef]

- Krell, A.; Schädlich, S. Nanoindentation hardness of submicrometer alumina ceramics. Mater. Sci. Eng. A 2001, 307, 172–181. [Google Scholar] [CrossRef]

- Aragón-Duarte, M.C.; Nevarez-Rascón, A.; Esparza-Ponce, H.E.; Nevarez-Rascón, M.M.; Talamantes, R.P.; Ornelas, C.; Mendez-Nonell, J.; González-Hernández, J.; Yacamán, M.J.; Hurtado-Macías, A. Nanomechanical properties of zirconia-yttria and alumina-zirconia composites obtained by colloidal processing and spark plasma sintering. Ceram. Int. 2015, 41, 6346–6356. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).