Investigation of Microstructural, Mechanical, and Tribological Properties of TiC and MWCNT Reinforced Hot-Pressed Scalmalloy® Hybrid Composites

Abstract

1. Introduction

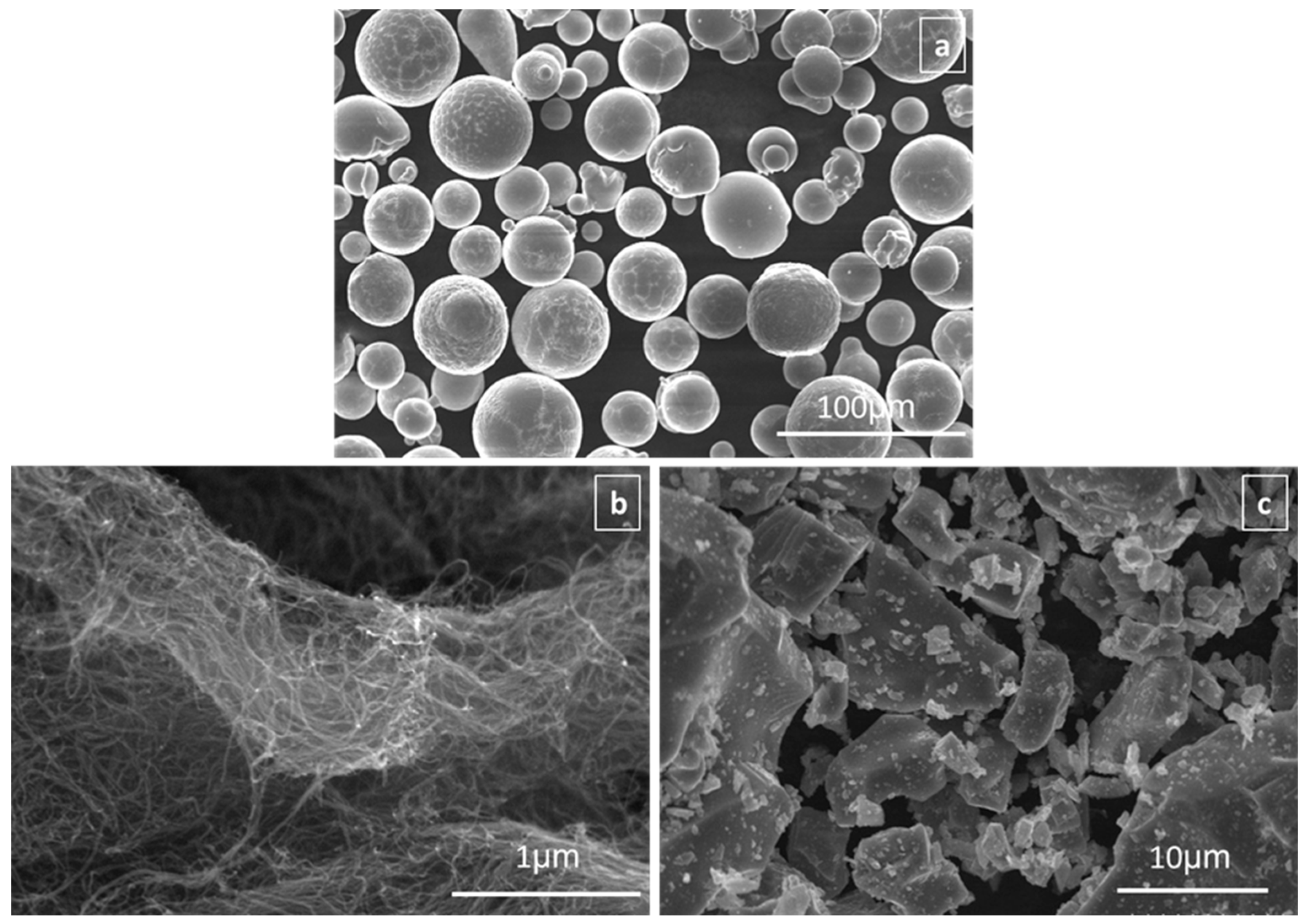

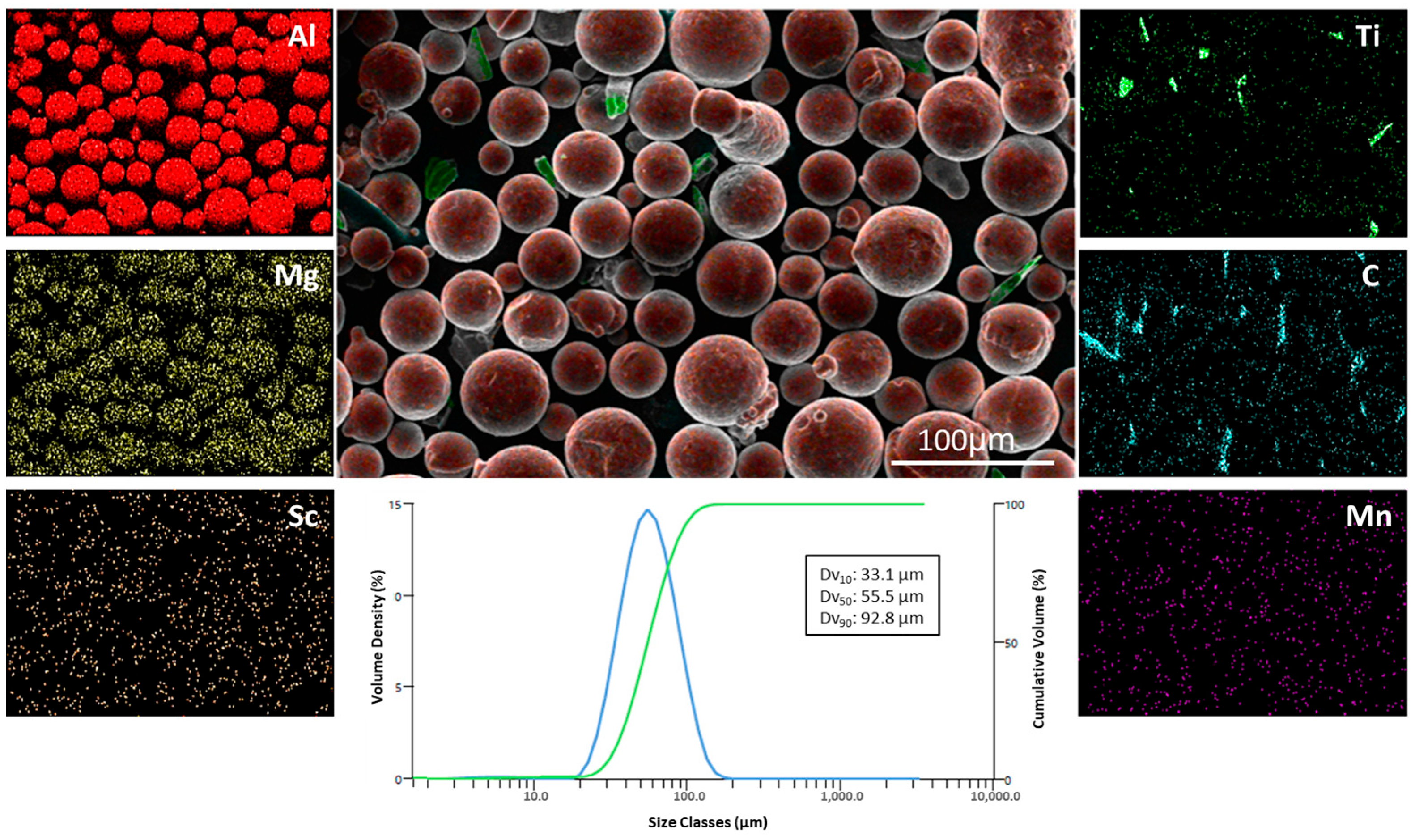

2. Materials and Methods

2.1. Preparation of Hybrid Composite Samples

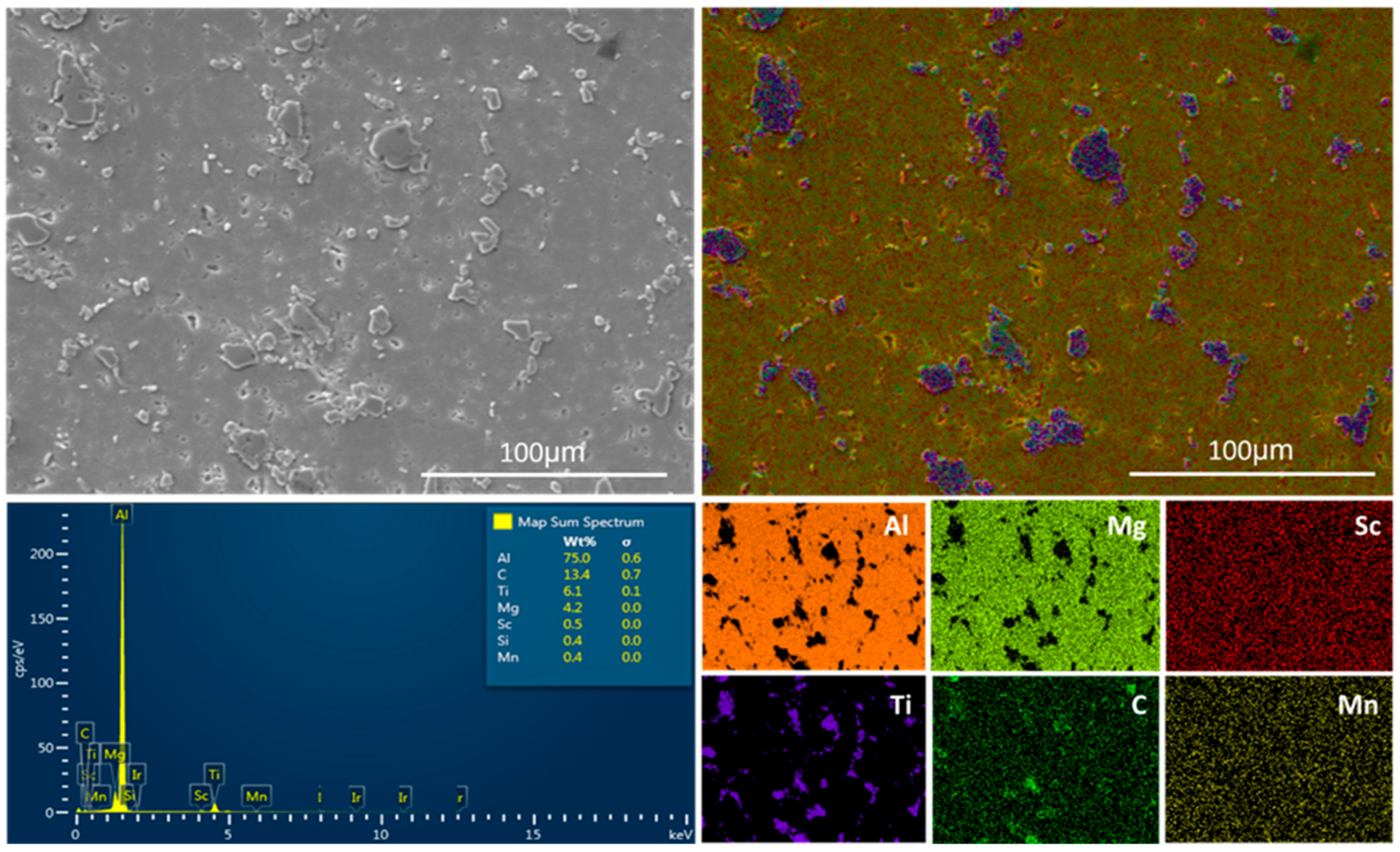

2.2. Microstructure Characterization and Phase Analysis

2.3. Density and Microhardness Tests

2.4. Transverse Rupture Strength (TRS) Test and Characterization

2.5. Tribological Behaviors and Characterization

3. Results and Discussion

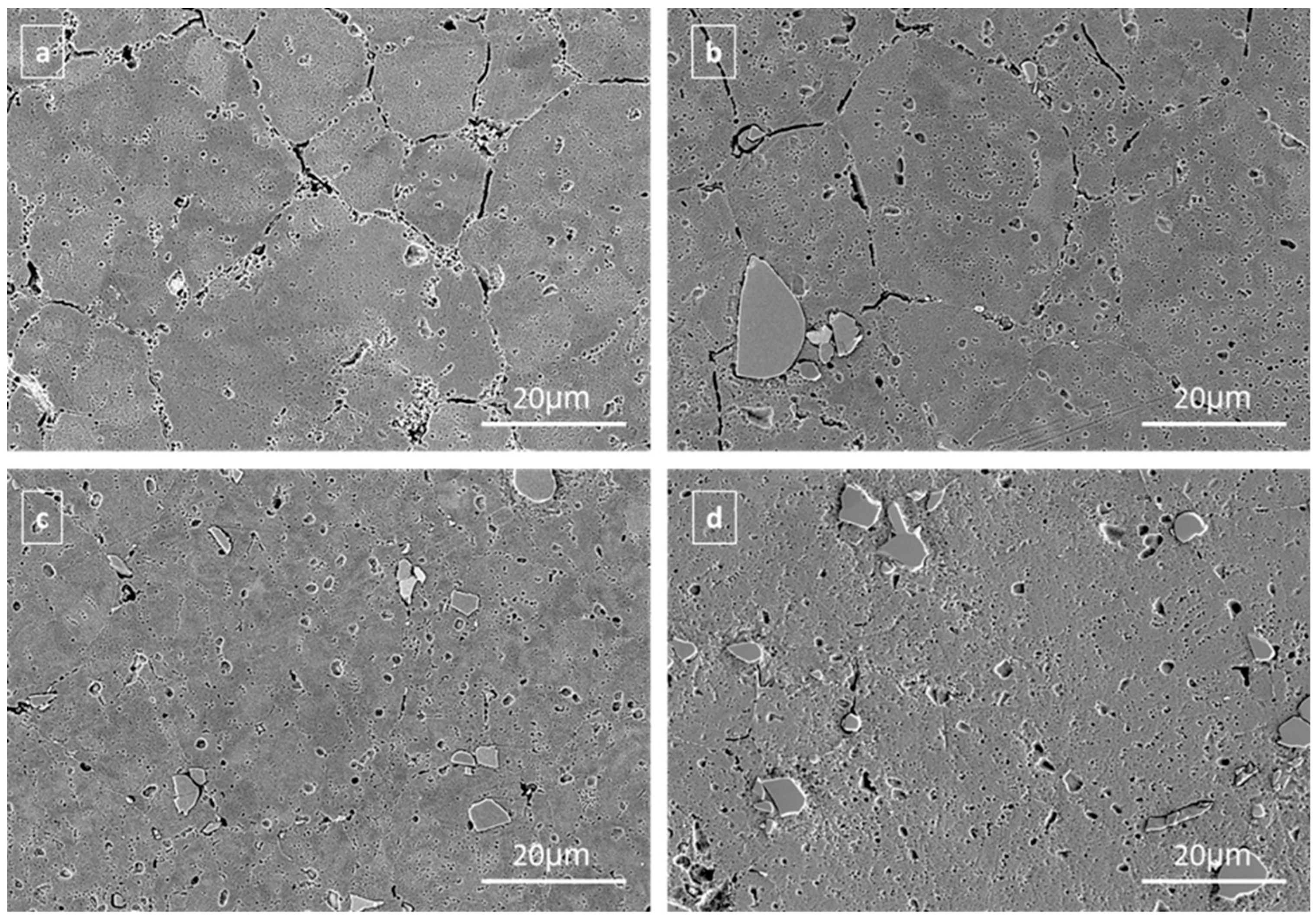

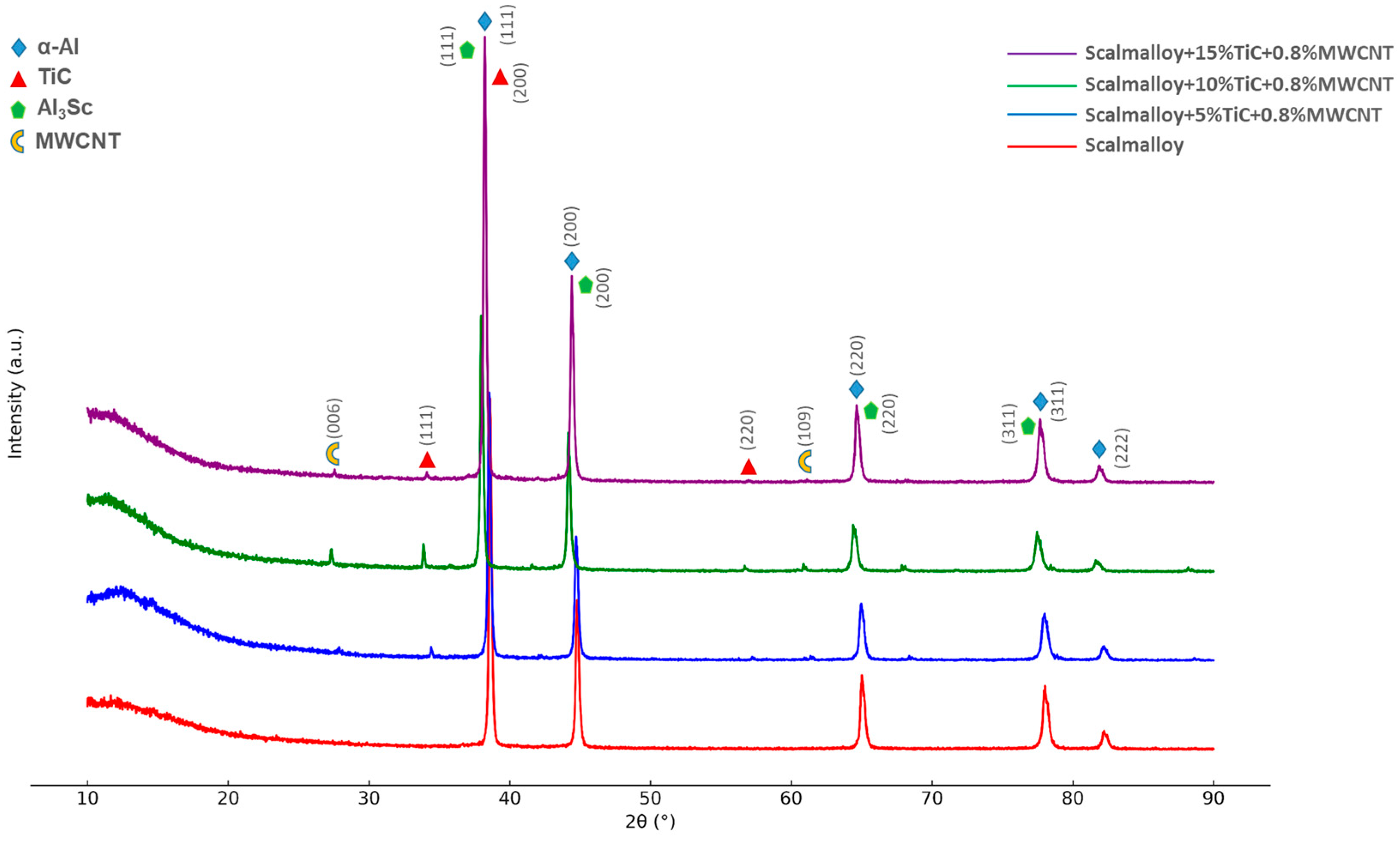

3.1. Microstructure Characterization

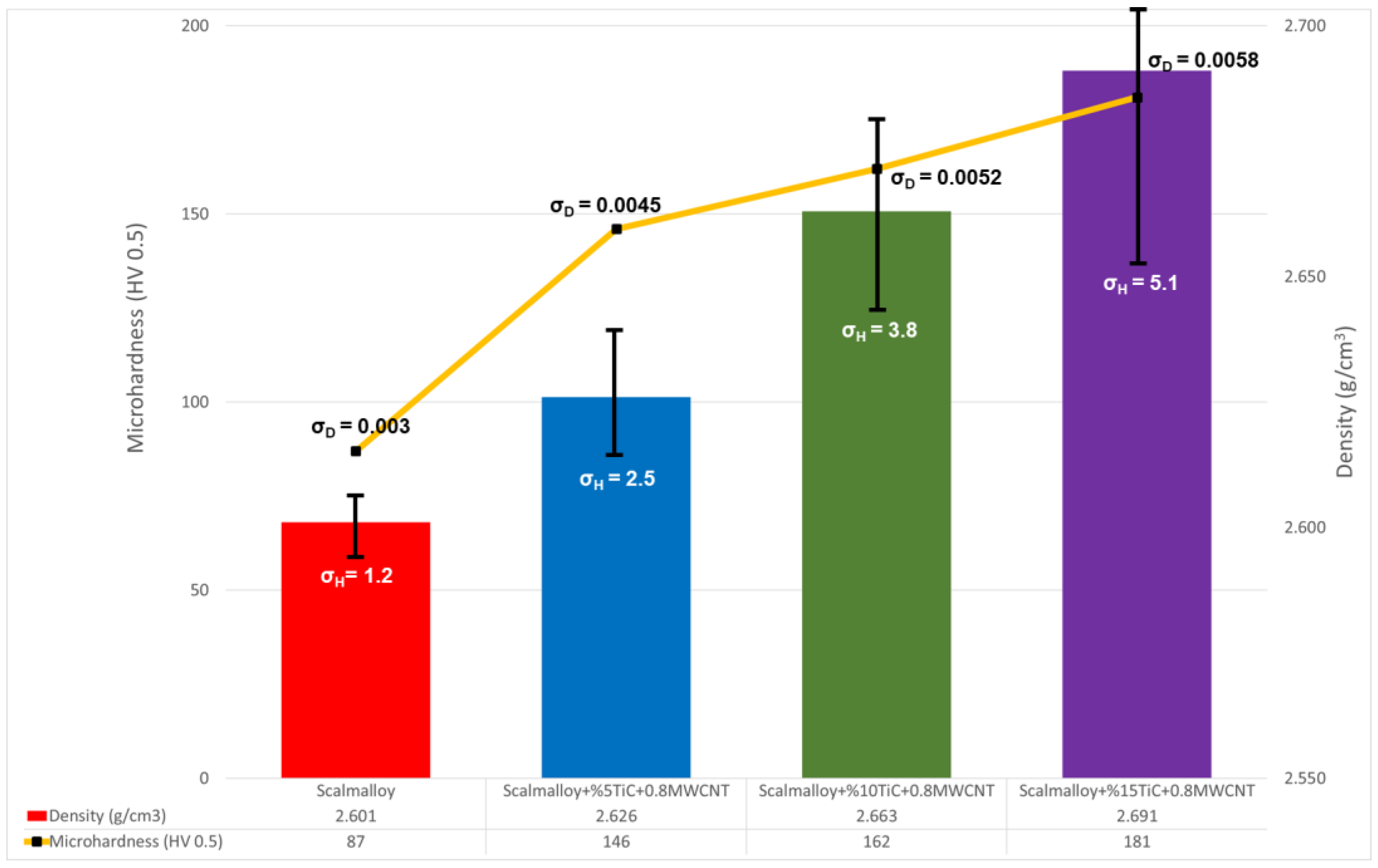

3.2. Density and Hardness Tests

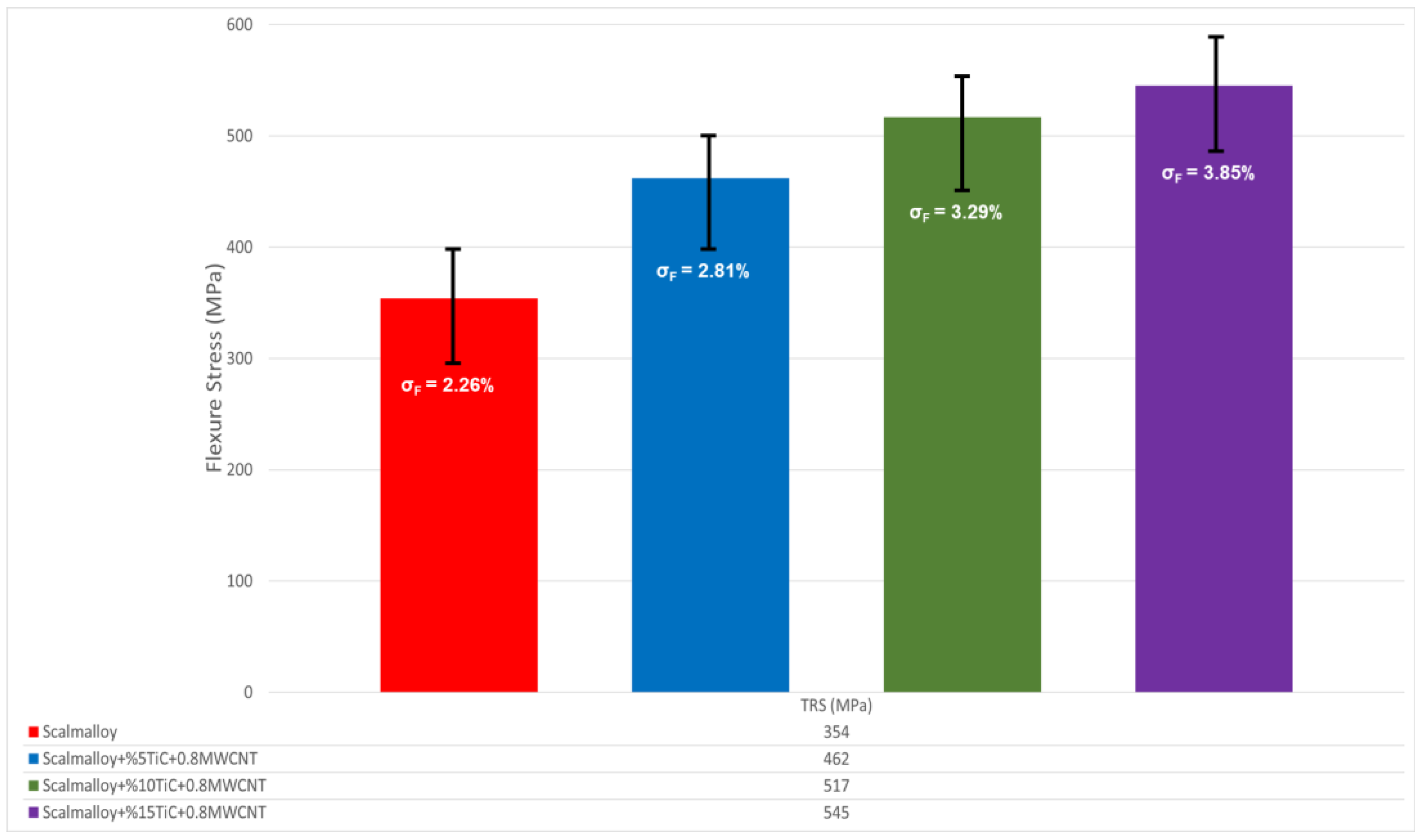

3.3. TRS Testing and Fractured Surface Analysis

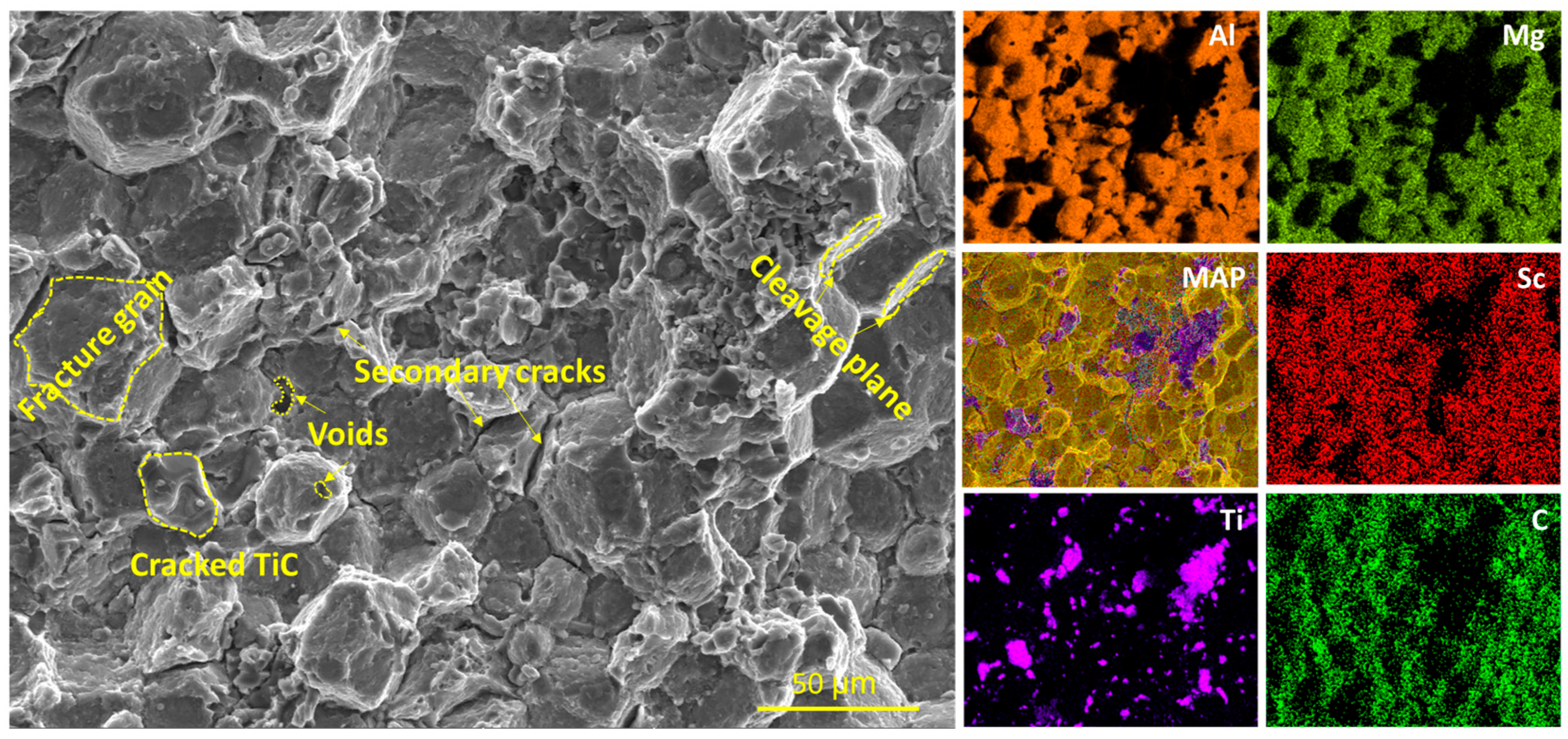

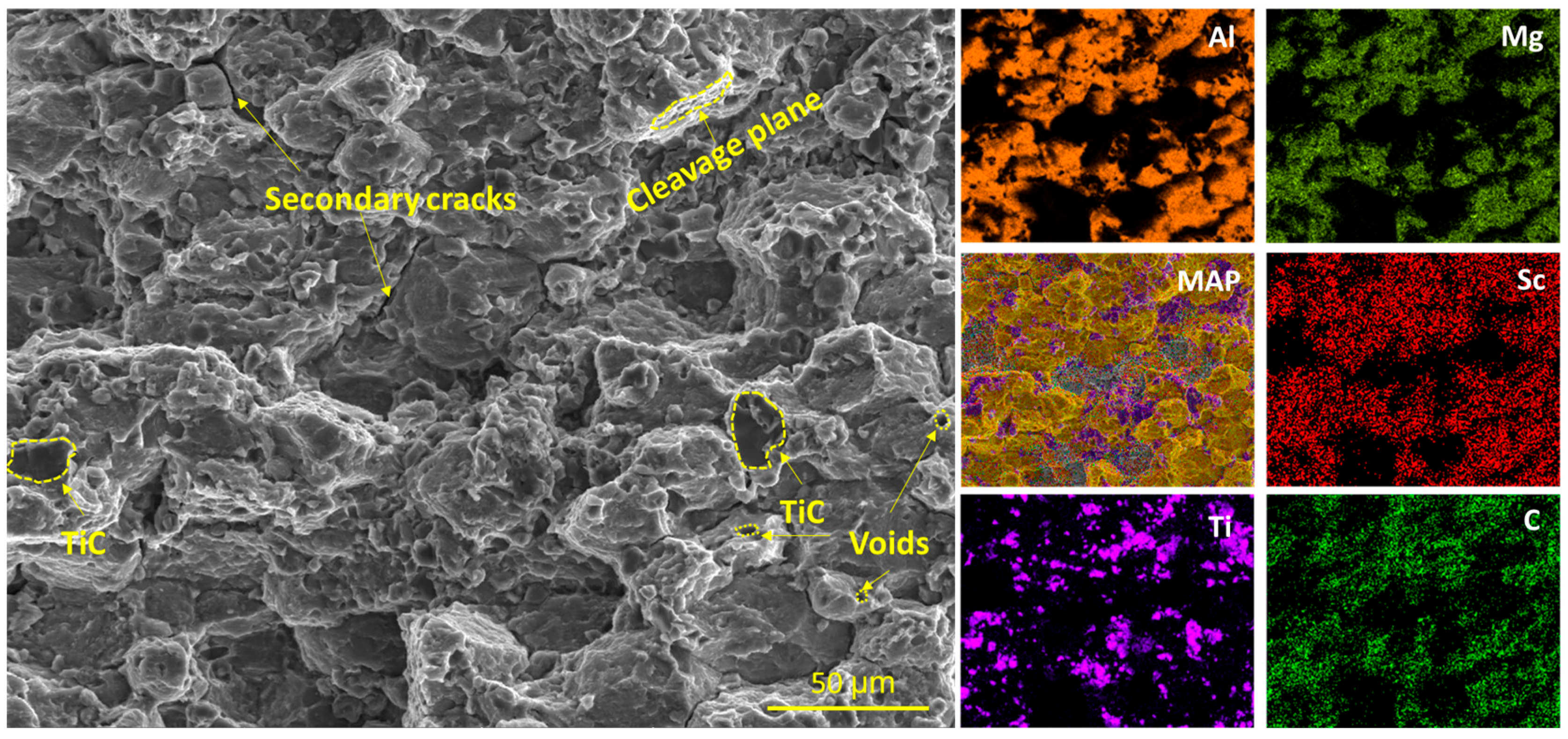

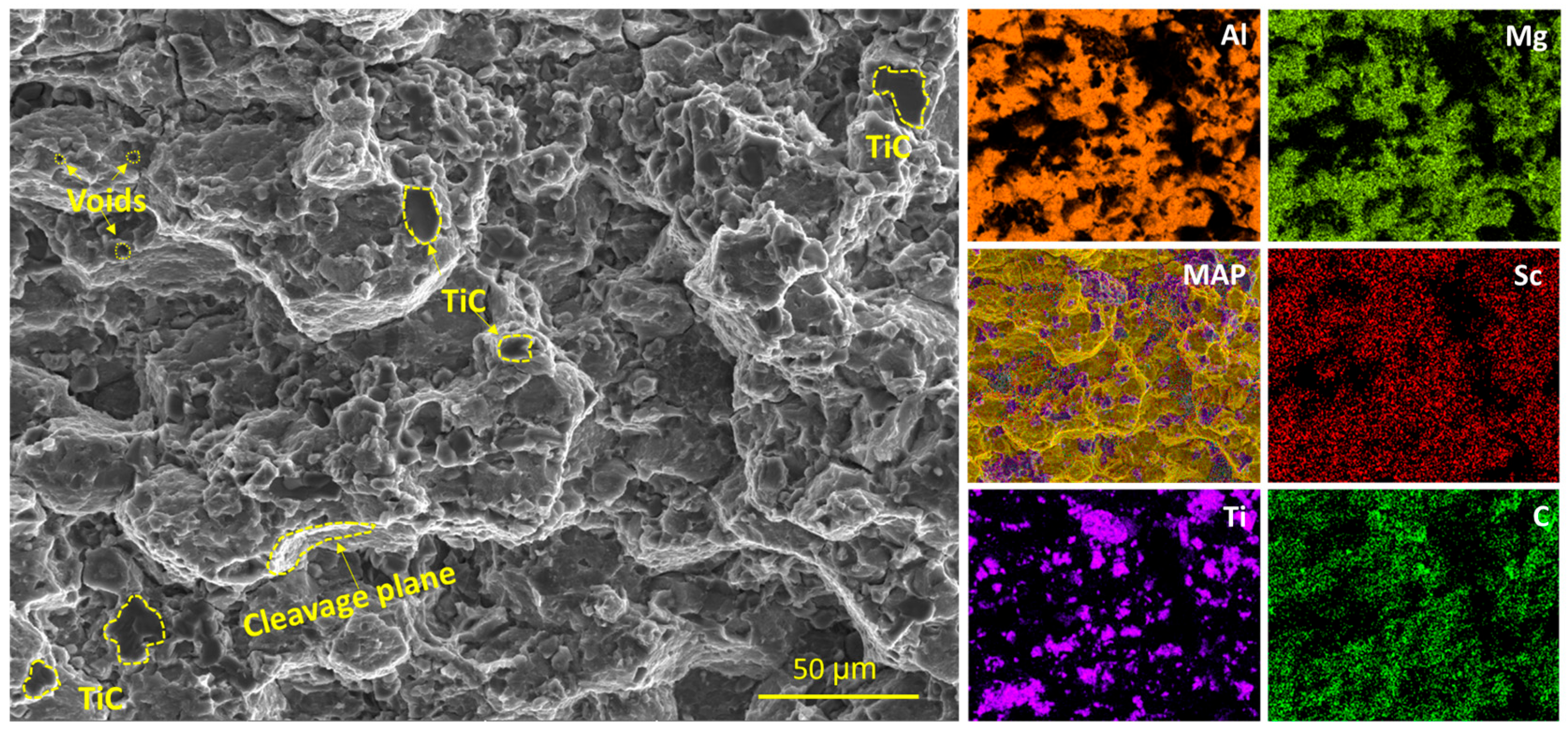

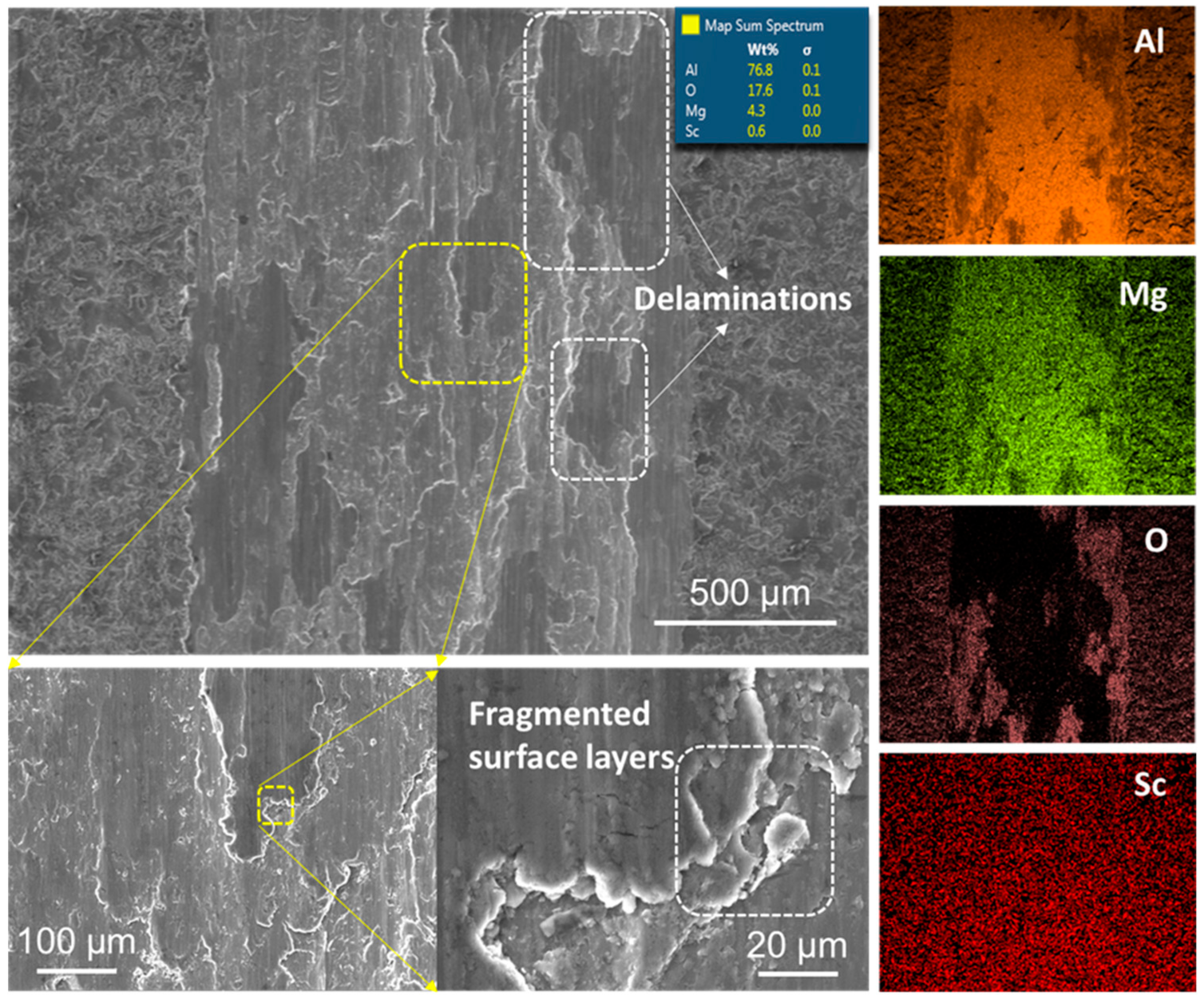

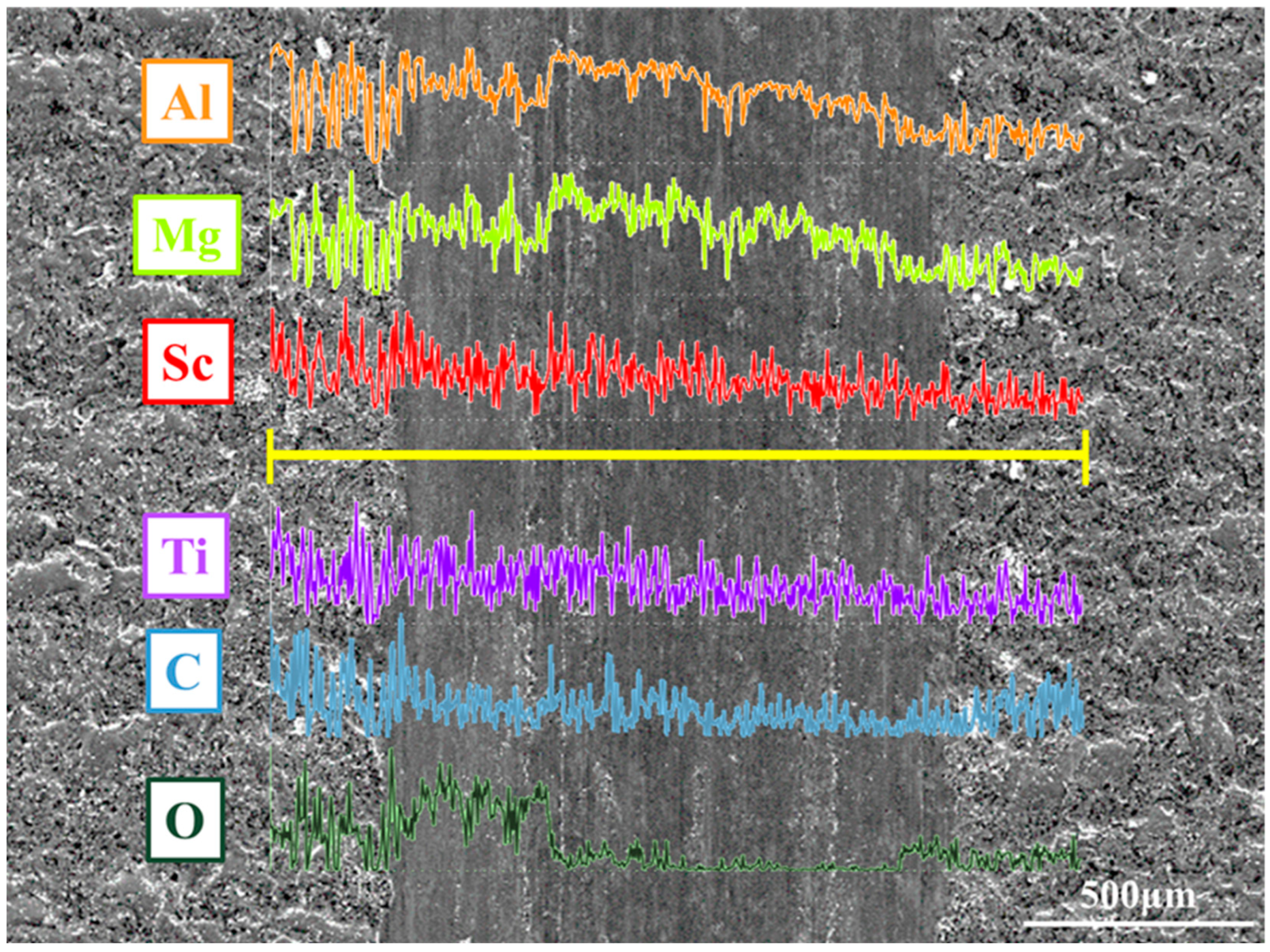

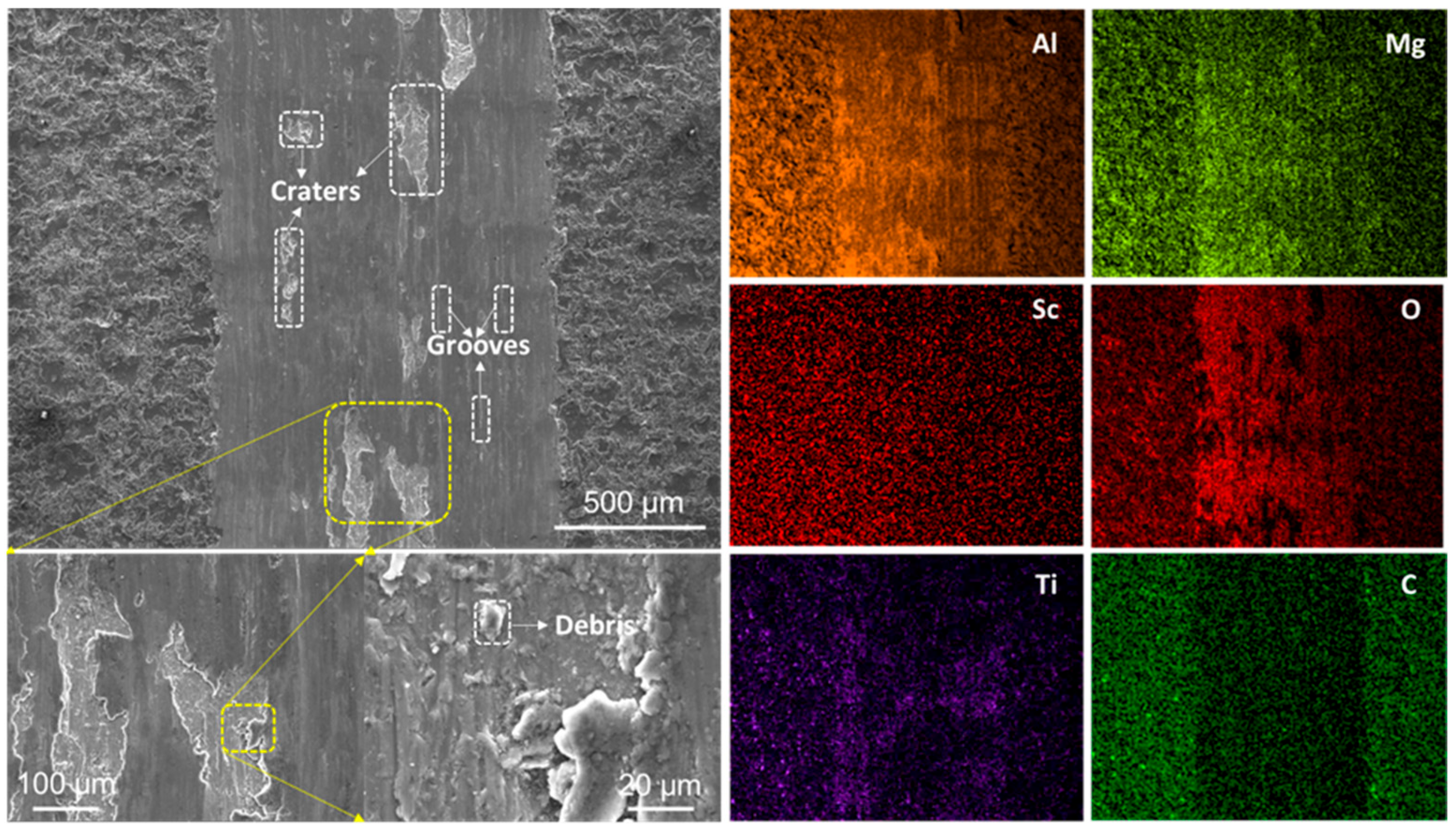

3.4. Wear Testing and Worn Surface Examination

4. Conclusions

- –

- Microstructural characterizations showed that the reinforcement phases were homogeneously distributed in the produced composites; TiC particles were concentrated especially at grain boundaries, and MWCNTs increased the integrity of the structure by forming network-like structures. As a result of the hot-pressing process, a more isotropic and equiaxed grain morphology was obtained, unlike the oriented and columnar grain structures frequently encountered in additive manufacturing.

- –

- Vickers microhardness tests showed that the reinforcement phases caused an increase in hardness in the matrix by limiting the dislocation movement. The hardness value increased from 87 HV in the unreinforced sample to 181 HV in the 15% TiC reinforcement. In terms of density values, it was determined that the sample with the highest reinforcement showed a 3.46% increase compared to the unreinforced one.

- –

- According to the TRS test results, the flexural strength increased significantly with the increase in the reinforcement ratio; in the sample containing 15% TiC + 0.8% MWCNT, the TRS value increased by approximately 54% compared to the unreinforced Scalmalloy® sample and reached 545 MPa.

- –

- Tribological analyses revealed that adhesive wear behavior dominated the unreinforced sample, while the abrasive wear mechanism became dominant in the hybrid reinforced samples. In the 15% TiC-reinforced sample, narrower wear scars and lower friction coefficients were observed; this development was associated with increased hardness and interface integrity.

- –

- Hybrid Scalmalloy® composites produced by hot pressing provide high hardness, increased TRS values, and improved wear resistance, making significant contributions to the production of high-performance structural materials by methods other than additive manufacturing.

Funding

Data Availability Statement

Conflicts of Interest

References

- Ravi, L.; Vanaraj, P.W.; Subathra, B.S.; Perumal, S.; Kumar, S.; Kirana, R. Enhancing Mechanical, and Tribological Properties of Aluminum Metal Matrix Composite Reinforced with High Entropy Alloy Using Friction Stir Processing. Mater. Chem. Phys. 2025, 338, 130614. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K.; Sayed, A.; Gawad, A.A.; Borah, P. Fabrication and Properties of Dispersed Carbon Nanotube–Aluminum Composites. Mater. Sci. Eng. A 2009, 508, 167–173. [Google Scholar] [CrossRef]

- Pole, M.; Mukhopadhyay, S.; Kastamo, S.; Loukus, A.; Choi, J.P.; Olszta, M.; Herling, D.R.; Grant, G.J.; Devaraj, A.; Efe, M. Tribological Behavior of Hybrid Aluminum-TiB2 Metal Matrix Composites for Brake Rotor Applications. Wear 2025, 562–563, 205639. [Google Scholar] [CrossRef]

- Cerri, E.; Curti, L.; Ghio, E. Main Heat Treatments Currently Applied on Laser Powder Bed-Fused Scalmalloy®: A Review. Crystals 2025, 15, 25. [Google Scholar] [CrossRef]

- Røyset, J.; Ryum, N. Scandium in Aluminium Alloys. Int. Mater. Rev. 2005, 50, 19–44. [Google Scholar] [CrossRef]

- Norman, A.F.; Prangnell, P.B.; McEwen, R.S. The Solidification Behaviour of Dilute Aluminium–Scandium Alloys. Acta Mater. 1998, 46, 5715–5732. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Nagy, S.; Hájovská, Z.; Nosko, M.; Ploshikhin, V. Understanding Precipitation during In-Situ and Post-Heat Treatments of Al-Mg-Sc-Zr Alloys Processed by Powder-Bed Fusion. Addit. Manuf. 2024, 90, 104315. [Google Scholar] [CrossRef]

- Kürnsteiner, P.; Bajaj, P.; Gupta, A.; Benjamin, W.; Weisheit, A.; Li, X.; Leinenbach, C.; Gault, B.; Jägle, E.A.; Raabe, D. Control of Thermally Stable Core-Shell Nano-Precipitates in Additively Manufactured Al-Sc-Zr Alloys. Addit. Manuf. 2020, 32, 100910. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.-H.; Kumar, M.S. Influence of Coherent Intermetallic Nano-Precipitates on the Nano-Level Mechanical and Tribological Properties of the Laser-Powder Bed Fused Scalmalloy. Mater. Charact. 2022, 193, 112269. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural Features of Sc- and Zr-Modified Al-Mg Alloys Processed by Selective Laser Melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Awd, M.; Tenkamp, J.; Hirtler, M.; Siddique, S.; Bambach, M.; Walther, F. Comparison of Microstructure and Mechanical Properties of Scalmalloy® Produced by Selective Laser Melting and Laser Metal Deposition. Materials 2018, 11, 17. [Google Scholar] [CrossRef] [PubMed]

- Cabrera-Correa, L.; González-Rovira, L.; de Dios López-Castro, J.; Botana, F.J. Pitting and Intergranular Corrosion of Scalmalloy® Aluminium Alloy Additively Manufactured by Selective Laser Melting (SLM). Corros. Sci. 2022, 201, 110273. [Google Scholar] [CrossRef]

- Boillat-Newport, R.; Isanaka, S.P.; Liou, F. Impact of Delayed Artificial Aging on Tensile Properties and Microstructural Evolution of Directed Energy Deposited Scalmalloy®. Appl. Sci. 2025, 15, 3674. [Google Scholar] [CrossRef]

- Boillat-Newport, R.; Isanaka, S.P.; Liou, F. Heat Treatment Post-Processing for the Improved Mechanical Properties of Scalmalloy® Processed via Directed Energy Deposition. Crystals 2024, 14, 688. [Google Scholar] [CrossRef]

- Cortis, D.; Campana, F.; Orlandi, D.; Sansone, S. Strength and Fatigue Behavior Assessment of the SCALMALLOY® Material to Functionally Adapt the Performance of L-PBF Components within CAE Simulations. Prog. Addit. Manuf. 2023, 8, 933–946. [Google Scholar] [CrossRef]

- van der Rest, C.; De Raedemacker, S.; Avettand-Fènoël, M.-N.; Pyka, G.; Cocle, R.; Simar, A. Improving the Fatigue Life of Laser Powder Bed Fusion Scalmalloy® by Friction Stir Processing. Mater. Des. 2024, 244, 113193. [Google Scholar] [CrossRef]

- Deillon, L.; Jensch, F.; Palm, F.; Bambach, M. A New High Strength Al–Mg–Sc Alloy for Laser Powder Bed Fusion with Calcium Addition to Effectively Prevent Magnesium Evaporation. J. Mater. Process. Technol. 2022, 300, 117416. [Google Scholar] [CrossRef]

- Schimbäck, D.; Mair, P.; Kaserer, L.; Perfler, L.; Palm, F.; Leichtfried, G.; Pogatscher, S. An Improved Process Scan Strategy to Obtain High-Performance Fatigue Properties for Scalmalloy®. Mater. Des. 2022, 224, 111410. [Google Scholar] [CrossRef]

- Isaac, J.P.; Lee, S.; Shamsaei, N.; Tippur, H.V. Dynamic Fracture Behavior of Additively Manufactured Scalmalloy®: Effects of Build Orientation, Heat-Treatment and Loading-Rate. Mater. Sci. Eng. A 2021, 826, 141978. [Google Scholar] [CrossRef]

- Best, J.P.; Maeder, X.; Michler, J.; Spierings, A.B. Mechanical Anisotropy Investigated in the Complex SLM-Processed Sc- and Zr-Modified Al–Mg Alloy Microstructure. Adv. Eng. Mater. 2019, 21, 1801113. [Google Scholar] [CrossRef]

- Maurya, M.; Kumar, S.; Bajpai, V. Assessment of the Mechanical Properties of Aluminium Metal Matrix Composite: A Review. J. Reinf. Plast. Compos. 2018, 38, 267–298. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, R.; Hashmi, M.S.J. Metal Matrix Composite: A Methodological Review. Adv. Mater. Process. Technol. 2020, 6, 13–24. [Google Scholar] [CrossRef]

- Nair, S.V.; Tien, J.K.; Bates, R.C. SiC-Reinforced Aluminium Metal Matrix Composites. Int. Met. Rev. 1985, 30, 275–290. [Google Scholar] [CrossRef]

- Zhao, Z.; Bai, P.; Du, W.; Liu, B.; Pan, D.; Das, R.; Liu, C.; Guo, Z. An Overview of Graphene and Its Derivatives Reinforced Metal Matrix Composites: Preparation, Properties and Applications. Carbon 2020, 170, 302–326. [Google Scholar] [CrossRef]

- Samer, N.; Andrieux, J.; Gardiola, B.; Karnatak, N.; Martin, O.; Kurita, H.; Chaffron, L.; Gourdet, S.; Lay, S.; Dezellus, O. Microstructure and Mechanical Properties of an Al–TiC Metal Matrix Composite Obtained by Reactive Synthesis. Compos. Part A Appl. Sci. Manuf. 2015, 72, 50–57. [Google Scholar] [CrossRef]

- Rao, V.R.; Ramanaiah, N.; Sarcar, M.M.M. Mechanical and Tribological Properties of AA7075–TiC Metal Matrix Composites under Heat Treated (T6) and Cast Conditions. J. Mater. Res. Technol. 2016, 5, 377–383. [Google Scholar]

- Ghahremani, A.; Abdullah, A.; Fallahi Arezoodar, A. Wear Behavior of Metal Matrix Nanocomposites. Ceram. Int. 2022, 48, 35947–35965. [Google Scholar] [CrossRef]

- Kumar, L.; Nasimul Alam, S.; Kumar Sahoo, S. Influence of Nanostructured Al on the Mechanical Properties and Sliding Wear Behavior of Al-MWCNT Composites. Mater. Sci. Eng. B 2021, 269, 115162. [Google Scholar] [CrossRef]

- Zhou, M.Y.; Ren, L.B.; Fan, L.L.; Zhang, Y.W.X.; Lu, T.H.; Quan, G.F.; Gupta, M. Progress in Research on Hybrid Metal Matrix Composites. J. Alloys Compd. 2020, 838, 155274. [Google Scholar] [CrossRef]

- Ravindran, S.; Mani, N.; Balaji, S.; Abhijith, M.; Surendaran, K. Mechanical Behaviour of Aluminium Hybrid Metal Matrix Composites—A Review. Mater. Today Proc. 2019, 16, 1020–1033. [Google Scholar] [CrossRef]

- Muley, A.V.; Aravindan, S.; Singh, I.P. Nano and Hybrid Aluminum Based Metal Matrix Composites: An Overview. Manuf. Rev. 2015, 2, 15. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R. Dry Sliding Wear Performances of AA5052 Hybrid Composite Brake Disc Materials Reinforced With In Situ Synthesized TiC and Multi-Walled Carbon Nanotube. J. Tribol. 2023, 145, 101705. [Google Scholar] [CrossRef]

- Aborkin, A.; Khorkov, K.; Prusov, E.; Ob’edkov, A.; Kremlev, K.; Perezhogin, I.; Alymov, M. Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials 2019, 9, 1596. [Google Scholar] [CrossRef]

- Wei, S.; Tang, J.J.; Jha, A.; Lau, K.B.; Wuu, D.; Soh, V.; Zhu, Q.; Tan, C.C.; Wang, P.; Chi, D. Individual and Collective Effects of Titanium Carbides and Multi-Walled Carbon Nanotubes on Reinforcing the Inconel 625 Alloy Fabricated by Laser Powder Bed Fusion. Mater. Charact. 2024, 207, 113555. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Babin, D.M.; Zalesnov, A.I.; Ob’’edkov, A.M.; Kremlev, K.V.; Alymov, M.I. Changes in the Mechanical Properties of Powder Aluminum Matrix Composites Modified by Microadditives of Hybrid Materials Based on Multiwall Carbon Nanotubes Decorated with Titanium Carbide Nanoparticles. Dokl. Phys. Chem. 2019, 488, 113–116. [Google Scholar] [CrossRef]

- ASTM B311-17; Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E92-16; Standard Test Methods Vickers Hardness Knoop Hardness Met. ASTM International: West Conshohocken, PA, USA, 2017.

- Backensto, A.B. Powder Metallurgy Standards from the Metal Powder Producers Association of the Metal Powder Industries Federation. In Advances in Powder Metallurgy: Properties, Processing and Applications; Woodhead Publishing: Sawston, UK, 1992. [Google Scholar]

- ASTM B528-16; Standard Test Method for Transverse Rupture Strength of Metal Powder Specimens. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM G133-05; Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM International: West Conshohocken, PA, USA, 2016.

- Wang, Z.; Lin, X.; Kang, N.; Chen, J.; Tan, H.; Feng, Z.; Qin, Z.; Yang, H.; Huang, W. Laser Powder Bed Fusion of High-Strength Sc/Zr-Modified Al–Mg Alloy: Phase Selection, Microstructural/Mechanical Heterogeneity, and Tensile Deformation Behavior. J. Mater. Sci. Technol. 2021, 95, 40–56. [Google Scholar] [CrossRef]

- Chandrakanth, R.G.; Rajkumar, K.; Aravindan, S. Fabrication of Copper–TiC–Graphite Hybrid Metal Matrix Composites through Microwave Processing. Int. J. Adv. Manuf. Technol. 2010, 48, 645–653. [Google Scholar] [CrossRef]

- Nyanor, P.; El-Kady, O.; Yehia, H.M.; Hamada, A.S.; Hassan, M.A. Effect of Bimodal-Sized Hybrid TiC–CNT Reinforcement on the Mechanical Properties and Coefficient of Thermal Expansion of Aluminium Matrix Composites. Met. Mater. Int. 2021, 27, 753–766. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, K.; Dong, Y.; Hua, A.; Su, Y.; Ouyang, Q.; Zhang, D. Enhanced Intragranular Precipitation Strengthening in Sc-Microalloyed Ultrafine-Grained SiCp/Al-Cu-Mg Composites via Retrogression and Re-Ageing Heat Treatment. Mater. Des. 2025, 252, 113789. [Google Scholar] [CrossRef]

- Novotny, G.M.; Ardell, A.J. Precipitation of Al3Sc in Binary Al-Sc Alloys. Mater. Sci. Eng. A 2001, 318, 144–154. [Google Scholar] [CrossRef]

- Kuo, C.N.; Peng, P.C.; Liu, D.H.; Chao, C.Y. Microstructure Evolution and Mechanical Property Response of 3D-Printed Scalmalloy with Different Heat-Treatment Times at 325 °C. Metals 2021, 11, 555. [Google Scholar] [CrossRef]

- Dorbani, T.; Bouleklab, M.C.; Settar, A.; Chetehouna, K.; Naoui, Y.; Revo, S.; Hamamda, S. Synthesis and Characterization of Al+0.25%MWCNTs Nanocomposite with Reduced Thermal Expansion Coefficient. J. Mater. Res. Technol. 2022, 19, 1484–1492. [Google Scholar] [CrossRef]

- Sharma, M.; Sharma, V. Investigation of Thermal Expansion and Physical Properties of Carbon Nanotube Reinforced Nanocrystalline Aluminum Nanocomposite. Z. Naturforschung A 2016, 71, 165–174. [Google Scholar] [CrossRef]

- Nayim, S.M.T.I.; Hasan, M.Z.; Seth, P.P.; Gupta, P.; Thakur, S.; Kumar, D.; Jamwal, A. Effect of CNT and TiC Hybrid Reinforcement on the Micro-Mechano-Tribo Behaviour of Aluminium Matrix Composites. Mater. Today Proc. 2020, 21, 1421–1424. [Google Scholar] [CrossRef]

- Guo, R.F.; Wang, Y.; Shen, P.; Shaga, A.; Ma, Y.H.; Jiang, Q.C. Influence of Matrix Property and Interfacial Reaction on the Mechanical Performance and Fracture Mechanism of TiC Reinforced Al Matrix Lamellar Composites. Mater. Sci. Eng. A 2020, 775, 138956. [Google Scholar] [CrossRef]

- Pradeep Kumar, G.S.; Koppad, P.G.; Keshavamurthy, R.; Alipour, M. Microstructure and Mechanical Behaviour of in Situ Fabricated AA6061–TiC Metal Matrix Composites. Arch. Civ. Mech. Eng. 2017, 17, 535–544. [Google Scholar] [CrossRef]

- Wronski, A.S.; Cias, A. The Determination of Fracture Strength from Ultimate Tensile and Transverse Rupture Stresses. Powder Metall. Prog. 2003, 3, 119–127. [Google Scholar]

- McGarry, D. Mechanisms and Appearances of Ductile and Brittle Fracture in Metals. In Failure Analysis and Prevention; ASM International: Almere, The Netherlands, 2021. [Google Scholar]

- Zhao, L.; Zheng, W.; Hu, Y.; Guo, Q.; Zhang, D. Heterostructured Metal Matrix Composites for Structural Applications: A Review. J. Mater. Sci. 2024, 59, 9768–9801. [Google Scholar] [CrossRef]

- Xiong, H.; Gu, L.; Wang, J.; Zhou, L.; Ying, T.; Wang, S.; Zhou, H.; Li, J.; Gao, Y.; Zeng, X. The Interface Structure and Property of Magnesium Matrix Composites: A Review. J. Magnes. Alloys 2024, 12, 2595–2623. [Google Scholar] [CrossRef]

- Mantha, S.R.V.; Veeresh Kumar, G.B.; Pramod, R.; Rao, C.S.P. Studies of SiC-Filled Al6061 Metal Matrix Composite Optical, Mechanical, Tribological, and Corrosion Behavior with Strengthening Mechanisms. Adv. Eng. Mater. 2024, 26, 2401997. [Google Scholar] [CrossRef]

- Samal, P.; Raj, H.; Meher, A.; Surekha, B.; Vundavilli, P.R.; Sharma, P. Synergistic Effect of B4C and Multi-Walled CNT on Enhancing the Tribological Performance of Aluminum A383 Hybrid Composites. Lubricants 2024, 12, 213. [Google Scholar] [CrossRef]

- Abdeltawab, N.M.; Esawi, A.M.K.; Wifi, A. Investigation of the Wear Behavior of Dual-Matrix Aluminum–(Aluminum–Carbon Nanotube) Composites. Metals 2023, 13, 1167. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Influence of TiC on Dry Sliding Wear and Mechanical Properties of in Situ Synthesized AA5052 Metal Matrix Composites. J. Compos. Mater. 2019, 53, 4323–4336. [Google Scholar] [CrossRef]

- Kumar Patel, S.; Nateriya, R.; Kuriachen, B.; Pratap Singh, V. Slurry Abrasive Wear, Microstructural and Morphological Analysis of Titanium Carbide and Zirconium Sand Aluminium Alloy (A5052) Metal Matrix Composite. Mater. Today Proc. 2018, 5, 19790–19798. [Google Scholar] [CrossRef]

- Golla, C.B.; Babar Pasha, M.; Rao, R.N.; Ismail, S.; Gupta, M. Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting. Crystals 2023, 13, 1360. [Google Scholar] [CrossRef]

| Element | Mg | Sc | Zr | Mn | Si | Fe | Zn | Ti | Cu | V |

|---|---|---|---|---|---|---|---|---|---|---|

| %wt. | 4–4.9 | 0.6–0.8 | 0.2–0.5 | 0.3–0.8 | 0–0.4 | 0–0.4 | 0–0.25 | 0–0.15 | 0–0.10 | 0–0.05 |

| Element | Al | C | Ti | Mg | Sc | Si | Mn |

|---|---|---|---|---|---|---|---|

| %wt. | 75.0 | 13.4 | 6.1 | 4.2 | 0.5 | 0.4 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yilmaz, T.A. Investigation of Microstructural, Mechanical, and Tribological Properties of TiC and MWCNT Reinforced Hot-Pressed Scalmalloy® Hybrid Composites. Lubricants 2025, 13, 276. https://doi.org/10.3390/lubricants13070276

Yilmaz TA. Investigation of Microstructural, Mechanical, and Tribological Properties of TiC and MWCNT Reinforced Hot-Pressed Scalmalloy® Hybrid Composites. Lubricants. 2025; 13(7):276. https://doi.org/10.3390/lubricants13070276

Chicago/Turabian StyleYilmaz, Taha Alper. 2025. "Investigation of Microstructural, Mechanical, and Tribological Properties of TiC and MWCNT Reinforced Hot-Pressed Scalmalloy® Hybrid Composites" Lubricants 13, no. 7: 276. https://doi.org/10.3390/lubricants13070276

APA StyleYilmaz, T. A. (2025). Investigation of Microstructural, Mechanical, and Tribological Properties of TiC and MWCNT Reinforced Hot-Pressed Scalmalloy® Hybrid Composites. Lubricants, 13(7), 276. https://doi.org/10.3390/lubricants13070276