Investigation on the Coupling Effect of Bionic Micro-Texture Shape and Distribution on the Tribological Performance of Water-Lubricated Sliding Bearings

Abstract

1. Introduction

2. Materials and Methods

2.1. Governing Equations

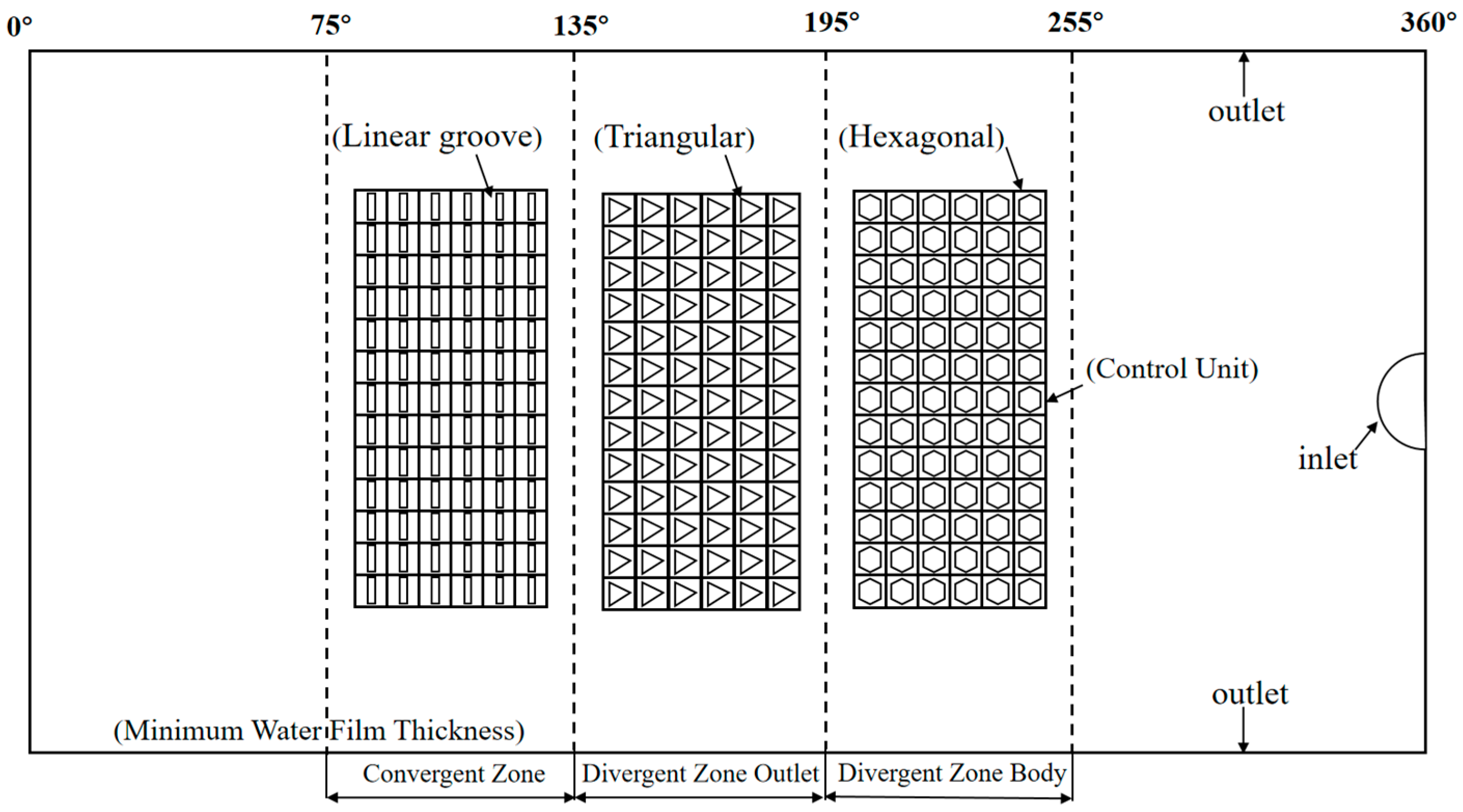

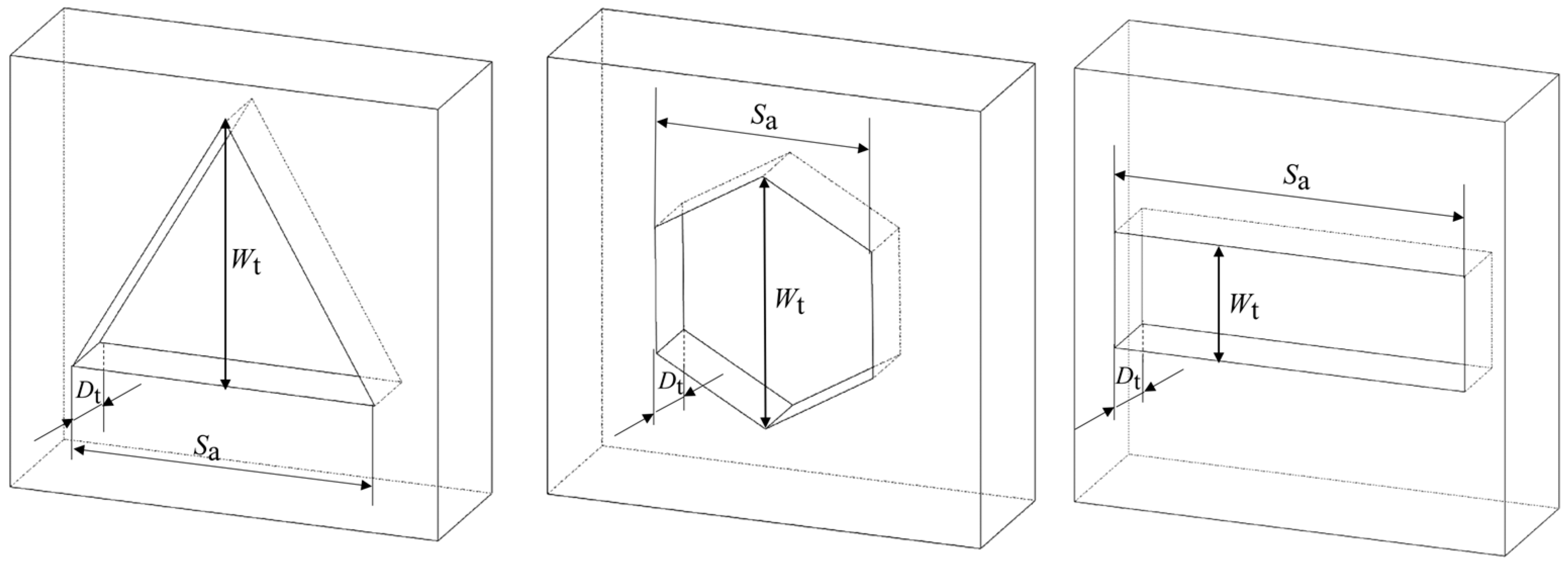

2.2. Three-Dimensional Geometric Model

2.3. Simulation Model

2.4. Boundary Conditions and Solver Settings

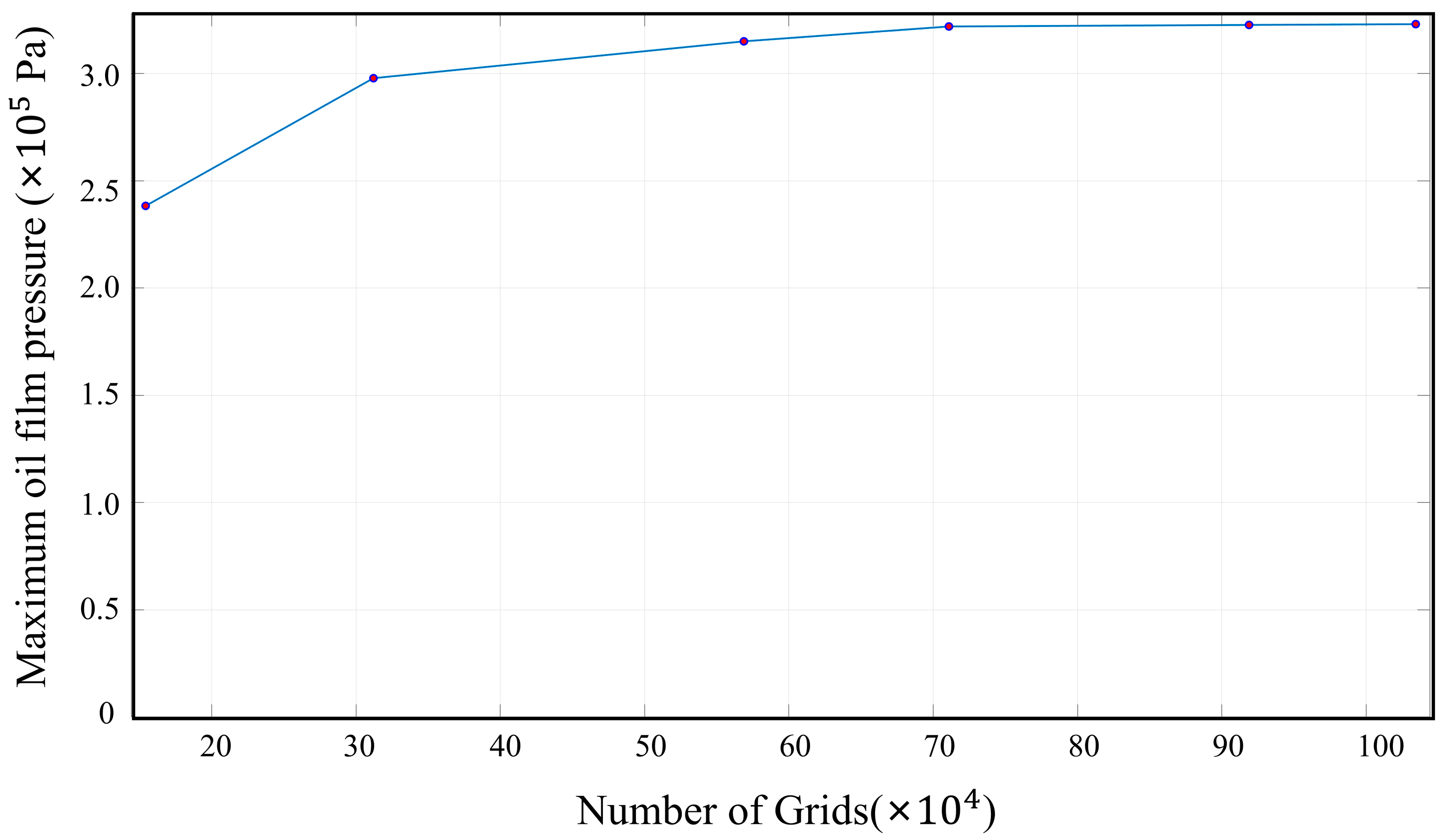

2.5. Mesh Convergence Analysis

3. Results and Analysis

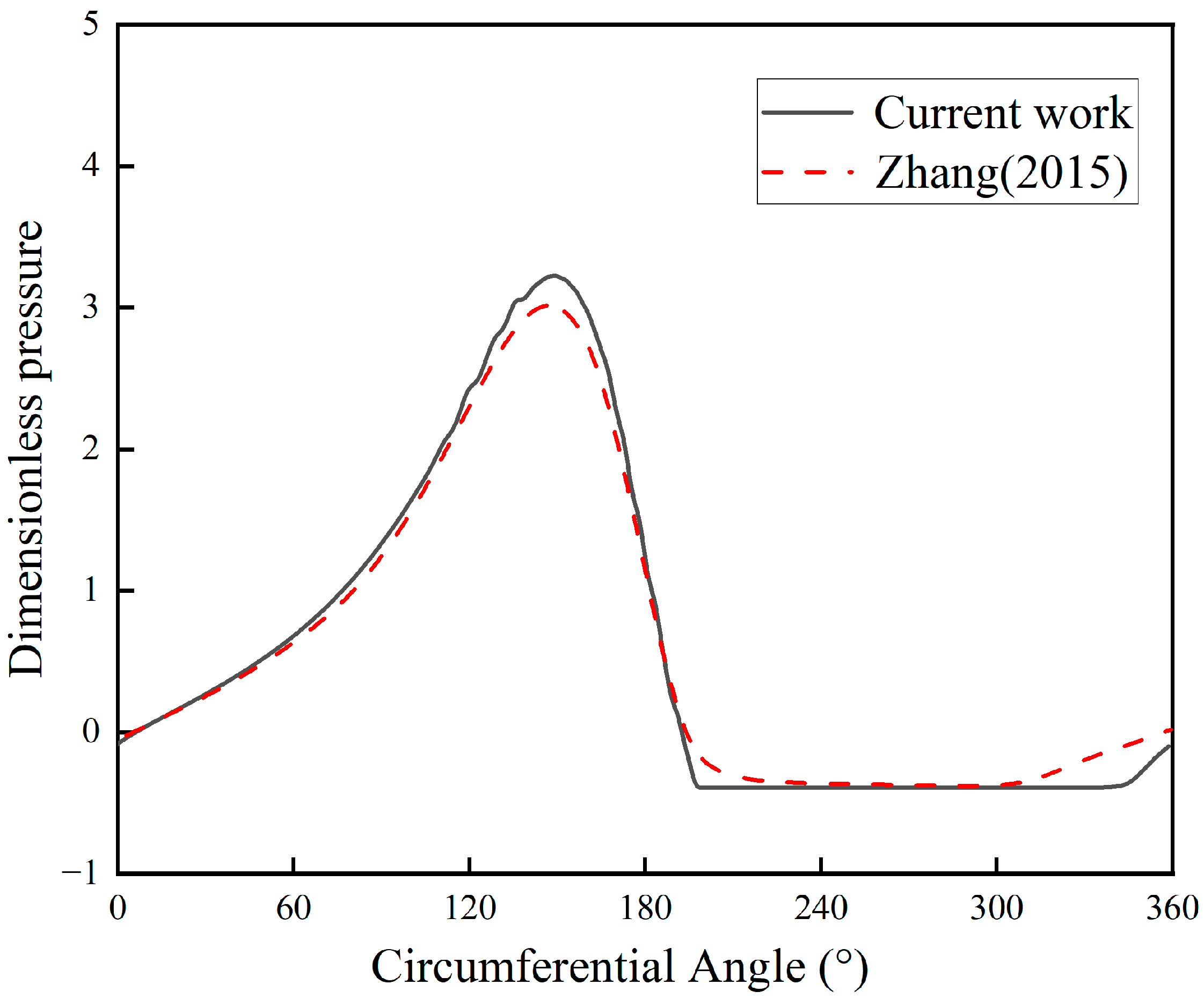

3.1. Validation of Model Rationality

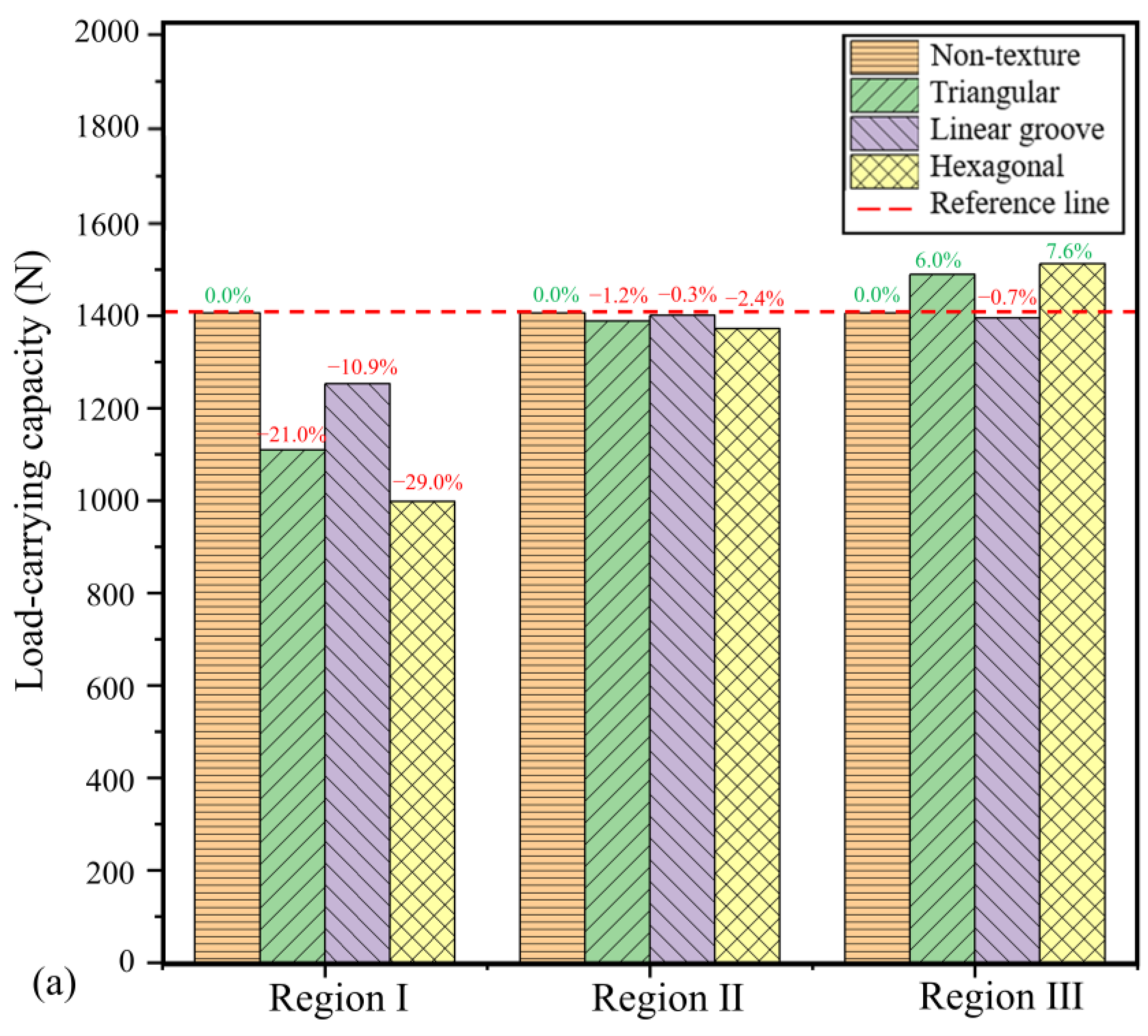

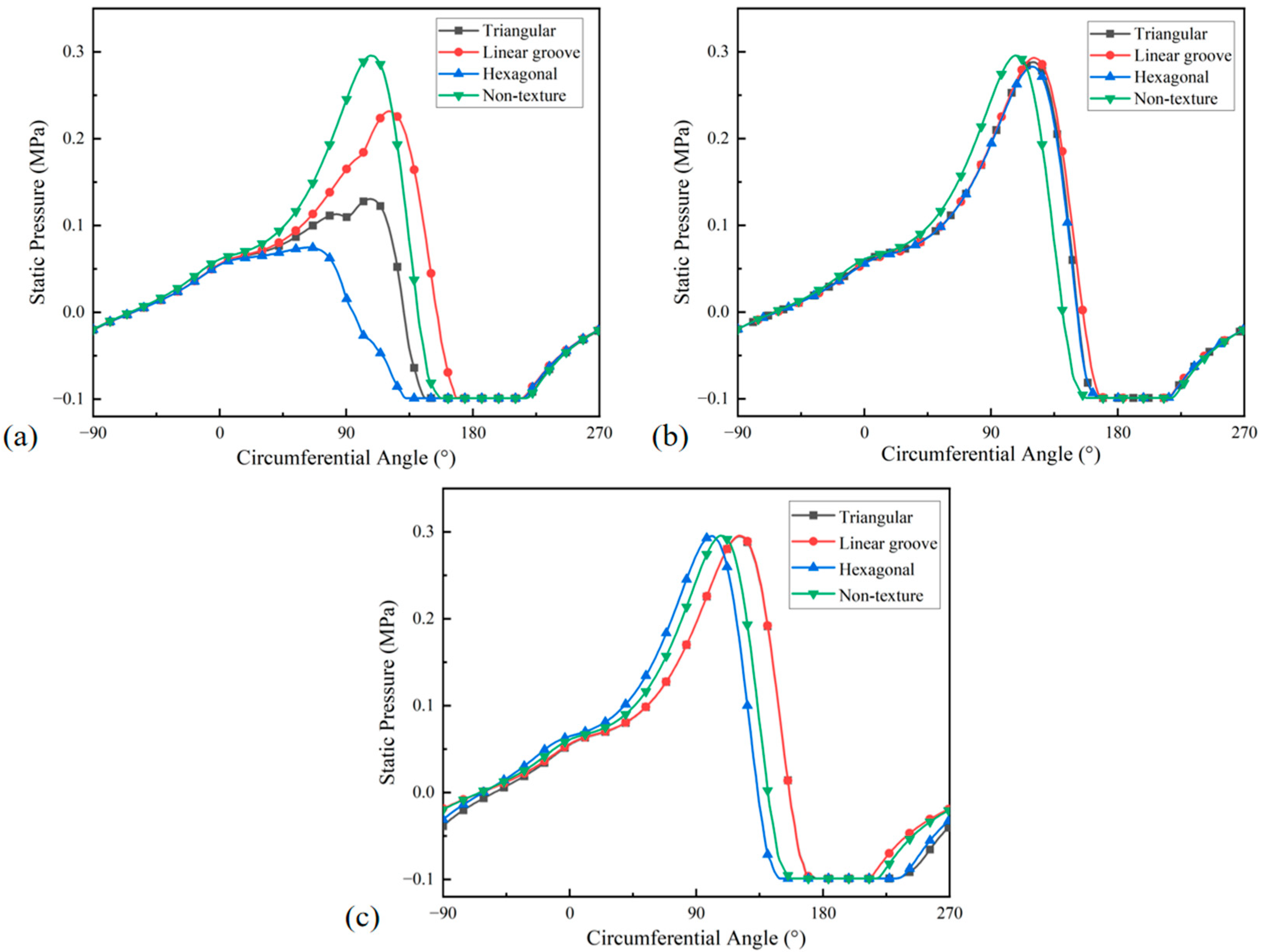

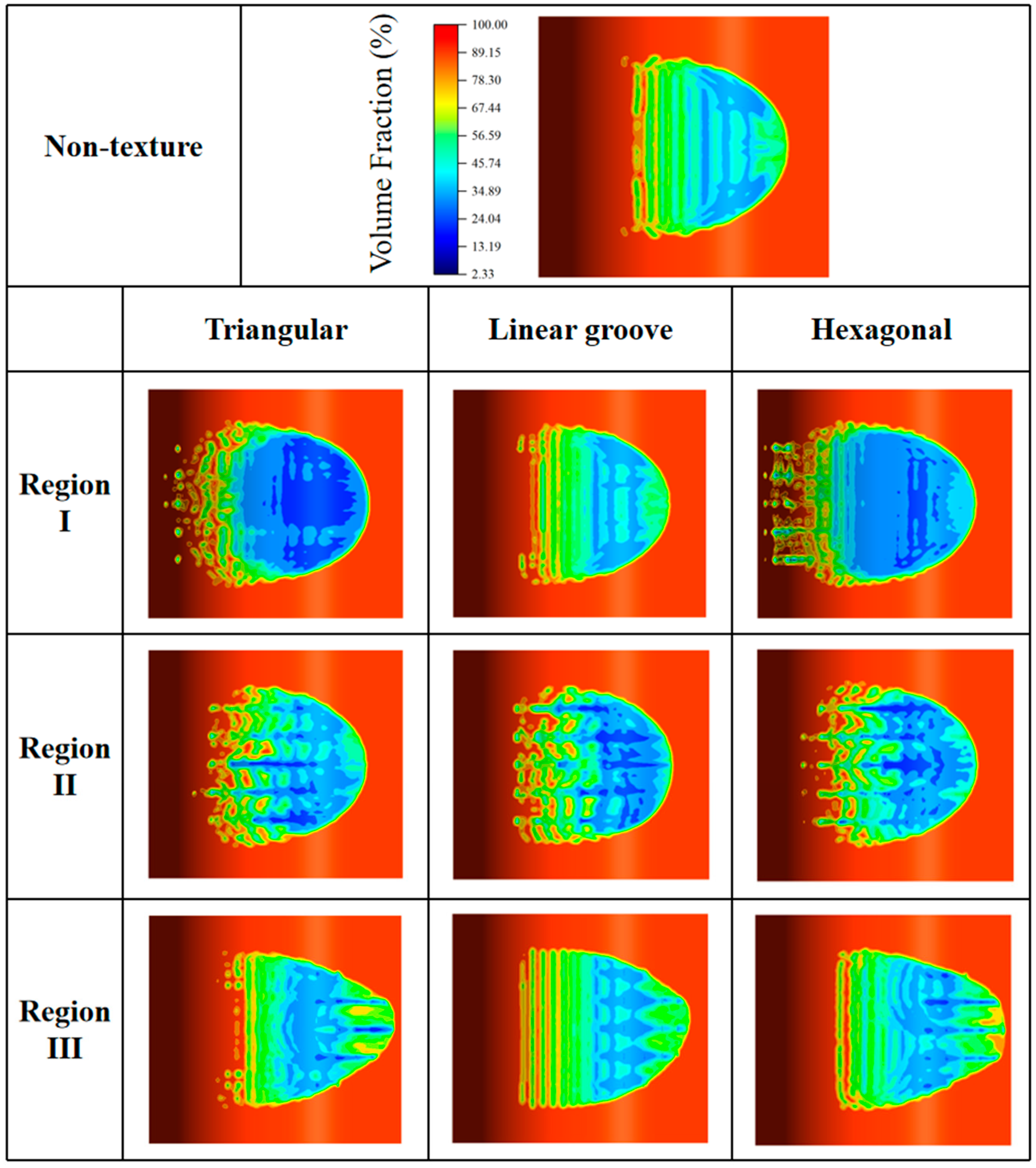

3.2. Effect of Single Micro-Texture Arrangement in Different Regions on the Bearing Performance

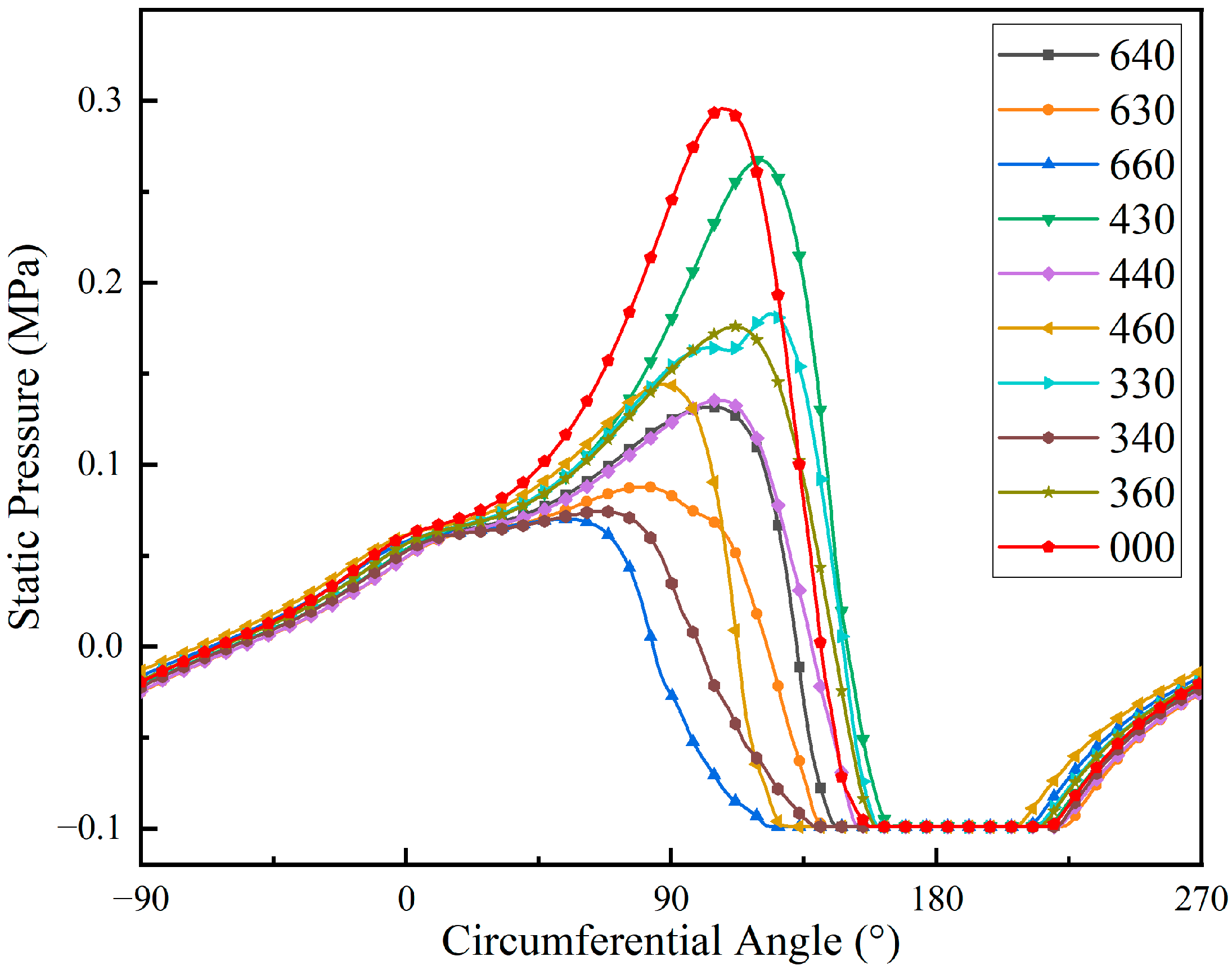

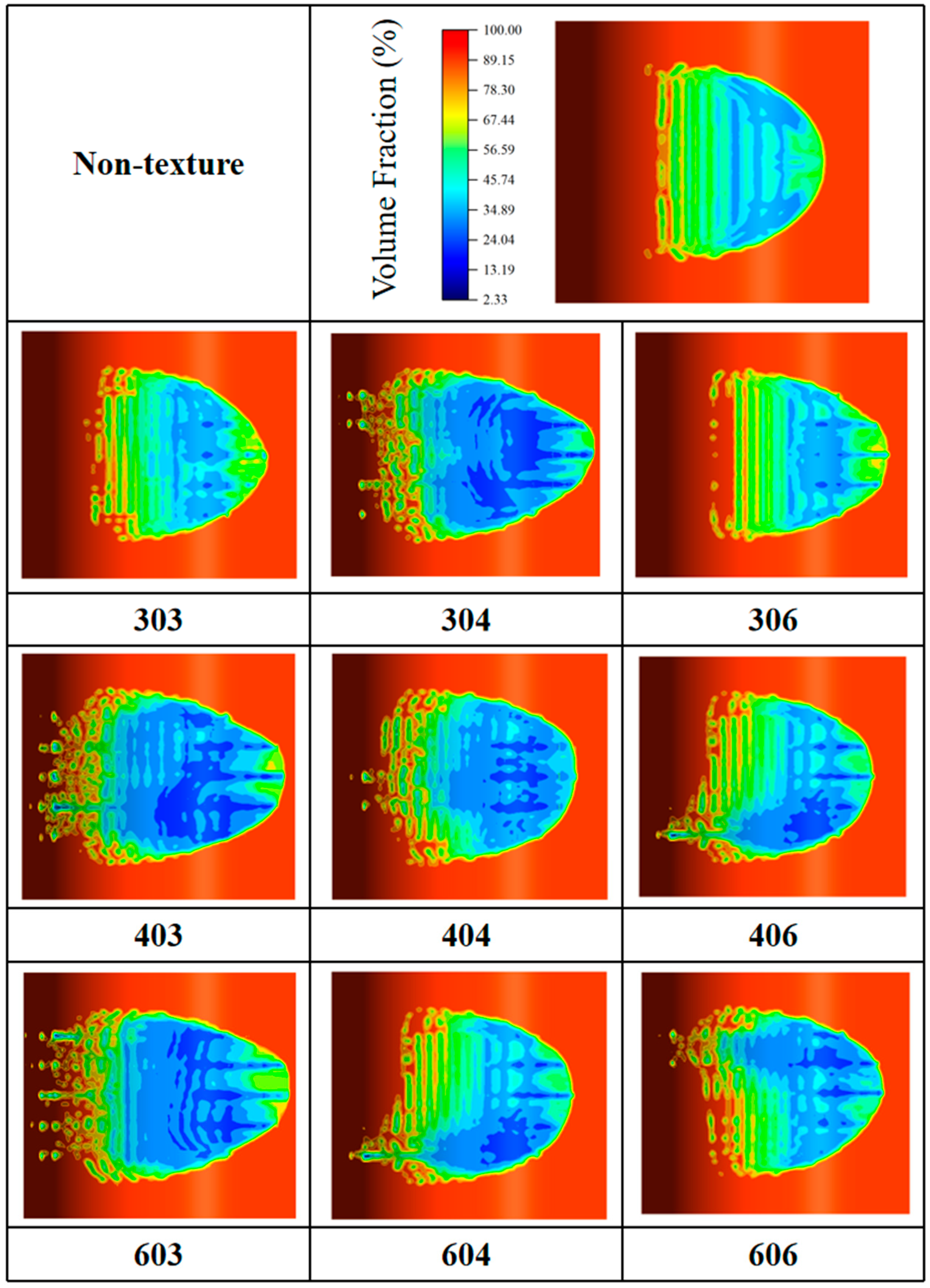

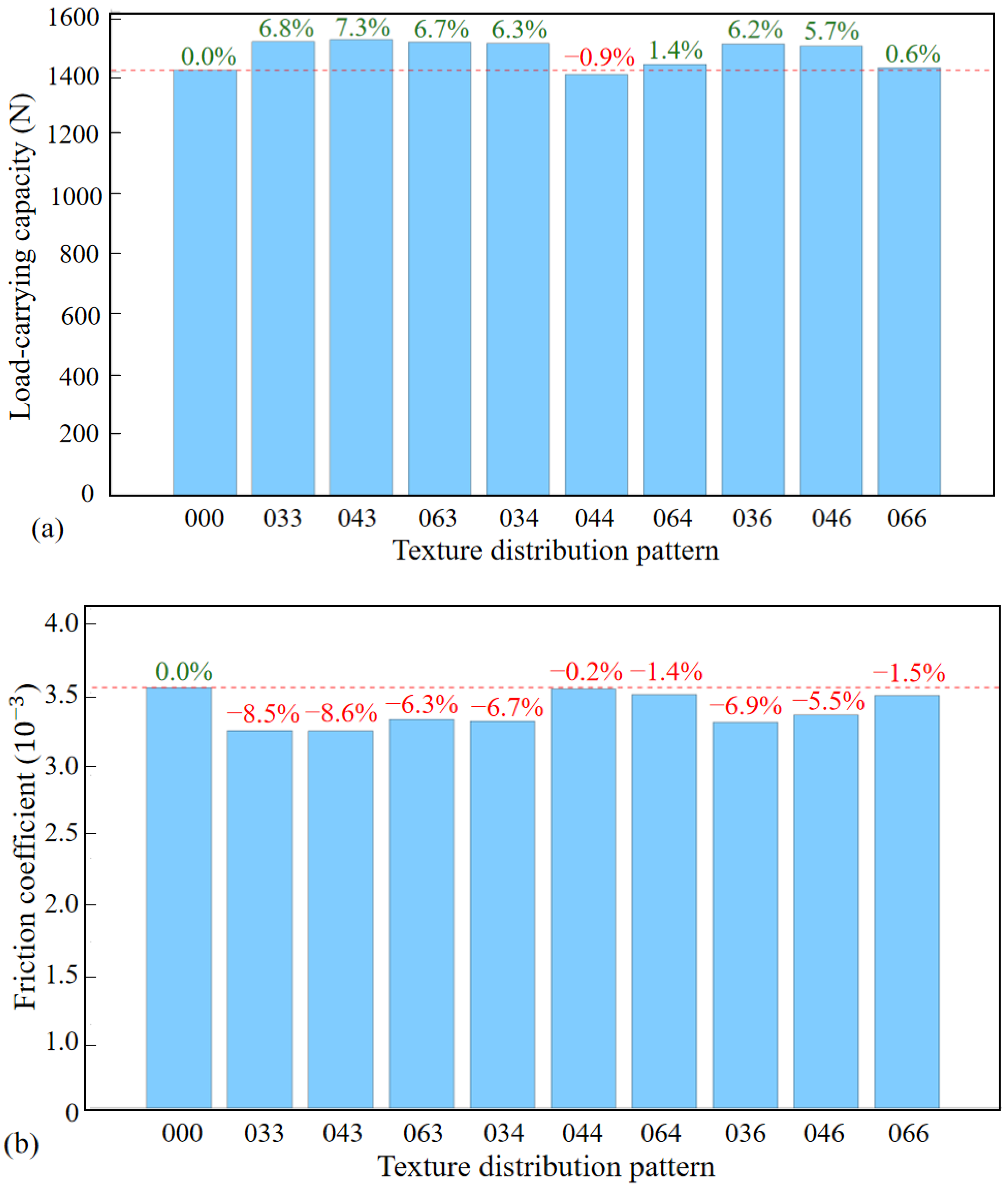

3.3. Effect of Mixed Micro-Textures Coupled in Two Different Regions on Bearing Performance

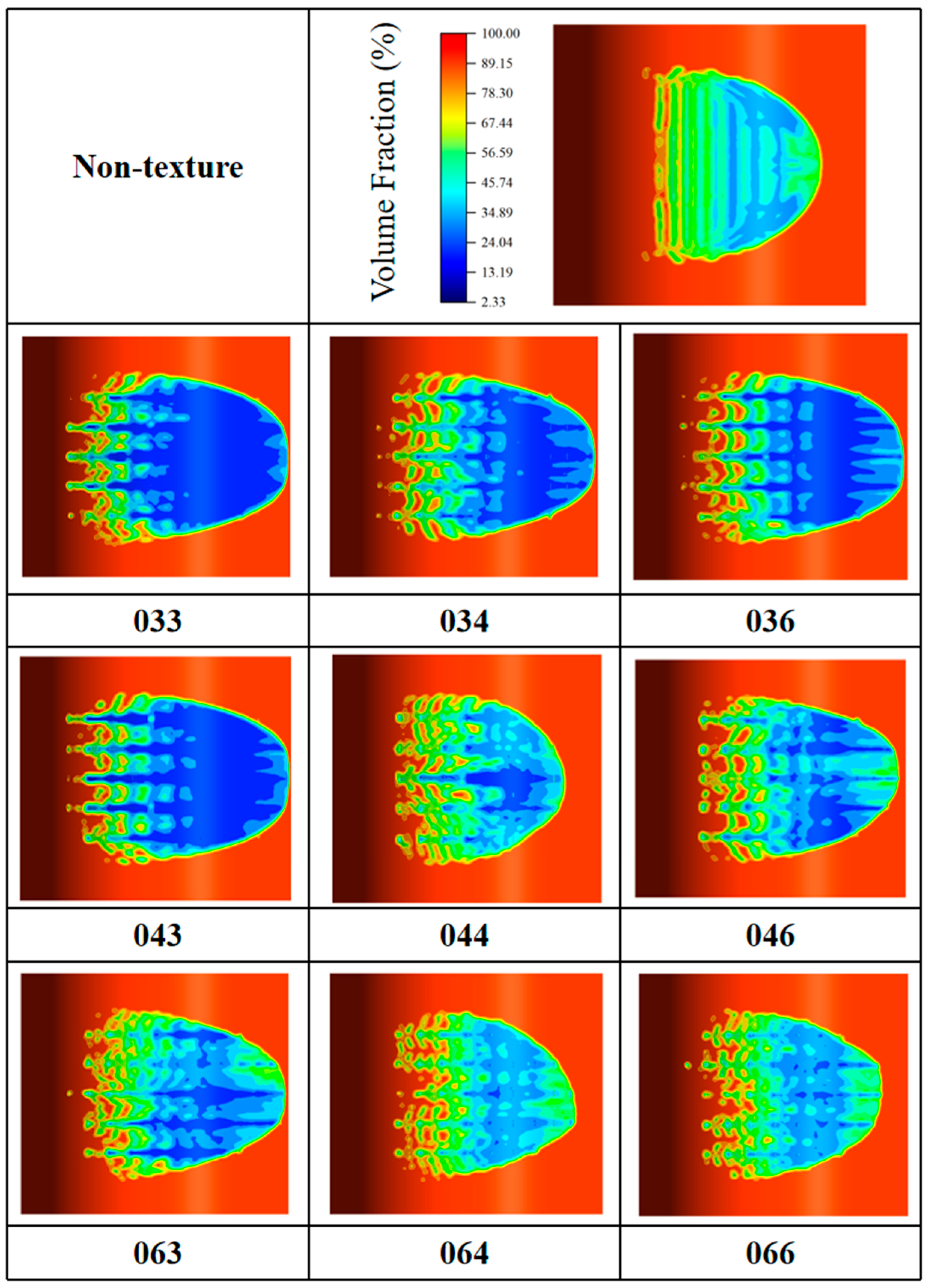

3.4. Effect of Mixed Micro-Textures Coupled in Three Different Regions on Bearing Performance

4. Conclusions

- When textures were placed in Region I (Convergent Zone), the load-carrying capacity of the bearing decreased, and the friction coefficient increased. The reason is that the convergent zone has the thinnest water film and the highest pressure, creating harsh operating conditions that negatively impact the frictional performance.

- The best frictional performance and optimal lubrication occur when textures are arranged in both Region II (Divergent Zone Outlet) and Region III (Divergent Zone Body). This effect is particularly significant when linear groove textures are used in Region II and triangular textures in Region III, resulting in a 7.3% increase in load-carrying capacity and an 8.6% reduction in the friction coefficient.

- Arranging textures in all three regions simultaneously has an overall negative effect on the frictional performance. This indicates that textures cannot be arbitrarily distributed across all regions and that increasing the number of textures does not necessarily lead to better performance.

- When textures are distributed in multiple regions, the negative effect of textures in Region I (Convergent Zone) on the frictional performance is significantly greater than the positive effects achieved by textures in the other two regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, Z.; Li, J.; Tian, Y.; Du, P.; Zhao, B.; Xu, F. Theoretical and experimental study on influences of surface texture on lubrication performance of a novel bearing. Tribol. Int. 2024, 193, 109351. [Google Scholar] [CrossRef]

- Xie, Z.; Jiao, J.; Yang, K.; Zhang, H. A state-of-art review on the water-lubricated bearing. Tribol. Int. 2023, 180, 108276. [Google Scholar] [CrossRef]

- Fedorynenko, D.; Nakao, Y. Evaluation of thermal stability of ultra-precision water-lubricated spindle. Precis. Eng. 2023, 80, 127–137. [Google Scholar] [CrossRef]

- Shi, G.; Yu, X.; Meng, H.; Zhao, F.; Wang, J.; Jiao, J.; Jiang, H. Effect of surface modification on friction characteristics of sliding bearings: A review. Tribol. Int. 2023, 177, 107937. [Google Scholar] [CrossRef]

- Wang, J.; Shen, J.F.; Fan, Y.W. Static characteristics analysis of spherical hybrid sliding bearings. Ind. Lubr. Tribol. 2020, 72, 93–100. [Google Scholar] [CrossRef]

- Xiong, G.; Mao, Z.; Zhang, J.; Wang, Z.; Wang, H.; Jiang, Z. Coupled effects of misalignment and viscoelastic deformation on dynamically loaded journal bearings. Int. J. Mech. Sci. 2023, 251, 108347. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, S.; Lin, X. Study of dynamic characteristics of water-lubricated journal bearings using thermohydrodynamic cavitating lubrication model. Tribol. Trans. 2023, 66, 381–397. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, C.; Yuan, C.; Bai, X. Frictional vibration behaviors of a new piezo-damping composite under water-lubricated friction. Wear 2023, 522, 204842. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, X.; Sun, J.; Wang, D. A study of misaligned compliant journal bearings lubricated by non-Newtonian fluid considering surface roughness. Tribol. Int. 2023, 179, 108138. [Google Scholar] [CrossRef]

- Gimeno, S.; Mescheder, H.; Quintana, I.; Gasion, A.; Arias-Egido, E.; Carbonell, A.; Carlos, M.; Ignacio, M.; Paredes, J.; Zalakain, I. Effect of different laser texturing patterns on rolling contact surface and its tribological & fatigue life behavior on 100Cr6 bearing steel. Wear 2023, 522, 204717. [Google Scholar]

- Xu, J.; Zhang, X.; Dai, J.; Yu, D.; Ji, M.; Chen, M. Biomimetic microtextured surfaces to improve tribological and antibacterial behaviors of 3Y-TZP ceramics. J. Mater. Res. Technol. 2023, 23, 1360–1374. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, T.; Liu, J.; Li, J. Study on synergistic friction between surface micro-texture and hot-pressing filling coal-to-oil soot solid lubricant. Surf. Coat. Technol. 2024, 489, 131167. [Google Scholar] [CrossRef]

- Tala-Ighil, N.; Fillon, M.; Maspeyrot, P. Effect of textured area on the performances of a hydrodynamic journal bearing. Tribol. Int. 2011, 44, 211–219. [Google Scholar] [CrossRef]

- Mourya, V.; Bhore, S.P.; Wandale, P.G. Comparative investigation on wear properties of 3D-printed textured journal bearings. J. Manuf. Process. 2023, 103, 337–353. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M.M. An Experimental Investigation of Dimple Effect on the Stribeck Curve of Journal Bearings. Tribol. Lett. 2007, 27, 169–176. [Google Scholar] [CrossRef]

- Denkena, B.; Bergmann, B.; Keitel, M.; Wege, C.; Poll, G.; Kelley, J.; Pape, F. Process strategies for milling of dimples on tapered roller bearings. Prod. Eng.-Res. Dev. 2023, 17, 893–905. [Google Scholar] [CrossRef]

- Oliveira, J.F.G.D.; Bottene, A.; Franca, T. A novel dressing technique for texturing of ground surfaces. CIRP Ann.-Manuf. Technol. 2010, 59, 361–364. [Google Scholar] [CrossRef]

- Tønder, K. Inlet roughness tribodevices: Dynamic coefficients and leakage. Tribol. Int. 2001, 34, 847–852. [Google Scholar] [CrossRef]

- Cupillard, S.; Glavatskih, S.; Cervantes, M. Computational fluid dynamics analysis of a journal bearing with surface texturing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 222, 97–107. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Tala-Ighil, N.; Maspeyrot, P.; Fillon, M.; Bounif, A. Effects of surface texture on journal-bearing characteristics under steady-state operating conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 623–633. [Google Scholar] [CrossRef]

- Jin, L.; Yang, J.; Li, C. Numerical coupled model of mixed lubrication wear for textured journal bearing. Lubr. Eng. 2020, 45, 67–74. [Google Scholar]

- Yin, M.H.; Chen, G.D.; Gao, D.C.; Wang, L. Effects of three types of surface texture on the performances of journal bearing. J. Harbin Inst. Technol. 2016, 48, 159–164. [Google Scholar]

- Wang, L.; Guo, S.; Yin, G.; Wei, Y.L.; Yuan, G.T. Research on micro-textured journal bearing characteristics considering the effect of cavitation. Lubr. Eng. 2018, 43, 65–69. [Google Scholar]

- Nie, T.; Yang, K.; Zhou, L.; Wu, X.; Wang, Y. CFD analysis of load capacity of journal bearing with surface texture. Energy Rep. 2022, 8, 327–334. [Google Scholar] [CrossRef]

- Wang, L.; Han, Z.; Chen, G.; Su, H. Thermo-hydrodynamic analysis of large-eccentricity hydrodynamic bearings with texture on journal surface. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2018, 232, 3564–3569. [Google Scholar] [CrossRef]

- Yu, R.; Chen, W.; Li, P. The analysis of elastohydrodynamic lubrication in the textured journal bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1197–1208. [Google Scholar] [CrossRef]

- Galda, L.; Sep, J.; Olszewski, A.; Zochowski, T. Experimental investigation into surface texture effect on journal bearings performance. Tribol. Int. 2019, 136, 372–384. [Google Scholar] [CrossRef]

- Hao, X.; Sun, H.; Wang, L.; Ali, Q.; Li, L.; He, N. Fabrication of micro-texture on cylindrical inner surface and its effect on the stability of hybrid bearing. Int. J. Adv. Manuf. Technol. 2020, 109, 1671–1680. [Google Scholar] [CrossRef]

- Filgueira Filho, I.C.M.; Bottene, A.C.; Silva, E.J.D.; Nicoletti, R. Static behavior of plain journal bearings with textured journal-experimental analysis. Tribol. Int. 2021, 159, 106970. [Google Scholar] [CrossRef]

- Xie, Z.; Yang, K.; He, T.; Jiao, J. Experimental and theoretical analysis on the nonlinear rotor-dynamic performances and vibration characteristics of a novel bearing-rotor system. Mech. Syst. Signal Process. 2023, 199, 110416. [Google Scholar] [CrossRef]

- Xie, Z.; Tian, Y.; Li, J.; Du, P. Lubrication performance of a novel double-film bearing: Theory & experiment. Tribol. Int. 2023, 189, 108958. [Google Scholar]

- Zhang, X.; Yin, Z.; Gao, G.; Li, Z. Determination of stiffness coefficients of hydrodynamic water-lubricated plain journal bearings. Tribol. Int. 2015, 85, 37–47. [Google Scholar] [CrossRef]

- Čech, J.; Sťahel, P.; Prokeš, L.; Trunec, D.; Horňák, R.; Rudolf, P.; Maršálek, B.; Maršálková, E.; Lukeš, P.; Lavrikova, A.; et al. CaviPlasma: Parametric study of discharge parameters of high-throughput water plasma treatment technology in glow-like discharge regime. Plasma Sources Sci. Technol. 2024, 33, 115005. [Google Scholar] [CrossRef]

- Xie, Z.L.; Ta, N.; Rao, Z.S. The lubrication performance of water lubricated bearing with consideration of wall slip and inertial force. J. Hydrodyn. Ser. B 2017, 29, 52–60. [Google Scholar] [CrossRef]

- Li, J.; Zhou, F.; Wang, X. Modify the friction between steel ball and PDMS disk under water lubrication by surface texturing. Meccanica 2011, 46, 499–507. [Google Scholar] [CrossRef]

| Symbol | Meaning | Value |

|---|---|---|

| Bearing radius | 50.06 mm | |

| Shaft radius | 50.0 mm | |

| Bearing width | 90.0 mm | |

| Eccentricity distance | 0.042 mm | |

| Eccentricity ratio | 0.7° | |

| Attitude angle | 45° | |

| Texture space in circumferential direction | 10° | |

| Minimum water film thickness | 0.018 mm | |

| Maximum water film thickness | 0.102 mm |

| Texture Type | (μm) | (mm) | (mm) | Axial Quantity | Circumferential Quantity |

|---|---|---|---|---|---|

| Triangular | 20 | 2.1200 | 1.8360 | 6 | 5 |

| Linear groove | 20 | 2.4375 | 0.8000 | 6 | 5 |

| Hexagonal | 20 | 1.5000 | 1.7320 | 6 | 5 |

| Parameter | Air | Water |

|---|---|---|

| Density ρ (kg/m3) | 1.225 | 1000 |

| Viscosity η (Pa·s) |

| ID | Mesh Numbers | Maximum Water Film Pressure (Pa) |

|---|---|---|

| 1 | 154,162 | 238,349 |

| 2 | 312,086 | 297,889 |

| 3 | 568,798 | 315,066 |

| 4 | 710,910 | 321,995 |

| 5 | 918,908 | 322,713 |

| 6 | 1,098,804 | 323,080 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; Lan, Y.; Bosiakov, S.; Zhuravkov, M.; He, T.; Xia, Y.; Lyu, Y. Investigation on the Coupling Effect of Bionic Micro-Texture Shape and Distribution on the Tribological Performance of Water-Lubricated Sliding Bearings. Lubricants 2025, 13, 305. https://doi.org/10.3390/lubricants13070305

Tang X, Lan Y, Bosiakov S, Zhuravkov M, He T, Xia Y, Lyu Y. Investigation on the Coupling Effect of Bionic Micro-Texture Shape and Distribution on the Tribological Performance of Water-Lubricated Sliding Bearings. Lubricants. 2025; 13(7):305. https://doi.org/10.3390/lubricants13070305

Chicago/Turabian StyleTang, Xiansheng, Yunfei Lan, Sergei Bosiakov, Michael Zhuravkov, Tao He, Yang Xia, and Yongtao Lyu. 2025. "Investigation on the Coupling Effect of Bionic Micro-Texture Shape and Distribution on the Tribological Performance of Water-Lubricated Sliding Bearings" Lubricants 13, no. 7: 305. https://doi.org/10.3390/lubricants13070305

APA StyleTang, X., Lan, Y., Bosiakov, S., Zhuravkov, M., He, T., Xia, Y., & Lyu, Y. (2025). Investigation on the Coupling Effect of Bionic Micro-Texture Shape and Distribution on the Tribological Performance of Water-Lubricated Sliding Bearings. Lubricants, 13(7), 305. https://doi.org/10.3390/lubricants13070305