1. Introduction

Recently, sustainable machining has been drawing growing attention within the metal cutting industry. The simplest way to ensure environmentally friendly characteristics is to eliminate or maximally reduce the usage of cutting oil. Another approach is the replacement of mineral cutting oils with biodegradable ones, like vegetable oil and vegetable-based oil. Many studies have been carried out in line with these directions. Among them, dry hard milling has been applied to machines, such as steels with high hardness (usually above 45 HRC) [

1]. This process has brought an improvement in productivity [

2] while ensuring a high machined-surface quality, as well as environmentally friendly properties [

3]. However, the huge amount of cutting heat required is a major cause of early worn tools and the machined surface’s deterioration [

4]. In addition to that, thermal shock phenomena result in the discontinuous cutting character of hard milling, which limits the use of cutting fluid under flood conditions [

3,

4]. To overcome these problems, the requirements for cooling, lubrication, and cutting tool materials play crucial roles in successful hard milling. The cutting inserts used for hard machining must possess high hardness and good heat resistance, like coated carbide [

3], ceramics [

5], Cubic Boron Nitride (CBN) [

6], diamond [

7], and so forth. Moreover, the minimum quantity cooling (MQC), minimum quantity lubrication (MQL), and nanofluid minimum quantity lubrication (NF MQL) have been studied and proven to be suitable for hard machining technology. Sartori et al. [

8] used cooled gaseous nitrogen in a range of temperatures between 0° and −150 °C to assist the semi-finishing turning of a Ti6Al4V titanium alloy. The findings indicated a significant reduction in tool wear under N2 cooled at −150 °C compared to Liquid Nitrogen (LN2) and wet conditions. Additionally, the machined-surface integrity under the cooled N2 conditions was improved in terms of the deformed layer and the main typologies of the surface defects. Pereira et al. [

9] investigated the hybrid CO2 + MQL’s effectiveness for milling Inconel 718. The authors also made a comparison with dry, wet, CO2 standalone, and MQL conditions. They concluded that the milling performance under the hybrid CO2 + MQL environment showed the best results and reached values about 90% higher than those from wet machining. The superior cooling and lubricating effects were the main factors behind the obtained results. Sharma et al. [

10] conducted a review of the nanofluid minimum quantity lubrication (NF MQL) in machining and compared it to dry and wet cutting as well as to MQL using conventional oils. The authors claimed that most studies have shown that better cooling and lubricating effects result from NF MQL and MQL conditions. They could be a viable alternative to a flood coolant to achieve sustainable characteristics.

In the MQL method, the lubricant, in the form of an oil mist with high pressure, is directly sprayed onto the cutting zone, so better lubrication has been reported when compared to flood coolants in terms of cutting forces, cutting temperature, tool life, and surface quality [

11]. However, the application of this method in hard machining does not show the findings expected to result from the low cooling efficiency [

4]. The utilization of nanofluid as the base fluid for MQL to improve the cooling and lubricating performance is an up-to-date topic, and some studies have pointed out promising results. Nanofluids are formed by suspending nanoparticles, such as Al

2O

3, graphite, graphene, MoS

2, TiO

2, SiC, and so forth, with a suitable concentration. The objective is to enhance the cooling and lubricating effects of the base oil [

12]. In addition, nanoparticles also play a role in reducing the base oil viscosity [

13]. Hence, many researchers have pointed out the effectiveness of nanofluid MQL for hard cutting processes. Abbas et al. [

14] studied the effects of Al

2O

3 nanofluid MQL conditions on the hard turning performance of AISI 1045 steel. A better thermal conductivity was noted, and the friction coefficient was reduced, leading to an improvement in machining efficiency. Şirin and Kıvak found better results when milling the Inconel X-750 superalloy, due to an enhancement in the thermal conductivity and lubricity by using nano cutting oil [

15]. Uysala et al. [

16] investigated the impact of MoS

2 nanofluid MQL on the milling performance of AISI 420 stainless steel. The findings indicated that a longer tool life and better machined-surface quality resulted from the superior lubricating performance of the MoS

2 nano cutting oil. Also, the nanoparticle concentration and oil flow rate exhibited significant influences and should be focused upon and optimized. Lee et al. [

17] achieved a reduction in the friction coefficient of up to 23% by using diamond nanofluid, thereby improving the cutting outcomes in terms of the surface quality and cutting heat when compared to cutting oil without nanoparticles. In a study by Ali et al. [

13] on the application of Al

2O

3 and TiO

2 nano solutions in engine lubricating oils, the friction coefficient and wear amount were reduced by 11% and 2.6%, respectively, due to the superior lubricating performance of Al

2O

3 and TiO

2 nanoparticles. Maruda et al. [

18] studied the different copper nanoparticle sizes (22 nm, 35 nm, 65 nm, and 80 nm) and concentrations (0.25%, 0.5%, 0.75%, and 1.0%) in the base oil of the MQL system for the turning process of 316L stainless steel. The obtained findings revealed that the better surface topography was tightly related to the usage of the smaller nanoparticle size. Among the investigated concentrations, the concentration of 0.5% is more suitable for better surface quality and lower power consumption. In addition, the agglomerations of copper nanoparticles can occur in the case of increasing the concentration from 0.5% to 0.8%, which negatively impacts the machining outputs [

19].

The technological parameters of nano cutting oils include the base oil type and the characteristics of nanoparticles (grain size, morphology, and concentration). Hegab et al. [

20] investigated the effectiveness of a carbon nanotube (CNT) nanofluid MQL on the turning performance of the Ti-6Al-4V alloy. The superior cooling effect of the carbon nanotube plays a key role in surface quality improvement and tool wear reduction. Also, the CNT concentration and feed rate strongly influence the machined-surface quality. In addition, a better lubricating performance resulting from the high hardness and nearly spherical morphology of Al

2O

3 nanoparticles was reported, which enhanced the tool machinability when turning the Inconel 718 alloy [

21]. Eltaggaz et al. [

22] compared the different cooling lubrication modes including dry, flooded, MQL, and nanofluid MQL for the hard milling of ADI steel. The obtained findings indicated an improvement in the thermal conductivity of vegetable oil containing Al

2O

3 nanoparticles. In addition, the presence of Al

2O

3 nanoparticles effectively contributed to reducing the coefficient friction in the cutting zone and improving lubrication and cooling performance, thereby decreasing the cutting forces and enhancing the machined-surface quality. The similar results were reported when Al

2O

3 nanoparticles were suspended in palm oil for MQL grinding of the nickel alloy GH4169 [

23]. Luo et al. [

24] found a good resistance of Al

2O

3 nanofluid to high temperature.

In order to improve the cooling effect of the MQL technique, minimum quantity cooling lubrication (MQCL) has been developed and studied. The better cooling and lubricating performance of the MQCL technique in turning the Ti6Al4V alloy was reported when compared to dry and flooded conditions [

25]. Maruda et al. [

26] investigated the effects of MQCL parameters on the hard turning performance of AISI 1045 steel and found out that the emulsion mist formation in contact zones effectively improves the cooling and lubricating property. The more favorable condition for chip formation and the reduction in the chip-thickening coefficient was noted in the turning process of austenitic stainless steel 316L under the MQCL condition [

27]. Nevertheless, the cooling effect of the MQCL condition in these studies resulted from the good cooling property of the emulsion cutting oil (water-soluble cutting oil).

Zhang et al. [

28] evaluated the tool life and cutting forces in end milling of Inconel 718 under dry and MQCL environments. Through the experimental results, MQCL with biodegradable vegetable oil improved the end milling performance with tool life extension and cutting force reduction. Hariprasad and his co-authors [

29] studied the impacts of the cutting edge radius on chip formation and surface quality in the MQCL end milling of Ti6Al4V. In this work, the sub-zero air from the vortex tube mechanism is supplied to an MQL nozzle to form an MQCL condition. The larger edge radius of the tools led to the better penetration of MQCL aerosol into the cutting zone, which contributed to decrease the cutting force, cutting temperature, tool wear, and surface roughness values. Anand et al. [

30] conducted an experimental investigation on the MQCL technique using soluble oil in turning Ti-6Al-4V. The obtained results indicated the better machining efficiency based on cutting forces, tool wear, and contact faces when compared to wet cutting. Nevertheless, the use of a true MQCL device to a spray-cooled minimal quantity oil based on the principle of the Ranque–Hilsch vortex tube is still limited [

31,

32]. Hence, in this paper, the Frigid-X Sub-Zero Vortex Tool Cooling Mist System made by Nex Flow™, Richmond Hill, ON, Canada [

33], was used to create the MQCL environment for the hard milling process of Hardox 500 steel.

Hardox 500 steel, produced by the SSAB company in Sweden [

34], is not intended for further heat treatment and possesses a fairly high hardness (470–530 HBW). In addition, this type of steel has high strength and superior wear resistance as well as high ductility. Hence, it is widely used in heavy industries such as stone mining, coal mining, oil exploitation, cement production, electricity production, and mechanical processing industries, making vehicle bodies, crushers, bucket trucks, bulldozers, and so forth. Nevertheless, possessing many good mechanical properties at the same time, Hardox 500 steel has low machinability and is grouped among the difficult-to-cut materials [

35]. The additives of hybrid nanoparticles in the base oil for the MQCL system will result in supplementary cooling and lubricating effects that improve the cutting performance. Therefore, the application of Al

2O

3/MoS

2 hybrid nanofluid MQCL in the hard milling of Hardox 500 steel will create economic, technical, and environmental significance. This is a novel research topic, but little information has been reported [

35,

36]. This article aims to study the influence of the investigated parameters (nanoparticle concentration, cutting speed, and feed rate) on the total cutting force

F (N) and cutting force coefficient

Fy/

Fz in the hard milling process of Hardox 500 steel under an MQCL environment using Al

2O

3/MoS

2 hybrid nano cutting oil.

2. Materials and Methods

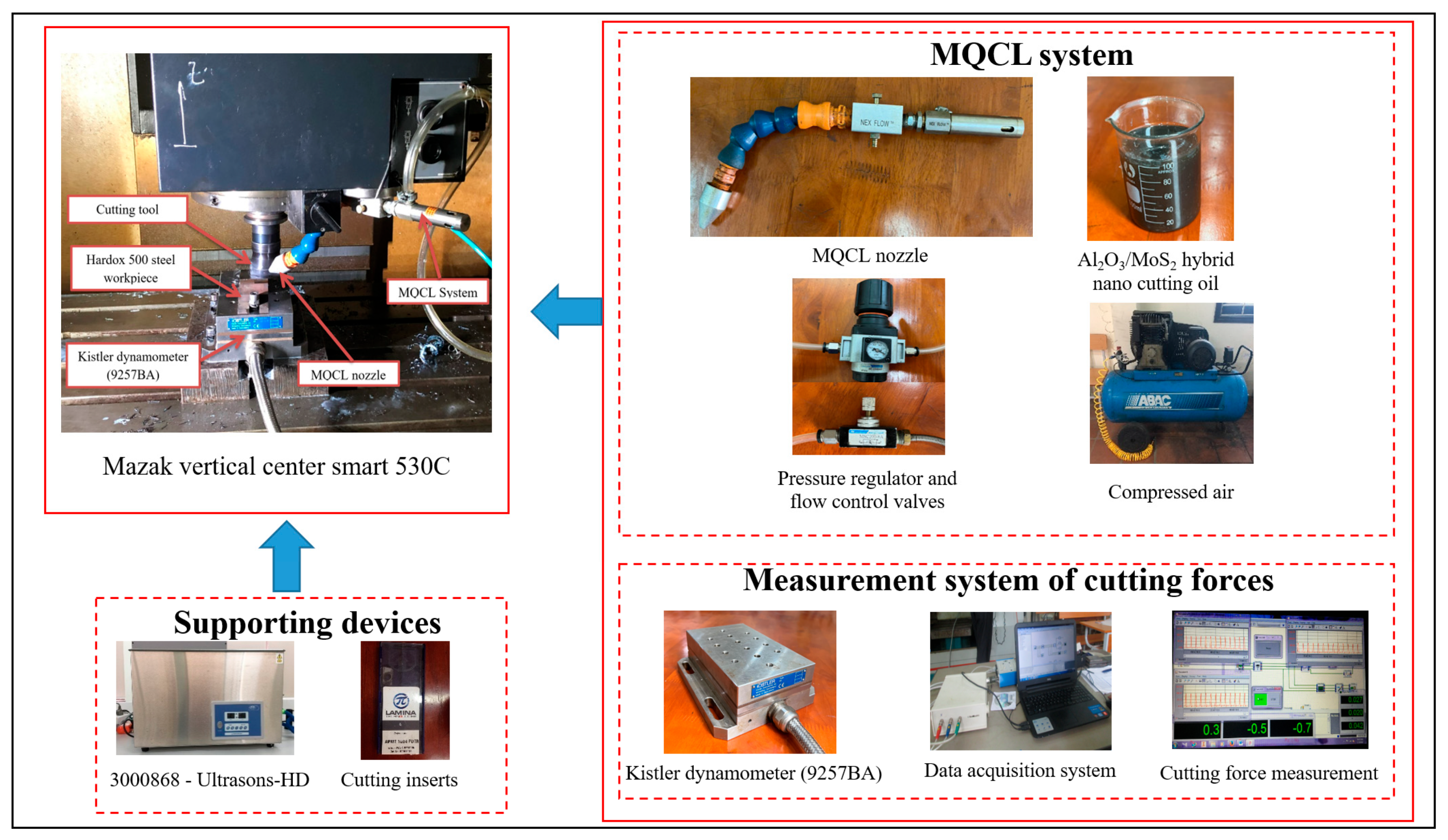

The set-up diagram of the experiments and measurements is shown in

Figure 1. A Mazak vertical center smart 530C (Yamazaki Mazak Corporation, 1–131 Takeda, Oguchi-cho, Niwa-gun, Aichi-Pref, Japan) was used for the experiments. The APMT 1604 PDTR LT30 PVD TiAlN-coated carbide inserts (flank angle (11°), nose radius (0.66 mm)) were mounted on the SHIJIE BAP 400R-50-22-4T face mill head. The diameter of the face mill head was 50 mm, and a single cutting edge was used. After each cutting trial, the cutting insert was replaced by a new one. For the MQCL system, the Frigid-X Sub-Zero Vortex Tool Cooling Mist System (Nex Flow™, Richmond Hill, ON, Canada) was used, alongside Al

2O

3/MoS

2 hybrid nanofluid with soybean oil as the base oil, the air pressure regulator, and PT-0136 compressed air. Al

2O

3 nanoparticles and MoS

2 nanosheets with an average grain size of 30 nm were produced by Soochow Hengqiu Graphene Technology Co., Ltd. (Suzhou, China) and Luoyang Tongrun Info Technology Co., Ltd. (Luoyang, China), respectively. The mixing ratio of Al

2O

3/MoS

2 hybrid nanofluid in the soybean oil is 80:20 by the suggestion of some works in the literature [

36,

37]. The Ultrasons-HD ultrasonicator (JP SELECTA, Abrera, Spain) generated 600W ultrasonic pulses at 40 kHz for one hour to uniformly suspend the nanoparticles in the soybean oil to prepare the Al

2O

3/MoS

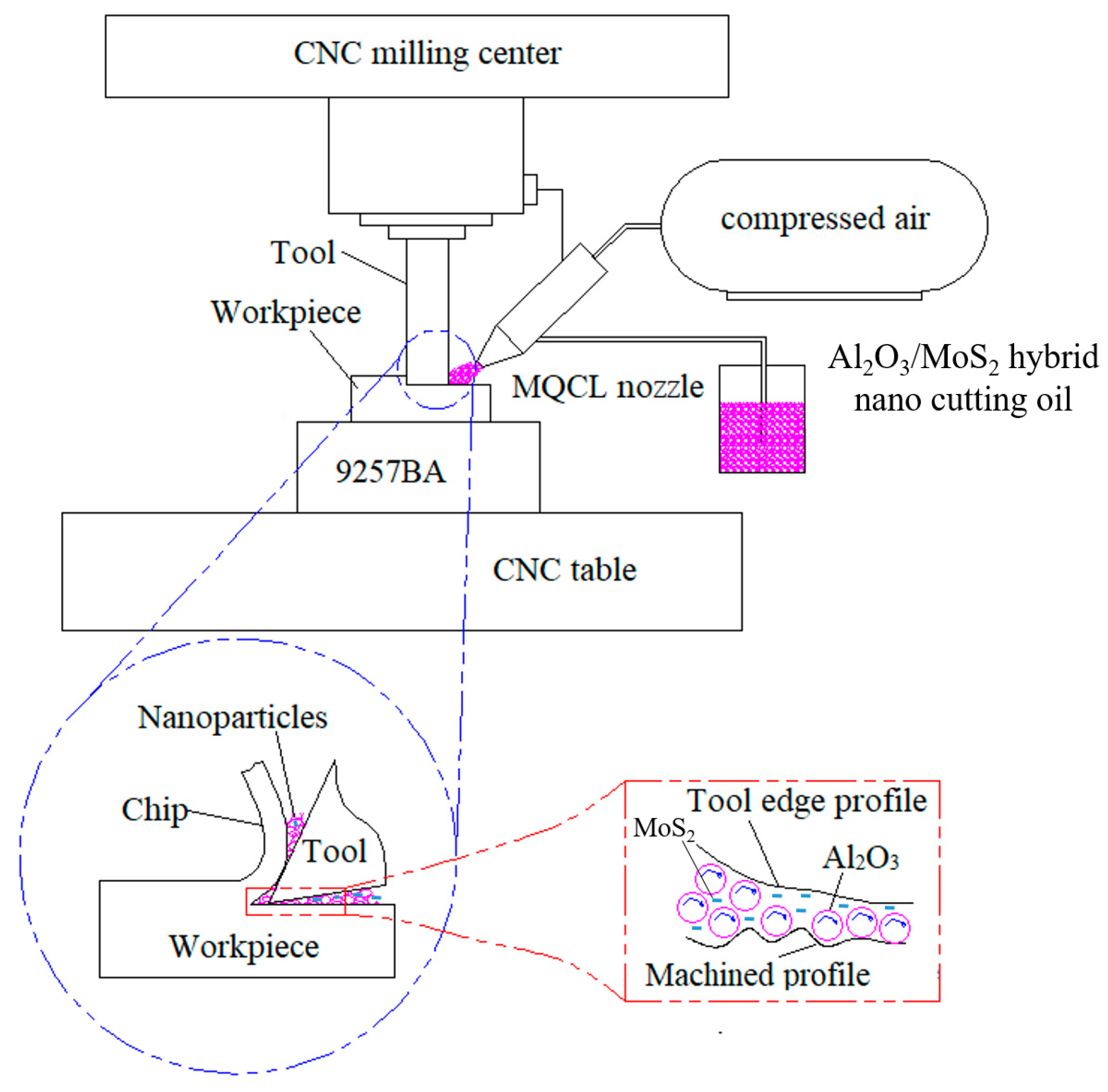

2 hybrid nano cutting oil, which was directly used for the MQCL system. The schematic shown in

Figure 2 illustrates how the Al

2O

3/MoS

2 hybrid nanofluid MQCL environment assisted to hard milling process. The Al

2O

3/MoS

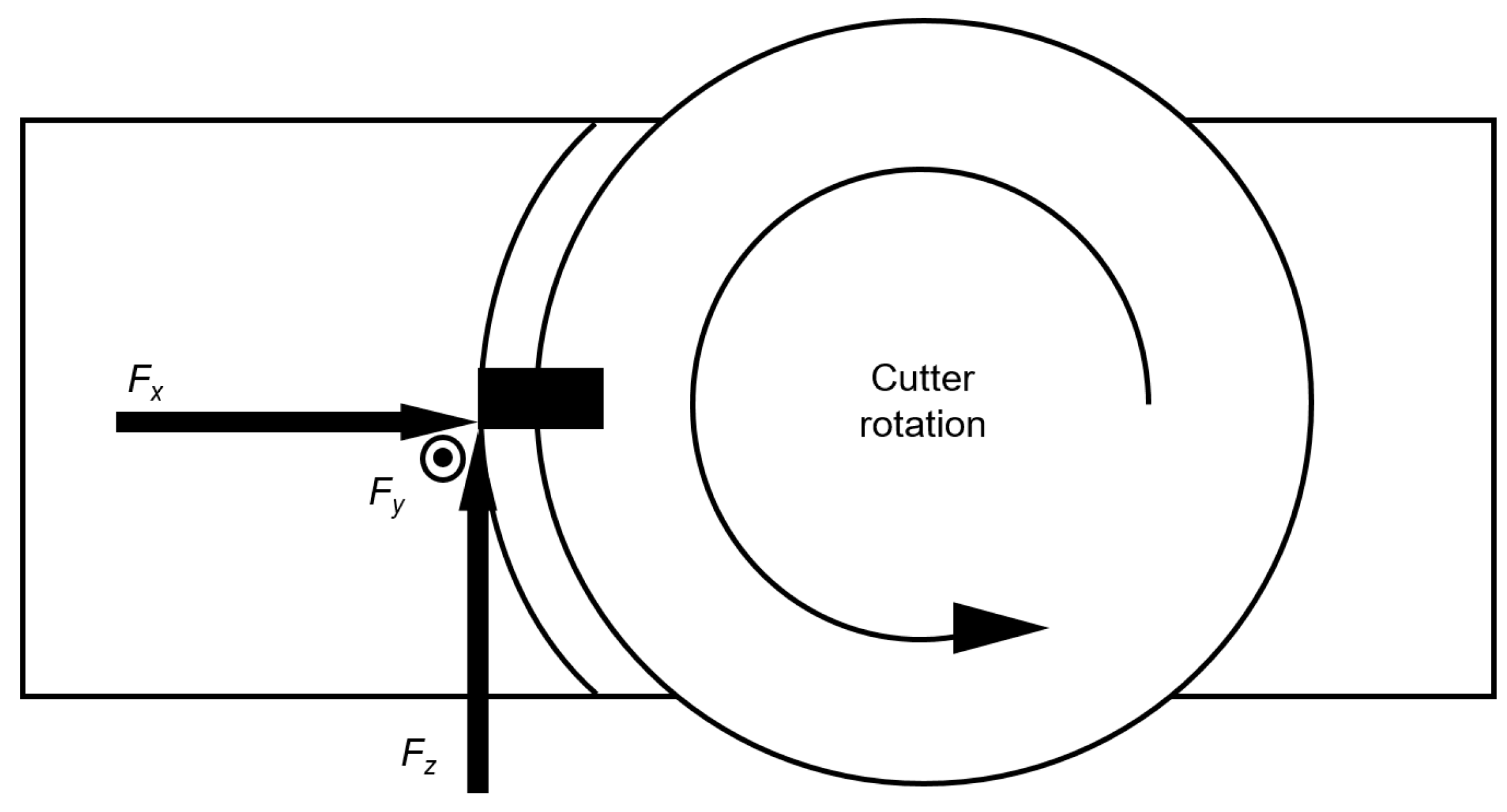

2 hybrid nanofluid is siphoned into the MQCL device and cooled by means of a small vortex tube. The sub-zero hybrid nanofluid was directly introduced to the flank face of the cutting tool. The cutting force component values were measured by a Kistler quartz three-component dynamometer (9257BA). The designation of cutting force direction in single-insert face milling is shown in

Figure 3. In this study, the dimension of Hardox 500 steel workpieces is 150 ×100 ×15 mm.

Table 1 and

Table 2 show the elemental composition and mechanical properties of Hardox 500 steel. The resultant cutting force

F and its values are calculated by Equations (1) and (2).

3. Results and Discussion

The experimental design was built by using the Box–Behnken response surface methodology. The influences of the investigated parameters (nanoparticle concentration (

NC), cutting speed (

v), and feed rate (

f)) on the total cutting force

F (N) and cutting force coefficient

Fy/

Fz were evaluated as shown in

Table 3. The selection of input variables and their values was based on previous works [

36,

38].

The experiments were carried out by following the RunOrder. Each of the cutting trials was repeated three times under the same cutting condition and the average values of the cutting forces were reported. The measured output variables of the experimental design are summarized in

Table 4.

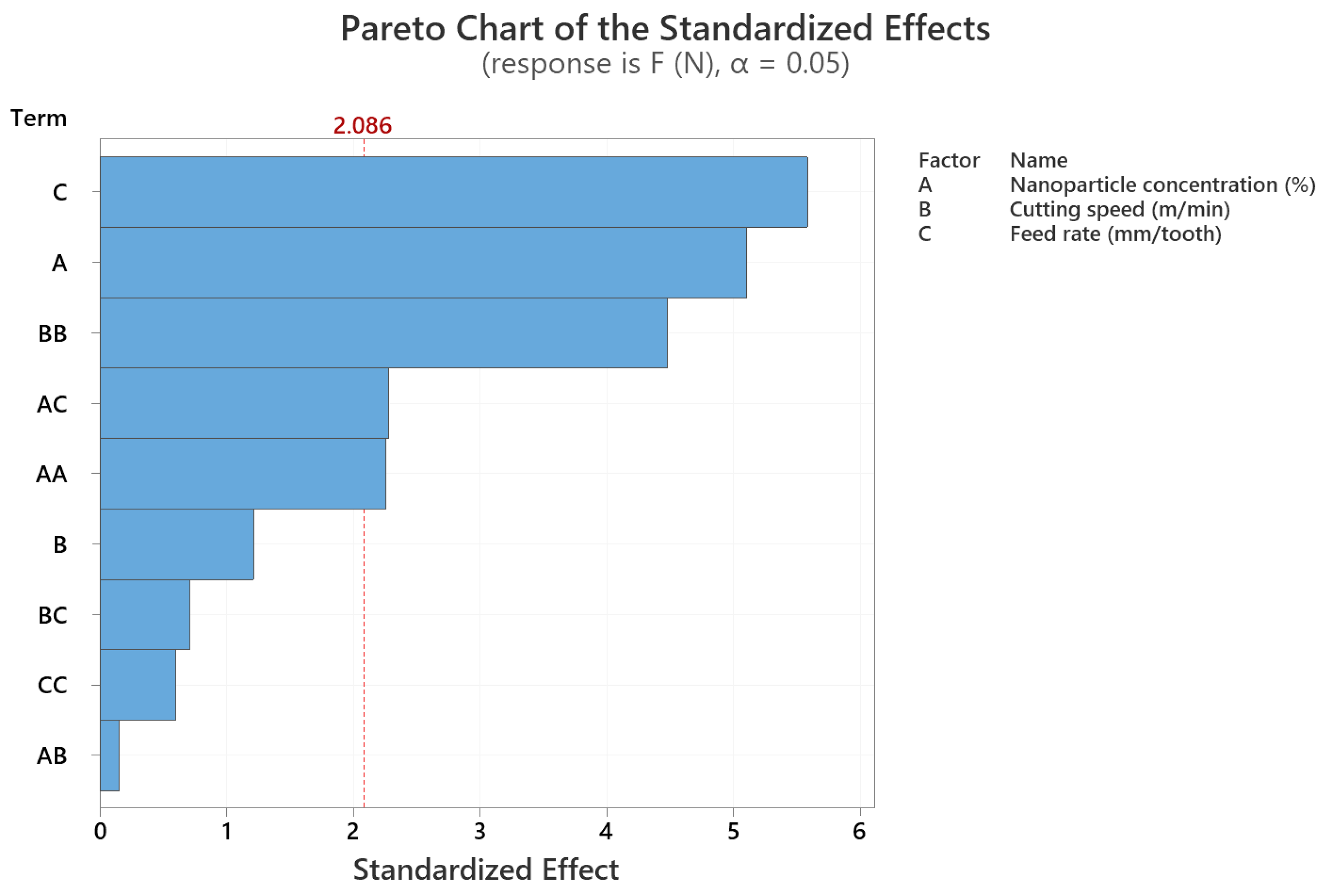

Minitab 19 software was used to study the experimental data with a significance level α = 0.05 and obtain the results. Equation (3) is the regression model for the influences of the investigated parameters on the total cutting force

F. The coefficient of determination R

2 = 81.51% proves that the proposed model is consistent with the experimental data. The Pareto charts evaluate the influences of the input parameters on the total cutting force

F and cutting force coefficient

Fy/

Fz given in

Figure 4 and

Figure 5.

In

Figure 4, the factors that exceed the reference line with the value of 2.086 are statistically significant and cause a strong influence on the total cutting force. Among the investigated variables, the feed rate

f has the largest influence on the total cutting force, followed by the nanoparticle concentration and the second-order interaction effect of cutting speed. In addition, it was noticeable that the interaction effect between nanoparticle concentration and feed rate and the second-order interaction effect of nanoparticle concentration (

NC∗

NC) also had significant influences. For the cutting force coefficient

Fy/

Fz in

Figure 5, the feed rate is still the factor with the strongest impact, while the nanoparticle concentration and cutting speed (

NC∗

v) have little influence. However, the second-order interaction effect of the nanoparticle concentration (

NC∗

NC) and cutting speed (

v∗

v), as well as the interaction effect between the cutting speed and feed rate (

v∗

f), strongly affects the cutting force coefficient

Fy/

Fz.

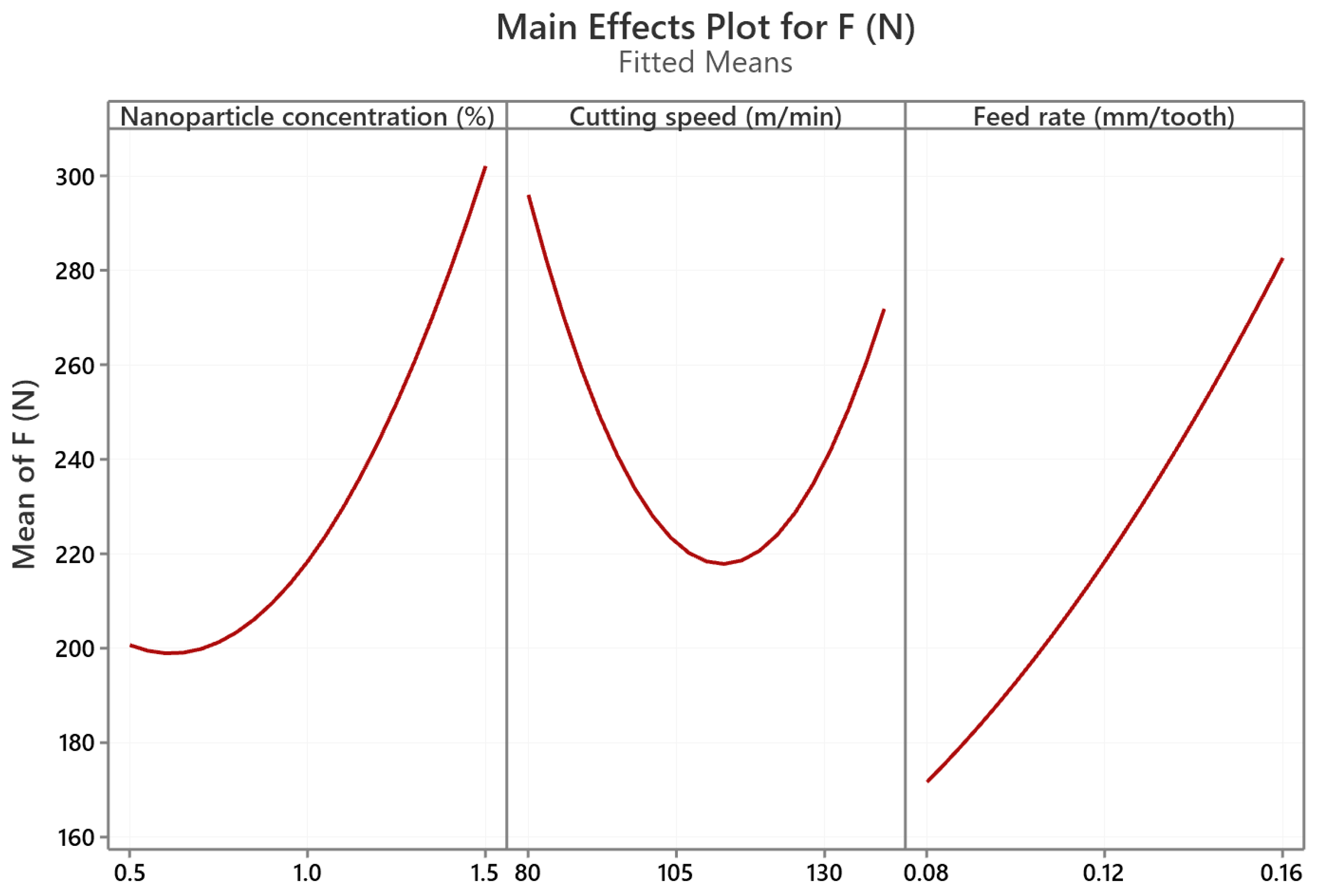

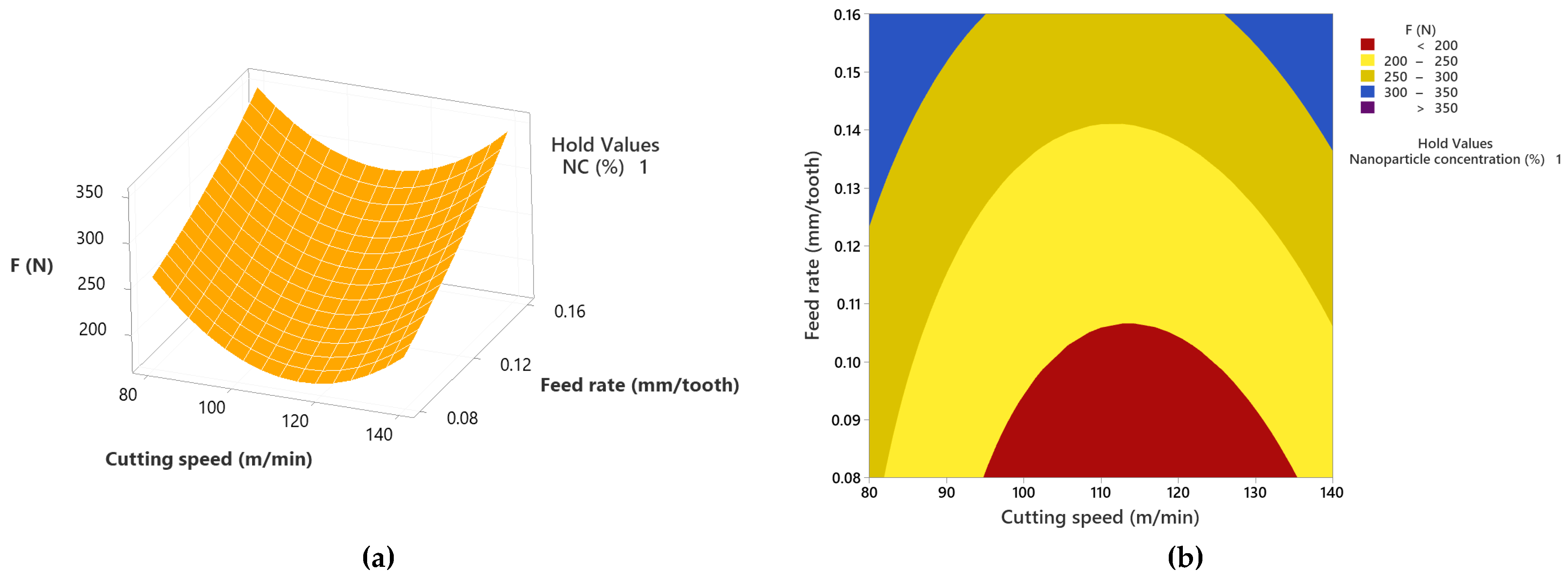

From

Figure 6, it can be seen that the total cutting force value increases sharply with the growth in feed rate. The main reason is the increased area of the cutting layer combined with the high strength and toughness of Hardox 500 steel. When

NC increased from 0.5% to about 0.6%, the total cutting force decreased slightly and reached the smallest value in the survey range. This is a reasonable value range for the nanoparticles to penetrate into the cutting zone and exert their cooling lubrication characteristics, thereby decreasing the friction coefficient and cutting heat [

24]. The total cutting force

F value increased rapidly with the increase in the nanoparticle concentration to 1.5%, reflecting that the large number of nanoparticles entering the cutting zone caused compression and impedance phenomena [

4]. Hence, it interrupts the lubrication process and hinders the cutting process [

10]. Meanwhile, when the cutting speed went up from 80 m/min to 110 m/min, the total cutting force decreased but increased with the growth in the cutting speed from 110 m/min to 130 m/min. It can be explained that the unique combination of high temperatures on the contact faces between the cutting tool and workpiece combined with low feed rate in hard milling generates self-induced heat, leading to decreased cutting forces [

1].

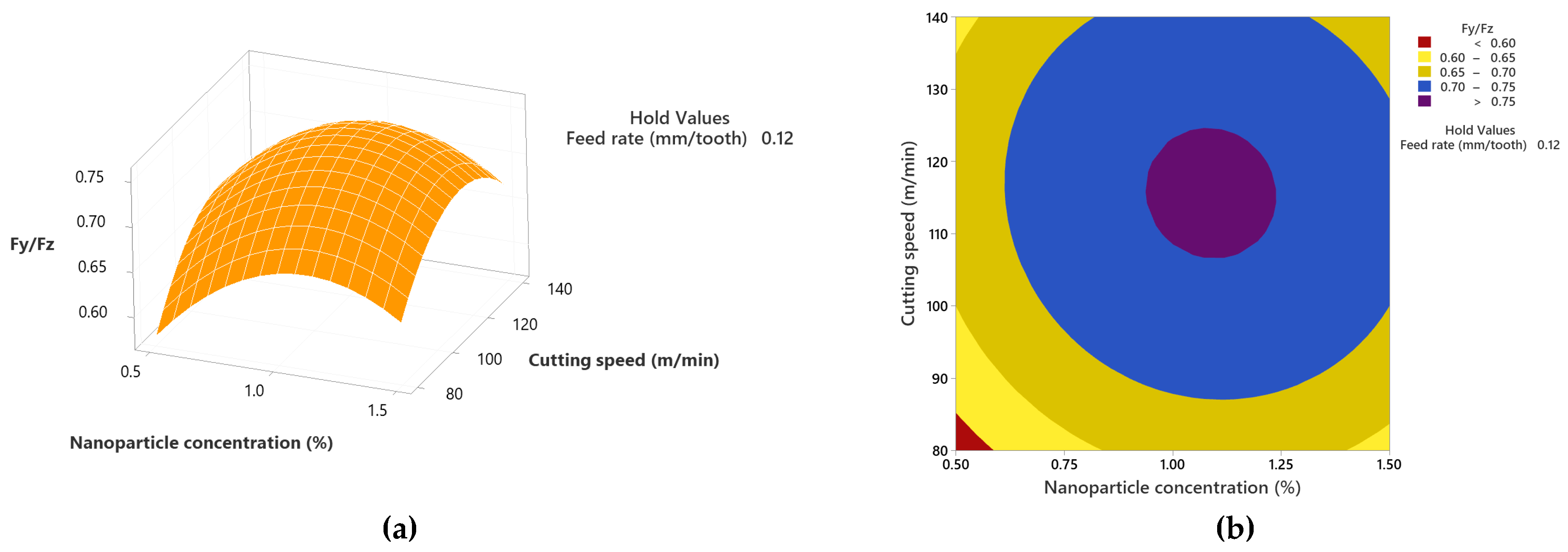

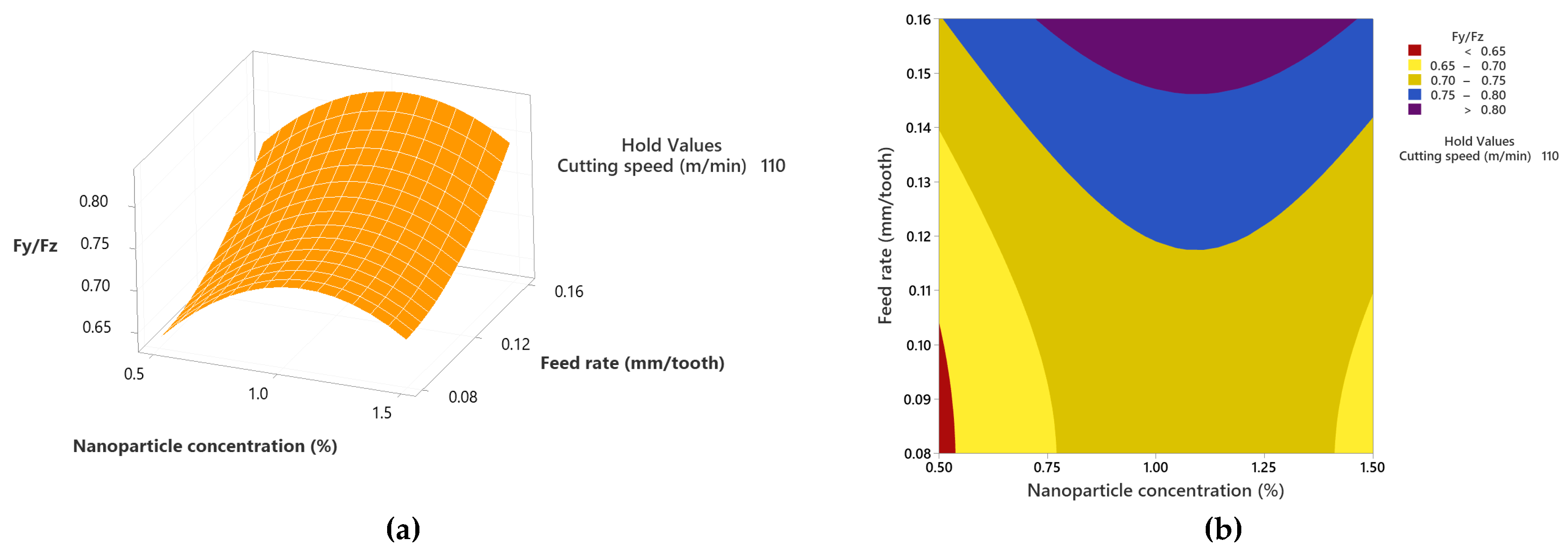

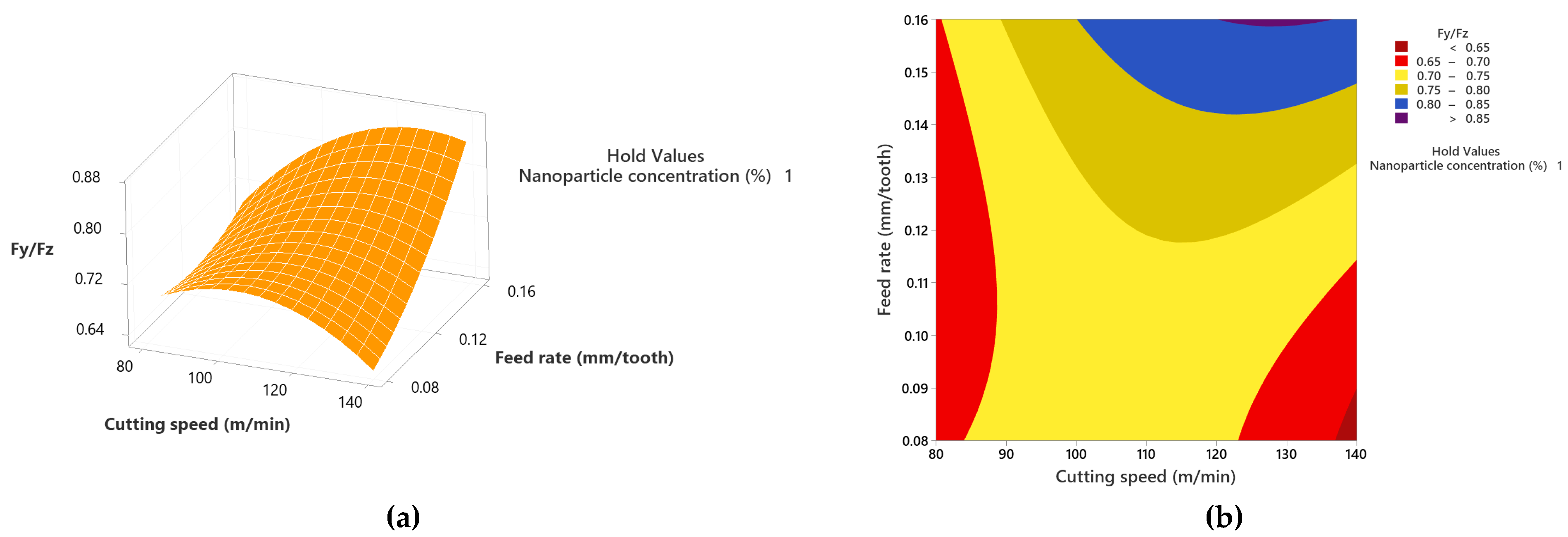

For the cutting force coefficient

Fy/

Fz in

Figure 7, the impacts of

NC and

v are similar. In the case of the rise in

NC from 0.5% to 1.1% and

v from 80 m/min to 115 m/min, the cutting force coefficient increased and reached a peak. This coefficient decreased when

NC further increased to 1.5% and

v reached 140 m/min. At the same time, the cutting force coefficient

Fy/

Fz rapidly increased with the growing feed rate. This indicates that the increasing rate of the axial thrust component

Fy is faster than that of the tangential force

Fz. This phenomenon reflects the impact of the high strength and high toughness of Hardox 500 steel which has a significant influence on the cutting force variation. Also, it causes elastic deformation affecting

Fy. The smaller the cutting force coefficient

Fy/

Fz, the more favorable the chip formation process is. However, if this coefficient is large, the process of chip formation is difficult, causing vibration and dimensional errors [

39]. Therefore, the study of the cutting force coefficient

Fy/

Fz is significant in the efficiency evaluation of the cutting process as well as choosing reasonable technological conditions.

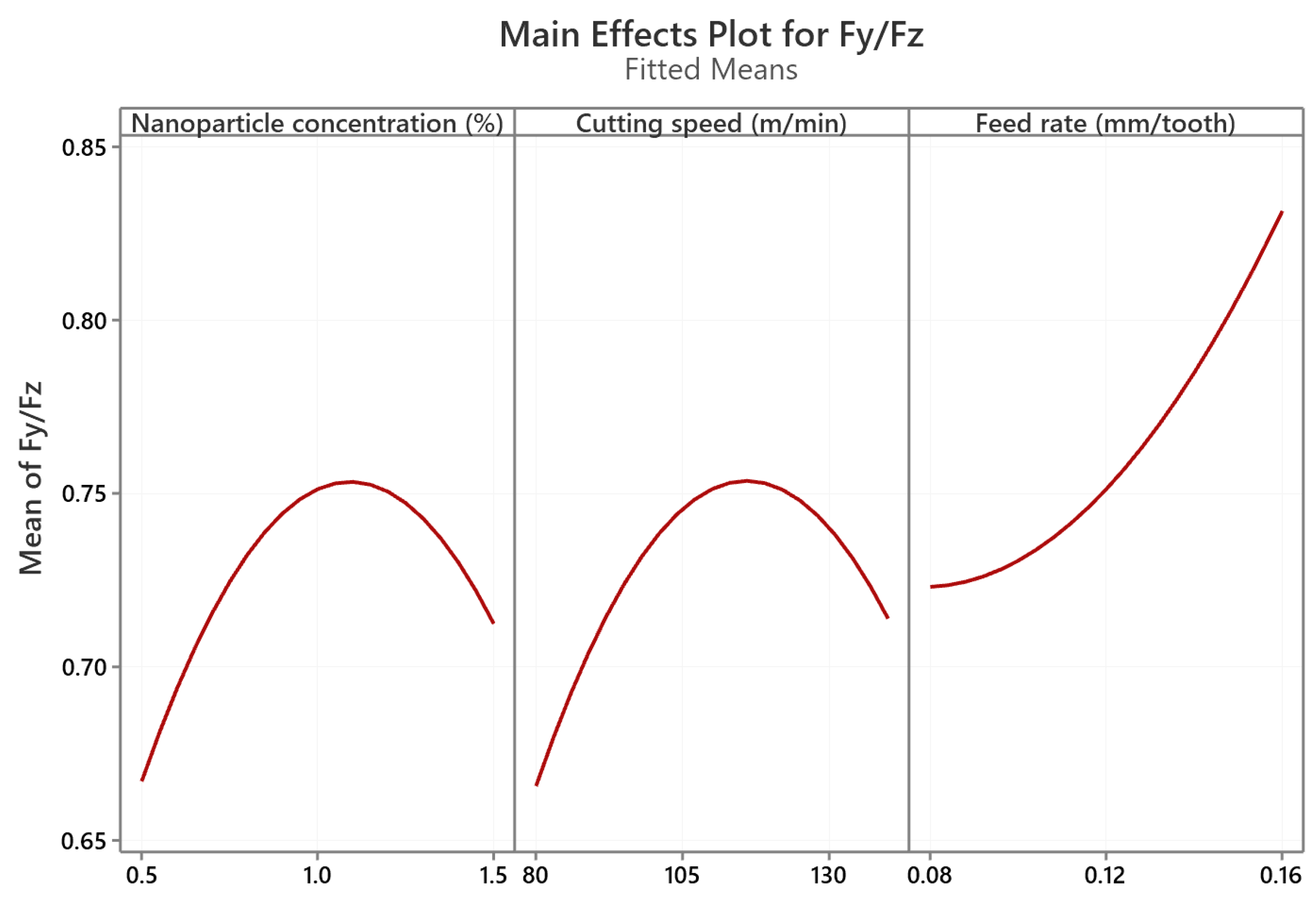

The effects of the surveyed factors on the total cutting force values are shown in

Figure 8,

Figure 9 and

Figure 10. In

Figure 8, for

f = 0.12 mm/tooth, it can be observed that a low concentration of nanoparticles combined with a medium cutting speed will result in the smallest total cutting force (

Figure 8a). Specifically,

NC = 0.55–0.70% and

v = 109–115 m/min should be used to achieve a total cutting force

F < 200 N (

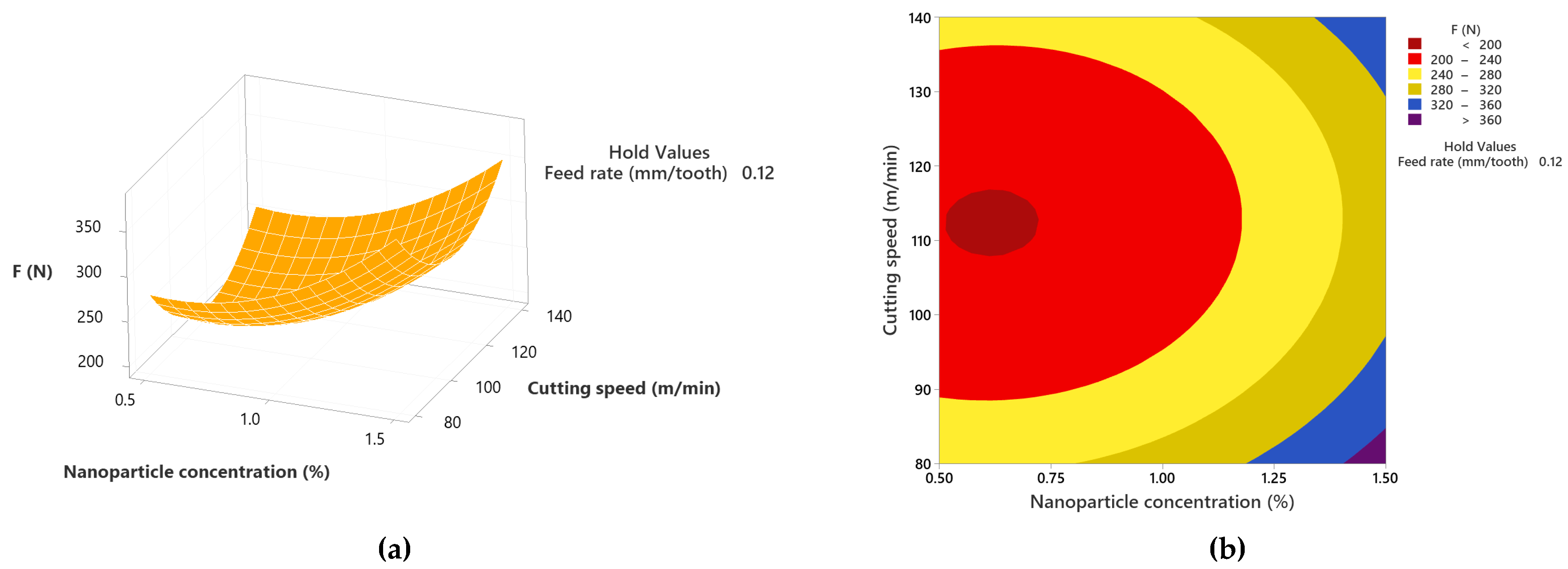

Figure 8b). For

v = 110 m/min, a feed rate of

f = 0.08–0.12 mm/tooth and

NC = 0.5–1.3% are recommended to achieve the total cutting force

F < 200 N (

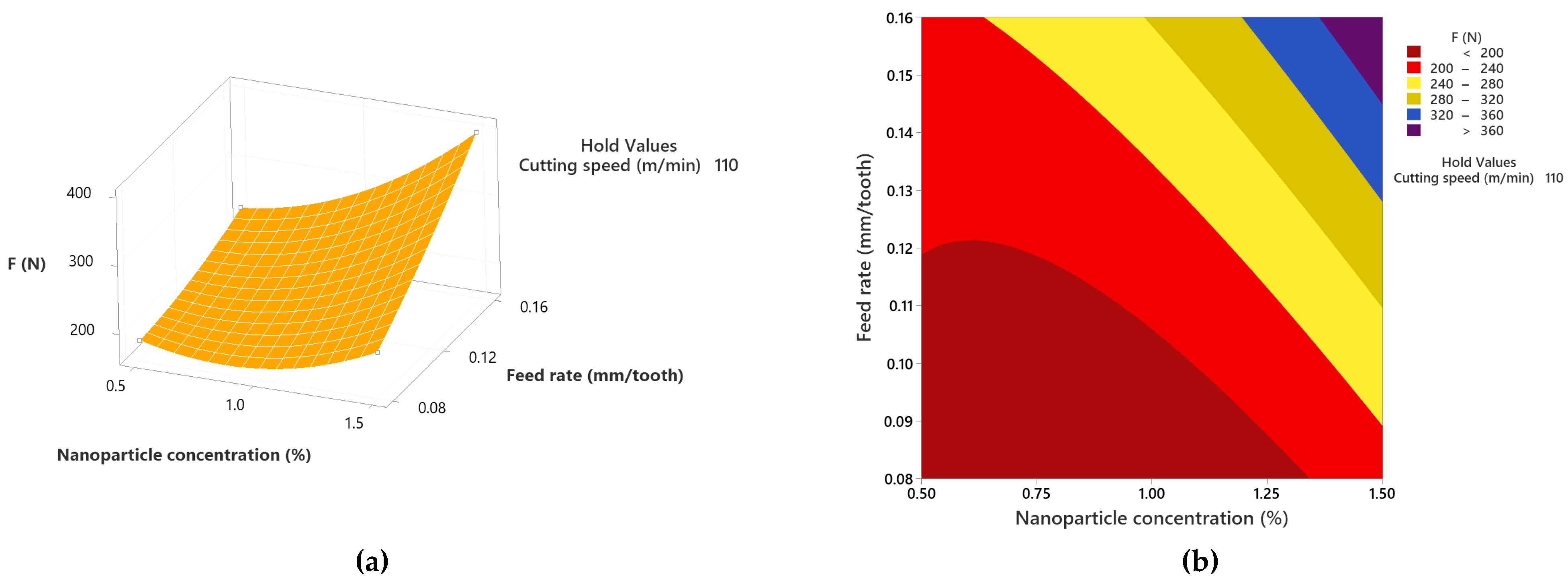

Figure 9). For

NC = 1.0%, a feed rate of

f = 0.08–0.10 mm/tooth and

v = 95–135 m/min are suggested to achieve a total cutting force

F < 200 N (

Figure 10).

Thus, for the requirement of smaller cutting forces, the reasonable ranges of NC = 0.5–0.7%, v =110–115 m/min, and f =0.08–0.10 mm/tooth can be selected for F < 200 N.

The impacts of the surveyed factors on the cutting force coefficient

Fy/

Fz are shown in

Figure 11,

Figure 12 and

Figure 13. In

Figure 11, for

f = 0.12 mm/tooth, the plot indicates that a low concentration of nanoparticles combined with a low cutting speed will give the smallest cutting force coefficient (

Figure 11a). Specifically,

NC = 0.5% and

v = 80–85 m/min are selected to achieve

Fy/

Fz < 0.6 (

Figure 11b). In the case of

v = 110 m/min, the feed rate

f = 0.08–0.10 mm/tooth and

NC = 0.5% are used for the cutting force coefficient

Fy/

Fz < 0.65 (

Figure 12). If

NC is kept fixed at 1.0%, a feed rate of

f = 0.08–0.09 mm/tooth and

v = 138–140 m/min are chosen to reach a smaller

Fy/

Fz (

Fy/

Fz < 0.65) (

Figure 13).

Accordingly, NC = 0.5%, v = 138–140 m/min, and f = 0.08–0.09 mm/tooth are the reasonable ranges and are selected to achieve a smaller cutting force coefficient Fy/Fz.

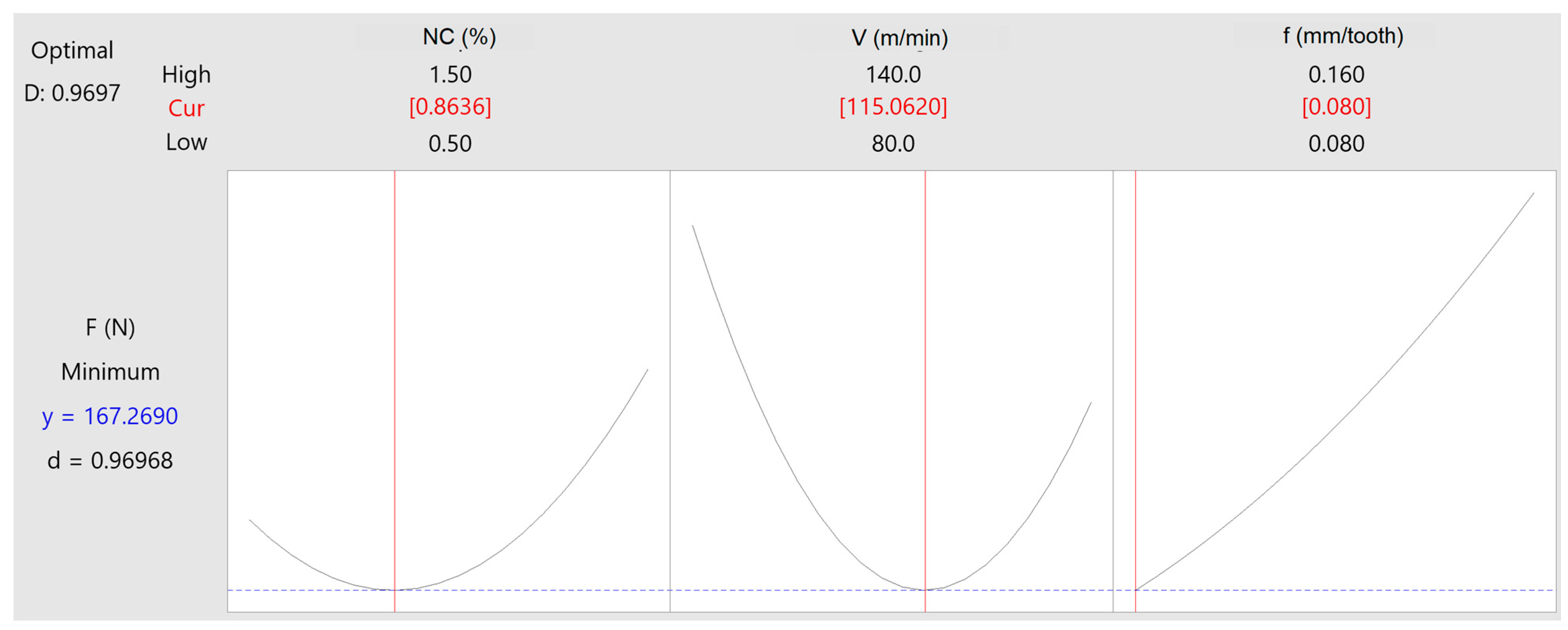

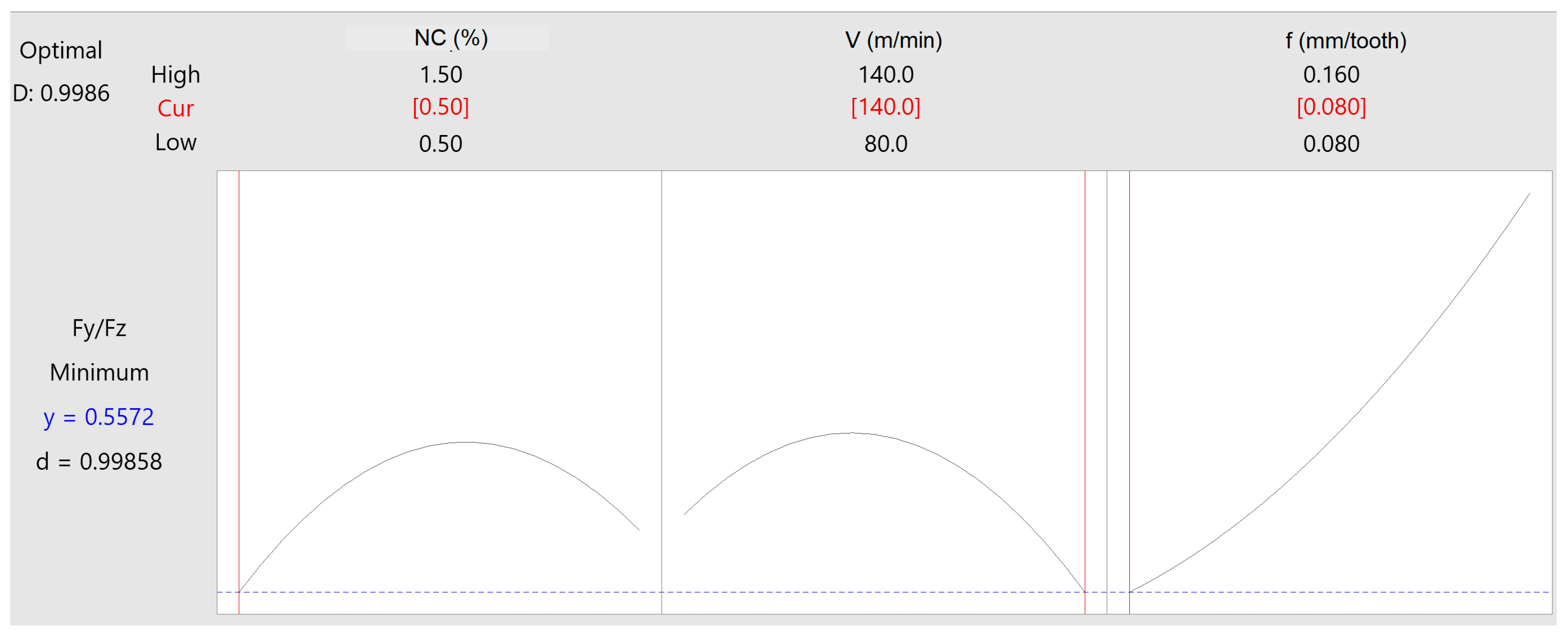

Through the obtained results shown in the surface and contour graphs, the selection process for the technological parameters will be quickly performed to achieve the desired output values. However, to obtain the exact values, optimization is needed. The optimization results for each output variable including the total cutting force

F and the cutting force coefficient

Fy/

Fz are given in

Figure 14 and

Figure 15. In

Figure 14, the optimal value set

NC = 0.8636%,

v = 115.0620 m/min, and

f = 0.08 mm/tooth is determined to achieve the smallest total cutting force value

F = 167.2690 N. For convenience in practical application,

NC = 0.9%,

v = 115 m/min, and

f = 0.08 mm/tooth are used. In

Figure 15, the optimal value set

NC = 0.5%,

v = 140 m/min, and

f = 0.08 mm/tooth is determined to achieve the smallest cutting force coefficient value

Fy/

Fz = 0.5572.

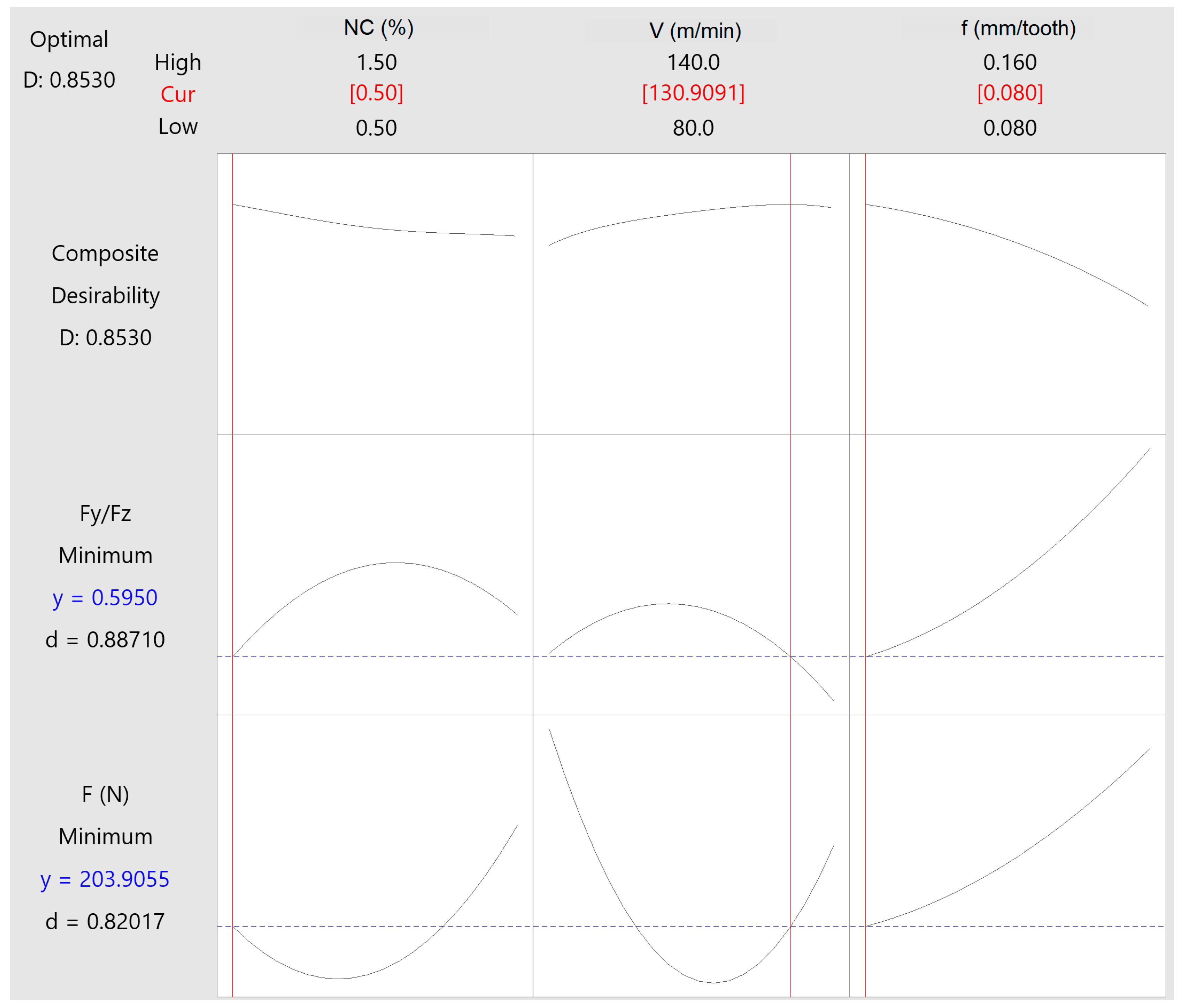

Figure 16 illustrates the result of multi-objective optimization for the responses including the total cutting force and cutting force coefficient. In order to simultaneously achieve the smallest total cutting force (

F = 203.9055 N) and cutting force coefficient (

Fy/

Fz = 0.5950),

NC = 0.5%,

v = 130.9091 m/min, and

f = 0.08 mm/tooth are determined to be the optimal set. For practical application,

NC = 0.5%,

v = 131 m/min, and

f = 0.08 mm/tooth are chosen.

4. Conclusions

In the presented work, the influences of Al2O3/MoS2 hybrid nano cutting oil on the hard milling performance of Hardox 500 steel were investigated. The effects of the input parameters (nanoparticle concentration, cutting speed, and feed rate) on the total cutting force F and cutting force coefficient Fy/Fz were studied and evaluated. The main contributions of the study are summarized as follows:

Al2O3/MoS2 hybrid nano cutting oil promoted the lubricating and cooling advantages of the nanoparticle component, hence contributing to improvement of the cooling lubrication capacity of the base cutting oil as well as the machinability of coated carbide inserts. Specifically, the cutting speed was increased from 50–55 m/min as recommended by the manufacturer to 130–140 m/min in the hard milling of Hardox 500 steel (49–50 HRC). Furthermore, the applicability of vegetable oil is extended to the hard milling, which contributes to ensuring sustainability.

Among the investigated parameters, the feed rate has the greatest influence on the total cutting force and cutting force coefficient. Additionally, it was noticeable that the nanoparticle concentration significantly influences the total cutting force

F, while for the cutting force coefficient

Fy/

Fz, the second-order interaction of nanoparticle concentration shows a significant effect. The force component

Fz is the tangential force and is the active force, while the force component

Fy is the passive force, caused by the elasticity of the workpiece and the technological system. This coefficient has a great influence on tool wear and machined-surface quality and causes dimensional errors. In particular, in grinding or machining hard materials and difficult-to-cut materials, this coefficient not only reflects the magnitude ratio of these two force components but can also be used as a criterion to indirectly evaluate the machinability, flank wear, and tool life [

39,

40].

The reasonable technological guidelines for achieving the smaller total cutting force F and cutting force coefficient Fy/Fz are provided. Specifically, NC = 0.5–0.7%, v = 110–115 m/min, and f = 0.08–0.10 mm/tooth are suitable and are chosen for the smaller total cutting force F. Meanwhile, NC = 0.5%, v = 138–140 m/min, and f = 0.08–0.09 mm/tooth should be suggested to achieve the smaller cutting force coefficient Fy/Fz. In addition, the cutting force coefficient Fy/Fz has practical significance in evaluating the machinability and monitoring the wear condition of cutting tools because cutting forces can be directly measured and monitored continuously during the cutting process while wear measurements can only be performed by stopping the cutting process and removing the cutting inserts.

Single-objective and multi-objective optimization was performed to determine the optimal set of values for the investigated parameters. These optimal sets provide the valued guidelines for further studies and practical applications.

In future studies, further investigations should focus on the feed force Fx and the ratios of Fx/Fz and Fx/Fy. Also, tool wear, tool life, and wear mechanisms under MQCL using nano hybrid cutting oil require further study.