Abstract

Laser-boronized parts manufactured by a selective laser melting process from 18Ni to 300 maraging steel are investigated in this study. Two main issues are addressed, namely (i) the possibility to restore the hardness of the heat-affected zone (HAZ) formed during laser processing and (ii) the effect of re-aging on the hardness and wear resistance of the laser-boronized layer with a hypoeutectic structure. Optical microscopy, scanning electron microscopy, energy-dispersive spectroscopy, X-ray diffraction analysis, microhardness measurements, the “ball-on-plate” dry sliding test, and the two-body dry abrasive wear test were employed to answer the questions. The results confirmed that HAZ is formed with the dissolution of intermetallides formed before and undergo full (near the molten pool) or partial (at some distance from the molten pool) iron–base matrix recrystallization. The hardness of HAZ (350–550 HK0.05) has been restored after re-aging to the 550–600 HK0.05 level. Moreover, a certain positive effect of re-aging on the laser-boronized layer with a hardness of ~470–750 HK0.2 is established, associated with structural transformations induced by aging in the iron-based solid solution phase. The hardness increased by ~9–25%. The wear resistance of the hardest boronized samples (~750 HK0.2) under dry sliding and dry abrasive wear conditions was ~5.8 times and 3.7 times higher than that of the aged control sample, while re-aging provided further improvement of these characteristics. The presented results provide insights into the effectiveness of laser-boronized layers having a hypoeutectic structure in terms of increasing the wear resistance of maraging steel.

1. Introduction

The surface modification of metal components plays a crucial role in the improvement of their performance characteristics, for example, hardness, wear resistance, and corrosion resistance. Conventional thermochemical methods, including boriding, nitriding, and carburizing, are commonly used to achieve such improvements. These processes require the diffusion of elements such as boron, nitrogen, or carbon into the surface layer of the material at high temperatures, which consumes time and energy [1]. Boriding, for illustration, is typically carried out at temperatures between 700 °C and 1000 °C for several hours to form a boride layer [2]. There are not any laws that outright ban energy-intensive thermochemical metal treatments, but tightening environmental rules, efficiency standards, and economic pressures are steering industry toward cleaner, more energy-savvy alternatives. With energy costs increasing and regulations growing stricter, finding sustainable manufacturing methods has never been more important.

Recent progress in laser technology has introduced new applications for surface modification. Laser-based alloying stands apart from other methods by its advantages, including local processing, which minimizes energy consumption and thermal deformation, as well as the possibilities to precisely control the composition and depth of the modified layer [3,4]. Furthermore, laser processes are characterized by high speed and flexibility, making them suitable for a wide range of applications. Such characteristics make laser alloying a perspective method for hardening steel surfaces, especially in applications where high precision and efficiency are required.

Maraging steels (MSts) investigated in the present paper are a specific class of high-strength, highly ductile alloys widely used in the aerospace, tooling, and casting industries through their outstanding mechanical properties. Specifically, 18Ni-300-grade steel is characterized by low carbon content (≤0.03%) and high nickel content (18%), with additions of cobalt (9%), molybdenum (4.8%), titanium (0.6%), and aluminum (0.1%) [5,6]. This composition ensures an outstanding weldability, making this steel an ideal candidate for additive technologies such as selective laser melting (SLM) [7,8,9], which has led to increased interest in such steels recently.

The most recent papers primarily focus on identifying optimal manufacturing parameters to enhance the microstructure and sub-microstructure and improve the properties of additively manufactured (AM) maraging steel (MSt) parts [10]. Particular attention is paid to the optimization of the heat treatment stage, which allows for achieving maximum mechanical characteristics [11]. Furthermore, the combination of MSt with other steel grades, for example, possessing corrosion resistance [12] and hardening phases such as TiC [13], is investigated to enhance the performance of AM parts. The surface processing is studied largely to improve the overall quality of the 18Ni-300 steel surface after SLM fabrication by reducing typical defects such as pores and cracks [14]. At the same time, the authors of [11] note the need for surface hardening for effective use in wear conditions. However, nitriding remains the main technology used [15], and data on alternative methods are critically lacking.

Maraging steels such as 18Ni-300, despite their high strength, frequently demonstrate insufficient wear resistance for responsible applications. Thermochemical nitriding has traditionally been used to increase the surface hardness of such steels to reach levels as high as 70 HRC or 900 HV, as found in early studies [2,16,17,18]. However, this process is time-consuming and expensive, often requiring hours or even days of treatment at increased temperatures (e.g., 430–520 °C for 10–90 h, depending on the requested layer thickness). Laser alloying, such as laser boriding, is being explored as a perspective alternative. This method involves rapid localized laser melting of the surface in the presence of boron, which significantly reduces processing time and energy consumption compared to nitriding.

An application of laser boriding in 18Ni-300 steel fabricated by SLM was investigated in our previous study [19]. The process involved depositing a paste of amorphous boron on the steel surface and using a continuous fiber laser for melting the surface, which ensured the incorporation of boron into the iron-based matrix and formation of borides. The results demonstrated a significant increase in hardness and wear resistance: boronized layers achieved hardness up to 2200 HK0.2, providing visible improvement in wear resistance compared to aged samples fabricated by the SLM process. However, the study revealed two major problems, namely the formation of cracks in the boronized layers and the formation of a heat-affected zone (HAZ) with significantly reduced hardness. The cracks were due to the brittleness of the higher borides and thermal stresses, while the softening of the HAZ was assumed to be due to the dissolution of hardening phases and formation of reverted austenite.

These problems are further investigated in the present study focusing on re-aging, which is expected to restore the strength of the HAZ by the re-deposition of hardening phases. Furthermore, laser-boronized surfaces with a hypoeutectic structure are investigated after re-aging. As was shown earlier [20], at a certain mixing ratio of boron paste and base metal, a boronized layer with hypoeutectic structures can be obtained that is less prone to cracking due to the reduced content of brittle boride phases but possesses increased hardness if compared to an aged SLM part.

Maraging steels obtain their strength by the precipitation of intermetallic compounds during their aging. Laser treatment can dissolve these precipitates in the HAZ, which results in a reduction in strength. Re-aging should regenerate the structure of the precipitates and, consequently, the mechanical properties of the base material. Since the aging temperature for maraging steels is typically around 480–500 °C, which is lower than the temperatures of boride dissolution, it is likely that the boride layer will remain stable during this treatment. Previous studies confirm that aging at such temperatures can significantly improve the hardness and strength of martensitic-aged steels fabricated by additive manufacturing due to the deposition of intermetallic phases [19,20,21,22].

This investigation focuses on improving the knowledge of the effects of re-aging on the properties of laser-boronized surfaces with a hypoeutectic structure. Particular attention is paid to the recovery of the hardness of HAZ, formed after the laser boronizing of parts with a specific structure obtained during SLM manufacturing. Furthermore, the potential changes in the hardness and wear resistance of the boronized surface layer after re-aging are investigated. Such new results have important implications for the optimization of surface modification processes for additively fabricated maraging steels, which may expand their application in high-tech industries.

2. Materials and Methods

2.1. Materials and Sample Manufacturing

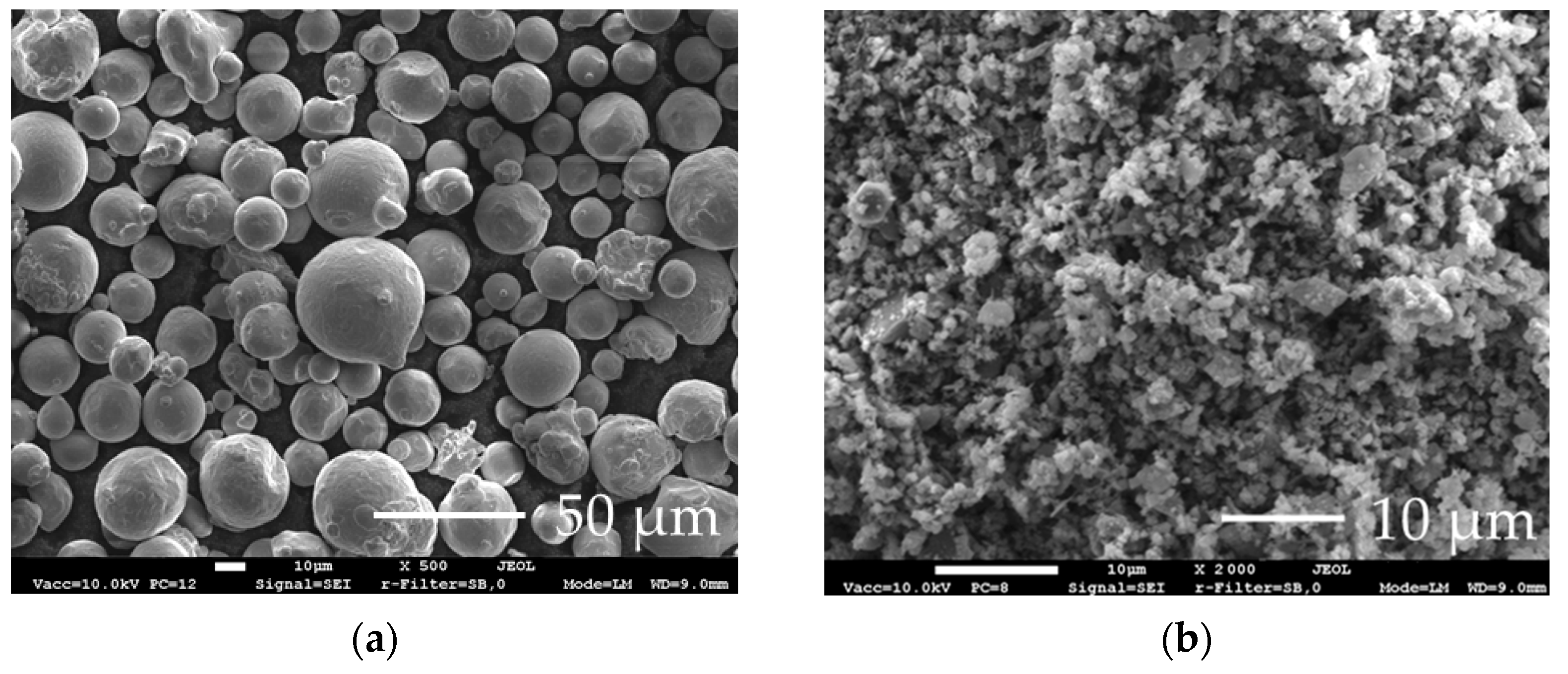

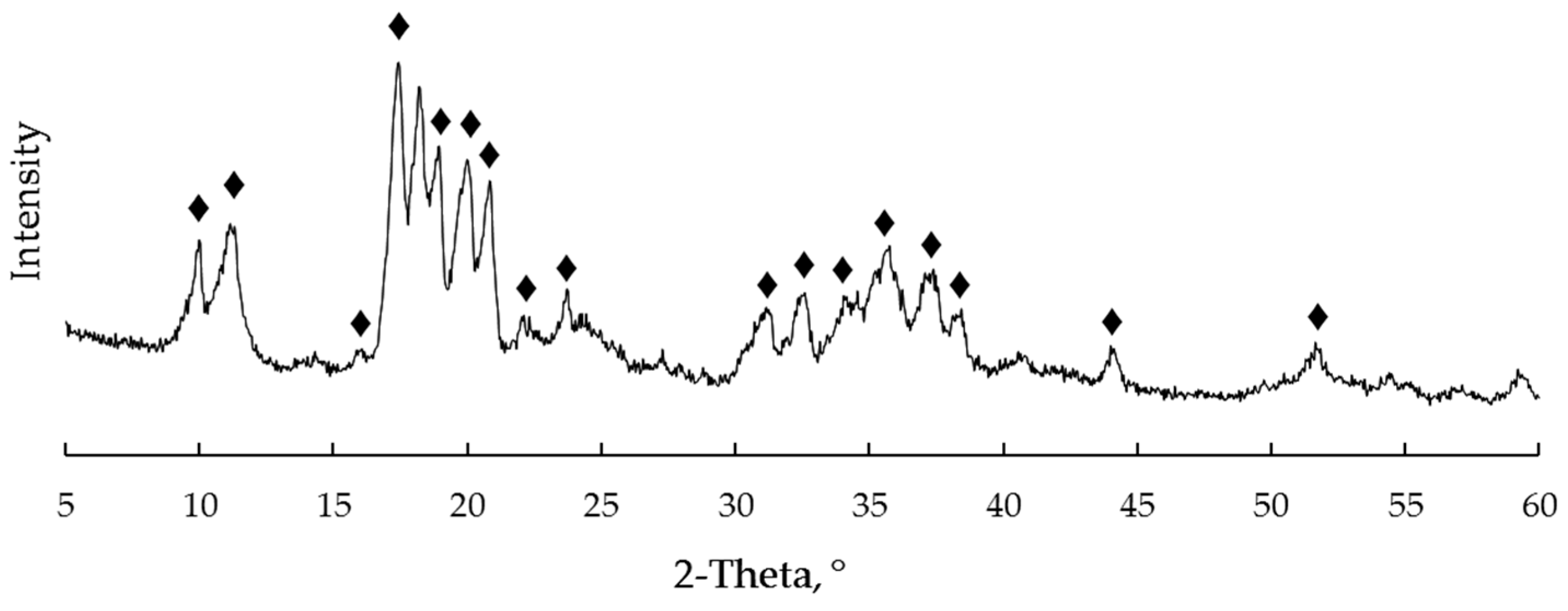

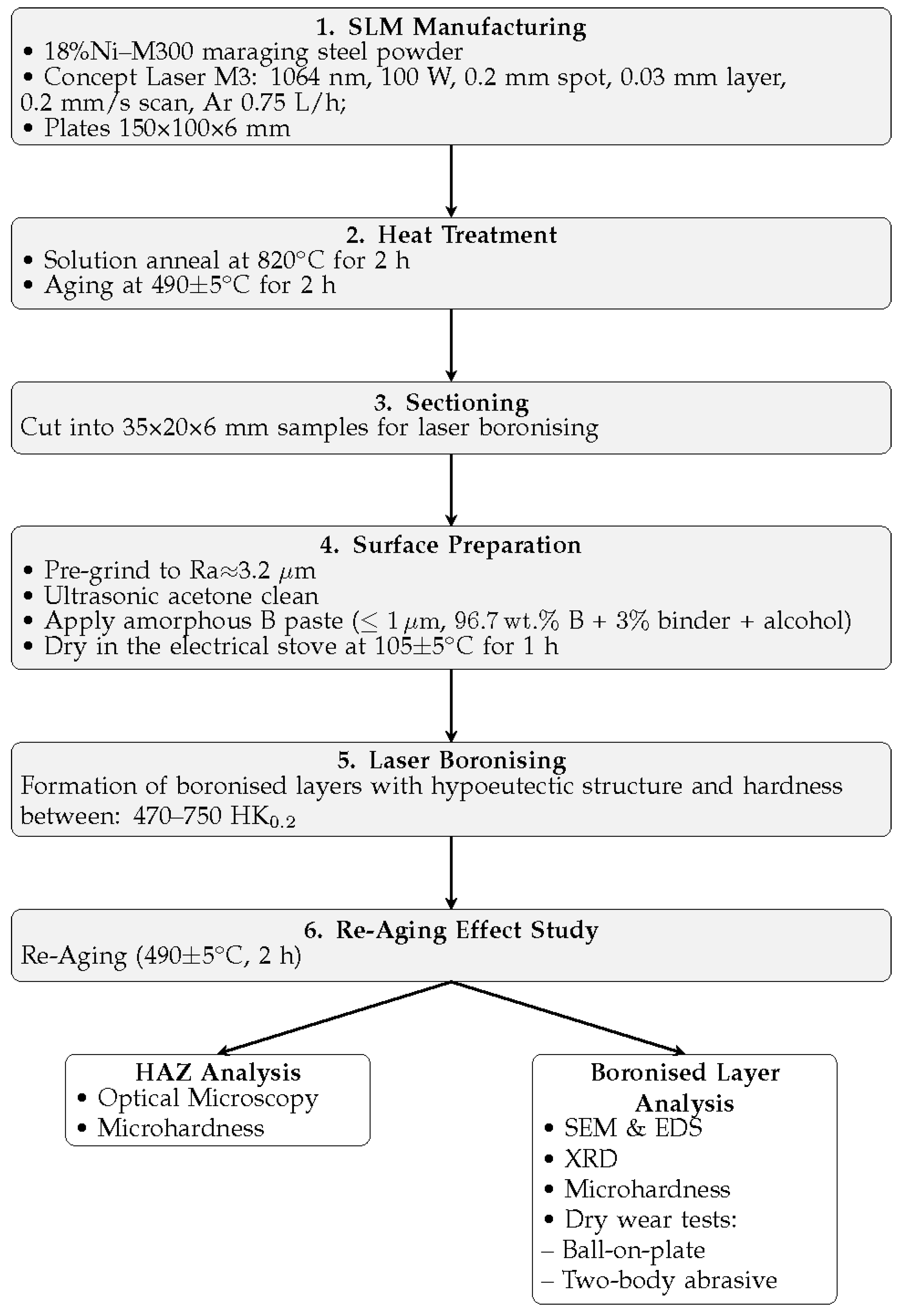

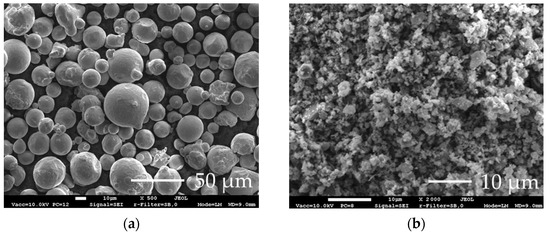

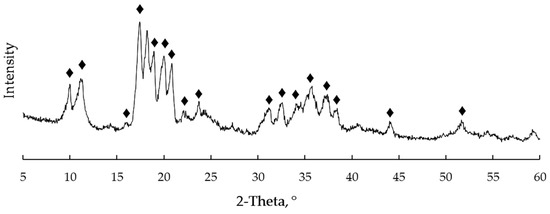

Maraging steel 18Ni-300 was chosen for this study as one of the most widely used and commercially available maraging steel grades. Samples manufactured by the selective laser melting (SLM) using Concept Laser M3 equipment (Concept Laser GmbH, Lichtenfels, Germany) were used in experiments. The chemical composition of steel powder is (in wt.%) C 0.03%; Si < 0.1%; Mn < 0.1%; Ni (17–19)%; Mo 4.8%; Ti < 0.8%; Co (8.5–9.5)%; Al < 0.1%; and Fe—balance. Powder with particles sized from 7 to 30 μm was used (Figure 1a). The parameters of SLM were as follows: laser wave length—1064 nm; laser power—100 W; laser spot size—0.2 mm; thickness of single layer—0.03 mm; sintering rate—0.2 mm/s; shielding gas—Ar 0.75 L/h. Plates that were 150 mm × 100 mm × 6 mm in size were manufactured by SLM; then, 35 mm × 20 mm × 6 mm samples were cut out for laser boronizing (LB). The “chessboard” scanning strategy [23] was used in the SLM process. Before the LB, samples were pre-ground (providing roughness Ra ≈ 3.2 μm and the adhesion of boron paste was good enough to avoid its delamination during laser processing), washed with acetone in an ultrasound bath, covered with boron paste, and dried in an electrical stove at 105 ± 5 °C for 1 h. Amorphous boron powder from Sigma-Aldrich was used (color—very dark brown; particle size ≤ 1.0 μm; 96.7 wt.% B) (Figure 1b). The XRD pattern of the used boron powder showed mostly reflections attributable to rhombohedral B modification (Figure 2). Wide peaks and the halo on the diffraction curve indicated the amorphous nature of the powder and presence of the amorphous phase in the powder. The paste was prepared by mixing boron powder with 3% organic binder and then with alcohol to obtain a fluid consistency.

Figure 1.

Morphology of MSt powder (a) and boron powder (b) used in the study (by SEM).

Figure 2.

XRD pattern of boron powder used: ♦—rhombohedral boron.

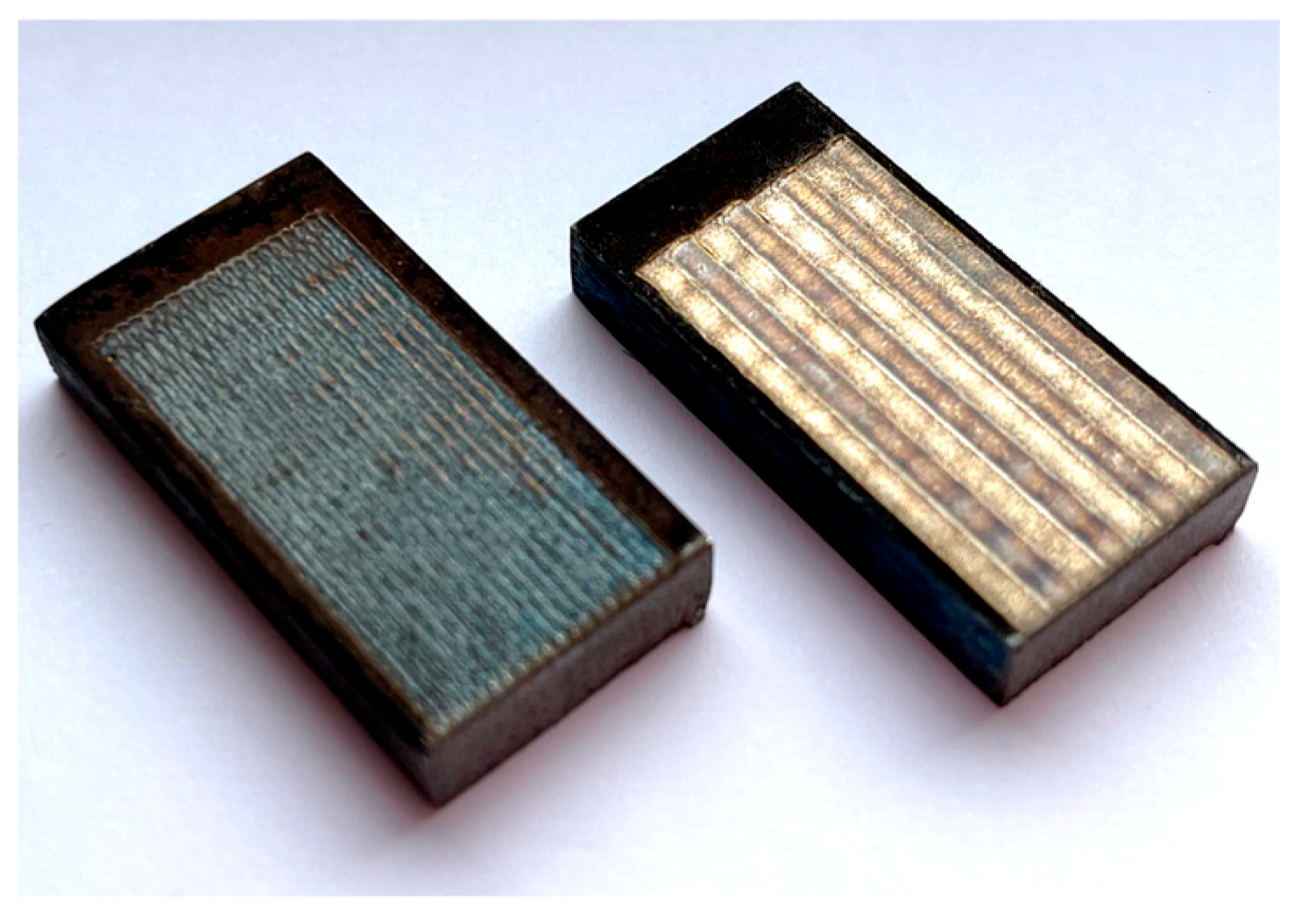

Laser boronizing was performed using a fiber laser machine FANUCI® PRO 1500 (Fanuci, Gdansk, Poland) with a single-module optical fiber laser source and a wavelength of 1070 nm. For the present study, several samples were selected with a hypoeutectic structure of a boronized layer and microhardness from ~470 to ~730 HK0.2 (before aging), which were obtained without and with laser beam oscillation (Table 1). Principal parameters of laser processing were as follows: 300 W laser power; 1.0 mm spot size; 500–1500 mm/min laser speed; 120 Hz oscillation frequency (when oscillation was applied); and 0.4–1.5 mm step between adjacent laser paths. A linear bidirectional laser scanning strategy and simple transverse oscillation mode were applied. The examples of the obtained laser-boronized samples and general view of boronized layers are presented in Figure 3. The sequence of the experiment stages is shown in the schema (Figure 4).

Table 1.

Parameters of laser boronizing process and sample designation.

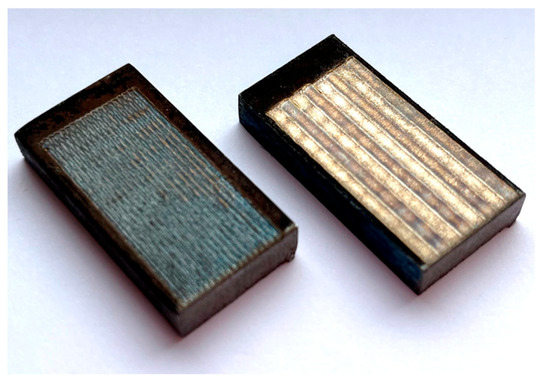

Figure 3.

General view of the laser-boronized samples (35 mm × 20 mm × 6 mm) without (left) and with (right) laser beam oscillation.

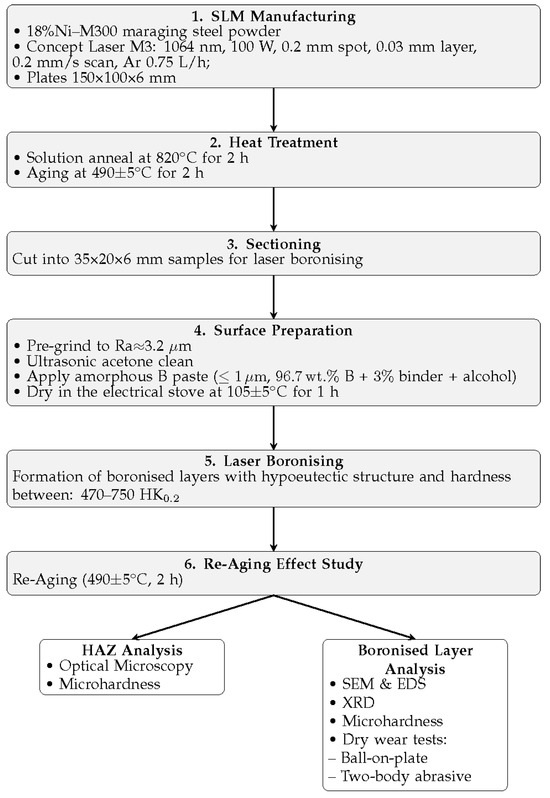

Figure 4.

Summary of the study.

2.2. Testing Methods

For microstructural analysis, an analytical optical microscope Nikon ECLIPSE MA200 (Nikon, Tokyo, Japan) and scanning electron microscope SEM JEOL JSM-7600F (JEOL, Akishima, Japan) equipped with an energy-dispersive spectrometer Inca Energy 350 SDD X-Max 20 mm2 (Oxford Instruments, Oxford, UK) for X-ray microanalysis were used. The phase composition of the coatings was analyzed by means of X-ray diffractometer Dron-7 equipped with an X-ray tube with a Cu anode. The measurements were made using Bragg–Brentano geometry with a scanning step of 0.02° (in 2θ scale) and a counting time of 2 s per step.

The microhardness measurements were performed in polished cross-sections of the samples with a “Zwick Roell ZHμ” universal automated hardness tester (Zwick-Roell GmbH & Co. KG, Ulm, Germany). The Knoop method was applied. To evaluate the average microhardness of laser-boronized layers before and after aging, a 200 g load and a 15 s duration were used. To assess the microhardness depth profile (including the boronized layer, HAZ, and non-affected parent metal), the indentation with a 30 µm step was performed applying a 50 g load and 15 s duration.

The tribological characteristics of the laser-boronized layer before and after aging was determined through the “Ball-on-disc” dry sliding test using a Microtest tribometer. Before testing, the surface of the samples was pre-polished to Ra ~0.46 μm. Profilometer TR-200 was used for the roughness control of the surfaces to be tested, with a measurement accuracy ± 0.01 μm. The counter-body used was a 6 mm diameter ball made of steel AISI 52100 (following the recommendations of ASTM G99-23 [24]). The other test parameters were as follows: sliding distance—200 m; sliding speed—100 rpm; rotation mode of the test; radii of a sliding trajectory—4.5 mm; load—20 N; temperature—22 ± 1 °C; relative humidity—31 ± 1%; and laboratory air. The wear of the samples was evaluated by mass losses. The samples were weighed before and after testing using an analytical balance Vesi Radwag AS/220.R2 with an accuracy of 0.00001 g. Before mass measurements, samples were washed in alcohol in an ultrasonic bath for 5 min and dried in a hot air stream. The wear intensity was calculated as the mass loss divided by the sliding distance and expressed in μg/m. Wear resistance was calculated by dividing the sliding distance by the mass loss and was expressed in m/μg. An arithmetic mean of three tests is given with the standard deviation. The friction coefficients were calculated after the test data for the first 30 m of the sliding distance were eliminated; the average values are presented in the paper with standard deviation.

The dry two-body abrasive wear resistance test was performed using a 2101TP machine at a 10 N load and SiC grinding paper #220 (grit size of ~58 μm) as a counter-abrasive. Two samples were tested from each batch. Each sample was tested during an 1800 m sliding distance. The abrasive paper was renewed, and the samples were weighted every 300 m using a Vesi Radwag AS/220.R2 balance with a precision of 0.00001 g. Test conditions were as follows: temperature—22 ± 1 °C; relative humidity—31 ± 1%; and laboratory air. An arithmetic mean of mass changes in two samples is given in the graphs.

3. Results

3.1. Brief Characterization of Laser-Boronized Layers

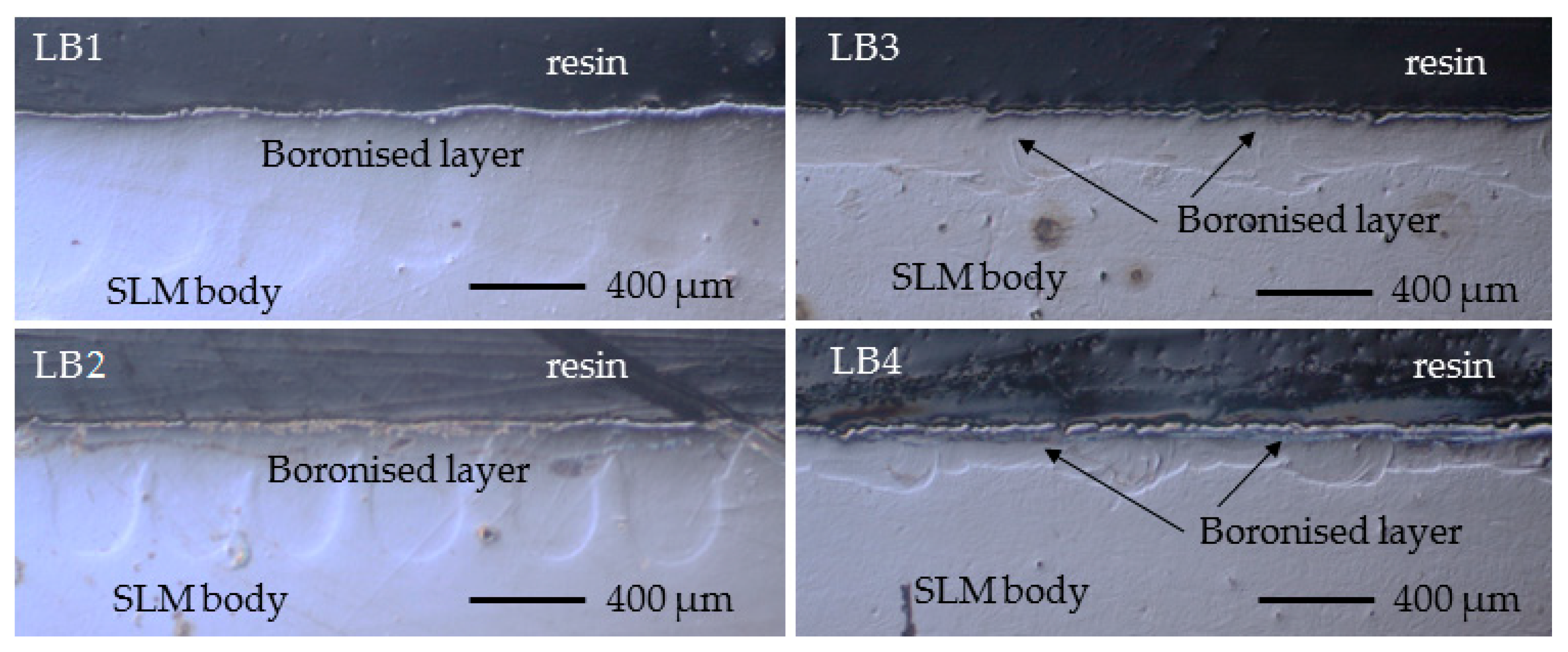

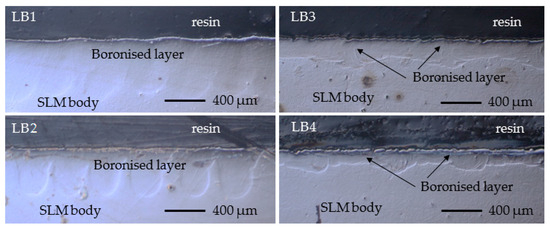

In order to assess the influence of post-aging on the laser-boronized layers, four samples were selected, each boronized under different laser processing parameters, which made it possible to produce layers with varying boride-phase contents. The overall appearance of the boronized layers is shown in Figure 5. The “saw-shaped” profile of LB1 and LB2 layers is predetermined by the parabolic geometry of the single molten pool formed without laser beam oscillation. The geometry of molten pools obtained with oscillation was different—they were wider with lower melting depth in the central part and deeper melting at the edges, which predetermined a “wavy” profile of laser-boronized layers for samples LB3 and LB4. The average depth of boronized layers LB1 and LB2, estimated by the maximum depth of a single molten pool, was 529 ± 19 µm and 427 ± 12 µm, respectively. The depth of the boronized layers LB3 and LB4, evaluated for the maximum and minimal depth of the layer, was from 165 ± 9 µm to 266 ± 9 µm and from 144 ± 4 µm to 223 ± 9 µm, respectively.

Figure 5.

Cross-sectional optical micrographs of the studied boronized samples. LB1 and LB2—laser-boronized without oscillation; LB3 and LB4—with laser beam oscillation.

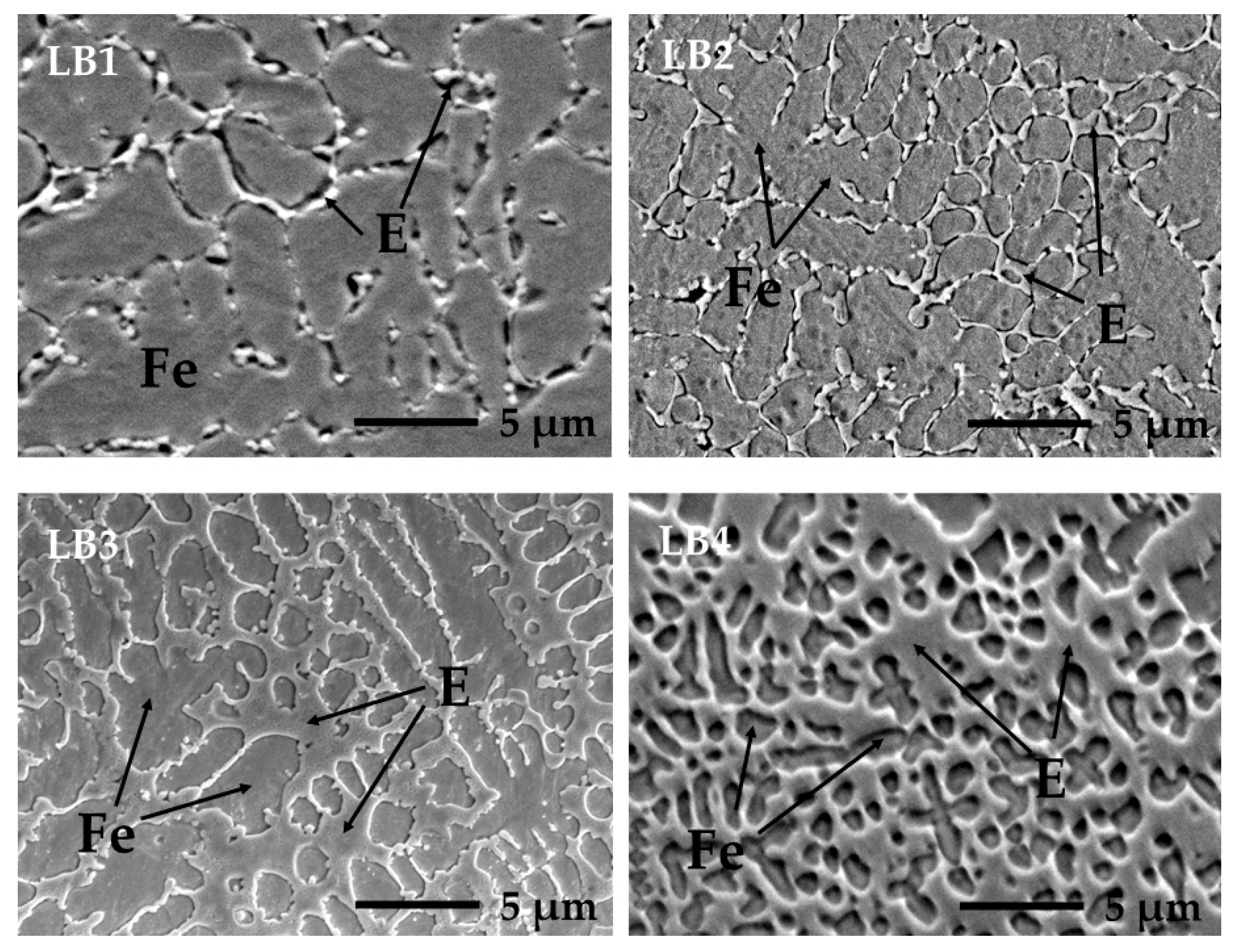

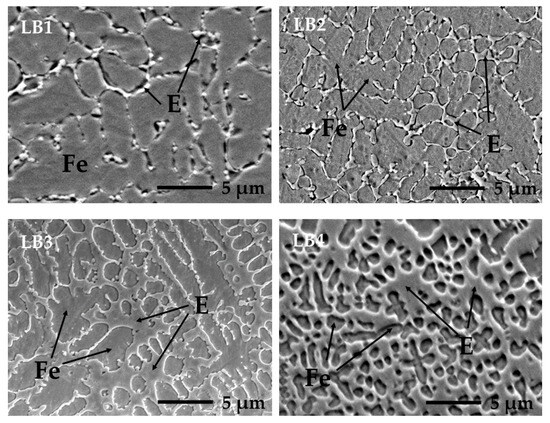

All the samples studied had a hypoeutectic microstructure consisting (as was determined in earlier work [19]) of an iron-based solid solution phase and boride-based eutectic phase. Figure 6 shows the typical observed microstructures of samples. The content of the eutectic phase increases with sample number (from LB1 to LB4), providing a corresponding increase in hardness of the boronized layer. Respectively, the following HK0.2 microhardness values were determined for the studied LB layers: 469 ± 17 for LB1, 477 ± 13 for LB2, 657 ± 55 for LB3, and 748 ± 47 for LB4.

Figure 6.

Microstructure of laser-boronized layers showing increasing amount of boride-based eutectic phase (E) in samples LB1, LB2, LB3, and LB4. Fe—iron-based solid solution.

Laser alloying with laser beam oscillation has not been studied widely before. According to the results reported for welding [25,26], it contributes to microstructure homogenization and refinement. However, at the parameters (oscillation amplitude and frequency) applied in the current study, no so-called “stirring” effect was observed, which would contribute to more homogenous distribution of the alloying component in a molten pool. The microstructure and hardness in each cross-section of the alloyed layer were found to be dependent on the melting depth at that point, which determines a mixing ratio of an alloying component and base metal. As a result, more of the eutectic phase was observed and, correspondingly, higher hardness was determined for the LB3 and LB4 layers in the areas of lower-layer depth, resulting in a wider variation in hardness for these samples.

Furthermore, a refined microstructure can be pointed out for samples LB2, LB3, and LB4, processed at a higher processing speed and by applying the oscillation mode, which introduces additional movement of the molten pool. It is well established that as the microstructure becomes finer, material hardness increases; according to the Hall–Petch relationship [27], this hardness enhancement is driven by a reduction in grain size, which could have certain effect in our case as well.

3.2. Effect of Post-Aging on HAZ

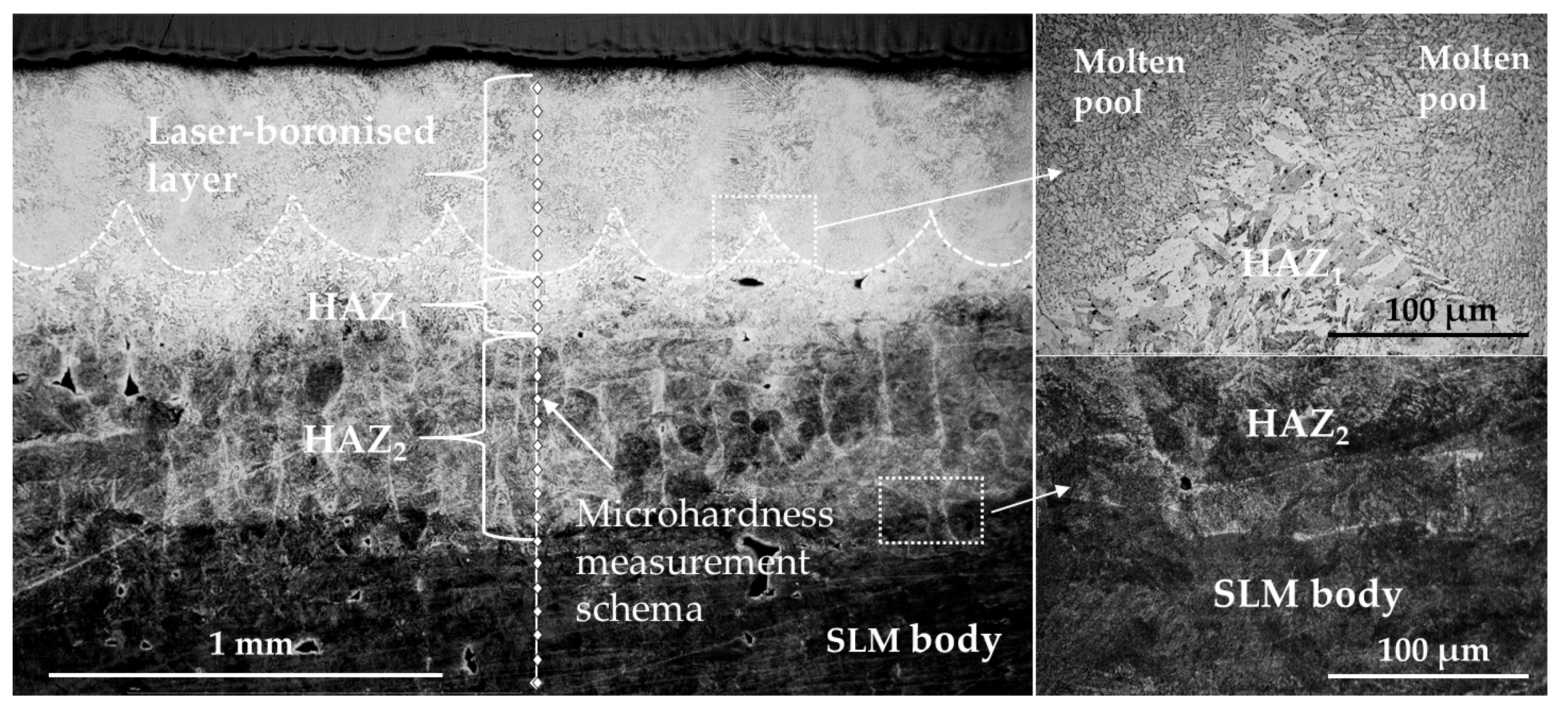

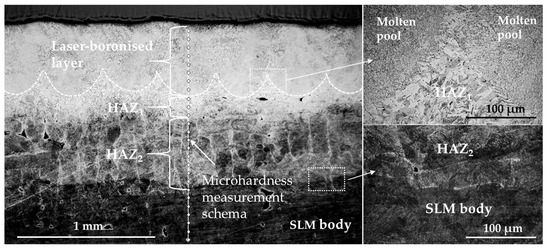

The effect of a hardness drop in the heat-affected zone after the laser processing of maraging steel was established in our earlier work [19]. According to the observed optical images, two zones were distinguished with different hardnesses, and it was assumed that the formation of those zones depends on the temperature—which is reached during the processing—below or above the austenization temperature for 18Ni-300 steel. It was also determined that the heat input, which depends on the parameters of laser processing, had a strong influence on the thickness of the HAZ formed. To establish whether it is possible to restore the hardness of the HAZ by re-aging, in this work, a sample LB1 laser-processed with a maximum heat input was selected. Figure 7 demonstrates different microstructures of HAZ1 and HAZ2 observed after etching.

Figure 7.

Cross-sectional optical micrographs of LB1 with heat-affected zones (HAZ1 and HAZ2), microhardness measurement schema, and enlarged microstructures of HAZ1 and HAZ2.

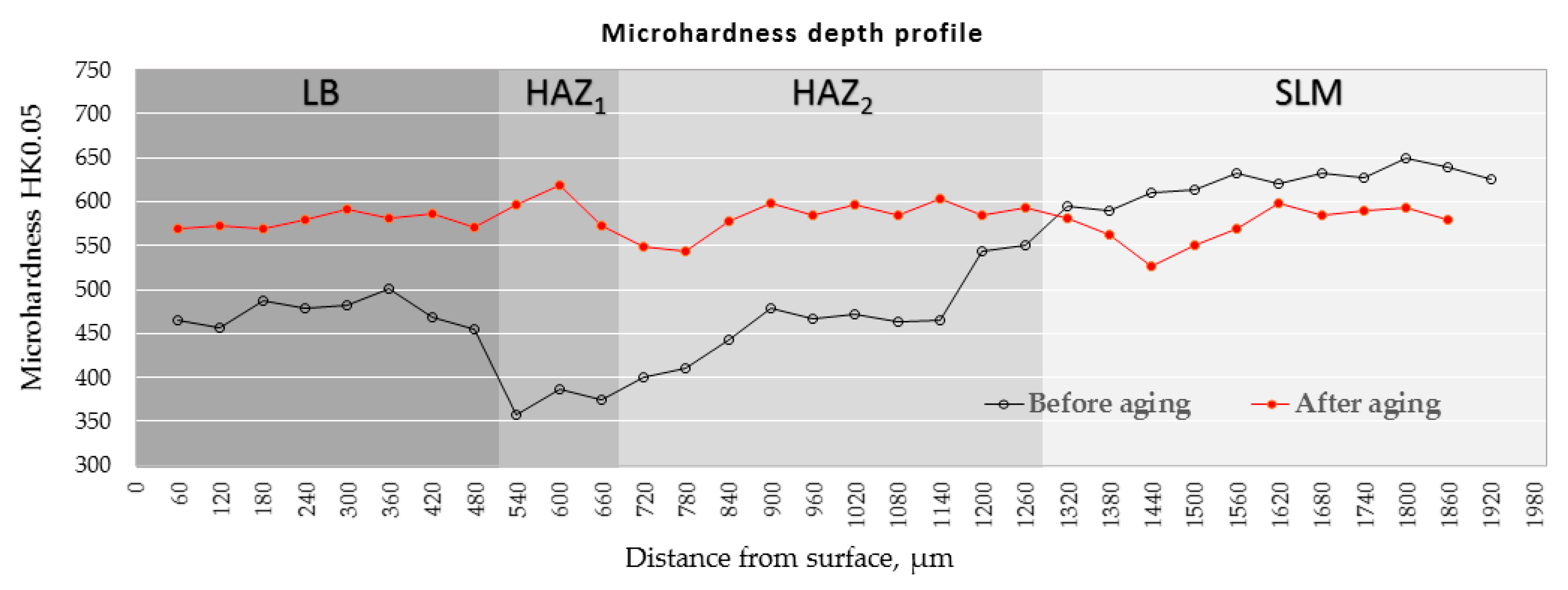

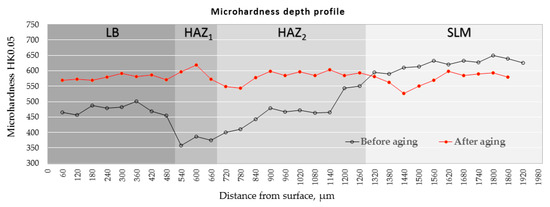

In HAZ1, the microstructure has the appearance of typical lath martensite, which corresponds to the MSt heated over the austenization temperature and then cooled. The substructure formed by the SLM process disappeared, showing full recrystallization in this zone. As was determined by the measurements (Figure 8), the microhardness of HAZ1 was ~350–380 HK0.05, which is close to 18Ni-300 steel’s hardness after solution annealing (which forms soft lath martensite) and confirms a full martensite transition to austenite, with the dissolution of hardening phases in this zone during laser processing.

Figure 8.

Microhardness depth profiles before and after aging LB1 sample. LB—laser-boronized layer; HAZ1—heat-affected zone “1”; HAZ2—heat-affected zone “2”; SLM—non-affected part of the SLM sample.

HAZ2 retained a substructure typical for an additively manufactured part, similar to the non-affected part of the sample, indicating that the material was not fully recrystallized in this zone, that is, the austenization temperature was not reached or the exposure to this temperature was too short. At the same time, it can be clearly seen that compared to the non-affected zone, there are more structural elements showing light etching in zone HAZ2, which is typical for austenite. The hardness of HAZ2 ranged from ~400 to ~550 HK0.05 and showed a gradual increase in hardness with distance from the laser-processed surface, showing a direct correlation with the distribution of temperature fields in this zone.

Sample LB1 was sectioned, and one part of the sample was heat-treated at 490 ± 5 °C for two hours (re-aged). The microhardness depth profile obtained for LB1 after re-aging is shown in Figure 8. As can be observed, HAZ1 restored the hardness to ~570–620 HK0.05, which is almost the hardness of the non-affected part of the sample. This is in accordance with the following theory [28]: the aging of 18Ni-300 steel following full austenization results in a precipitation of intermetallides Ni3Mo/Ni3Ti in a martensite matrix, increasing the hardness and strength of the steel, which happened here in HAZ1. HAZ2 increased hardness as well, up to ~550–600 HK0.05.

As is known, the prolonged heating of MSt at aging temperatures or higher temperatures, which do not exceed the beginning of austenization, results in a coarsening of Ni3Ti/Ni3Mo precipitates and the loss of their semi-coherency (so they become less effective at blocking dislocations), and it also replaces nickel by iron in intermetallics with the nucleation of Fe2Mo equilibrium and the transition of nickel into the matrix, forming so-called “reverted” austenite, which remains stable at room temperature and lowers strength and hardness. This effect was assumed to occur in HAZ2 during laser boronizing. The hardness of 18Ni-300 steel in such a condition can be restored only by the full heat treatment, involving solution treatment and aging. However, the experiment has shown the restored hardness after re-aging. It allows for the assumption that in HAZ2, nonetheless, the dissolution of intermetallics in a matrix took place with the formation of austenite, which transforms to martensite at cooling, making it capable for further re-precipitation of the intermetallides.

3.3. Effect of Post-Aging on Laser-Boronized Layer

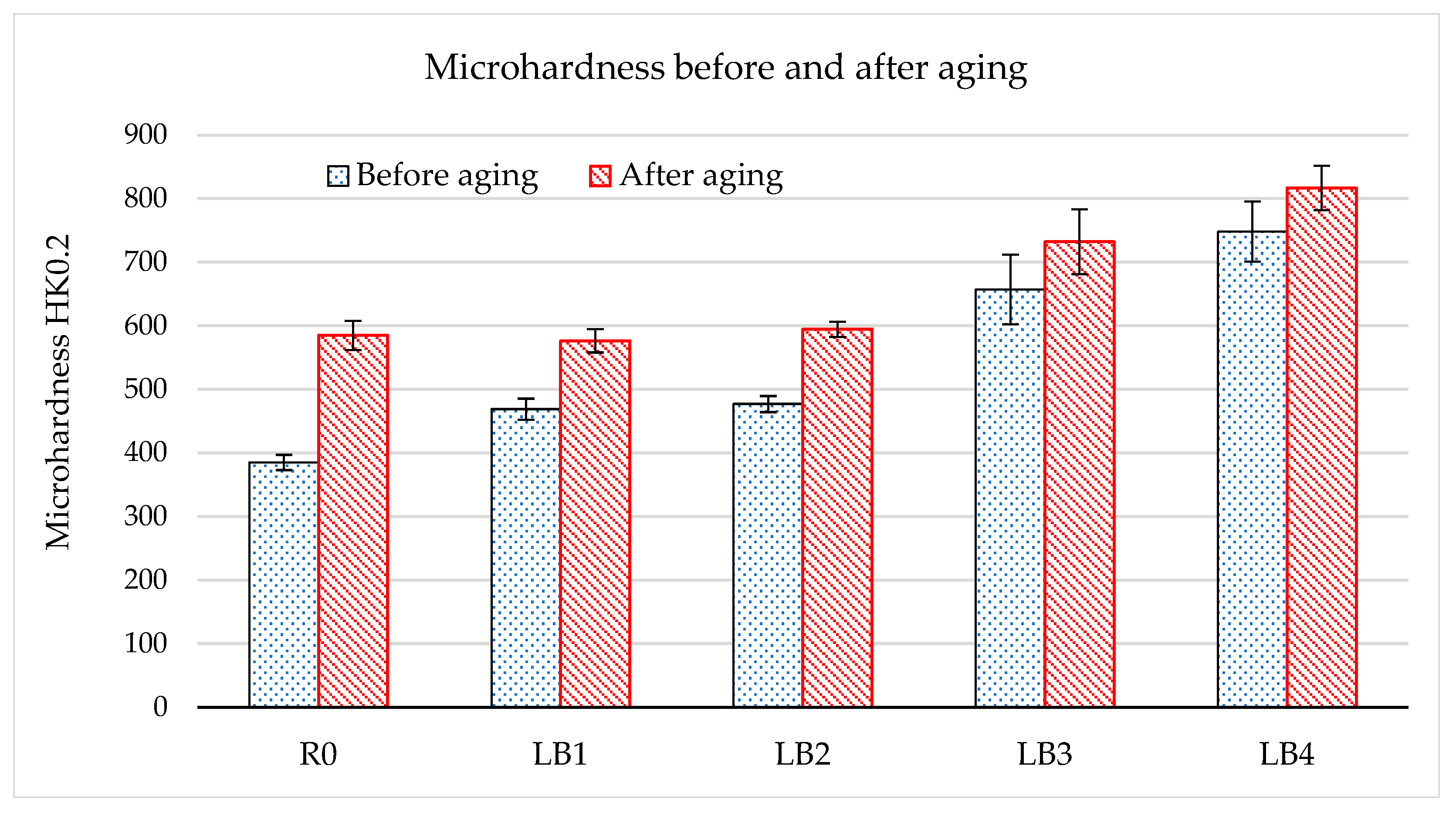

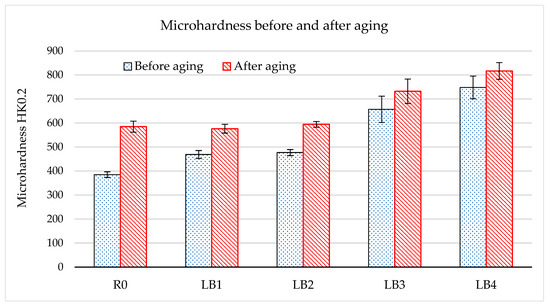

The change in the hardness of laser-boronized layers after re-aging was studied on all the samples—LB1, LB2, LB3, and LB4. For comparison, the hardness of the base SLM part after additive manufacturing and after full heat treatment is provided as well (Figure 9). Thus, the microhardness of as-manufactured part was ~385 HK0.2, which is slightly higher than indicated for lath martensite after solution annealing [28], which can be due to the very fine microstructure and partial precipitation of the already existing intermetallides during the SLM. Heat treatment at 820 °C for 2 h followed by aging at 490 ± 5 °C for 2 h increased the hardness up to ~585 HK0.2, i.e., by ~52%.

Figure 9.

Microhardness of SLM sample (R0) and laser-boronized layers (LB) before and after heat-treatment. Solution annealing + aging—for R0; re-aging—for LB.

No deterioration of the hardness of the laser-boronized layers was observed. On the contrary, the hardness of LB layers increased too. A more pronounced effect was observed for LB1 and LB2 samples containing fewer boride phases and possessing lower initial hardness. The mean hardness increased by ~107 and ~118 hardness units, or ~23 and ~25 percent, respectively. For the harder LB3 and LB4, this effect was less expressed, at ~9–11%.

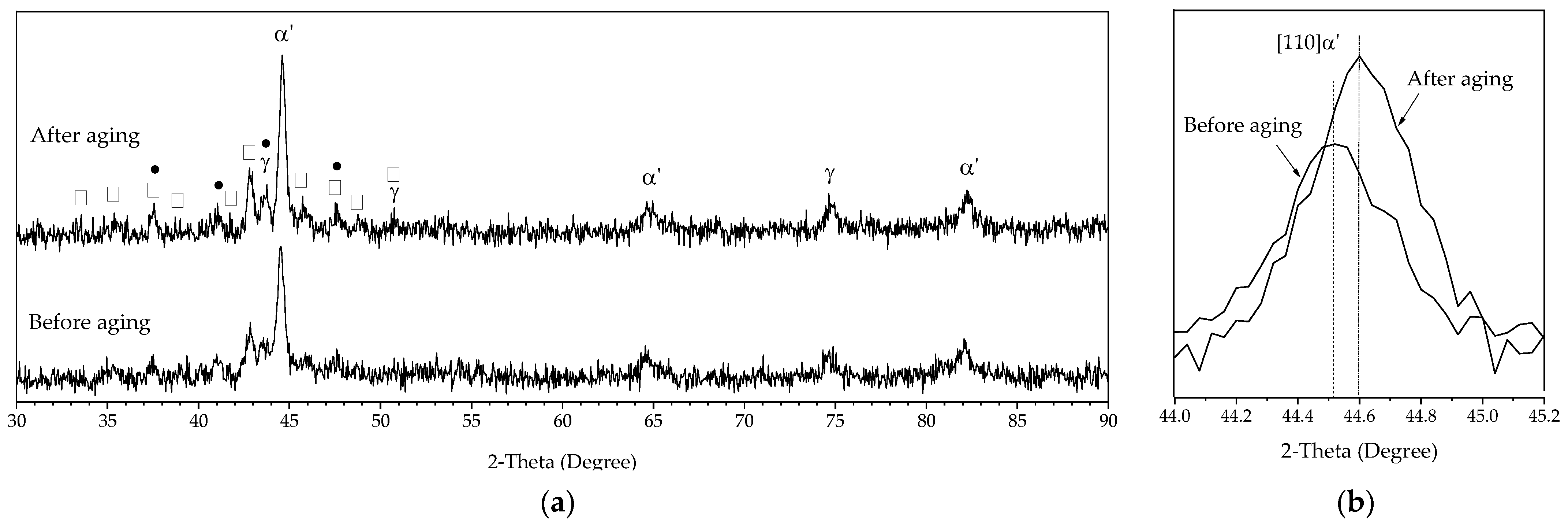

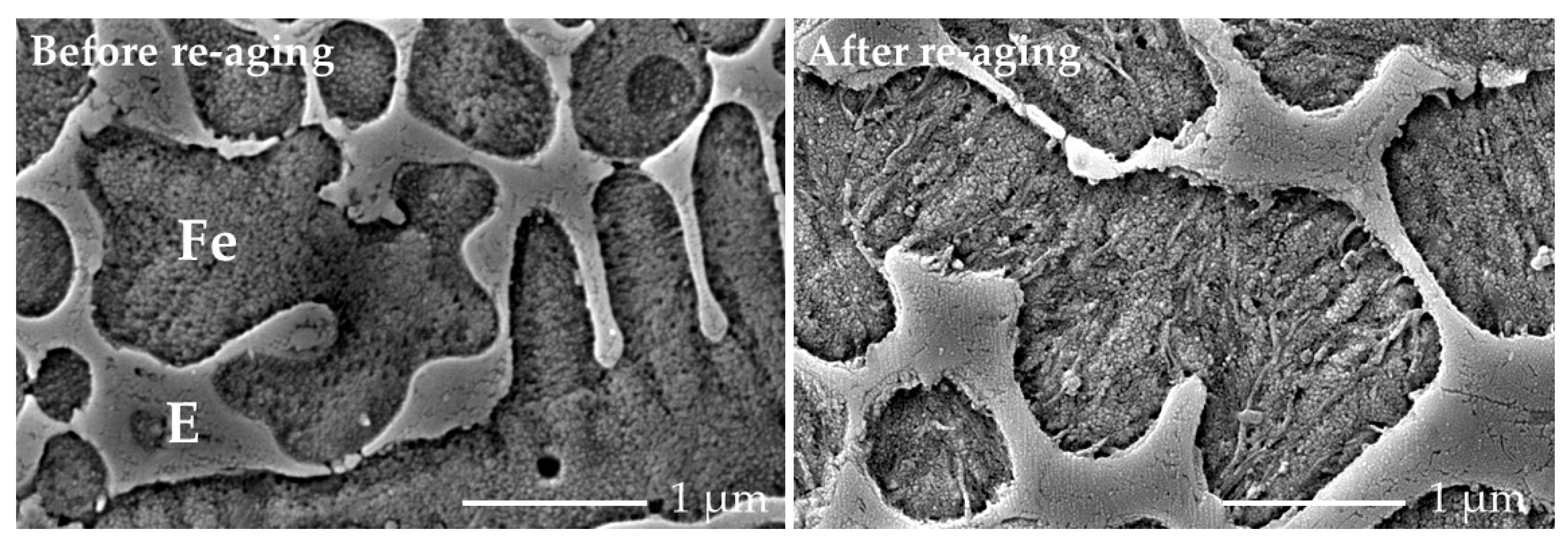

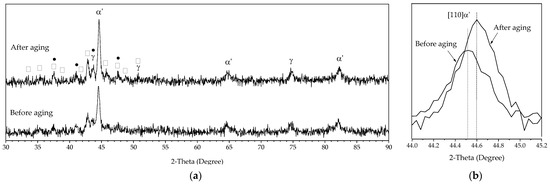

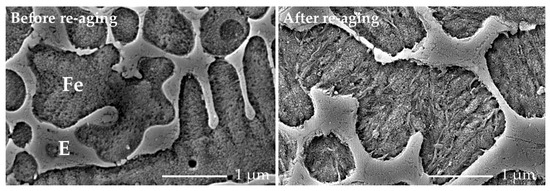

According to the XRD analysis performed (Figure 10a), LB consists of an iron-based solid solution phase mainly represented in the form of martensite and also fewer austenite phases along with boride phases, which are highly likely to be of Fe3B and Fe23B6 types, in which Fe is partially replaced by other metals composing 18Ni-300 steel. Since metal borides typically possess high thermal stability, the hardness increase can be associated with structural changes in the iron solid solution phase rather than with borides. According to the EDS performed, the iron-based solid solution phase in the laser-boronized layer contains ~18.4–18.5% Ni, ~7.6–8.3% Co, ~1.5–4.8% Mo, and ~0.4–1.1% Ti, which is close to the initial composition of 18Ni-300 steel, which is Ni (17–19)%, Mo 4.8%, Ti < 0.8%, and Co (8.5–9.5)%. As stated in [28], Ni3Mo is the major hardening phase in 18%Ni maraging steels with the secondary Ni3Ti, and cobalt accelerates the precipitation by reducing the Mo solubility in the iron matrix. That is, the iron-based solid solution phase in the hypoeutectic laser-boronized layer contains major elements forming hardening phases such as Ni3Ti/Ni3Mo and, theoretically, it is capable of forming a certain amount of reinforcing intermetallides during aging as well. Intermetallic precipitations are typically nano-sized [29], making it challenging to see them even with the use of SEM. However, the analysis of the LB microstructure performed in this study before and after re-aging clearly revealed the difference in the appearance of the iron-based solid solution phase: after re-aging, a lot of precipitation in the form of very fine nano-sized particles and thin lamellas were observed (Figure 11), confirming the assumption made. A similar transformation of the microstructure after aging can be observed in [30], investigating the effect of solution annealing and aging of 18%-300M steel under different conditions. XRD analysis did not show any additional peaks attributable to the intermetallides formed after re-aging, which can be associated with too little an amount of the formed phases. This is consistent with the results of other authors; for example, on the curves presented in work by Strakosova et al. [31] for 18Ni300 steel samples synthesized by spark plasma sintering and aging, peaks corresponding to intermetallides were also not observed. However, a slight shift in the martensite peaks (by 2-Theta 0.07°) to higher reflection angles was established for LB after re-aging (Figure 10b). As was found earlier [32], the martensite phase shows a reduction in the lattice parameters after aging associated with the precipitation of intermetallides.

Figure 10.

XRD patterns of laser-boronized layer LB4 before and after re-aging (a) and major peak for martensite (b): α’—martensite, γ—austenite; ▯—Fe3B-type boride; ●—Fe23B6-type boride.

Figure 11.

Microstructure of laser-boronized layer before and after re-aging.

The size of the formed precipitations is much smaller than the resolution of X-ray microanalysis (~1 µm), which does not allow us to reliably establish their elemental composition and determine precisely which phases are formed. However, taking into account the elemental composition of the iron–base solid solution phase and based on the morphological changes observed in the microstructure, it can be assumed that the transformations occurring in the boronized layer are similar to changes in the base metal. In turn, this suggests that laser boronizing can be applied after the complete heat treatment of parts with further re-aging or, which seems more logical, after solution annealing and then aging without the deterioration of properties. At the same time, including the base metal, such a structure will depend on the full thermal history, which can include numerous thermal cycles, especially in the laser treatment of large surfaces, and it can be sensitive to over-aging. This should be considered when the technological process is created.

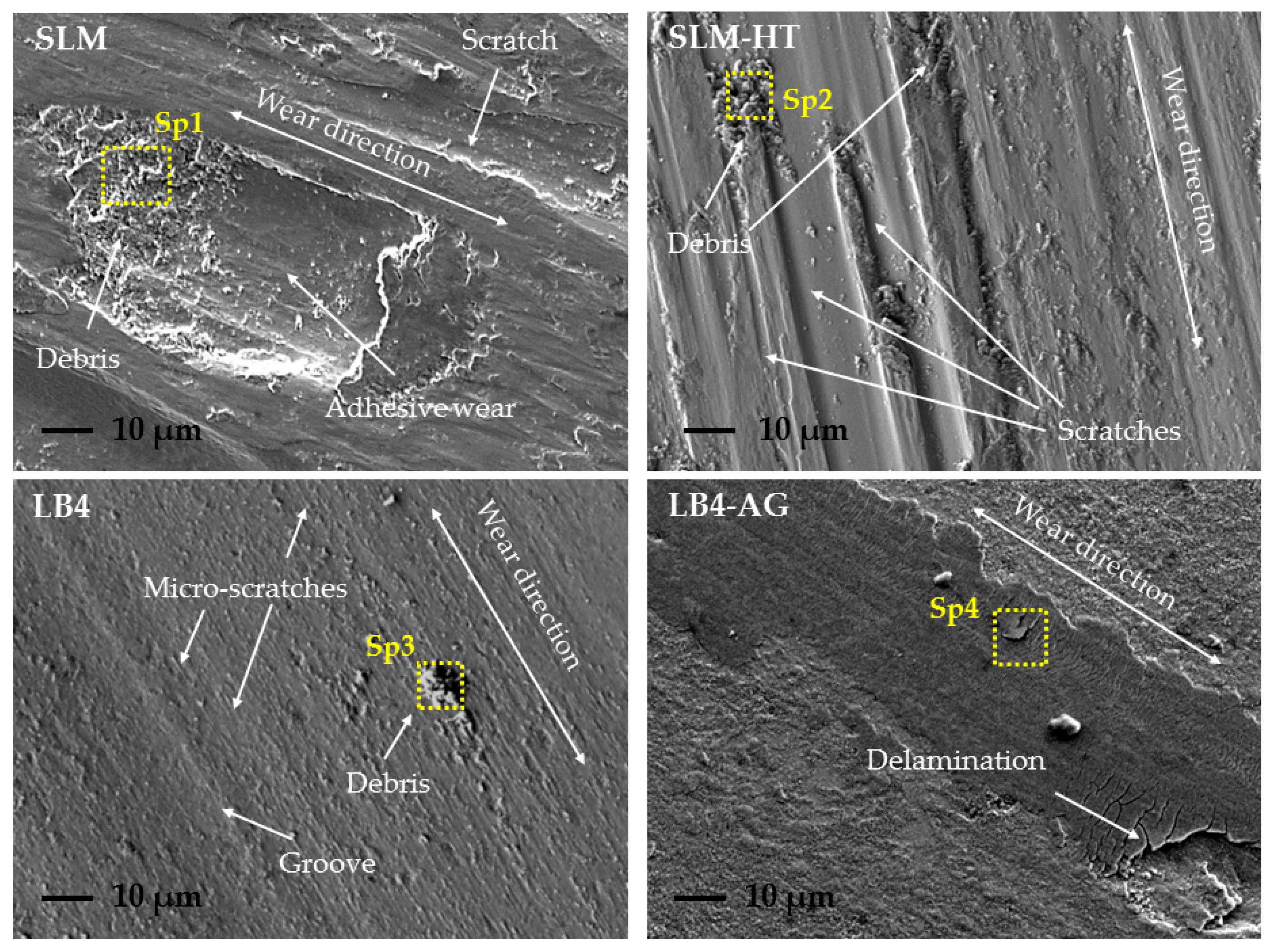

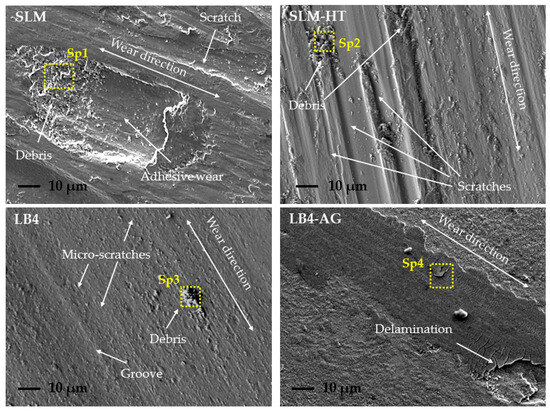

3.4. Tribology

To evaluate the effect of re-aging on the tribology of the laser-boronized layers with a hypoeutectic structure, the LB4 series was chosen, as it possesses the highest hardness among the studied LB series, with ~748 HK0.2 after laser alloying and ~817 HK0.2 after re-aging. Such hardness values are comparable to those obtainable for M300 MSt after thermochemical nitriding, which is conventionally applied to improve the wear resistance of MSt [33,34]. The tribological properties of the laser-boronized part under dry sliding conditions were determined and compared with the SLM part properties before and after heat treatment. The major characteristics determined are listed in Table 2. All the tested samples showed relatively high friction coefficients, which can be associated with a relatively high load applied (20 N). For the less hard as-manufactured SLM sample, it can be also related to the prevailing adhesive mechanism of wear (Figure 12, SLM), which resulted in a most intensive wear among samples (29.35 ± 4.35 μg/m). After the heat treatment, the coarse signs of the adhesive removal of the material from the surface were not observed for the control sample (Figure 12, SLM-HT), while scratches and grooves present mainly indicated the transition to a deformative–abrasive wear mechanism. At the same time, the coefficient of friction was slightly reduced and wear resistance improved by ~2.9 times.

Table 2.

Results of tribological test.

Figure 12.

Wear tracks at the surface of samples after dry sliding test. Sp1–Sp4—EDS analysis points.

The wear track of LB4 showed a different appearance, in which deep grooves disappeared, indicating a visible reduction in surface plastic deformation, and micro-scratches replaced the coarse ones, so the intensity of the abrasive wear seemed to be reduced as well. This was confirmed by the mass control of samples, showing a ~5.8 times lower wear intensity if compared to SLM-HT. On the surface of LB4, the presence of very fine hard precipitations, uniformly distributed in a metal matrix, can be clearly seen, which are known to provide a wear improvement effect due to their load-bearing capacity (Figure 12, LB4). At the same time, the presence of hard particles could be a reason for the increased friction coefficient of LB4.

After re-aging, the appearance of signs of brittle delamination was established, which is associated with the increased hardness of LB4-AG. However, the friction coefficient was reduced, while the overall resistance to wear was improved by ~1.7 times. Firstly, this was reached due to the hardened iron-based matrix. Furthermore, the effect of restoring HAZ could be involved as well.

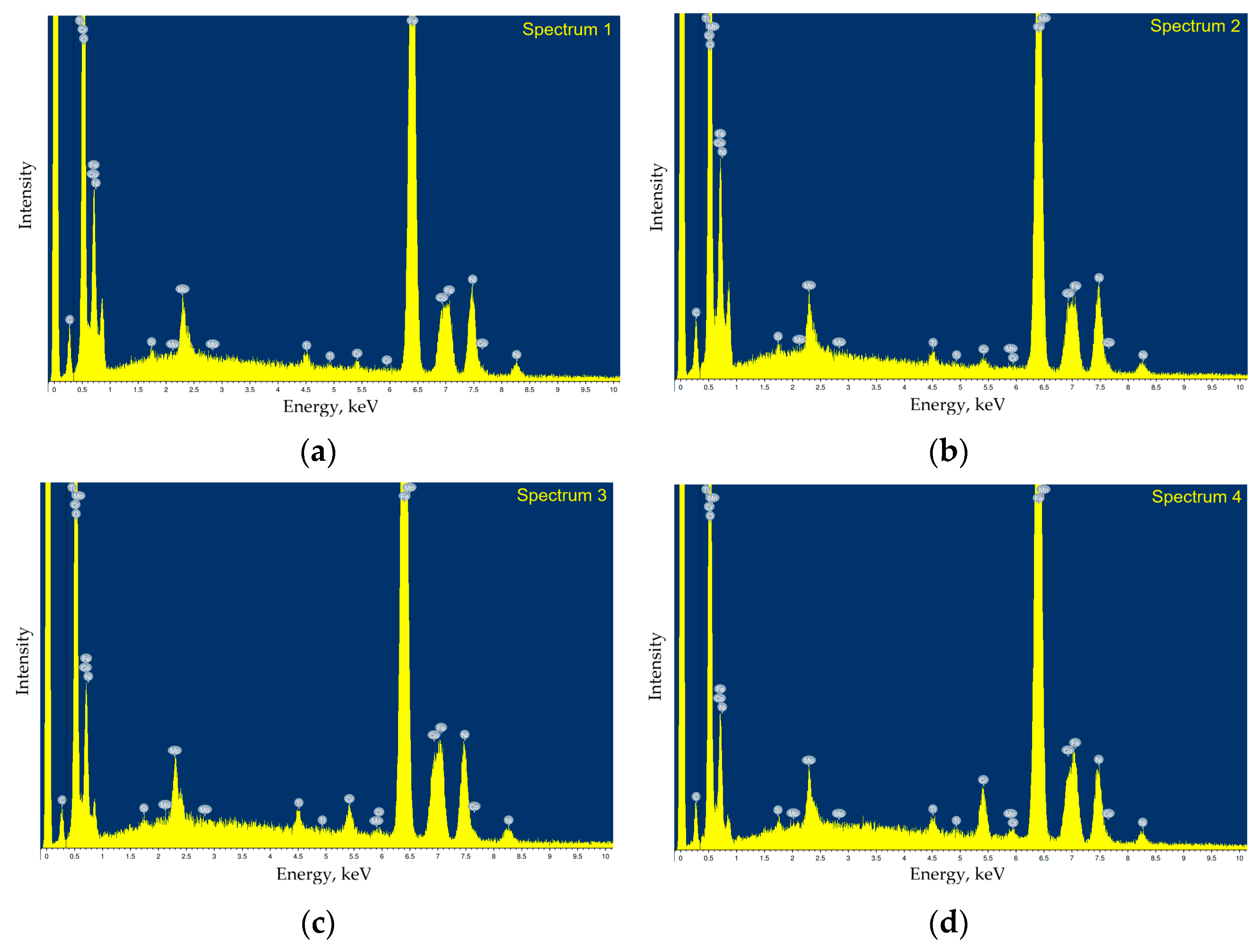

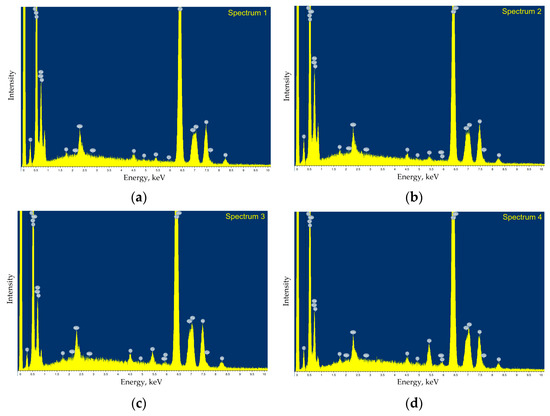

The EDS analysis of the wear products (Table 3 and Figure 13) observed on wear tracks after tribological tests revealed that they consisted largely of the elements attributable to the laser-boronized layer—Fe, Ni, Co, Mo, and Ti. The analysis was performed at a 20 kV accelerating voltage, which is too high for the analysis of light elements; therefore, boron was not detected. Furthermore, high concentrations of oxygen and carbon were established, because the surfaces of the sample and counter-body, as well as metal debris formed during wear, intensively react with air at elevated temperatures due to dry friction. Moreover, Cr, Mn, and Si were determined at lower concentrations, indicating the wear of the counter-body as well. Both quantitative results (Table 3) and the obtained spectra (Figure 13) showed an increase in the concentration of these elements when moving from the SLM sample to heat-treated SLM, laser-boronized LB4, and finally to aged LB4, which is due to an increase in the hardness of the samples and more intense wear of the counter-body when the hardness of the samples approaches the level of the counter-body material (~800 HV).

Table 3.

Elemental composition of wear products observed at wear tracks after two-body dry sliding test (by EDS, in mass.%).

Figure 13.

EDS spectrum for wear products observed at wear tracks after two-body dry sliding test: (a) for SLM sample; (b) for SLM-HT sample; (c) for LB4 sample; and (d) for LB4-AG sample.

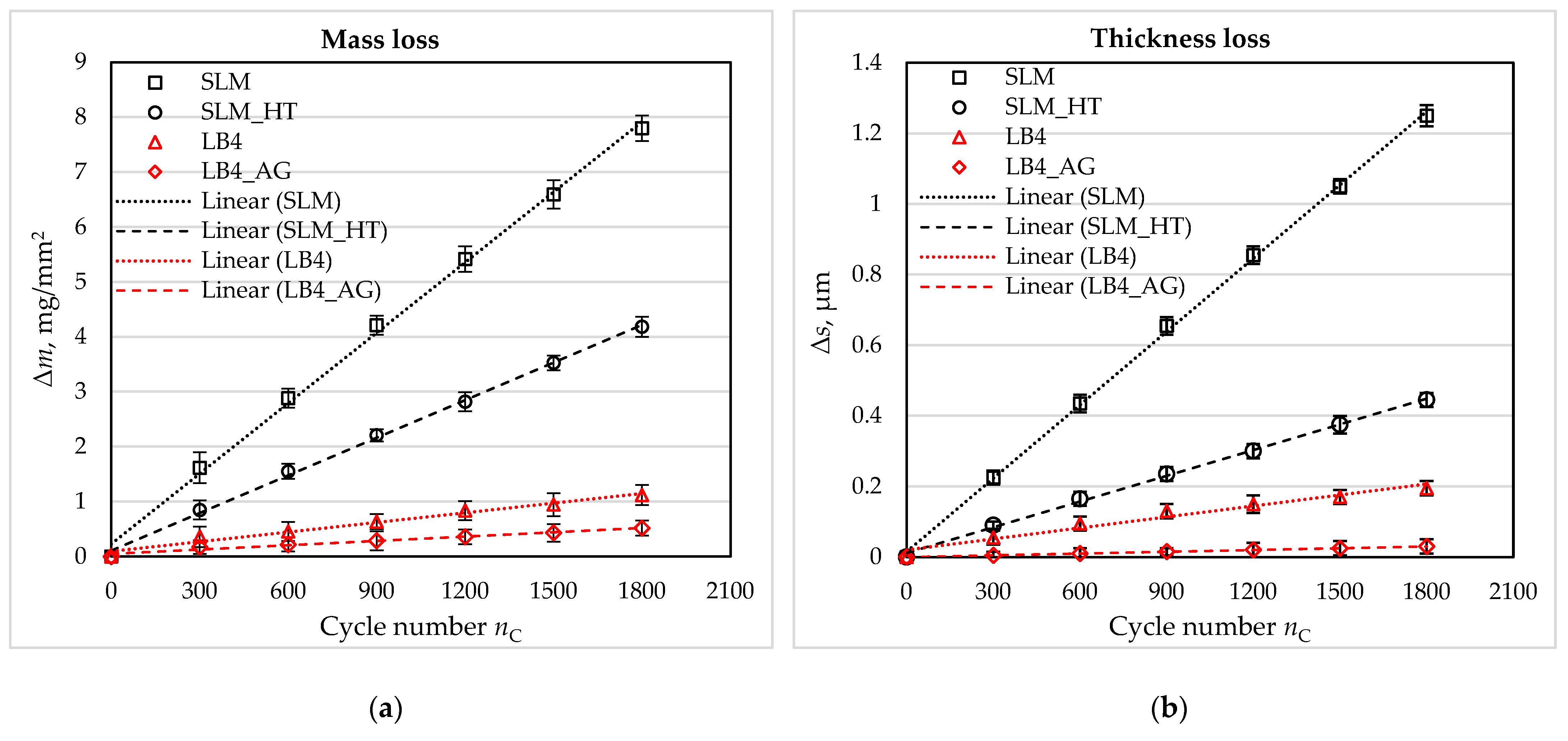

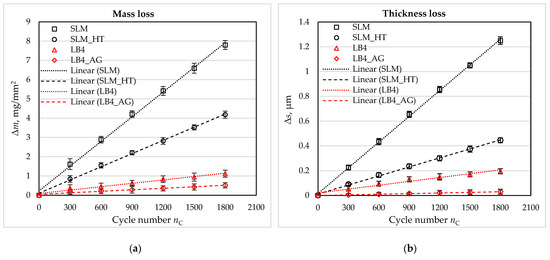

The two-body dry abrasive wear test essentially confirmed the improvement in the wear resistance of maraging steel after laser boronizing and the positive response of the LB layer on re-aging, which can be applied to restore HAZ after LB. The results of the test by mass loss and thickness loss correlated and showed an essentially linear increase in wear losses with time (Figure 14a,b). If compared total mass losses after 1800 wear cycles, and the ~52% hardness increase provided by heat treatment of the SLM part allowed for reducing abrasive wear by ~86%, while a further increase in hardness by 28% due to laser boronizing improved wear resistance by ~3.7 times. The re-aging of LB improved this characteristic by two more times.

Figure 14.

Wear losses of samples without and with heat treatment (HT for SLM) or aging (AG for LB) by mass (a) and by sample thickness (b).

4. Conclusions

18Ni-M300 maraging steel parts, manufactured by SLM and laser–boronizing to improve the hardness and wear resistance of the surface, were investigated in the present study to establish whether it is possible to restore the hardness of a heat-affected zone, softened during laser processing, by re-aging, as well as how the re-aging can influence the properties of the laser-boronized layer with a hypoeutectic structure. Based on the results obtained, the following major conclusions can be drawn:

- Near the molten pool, a heat-affected zone (HAZ1) possessing ~350–380 HK0.05 hardness is fully recrystallized and has the typical structure of lath martensite. Furthermore, HAZ2 is formed, which retains the substructure formed by the SLM process and has a hardness of ~400 to ~550 HK0.05. After re-aging, both HAZ1 and HAZ2 showed the capability of restoring hardness, indicating that in both zones, a dissolution of hardening phases takes place during laser processing, as well as the formation of austenite capable of forming martensite upon cooling and further restoring hardness upon re-aging. Re-aging at 490 ± 5 °C for 2 h allowed for an increase in the hardness of HAZ up to ~550–620 HK0.05, which is comparable to the hardness of non-affected base metal.

- Laser-boronized layers formed on 18Ni-300 maraging steel and having a hypoeutectic structure with a hardness between ~470 and ~750 HK0.2 showed a tendency to increase in hardness after re-aging at 490 °C for two hours by 9–25%, which is assumed to be due to microstructural transformations in the iron-based solid solution phase, similar to those in the base metal during aging—namely due to the precipitation of dispersive hardening phases. Such a positive response to aging makes it possible to re-age the laser-boronized parts without degrading the properties of the modified layer or to perform laser boronizing after solution annealing followed by aging.

- Laser-boronized layers of hypoeutectic structure and a hardness of ~750 HK0.2 significantly (by times) improved the wear resistance of additively manufactured 18Ni-300 maraging steel parts in both dry sliding and dry abrasion conditions. Moreover, after appropriate post-aging, their effectiveness can be further increased.

The results of the present study show that laser boronizing can be applied after the complete heat treatment of additively manufactured 18Ni-M300 steel parts with further re-aging or, which would be more rational, after solution annealing and then aging without deterioration of the properties of the modified surface. At the same time, including the base metal, the laser-alloyed surface and heat-affected zone are dependent on the full temperature history, which can include numerous thermal cycles, especially in the laser treatment of large surfaces, and it can be sensitive to over-aging. This should be considered when the technological process of alloying and heat treatment is created.

Author Contributions

Conceptualization. J.Š.; methodology. J.Š. and O.Č.; formal analysis. K.B., J.Š., O.Č. and O.K.; investigation. K.B., J.Š., O.Č. and O.K.; resources. O.Č., K.B. and J.Š.; data curation. J.Š.; writing—original draft preparation. J.Š. and O.K.; writing—review and editing. J.Š. and O.Č.; supervision. J.Š. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| MSt | Maraging steel |

| HAZ | Heat-affected zone |

| SLM | Selective laser melting |

| HT | Heat treatment |

| AG | Aging |

| LB | Laser boronizing |

| HK | Hardness by Knoop method |

References

- Czerwinski, F. Thermochemical Treatment of Metals [Internet]. Heat Treatment—Conventional and Novel Applications; InTech: London, UK, 2012. [Google Scholar] [CrossRef]

- Zimmerman, C. Steel Heat Treating Fundamentals and Processes; ASM International: Novato, CA, USA, 2023. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.-H.; Raj Kumar, D. Laser Surface Modification of Materials; IntechOpen: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Mphasha, N.P.; Rabothata, M.S. Advanced Surface Modification Techniques. Surface Engineering—Foundational Concepts, Techniques and Future Trends; IntechOpen: New York, NY, USA, 2025. [Google Scholar] [CrossRef]

- Sun, K.; Peng, W.; Wei, B.; Yang, L.; Fang, L. Friction and Wear Characteristics of 18Ni(300) Maraging Steel under High-Speed Dry Sliding Conditions. Materials 2020, 13, 1485. [Google Scholar] [CrossRef] [PubMed]

- Bae, K.; Shin, D.; Kim, J.-H.; Lee, W.; Jo, I.; Lee, J. Influence of Post Heat Treatment Condition on Corrosion Behavior of 18Ni300 Maraging Steel Manufactured by Laser Powder Bed Fusion. Micromachines 2022, 13, 1977. [Google Scholar] [CrossRef] [PubMed]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Kelliger, T.; Meurer, M.; Bergs, T. Potentials of Additive Manufacturing for Cutting Tools: A Review of Scientific and Industrial Applications. Metals 2024, 14, 982. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A review of various materials for Additive Manufacturing: Recent trends and Processing issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Yao, X.; Wang, Q.; Chen, S.; Wang, Y.; Wei, S.; Lau, K.B.; Wang, P.; Dai, C.; Hu, J. Precipitation and TRIP enhanced spallation resistance of additive manufactured M350 steel. Mater. Sci. Eng. A 2025, 920, 147547. [Google Scholar] [CrossRef]

- Pustički, D.; Alar, Ž.; Bandov, Z. Additively Manufactured Maraging Steel: Influence of Heat Treatment on Corrosion and Mechanical Properties. Materials 2025, 18, 1999. [Google Scholar] [CrossRef]

- Bai, Y.; Yan, Y.; Chen, J.; Liang, C.; Bi, G.; Zhao, C. Microstructure and mechanical property evolution of 316L/18Ni300 bimetallic structure manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2025, 929, 148141. [Google Scholar] [CrossRef]

- Leite, F.F.; Coondoo, I.; Vieira, J.S.; Oliveira, J.M.; Miranda, G. Thermal and Mechanical Properties of Nano-TiC-Reinforced 18Ni300 Maraging Steel Fabricated by Selective Laser Melting. J. Manuf. Mater. Process. 2024, 8, 268. [Google Scholar] [CrossRef]

- Zeng, X.; Sun, Y.; Zhang, H.; Jia, Z.; Kang, Q. A Mechanism of Argon Arc Remelting of LPBF 18Ni300 Steel Surfaces. Coatings 2025, 15, 481. [Google Scholar] [CrossRef]

- Funch, C.V.; Christiansen, T.L.; Somers, M.A.J. Gaseous nitriding of additively manufactured maraging steel; nitriding kinetics and microstructure evolution. Surf. Coat. Technol. 2022, 432, 128055. [Google Scholar] [CrossRef]

- Seabrook, J.B. Working with maraging steels—Nitriding. Metal. Progress. 1963, 84, 78–80. [Google Scholar]

- Wahab Hashmi, A.; Singh Mali, H.; Meena, A. Improving the surface characteristics of additively manufactured parts: A Review. Mater. Today Proc. 2023, 81, 723–738. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Puerta, A.P.V.; Kunkel, M.E. Surface characteristics improvement methods for metal additively manufactured parts: A review. Adv. Mater. Process. Technol. 2022, 8, 4524–4563. [Google Scholar] [CrossRef]

- Škamat, J.; Bučelis, K.; Černašėjus, O.; Indrišiūnas, S. Fiber Laser Alloying of Additively Manufactured 18Ni-300 Maraging Steel Part Surface: Effect of Processing Parameters on the Formation of Alloyed Surface Layer and Its Properties. Materials 2023, 16, 4732. [Google Scholar] [CrossRef] [PubMed]

- Kwak, N.; Lim, Y.; Heo, S.; Jeon, C.; Jo, I. Effect of Aging Temperature on Microstructure, Mechanical, and Wear Properties of 18Ni-300 Maraging Steel Produced by Powder Bed Fusion. Metals 2024, 14, 375. [Google Scholar] [CrossRef]

- Yin, S.; Chen, C.; Yan, X.; Feng, X.; Jenkins, R.; O’Reilly, P.; Lupoi, R. The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel. Addit. Manuf. 2018, 22, 592–600. [Google Scholar] [CrossRef]

- Strakosova, A.; Průša, F.; Jiříček, P.; Houdková, J.; Michalcová, A.; Vojtěch, D. High-temperature exposure of the high-strength 18Ni-300 maraging steel manufactured by laser powder bed fusion: Oxidation, structure and mechanical changes. J. Mater. Sci. 2024, 59, 15859–15882. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- ASTM G99-23; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- Chen, L.; Mi, G.; Zhang, X.; Wang, C. Effects of sinusoidal oscillating laser beam on weld formation, melt flow and grain structure during aluminum alloys lap welding. J. Mater. Process. Technol. 2021, 298, 117314. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, X.; Li, H.; Lei, Z.; Chen, Y.; Wu, S.; Wang, Y. Grain refinement and laser energy distribution during laser oscillating welding of Invar alloy. Mater. Des. 2020, 186, 108195. [Google Scholar] [CrossRef]

- Lumley, R.; Morton, A.; Polmear, I. 9—Nanoengineering of metallic materials. In Nanostructure Control of Materials; Hannink, R.H.J., Hill, A.J., Eds.; Woodhead Publishing: Sawston, UK, 2006; pp. 219–250. [Google Scholar] [CrossRef]

- Lang, F.H.; Kenyon, N. Welding of Maraging Steels; Welding Research Council Bulletin 159; Welding Research Council, INC: New York, NY, USA, 1971; 41p. [Google Scholar]

- Kučerová, L.; Benediktová, A.; Burdová, K.; Jandová, D. Low-temperature precipitation strengthening of maraging steel 1.2709 produced by powder bed fusion. Mater. Des. 2024, 241, 112938, ISSN 0264-1275. [Google Scholar] [CrossRef]

- Kučerová, L.; Burdová, K.; Jeníček, Š.; Chena, I. Effect of solution annealing and precipitation hardening at 250 °C–550 °C on microstructure and mechanical properties of additively manufactured 1.2709 maraging steel. Mater. Sci. Eng. A 2021, 814, 141195. [Google Scholar] [CrossRef]

- Strakosova, A.; Průša, F.; Michalcová, A.; Vojtěch, D. Structure and Mechanical Properties of the 18Ni300 Maraging Steel Produced by Spark Plasma Sintering. Metals 2021, 11, 748. [Google Scholar] [CrossRef]

- Habiby, F.; Siddiqui, T.N.; Hussain, H.; Haq, U.; Khan, A.Q. Lattice changes in the martensitic phase due to ageing in 18 wt% nickel maraging steel grade 350. J. Mater. Sci. 1996, 31, 305–309. [Google Scholar] [CrossRef]

- INCO Databooks. 18 per Cent Maraging Steels. Engineering Properties. Available online: https://nickelinstitute.org/media/1598/18_nickelmaragingsteel_engineeringproperties_4419_.pdf (accessed on 22 May 2025).

- Reis, A.G.; Reis, D.A.P.; Abdalla, A.J.; Otubo, J.; Couto, A.A.; Neto, F.P. Hot Tensile Behavior and Fracture Characteristics of a Plasma Nitrided Maraging 300 Steel. Mater. Sci. Forum 2017, 899, 436–441. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).