Tailored Cage Shapes on Lubricant Migration and Friction Behaviours in Both Ball-Cage and EHL Contacts

Abstract

1. Introduction

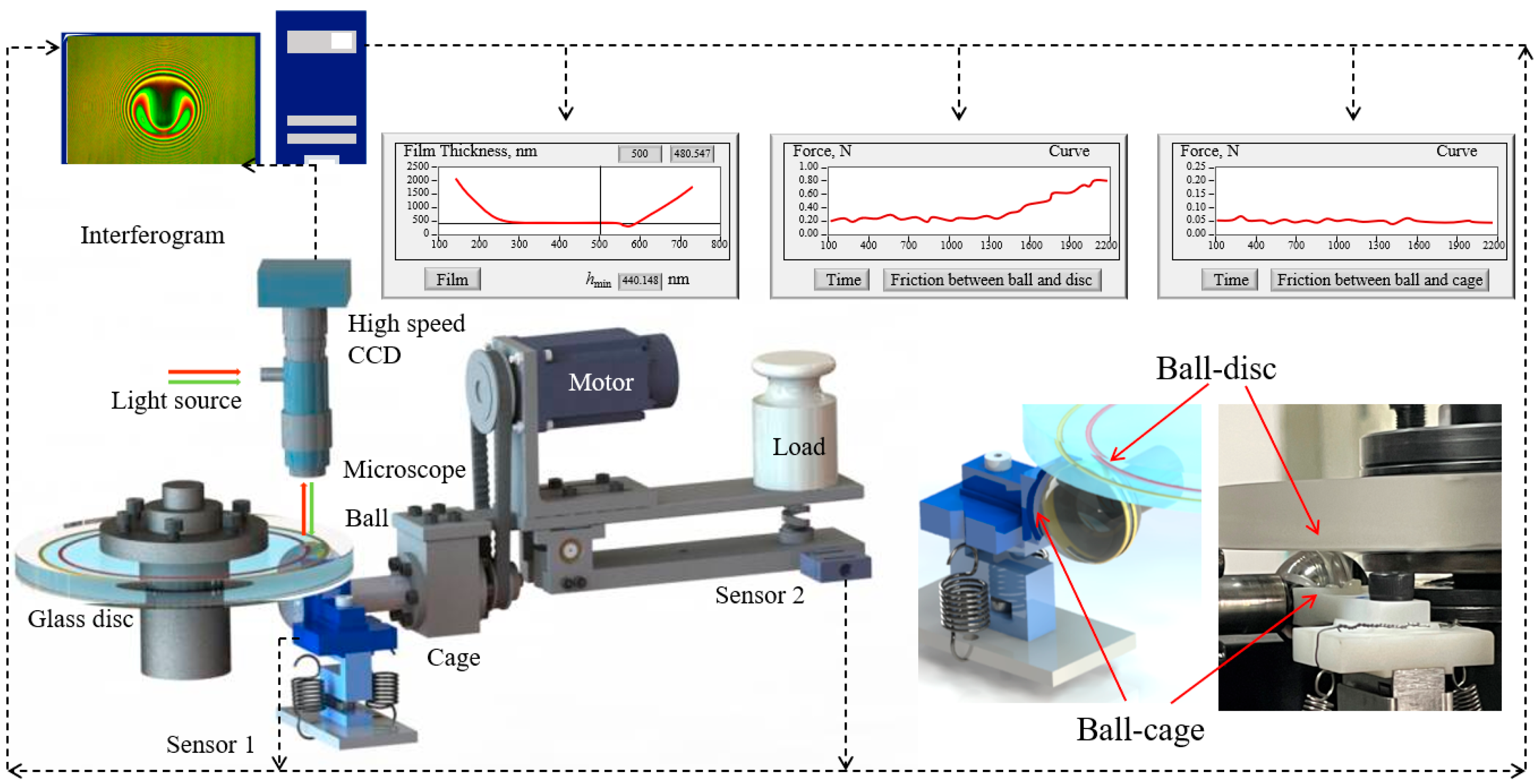

2. Experimental

2.1. Test Apparatus and Scheme

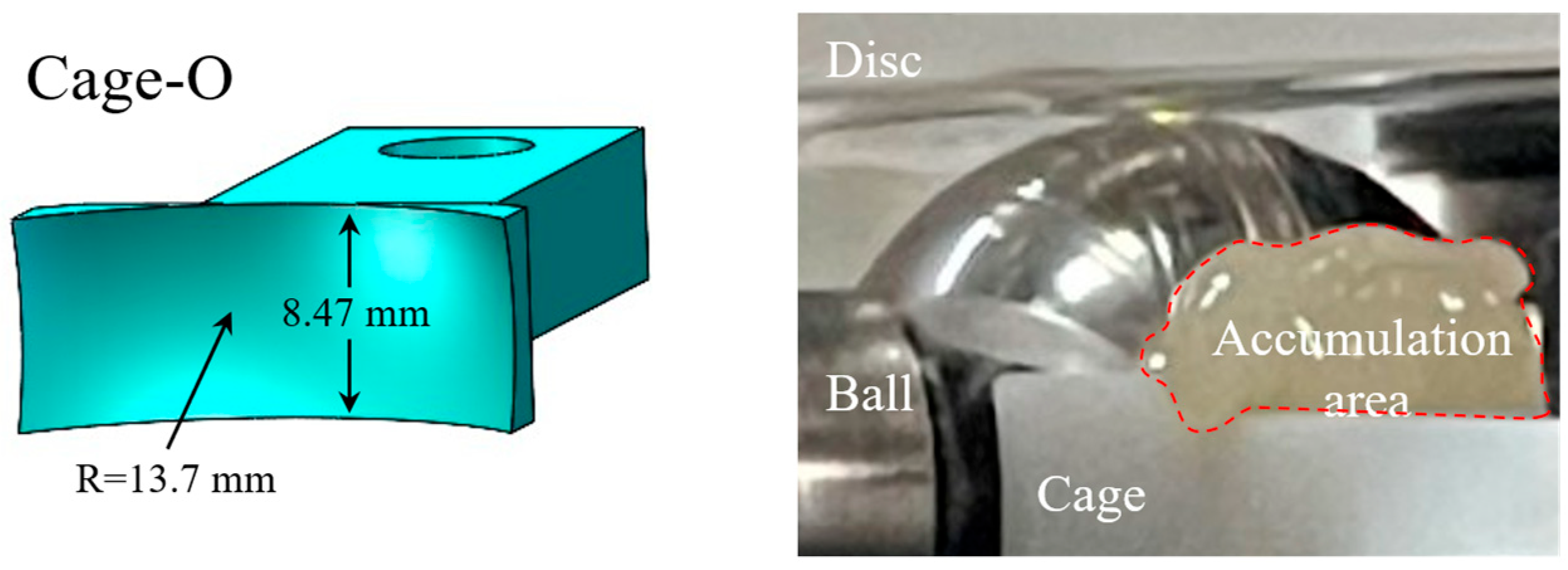

2.2. Design of Cage Pockets

2.3. Lubricants and Experimental Procedure

3. Results and Discussion

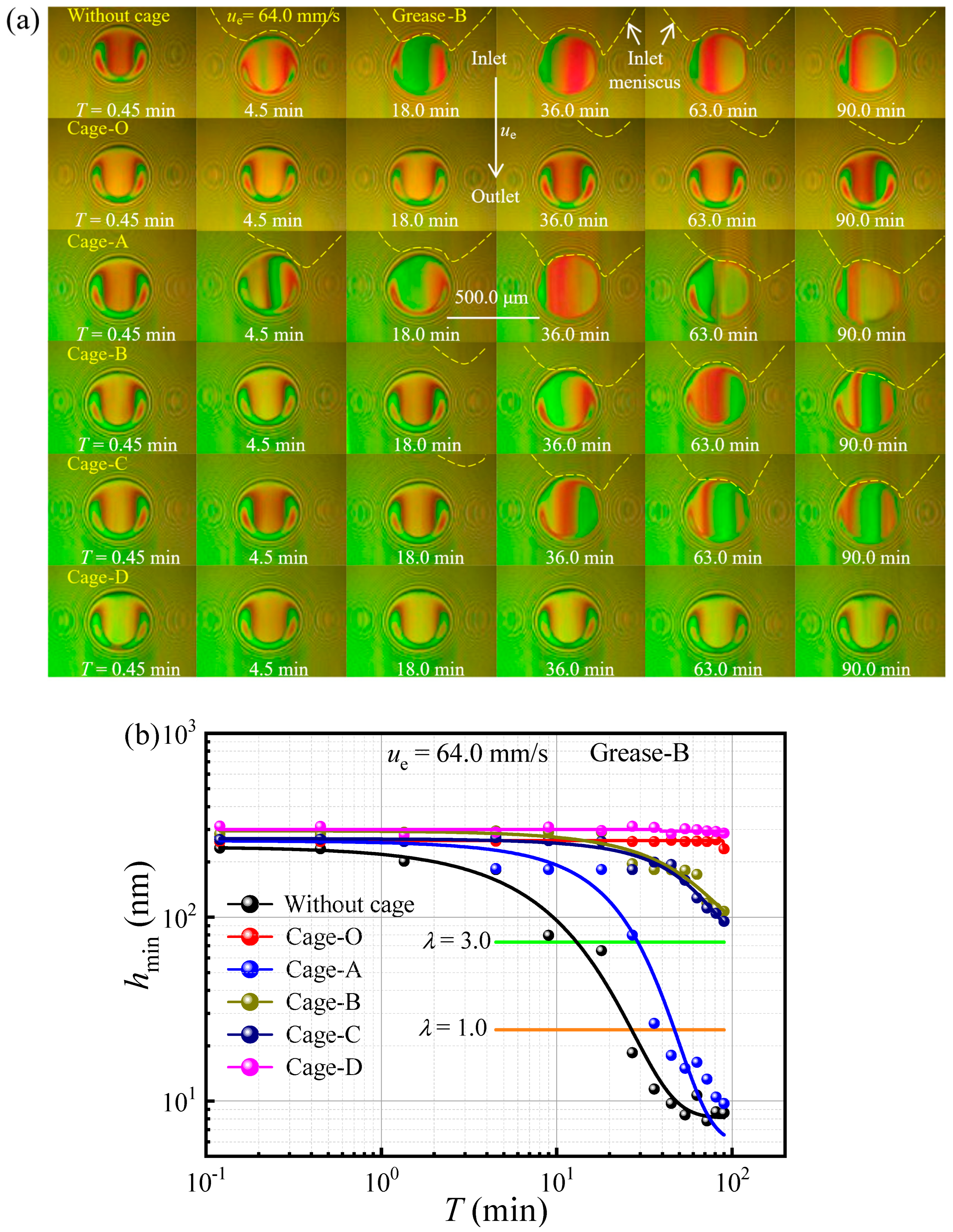

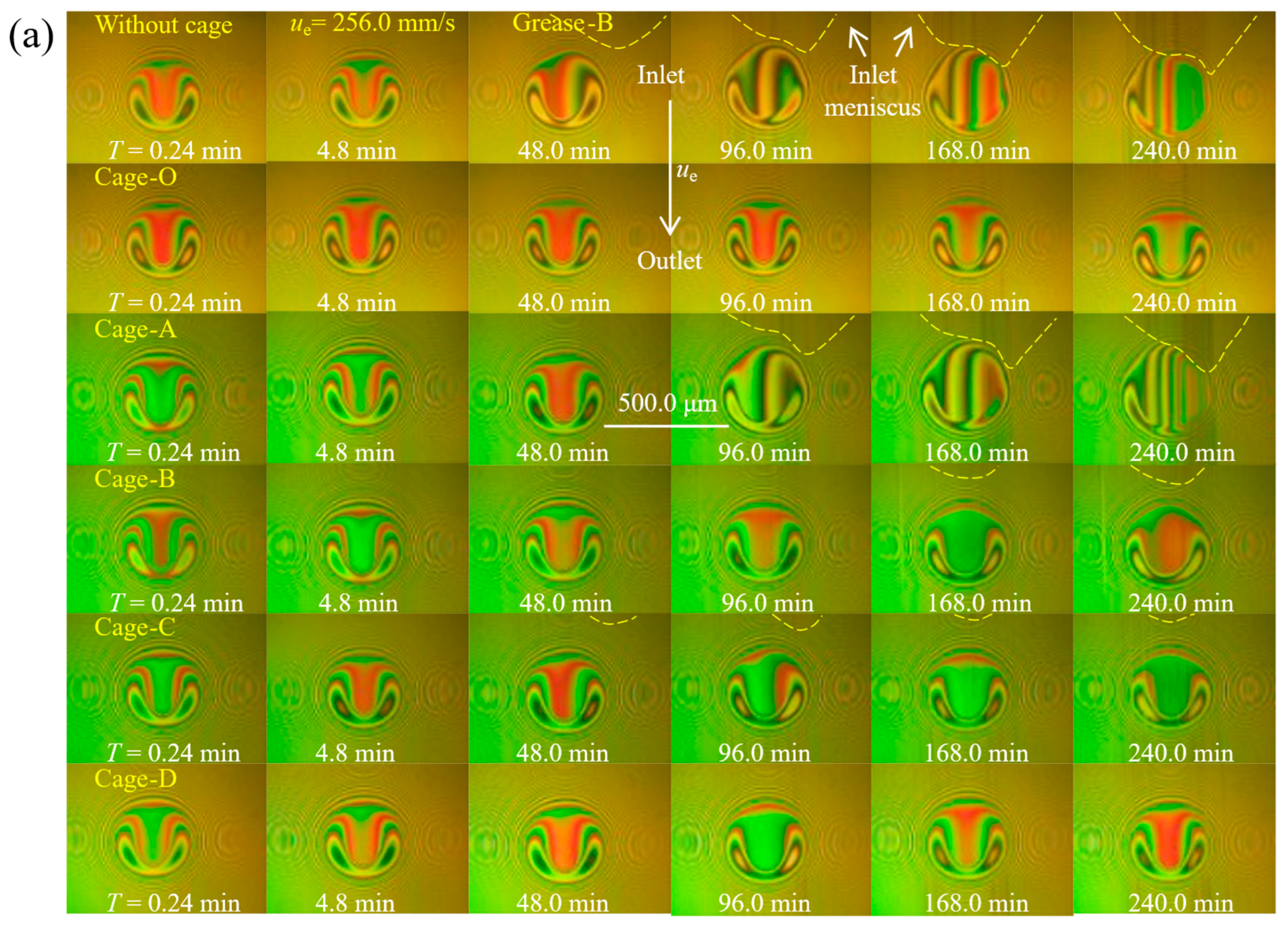

3.1. Effect of Entrainment Speed on Lubrication and Friction

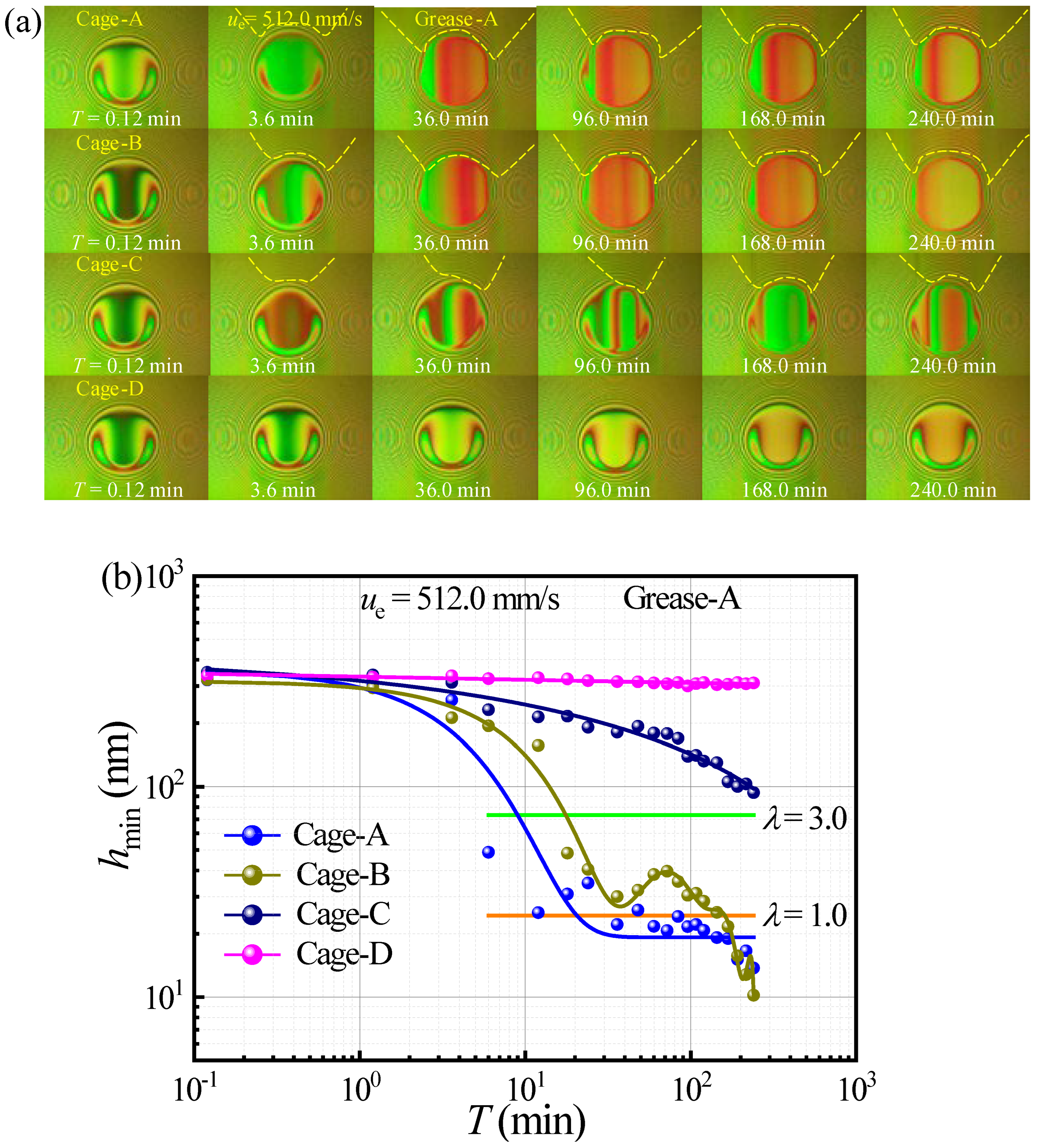

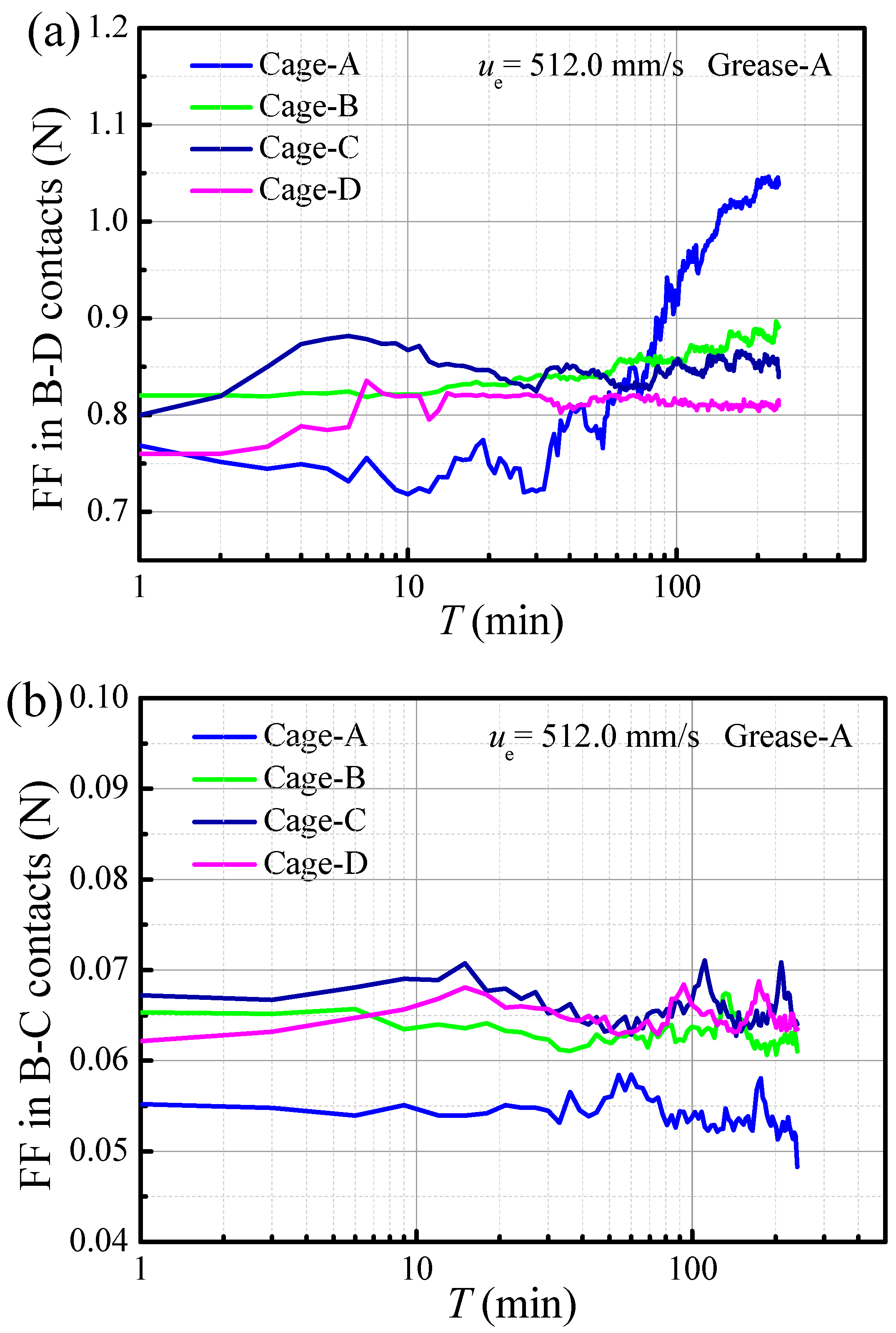

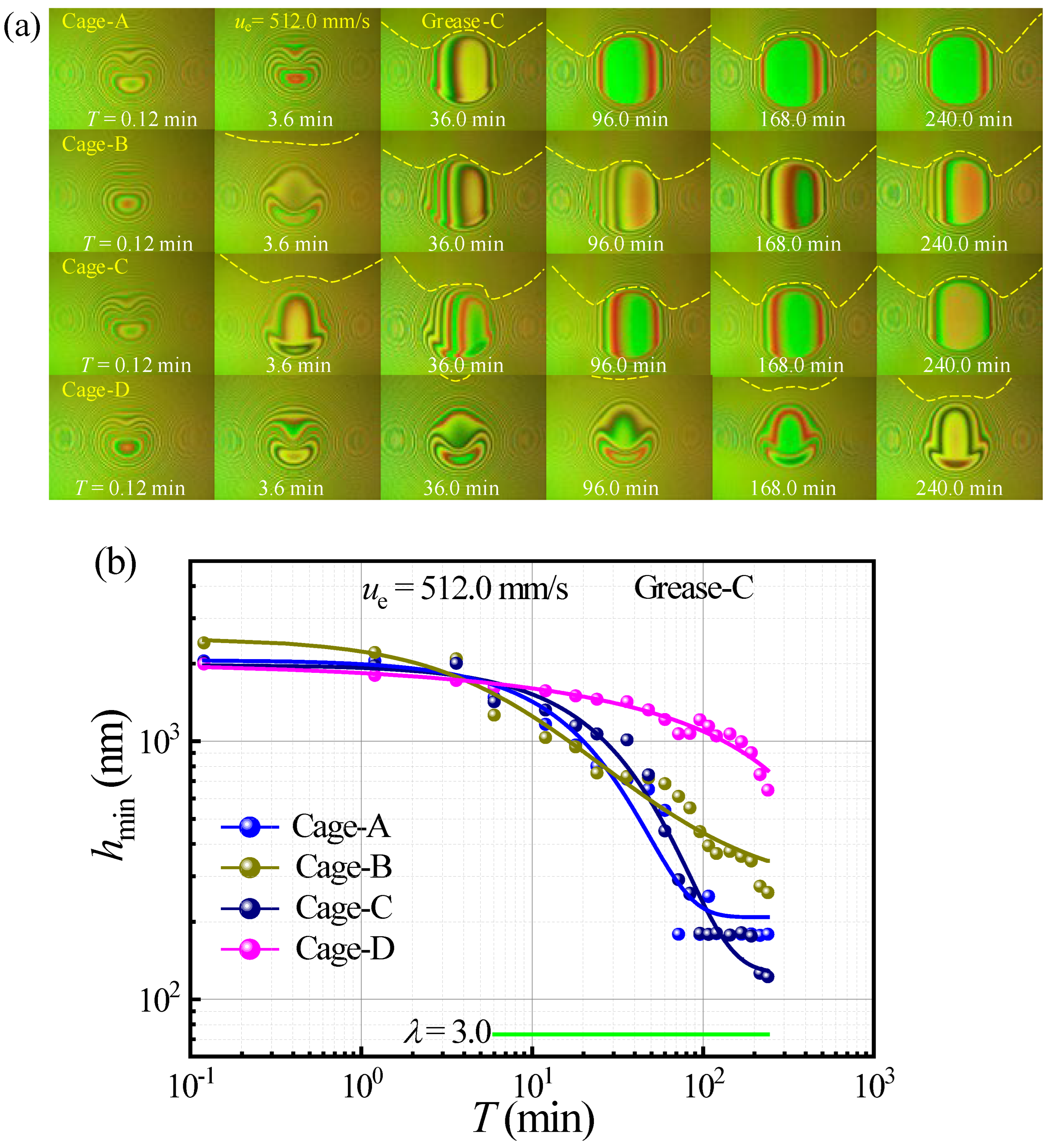

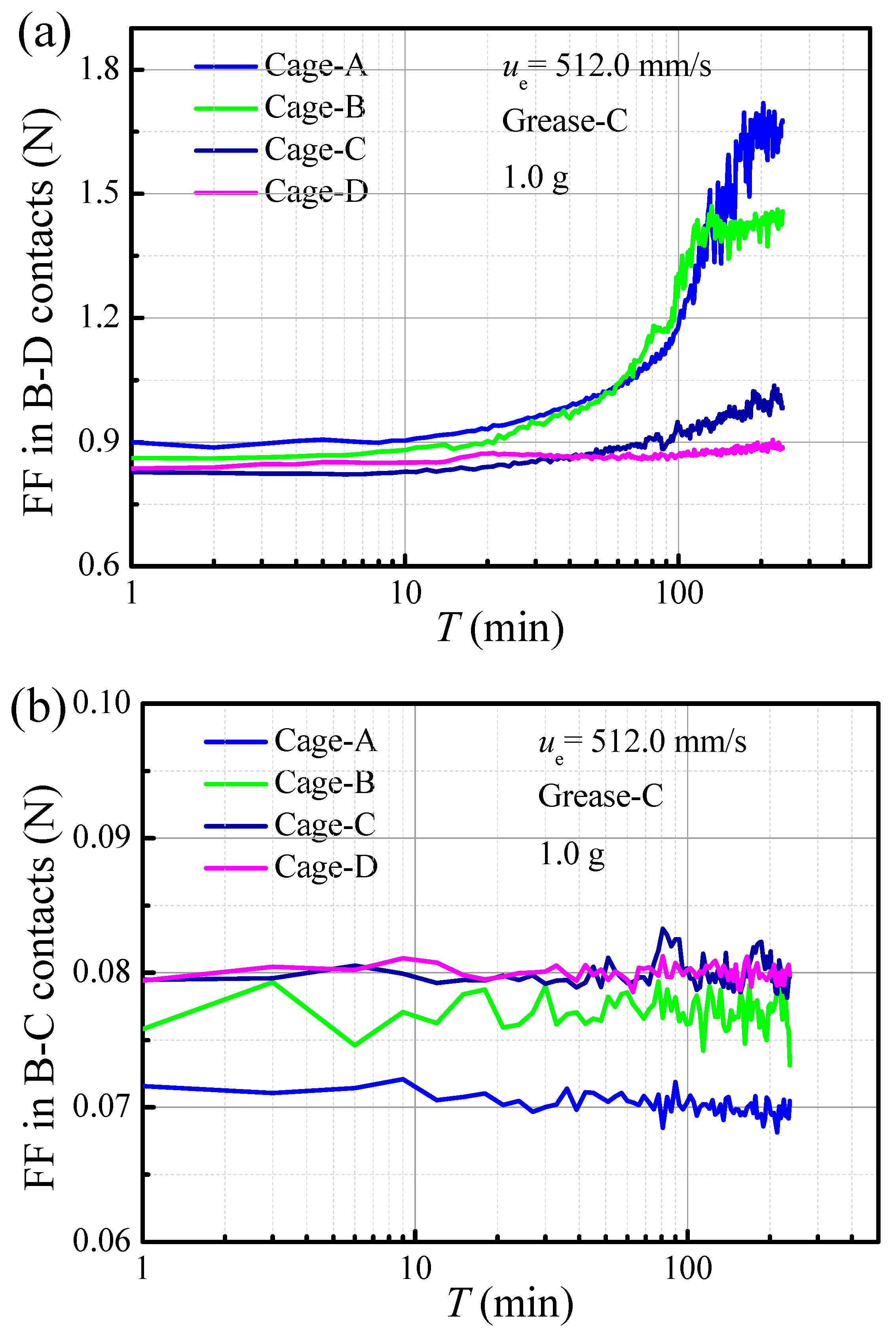

3.2. Effect of Base Oil Viscosity on Evolutions of Film and Friction

3.3. Effect of Supply Grease Amount on Film Evolution and Friction

4. Discussion and Mechanisms

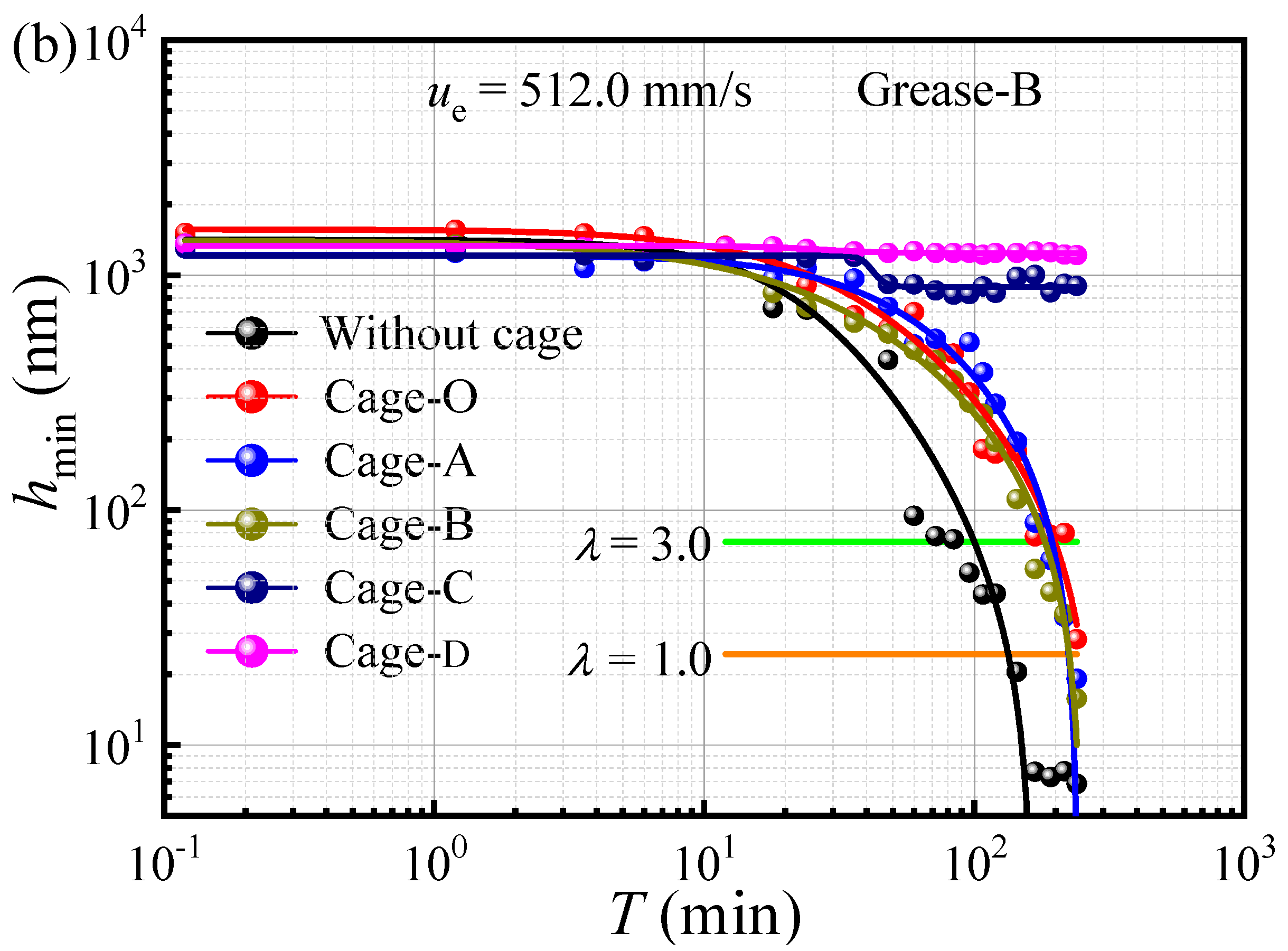

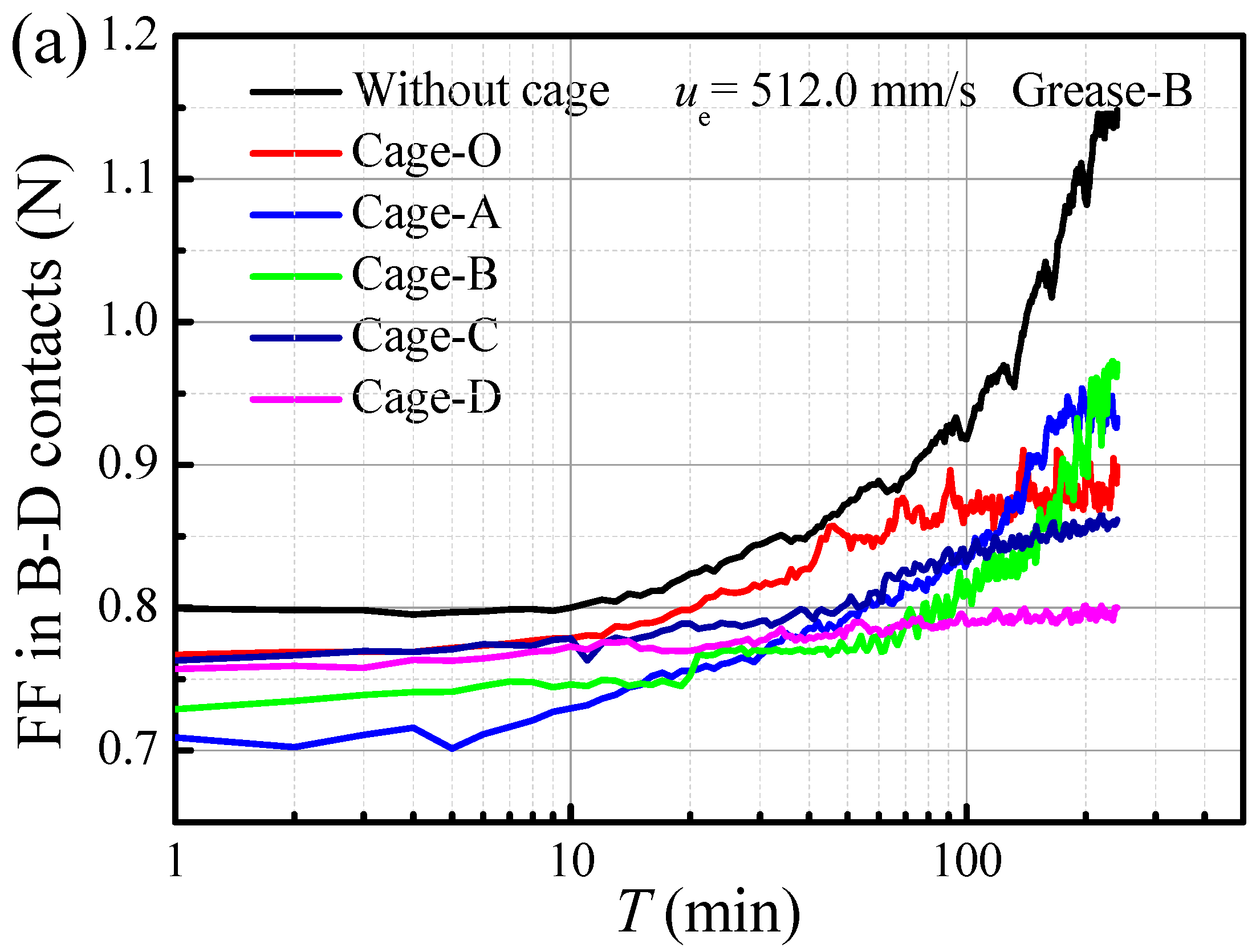

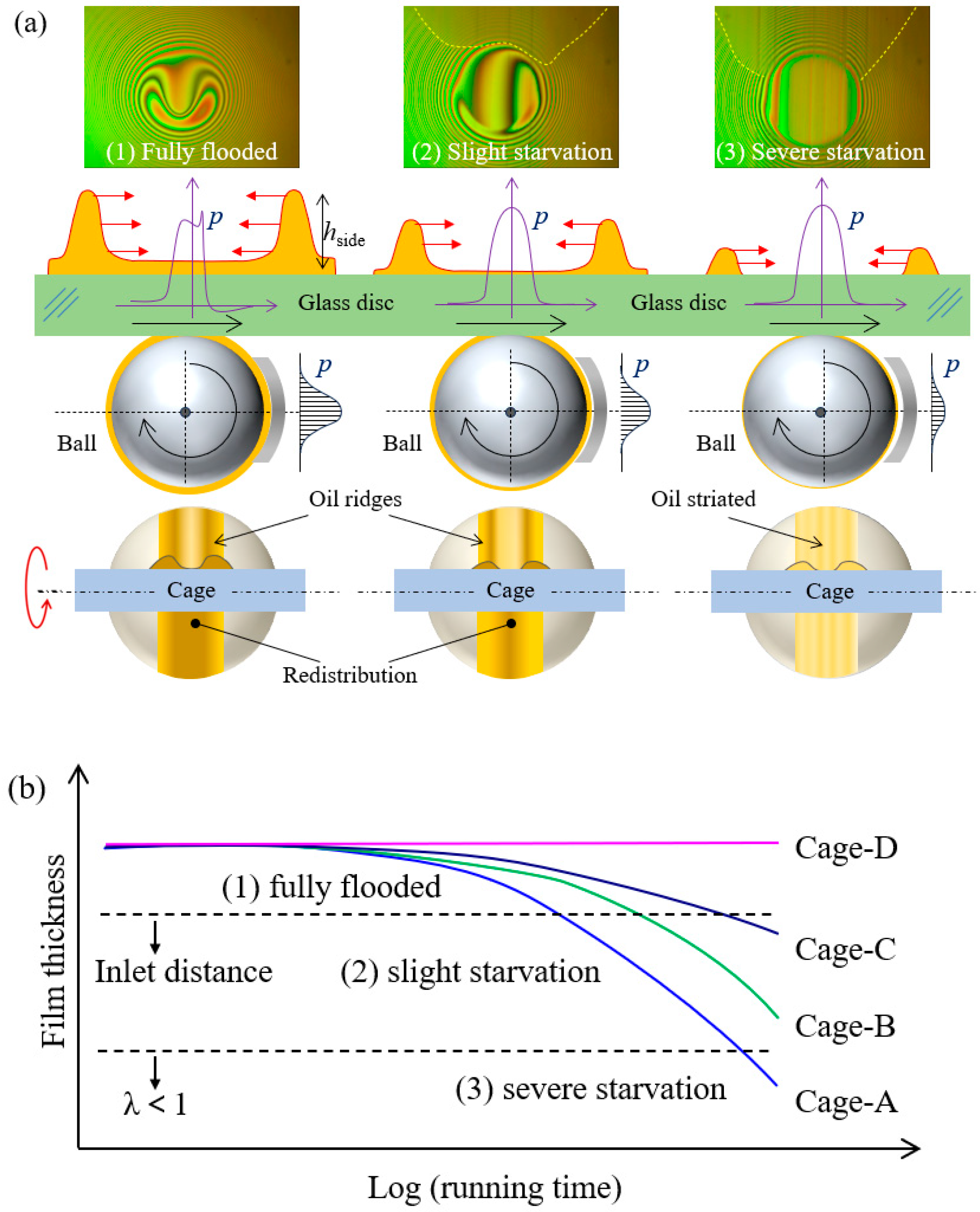

4.1. Effect of Cage on Lubrication State Transition

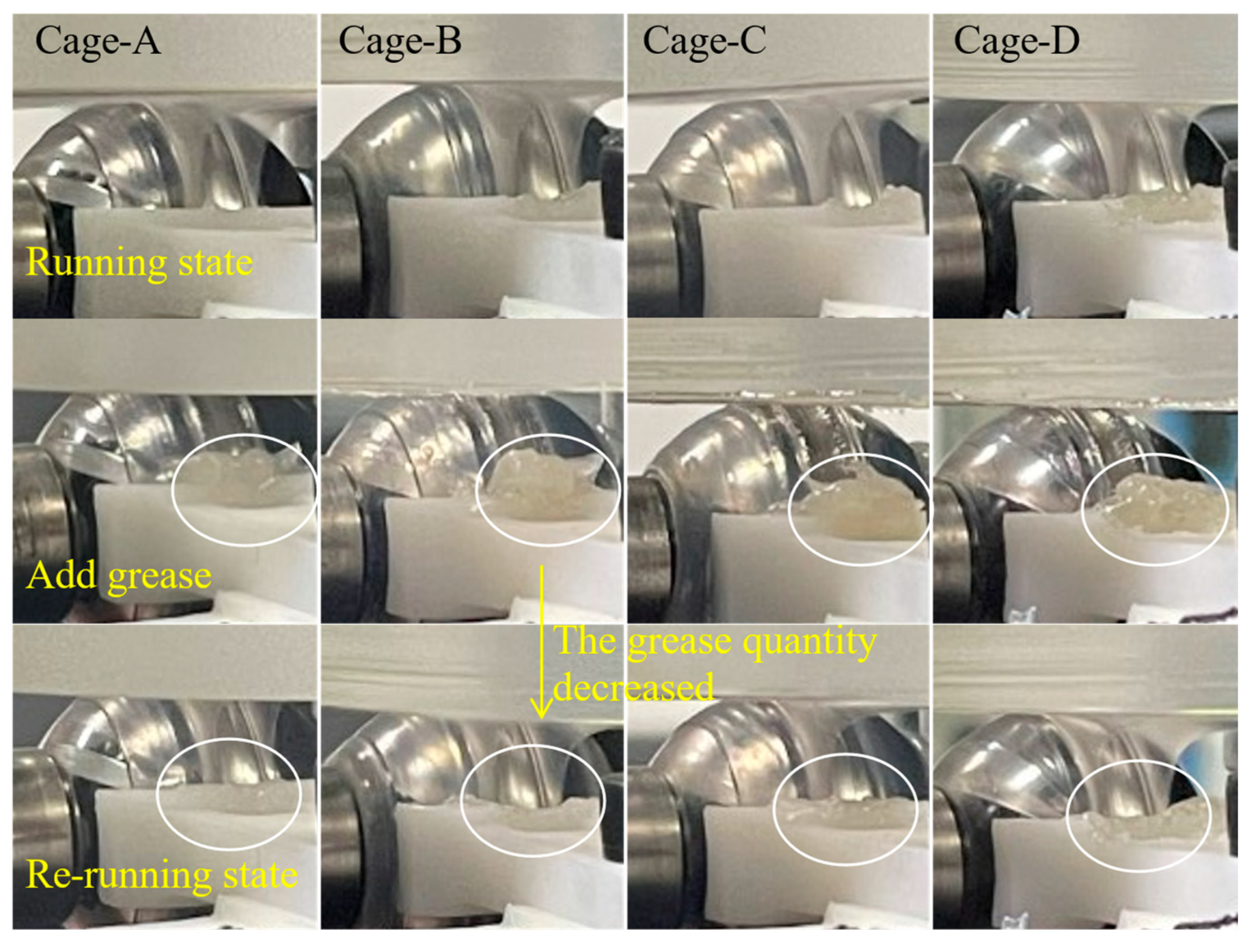

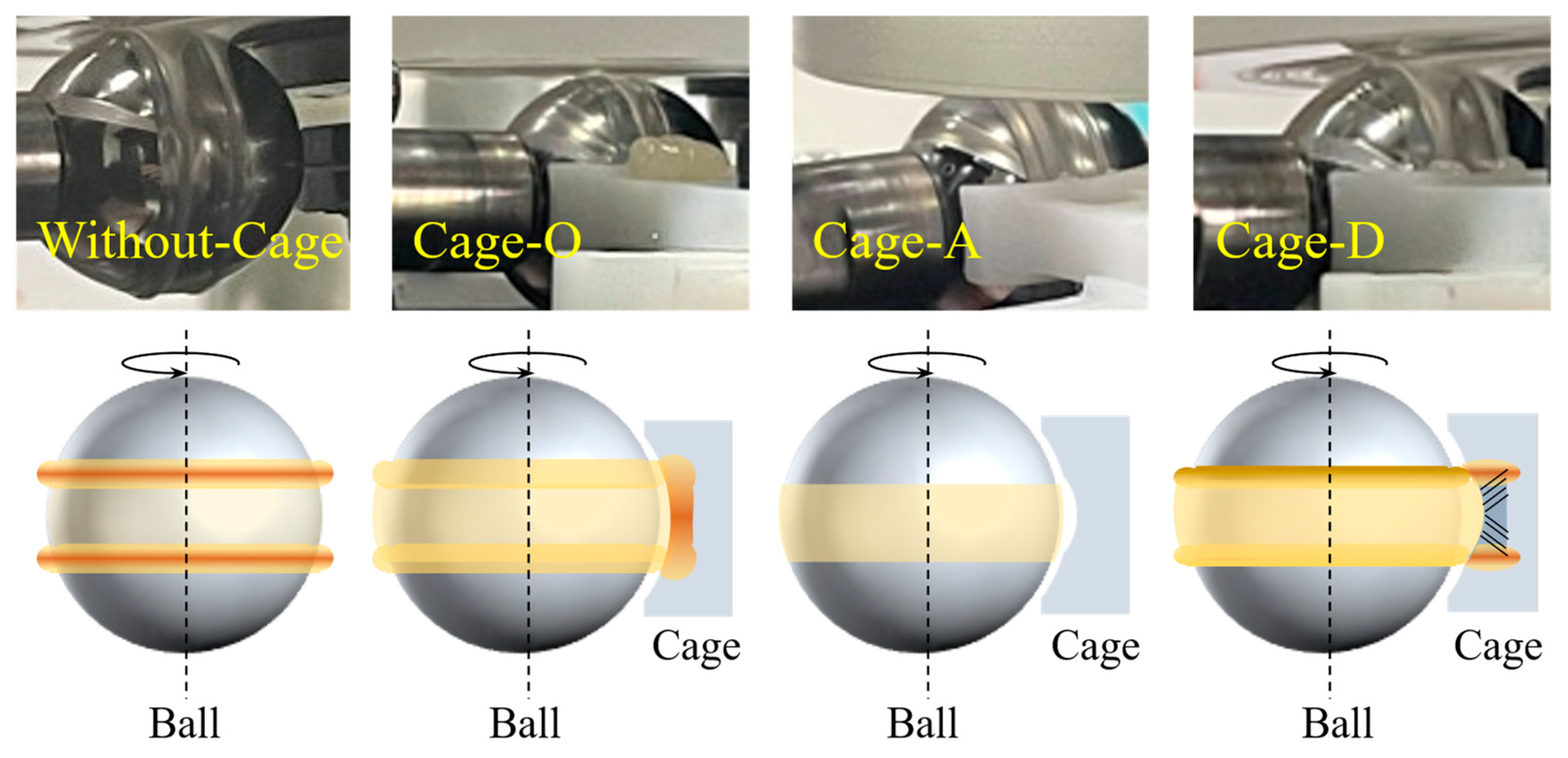

4.2. Effect of Cage on the Film Formation and Replenishment

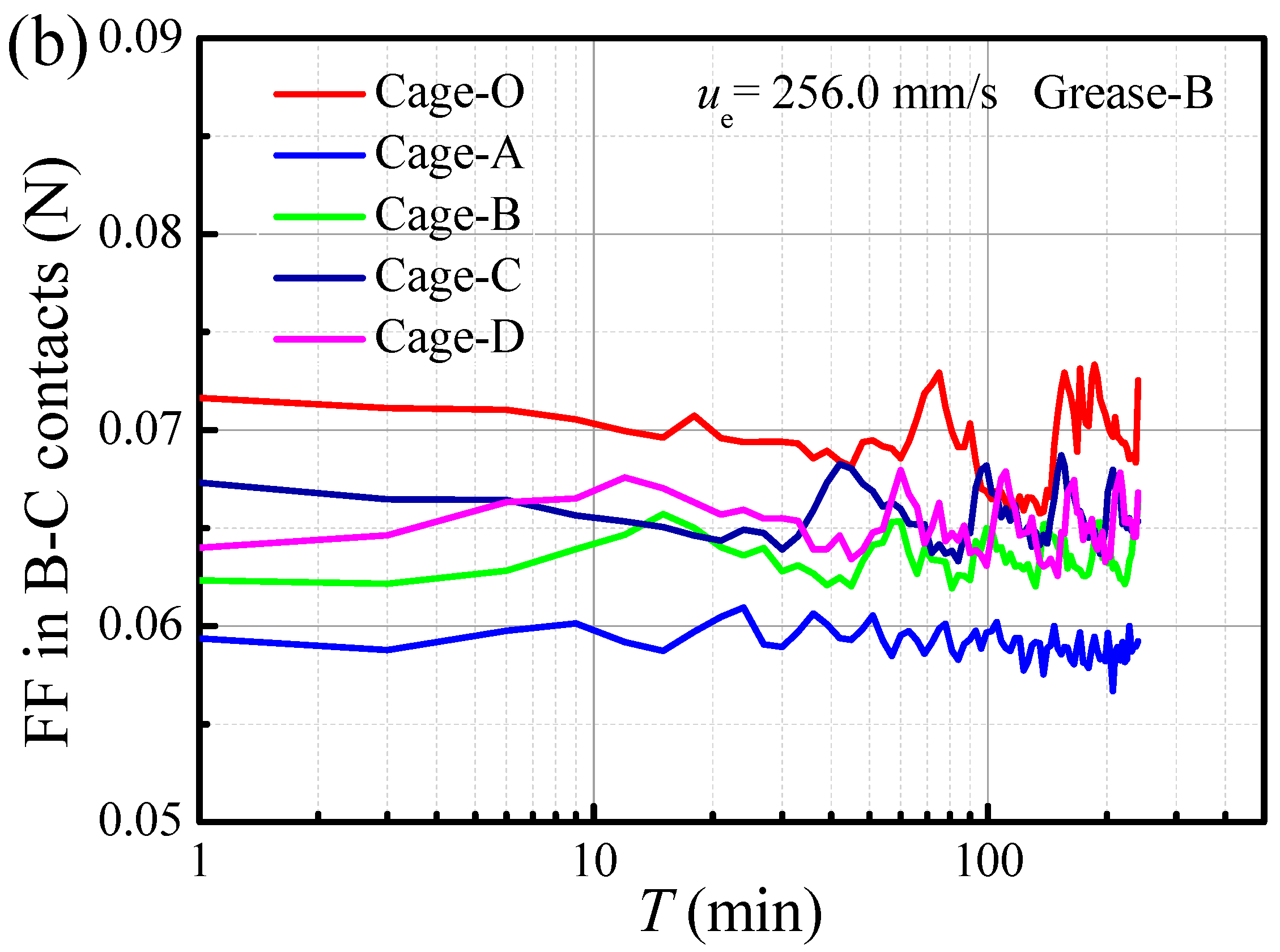

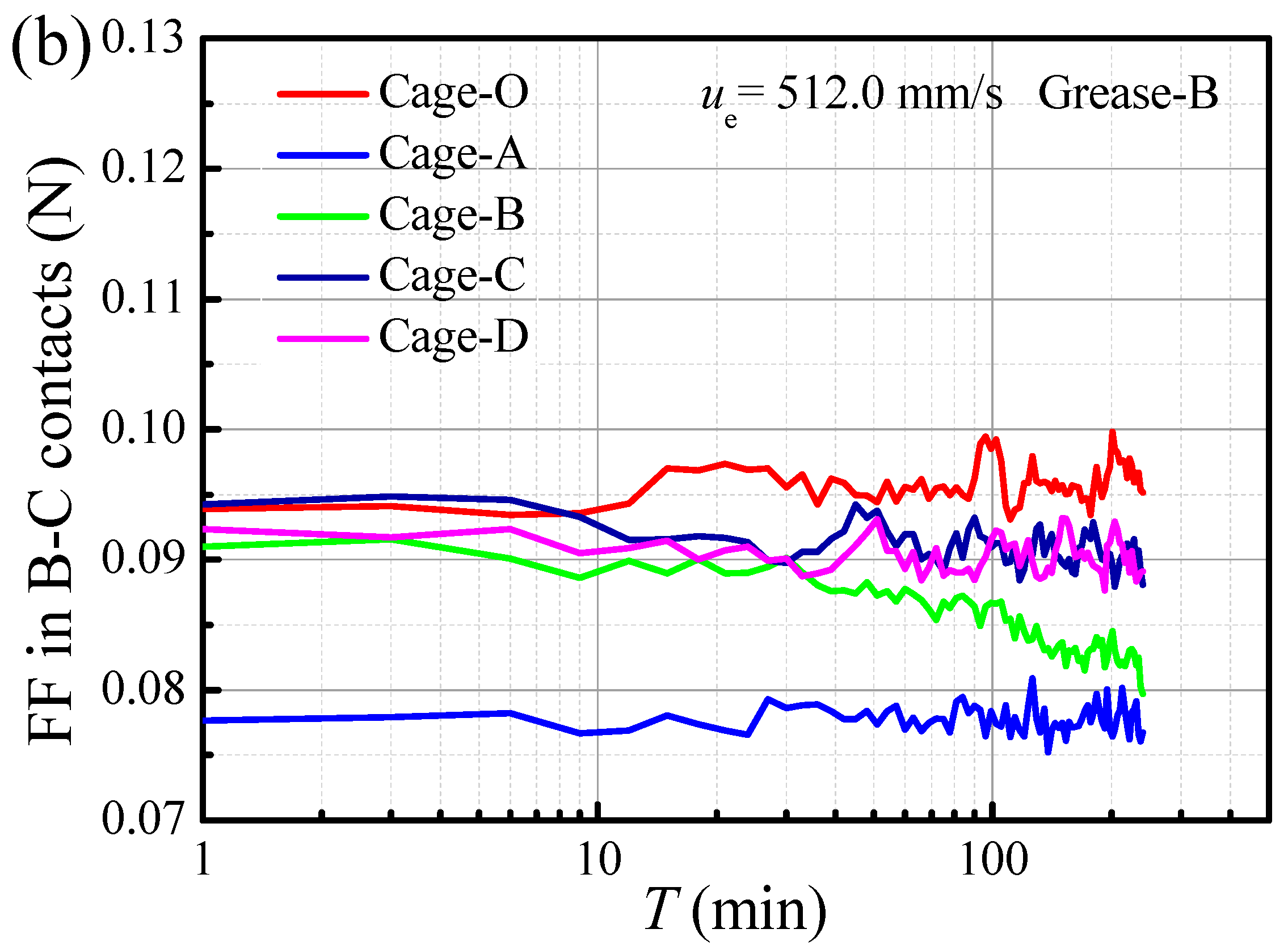

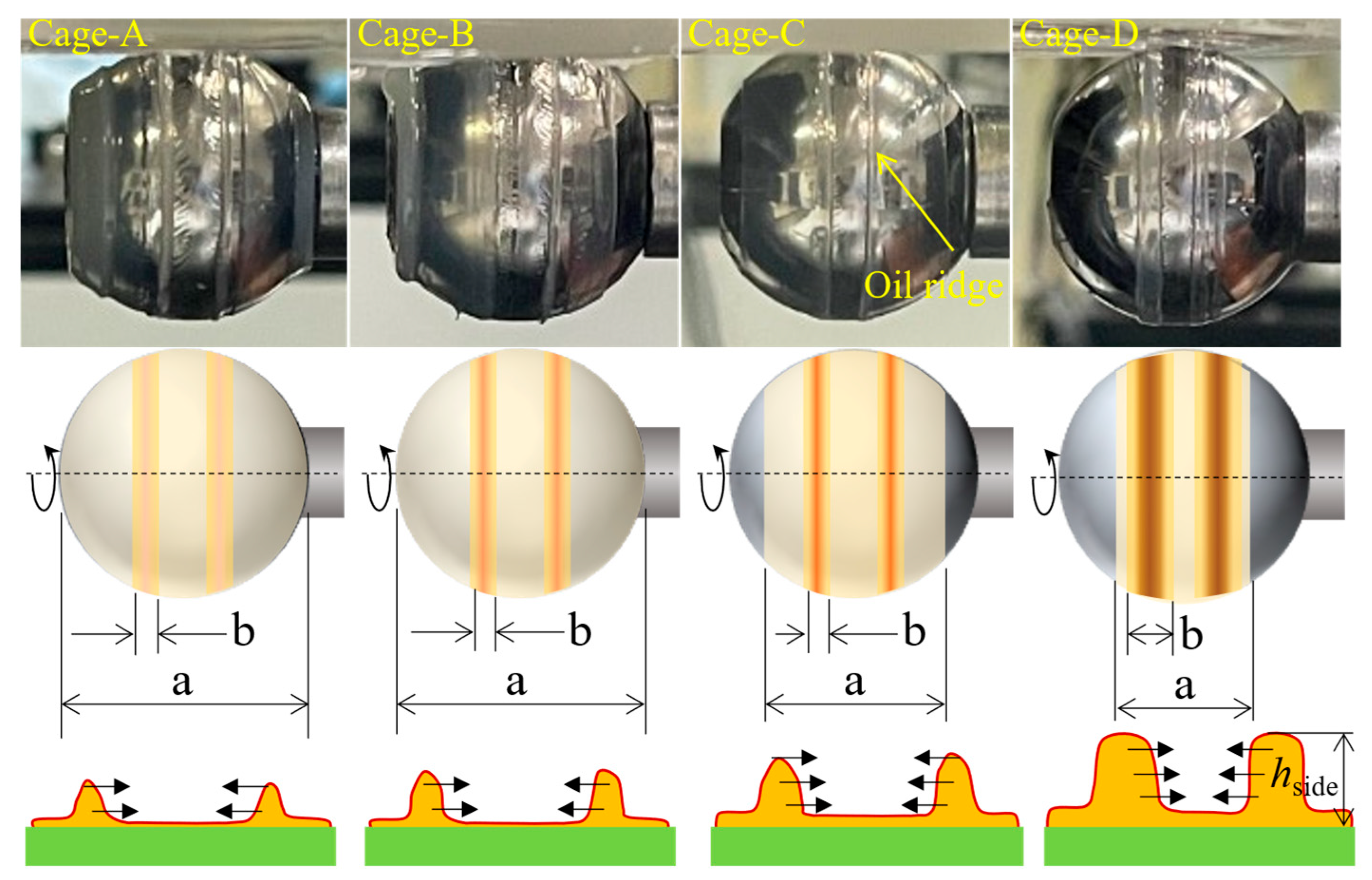

4.3. Comparisons of Replenishment and Distribution with Four Cage Pocket Shapes

5. Conclusions

- (1)

- The cage critically modulates lubrication evolution by defining three regimes: fully flooded, slight starvation, and severe starvation. Acting as a lubricant reservoir, it governs the replenishment rate that determines starvation severity: sufficient supply sustains mild starvation, while inadequate supply accelerates severe starvation and increases friction.

- (2)

- In the ball-cage (B-C) contact, the cage enhances lubrication by enlarging the oil ridge, thus expanding the local lubricant reservoir and facilitating flow toward the ball-disc (B-D) contact. The coupled replenishment mechanism consistently delivers grease to the raceway, producing a thicker, more stable lubricating film and thereby reducing friction, as confirmed by BCFL measurements.

- (3)

- Comparative evaluation of four cage designs demonstrated that pocket geometry plays a decisive role in lubricant redistribution efficiency; the grooved design (Cage-D), in particular, effectively guided grease flow to form the widest oil ridges on the ball surface and sustained a superior lubrication regime with thicker films and lower friction levels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Zhou, Y.Q.; Peng, X.; Chen, Y. An approach for predicting the vibro-impact behavior of angular contact ball bearing considering variable clearance. Lubricants 2025, 13, 216. [Google Scholar] [CrossRef]

- Cojocaru, D.; Ianuș, G.; Cârlescu, V.; Chiriac, B.; Olaru, D. Grease Film Behavior in Ball Bearings. Lubricants 2025, 13, 429. [Google Scholar] [CrossRef]

- Yu, C.; Cheng, R.; Zhang, H.; Ma, C.; Yu, S. The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication. Lubricants 2025, 13, 409. [Google Scholar] [CrossRef]

- Pei, X. Scale Effects of Surface-Texture Distribution on Lubrication and Friction. Tribol. Lett. 2025, 73, 86. [Google Scholar] [CrossRef]

- Yue, L.; Cao, H.; Meng, Y.; Wei, P.; Zhao, H.; Xu, W.; Bai, P.P.; Meng, Y.G.; Tian, Y. Frictional mechanisms of a novel base lubricant material: Optimizing tribological performance through viscosity-wear design. Friction 2025, accepted. [Google Scholar] [CrossRef]

- Gu, T.; Jane Wang, Q.; Xiong, S.; Liu, Z.; Gangopadhyay, A.; Liu, Z. Profile design for misaligned journal bearings subjected to transient mixed lubrication. J. Tribol. 2019, 141, 071701. [Google Scholar] [CrossRef]

- Sperka, P.; Krupka, I.; Hartl, M. Lubricant flow in thin-film elastohydrodynamic contact under extreme conditions. Friction 2016, 4, 380–390. [Google Scholar] [CrossRef]

- Okal, M.; Kostal, D.; Sperka, P.; Krupka, I.; Hartl, M. Effect of contact conformity on grease lubrication. Lubricants 2022, 10, 289. [Google Scholar] [CrossRef]

- Qiang, H.; Anling, L.; Yangming, Z.; Liu, S.; Yachen, G. Experimental study of tribological properties of lithium-based grease with Cu nanoparticle additive. Tribol.-Mater. Surf. Interfaces 2017, 11, 75–82. [Google Scholar] [CrossRef]

- Wen, C.W.; Meng, X.H.; Gu, J.M.; Xiao, L.; Jiang, S.; Bi, H.B. Starved lubrication analysis of angular contact ball bearing based on a multi-degree-of-freedom tribo-dynamic model. Friction 2023, 11, 1395–1418. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Chen, Z.G.; Tang, L.; Zhai, W.M. Skidding dynamic performance of rolling bearing with cage flexibility under accelerating conditions. Mech. Syst. Signal Process. 2021, 150, 107257. [Google Scholar] [CrossRef]

- Su, B.; Li, H.; Zhang, G.T.; Liu, F.B.; Cui, Y.C. Study on cage stability of solid-lubricated angular contact ball bearings in an ultra-low temperature environment. Lubricants 2024, 12, 124. [Google Scholar] [CrossRef]

- Guerzoni, F. Lubricants’ role in blade performance. Renew. Energy Focus 2014, 15, 28–29. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Fang, B.; Kong, L.F.; Li, Y. Effect of the ring misalignment on the service characteristics of ball bearing and rotor system. Mech. Mach. Theory 2020, 151, 103889. [Google Scholar] [CrossRef]

- Chen, H.B.; Liang, H.; Wang, W.Z.; Zhang, S.G. Investigation on the oil transfer behaviors and the air-oil interfacial flow patterns in a ball bearing under different capillary conditions. Friction 2023, 11, 228–245. [Google Scholar] [CrossRef]

- Gao, S.; Han, Q.H.; Pennacchi, P.; Chatterton, S.; Chu, F.L. Dynamic, thermal, and vibrational analysis of ball bearings with over-skidding behavior. Friction 2022, 11, 580–601. [Google Scholar] [CrossRef]

- Sadeghi, F.; Arya, U.; Aamer, S.; Meinel, A. A review of computational fluid dynamics approaches used to investigate lubrication of rolling element bearings. J. Tribol. 2024, 146, 100801. [Google Scholar] [CrossRef]

- Wang, P.F.; Yang, Y.; Ma, H.; Xu, H.Y.; Li, X.; Luo, Z.; Wen, B.C. Vibration characteristics of rotor-bearing system with angular misalignment and cage fracture: Simulation and experiment. Mech. Syst. Signal Process. 2023, 182, 109545. [Google Scholar] [CrossRef]

- You, J.Y.; Ma, X.Q.; Liu, C.Y.; Zuo, M.J.; Jin, D.L.; Zhang, H. Measurement and dynamic analysis of the centroid trajectories of angular-contact ball bearing cages. Lubricants 2024, 12, 379. [Google Scholar] [CrossRef]

- Yang, Y.; Qi, X.Y.; Wang, Y.J.; Wang, M.L.; Wen, B.G.; Zhai, J.Y. Dynamic characteristics of a cylindrical roller bearing with cage cracks. Lubricants 2025, 13, 25. [Google Scholar] [CrossRef]

- Yuan, D.; Wang, R.; Chen, S.; Chen, X. Experimental research on cage motion with different pocket shapes in angular contact ball bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1325–1335. [Google Scholar] [CrossRef]

- Zhang, G.; Shi, Y.; Li, C.; Xu, M.; Yin, Y. Unsteady seepage behavior of lubricant on loaded porous surface. Phys. Fluids 2022, 34, 072110. [Google Scholar] [CrossRef]

- Chen, W.; Wang, W.; Liang, H.; Zhu, P. Study on lubricant release-recycle performance of porous polyimide retainer materials. Langmuir 2022, 38, 11440–11450. [Google Scholar] [CrossRef]

- Zhao, H.; Prieto- López, L.O.; Zhou, X.; Deng, X.; Cui, J. Multistimuli responsive liquid-release in dynamic polymer coatings for controlling surface slipperiness and optical performance. Adv. Mater. Interfaces 2019, 6, 1901028. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, T.M.; Wang, Q.H.; Wang, C. Selectively enhanced oil retention of porous polyimide bearing materials by direct chemical modification. J. Appl. Polym. Sci. 2017, 134, 45106. [Google Scholar] [CrossRef]

- Maccioni, L.; Chernoray, V.G.; Concli, F. Investigating lubricant behavior in a partially flooded tapered roller bearing: Validation of a multiphase CFD solver for aerated oil sump via particle image velocimetry studies and high-speed camera acquisitions. Tribol. Int. 2025, 201, 110274. [Google Scholar] [CrossRef]

- Li, J.B.; Liu, J.Y.; Li, K.; Zhou, N.N.; Liu, Y.; Hu, X.D.; Yin, S.L.; Wang, G.R. Tribological properties of oil-impregnated polyimide in double-contact friction under micro-oil lubrication conditions. Friction 2023, 11, 1493–1504. [Google Scholar] [CrossRef]

- Russell, T.; Sadeghi, F.; Peterson, W.; Aamer, S.; Arya, U. A novel test rig for the investigation of ball bearing cage friction. Tribol. Trans. 2021, 64, 943–955. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, Y.; Wang, W.Z. Influence of the cage on the migration and distribution of lubricating oil inside a ball bearing. Friction 2021, 10, 1035–1045. [Google Scholar] [CrossRef]

- Damiens, B.; Lubrecht, A.; Cann, P.M. Influence of cage clearance on bearing lubrication. Tribol. Trans. 2004, 47, 2–6. [Google Scholar] [CrossRef]

- Jin, X.Y.; Li, X.M.; Liu, Y.; Gao, J.B.; Bai, L.Q. Experimental study of lubricant distribution and lubrication enhancement induced by ball bearing cage. J. Tribol. 2024, 146, 074103. [Google Scholar] [CrossRef]

- Jin, X.Y.; Wang, Y.H.; Bai, Q.H.; Li, X.M.; Jiang, H.; Guo, F.; Bai, X.Y.; Poll, G. Cage parameters on friction within cage-pockets contacts and lubrication behaviors in ball-raceway contacts. Tribol. Int. 2025, 209, 110747. [Google Scholar] [CrossRef]

- Liu, H.C.; Guo, F.; Guo, L.; Wong, P.L. A dichromatic interference intensity modulation approach to measurement of lubricating film thickness. Tribol. Lett. 2015, 58, 15–25. [Google Scholar] [CrossRef]

- Li, X.M.; Guo, F.; Poll, G.; Fei, Y.; Yang, P. Grease film evolution in rolling elastohydrodynamic lubrication contacts. Friction 2021, 9, 179–190. [Google Scholar] [CrossRef]

- Gershuni, L.; Larson, M.G.; Lugt, P.M. Lubricant replenishment in rolling bearing contact. Tribol. Trans. 2008, 51, 643–651. [Google Scholar] [CrossRef]

- Molina, M.; Gohar, R. Hydrodynamic lubrication of ball-bearing cage pockets. Arch. J. Mech. Eng. Sci. 1978, 20, 11–20. [Google Scholar] [CrossRef]

- Sathwik, C.K.R.; Osara, J.A.; Lugt, P.M. Impact of grease churning on grease leakage, oil bleeding, and grease rheology. Tribol. Int. 2022, 176, 107926. [Google Scholar] [CrossRef]

- Wedeven, L.; Evans, D.; Cameron, A. Optical analysis of ball bearing starvation. J. Tribol. 1971, 93, 349–361. [Google Scholar] [CrossRef]

- Chiu, Y. An analysis and prediction of lubricant film starvation in rolling contact systems. ASLE Trans. 1973, 17, 22–35. [Google Scholar] [CrossRef]

- Molina, M.; Gohar, R. Hydrodynamic design of ball bearing cage pockets. Tribol. Int. 1979, 12, 15–20. [Google Scholar] [CrossRef]

- Russell, T.; Sadeghi, F.; Kang, Y.S.; Mazzitelli, I. The influence of cage pocket lubrication on the simulation of deep groove ball bearing cage motion. J. Tribol. 2024, 146, 022201. [Google Scholar] [CrossRef]

- Shao, X.Y.; Cai, B.P.; Zou, Z.X.; Shao, H.D.; Yang, C.; Liu, Y.H. Artificial intelligence enhanced fault prediction with industrial incomplete information. Mech. Syst. Signal Process. 2025, 224, 112063. [Google Scholar] [CrossRef]

| Grease Samples | Viscosity of Base Oil (mm2/s) | Cone Penetration (0.1 mm) |

|---|---|---|

| Grease A | 66 ± 0.66 | 281 ± 1 |

| Grease B | 614 ± 6.14 | 293 ± 1 |

| Grease C | 1240 ± 12.4 | 284 ± 1 |

| Parameter | Values |

|---|---|

| Entrainment speed (mm/s), ue | 64.0 ± 0.5, 256.0 ± 0.5, 512.0 ± 0.5 |

| Load (N) | 30.0 |

| SRR | 0.05 |

| Ball diameter, (mm) | 25.4 |

| Ball surface roughness (Ra), nm | 14 ± 1 |

| Disc diameter, (mm) | 150 |

| Disc surface roughness (Ra), nm | 20 ± 1 |

| Grease amount (g) Temperature (°C) | 2.0, 1.0 22.0 ± 1 |

| Grease types | G-A, G-B, G-C |

| X axis-clearance (mm) | 0.2 |

| Y axis-height (mm) | 0.0 |

| Cage type Cage pocket radius (mm) | Cage-A, Cage-B Cage-C Cage-D 13.7 |

| Cage height (mm) | 8.47 |

| ue, mm/s | 64.0 ± 0.5 | 256.0 ± 0.5 | 512.0 ± 0.5 |

| ud, mm/s | 65.6 ± 0.5 | 262.4 ± 0.5 | 524.8 ± 0.5 |

| ub, mm/s | 62.4 ± 0.5 | 249.6 ± 0.5 | 499.2 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Jin, X.; Li, X.; Bai, Q.; Huang, X.; Jiang, H.; Zhang, G.; Guo, F.; Liu, C.; Li, J. Tailored Cage Shapes on Lubricant Migration and Friction Behaviours in Both Ball-Cage and EHL Contacts. Lubricants 2025, 13, 501. https://doi.org/10.3390/lubricants13110501

Zhou K, Jin X, Li X, Bai Q, Huang X, Jiang H, Zhang G, Guo F, Liu C, Li J. Tailored Cage Shapes on Lubricant Migration and Friction Behaviours in Both Ball-Cage and EHL Contacts. Lubricants. 2025; 13(11):501. https://doi.org/10.3390/lubricants13110501

Chicago/Turabian StyleZhou, Kecheng, Xuyang Jin, Xinming Li, Qinghua Bai, Xiongrong Huang, Hao Jiang, Guohui Zhang, Feng Guo, Chenglong Liu, and Jinjie Li. 2025. "Tailored Cage Shapes on Lubricant Migration and Friction Behaviours in Both Ball-Cage and EHL Contacts" Lubricants 13, no. 11: 501. https://doi.org/10.3390/lubricants13110501

APA StyleZhou, K., Jin, X., Li, X., Bai, Q., Huang, X., Jiang, H., Zhang, G., Guo, F., Liu, C., & Li, J. (2025). Tailored Cage Shapes on Lubricant Migration and Friction Behaviours in Both Ball-Cage and EHL Contacts. Lubricants, 13(11), 501. https://doi.org/10.3390/lubricants13110501