Toughening Mechanisms of Diamond-like Carbon Films via Non-Carbide Metal Doping

Abstract

1. Introduction

2. Effect of Metal Doping on DLC Properties

2.1. Distinction Between Carbide-Forming and Non-Carbide-Forming Metals

| Deposition Method | Metal Content (at.%) | Thickness (μm) | Hardness (GPa) | Wear Rate (×10−7 mm3/N·m) | Toughness Evaluation Method | Toughness/ Mechanism |

|---|---|---|---|---|---|---|

| Magnetron Sputtering [21] | Ti/10 | 1.5 | 28 | 5.0 | Scratch Test (Critical Load) | TiC nanocrystals refined structure and moderately improved adhesion/toughness; excessive doping led to brittleness. |

| Unbalanced Magnetron Sputtering [26] | Cr/15 | ~2.0 | 22 | 3.2 | Scratch Test, Impact Test | Nanocomposite (nc-CrCx/a-C) showed high hardness but limited toughness gain; failure often occurred via brittle fracture of carbides. |

| Filtered Cathodic Vacuum Arc [27] | W/5 | 1.0–1.5 | 35–40 | 0.5–1.5 | Nanoindentation (Fracture toughness model) | Ultra-high hardness maintained; moderate toughness improvement attributed to compressive stress and nanocrystalline WC formation, but ductile deformation is minimal. |

| Closed Field Unbalanced Magnetron Sputtering [28] | Mo/8 | ~1.8 | 25 | 2.8 | Rockwell-C Adhesion, Wear Track Analysis | MoCx formation increased hardness and thermal stability. Adhesion was improved, but the fracture toughness improvement was marginal compared to non-carbide metals. |

| Metal Content (at.%) | Deposition | Thickness (μm) | Hardness (GPa) | Wear Rate (×10−7 mm3/N·m) | Toughness Evaluation Method | Toughness/ Mechanism |

|---|---|---|---|---|---|---|

| Ag/15 [20] | Ion Beam Assisted Deposition | 1.0 | 15 | 0.2 | Impact Test & Scratch Test | Optimal Ag content resulted in significant toughness improvement via crack bridging and plastic deformation of Ag particles. |

| Cu/10.5 [33] | Magnetron Sputtering | 1.2 | 18 | 0.8 | Scratch Test (CPRS) | Maximum crack propagation resistance achieved; Cu particles act as bridges and blunt crack tips |

| Au/6 [34] | Pulsed Laser Deposition | 0.8 | 12 | 1.0 | Nanoindentation | Ductile Au nanoparticles improved toughness and reduced friction, but caused significant hardness loss. |

| Al/5 [35] | Plasma-Enhanced CVD | 1.5 | 20 | 2.5 | Scratch Test | Moderate toughness improvement; complex behavior due to potential for very fine AlxCy formation influencing interface strength. |

2.2. Influence on Structure, Hardness, Stress, and Tribological Properties

3. Toughening Mechanisms of Non-Carbide Metal Doping

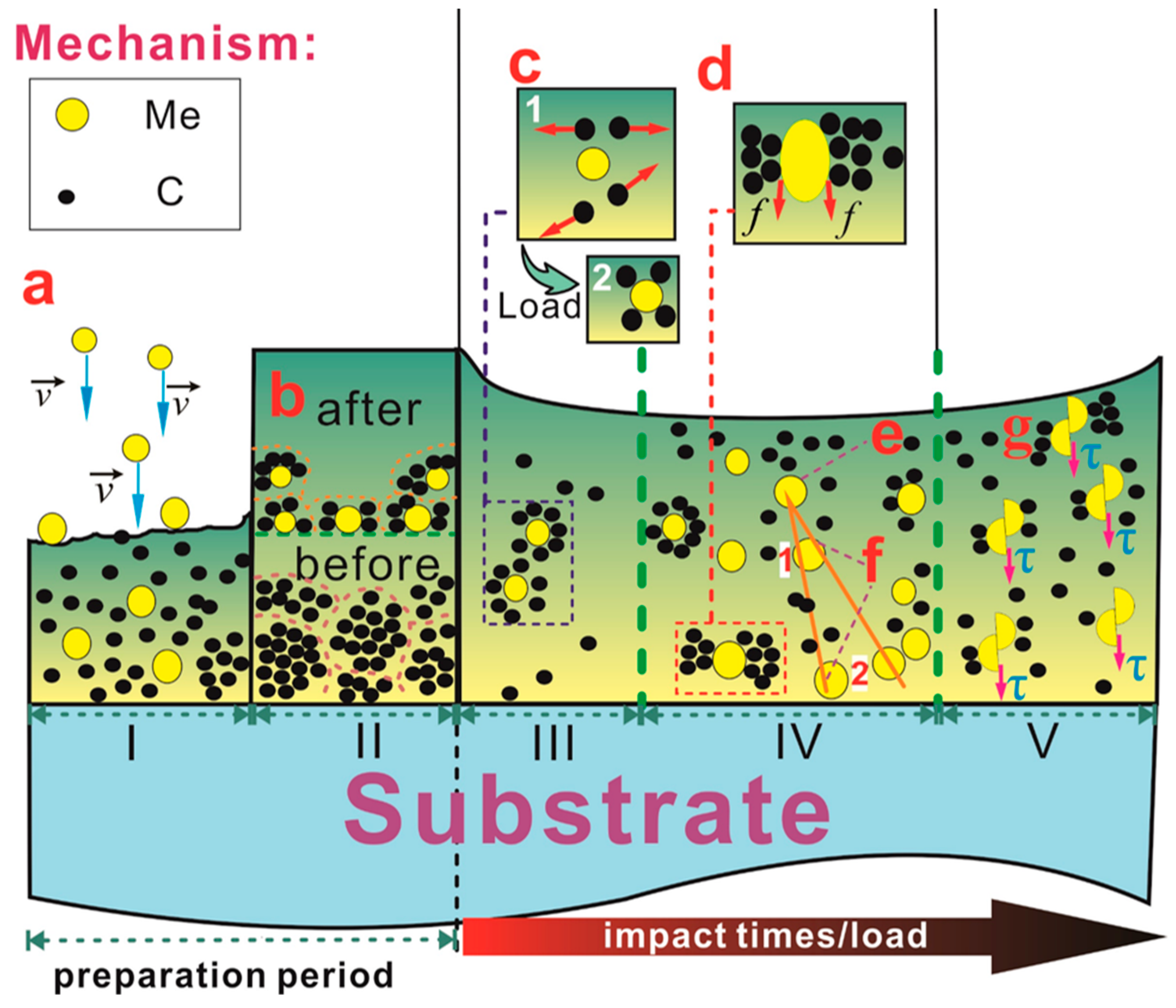

- Mechanism I: Bombardment-Induced Compressive Stress Relief (Figure 4a)

- Mechanism II: Atomic Cluster Refinement and Boundary Multiplication (Figure 4b)

- Mechanism III: Carbon Atom Rearrangement and Dislocation Accumulation Inhibition (Figure 4c)

- Mechanism IV: Plastic Deformation and Crack Bridging (Figure 4d–f)

- Mechanism V: Shear-Induced Stress Relief (Figure 4g).

4. Influential Factors and Optimal Doping Content

4.1. Seven Influential Factors (a-g)

4.2. Determination of Optimal Doping Content and Negative Effects of Over-Doping

5. Case Studies: Experimental Validation of Toughening Mechanisms

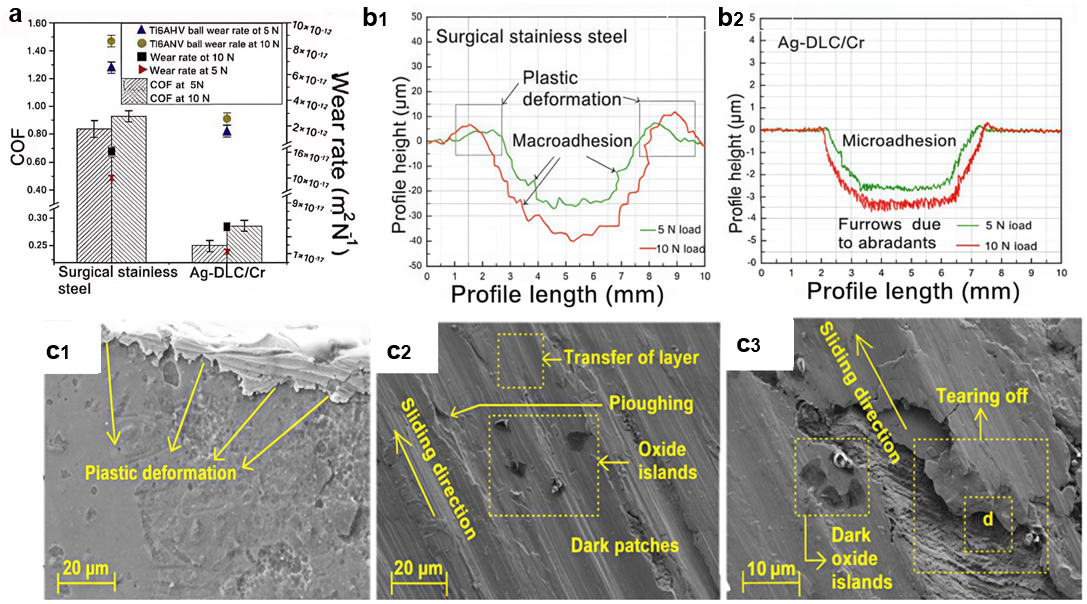

5.1. Ag-DLC: The Paradigm of Ductile Phase Toughening

5.2. Cu-DLC: Balancing Toughness and Hardness

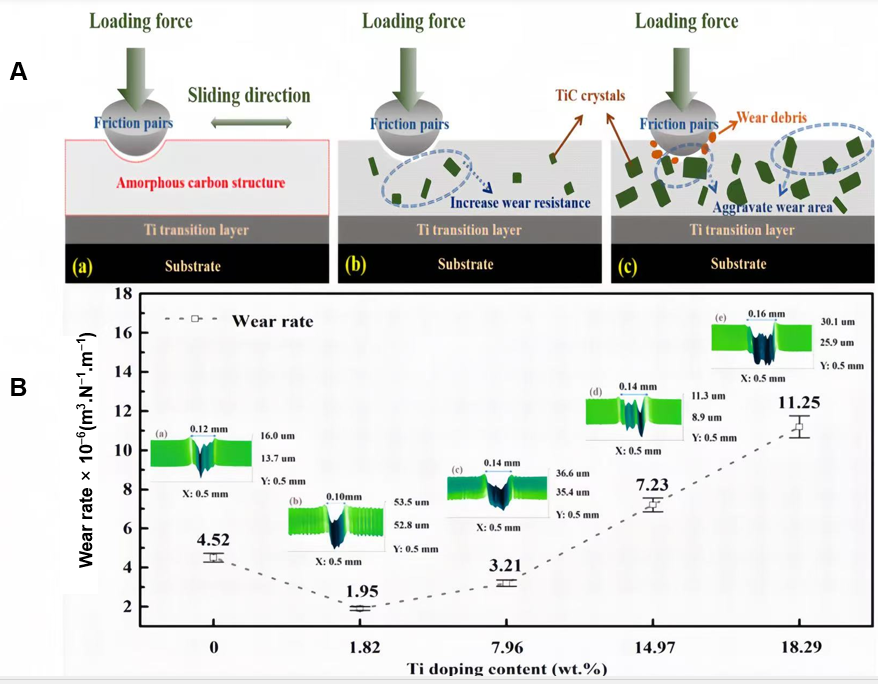

5.3. Ti-DLC: A Contrasting Case of Carbide-Forming Metal

6. Conclusions and Outlook

6.1. Summary of Mechanisms

6.2. Future Research Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Li, X.; Xu, P.; Zhang, H.; Liu, L. Recent advances and challenges in tribology of diamond-like carbon films: A critical review. Diam. Relat. Mater. 2025, 154, 112206. [Google Scholar] [CrossRef]

- Yang, C.; Ou, Z.; Mu, Y.; Chen, X.; Yang, S.; Guo, P.; Jiang, N.; Nishimura, K.; Mao, X.; Song, H.; et al. Tribological Properties of Diamond/Diamond-like Carbon (DLC) Composite Coating in a Dry Environment. Materials 2025, 18, 3879. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced characterization methods for wear resistant hard coatings: A review on recent progress. Surf. Coat. Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. Approaches to investigate delamination and interfacial toughness in coated systems: An overview. J. Phys. D Appl. Phys. 2011, 44, 34001. [Google Scholar] [CrossRef]

- Jiang, Z.T.; Li, Y.G.; Lei, M.K. An inverse problem in estimating fracture toughness of TiAlN thin films by finite element method based on nanoindentation morphology. Vacuum 2021, 192, 110458. [Google Scholar] [CrossRef]

- Shin, D.; Jang, D. Crack-tip plasticity and intrinsic toughening in nano-sized brittle amorphous carbon. Int. J. Plast. 2020, 127, 102642. [Google Scholar] [CrossRef]

- Beake, B.D. Nano-and Micro-Scale Impact Testing of Hard Coatings: A Review. Coatings 2022, 12, 793. [Google Scholar] [CrossRef]

- Liu, M.; Yan, F. Scratch-induced deformation and damage behavior of doped diamond-like carbon films under progressive normal load of Vickers indenter. Thin Solid Film. 2022, 756, 139351. [Google Scholar] [CrossRef]

- Beake, B.D.; Liskiewicz, T.W.; Bird, A.; Shi, X. Micro-scale impact testing—A new approach to studying fatigue resistance in hard carbon coatings. Tribol. Int. 2020, 149, 105732. [Google Scholar] [CrossRef]

- Jeng, Y.-R.; Islam, S.; Wu, K.-T.; Erdemir, A.; Eryilmaz, O. Investigation of Nano-Mechanical and-Tribological Properties of Hydrogenated Diamond Like Carbon (DLC) Coatings. J. Mech. 2016, 33, 769–776. [Google Scholar] [CrossRef]

- Miyake, S.; Saito, T.; Yasuda, Y.; Okamoto, Y.; Kano, M. Improvement of boundary lubrication properties of diamond-like carbon (DLC) films due to metal addition. Tribol. Int. 2004, 37, 751–761. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, X.; Du, Z.; Zhu, Z.; Wu, Z.; Liu, L. Synergistic effect of surface textures and DLC coatings for enhancing friction and wear performances of Si3N4/TiC ceramic. Ceram. Int. 2022, 48, 514–524. [Google Scholar] [CrossRef]

- Yetim, A.F.; Kovacı, H.; Kasapoğlu, A.E.; Bozkurt, Y.B.; Çelik, A. Influences of Ti, Al and V metal doping on the structural, mechanical and tribological properties of DLC films. Diam. Relat. Mater. 2021, 120, 108639. [Google Scholar] [CrossRef]

- Peckus, D.; Meškinis, Š.; Vasiliauskas, A.; Rajackaitė, E.; Andrulevičius, M.; Kopustinskas, V.; Tamulevičius, S. Structure and optical properties of diamond like carbon films containing aluminium and alumina. Appl. Surf. Sci. 2020, 529, 147040. [Google Scholar] [CrossRef]

- Lim, D.K.; Rudd, D.; Khoo, K.G.; Che, F.X.; Vempaty, V.R.S.P.; Sim, W.H.; Singh, H.V.; Yan, W.; Lim, Y.K. An integrated nanoindentation-finite element analysis approach for fracture toughness characterization and yield strength prediction in semiconductor thin films. Mater. Des. 2025, 257, 114437. [Google Scholar] [CrossRef]

- Bird, A.; Yang, L.; Wu, G.; Inkson, B.J. Failure mechanisms of diamond like carbon coatings characterised by in situ SEM scratch testing. Wear 2023, 530–531, 205034. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Yuan, G.; Zhang, Y.X.; Liu, C.Y.; Wang, Y.; Fang, F.; Wang, G.D.; Pang, Y.Y. Microstructure and mechanical properties of Zr55Cu30Al10Ni5 amorphous alloy with high-energy states produced by strip casting. J. Alloys Compd. 2021, 861, 158542. [Google Scholar] [CrossRef]

- Hu, Z.; Dong, H.; Mu, Y.; Fan, C.; Jia, Y.; Ren, J.; Qi, A.; Wang, G. High strength and ductility high-entropy intermetallic matrix composites reinforced with in-situ hierarchical TiB2 particles. Compos. Part B-Eng. 2024, 283, 111556. [Google Scholar] [CrossRef]

- Gu, K.; Zheng, Y.; Luo, J.; Qin, X.; Yang, X.; Abbas, N.; Tang, J. Microstructure, mechanical and tribological properties of DLC/Cu-DLC/W-DLC composite films on SUS304 stainless steel substrates. Mater. Res. Express 2019, 6, 086406. [Google Scholar] [CrossRef]

- Jing, P.P.; Ma, D.L.; Gong, Y.L.; Luo, X.Y.; Zhang, Y.; Weng, Y.J.; Leng, Y.X. Influence of Ag doping on the microstructure, mechanical properties, and adhesion stability of diamond-like carbon films. Surf. Coat. Technol. 2021, 405, 126542. [Google Scholar] [CrossRef]

- Sui, X.; Liu, J.; Zhang, S.; Yang, J.; Hao, J. Microstructure, mechanical and tribological characterization of CrN/DLC/Cr-DLC multilayer coating with improved adhesive wear resistance. Appl. Surf. Sci. 2018, 439, 24–32. [Google Scholar] [CrossRef]

- Moskalewicz, T.; Wendler, B.; Czyrska-Filemonowicz, A. Microstructural characterisation of nanocomposite nc-MeC/a-C coatings on oxygen hardened Ti-6Al-4V alloy. Mater. Charact. 2010, 61, 959–968. [Google Scholar] [CrossRef]

- Li, W.; Wang, X.; Zhang, S.; Xu, C.; Chen, L.; Zhang, B. Advances in Diamond-like Carbon Films for Friction Nanogenerator Applications. Surf. Technol. 2025, 54, 17–31. [Google Scholar]

- Gershman, I.; Mironov, A.; Mezrin, A.; Torskaya, E.; Kuznetsova, T.; Lapitskaya, V.; Rogachev, A. Effect of sp3–sp2 Transformation on the Wear Rate of the DLC Coating. Lubricants 2022, 10, 85. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, L.; Shao, W.; Chen, Z.; Wang, S.; Xing, X.; Yang, Q. Mechanical and tribological behaviors of Ti-DLC films deposited on 304 stainless steel: Exploration with Ti doping from micro to macro. Diam. Relat. Mater. 2020, 107, 107870. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Ding, X.; Zhou, Z.; Wang, C.; Zhang, W.; Li, L.K.Y.; Lee, S.T. Structure and water-lubricated tribological properties of Cr/a-C coatings with different Cr contents. Tribol. Int. 2013, 67, 104–115. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Blagoveshchenskii, Y.V.; Sakharov, N.V.; Boldin, M.S.; Nokhrin, A.V.; Isaeva, N.V.; Shotin, S.V.; Lopatin, Y.G.; Smirnova, E.S. Preparation and investigation of ultrafine-grained tungsten carbide with high hardness and fracture toughness. Dokl. Phys. 2015, 60, 288–291. [Google Scholar] [CrossRef]

- Sun, Q.; Mao, X.; Yao, Y.; Li, J.; Shen, Z.; Tu, K.N.; Liu, Y. Effect of WC thickness on the microstructure and properties of WC-C/DLC coated 304 steel. Appl. Surf. Sci. 2025, 704, 163418. [Google Scholar] [CrossRef]

- Gupta, S.; Goswami, D.K. A progress review on diamond–like carbon film by electrodeposition technique, current status and challenges. Electrochim. Acta 2023, 468, 143123. [Google Scholar] [CrossRef]

- Endrino, J.L. Elucidating the structure of amorphous-carbon films containing carbide and non-carbide-forming metals. J. Electron. Spectrosc. Relat. Phenom. 2024, 277, 147500. [Google Scholar] [CrossRef]

- Yang, Z.; Ni, Z.; Yan, J.; Fan, L.; Zhang, J.; Chen, X.; Guan, R. Towards high performance nano multilayered graphene/5052 Al composite: In situ interfacial tailoring via accumulative roll bonding. Carbon 2025, 238, 120213. [Google Scholar] [CrossRef]

- Patnaik, L.; Maity, S.R.; Kumar, S. Comprehensive structural, nanomechanical and tribological evaluation of silver doped DLC thin film coating with chromium interlayer (Ag-DLC/Cr) for biomedical application. Ceram. Int. 2020, 46, 22805–22818. [Google Scholar] [CrossRef]

- Ning, Z.W.; Yu, X.; Hua, M.; Wang, C.B. Influence of copper content and nanograin size on toughness of copper containing diamond-like carbon films. Mater. Res. Innov. 2013, 17, s66–s69. [Google Scholar] [CrossRef]

- Panda, M.; Krishnan, R.; Krishna, N.G.; Amirthapandian, S.; Magudapathy, P.; Kamruddin, M. Tuning the tribological property of PLD deposited DLC-Au nanocomposite thin films. Ceram. Int. 2019, 45, 8847–8855. [Google Scholar] [CrossRef]

- Zou, Y.S.; Zhou, K.; Wu, Y.F.; Yang, H.; Cang, K.; Song, G.H. Structure, mechanical and tribological properties of diamond-like carbon films on aluminum alloy by arc ion plating. Vacuum 2012, 86, 1141–1146. [Google Scholar] [CrossRef]

- Iliescu, I.; Gazal, Y.; Michau, A.; Addou, F.; Duguet, T.; Monsifrot, E.; Schuster, F.; Maury, F. Low temperature Direct Liquid Injection MOCVD of amorphous CrCx coatings in large-scale reactors: An original route to nanostructured multilayer coatings. Surf. Coat. Technol. 2021, 416, 127174. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, X.; Zhang, Z.; Shu, W.; Li, J. Attempting AG-doped diamond-like carbon film to improve seal performance of hydraulic servo-actuator. Materials 2020, 13, 2618. [Google Scholar] [CrossRef] [PubMed]

- Wongpanya, P.; Silawong, P.; Photongkam, P. Adhesion and corrosion of Al–N doped diamond-like carbon films synthesized by filtered cathodic vacuum arc deposition. Ceram. Int. 2022, 48, 20743–20759. [Google Scholar] [CrossRef]

- Ren, Y.; He, X.; Wang, X.Z.; Liu, J.; Yu, H.; Hu, X.; Du, C.F.; Wu, G.; Wang, L. Tribo-induced amorphous nanocomposite for tribological improvement of multilayer (AlCrZrNbV)N-Ag film. Appl. Surf. Sci. 2025, 713, 164283. [Google Scholar] [CrossRef]

- Ţălu, Ş.; Astinchap, B.; Abdolghaderi, S.; Shafiekhani, A.; Morozov, I.A. Multifractal investigation of Ag/DLC nanocomposite thin films. Sci. Rep. 2020, 10, 22266. [Google Scholar] [CrossRef]

- Kametani, N.; Nakamura, M.; Yashiro, K.; Takaki, T. Molecular dynamics simulation of the residual stresses within diamond-like carbon films on iron substrates. Diam. Relat. Mater. 2025, 151, 111860. [Google Scholar] [CrossRef]

- Garmroudi Nezhad, E.; Saba, F.; Fan, G.; Tan, Z.; Li, Z. Towards overcoming hetero-deformation-induced hardening and strain localization Trade-off: A review of micro/nano hybrid-reinforced composites. Compos. Part B-Eng. 2026, 308, 113028. [Google Scholar] [CrossRef]

- Wu, Y.; Qi, J.; Li, K.; Zhou, X.; Yu, S.; Zhang, C.; Liu, Y. Preparation and tribological properties of Ni/DLC multilayer film. J. Vac. Sci. Technol. A 2024, 42, 023419. [Google Scholar] [CrossRef]

- Cemin, F.; Abadias, G.; Minea, T.; Furgeaud, C.; Brisset, F.; Solas, D.; Lundin, D. Benefits of energetic ion bombardment for tailoring stress and microstructural evolution during growth of Cu thin films. Acta Mater. 2017, 141, 120–130. [Google Scholar] [CrossRef]

- Ramírez, G.; Gonzalez Castro, J.M.; Orrit-Prat, J.; Bonet, R.; Cuadrado, N.; Vilaseca, M.; Carreras, L.; Caro, J. Super-Hard DLC Coatings as an Alternative to Polycrystalline Diamond for Cutting Tools: Predictive Analysis of Aluminium Alloy Surface Quality. Lubricants 2022, 10, 135. [Google Scholar] [CrossRef]

- Zhao, Y. Combined effect of nanoparticle and grain refinement on yield stress of nanocomposite. Philos. Mag. 2020, 100, 267–311. [Google Scholar] [CrossRef]

- Bui, X.L.; Pei, Y.T.; Mulder, E.D.G.; De Hosson, J.T.M. Adhesion improvement of hydrogenated diamond-like carbon thin films by pre-deposition plasma treatment of rubber substrate. Surf. Coat. Technol. 2009, 203, 1964–1970. [Google Scholar] [CrossRef]

- Feng, S.D.; Li, L.; Chan, K.C.; Qi, L.; Zhao, L.; Wang, L.M.; Liu, R.P. Control of shear band dynamics in Cu50Zr50 metallic glass by introducing amorphous-crystalline interfaces. J. Alloys Compd. 2019, 770, 896–905. [Google Scholar] [CrossRef]

- Poletaev, G.; Sannikov, A.; Bebikhov, Y.; Semenov, A. Molecular dynamics study of melting and crystallization of nickel nanoparticles with carbon impurity. Mol. Simul. 2024, 50, 710–716. [Google Scholar] [CrossRef]

- Çelik, Ş.; Andersen, R.G.; Tekoğlu, C.; Nielsen, K.L. On the dependence of crack surface morphology and energy dissipation on microstructure in ductile plate tearing. Int. J. Fract. 2021, 230, 115–132. [Google Scholar] [CrossRef]

- Shu, K.; Zhang, C.; Hou, P.; Zheng, D.; Gu, L.; Wang, L. Crack evolution in diamond-like carbon films on steel substrates during nano-indentation. Diam. Relat. Mater. 2020, 106, 107829. [Google Scholar] [CrossRef]

- Kasperski, A.; Weibel, A.; Estournès, C.; Laurent, C.; Peigney, A. Preparation-microstructure-property relationships in double-walled carbon nanotubes/alumina composites. Carbon 2013, 53, 62–72. [Google Scholar] [CrossRef]

- Aditya, S.S.; Al Amin, M.D.; Roy, S. Atomistic simulation of crack tip shielding effect due to embedded nanoparticles in amorphous carbon. Theor. Appl. Fract. Mech. 2025, 140, 105198. [Google Scholar] [CrossRef]

- Vieira, L.; Lucas, F.L.C.; Fisssmer, S.F.; dos Santos, L.C.D.; Massi, M.; Leite, P.M.S.C.M.; Costa, C.A.R.; Lanzoni, E.M.; Pessoa, R.S.; Maciel, H.S. Scratch testing for micro- and nanoscale evaluation of tribocharging in DLC films containing silver nanoparticles using AFM and KPFM techniques. Surf. Coat. Technol. 2014, 260, 205–213. [Google Scholar] [CrossRef]

- Li, R.; Yang, X.; Wang, Y.; Zhang, J.; Li, J. Graphitic encapsulation and electronic shielding of metal nanoparticles to achieve metal-carbon interfacial superlubricity. ACS Appl. Mater. Interfaces 2021, 13, 3397–3407. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Ning, Z.W.; Hua, M.; Wang, C.B. Influence of silver incorporation on toughness improvement of diamond-like carbon film prepared by ion beam assisted deposition. J. Adhes. 2013, 89, 578–593. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Sun, D. Crack propagation resistance of Cu-doped diamond-like carbon films. Surf. Coat. Technol. 2013, 235, 495–500. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Yang, Z.; Cui, G.; Lv, J.; Yu, X. Toughening Mechanisms of Diamond-like Carbon Films via Non-Carbide Metal Doping. Lubricants 2025, 13, 496. https://doi.org/10.3390/lubricants13110496

Liu J, Yang Z, Cui G, Lv J, Yu X. Toughening Mechanisms of Diamond-like Carbon Films via Non-Carbide Metal Doping. Lubricants. 2025; 13(11):496. https://doi.org/10.3390/lubricants13110496

Chicago/Turabian StyleLiu, Jiahao, Zhifang Yang, Guangying Cui, Jiayin Lv, and Xiang Yu. 2025. "Toughening Mechanisms of Diamond-like Carbon Films via Non-Carbide Metal Doping" Lubricants 13, no. 11: 496. https://doi.org/10.3390/lubricants13110496

APA StyleLiu, J., Yang, Z., Cui, G., Lv, J., & Yu, X. (2025). Toughening Mechanisms of Diamond-like Carbon Films via Non-Carbide Metal Doping. Lubricants, 13(11), 496. https://doi.org/10.3390/lubricants13110496