Study of the Micropore Structure and Tribological Properties of PTFE-Modified Porous Polyimide

Abstract

1. Introduction

2. Experiments

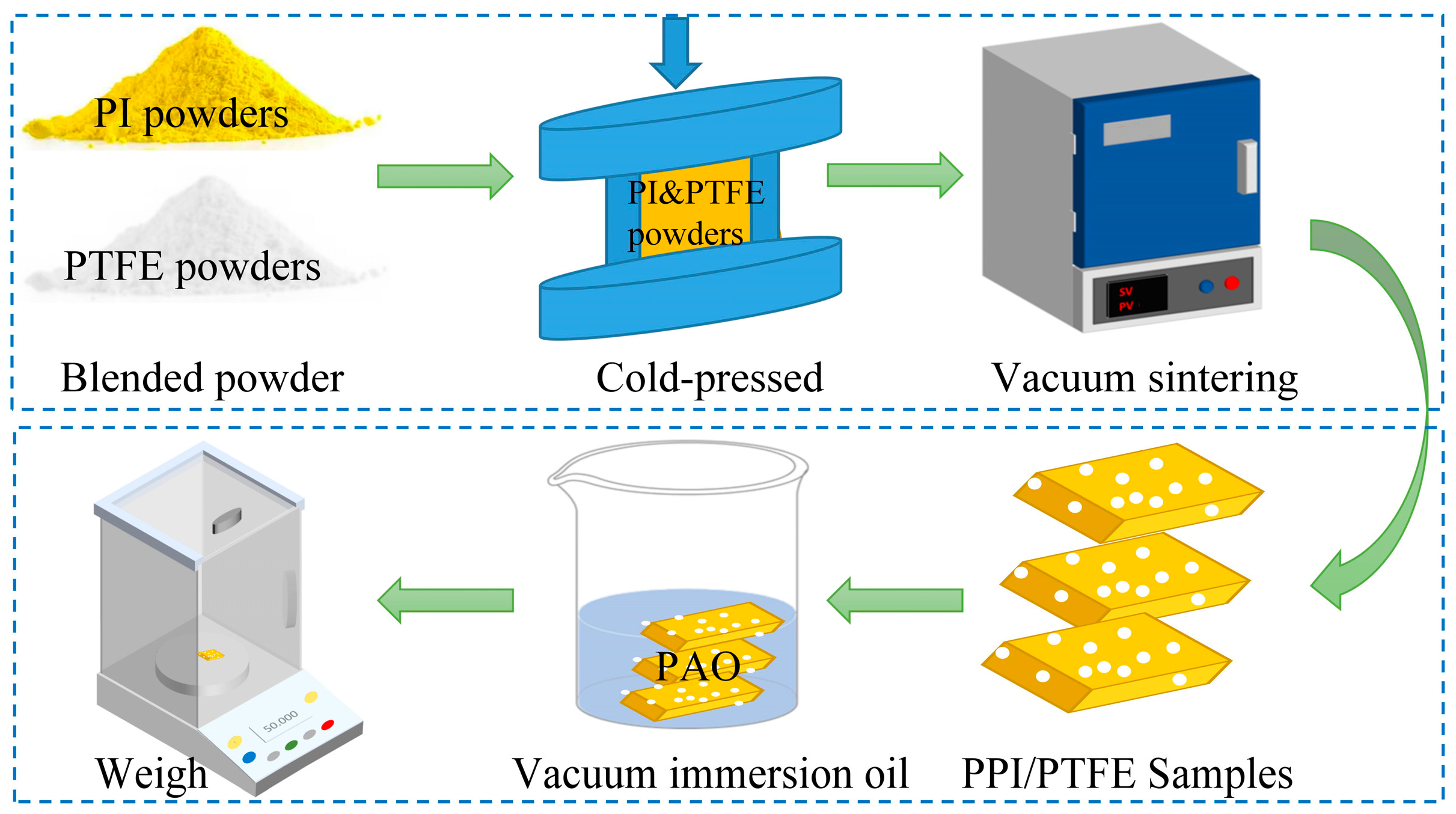

2.1. Preparation of PPI/PTFE

2.2. Preparation of Oil-Containing PPI/PTFE (OCPPI/PTFE)

2.3. Materials Characterizations

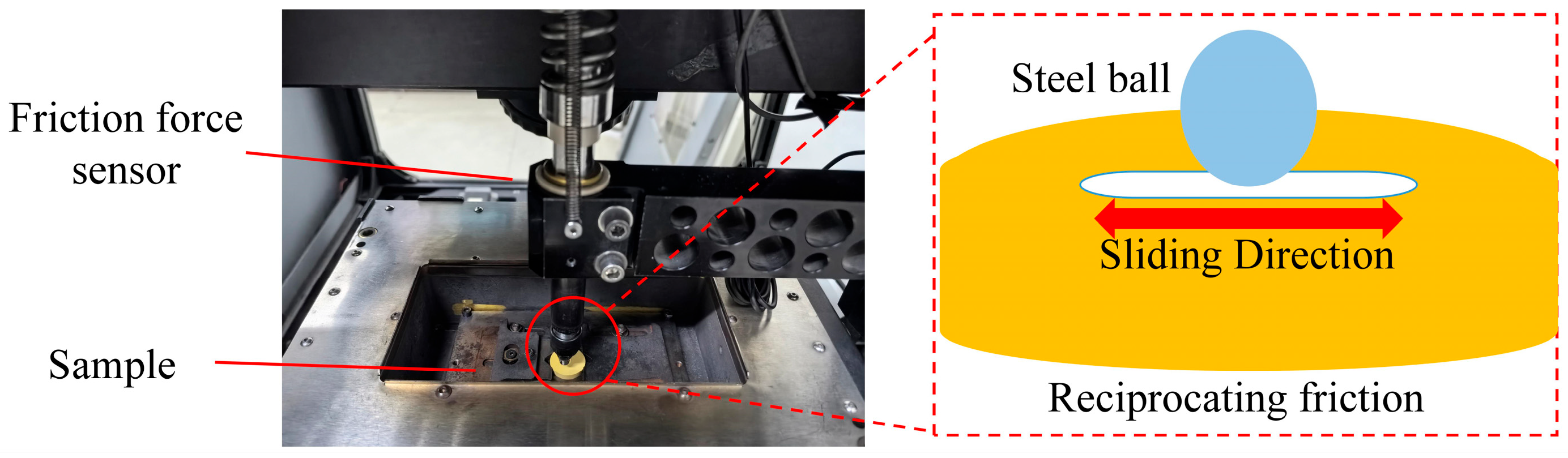

2.4. Tribological Performances

3. Results and Discussion

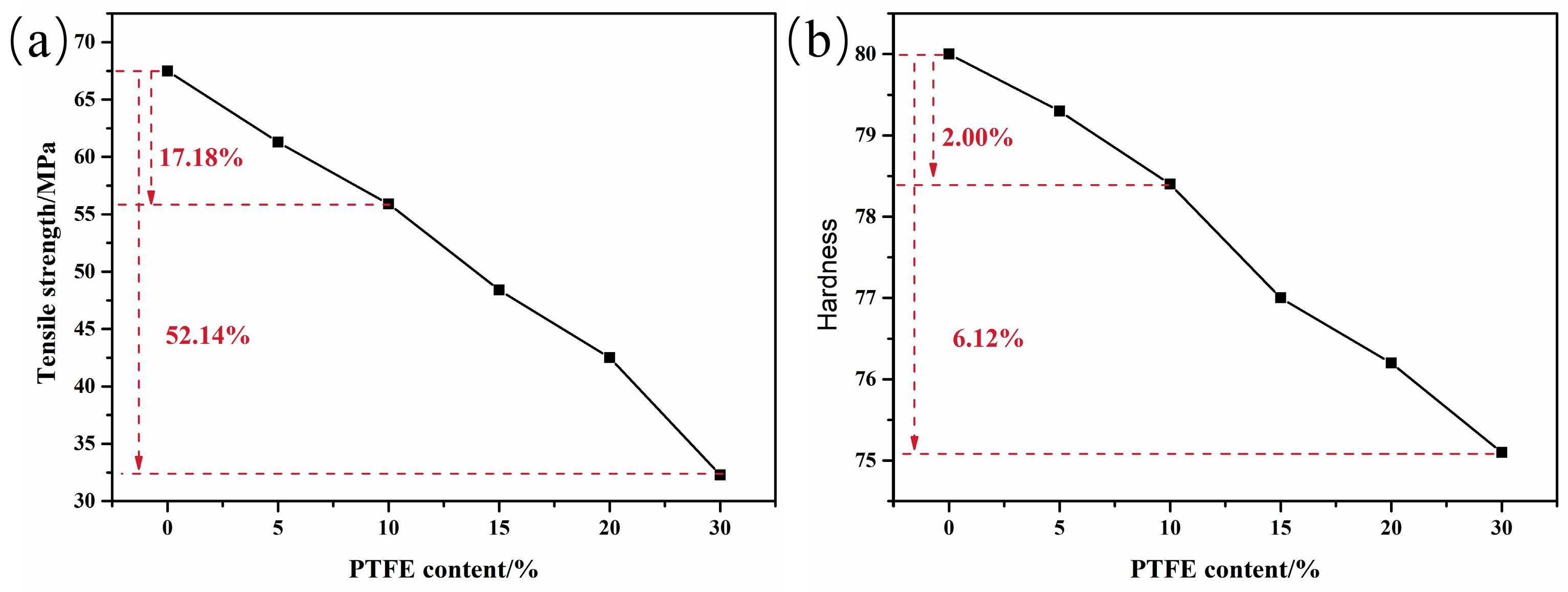

3.1. Mechanical Properties

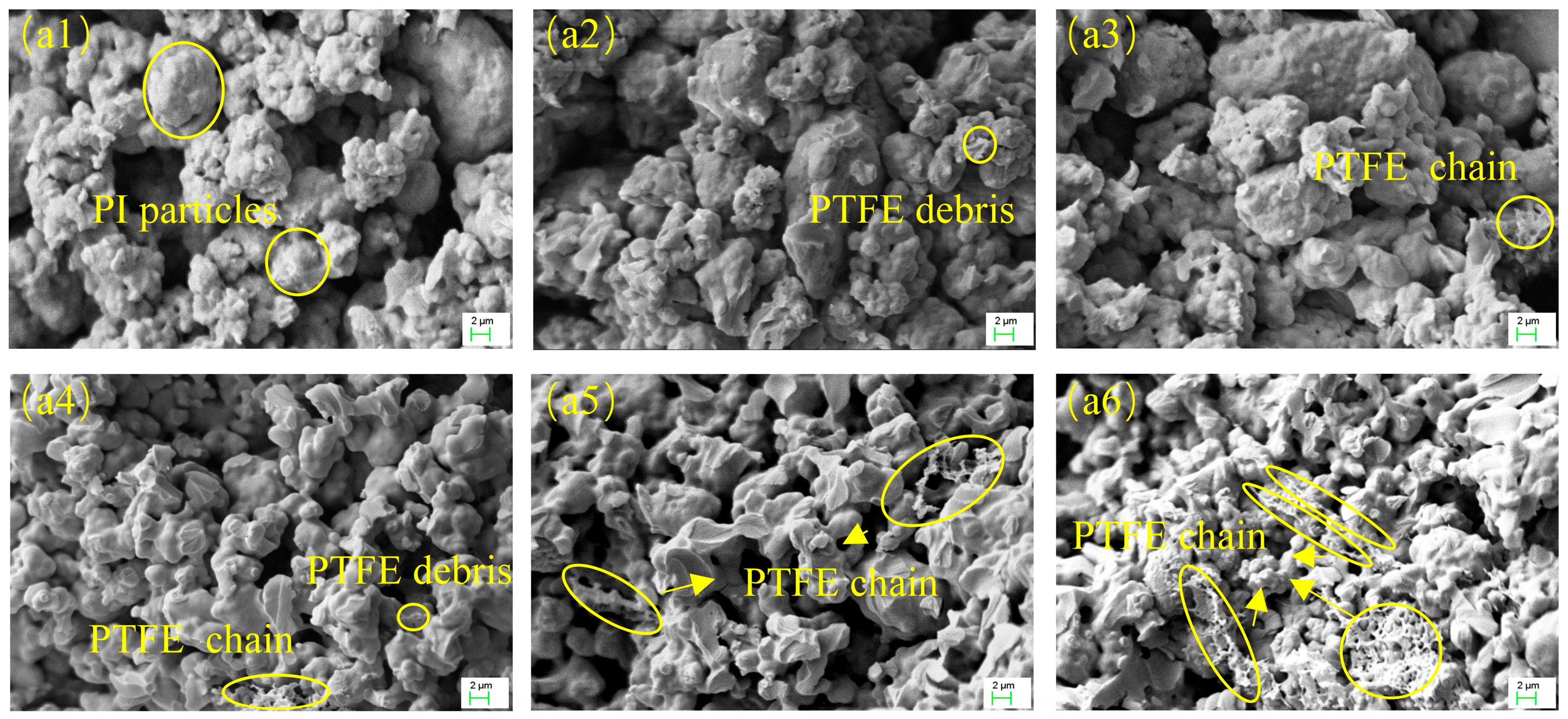

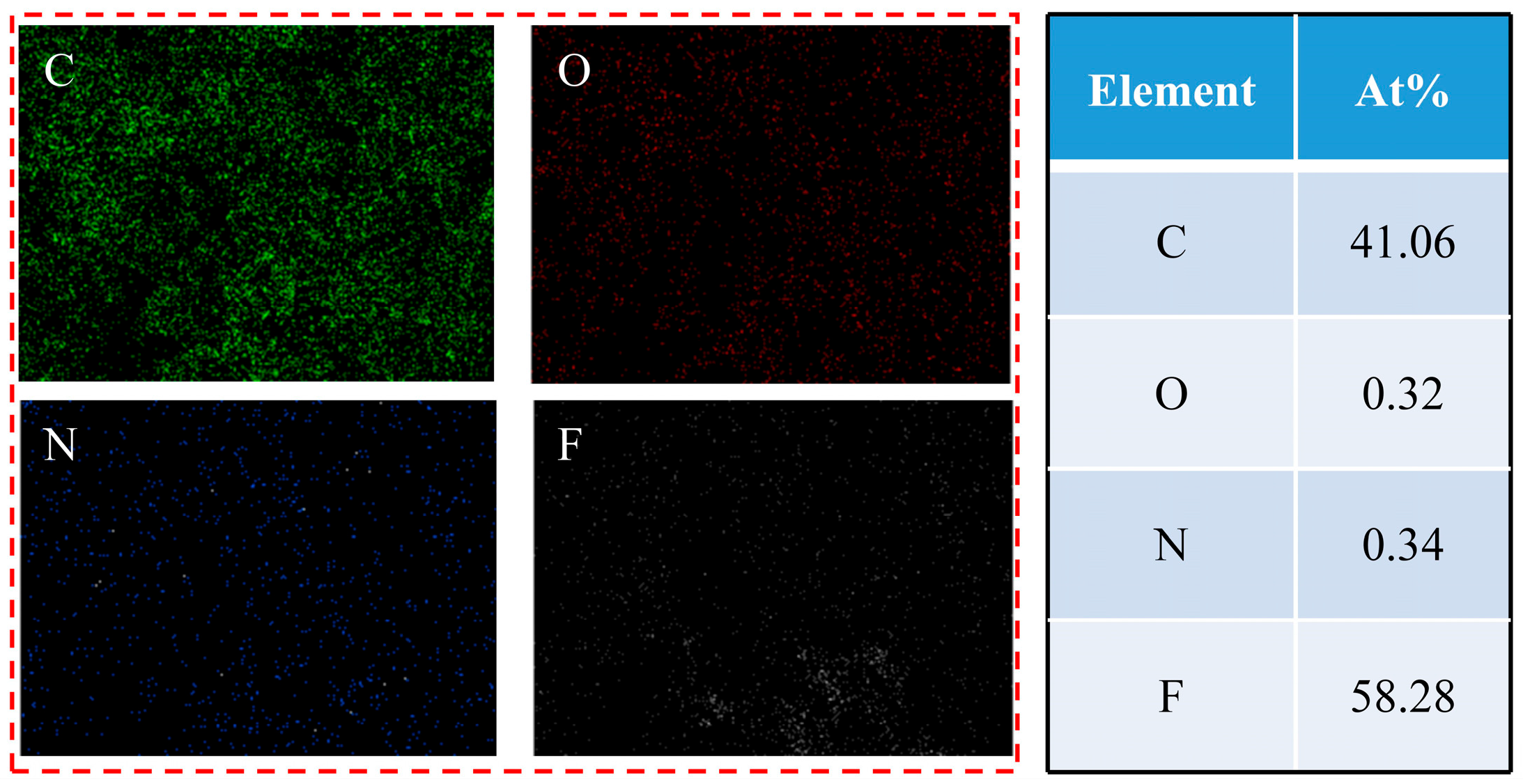

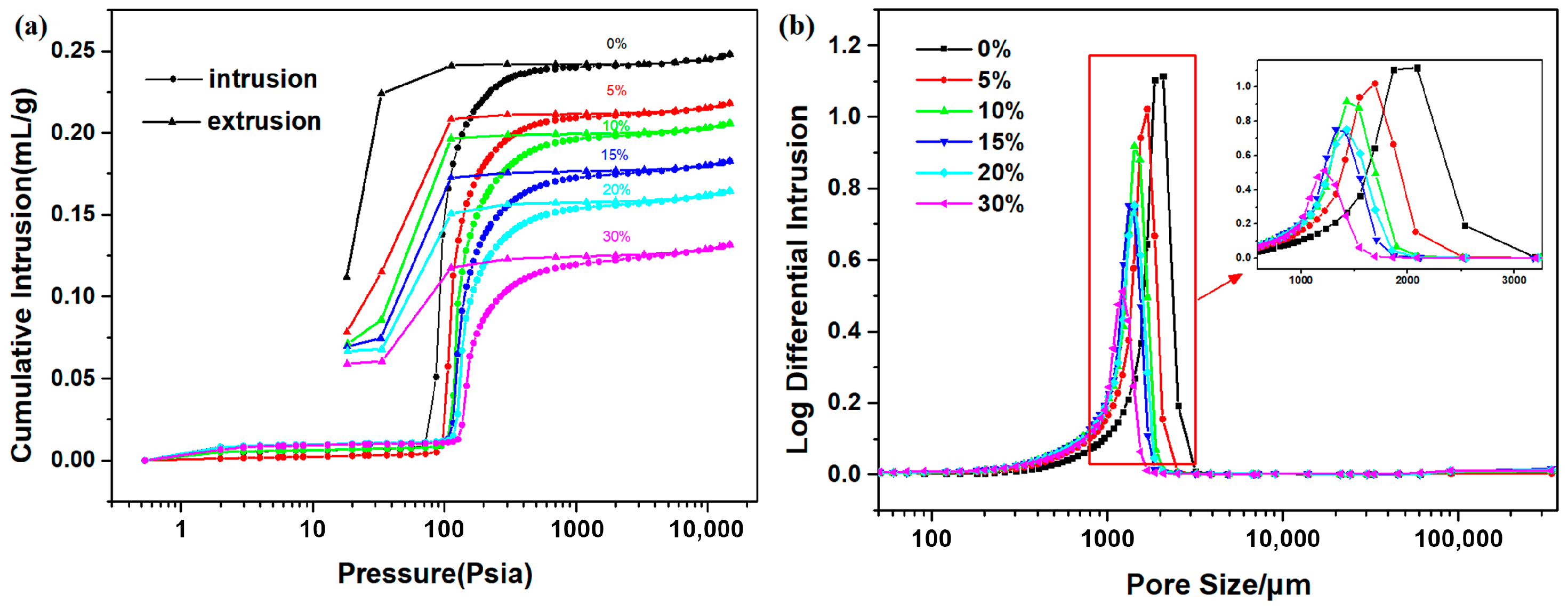

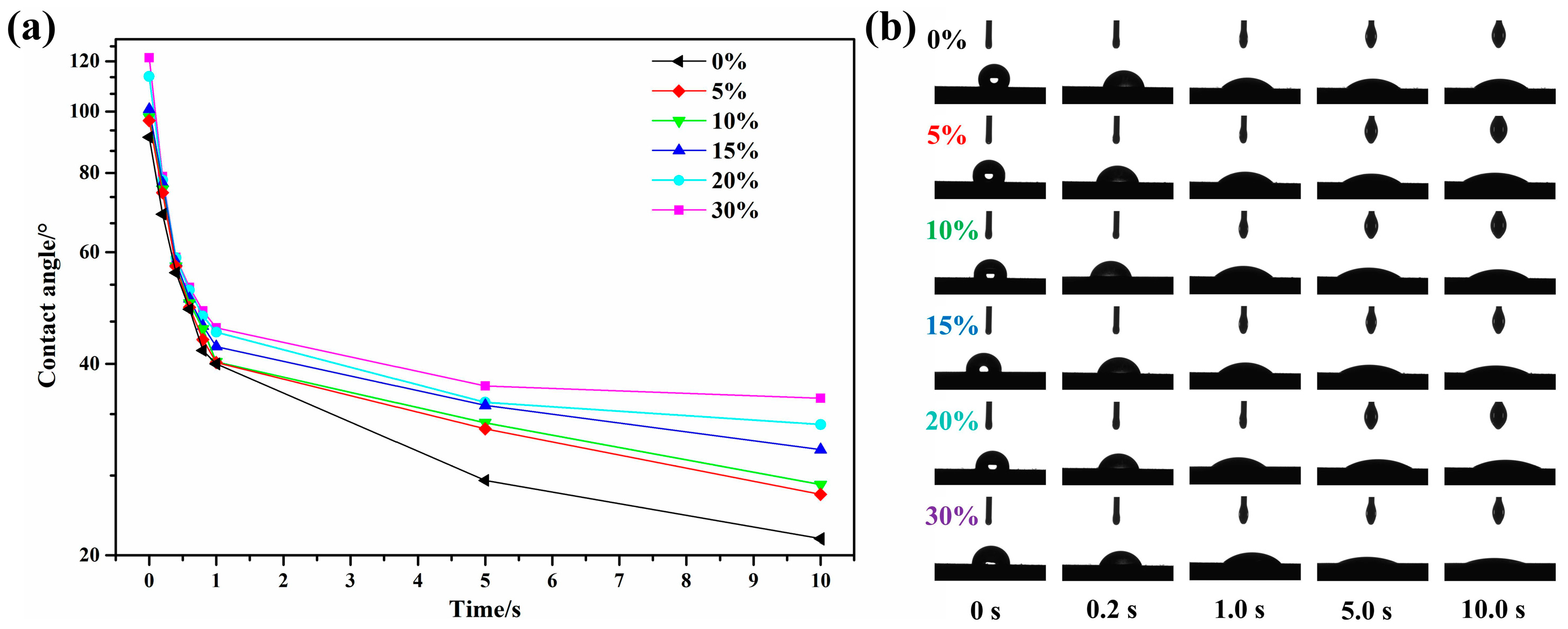

3.2. Micropore Properties

3.3. Tribological Properties

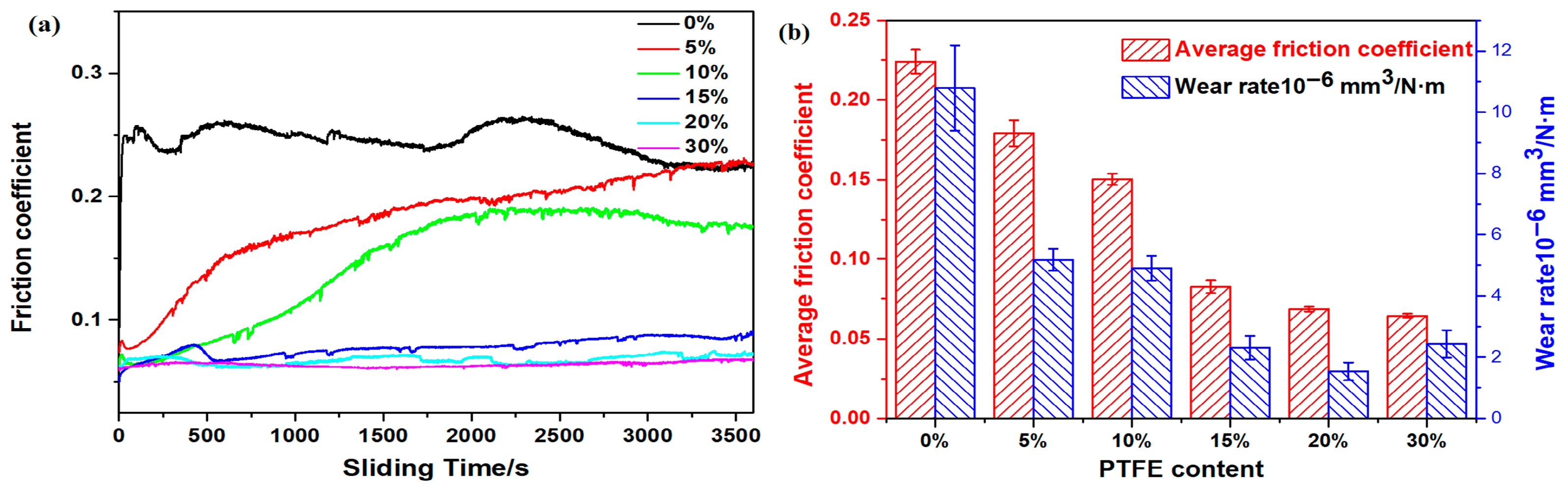

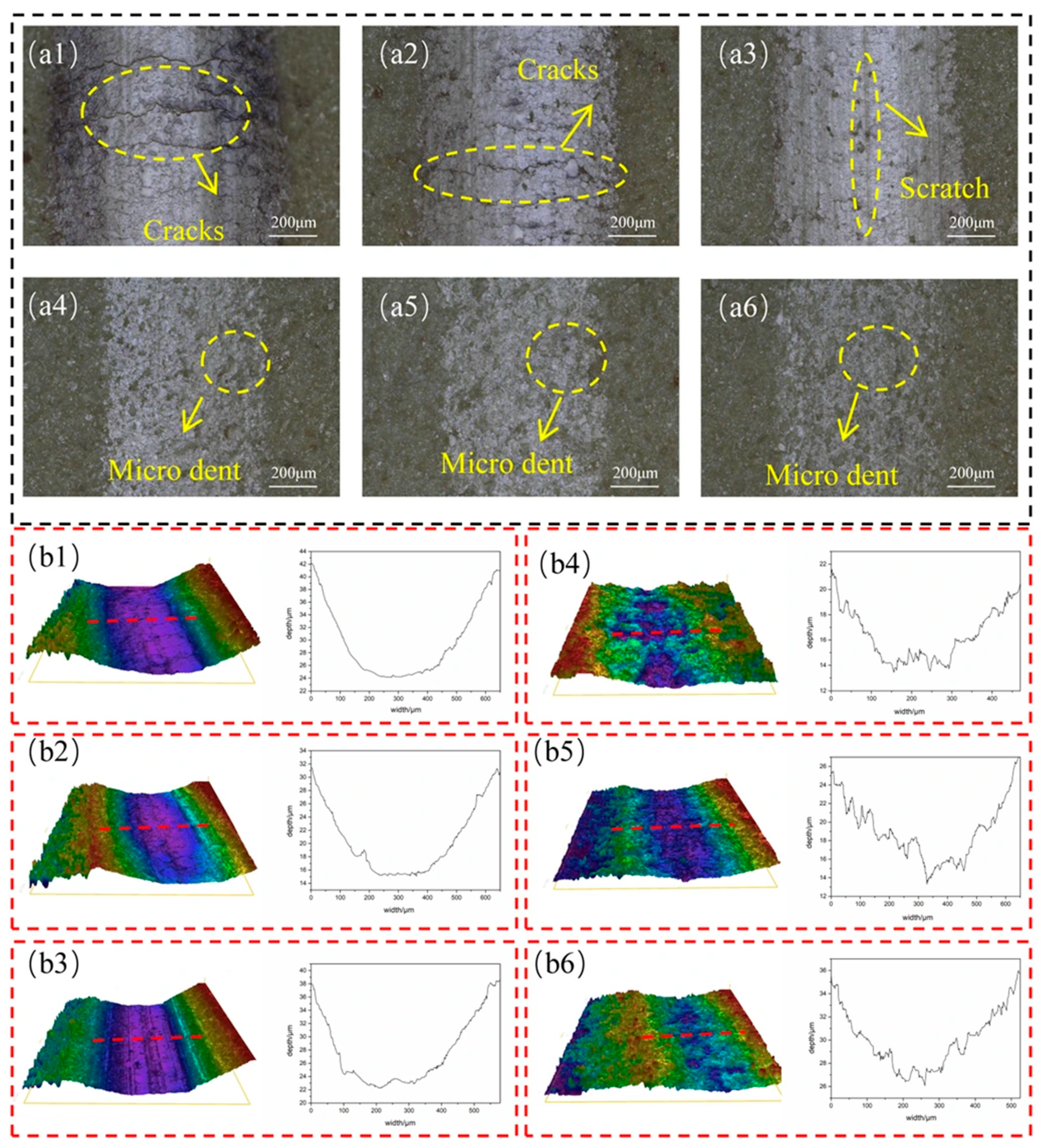

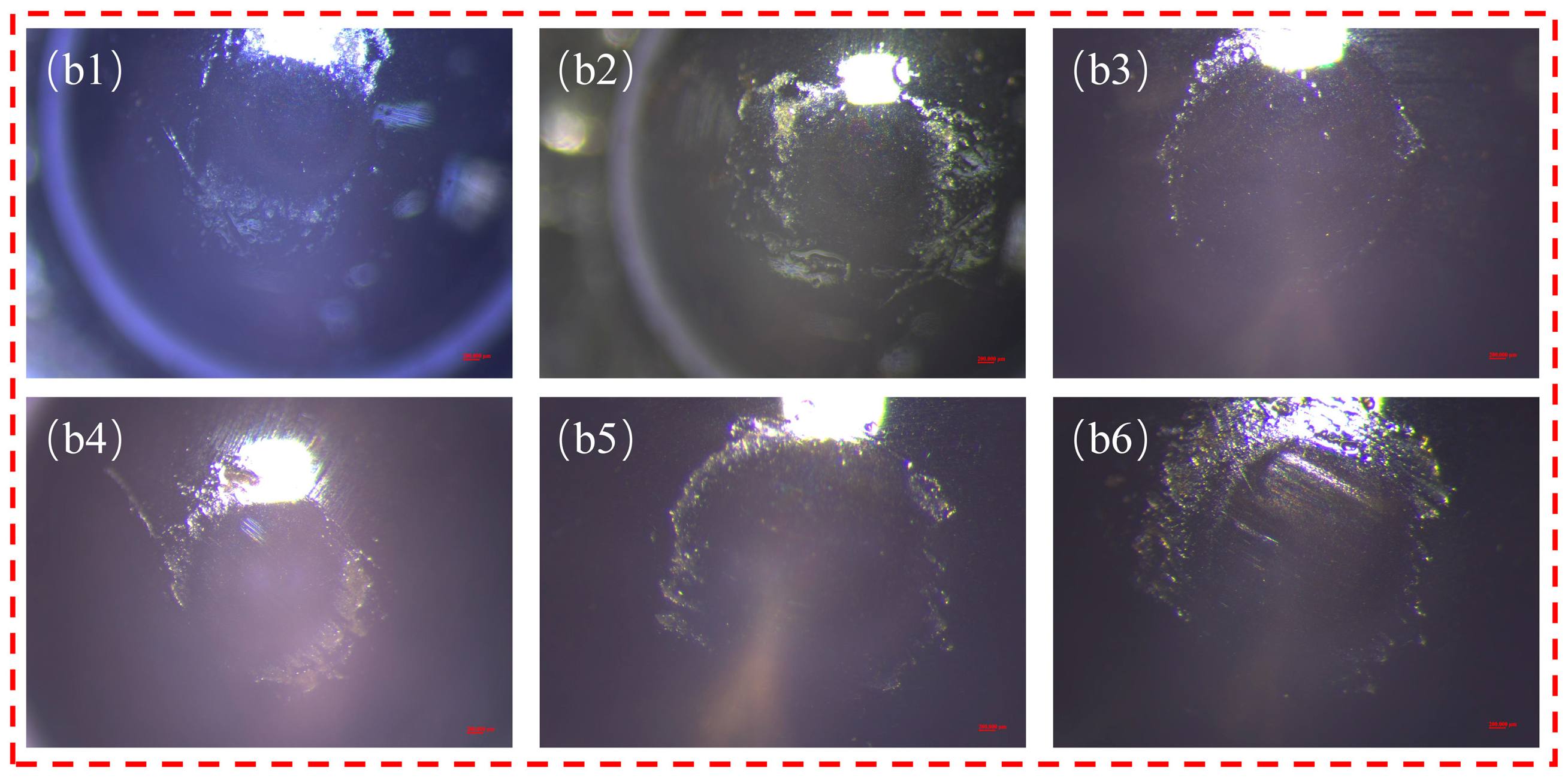

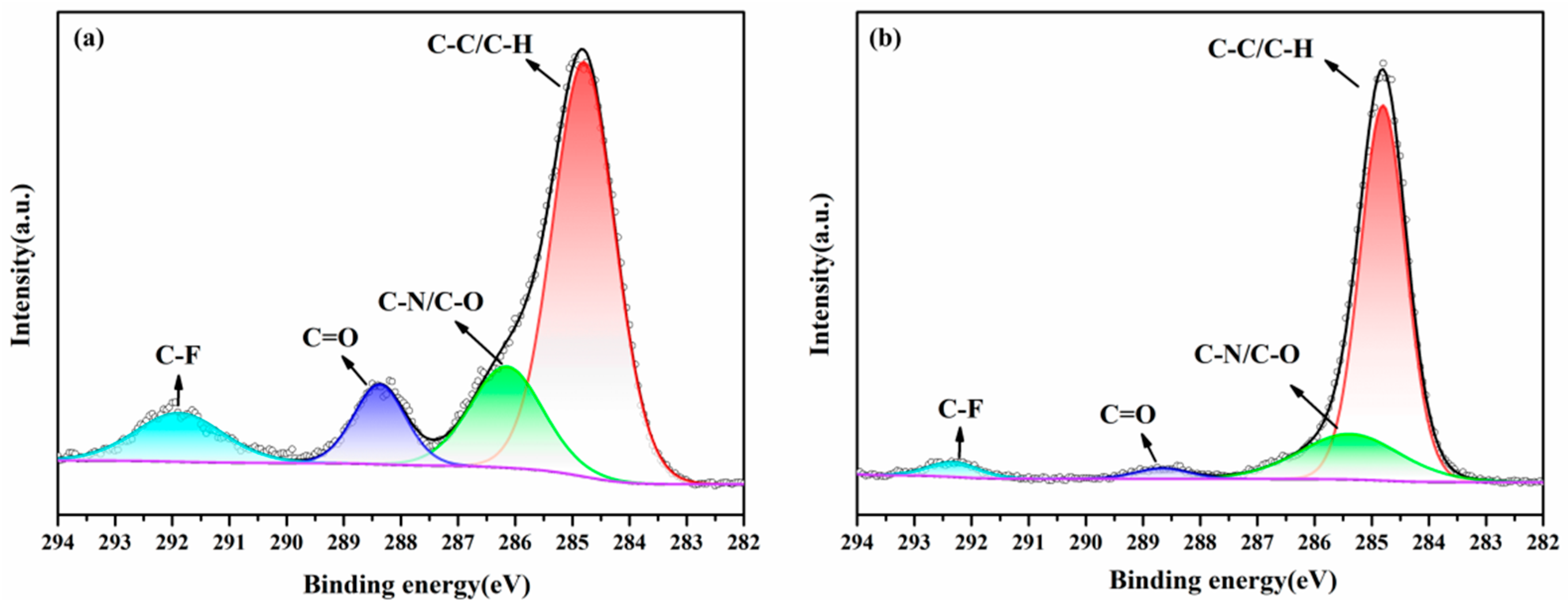

3.3.1. Dry Friction

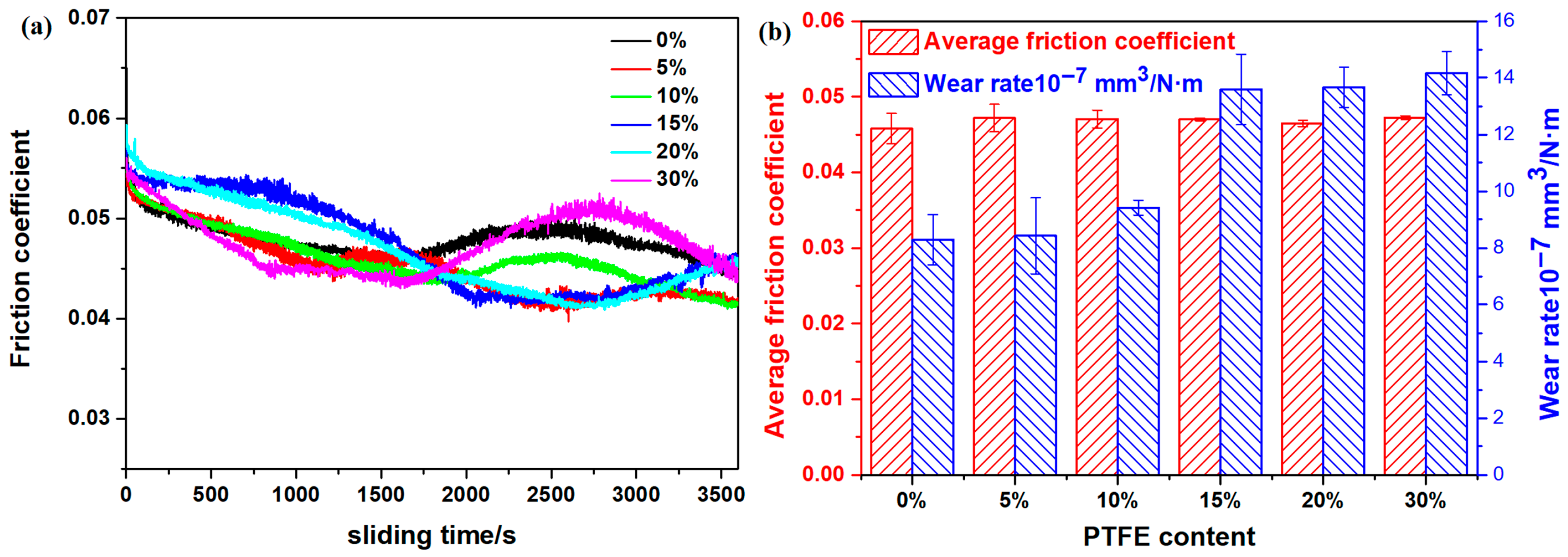

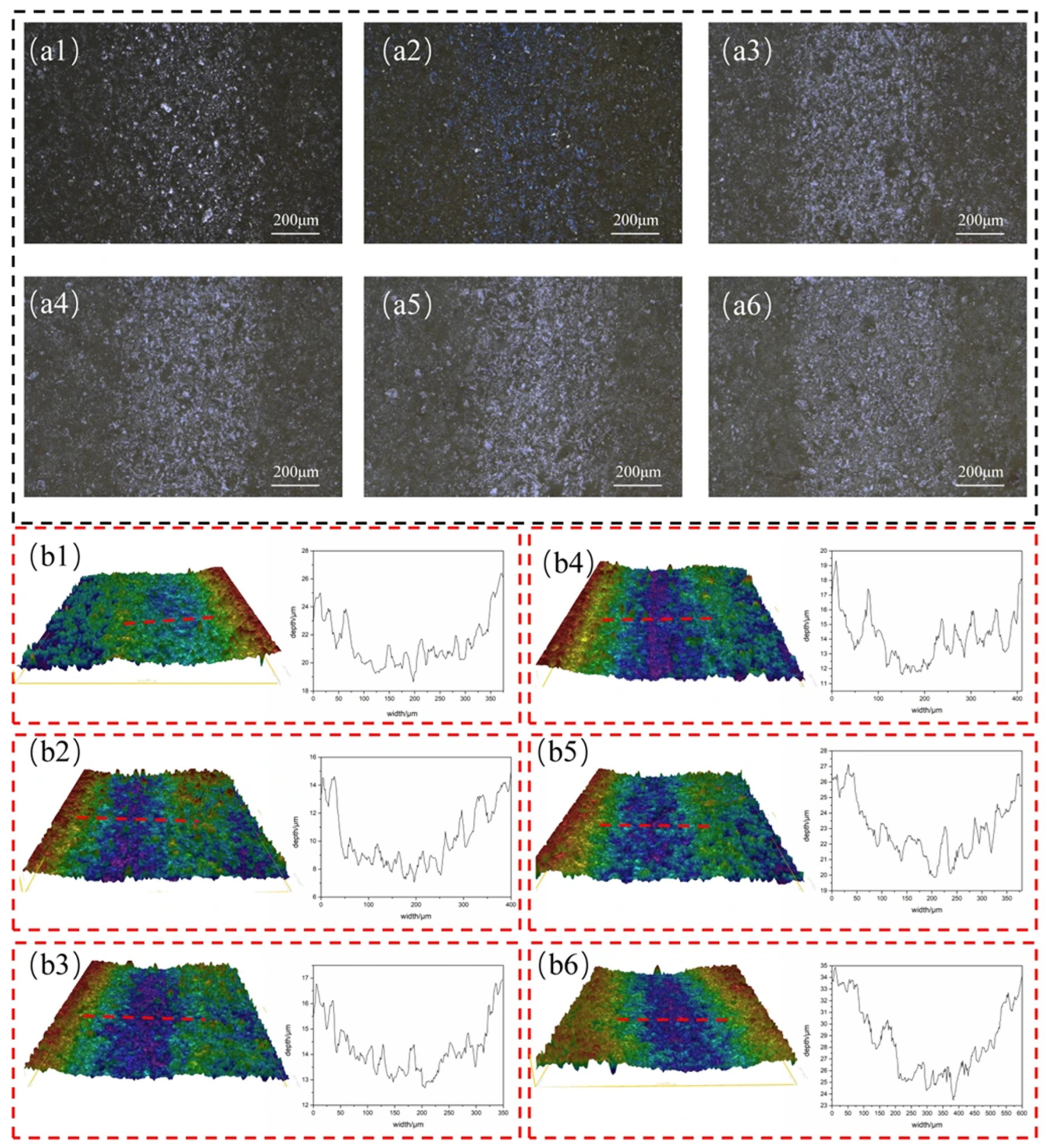

3.3.2. Oil-Containing Friction

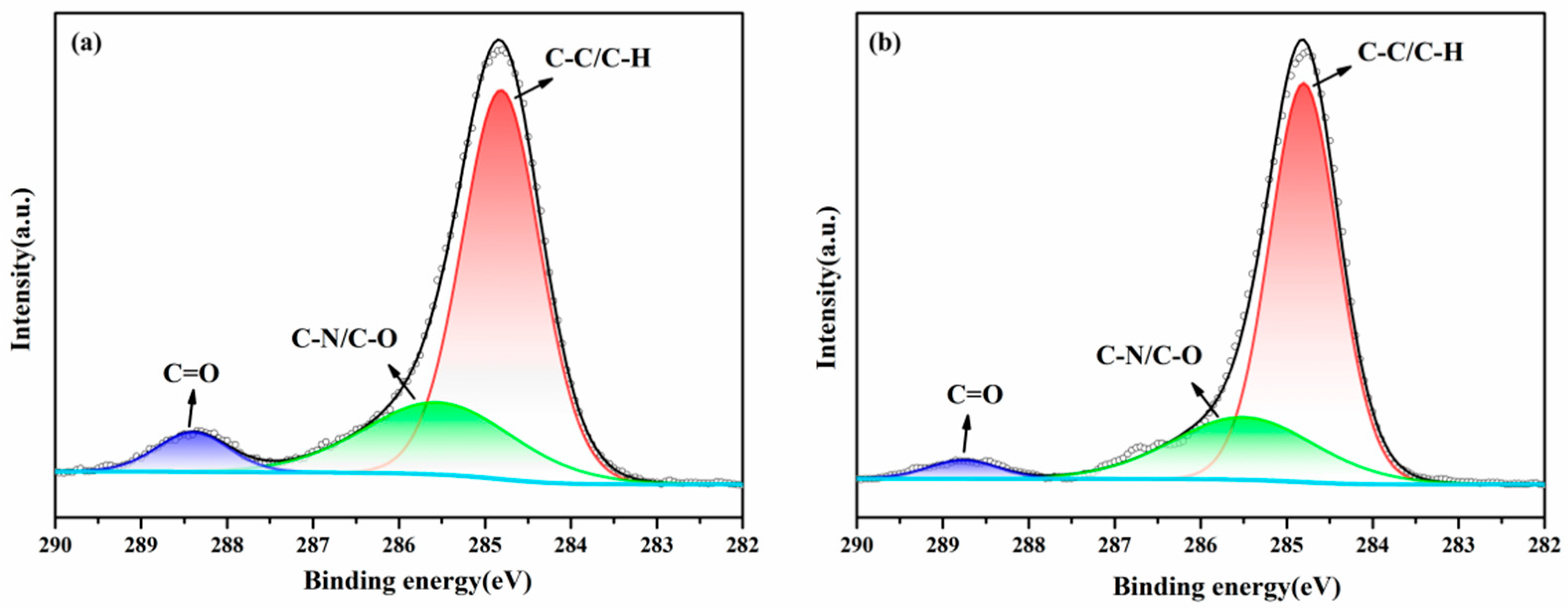

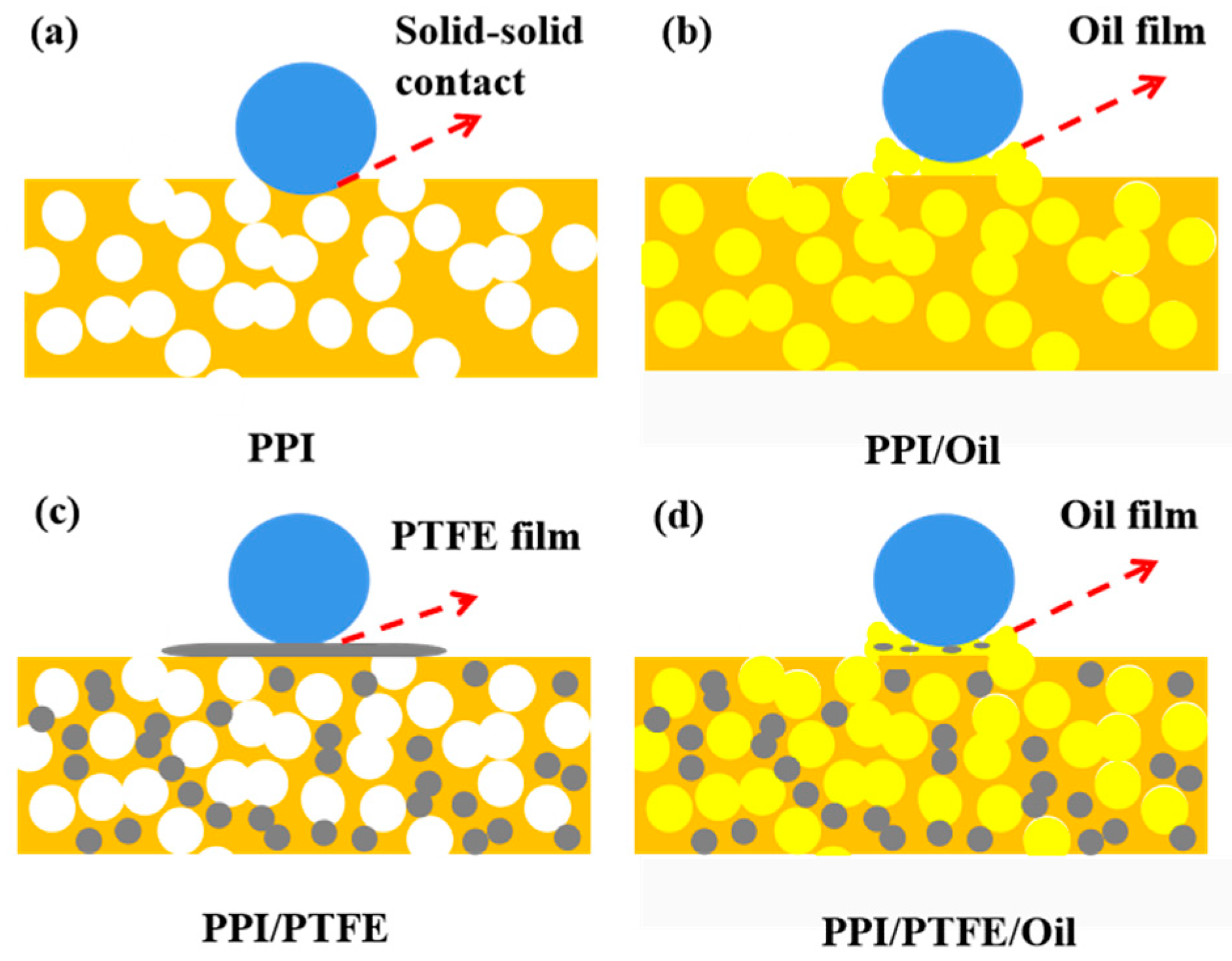

3.4. Wear and Lubrication Mechanism

4. Conclusions

- (1)

- PPI/PTFE forms an interconnected microporous structure. With increasing PTFE content, the pore size and porosity of PPI decrease, and the oil-containing rate also decreases.

- (2)

- Under dry friction conditions, the friction coefficient of PPI gradually decreases with increasing PTFE content. When PTFE content is below 10%, fatigue wear occurs. When it is above 10%, adhesive wear occurs, with PTFE forming a continuous transfer film. The optimal tribological performance is achieved at 20% PTFE, with the lowest friction coefficient and wear rate.

- (3)

- Under oil-containing friction conditions, PPI releases lubricating oil stored in its porous structure to the friction interface under frictional heat and load. This forms an oil film that significantly reduces friction and wear. The addition of PTFE can promote lubricant release to a certain extent but also increases the wear rate. Therefore, within the PTFE content range of 0–10%, both the regulation of porosity and good friction–wear performance can be achieved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.; Wang, C.; Qing, T.; Wang, Q.; Wang, T. Research progress of porous polymer bearing retainer materials used in aerospace. J. Mech. Eng. 2018, 9, 17–26. [Google Scholar] [CrossRef]

- Li, S.; Qu, C.; Shao, M.; Wang, C.; Wang, Q.; Wang, Y. Research progress in tribology of porous polymer self-lubricating composites. Polym. Bull. 2018, 8, 59–62. [Google Scholar] [CrossRef]

- Sun, X.; Wang, F.; Ge, S.; Zhang, H.; Wang, Z. Long-life lubricating technology for bearing used in aerospace. Bearing 2012, 3, 60–64. [Google Scholar] [CrossRef]

- Bertrand, P. Absorption of Water and Lubricating Oils into Porous Nylon; Nasacr-197344: Uniondale, NY, USA, 1995. Available online: https://ntrs.nasa.gov/citations/19950015966 (accessed on 20 January 2024).

- Sathyan, K.; Gopinath, K.; Lee, S.; Hsu, H.Y. Bearing retainer designs and retainer instability failures in spacecraft moving mechanical systems. Tribol. Trans. 2012, 55, 503–511. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Zhou, G.; Zhang, J.; Qing, T.; Zhou, N. The tribological properties of porous cotton/phenolic bearing retainer on different surfaces. Proc. Inst. Mech. Eng. Part J J. Eng. 2021, 7, 1470–1477. [Google Scholar] [CrossRef]

- Sathyan, K. Processing of cotton-phenolic bearing retainers for optimum performance of spacecraft high-speed rotating systems. Tribol. Trans. 2015, 4, 704–711. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, H.; Huang, W.; Wang, X. Investigation of porous polyimide lubricant retainers to improve the performance of rolling bearings under conditions of starved lubrication. Wear 2017, 380, 52–58. [Google Scholar] [CrossRef]

- Chen, W.; Zhu, P.; Liang, H.; Wang, W. Molecular dynamics simulations of lubricant recycling in porous polyimide retainers of bearing. Langmuir 2021, 7, 2426–2435. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Duan, M.; Qin, S.; Zhang, Z. Preparation and modificaton and porous polyetheretherketon (PEEK) cage material based on fused deposition modeling (FDM). Polymer 2022, 24, 5403. [Google Scholar] [CrossRef]

- Sun, X.; Li, Y. Preparation and properties of porous polyimide cage materials with small pore diameter and narrow pore distribution. Bearing 2022, 2, 44–47. [Google Scholar] [CrossRef]

- Marchetti, M.; Meusrisse, M.; Vergne, P.; Sicre, J.; Durand, M. Analysis of oil supply phenomena by sintered porous reservoirs. Tribol. Lett. 2001, 3, 163–170. [Google Scholar] [CrossRef]

- Marchetti, M.; Meusrisse, M.; Vergne, P.; Sicre, J.; Durand, M. Lubricant supply by porous reservoirs in space mechanisms. Tribol. Ser. 2000, 38, 777–785. [Google Scholar] [CrossRef]

- Sun, X.; Shang, X.; Li, Y.; Chu, T.; Yan, Y. Study on material properties of restrictor for bearing assembly. Bearing 2022, 8, 22–25. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, Q.; Wang, C.; Wang, Y. Oil-containing and tribological properties of porous polyimide containing lubricant oil. J. Tribol. 2012, 32, 538–543. [Google Scholar] [CrossRef]

- Xu, X.; Shu, X.; Pei, Q.; Qin, H.; Guo, R.; Wang, X.; Wang, Q. Effects of porosity on the tribological and mechanical properties of oil-impregnated polyimide. Tribol. Int. 2022, 170, 107502. [Google Scholar] [CrossRef]

- Ye, J.; Li, J.; Tao, Q.; Qing, T.; Huang, H.; Zhou, N. Effects of surface pore size on the tribological properties of oil-impregnated porous polyimide material. Wear 2021, 484, 204042. [Google Scholar] [CrossRef]

- Chu, T.; Li, Y.; Mai, N.; Sun, X.; Hu, P.; Xi, B.; Dong, Y. Study on compatibility between porous polyimide cage and space lubricating oil. Bearing 2021, 9, 109–114. [Google Scholar] [CrossRef]

- Zhou, N.; Qing, T.; Zhang, S.; Qu, J.; Huang, Z. Research on oil-containing performance of porous polymer materials filled with carbon nanotubes. Lubr. Eng. 2017, 42, 120–123. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, T.; Wang, Q.; Wang, C. Selectively enhanced oil retention of porous polyimide bearing materials by direct chemical modification. J. Appl. Polym. Sci. 2017, 134, 45106. [Google Scholar] [CrossRef]

- Samyn, P.; De Baets, P.; Schoukens, G. Role of internal additives in the friction and wear of carbon-fiber-reinforced polyimide. Appl. Polym. 2010, 116, 1146–1156. [Google Scholar] [CrossRef]

- Wang, F.; Sun, X.; Shi, L. Effect of polytetrafluoroethylene on properties of polyimide cage materials. Bearing 2005, 2, 25–27. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, L.; Xiao, C.; Zhou, N.; Qing, T.; Qian, L. Friction and wear behaviors of steel ball against polyimide-PTFE composite under rolling-sliding motion. Tribol. Lett. 2021, 69, 100. [Google Scholar] [CrossRef]

- Yan, P.; Zhu, P.; Gu, H.; Huang, P. Exploration of preparation process of thermoplastic polyimide porous materials. Lubr. Sealing 2007, 01, 79–82+104. [Google Scholar] [CrossRef]

- GB/T 21650.1-2008; Pore Size Distribute and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption-Part 1: Mercury Porosimetry. China Standards Press: Beijing, China, 2008.

- Conte, M.; Igartua, A. Study of PTFE composites tribological behavior. Wear 2012, 296, 568–574. [Google Scholar] [CrossRef]

- Biswas, S.; Kalyani, V. Friction and wear of PTFE-a review. Wear 1992, 158, 193–211. [Google Scholar] [CrossRef]

- Huang, R.; Ma, S.; Zhang, M.; Yang, J.; Wang, D.; Zhang, L.; Xu, J. Wear Evolution of the glass fiber-reinforced PTFE under dry sliding and elevated temperature. Materials 2019, 12, 1082. [Google Scholar] [CrossRef]

- Zhen, J.; Han, Y.; Wang, H.; Jiang, Z.; Wang, L.; Huang, Y.; Jia, Z.; Zhang, R. High temperature friction and wear behavior of PTFE/MoS2 composites. Lubricants 2023, 11, 312. [Google Scholar] [CrossRef]

| PTFE/wt% | 0% | 5% | 10% | 15% | 20% | 30% |

| Porosity/% | 25.1 | 23.3 | 22.8 | 20.7 | 19.7 | 17.2 |

| Pore diameter/μm | 1.92 | 1.56 | 1.39 | 1.33 | 1.26 | 1.14 |

| oil-containing rate/% | 21.3 | 19.3 | 17.0 | 15.4 | 14.0 | 10.2 |

| C 1s Component | C-C/C-H | C-O/C-N | C=O | C-F | |

|---|---|---|---|---|---|

| Binding energy (eV) | 284.8 | 285.5 | 288.4 | 292.0 | |

| Area fraction (%) | PI | 69.1 | 24.4 | 6.5 | 0 |

| PI-PAO | 72.6 | 23.9 | 3.5 | 0 | |

| PI/PTFE | 62.1 | 17.7 | 10.0 | 10.2 | |

| PI/PTFE-PAO | 74.5 | 19.9 | 2.4 | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Shang, X.; Li, Y.; Zhang, X.; Chen, F.; Li, K.; Yan, K. Study of the Micropore Structure and Tribological Properties of PTFE-Modified Porous Polyimide. Lubricants 2025, 13, 455. https://doi.org/10.3390/lubricants13100455

Sun X, Shang X, Li Y, Zhang X, Chen F, Li K, Yan K. Study of the Micropore Structure and Tribological Properties of PTFE-Modified Porous Polyimide. Lubricants. 2025; 13(10):455. https://doi.org/10.3390/lubricants13100455

Chicago/Turabian StyleSun, Xiaobo, Xiaohui Shang, Yuanyuan Li, Xiaoya Zhang, Fei Chen, Keying Li, and Ke Yan. 2025. "Study of the Micropore Structure and Tribological Properties of PTFE-Modified Porous Polyimide" Lubricants 13, no. 10: 455. https://doi.org/10.3390/lubricants13100455

APA StyleSun, X., Shang, X., Li, Y., Zhang, X., Chen, F., Li, K., & Yan, K. (2025). Study of the Micropore Structure and Tribological Properties of PTFE-Modified Porous Polyimide. Lubricants, 13(10), 455. https://doi.org/10.3390/lubricants13100455