1. Introduction

With the advancement of intelligent and precision-oriented modern industrial equipment, the pervasiveness of electromagnetic fields in engineering applications has become increasingly prominent. Critical tribological pairs (such as bearings, gears, and brake pads) in devices ranging from new energy vehicles and maglev trains to aerospace propulsion systems, high-speed rail braking systems, and disk drives in micro-electromechanical systems are consistently exposed to complex electromagnetic environments [

1]. For instance, in scenarios such as electromagnetic coupling between motor rotors and stators, active magnetic field regulation in maglev systems, and high-frequency electromagnetic control of adjustable nozzles in aero-engines, tribological materials are subjected not only to mechanical loads but also to interactions with electromagnetic fields [

2,

3,

4,

5]. Such multiphysics coupling environments may induce alterations in the material microstructure, thereby influencing friction and wear properties [

6,

7,

8]. Magnetorheological fluids, as lubricants significantly affected by magnetic fields, represent a class of potential smart lubricants for active friction control and have already been applied in fields such as drug delivery, sensors, energy harvesting, and dampers [

9,

10,

11,

12,

13,

14]. Investigating the influence of electromagnetic fields on friction and wear is not only crucial for addressing bottlenecks in traditional tribology but also constitutes a core technology for advancing high-end equipment, green manufacturing, and smart industry. This paper systematically reviews recent studies on the effects and underlying mechanisms of electromagnetic fields (excluding current-carrying friction) on tribological behavior.

2. Electromagnetic Field Excitation Device Used in Friction Research

Research on the effects of electromagnetic fields on friction and wear has primarily focused on three main directions: investigations into the influence of steady-state magnetic fields on friction and wear; studies on the impact of alternating electromagnetic field environments on tribological behavior; and research concerning alterations in the friction and wear properties of materials after electromagnetic field treatment. These three categories of studies employ distinct technical approaches and experimental setups to enable systematic analysis of the effects of electromagnetic fields.

2.1. Steady-State Magnetic Field Excitation Device

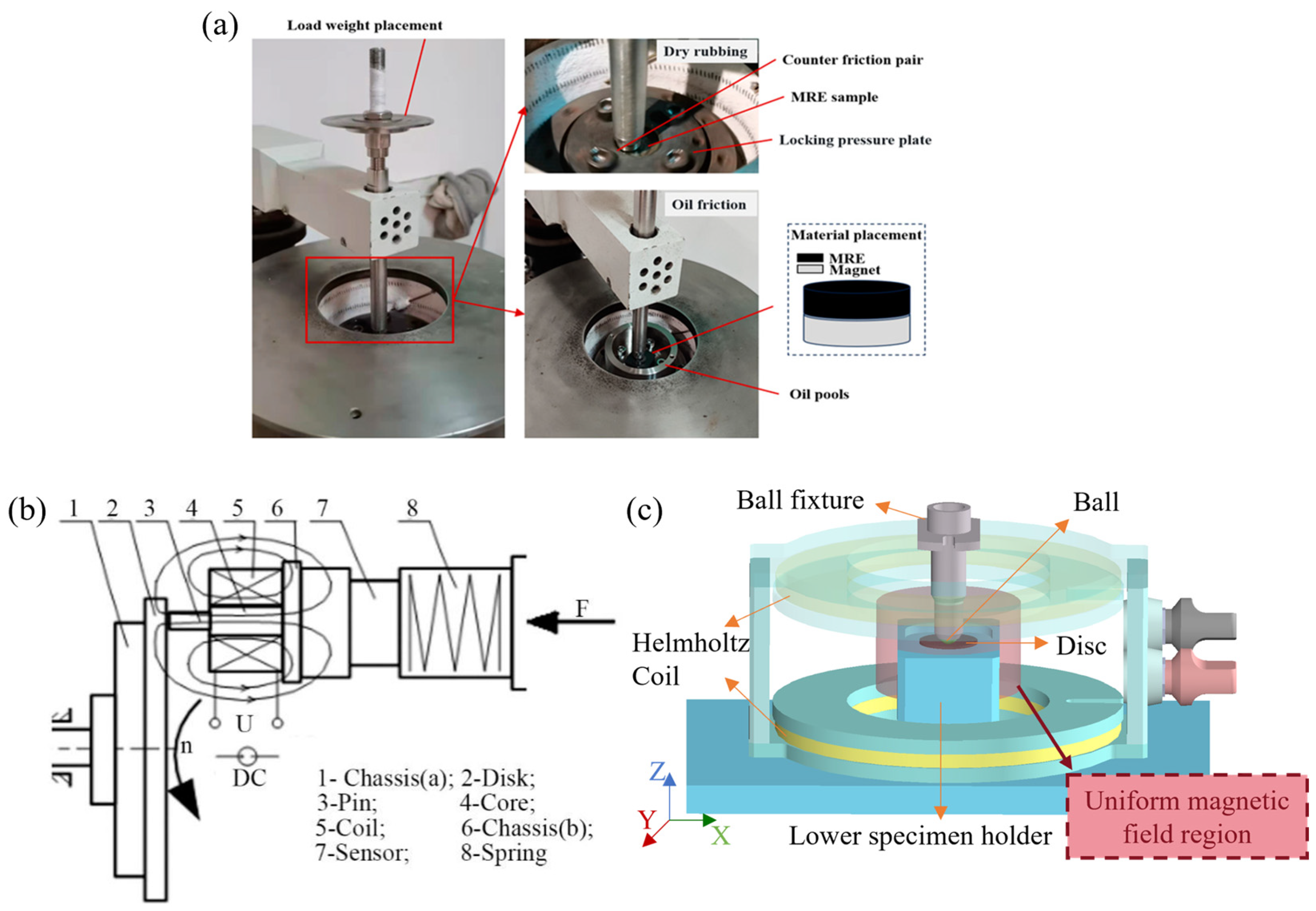

In the field of research on electromagnetic field effects under dry friction conditions, commonly used experimental devices include ball-on-disk, block-on-ring, and pin-on-disk configurations, as illustrated in

Figure 1. The electromagnetic fields are typically applied using external permanent magnets, electromagnets, or electromagnetic coils, with the magnetic field direction oriented either parallel or perpendicular to the friction contact surface [

15,

16,

17]. Zhao et al. employed permanent magnets to generate a magnetic field, as shown in

Figure 1a [

18]. Stolarski et al. designed a tribometer capable of adjusting the magnetic field orientation [

19]. Han and Zhao et al. employed direct current electromagnetic coils to generate high magnetic field intensities at the pin-disk contact interface, as shown in

Figure 1b [

20,

21].

Furthermore, Gao et al. developed a tribometer equipped with a shielding device to investigate the potential influence of the geomagnetic field on tribo-magnetization phenomena [

22]. The reciprocating tribometer incorporates a magnetic shielding design, and all components are constructed from non-magnetic materials to minimize magnetic interference. This system provides an ideal experimental platform for studying the effects of the Earth’s magnetic field on tribological behavior.

2.2. Alternating Electromagnetic Field Excitation Device

In certain specialized working conditions, such as those encountered in motor bearings, electromagnetic railgun rails, and friction discs of electromagnetic torque limiters, components are continuously subjected to interference from alternating magnetic fields. The primary experimental approach for studying the influence of alternating electromagnetic fields on friction and wear involves generating such fields using electromagnets or excitation coils, which are applied during dynamic friction processes. A magnetic braking tribological test setup—comprising a magnetic organic friction plate and a metallic disc brake—utilizes four excitation coils (connected in two series pairs) to produce an alternating electromagnetic field [

23]. To ensure magnetic field uniformity within the friction contact zone, researchers have employed Helmholtz coils to generate a homogeneous alternating electromagnetic field. As illustrated in

Figure 1c, this system consists of a signal generator, a power amplifier, and a pair of Helmholtz coils [

24]. Additionally, a representative example is the NG-x reciprocating friction tester, which employs an electromagnet to generate an alternating electromagnetic field for friction testing under lubricated conditions [

25].

Figure 1.

(

a) Friction experiments [

18]; (

b) Schematic diagram of the tribometer [

21]; (

c) Helmholtz coil model [

24].

Figure 1.

(

a) Friction experiments [

18]; (

b) Schematic diagram of the tribometer [

21]; (

c) Helmholtz coil model [

24].

It is noteworthy that electromagnetic coils offer the capability to generate both DC steady magnetic fields and AC magnetic fields, with adjustable field orientation, thereby providing greater experimental flexibility compared to permanent magnets. Furthermore, the pin-on-disk configuration offers a relatively large contact area. In contrast to point-contact or line-contact configurations such as ball-on-disk, block-on-ring, or twin-disk rolling contacts, this setup results in reduced magnetic flux leakage. The continuously changing contact geometry in point or line contact configurations may introduce uncontrolled variables, potentially compromising the accuracy of experimental results.

3. Effect of Electromagnetic Field on Friction Behavior

A substantial body of literature indicates that electromagnetic fields can significantly influence the tribological properties of materials [

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40]. However, due to variations in experimental conditions such as lubrication regime, form of contact, materials of the tribo-pair, and method of electromagnetic field application, notable discrepancies exist among the results reported by different researchers.

3.1. Lubrication Condition

Generally, the lubrication states of tribo-pairs can be classified into four regimes: dry friction, boundary lubrication, mixed lubrication, and fluid lubrication. Based on the presence or absence of lubricants, these can be broadly categorized into dry friction and lubricated conditions.

Under dry friction conditions, most studies indicate that electromagnetic fields can effectively reduce both the coefficient of friction and wear volume [

26,

27,

28,

29]. Han conducted dry sliding wear tests on 45# steel with and without an applied magnetic field, revealing that a DC magnetic field reduced both the coefficient of friction and the wear rate [

26]. Li employed macroscopic experimental methods to investigate the influence of a magnetic field on the frictional properties of magnetorheological elastomers, demonstrating a 24.7% reduction in the coefficient of friction under a magnetic field of 400 mT [

27]. Amirat studied the wear behavior of an AISI 1045 steel pin-on-disk pair in different gaseous environments and found that the magnetic field contributed to a decrease in wear rate [

28]. Shi performed pin-on-disk tests with and without wear debris removal, observing a transition from severe to mild wear modes under the influence of a magnetic field [

21].

However, some studies have reported conflicting results. Xie investigated the dry sliding friction and wear properties of normalized and annealed 45# steel under different magnetic field intensities, noting that heat treatment conditions significantly influenced the frictional response of this ferromagnetic material. With increasing magnetic field strength, the coefficient of friction of normalized 45# steel first increased and then gradually decreased, remaining higher than that under zero-field conditions. In contrast, the coefficient of friction of annealed 45# steel first decreased and then increased slowly, ultimately being lower under a magnetic field [

30]. Bao explored the tribological behavior of brake disc pairs under alternating magnetic fields and found that the frequency of the magnetic field had a dual effect: it could optimize frictional properties within a certain range, but excessively high frequencies could lead to adverse outcomes [

22]. It has been found that under dry friction conditions, the changes in the tribological properties of materials after the introduction of an electromagnetic field are not uniform and are also subject to constraints such as heat treatment and electromagnetic field parameters.

Under lubricated conditions, the effect of electromagnetic fields varies significantly depending on the type of lubricant.

Table 1 summarizes the influence of magnetic fields on the tribological behavior of friction pairs with different lubricants. Hu found that the magnetic field had almost no effect on the coefficient of friction of DIOS containing nano-Ni, while the wear volume increased with increasing magnetic field strength [

31]. Zhang investigated the frictional behavior of different magnetorheological fluids under magnetic fields and found that the coefficient of friction increased with magnetic field strength in all cases. These studies were conducted under boundary lubrication conditions.

As the lubrication condition improves, the influence of magnetic fields also changes. Wang measured the Stribeck curves of oleic acid-modified Fe

3O

4 magnetic fluids with different mass fractions, both with and without a magnetic field [

32]. It was observed that the magnetic field promoted an earlier transition to mixed lubrication, thereby facilitating improved lubrication and reduced friction. Clearly, the influence of electromagnetic fields also varies under lubricated conditions. It is noteworthy that the concentration of magnetic particles differs significantly between the nanolubricants and magnetorheological fluids mentioned in the aforementioned studies. Specifically, magnetorheological fluids typically contain a substantially higher volume fraction of magnetic particles, which likely accounts for their differential response to external electromagnetic fields.

3.2. Forms of Contact

In tribological experiments, common contact configurations are primarily categorized into three types: point contact, line contact, and surface contact. The effect of electromagnetic fields on tribological behavior varies significantly across these different contact forms.

Table 2 summarizes the influence of electromagnetic fields on the tribological behavior of friction pairs under various contact configurations.

Under point contact conditions, the contact pressure is relatively high, typically on the order of GPa. The influence of electromagnetic fields on friction under such conditions varies. Kadıoğlu et al. reported an increase in the coefficient of friction under a magnetic field intensity of 2.5 mT. Interestingly, under conditions of 400 rpm, 40 N, and 5 mT, the coefficient of friction decreased compared to the non-field scenario [

43].

In line contact configurations, where contact pressure is generally on the order of hundreds of MPa, most studies indicate that electromagnetic fields contribute to improved tribological behavior [

44,

45,

46,

47].

For surface contact, which involves lower contact pressures (on the order of MPa), electromagnetic fields have also been observed to enhance the friction and wear behavior of the tribo-pairs [

48,

49].

The contact configuration directly influences the distribution of contact stress, lubrication regime, wear mechanisms, and thermal management. It also determines the target sites and underlying mechanisms through which electromagnetic fields act. Consequently, the same electromagnetic field treatment may yield considerably different effects depending on the contact form.

3.3. Materials of Tribo-Pairs

Based on magnetic properties, friction pair materials can be classified into three categories: ferromagnetic, paramagnetic, and diamagnetic. The selection of friction pair materials may have a decisive influence on the effect of electromagnetic fields.

Table 3 summarizes the influence of electromagnetic fields on the tribological properties of friction pair materials with different magnetic characteristics.

For ferromagnetic-ferromagnetic pairs, Lu et al. investigated the effect of a permanent magnetic field on the fretting wear behavior and mechanisms of a ferromagnetic pair consisting of an AISI 52100 steel ball and an AISI 1045 steel block [

51]. The results indicated that under the influence of a magnetic field perpendicular to the contact area, both the average coefficient of friction and the wear volume were reduced. Chen et al. studied the tribological behavior of laser-textured micro-dimpled surfaces on medium-carbon steel under three conditions: normal, demagnetized, and with an applied magnetic field perpendicular to the contact surface [

52]. The experimental results indicated that, compared with the normal condition, the presence of a magnetic field reduced both abrasive wear and the coefficient of friction on the laser-textured surface.

For ferromagnetic–non-ferromagnetic pairs, Li et al. examined the effect of a magnetic field on the friction and wear of a textured surface using a friction pair of 1045 steel and a Si

3N

4 ball. The results indicated that a magnetic field perpendicular to the contact surface led to a reduction in the coefficient of friction and a decrease in wear volume [

53].

For non-ferromagnetic–non-ferromagnetic pairs, Li et al. studied the sliding friction properties of magnetorheological elastomer (MRE)–glass pairs using a newly developed test rig [

54]. The coefficient of friction varied by up to 41% under the combined influence of various surface texture parameters and a magnetic field applied perpendicular to the contact surface. The observed significant change in the friction coefficient is likely attributed to the influence of the magnetic field on the magnetorheological fluid used as the lubricant.

Wei et al. prepared specimens with different magnetic permeabilities and investigated the influence of permeability on dry sliding friction and wear under a DC magnetic field [

45]. They found that as the magnetic field intensity increased, the wear volume and average wear coefficient of the specimens first decreased and then stabilized. Higher permeability resulted in lower wear volume and average wear coefficient. From the perspective of magnetic field influencing wear debris movement, the effect of magnetic field strength on tribological performance is also related to the magnetic field distribution. If the magnetic force generated by the field configuration can drive wear debris away from the frictional contact area, a stronger magnetic field may be beneficial. Conversely, if the magnetic force tends to attract debris into the contact zone, a higher magnetic field intensity may lead to agglomeration of magnetic wear debris, resulting in abrasive wear.

For ferromagnetic pairs, an external magnetic field induces magnetization, a process accompanied by the movement of magnetic domain walls and the rearrangement of domain structures within the material [

55]. Furthermore, the magnetic field significantly affects the retention and removal of wear debris at the friction interface, thereby influencing the friction and wear process.

Table 3.

Effect of electromagnetic field on tribological properties of different friction sub-materials.

Table 3.

Effect of electromagnetic field on tribological properties of different friction sub-materials.

| Type of Friction Partner | Material of Friction Sub-Material | Magnetic Field Strength | Sliding Velocity or Rotational Speed | Contact Pressure or Load | Tribological Properties |

|---|

| Ferromagnetism-Ferrimagnetism | AISI 52100 steel ball and AISI 1045 steel block [51] | 713.3 mT | 0.1–0.4 mm/s | 25–46 N | Average coefficient of friction and cumulative energy dissipation decreased by 38.41% and 60.66% |

| | AISI 1045 grade medium carbon steel GCr15 steel [52] | 24 mT | 0.083 m/s | 10 N | Coefficients of friction were reduced by 11.23%, wear volume was reduced |

| | AISI 52 100 bearing steel [32] | 210 mT | 0.0000046–0.46 m/s | 0.95 GPa | Friction reduced by 41.2%, wear volume reduced by 94.7% |

| | GCr15 steel [56] | 0–11 mT | 300 r/min | 10 N | Coefficient of friction and wear volume decreased, respectively, by 14.0% and 21.6% |

| | Steel (SM45C) [57] | 15 G | 0.8–1.2 m/s | 63.66–190.98 kPa | Reduced wear |

| Ferromagnetic–non-ferromagnetic | 1045 steel and Si3N4balls [53] | 34–105 mT | 30 mm/s | 5–20 N | Coefficient of friction decreased by 22%, and the wear volume reduced by 28% |

| | Glass spheres and AISI 52100 disks [58] | 0.26 T | 0.01 m/s | 1.4 GPa | Wear reduction, which is only promoted by a magnetic field if the field is high enough to overcome friction |

| Non-ferromagnetic–non-ferromagnetic | Magnetorheological elastomer, glass [54] | 0–200 mT | 0.1 mm/s | - | Friction coefficient initially changed from 0.99 to 0.58 |

| | Aluminum pins, MR elastomers [59] | 80 mT | 10 mm/s | 2 N | Coefficient of friction and depth of wear reduced in all tests |

| Coatings | TiN and TiN coatings [60] | 800–1500 G | 10 mm/s | 3 N | Friction increases with magnetic field strength, magnetic field gives good wear resistance |

| | Graphene oxide waterborne polyurethane coating and GCr 15 steel balls [61] | 0–40 mT | 220 rpm | 3 N | Improved friction reduction and wear resistance |

3.4. Electromagnetic Field Application Method

The influence of electromagnetic fields on tribological behavior varies depending on their application methods—such as static/dynamic fields, direction, intensity, and coupling forms—which stems from the highly context-dependent physical mechanisms underlying the interaction between electromagnetic fields and tribosystems.

Table 4 summarizes the effects of different electromagnetic field application methods on tribological behavior.

Steady magnetic fields and alternating magnetic fields exert distinct influences on friction and wear due to their differing mechanisms of interaction. Lian et al. investigated the tribological behavior of magnetorheological elastomers under static magnetic fields [

62]. The results demonstrated a decrease in the coefficient of friction and reduced wear depth with increasing magnetic field intensity. In contrast, Bao et al. studied the tribological behavior of a braking pair composed of a magnetic organic friction sheet and an HT 250 brake disc under an alternating magnetic field [

22]. Their findings indicated that both magnetic flux density and frequency significantly influenced tribological behavior. Higher magnetic frequencies improved wear resistance up to a certain threshold, beyond which further increases led to a decline in properties. From a mechanical perspective, the influence of magnetic field frequency is related to the relaxation time of the magnetic-responsive entities (such as magnetic domains, wear debris, or lubricant molecules). When the frequency of the alternating magnetic field significantly exceeds the relaxation time of these entities, its impact on the tribological performance is likely to be weakened.

In wear tests, the presence and orientation of the magnetic field are among the most critical parameters affecting wear behavior. Yetim et al. conducted reciprocating wear tests under DC magnetic fields with different orientations to evaluate the wear behavior of samples [

66]. The results revealed that magnetic field direction considerably influenced the morphology of wear debris. A magnetic field applied parallel to the sliding direction increased both the wear rate and coefficient of friction, whereas samples tested under a perpendicular magnetic field exhibited superior wear resistance compared to those under parallel or non-magnetic conditions. However, in the presence of magnetic lubricating particles, the findings of Zin et al. diverge from those of Yetim. Zin et al. investigated the tribological behavior when using magnetic particles of different shapes as lubricant additives under varying magnetic field orientations [

69]. Their study revealed that the optimal friction performance was achieved when a magnetic field was applied parallel to the sliding direction in combination with rod-shaped magnetic particles. The fundamental reason for the divergent magnetic field responses reported above may lie in the different primary subjects affected by the magnetic field. Under dry friction conditions, the wear volume is significant, and the movement of magnetic wear debris is the dominant factor influencing the friction results. In contrast, under lubricated conditions, the wear volume is relatively low, and the magnetic particles within the lubricant respond more markedly to the magnetic field.

Passive coupling refers to the magnetization of samples prior to friction experiments, which alters their physical properties and thereby affects their tribological behavior. Babutskyi et al. examined the effect of pulsed magnetic field pretreatment on the sliding friction and wear coefficient of an AISI 52100 steel pin-on-disc system [

68]. It was observed that magnetization treatment led to a reduction in both the coefficient of friction and the wear coefficient.

This study reports on the influences of magnetic field frequency, direction, and pre-treatment during friction on the tribological performance of the interface. To achieve active control of friction behavior in magnetic environments, a deeper investigation into the interaction mechanisms among these factors is essential. This requires designing a series of precise experiments where parameters such as magnetic field frequency, direction, and pre-treatment conditions are systematically varied, while key performance metrics like friction force and wear rate are meticulously recorded.

4. Mechanism of Electromagnetic Field Effect on Friction Behavior

With the growing body of research on the influence of electromagnetic fields on tribological behavior, the underlying mechanisms have become increasingly clear. It is now well-acknowledged that the effects of electromagnetic fields on friction mechanisms include dislocation motion, enhanced oxidation, control of wear debris, and alterations in lubricant properties, among others.

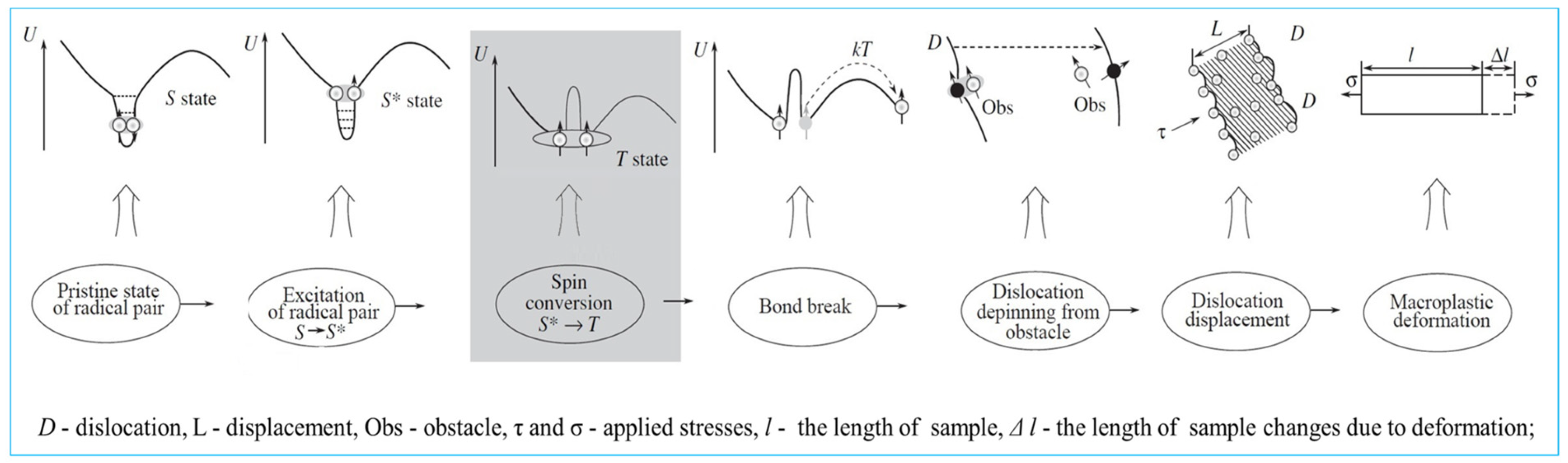

4.1. Dislocation Migration and Magnetic Domain Homogenization

Under electromagnetic fields, numerous microscopic behaviors on or beneath the surface of metallic materials undergo modifications during friction and wear, including electron movement, dislocation activity, stress distribution, vacancy migration, atomic diffusion, surface energy, and metallographic structure. Hu et al. found that the magnetic field accelerates dislocation unpinning, which enhances their mobility and leads to a more uniform distribution, thereby improving the material’s plastic deformability, as shown in

Figure 2 [

70]. Ma et al. experimentally observed that pulsed magnetic field treatment significantly increased the dislocation density in high-speed steel, accompanied by a maximum increase in microhardness of 50 HV [

71]. Moreover, Fu et al. discovered that magnetic fields promote the migration of dislocations toward the surface, thereby increasing surface hardness [

49]. These findings suggest that magnetic fields may influence the mechanical properties of materials through dislocation multiplication and dislocation migration. Bao et al. reported that the effect of magnetic field frequency on dislocation migration is bidirectional: within a certain range, it can optimize tribological behavior, but excessively high frequencies may lead to adverse effects [

22]. Furthermore, Wang et al. applied pulsed magnetic fields to enhance coating properties and found a more uniform magnetic domain distribution, the formation of numerous nanocrystalline and twin structures in the phase composition, and a reduction in coating residual stress [

72]. The pulsed magnetic field influences the residual stress and phase structure of the coating by affecting the magnetic moments within the coating grains. From a microscopic perspective, the application of an electromagnetic field enhances the plasticity of the material’s metallographic structure, leading to an elevated dislocation density which in turn results in surface hardening. This phenomenon is considered a potential reason for the improved wear resistance of the friction interface.

4.2. Enhanced Oxidation

Numerous studies have reported that magnetic fields can facilitate surface oxidation, which is primarily attributed to two factors. From a microscopic perspective, electromagnetic fields enhance the oxidation adsorption capacity of the contact surfaces of tribo-pairs by altering their surface electronic states. Specifically, magnetic fields can accelerate the nucleation of oxide embryos on the contact surface and increase the density of oxide film nucleation, thereby forming a denser and more protective oxide layer within the wear track [

47]. On the other hand, it is proposed that the magnetic wear debris generated is adsorbed at the friction interface and undergoes repeated rubbing, which enhances the formation rate of surface oxide films. This effect is particularly pronounced under dry friction conditions. Zaïdi et al. observed that magnetized contacts promote the growth of the ferromagnetic oxide Fe

3O

4 [

73]. The formation of an oxide film serves to shield the friction pair substrates from direct opposing wear, which is highly advantageous for wear reduction.

In addition, the generation of induced electric potentials and currents constitutes another key mechanism through which electromagnetic fields accelerate oxidation. Research by Han et al. demonstrated that in micro-asperity contact zones, induced potentials and currents are primarily concentrated on the contact surface. This phenomenon enhances the diffusion rates of electrons and iron ions, reduces the activation energy for diffusion, and thereby promotes the progression of oxidation reactions [

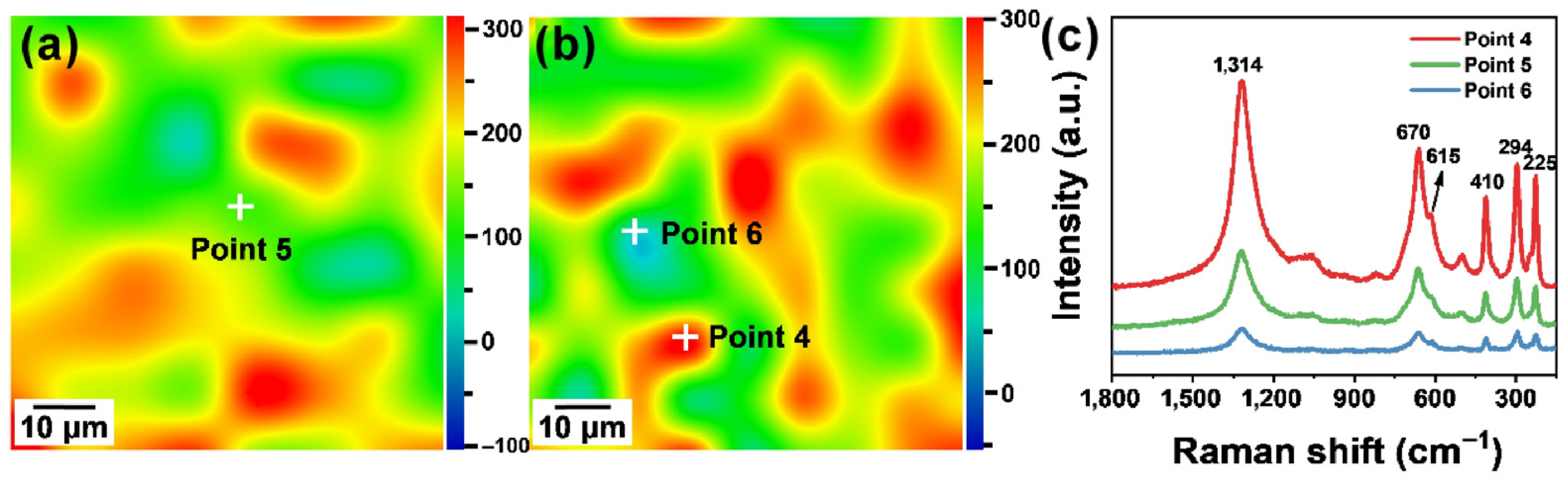

25]. Wang et al. found that magnetic fields increased the iron oxide content on friction surfaces, as shown in

Figure 3 [

32].

4.3. Attraction of Abrasive Debris

During the friction process of metallic tribo-pairs, ferromagnetic or paramagnetic wear debris is generated [

74,

75]. Under an external electromagnetic field, such debris tends to adhere to the metal substrate rather than being carried away by friction [

52]. Therefore, the motion of magnetic wear debris under the influence of a magnetic field at the friction interface also affects friction behavior.

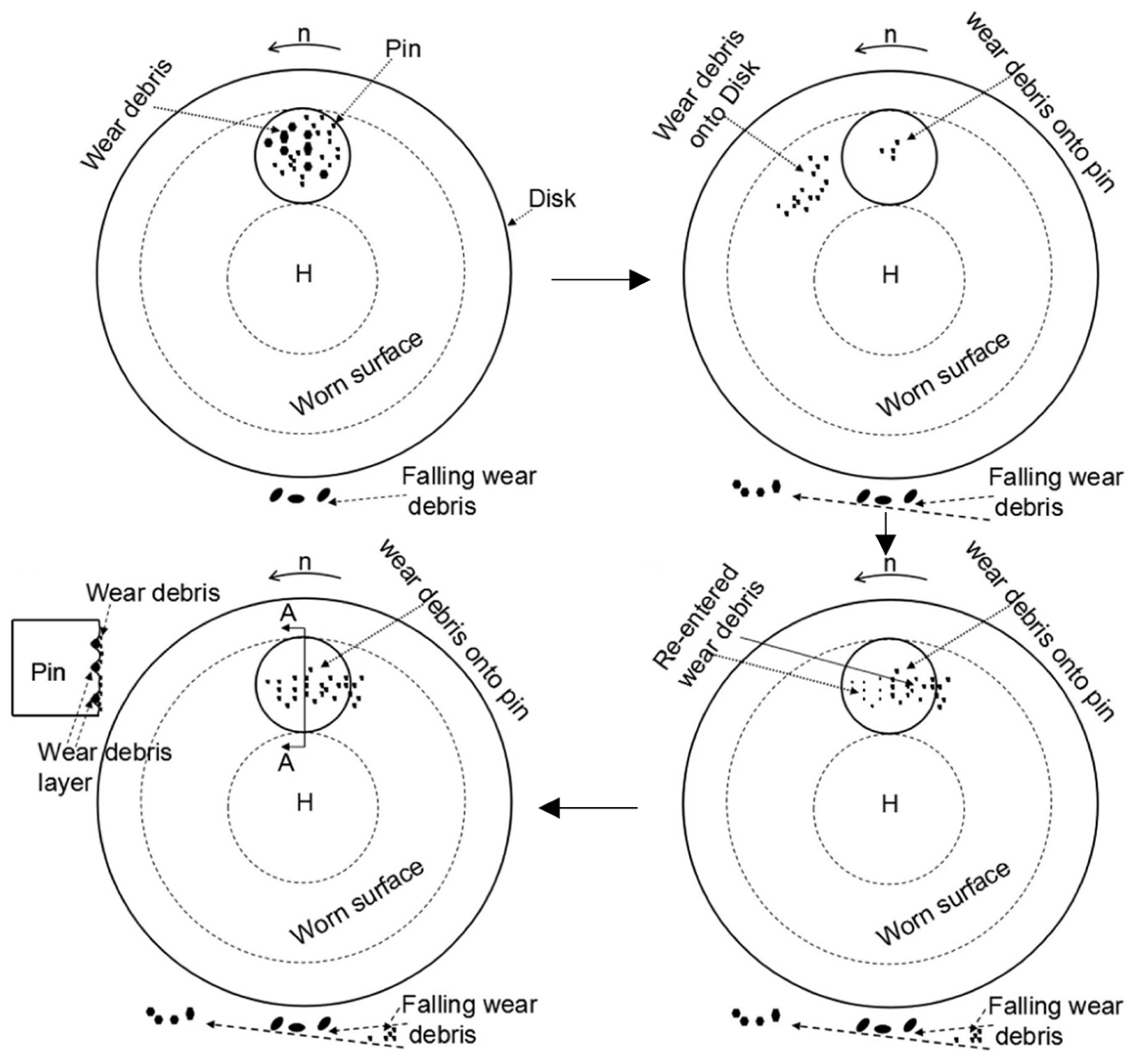

Shi et al. observed that wear debris adhering to the worn surface is compressed into grooves and, under pressure, forms a compact protective tribo-layer, thereby reducing wear [

21]. The behavior of wear debris under these conditions is illustrated in

Figure 4. However, Nasu et al. found that under the influence of a magnetic field, wear debris near the contact surface increased wear through an accumulation mechanism [

41]. Under no magnetic field, wear debris were expelled outward from the contact surface, forming a thick wear debris film. Under a magnetic field of B = 0.22 T, significant abrasive accumulation and embedment of flaky wear debris were also observed. However, if a specific magnetic field distribution causes an excessive accumulation of wear debris at the friction contact interface, it may also lead to adverse effects. In such cases, the wear debris can agglomerate under magnetic forces to form larger particles, which could potentially aggravate wear.

Furthermore, the orientation of the applied magnetic field significantly influences the morphology, size, and removal of wear debris from the sliding zone [

66]. When the magnetic field is applied parallel to the sliding direction, the debris exhibits a cubic shape and leads to a substantial increase in both the wear rate and the coefficient of friction. In contrast, when the magnetic field is perpendicular to the sliding direction, the debris becomes finer and nearly spherical, contributing to improved wear resistance.

4.4. Influence on Lubricant Properties

The regulatory effect of electromagnetic fields on lubricant properties manifests in multiple aspects. Jiang et al. suggested that T306 exhibits favorable magnetization properties perpendicular to the molecular plane, which facilitates its adsorption onto metal surfaces under a magnetic field [

76]. Abdel-Jaber et al. found that magnetic fields can promote the formation of closely packed, multi-molecular layered surface films from polar oil molecules. Huang et al. observed that, due to magnetic influence, ferrofluids spread more easily and uniformly on SUS316 surfaces, forming continuous lubricating films.

The lubrication mechanisms of nanofluid lubricants include self-repairing effects, “micro-bearing” action, and tribochemical film formation [

77,

78,

79]. However, under magnetic fields, the influence of nanoparticles on friction follows distinct mechanisms. Studies by Hu et al., Wang et al., and Sammaiah et al. revealed that magnetic fields promote the adsorption of nanoparticles onto worn surfaces, resulting in the formation of protective films [

80,

81,

82]. Further experiments indicated that magnetic fields may also alter the aggregation stability of magnetic fluids, leading to the formation of larger magnetic particle aggregates. This can deteriorate the micro-geometry of the wearing surface and consequently exacerbate wear [

83].

In addition, intermolecular forces play a crucial role in determining lubricant properties. Hydrogen bonding, as a type of intermolecular interaction, occurs primarily between molecules containing hydrogen atoms and atoms with high electronegativity [

84,

85]. The hydrogen-bond network in water not only endows it and other lubricants with exceptional physical and chemical properties but also significantly enhances lubrication properties at the friction interface [

86,

87]. Research by Zhou et al. showed that as magnetic field intensity increases, the number of hydrogen bonds decreases and the hydrogen-bond network becomes disrupted [

88]. Wang et al. also reported a reduction in hydrogen bonds in magnetized water [

89].

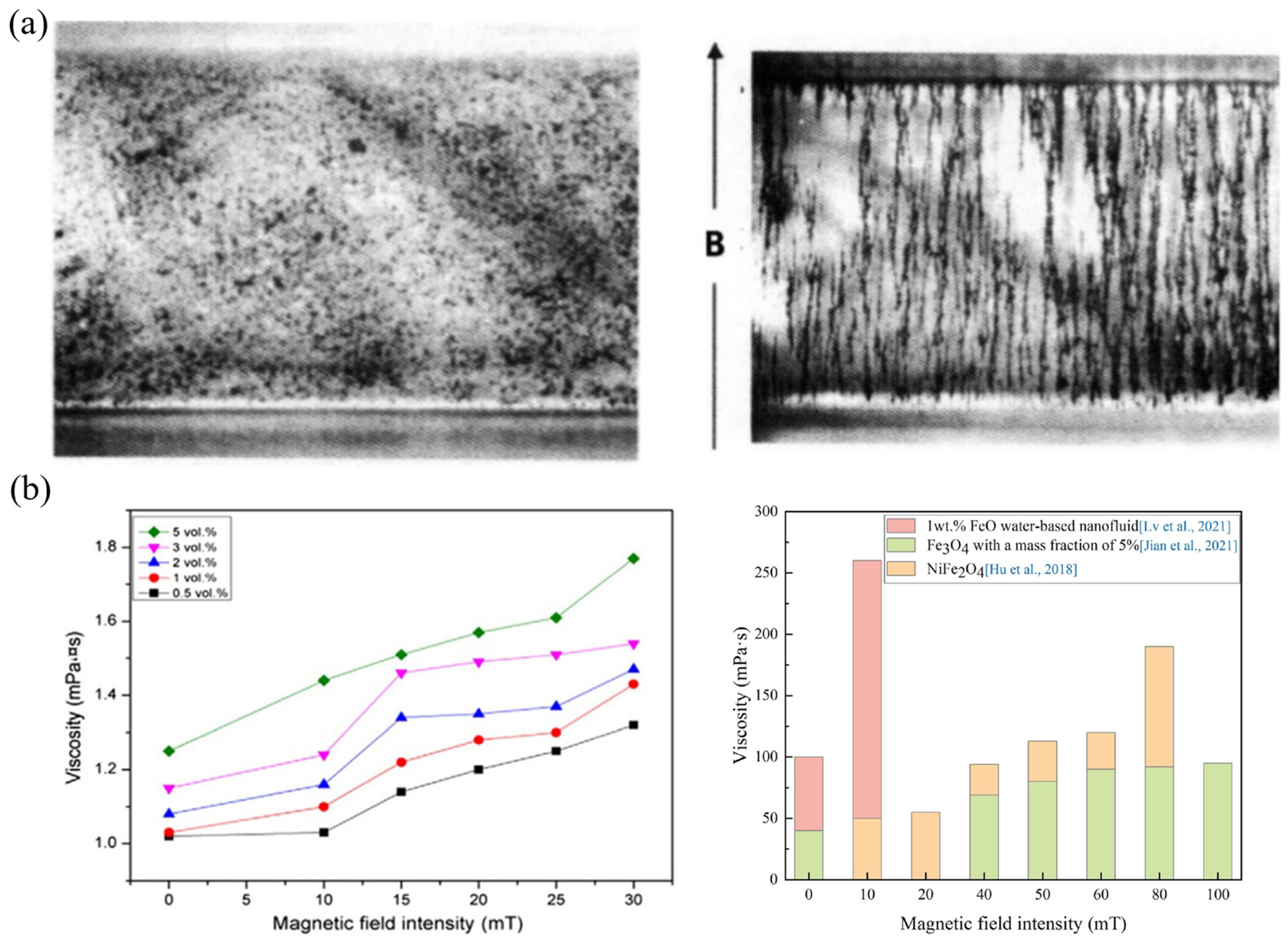

For lubricants containing magnetic particles, the application of an external electromagnetic field induces significant changes in their rheological properties. Studies by Huang et al. and Klingenberg et al. have demonstrated that the viscosity of such lubricants increases under an external magnetic field [

90,

91,

92]. The mechanism underlying this viscosity enhancement is illustrated in

Figure 5a. As magnetic field strength increases, both the volume fraction of droplet-like structures formed within the magnetic lubricant and its flow resistance increase, leading to a rise in viscosity, as shown in

Figure 5b [

93,

94,

95]. Using the Velocity Verlet algorithm, Ku et al. simulated the aggregation of magnetic particles under a magnetic field and their alignment into chain-like structures along the field direction [

96]. However, Yang et al. observed that as the shear rate increases, these chains undergo fracture and reorganization, leading to a stabilization of the macroscopic shear stress and a decrease in the dynamic viscosity index of the magnetic lubricant [

97]. In contrast, research by Chen et al. indicated that the reduction in viscosity occurs primarily at lower magnetic field intensities; beyond this range, viscosity increases [

98]. However, the relationship between lubricant viscosity and wear volume is not linear. Sun discovered that lubricants possess an optimal viscosity value that minimizes wear volume [

99]. It should be noted that the extent to which the magnetic field affects the viscosity of lubricants containing magnetic particles is dependent on the concentration of these particles. If the lubricant contains only trace amounts of magnetic particles, the influence of the magnetic field on viscosity is almost negligible.

5. Prospects of Electromagnetic Field Tribology

Looking ahead, research in electromagnetic field tribology is expected to advance along two major directions: “active control” and “passive design”.

In terms of active control, the core objective is to utilize electromagnetic fields as a technical means to actively regulate the tribological properties of friction interfaces. For instance, pre-magnetizing materials before friction can optimize magnetic domain structures and mechanical properties of the surface layer, thereby constructing interfaces with enhanced wear resistance and anti-fatigue characteristics. During the friction process, the application of external alternating electromagnetic fields can be explored to dynamically control the formation rate and composition of tribochemical reaction films, or to influence the distribution and expulsion behavior of wear debris through effects such as Lorentz forces. This enables active modulation of the friction coefficient and wear rate. Progress in this direction will drive the development of intelligent lubrication and online repair technologies based on electromagnetic fields, offering a novel paradigm for precise lifespan management of mechanical systems under extreme operating conditions.

On the other hand, passive design tailored to specific electromagnetic environments (such as those in high-field electrical equipment, magnetic levitation systems, and nuclear fusion devices) is equally critical. This direction focuses on screening novel alloys, ceramics, or composite materials with better compatibility to magnetic environments through materials genomics approaches, ensuring the stability of their intrinsic magnetic and mechanical properties. At the same time, developing functional lubricant additives or coatings that can synergize with magnetic fields to deliver excellent extreme-pressure and anti-wear performance under such conditions is key to enhancing lubrication reliability. The synergistic advancement of these two directions will jointly establish a solid technical foundation for achieving highly reliable and long-lasting operation of mechanical systems in electromagnetic environments.

6. Summary

Research on tribology under electromagnetic fields holds significant theoretical importance and engineering application value. This study systematically reviews different magnetic field application methods and their effects on tribological behavior, summarizes the underlying mechanisms in both dry and lubricated conditions, and proposes future research directions for electromagnetic tribology.

Various magnetic field application methods are enumerated, including steady magnetic fields, alternating magnetic fields, and magnetization treatments. Steady magnetic fields are primarily generated by permanent magnets, while alternating magnetic fields can be produced by applying direct or alternating current to electromagnetic coils. These application approaches form the basis for diverse utilization of magnetic fields in tribology.

The influence mechanisms of electromagnetic fields under different tribological conditions are summarized. Under dry friction conditions, electromagnetic fields primarily improve tribological behavior through three mechanisms: (1) dislocation migration and magnetic domain homogenization; (2) enhanced oxidation; and (3) attraction and control of wear debris. In lubricated conditions, the effects of electromagnetic fields are mainly manifested in three aspects: (1) regulation of rheological properties of magnetic fluids, where applied magnetic fields alter the arrangement of internal particles to modify their flow behavior; (2) control of lubricant molecule behavior, as magnetic fields induce structural changes in lubricant molecules affecting their adsorption and diffusion characteristics; and (3) modulation of intermolecular forces, where magnetic fields alter interactions between lubricant molecules.

The research prospects of electromagnetic field tribology are outlined from two main directions: “active control” and “passive design”. In terms of active control, electromagnetic fields are utilized as a technical means to achieve active regulation of the tribological properties at the friction interface. On the other hand, passive design in tribology focuses on adapting to specific electromagnetic environments.

Author Contributions

Conceptualization, Q.Z. and X.Y.; methodology, X.X.; software, X.Y.; validation, C.L. and Z.Y.; formal analysis, K.H.; investigation, X.Y.; resources, Q.Z.; data curation, Z.Y.; writing—original draft preparation, X.Y.; writing—review and editing, Q.Z. and T.Z.; visualization, X.X.; supervision, T.Z.; project administration, Q.Z. and X.X.; funding acquisition, X.H., X.X. and Q.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [National Nature Science Foundation of China] grant number [52475183], [Project of Center for Research on Efficient Intelligent Photovoltaic Module Engineering of Anhui Province] grant number [116010], [Open Foundation of Anhui Province Key Laboratory of Critical Friction Pair for Advanced Equipment] grant number [LCFP-2507], [Talent Startup Funding of Chaohu University] grant number [KYQD-2023035], and [Discipline Construction Quality Improvement Project of Chaohu University] grant number [XLZ202301]. And the APC was funded by [116010] and [KYQD-2023035].

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, G.; Ren, R. Study on Typical Failure Forms and Causes of High-Speed Railway Wheels. Eng. Fail. Anal. 2019, 105, 1287–1295. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical Bearing Failures in Electric Vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Zhao, Q.; He, R.; Hu, D.H. Fuzzy PID Control of the Integrated System of Electromagnetic Brake and Friction Brake of Car. Adv. Mater. Res. 2014, 988, 568–575. [Google Scholar] [CrossRef]

- Ren, S.; Feng, G.; Liu, S. Study on Wear of Electromagnetic Railgun. IEEE Access 2022, 10, 100955–100963. [Google Scholar] [CrossRef]

- Kircher, R.; Klühspies, J.; Palka, R.; Fritz, E.; Eiler, K.; Witt, M. Electromagnetic Fields Related to High Speed Transportation Systems. Transp. Syst. Technol. 2018, 4, 152–166. [Google Scholar] [CrossRef]

- Stolarski, T.A.; Makida, Y. Performance of Lubricated Sliding Contact in Magnetic Field. Tribol. Lett. 2012, 46, 113–121. [Google Scholar] [CrossRef]

- Jiang, J.; Tian, Y.; Meng, Y. Role of External Magnetic Field during Friction of Ferromagnetic Materials. Wear 2011, 271, 2991–2997. [Google Scholar] [CrossRef]

- Iida, Y.; Stolarski, T. Alternation on Rolling Contact Properties of Steel Due to Magnetic Field. Wear 2009, 266, 1098–1105. [Google Scholar] [CrossRef]

- Li, Y.; Han, P.; Li, D.; Chen, S.; Wang, Y. Typical Dampers and Energy Harvesters Based on Characteristics of Ferrofluids. Friction 2023, 11, 165–186. [Google Scholar] [CrossRef]

- Wang, W.; Timonen, J.V.I.; Carlson, A.; Drotlef, D.-M.; Zhang, C.T.; Kolle, S.; Grinthal, A.; Wong, T.-S.; Hatton, B.; Kang, S.H.; et al. Multifunctional Ferrofluid-Infused Surfaces with Reconfigurable Multiscale Topography. Nature 2018, 559, 77–82. [Google Scholar] [CrossRef]

- Khairul, M.A.; Doroodchi, E.; Azizian, R.; Moghtaderi, B. Advanced Applications of Tunable Ferrofluids in Energy Systems and Energy Harvesters: A Critical Review. Energy Convers. Manag. 2017, 149, 660–674. [Google Scholar] [CrossRef]

- Yun, H.R.; Lee, D.J.; Youn, J.R.; Song, Y.S. Ferrohydrodynamic Energy Harvesting Based on Air Droplet Movement. Nano Energy 2015, 11, 171–178. [Google Scholar] [CrossRef]

- Bibo, A.; Masana, R.; King, A.; Li, G.; Daqaq, M.F. Electromagnetic Ferrofluid-Based Energy Harvester. Phys. Lett. A 2012, 376, 2163–2166. [Google Scholar] [CrossRef]

- Ulbrich, K.; Holá, K.; Šubr, V.; Bakandritsos, A.; Tuček, J.; Zbořil, R. Targeted Drug Delivery with Polymers and Magnetic Nanoparticles: Covalent and Noncovalent Approaches, Release Control, and Clinical Studies. Chem. Rev. 2016, 116, 5338–5431. [Google Scholar] [CrossRef]

- Iida, Y.; Stolarski, T.A.; Sato, K. Surface Damage Resulting from Rolling Contact Operating in Magnetic Field. J. Phys. D Appl. Phys. 2007, 40, 7629–7637. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, X.; Liu, Y.; Xu, X. Magnetic-Field Tribological Behaviors of Aluminum-Alloy and Steel. AIP Adv. 2018, 8, 115014. [Google Scholar] [CrossRef]

- Tharajak, J.; Nicomrat, D. Friction Coefficient and Worn Surface of Ferromagnetic Materials under Magnetic Fields. Appl. Mech. Mater. 2016, 848, 31–34. [Google Scholar] [CrossRef]

- Zhao, X.; Appiah, E.; Tang, H. Study on the Magnetic Contact Mechanical Properties of Polyurethane-Based Magnetorheological Elastomer Sealing Materials. Lubricants 2025, 13, 88. [Google Scholar] [CrossRef]

- Stolarski, T.A.; Makida, Y. Influence of Permanent Magnetic Field on Wear Performance of Dry Sliding Contacts. Wear 2011, 271, 1109–1123. [Google Scholar] [CrossRef]

- Han, H.; Du, S.; Zhang, Y.; Liu, H.; Pan, R. Effect of DC Magnetic Field on Friction and Wear Properties of 45 Steel at Different Velocities. Tribol. Lett. 2016, 64, 38. [Google Scholar] [CrossRef]

- Shi, H.; Du, S.; Sun, C.; Song, C.; Yang, Z.; Zhang, Y. Behavior of Wear Debris and Its Action Mechanism on the Tribological Properties of Medium-Carbon Steel with Magnetic Field. Materials 2018, 12, 45. [Google Scholar] [CrossRef]

- Gao, F.; Fan, J. Research on the Effect of Remanence and the Earth’s Magnetic Field on Tribo-Magnetization Phenomenon of Ferromagnetic Materials. Tribol. Int. 2017, 109, 165–173. [Google Scholar] [CrossRef]

- Bao, J.; Huang, S.; Liu, Y.; Ge, S.; Yin, Y.; Liu, T. Tribological Behavior and Mechanism of a Magnetic Conductive Brake Pair under Action of Alternating Magnetic Field. Tribol. Int. 2019, 131, 465–475. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Q.; Li, C.; Xu, X.; Yang, Z.; Hu, X. Effect of Alternating Magnetic Fields on the Tribological Behaviors of Steel/Steel Contact Under Dry Sliding Conditions. Tribol. Lett. 2025, 73, 66. [Google Scholar] [CrossRef]

- Liu, H.B.; Li, J.S.; Xue, Y.J.; Ma, W. Study on the Friction Characteristics of Different Lubrication Modes under Alternating Magnetic Field. Key Eng. Mater. 2010, 455, 490–494. [Google Scholar] [CrossRef]

- Han, H.; Gao, Y.; Zhang, Y.; Du, S.; Liu, H. Effect of Magnetic Field Distribution of Friction Surface on Friction and Wear Properties of 45 Steel in DC Magnetic Field. Wear 2015, 328–329, 422–435. [Google Scholar] [CrossRef]

- Li, R.; Li, X.; Li, Y.; Yang, P.; Liu, J. Experimental and Numerical Study on Surface Roughness of Magnetorheological Elastomer for Controllable Friction. Friction 2020, 8, 917–929. [Google Scholar] [CrossRef]

- Amirat, M.; Zaidi, H.; Senouci, A. Nucleation and Formation of Oxide Film with the Magnetic Field on Dry Sliding Contact of Ferromagnetic Steel. Lubr. Sci. 2011, 23, 19–31. [Google Scholar] [CrossRef]

- Li, R.; Wang, D.; Li, X.; Liao, C.; Yang, P.; Ruan, H.; Shou, M.; Luo, J.; Wang, X. Study on Sliding Friction Characteristics of Magnetorheological Elastomer—Copper Pair Affected by Magnetic-Controlled Surface Roughness and Elastic Modulus. Smart Mater. Struct. 2022, 31, 015030. [Google Scholar] [CrossRef]

- Xie, Y.; Sun, C.; Zhang, Y.; Shi, H.; Song, C.; Du, S. Effect of Magnetic Oxidation and Surface Carbon Distribution on Friction and Wear Characteristics of 45 Steel under the DC Magnetic Field. Tribol. Trans. 2019, 62, 868–879. [Google Scholar] [CrossRef]

- Hu, J.; Wang, C.; Zhang, P.; Zhang, S.; Zhang, Y. Diisooctyl Sebacate-Containing Nickel Nanoparticles for Lubrication of Steel Sliding Parts under Magnetic Fields. ACS Appl. Nano Mater. 2021, 4, 7007–7016. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Liu, H.; Wang, X.; Lou, W.; Yang, J. Influence of External Magnetic Field on the Tribological Performance of Magnetic Fluids in Different Lubrication Regimes. Friction 2025, 13, 9440979. [Google Scholar] [CrossRef]

- Sundar, L.S.; Ramana, E.V. Influence of Magnetic Field Location on the Heat Transfer and Friction Factor of CoFe2O4-BaTiO3/EG Hybrid Nanofluids in Laminar Flow: An Experimental Study. J. Magn. Magn. Mater. 2023, 579, 170837. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Q.; Wang, C.; Liu, T.; Zhang, Y.; He, H.; Zhang, K. Effect of Magnetic Field on Cutting Performance of Micro-Textured Tools under Fe3O4 Nanofluid Lubrication Condition. J. Mater. Process. Technol. 2022, 299, 117382. [Google Scholar] [CrossRef]

- Zhang, P.; Lee, K.H.; Lee, C.H. Fretting Friction and Wear Characteristics of Magnetorheological Fluid under Different Magnetic Field Strengths. J. Magn. Magn. Mater. 2017, 421, 13–18. [Google Scholar] [CrossRef]

- Huang, W.; Shen, C.; Liao, S.; Wang, X. Study on the Ferrofluid Lubrication with an External Magnetic Field. Tribol. Lett. 2011, 41, 145–151. [Google Scholar] [CrossRef]

- Syam Sundar, L.; Alklaibi, A.M.; Sambasivam, S.; Chandra Mouli, K.V.V. Experimentally Determining the Thermophysical Properties, Heat Transfer and Friction Factor Fe3O4-TiO2 Magnetic Hybrid Nanofluids in a Mini-Heat Sink under Magnetic Field: Proposing New Correlations. J. Magn. Magn. Mater. 2024, 594, 171889. [Google Scholar] [CrossRef]

- Zhang, P.; Lee, K.-H.; Lee, C.-H. Friction Behavior of Magnetorheological Fluids with Different Material Types and Magnetic Field Strength. Chin. J. Mech. Eng. 2016, 29, 84–90. [Google Scholar] [CrossRef]

- Zhang, P.; Lee, G.; Lee, C.; Yoon, H. Friction and Wear Behavior of Pin-Bushing with Magnetorheological Fluids. Ind. Lubr. Tribol. 2017, 69, 912–918. [Google Scholar] [CrossRef]

- Bolotov, A.; Burdo, G. Effect of Magnetic Field on the Physical and Mechanical Properties of Oils and Non-Magnetic Substance. Krasn. Russ. Fed. 2022, 2467, 020004. [Google Scholar] [CrossRef]

- Nasu, Y.; Sato, K. The Effect of Magnetic Field on Fretting Wear under Gross Slip Condition. J. Environ. Eng. 2011, 6, 376–386. [Google Scholar] [CrossRef]

- Shahrivar, K.; De Vicente, J. Ferrofluid Lubrication of Compliant Polymeric Contacts: Effect of Non-Homogeneous Magnetic Fields. Tribol. Lett. 2014, 56, 281–292. [Google Scholar] [CrossRef]

- Kadıoğlu, M.; Durak, E. Study of the Tribological Properties of Rolling Element Bearings under the Effect of Magnetic Field. Ind. Lubr. Tribol. 2019, 71, 1200–1205. [Google Scholar] [CrossRef]

- Fan, S.; Gao, C.; Yang, G.; Zhang, Y.; Zhang, C.; Song, N.; Zhang, S.; Zhang, P.; Zhang, Z.; Ke, S. Enhancing Wear-Resistance of Cu Nanowires Filled Polyetheretherketone-Based Composites under Water Lubrication Conditions via Magnetic Response to Tribofilm. Tribol. Int. 2021, 153, 106601. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, Y.; Chen, Y.; Du, S. Impact of Material Permeability on Friction and Wear Properties under the Interference of DC Steady Magnetic Field. Tribol. Int. 2013, 57, 162–169. [Google Scholar] [CrossRef]

- Shah, K.R.; Shukla, A.; Patel, N.S.; Katiyar, J.K. Effect of Ferrofluid Lubrication on Tribological Performance of Metal Tribopairs. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2024, 238, 569–580. [Google Scholar] [CrossRef]

- Wei, Y.H.; Zhang, Y.Z.; Chen, Y.; Du, S.M. Influence of DC Steady Magnetic Field on Friction and Wear Characteristics of Friction Pair of High-Speed Steel/2Cr13 Stainless Steel. Adv. Mater. Res. 2011, 291–294, 1521–1525. [Google Scholar] [CrossRef]

- Amirat, M.; Zaïdi, H.; Beloufa, A. Friction in Vacuum and under Different Gaseous Environment of Magnetized Sliding Ferromagnetic Contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 18–32. [Google Scholar] [CrossRef]

- Fu, L.; Zhou, L. Effect of applied magnetic field on wear behaviour of martensitic steel. J. Mater. Res. Technol. 2019, 8, 2880–2886. [Google Scholar] [CrossRef]

- Chen, K.; Tian, Y.; Shan, L.; Zhang, X.; Meng, Y. The Rheological Properties of Magnetic Field Excited Magnetic Powders Sheared between Two Parallel Plates. Smart Mater. Struct. 2013, 22, 115036. [Google Scholar] [CrossRef]

- Lu, J.; He, J.; Kang, G.; Lan, B.; Liu, J.; Zhu, M. Effect of External Magnetic Field on the Fretting Wear Mechanism of the Ferromagnetic Materials. Tribol. Int. 2025, 202, 110305. [Google Scholar] [CrossRef]

- Chen, Q.; Yu, A.; Zhao, S.; Wu, M.; Yuan, J.; Sun, L.; Chi, J. Effect of Magnetic Field on Tribological Performance of Laser Dimple Textured Surface. Wear 2021, 468–469, 203584. [Google Scholar] [CrossRef]

- Li, X.; Fan, X.; Zhang, Y.; Zhang, Z.; Zhu, M. Magnetic-Manipulation of Tribofilm for Si3N4/1045 Steel Contact toward Sustainable Reduction in Friction and Wear. J. Clean. Prod. 2024, 475, 143766. [Google Scholar] [CrossRef]

- Li, R.; Zhang, X.; Zeng, C.; Yang, P.; Shou, M.; Zhu, D.; Cao, Z.; Xie, H.; Lee, C.-H. Magneto-Controlled Friction Behaviors of Magnetorheological Elastomers with Cosine-Shaped Surface Structure. Tribol. Int. 2023, 186, 108658. [Google Scholar] [CrossRef]

- Schumm, R.D.; Kunz, A. Magnetization Reversal in Ferromagnetic Spirals via Domain Wall Motion. Appl. Phys. Lett. 2016, 109, 202405. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, H.; Wu, B.; Feng, W.; Li, X.; Jiao, Y.; Hu, X. Effect of Magnetic Field on the Tribological Behaviors of Fe3O4@MoS2 as Polyalphaolefin Additive in the Steel/Steel Friction Interface. Wear 2021, 466–467, 203586. [Google Scholar] [CrossRef]

- Song, W.; Seong, M.-S.; Choi, S.-B.; Lee, C.-H.; Cho, M. Tribological Characteristics of Magneto-Rheological Fluid for Movement Sensor Application. Smart Mater. Struct. 2014, 23, 017001. [Google Scholar] [CrossRef]

- Guedes, A.E.D.S.; Mello, V.S.; Bohn, F.; Alves, S.M. Understanding the Influence of the Magnetic Field, Particle Size, and Concentration on the Tribological Performance of Superparananolubricants. Tribol. Trans. 2021, 64, 551–561. [Google Scholar] [CrossRef]

- Lian, C.; Lee, K.-H.; Lee, C.-H. Effect of Temperature and Relative Humidity on Friction and Wear Properties of Silicone-Based Magnetorheological Elastomer. Tribol. Trans. 2018, 61, 238–246. [Google Scholar] [CrossRef]

- Cho, D.-H.; Kim, Y.-S.; Lee, Y.-Z. Effect of Magnetic Field Intensity on Friction and Wear of TiN- and TiCN-Coated Neodymium Magnets. Wear 2023, 523, 204757. [Google Scholar] [CrossRef]

- Bai, T.; Liu, X. Effect of Magnetic Field on the Tribological Performance of Waterborne Polyurethane Coatings with Magnetized Graphene Oxide. Prog. Org. Coat. 2022, 167, 106839. [Google Scholar] [CrossRef]

- Lian, C.; Lee, K.-H.; Lee, C.-H. Friction and Wear Characteristics of Magnetorheological Elastomer under Vibration Conditions. Tribol. Int. 2016, 98, 292–298. [Google Scholar] [CrossRef]

- Rosa, W.O.; Vereda, F.; De Vicente, J. Tribological Behavior of Glycerol/Water-Based Magnetorheological Fluids in PMMA Point Contacts. Front. Mater. 2019, 6, 32. [Google Scholar] [CrossRef]

- Song, W.-L.; Choi, S.-B.; Choi, J.-Y.; Lee, C.-H. Wear and Friction Characteristics of Magnetorheological Fluid under Magnetic Field Activation. Tribol. Trans. 2011, 54, 616–624. [Google Scholar] [CrossRef]

- Chin, K.J.; Zaidi, H.; Nguyen, M.T.; Renault, P.O. Tribological Behavior and Surface Analysis of Magnetized Sliding Contact XC 48 Steel/XC 48 Steel. Wear 2001, 250, 470–476. [Google Scholar] [CrossRef]

- Yetim, A.F.; Kovacı, H.; Yildiz, F.; Bayrak, O.; Çelik, A. The Effect of Post Aging on Wear Properties of a Plasma Nitrided Ferromagnetic Steel under DC Magnetic Field. Wear 2015, 332–333, 988–994. [Google Scholar] [CrossRef]

- Pan, J.; Wang, J.; Wang, J.; Yang, G.; Wang, X. An Investigation of Tribological Properties of Magnetorheological Grease with Thermomagnetic Coupling. J. Magn. Magn. Mater. 2025, 615, 172809. [Google Scholar] [CrossRef]

- Babutskyi, A.; Chrysanthou, A.; Zhao, C. Effect of Pulsed Magnetic Field Pre-Treatment of AISI 52100 Steel on the Coefficient of Sliding Friction and Wear in Pin-on-Disk Tests. Friction 2014, 2, 310–316. [Google Scholar] [CrossRef]

- Zin, V.; Agresti, F.; Barison, S.; Litti, L.; Fedele, L.; Meneghetti, M.; Fabrizio, M. Effect of External Magnetic Field on Tribological Properties of Goethite (a-FeOOH) Based Nanofluids. Tribol. Int. 2018, 127, 341–350. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, H.; Zhang, Y.; Zhang, B.; Hu, K. Enhanced Mechanical Properties of QAl9-4 Aluminum Bronze for High-Speed-Rail Brake Systems with a Pulsed Magnetic Field. Materials 2023, 16, 5905. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, W.; Liang, Z.; Wang, X.; Xie, L.; Jiao, L.; Zhou, T. An Investigation on the Mechanical Property Changing Mechanism of High Speed Steel by Pulsed Magnetic Treatment. Mater. Sci. Eng. A 2014, 609, 16–25. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Guo, W.; Shan, D.; Xing, Z.; Wang, H. Effect of High Intensity Pulsed Magnetic Field (30 T) on Microstructure and Tribological Properties of Ni-Based Coatings. Mater. Lett. 2023, 347, 134639. [Google Scholar] [CrossRef]

- Zaïdi, H.; Amirat, M.; Frêne, J.; Mathia, T.; Paulmier, D. Magnetotribology of Ferromagnetic/Ferromagnetic Sliding Couple. Wear 2007, 263, 1518–1526. [Google Scholar] [CrossRef]

- Yadav, P.K.; Jayswal, S.C.; Saxena, K.K. Magnetic Abrasive Flow Finishing: A Review. Mater. Today Proc. 2020, 26, 3257–3264. [Google Scholar] [CrossRef]

- Kanish, T.C.; Narayanan, S.; Kuppan, P.; Denis Ashok, S. Investigations on Wear Behavior of Magnetic Field Assisted Abrasive Finished SS316L Material. Mater. Today Proc. 2018, 5, 12734–12743. [Google Scholar] [CrossRef]

- Jiang, Z.; Fang, J.; Chen, B.; Gu, K. Effect of Magnetic Field on Tribological Performances of Two Lubricating Oils with Phosphorus-containing Additives. Lubr. Sci. 2018, 30, 23–32. [Google Scholar] [CrossRef]

- Kong, L.; Sun, J.; Bao, Y. Preparation, Characterization and Tribological Mechanism of Nanofluids. RSC Adv. 2017, 7, 12599–12609. [Google Scholar] [CrossRef]

- Xu, C.; Schall, D.; Barber, G. Molecular Dynamics Simulation on the Friction Properties of Confined Nanofluids. Mater. Today Commun. 2023, 34, 105252. [Google Scholar] [CrossRef]

- Bhaumik, S.; Maggirwar, R.; Datta, S.; Pathak, S.D. Analyses of Anti-Wear and Extreme Pressure Properties of Castor Oil with Zinc Oxide Nano Friction Modifiers. Appl. Surf. Sci. 2018, 449, 277–286. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Wang, S.; Wang, P.; Zhang, Y.; Guo, X. Study on the Cooling and Lubrication Mechanism of Magnetic Field-Assisted Fe3O4@CNTs Nanofluid in Micro-Textured Tool Cutting. J. Manuf. Process. 2023, 85, 556–568. [Google Scholar] [CrossRef]

- Hu, Z.D.; Yan, H.; Qiu, H.Z.; Zhang, P.; Liu, Q. Friction and Wear of Magnetorheological Fluid under Magnetic Field. Wear 2012, 278–279, 48–52. [Google Scholar] [CrossRef]

- Sammaiah, A.; Dai, Q.; Huang, W.; Wang, X. Synthesis of GO-Fe3 O4-Based Ferrofluid and Its Lubrication Performances. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 1160–1167. [Google Scholar] [CrossRef]

- Bolotov, A.N.; Novikov, V.V.; Novikova, O.O. The Influence of a Magnetic Field on Skin Effects Lubricated by Magnetic Lubricants. Mater. Sci. Forum 2020, 989, 97–102. [Google Scholar] [CrossRef]

- Zhou, K.X.; Lu, G.W.; Zhou, Q.C.; Song, J.H.; Jiang, S.T.; Xia, H.R. Monte Carlo Simulation of Liquid Water in a Magnetic Field. J. Appl. Phys. 2000, 88, 1802–1805. [Google Scholar] [CrossRef]

- Mohammadnezhad, A.; Azizi, S.; Sousanabadi Farahani, H.; Tashan, J.; Habibnejad Korayem, A. Understanding the Magnetizing Process of Water and Its Effects on Cementitious Materials: A Critical Review. Constr. Build. Mater. 2022, 356, 129076. [Google Scholar] [CrossRef]

- Chen, L.; Qian, L. Role of Interfacial Water in Adhesion, Friction, and Wear—A Critical Review. Friction 2021, 9, 1–28. [Google Scholar] [CrossRef]

- Dhopatkar, N.; Defante, A.P.; Dhinojwala, A. Ice-like Water Supports Hydration Forces and Eases Sliding Friction. Sci. Adv. 2016, 2, e1600763. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, H.; Zhan, S.; Liu, L.; Yang, T.; Chen, S.; Jia, D. The Effect of Magnetic Field Intensity on the Tribological Properties of PA6 and UHMWPE in Pure Water and Seawater Environments. Tribol. Int. 2025, 206, 110482. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, B.; Gong, Z.; Gao, K.; Ou, Y.; Zhang, J. The Effect of a Static Magnetic Field on the Hydrogen Bonding in Water Using Frictional Experiments. J. Mol. Struct. 2013, 1052, 102–104. [Google Scholar] [CrossRef]

- Klingenberg, D.J. Magnetorheology: Applications and Challenges. AIChE J. 2001, 47, 246–249. [Google Scholar] [CrossRef]

- Huang, X.; Wang, W.; Ding, L.; Yang, B. Investigating the Lubrication Mechanism and Stiffness of Oil-Based Ferrofluids in Spur Gear Drives. Phys. Fluids 2021, 33, 043103. [Google Scholar] [CrossRef]

- Huang, W.; Shen, C.; Wang, X. Study on Static Supporting Capacity and Tribological Performance of Ferrofluids. Tribol. Trans. 2009, 52, 717–723. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, Y.; Cui, X.; An, Q.; Chen, Y.; Jia, D.; Gong, P.; Liu, M.; Dambatta, Y.S.; Li, C. Magnetic Lubricants: Preparation, Physical Mechanism, and Application. Friction 2025, 13, 9441010. [Google Scholar] [CrossRef]

- Lv, T.; Xu, X.; Yu, A.; Niu, C.; Hu, X. Ambient Air Quantity and Cutting Performances of Water-Based Fe3O4 Nanofluid in Magnetic Minimum Quantity Lubrication. Int. J. Adv. Manuf. Technol. 2021, 115, 1711–1722. [Google Scholar] [CrossRef]

- Jian, G.; Wang, Y.; Yu, X.; Li, Y.; Luo, H. Coupling on Ferrofluid Lubrication and Dynamics of Gear System. Tribology 2021, 41, 325–333. [Google Scholar] [CrossRef]

- Ku, J.; Chen, H.; He, K.; Yan, Q. Simulation and Observation of Magnetic Mineral Particles Aggregating into Chains in a Uniform Magnetic Field. Miner. Eng. 2015, 79, 10–16. [Google Scholar] [CrossRef]

- Yang, T.; Wang, X.; Liu, H.; Chen, S.; Liu, J.; Zhao, Q.; Gong, K.; Li, W.; Liang, Y.; Wang, X. Electrostatically Self-Assembled Magnetic Nanoparticles for High-Temperature Resistant and Friction-Controlled Lubrication System. Small 2024, 20, 2405018. [Google Scholar] [CrossRef]

- Chen, X.; Hou, L.; Li, W.; Li, S.; Chen, Y. Molecular Dynamics Simulation of Magnetic Field Influence on Waxy Crude Oil. J. Mol. Liq. 2018, 249, 1052–1059. [Google Scholar] [CrossRef]

- Sun, J.; Yang, J.; Yao, J.; Tian, J.; Xia, Z.; Yan, H.; Gao, L.; Li, S.; Bao, Z. The Effect of Lubricant Viscosity on the Performance of Full Ceramic Ball Bearings. Mater. Res. Express 2022, 9, 015201. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).