Tribological Performance of AlCrN, TiAlN, and Arc-DLC Coatings in Hot Forming of Aluminum Alloy †

Abstract

1. Introduction

2. Experiments

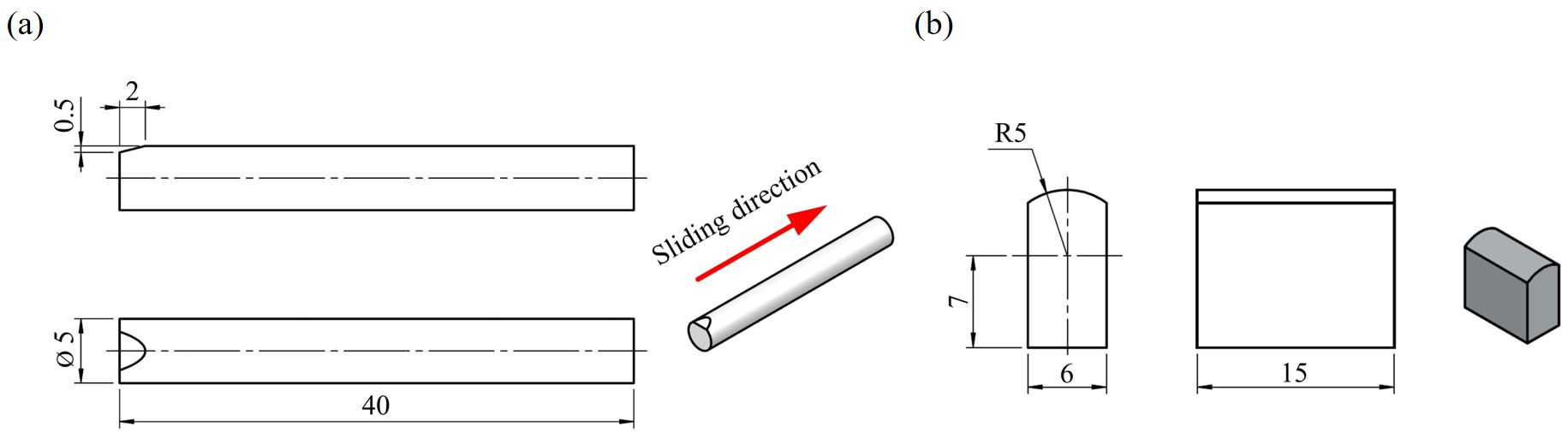

2.1. Warm and Hot Upsetting Sliding Test (WHUST)

2.2. Materials

2.2.1. Specimen

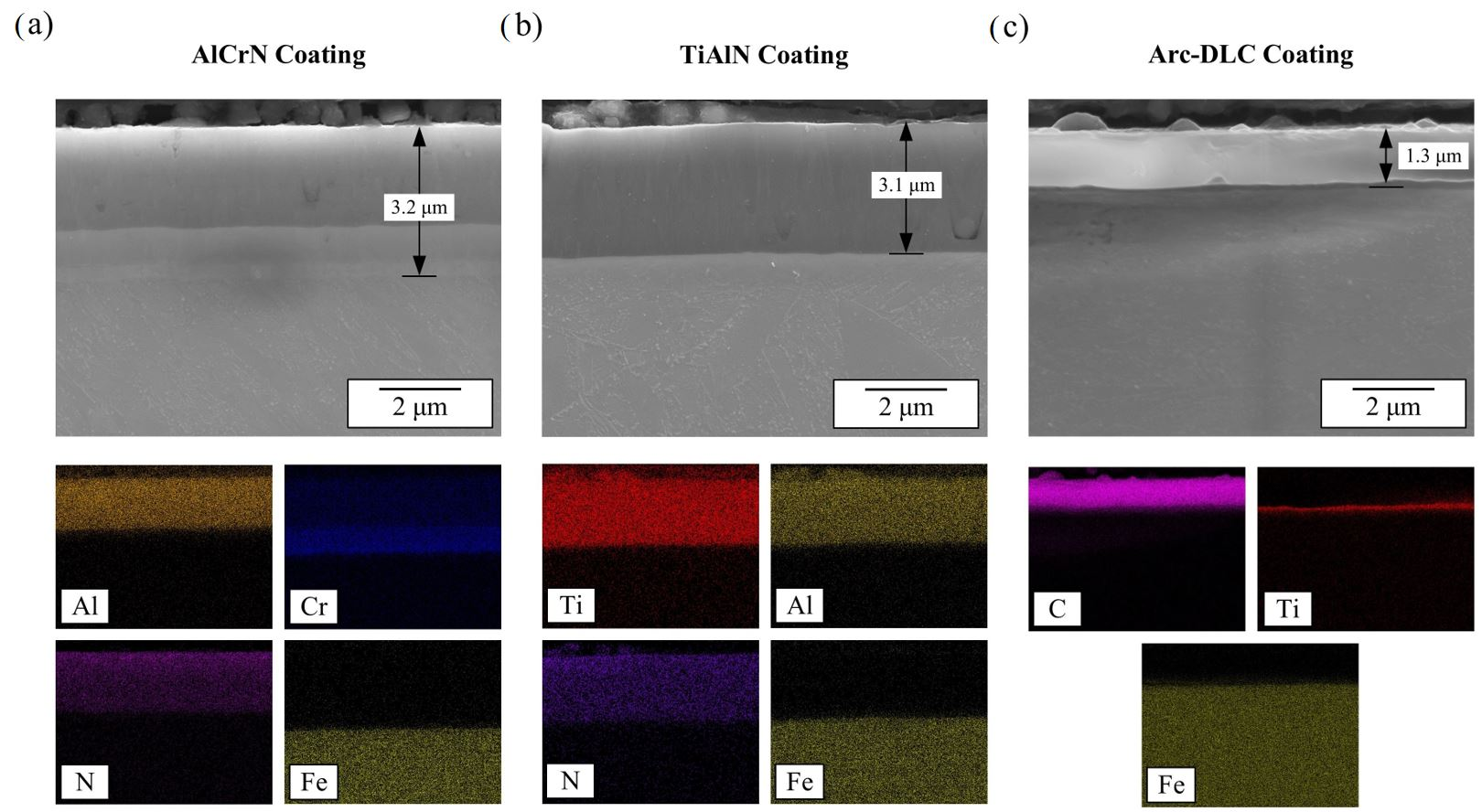

2.2.2. Contactor

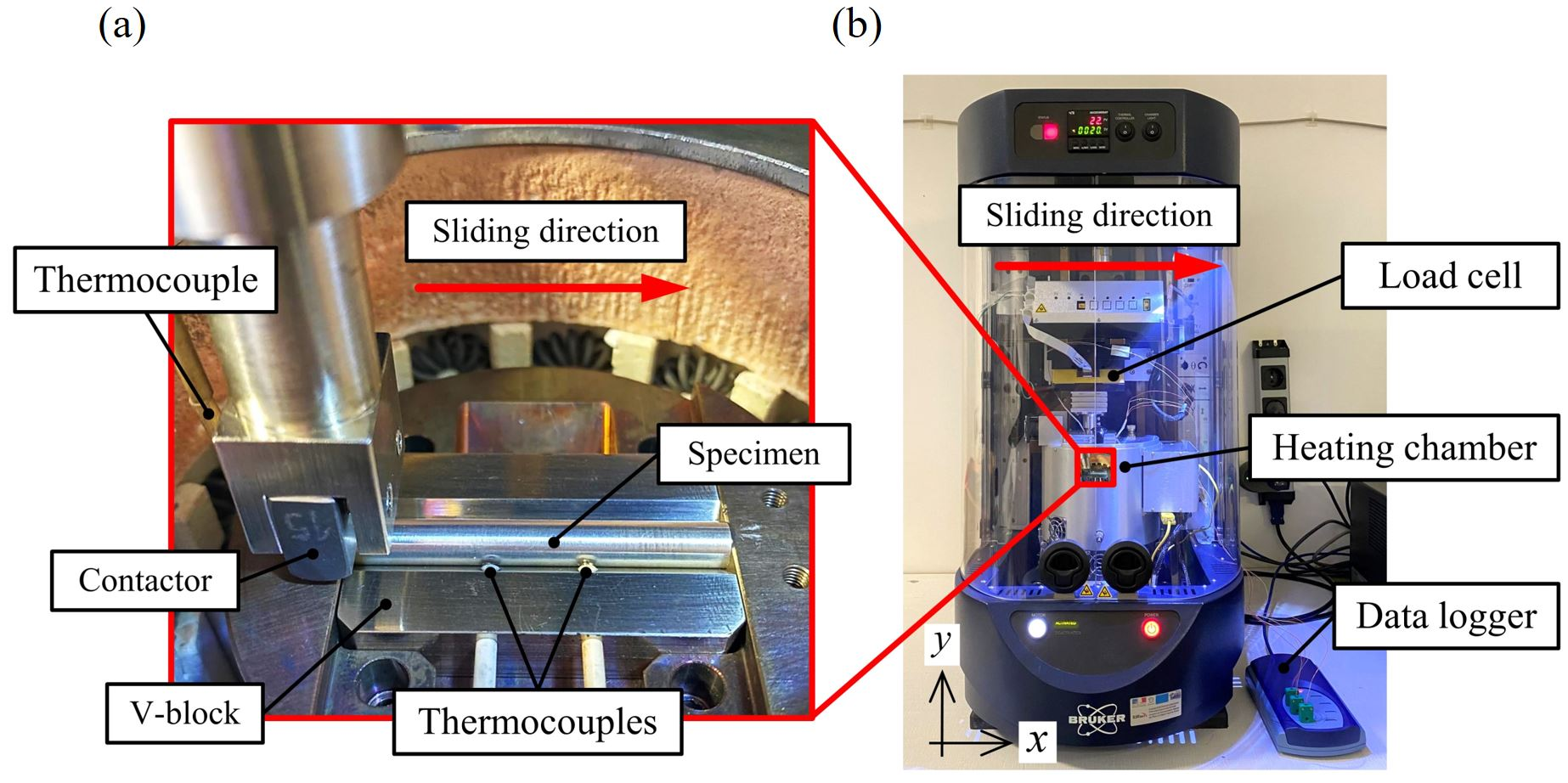

2.3. Experimental Setup and Procedures

2.4. Design of Experiments

3. Results

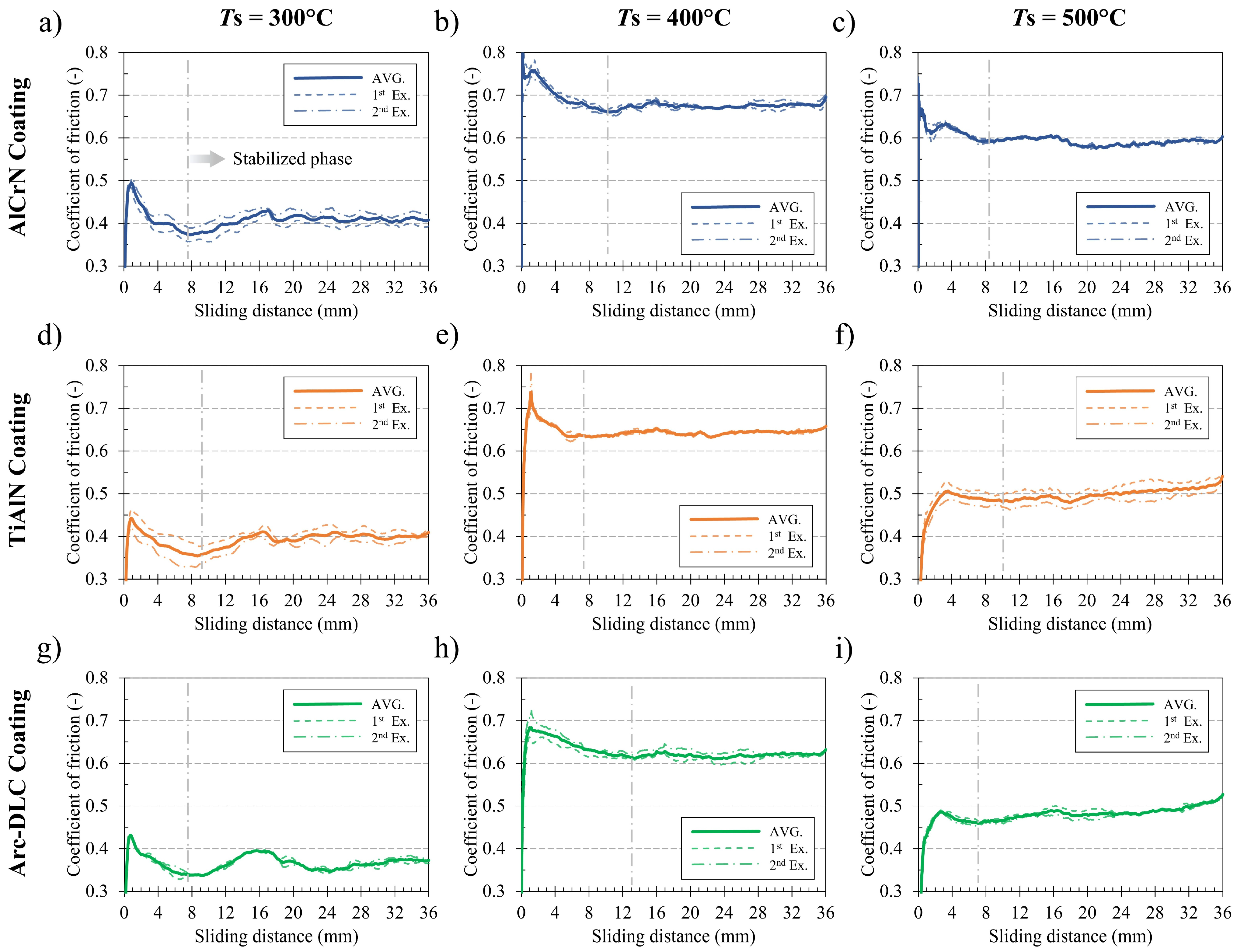

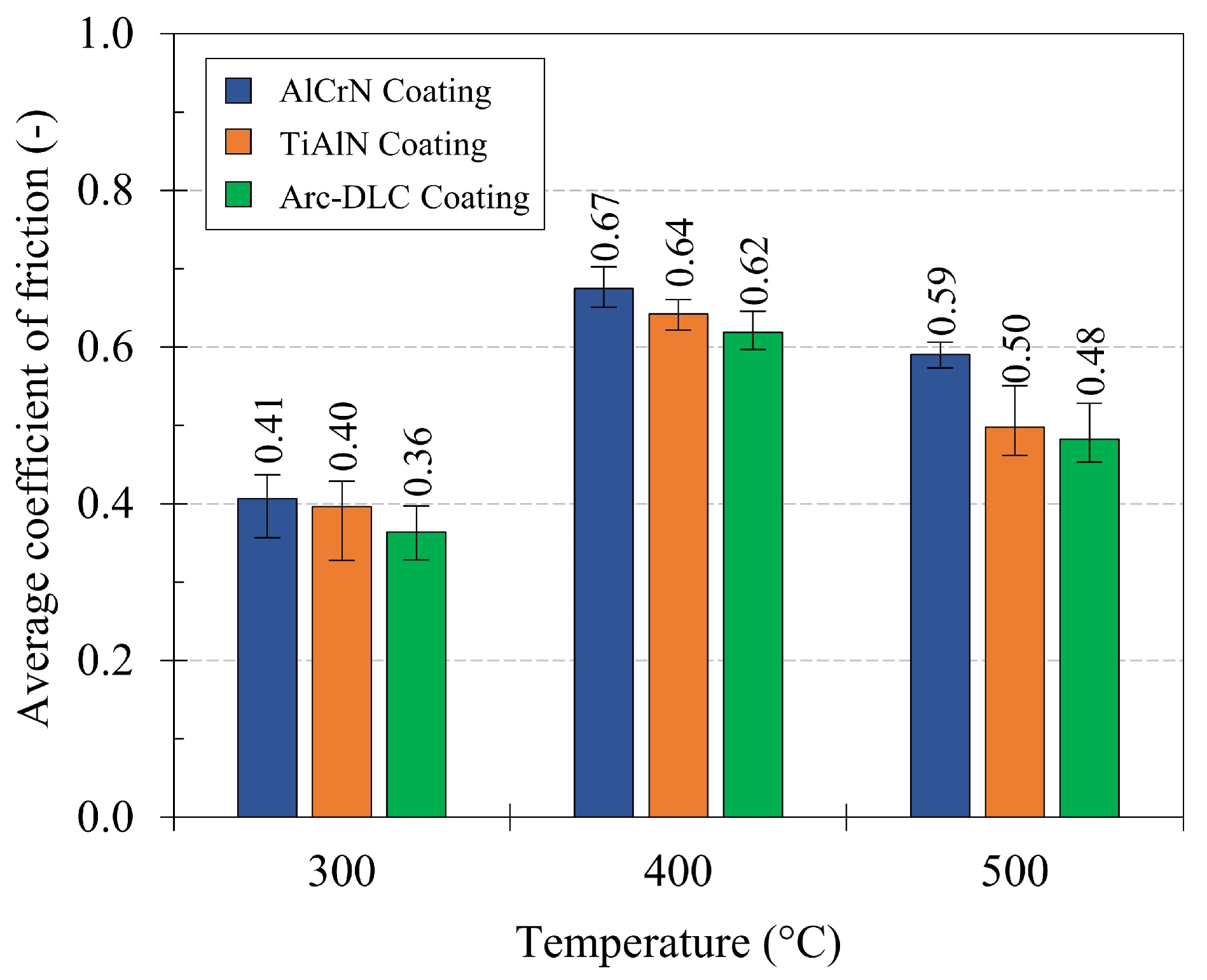

3.1. Coefficient of Friction (COF)

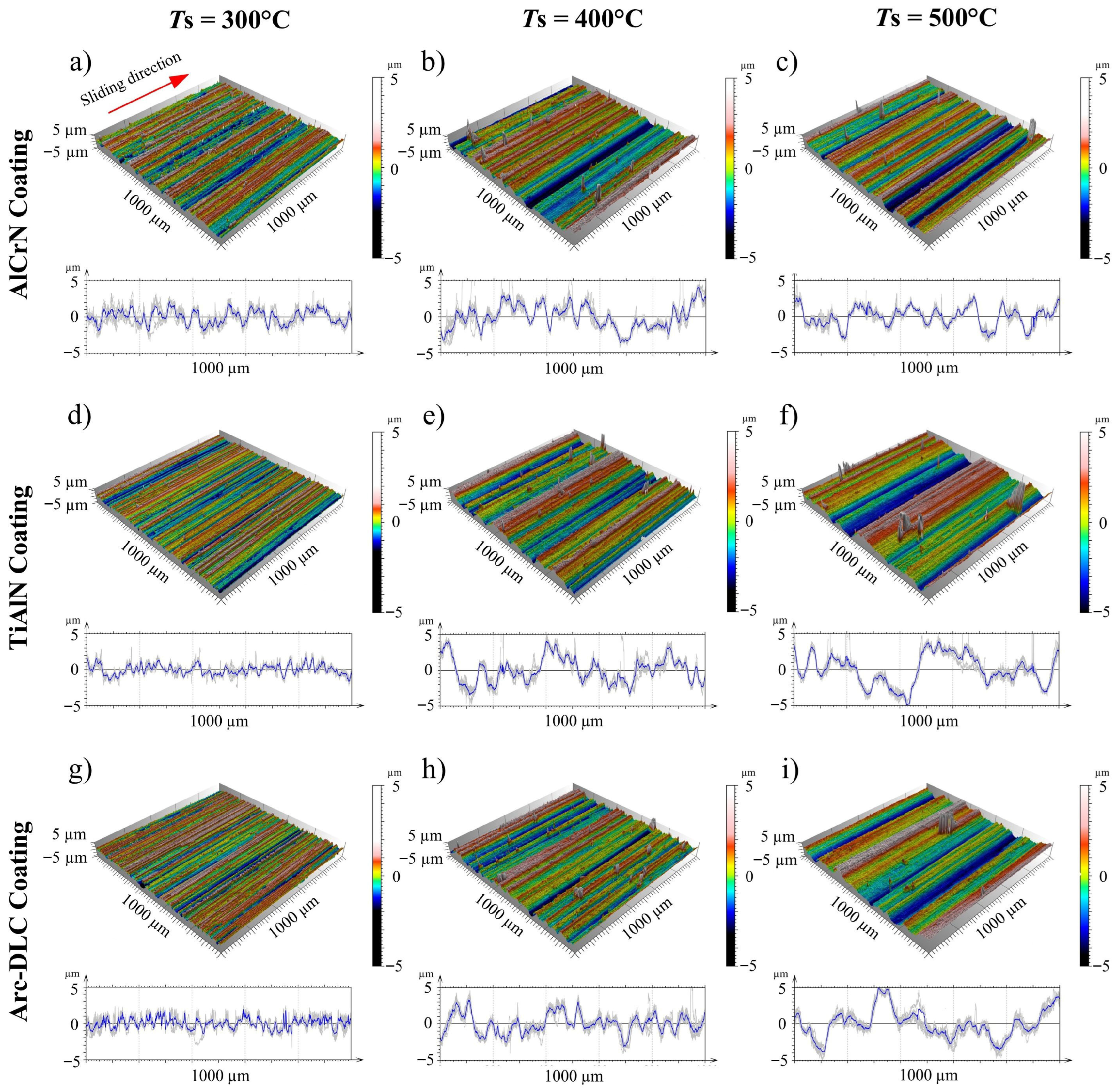

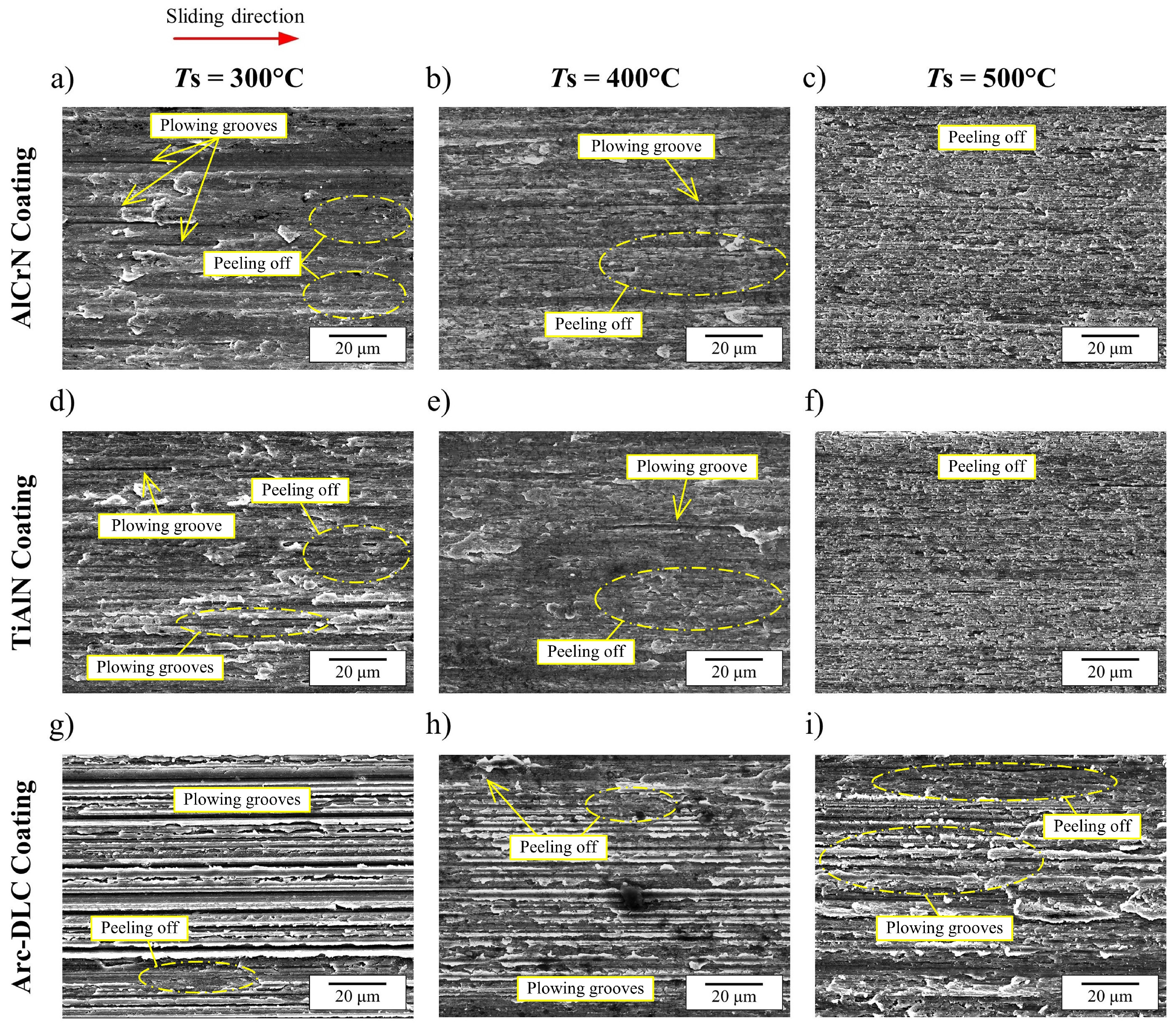

3.2. Three-Dimensional Topography and SEM Morphology Along the Wear Track

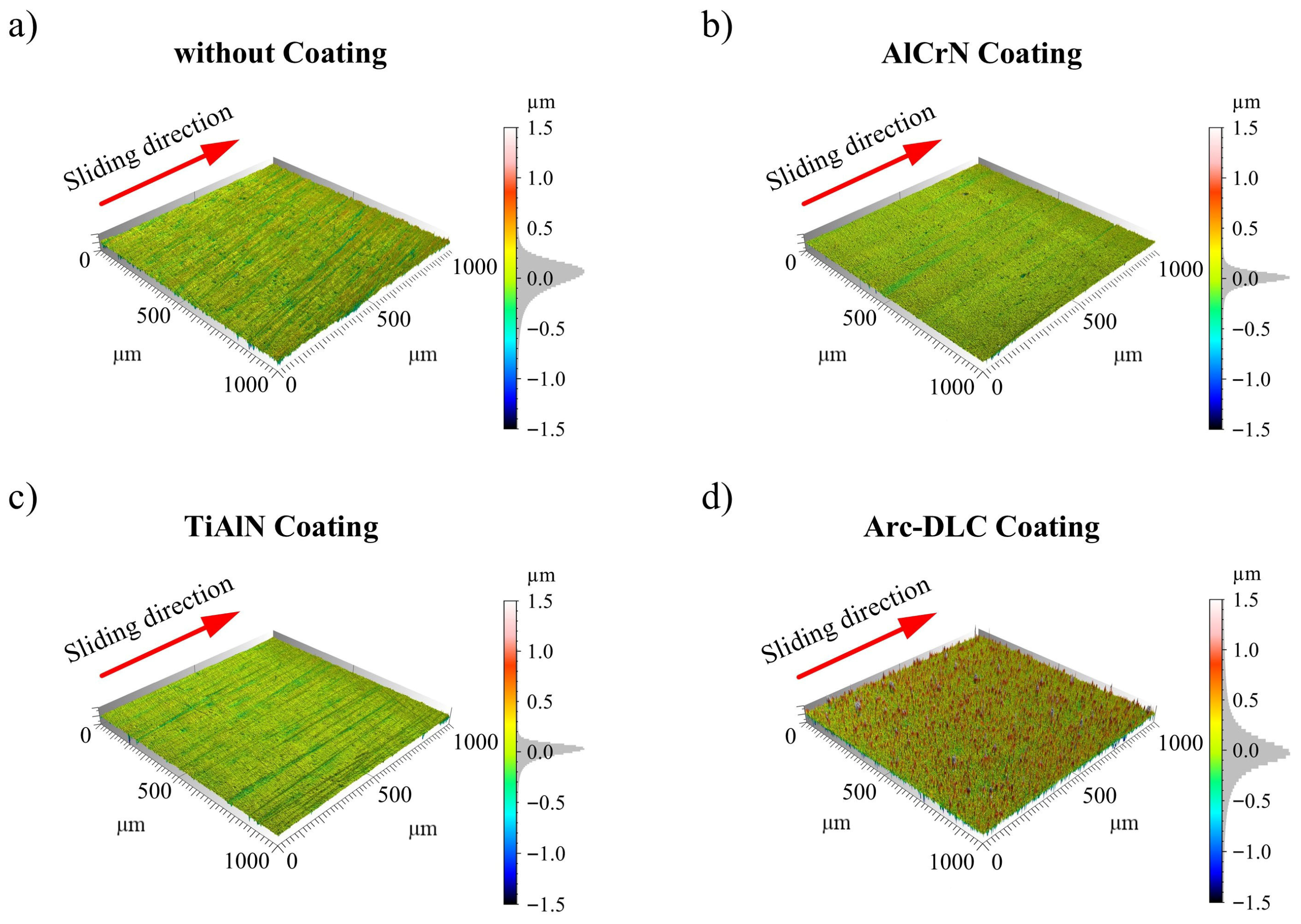

3.2.1. Three-Dimensional Topography Along the Wear Track

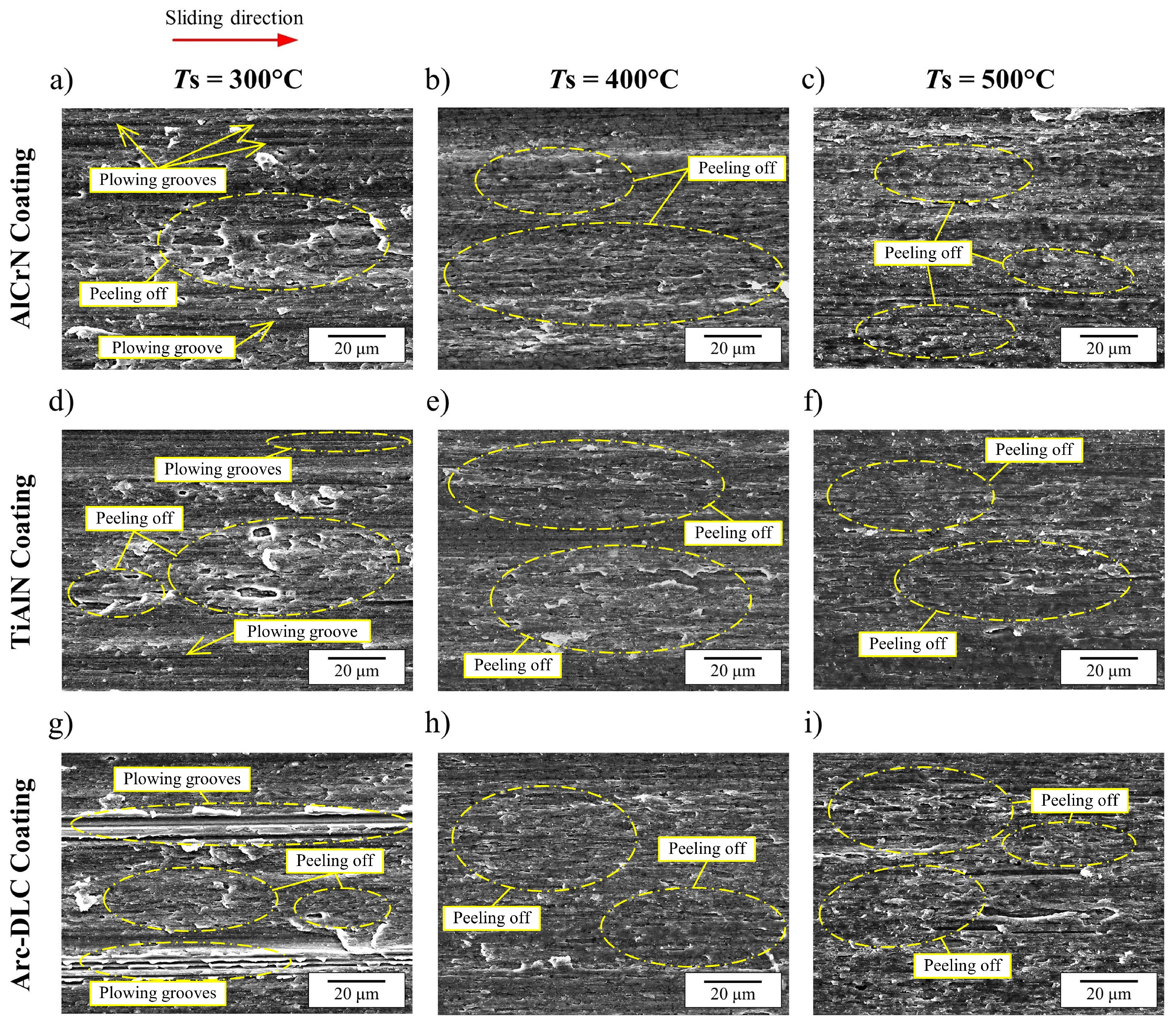

3.2.2. SEM Micrograph Along the Wear Track

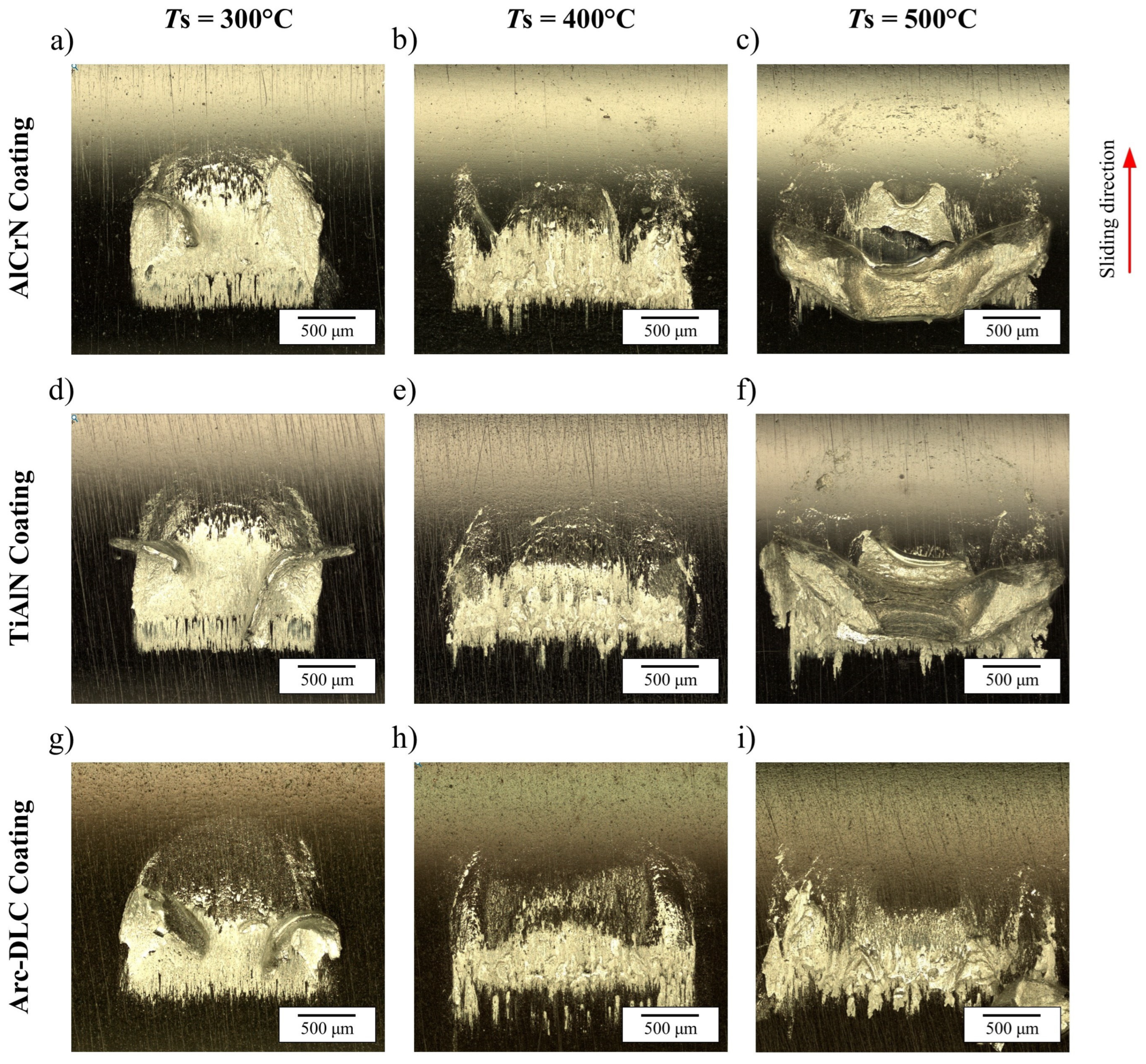

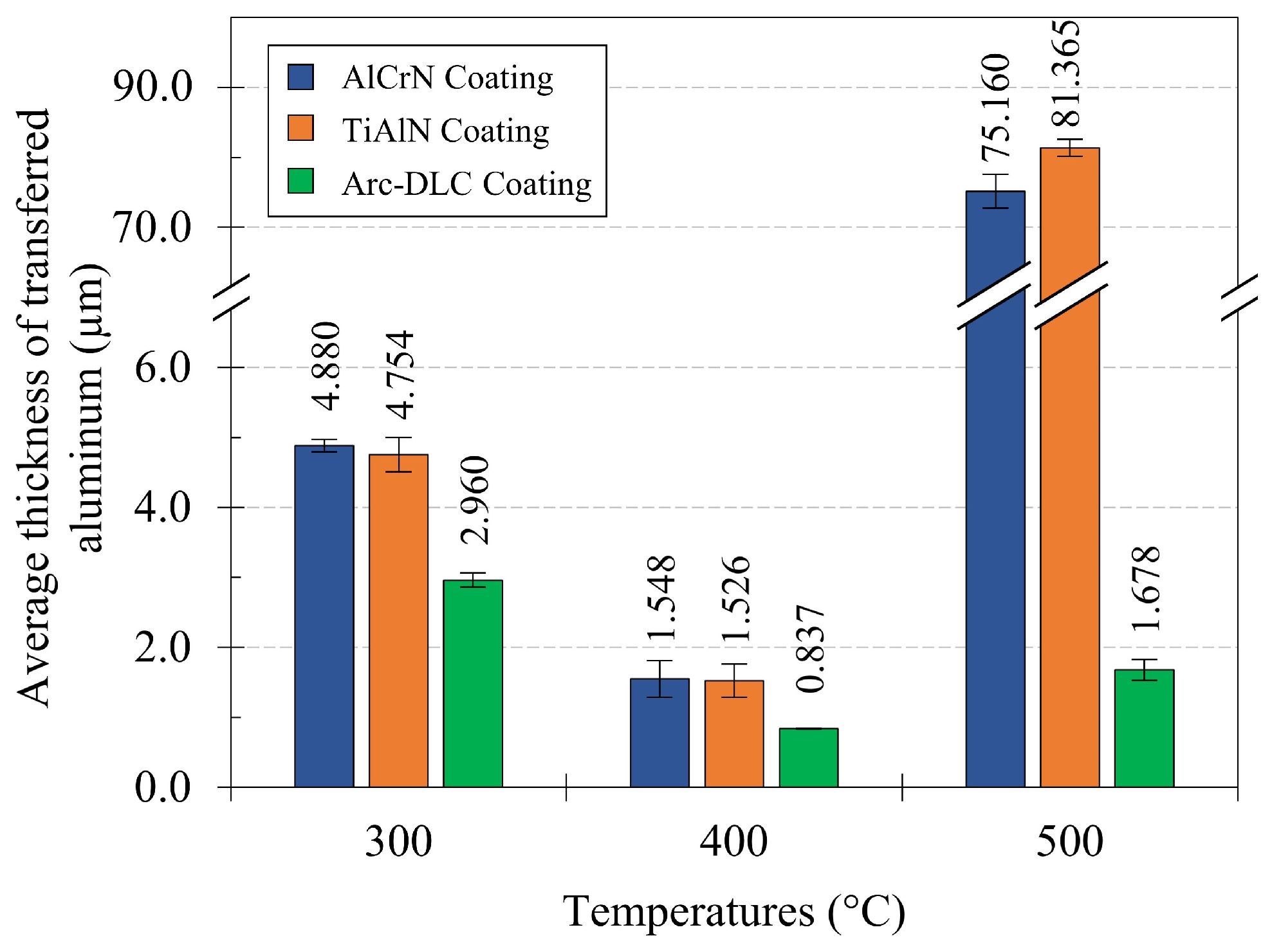

3.3. Adhered Aluminum Layer on the Coating Surface

4. Discussion

4.1. Initial Phase

4.2. Transient Phase

4.3. Stabilized Phase

5. Conclusions

- The adhered aluminum layer on the coating surface was found for all experimental conditions, whatever coatings and temperatures. The aluminum transfer took place in transient and stabilized phases. The transient phase was identified by the unstable COF and the pronounced increase in the Sa along the wear track of the specimen, while the stabilized phase was characterized by the rather stable COF.

- The AlCrN and TiAlN coatings demonstrated similar tribological performance. The initial aluminum transfer on those coatings was mainly caused by adhesive bonding. However, the AlCrN coating had a stronger chemical affinity to the aluminum alloy than the TiAlN coating since the AlCrN coating caused a higher COF in both transient and stabilized phases, even though the initial surface of the AlCrN coating was smoother.

- Mechanical plowing induced by droplets on the Arc-DLC coating dominated the initial aluminum transfer to the surface coating. Those droplets led to the Sa of the Arc-DLC coatings being higher than the AlCrN and the TiAlN coatings, approximately twice. Nonetheless, the Arc-DLC coating resulted in the lowest COF in both transient and stabilized phases. This indicates that the Arc-DLC coating had a weaker chemical affinity to the aluminum alloy than the other coatings.

- In the stabilized phase, the COF and the Sa along the wear track were slightly different between each coating. This is because the sliding contact was mainly driven by the transferred layer against the aluminum alloy. According to the presence of peeling off along the wear track in this phase, it implied that adhesive bonding dominated the aluminum transfer.

- The temperature also significantly influenced the tribological performance of all coatings. The COF rose with an increase in the temperature from 300 °C to 400 °C due to stronger adhesive bonding at the interface. Nevertheless, the COF dropped at 500 °C because of a significant decrease in the mechanical properties of the aluminum alloy.

- The transferred layer on all coatings at 300 °C was thicker than at 400 °C since the greater mechanical properties of the aluminum alloy at the lower testing temperature made it harder to distribute the adhered aluminum layer on the coating surface smoothly. In contrast, the adhered aluminum layer at 500 °C was thicker than at 400 °C. This resulted from a strong adhesive bonding at 500 °C, affecting less removal of the transferred aluminum.

- According to the experimental results in this study, the Arc-DLC coating could provide better tribological performance to alleviate the aluminum transfer than the AlCrN and the TiAlN coatings. This is because the Arc-DLC coating resulted in the lowest COF and the thinnest transferred layer when compared to the others.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tekkaya, A.E.; Min, J. Special Issue on Automotive Lightweight. Automot. Innov. 2020, 3, 193–194. [Google Scholar] [CrossRef]

- Music, O.; Allwood, J.M. Connecting Environmental Systems Analysis to Manufacturing Technology: A Catalogue of the World’s Steel and Aluminium Components. Resour. Conserv. Recycl. 2025, 212, 107949. [Google Scholar] [CrossRef]

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and Applications of Aluminum Alloys for Aerospace Industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Rosenthal, S.; Maaß, F.; Kamaliev, M.; Hahn, M.; Gies, S.; Tekkaya, A.E. Lightweight in Automotive Components by Forming Technology. Automot. Innov. 2020, 3, 195–209. [Google Scholar] [CrossRef]

- Dohda, K.; Yamamoto, M.; Hu, C.; Dubar, L.; Ehmann, K.F. Galling Phenomena in Metal Forming. Friction 2021, 9, 665–685. [Google Scholar] [CrossRef]

- Westlund, V.; Heinrichs, J.; Olsson, M.; Jacobson, S. Investigation of Material Transfer in Sliding Friction-Topography or Surface Chemistry? Tribol. Int. 2016, 100, 213–223. [Google Scholar] [CrossRef]

- Soranansri, P.; Dubois, A.; Moreau, P.; Funazuka, T.; Dohda, K.; Dubar, L. Initial and Grow-up Stages of Material Transfer on Arc-DLC Coating in Aluminum Forming Processes at High Temperatures. Wear 2024, 556–557, 205491. [Google Scholar] [CrossRef]

- Heinrichs, J.; Jacobson, S. Mechanisms of transfer of aluminium to PVD-coated forming tools. Tribol. Lett. 2012, 46, 299–312. [Google Scholar] [CrossRef]

- Lu, J.; Song, Y.; Zhou, P.; Lin, J.; Dean, T.A.; Liu, P. Process Parameters Effect on High-Temperature Friction and Galling Characteristics of AA7075 Sheets. Mater. Manuf. Process. 2021, 36, 967–978. [Google Scholar] [CrossRef]

- Decrozant-Triquenaux, J.; Pelcastre, L.; Prakash, B.; Hardell, J. Influence of Lubrication, Tool Steel Composition, and Topography on the High Temperature Tribological Behaviour of Aluminium. Friction 2021, 9, 155–168. [Google Scholar] [CrossRef]

- Podgornik, B.; Jerina, J. Surface Topography Effect on Galling Resistance of Coated and Uncoated Tool Steel. Surf. Coat. Technol. 2012, 206, 2792–2800. [Google Scholar] [CrossRef]

- Decrozant-Triquenaux, J.; Pelcastre, L.; Courbon, C.; Prakash, B.; Hardell, J. High Temperature Tribological Behaviour of PVD Coated Tool Steel and Aluminium under Dry and Lubricated Conditions. Friction 2021, 9, 802–821. [Google Scholar] [CrossRef]

- Heinrichs, J. On Transfer of Work Material to Tools. Ph.D. Dissertation, Acta Universitatis Uppsaliensis, Uppsala, Sweden, 2012. [Google Scholar]

- Dubois, A.; Filali, O.; Dubar, L. Effect of Roughness, Contact Pressure and Lubrication on the Onset of Galling of the 6082 Aluminium Alloy in Cold Forming, a Numerical Approach. Wear 2024, 536–537, 205179. [Google Scholar] [CrossRef]

- Vollertsen, F.; Schmidt, F. Dry Metal Forming: Definition, Chances and Challenges. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 59–62. [Google Scholar] [CrossRef]

- Geng, M.; Cai, L.; Kim, J.-C.; Choi, H.-S.; Hong, S.-T. Recent Development of Dry Metal Forming. Int. J. Precis. Eng. Manuf. 2023, 24, 309–324. [Google Scholar] [CrossRef]

- Heinrichs, J.; Jacobson, S. Laboratory Test Simulation of Aluminium Cold Forming—Influence from PVD Tool Coatings on the Tendency to Galling. Surf. Coat. Technol. 2010, 204, 3606–3613. [Google Scholar] [CrossRef]

- Riahi, A.R.; Alpas, A.T. Adhesion of AA5182 Aluminum Sheet to DLC and TiN Coatings at 25 °C and 420 °C. Surf. Coat. Technol. 2007, 202, 1055–1061. [Google Scholar] [CrossRef]

- Abraham, T.; Bräuer, G.; Flegler, F.; Groche, P.; Demmler, M. Dry Sheet Metal Forming of Aluminum by Smooth DLC Coatings—A Capable Approach for an Efficient Production Process with Reduced Environmental Impact. Procedia Manuf. 2020, 43, 642–649. [Google Scholar]

- Medea, F.; Ghiotti, A.; Bruschi, S.; Bellin, M. Novel spraying apparatus to investigate the lubricant deposition on metal sheets at high temperature. In AIP Conference Proceedings, Proceedings of the 19th International ESAFORM Conference on Material Forming, Nantes, France, 27–29 April 2016; AIP Publishing LLC: Melville, NY, USA, 2016; Volume 1769, p. 200017. [Google Scholar]

- Liu, Y.; Zhu, B.; Wang, K.; Li, S.; Zhang, Y. Friction Behaviors of 6061 Aluminum Alloy Sheets in Hot Stamping under Dry and Lubricated Conditions Based on Hot Strip Drawing Test. Tribol. Int. 2020, 151, 106504. [Google Scholar] [CrossRef]

- Schell, L.; Emele, M.; Holzbeck, A.; Groche, P. Investigation of Different Lubricant Classes for Aluminium Warm and Hot Forming Based on a Strip Drawing Test. Tribol. Int. 2022, 168, 107449. [Google Scholar] [CrossRef]

- Kalin, M.; Jerina, J. The Effect of Temperature and Sliding Distance on Coated (CrN, TiAlN) and Uncoated Nitrided Hot-Work Tool Steels against an Aluminium Alloy. Wear 2015, 330–331, 371–379. [Google Scholar] [CrossRef]

- Funazuka, T.; Dohda, K.; Takatsuji, N.; Hu, C.; Sukunthakan, N. Effect of Die Coating on Surface Crack Depth of Hot Extruded 7075 Aluminum Alloy. Friction 2023, 11, 1212–1224. [Google Scholar] [CrossRef]

- Rigas, N.; Merklein, M. Characterization of the Tribological Behavior of Different Tool Coatings and Dry Lubricant for High-Strength Aluminum Alloys at Elevated Temperatures. Adv. Eng. Mater. 2023, 25, 2201650. [Google Scholar] [CrossRef]

- Dubois, A.; Dubar, M.; Debras, C.; Hermange, K.; Nivot, C.; Courtois, C. New Environmentally Friendly Coatings for Hot Forging Tools. Surf. Coat. Technol. 2018, 344, 342–352. [Google Scholar] [CrossRef]

- Soranansri, P.; Dubois, A.; Moreau, P.; Funazuka, T.; Dohda, K.; Dubar, L. Identification of Coulomb and Constant Shear Frictions in Hot Aluminum Forming by Using Warm and Hot Upsetting Sliding Test. Int. J. Mater. Form. 2024, 17, 55. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A Review on Forming Techniques for Manufacturing Lightweight Complex—Shaped Aluminium Panel Components. Int. J. Lightweight Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Muldoon, K.; Marquard, E.; Lampman, H.; Karcher, C.; Musgrove, B.; Dragolich, K.; Schaefer, M. ASM Handbook; Metalworking: Bulk Forming; ASM International: Almere, The Netherlands, 2015; Volume 14A. [Google Scholar]

- Sousa, V.F.C.; Silva, F.J.G. Recent advances in turning processes using coated tools—A comprehensive review. Metals 2020, 10, 170. [Google Scholar] [CrossRef]

- Durmaz, Y.M.; Yildiz, F. The Wear Performance of Carbide Tools Coated with TiAlSiN, AlCrN and TiAlN Ceramic Films in Intelligent Machining Process. Ceram. Int. 2019, 45, 3839–3848. [Google Scholar] [CrossRef]

- Hawryluk, M. Review of Selected Methods of Increasing the Life of Forging Tools in Hot Die Forging Processes. Arch. Civil. Mech. Eng. 2016, 16, 845–866. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Hauert, R.; Thorwarth, K.; Thorwarth, G. An Overview on Diamond-like Carbon Coatings in Medical Applications. Surf. Coat. Technol. 2013, 233, 119–130. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, H.; Zhang, K.; Liu, X.; Feng, X.; Zhang, Y.; Chen, G.; Zheng, Y. Effects of Ti Interlayer on Adhesion Property of DLC Films: A First Principle Study. Diam. Relat. Mater. 2021, 111, 108188. [Google Scholar] [CrossRef]

- Vetter, J. 60years of DLC Coatings: Historical Highlights and Technical Review of Cathodic Arc Processes to Synthesize Various DLC Types, and Their Evolution for Industrial Applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar] [CrossRef]

- Yamada, Y.; Murashima, M.; Umehara, N.; Tokoroyama, T.; Lee, W.Y.; Takamatsu, H.; Tanaka, Y.; Utsumi, Y. Effect of Fracture Properties and Surface Morphology on Wear of DLC Coatings at Severe Contact Condition. Tribol. Int. 2022, 169, 107486. [Google Scholar] [CrossRef]

- Peng, J.; Liao, J.; Zhang, G.; Huang, J.; Qiu, X. Microstructure Evolution and Mechanical Performance of Tetrahedral Amorphous Carbon Coatings with Dense Droplets during Annealing. Mater. Chem. Phys. 2023, 301, 127697. [Google Scholar] [CrossRef]

- Tercelj, M.; Kugler, G.; Turk, R.; Cvahte, P.; Fajfar, P. Measurement of Temperature on the Bearing Surface of an Industrial Die and Assessment of the Heat Transfer Coefficient in Hot Extrusion of Aluminium: A Case Study. Int. J. Veh. Des. 2005, 39, 93. [Google Scholar] [CrossRef]

- Kugler, G.; Turk, R.; Večko-Pirtovšek, T.; Terčelj, M. Wear Behaviour of Nitrided Microstructures of AlSl H13 Dies for Hot Extrusion of Aluminium. Metalurgija 2006, 45, 21–29. [Google Scholar]

- Soranansri, P.; Dubois, A.; Moreau, P.; Funazuka, T.; Dohda, K.; Dubar, L. Tribological Performance of AlCrN and TiAlN Coatings in Aluminum Forming Process at High Temperature. In Solid State Phenomena; Trans Tech Publications Ltd.: Baech, Switzerland, 2025; Volume 370, pp. 89–97. [Google Scholar]

- Pujante, J.; Vilaseca, M.; Casellas, D.; Riera, M.D. The Role of Adhesive Forces and Mechanical Interaction on Material Transfer in Hot Forming of Aluminium. Tribol. Lett. 2015, 59, 10. [Google Scholar] [CrossRef]

- Kalin, M.; Jerina, J.; Sharma, S.K.; Kovač, J. The effect of temperature on the transfer layer of an aluminium alloy on tool steel and the effect of CrN coating. Tribol.-Mater. Surf. Interfaces 2024, 18, 11–19. [Google Scholar] [CrossRef]

- Yang, X.; Liu, H.; Zhang, L.; Hu, Y.; Politis, D.J.; Gharbi, M.M.; Wang, L. Interactive Mechanism and Friction Modelling of Transient Tribological Phenomena in Metal Forming Processes: A Review. Friction 2024, 12, 375–395. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. Friction, Lubrication and Wear: A Survey of Work during the Last Decade. Br. J. Appl. Phys. 1966, 17, 1521–1544. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Y.; Zhang, L.; Zheng, Y.; Politis, D.J.; Liu, X.; Wang, L. liang Experimental and Modelling Study of Interaction between Friction and Galling under Contact Load Change Conditions. Friction 2022, 10, 454–472. [Google Scholar] [CrossRef]

- Lu, J.; Song, Y.; Hua, L.; Zhou, P.; Xie, G. Effect of Temperature on Friction and Galling Behavior of 7075 Aluminum Alloy Sheet Based on Ball-on-Plate Sliding Test. Tribol. Int. 2019, 140, 105872. [Google Scholar] [CrossRef]

- Macêdo, G. Material Transfer Mechanisms during Interaction of Aluminium Alloy and Tool Steel at Elevated Temperatures. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2020. [Google Scholar]

| Mg | Si | Mn | Fe | Cu | Cr | Ti | Zn |

|---|---|---|---|---|---|---|---|

| 0.60 | 1.00 | 0.45 | 0.17 | 0.02 | 0.02 | 0.02 | 0.03 |

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.39 | 0.98 | 0.34 | 0.02 | 0.0005 | 4.89 | 1.13 | 0.33 |

| Commercial PVD Coatings | Coating Thickness | Surface Roughness (Sa) | Surface Hardness |

|---|---|---|---|

| AlCrN coating | 3.20 ± 0.40 μm | 0.08 ± 0.02 μm | 31 GPa |

| TiAlN coating | 3.10 ± 0.25 μm | 0.10 ± 0.02 μm | 29 GPa |

| Arc-DLC coating | 1.30 ± 0.20 μm | 0.19 ± 0.03 μm | 29 GPa |

| WHUST Parameters | Contact Conditions From Numerical Simulation [41] | |||||

|---|---|---|---|---|---|---|

| Penetration Depth | Initial Temperature of the Contactor | Initial Temperature of the Specimen | Speed of the Contactor | Mean Contact Pressure | Interface Temperature “Start–End” | Relative Sliding Velocity |

| (mm) | (°C) | (°C) | (mm/s) | (MPa) | (°C) | (mm/s) |

| 0.1 | 200 | 300 | 0.5 | 83.5 | 271–282 | 0.5 |

| 400 | 0.5 | 55.3 | 344–364 | 0.5 | ||

| 500 | 0.5 | 36.9 | 419–446 | 0.5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soranansri, P.; Dubois, A.; Moreau, P.; Funazuka, T.; Dohda, K.; Dubar, L. Tribological Performance of AlCrN, TiAlN, and Arc-DLC Coatings in Hot Forming of Aluminum Alloy. Lubricants 2025, 13, 430. https://doi.org/10.3390/lubricants13100430

Soranansri P, Dubois A, Moreau P, Funazuka T, Dohda K, Dubar L. Tribological Performance of AlCrN, TiAlN, and Arc-DLC Coatings in Hot Forming of Aluminum Alloy. Lubricants. 2025; 13(10):430. https://doi.org/10.3390/lubricants13100430

Chicago/Turabian StyleSoranansri, Panuwat, André Dubois, Philippe Moreau, Tatsuya Funazuka, Kuniaki Dohda, and Laurent Dubar. 2025. "Tribological Performance of AlCrN, TiAlN, and Arc-DLC Coatings in Hot Forming of Aluminum Alloy" Lubricants 13, no. 10: 430. https://doi.org/10.3390/lubricants13100430

APA StyleSoranansri, P., Dubois, A., Moreau, P., Funazuka, T., Dohda, K., & Dubar, L. (2025). Tribological Performance of AlCrN, TiAlN, and Arc-DLC Coatings in Hot Forming of Aluminum Alloy. Lubricants, 13(10), 430. https://doi.org/10.3390/lubricants13100430