The Influence of a Lubricant Medium on the Development of Fretting Wear in an Interference Fit Connection

Abstract

1. Introduction

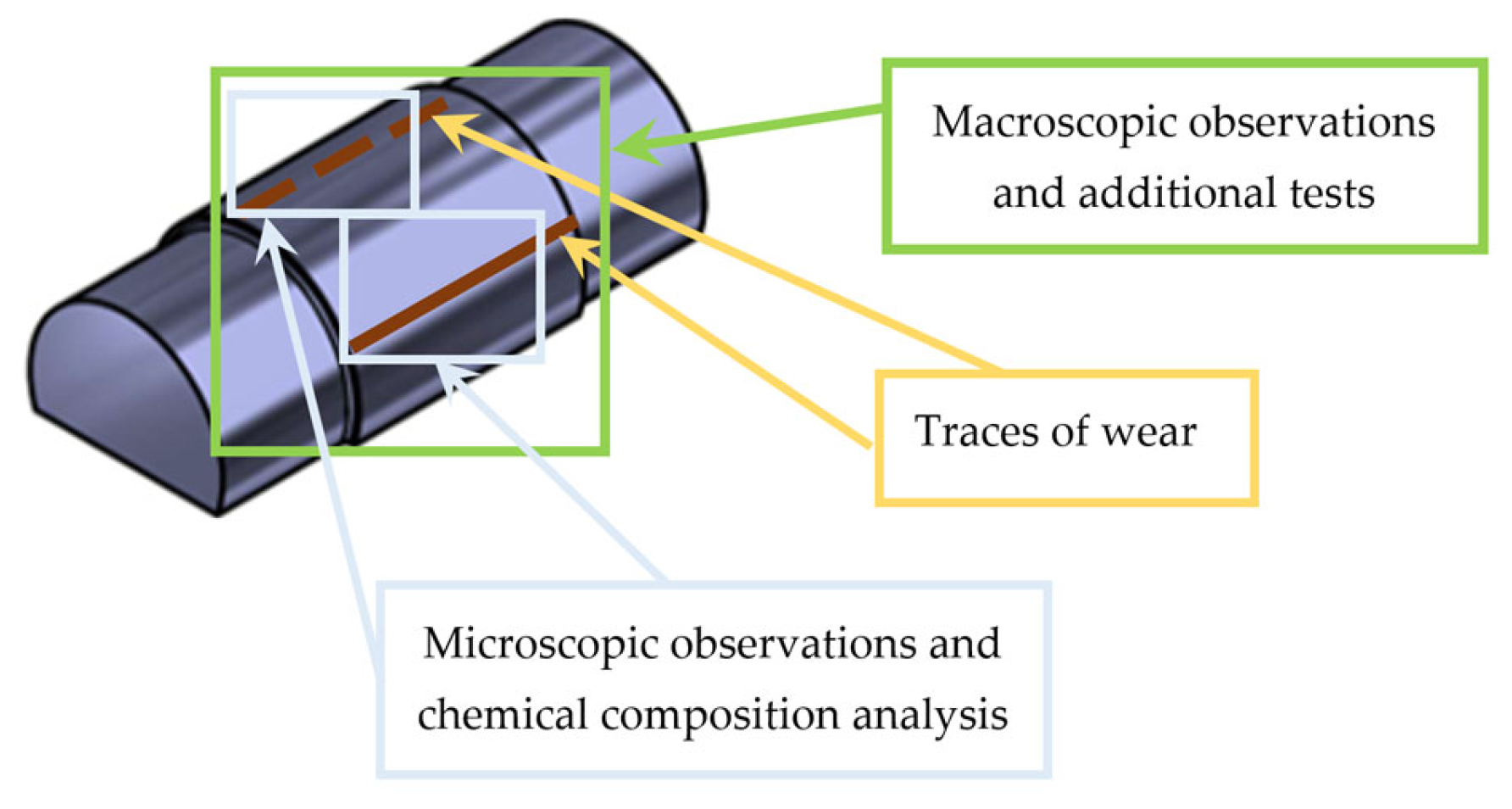

2. Materials and Methods

3. Results

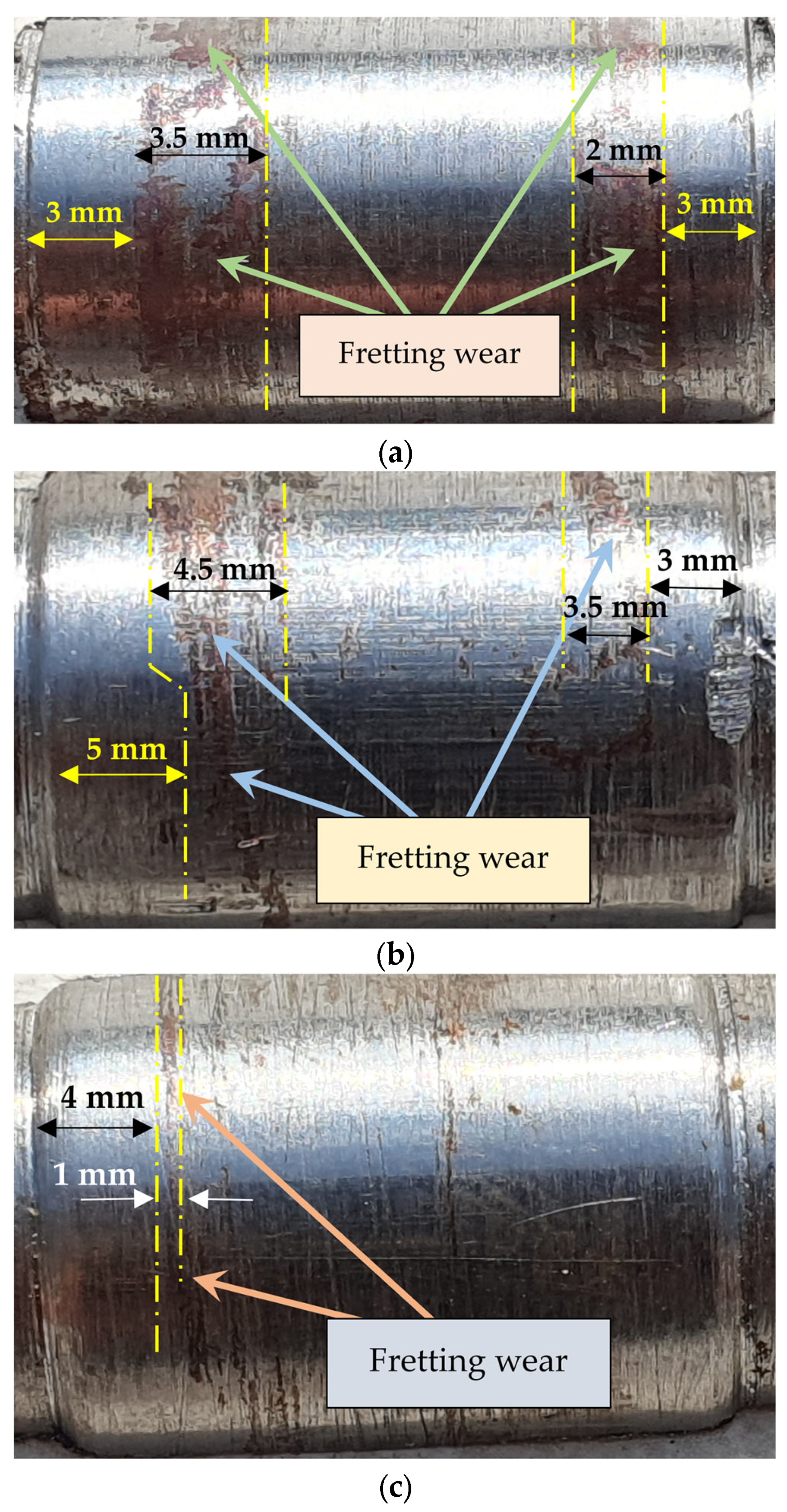

3.1. Macroscopic Observations of Shaft Surfaces

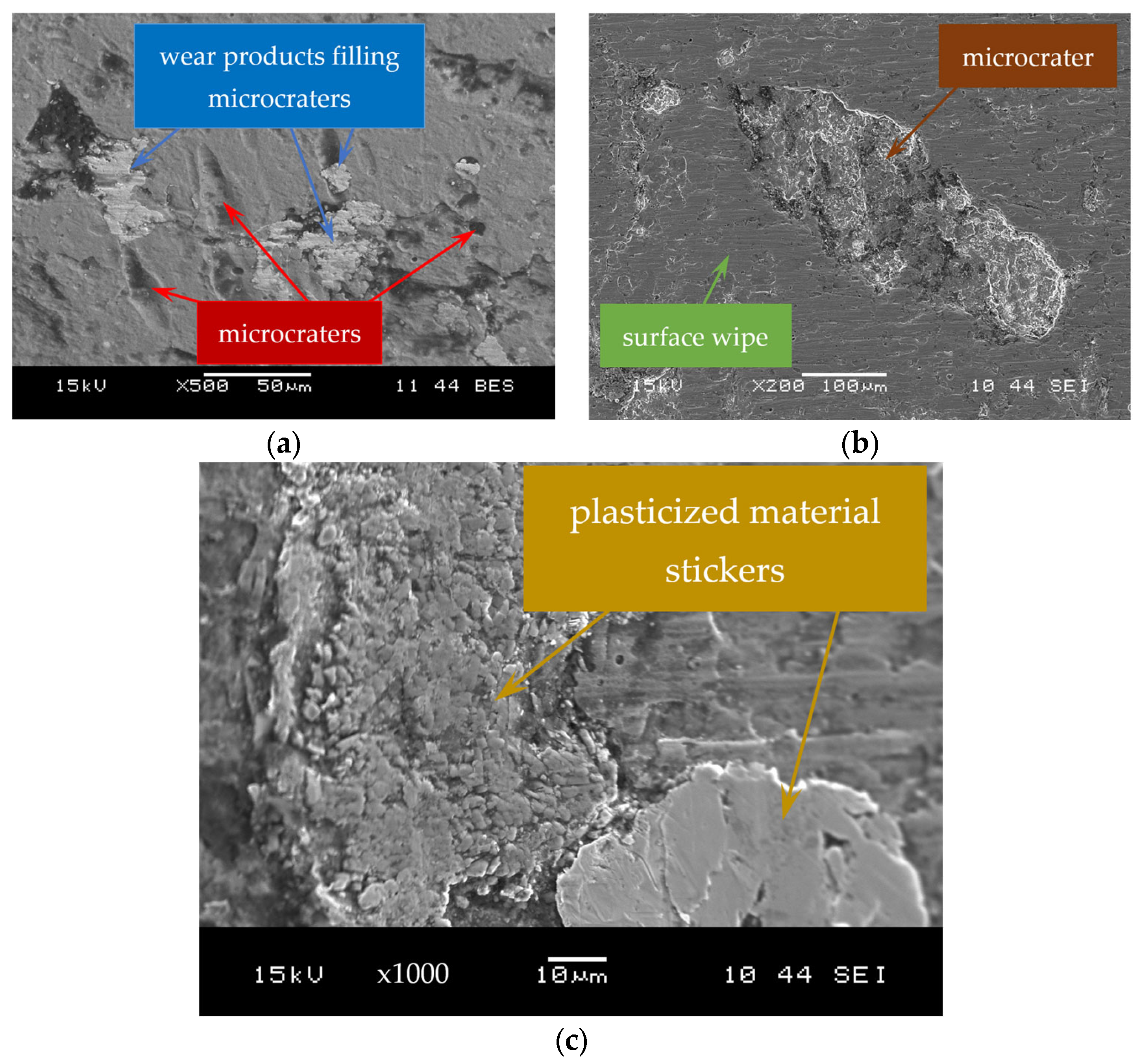

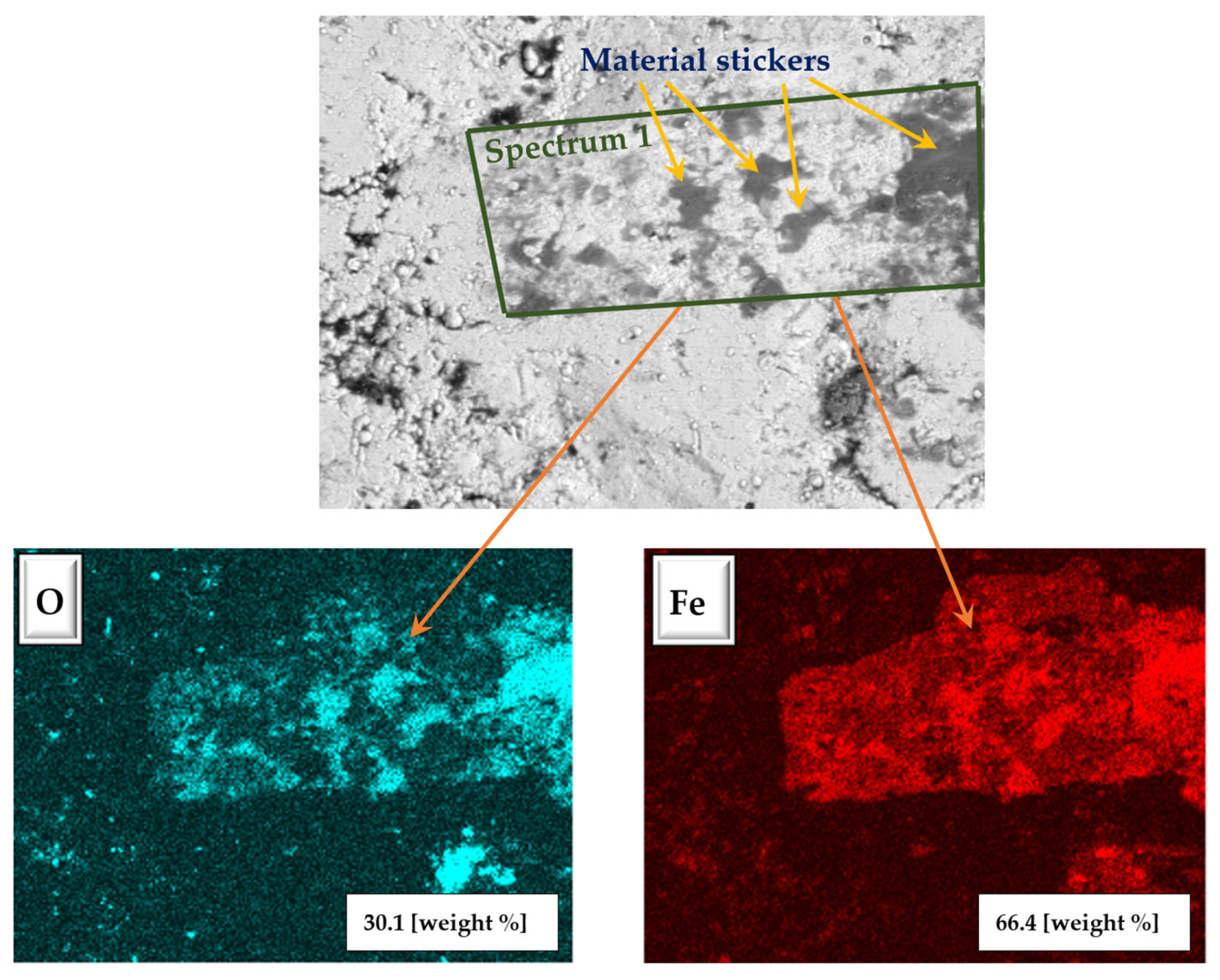

3.2. Microscopic Observations of Shaft Surfaces

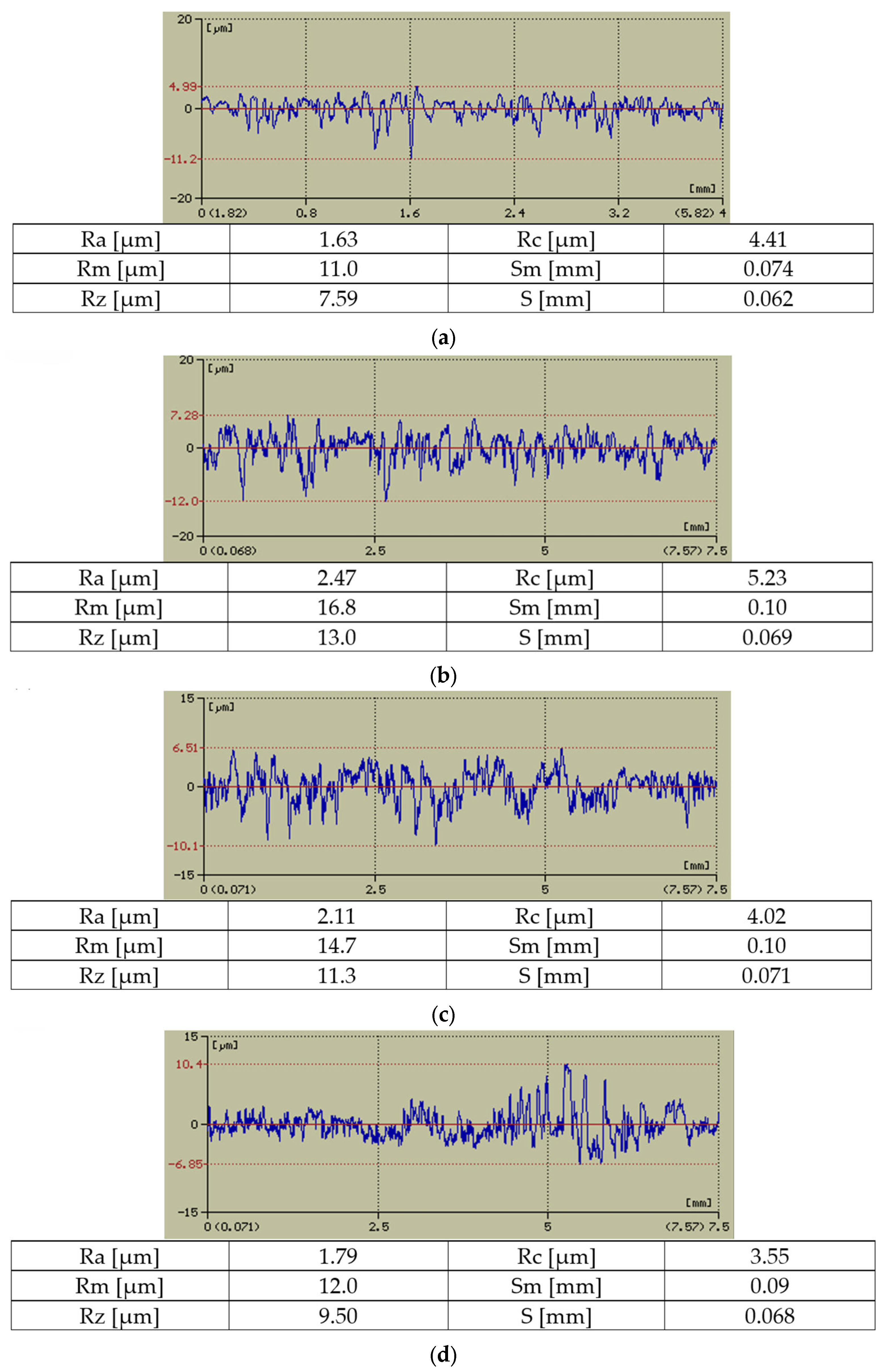

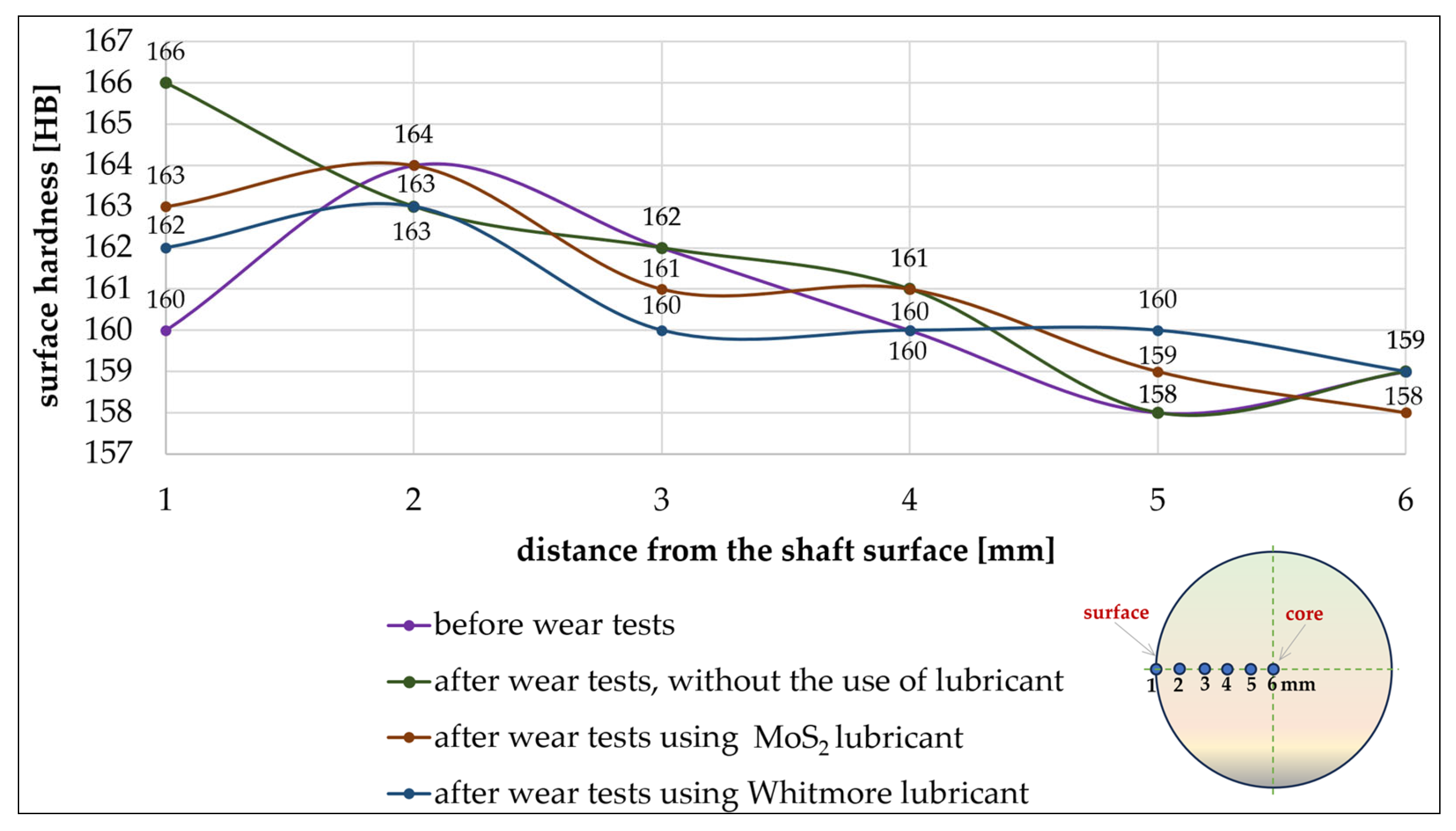

3.3. Shaft Surface Roughness and Hardness

3.4. The Measurement of the Coefficient of Friction and Wear Intensity

4. Conclusions

- The pre-set fatigue test conditions are conducive to the development of fretting wear, whose traces are noted on all the shaft surfaces under investigation. The macroscopic image of wear is formed in a similar way for all the samples and assumes the shape of a ring of various widths located at the edges of the shaft axle seat.

- The use of MoS2 grease restricted fretting wear to a small extent. In that case, wear traces occurred at random on either side of the shaft axle seat, and the intensity of those traces was similar to the wear traces on the surfaces of the shafts operating without a lubricant medium.

- The most advantageous effects of fretting wear reduction were achieved for the tribological kinematic pair with Whitmore grease. Its application did not eliminate wear, but reduced it effectively. In that case, wear traces were noted on one side of the shaft axle seat in the form of a ring comprising the entire shaft circumference. The ring width and wear intensity also clearly decreased.

- The macroscopic observations demonstrated the grey/dark brown colour of the wear traces, which is typical of metal corrosion. That phenomenon was the result of the presence, in the wear zone, of oxygen, which flowed through the gap between the shaft and sleeve, the gap coming into being as a result of shaft deflection.

- Fretting in the tribological kinematic pairs under analysis comprises mainly wear products in the form of material build-ups which become softened, oxidised and fragmented over time. Wear products hardened by oxidation as they move around cause further damage in the form of surface abrasion and micropits.

- The amount of wear products and the degree of their oxidation influence the change in the surface profile and shaft hardness. This is confirmed by the smallest change in roughness and hardness parameters of the shafts operating in the presence of Whitmore grease among all the samples tested.

- The coefficient of friction between the mating components, as measured after the wear tests, shows the lowest value for tribological kinematic pairs containing Whitmore grease, which is indicative of fewer material build-ups on the shaft surface. Wear intensity is similar, as was already observed at the macrographic analysis stage.

- Among the greases analysed in these tests, Whitmore deserves attention, as this grease effectively reduced the development of fretting wear in interference fit connections subjected to a bending rotational moment. Therefore, it is recommended that that grease be used in similar cases and that more in-depth scientific research be conducted into the use of that grease a means of preventing or reducing wear and tear.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.; Jiang, Q.; Zhang, Y.; Chen, Y.; Guo, B.; Xin, L. Influence of Chloride Concentration on Fretting Wear Behavior of Inconel 600 Alloy. Materials 2024, 17, 2950. [Google Scholar] [CrossRef]

- Shu, Y.; Yang, G.; Liu, Z. Simulation research on fretting wear of train axles with interference fit based on press-fitted specimen. Wear 2023, 523, 204777. [Google Scholar] [CrossRef]

- Swirad, S.; Pawlus, P. The Effect of Ball Burnishing on Dry Fretting. Materials 2021, 14, 7073. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Nie, H.; Dong, Y.; Xu, X.; He, J.; Li, Z.; Cai, Z.; Shen, H.; Zhu, M. Fretting wear behavior of different surface modified layers of a tight fit spline used for a gauge-changeable railway vehicle. Tribol. Int. 2024, 193, 109359. [Google Scholar] [CrossRef]

- Zhang, P.; Deng, Q.; Fu, Z.; Shen, Z.; Li, X.; Sun, D.; Cai, Z.; Gu, L. Effect of temperature on the fretting and sliding wear behaviors of M50 bearing steel. Tribol. Int. 2024, 198, 109909. [Google Scholar] [CrossRef]

- Xue, X.; Li, Y.; Lin, K.; Sui, L.; Jiang, Y.; Zhang, N. A Study on the Influence of Nonlinear Vibration on Fretting Damage of Involute Spline Pairs in Aero-Engines. Lubricants 2023, 11, 515. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, G.; Zhao, X.; Qian, L.; Ma, S.; Wang, F. Contact stress prediction and fretting wear measurement of aeronautic crowned involute splines. Tribol. Int. 2024, 193, 109407. [Google Scholar] [CrossRef]

- Ghadirinejad, K.; Day, C.; Milimonfared, R.; Taylor, M.; Solomon, L.; Hashemi, R. Fretting Wear and Corrosion-Related Risk Factors in Total Hip Replacement: A Literature Review on Implant Retrieval Studies and National Joint Replacement Registry Reports. Prosthesis 2023, 5, 55. [Google Scholar] [CrossRef]

- Feyzi, M.; Fallahnezhad, K.; Taylor, M.; Hashemi, R. An Overview of the Stability and Fretting Corrosion of Microgrooved Necks in the Taper Junction of Hip Implants. Materials 2022, 15, 8396. [Google Scholar] [CrossRef]

- Halmos, F.; Wartzack, S.; Bartz, M. Investigation of Failure Mechanisms in Oil-Lubricated Rolling Bearings under Small Oscillating Movements: Experimental Results, Analysis and Comparison with Theoretical Models. Lubricants 2024, 12, 271. [Google Scholar] [CrossRef]

- Bhaumik, S.; Anurag Krishna, B.; Reddy, B.; Hareesh, G.; Vikram, K.; Paleu, V.; Mavani, S. Investigating the Fretting Failure of Axial Thrust Steel Bearings in the Presence of Anti-Fretting Lubricating Paste. Metals 2023, 13, 2023. [Google Scholar] [CrossRef]

- Wang, G.; Peng, Y.; Chang, X.; Huang, K.; Li, C.; Imran, M.; Wahab, M. Effect of corrosion on fretting wear morphology and mechanical behaviors of wires. Tribol. Int. 2024, 199, 109939. [Google Scholar] [CrossRef]

- Zhan, C.; Shen, F.; Ke, L. A comparative study on the electrical contact behavior of CuZn40 and AgCu10 alloys under fretting wear: Effect of current load. Tribol. Int. 2024, 194, 109523. [Google Scholar] [CrossRef]

- Meng, Y.; Ren, W.; Han, Y.; Zhang, C. Effects of current load on wear and melt erosion of electrical contacts under fretting condition. Tribol. Int. 2024, 194, 109511. [Google Scholar] [CrossRef]

- Zhang, J.; Wheatley, A.; Pasaribu, R.; Worthington, E.; Matthews, S.; Zinser, C.; Cann, P. Wind turbine lubrication: Low temperature fretting wear behaviour of four commercial greases. Tribol. Int. 2023, 187, 108706. [Google Scholar] [CrossRef]

- Rauert, T.; Herrmanna, J.; Dalhoff, P.; Sander, M. Fretting fatigue induced surface cracks under shrink fitted main bearings in wind turbine rotor shafts. Procedia Struct. Integr. 2016, 2, 3601–3609. [Google Scholar] [CrossRef]

- Theiler, G.; Cano Murillo, N.; Hausberger, A. Effect of Hydrogen Pressure on the Fretting Behavior of Rubber Materials. Lubricants 2024, 12, 233. [Google Scholar] [CrossRef]

- Liu, R.; Su, J.; Zhang, T.; Ke, L. Fretting Wear Behaviors of Silicone Rubber under Dry Friction and Different Lubrication Conditions. Materials 2024, 17, 2598. [Google Scholar] [CrossRef]

- Zaïdi, H.; Tournis, S.; Deville, L.; Richard, C.; Aissa, M.; Bouguerra, K. Friction Evolution of Graphite Bearing Impregnated with Polymer Subjected to Vibration Fretting at High Temperature. Coatings 2024, 14, 207. [Google Scholar] [CrossRef]

- Zou, L.; Zeng, D.; Dong, Y.; Li, J.; Chen, X.; Zhao, H.; Lu, L. Experimental and numerical study on the fretting wear-fatigue interaction evolution in press-fitted axles. Int. J. Fatigue 2023, 175, 107793. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Gronba-Chyła, A.; Ciuła, J.; Wiewiórska, I.; Kwaśnicki, P.; Mala, M.; Chyła, K. Artificial Intelligence Methods for Analysis and Optimization of CHP Cogeneration Units Based on Landfill Biogas as a Progress in Improving Energy Efficiency and Limiting Climate Change. Energies 2023, 16, 5732. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Lu, L.; Zou, L.; Xu, T.; Dong, Y.; Zhao, H.; Zeng, D. Effect of interference magnitude on fretting wear and fatigue strength of scaled press-fitted railway axles. Wear 2024, 546–547, 205347. [Google Scholar] [CrossRef]

- Dong, Y.; Zeng, D.; Wu, P.; Lu, L.; Zhao, H.; Li, Y.; Zou, L. Study on fretting fatigue crack initiation of scaled railway axles in consideration of fretting wear. Wear 2023, 512–513, 204545. [Google Scholar] [CrossRef]

- Dong, Y.; Zeng, D.; Wu, P.; Lu, L.; Zou, L.; Xu, T. Numerical prediction of fretting fatigue crack growth in scaled railway axles considering fretting wear evolution. Int. J. Fatigue 2024, 181, 108150. [Google Scholar] [CrossRef]

- Chyła, K.; Gaska, K.; Gronba-Chyła, A.; Generowicz, A.; Grąz, K.; Ciuła, J. Advanced Analytical Methods of the Analysis of Friction Stir Welding Process (FSW) of Aluminum Sheets Used in the Automotive Industry. Materials 2023, 16, 5116. [Google Scholar] [CrossRef] [PubMed]

- Maich, A.; Gronsky, R.; Komvopoulos, K. Microstructure Evolution and Fretting Wear Mechanisms of Steels Undergoing Oscillatory Sliding Contact in Dry Atmosphere. Materials 2024, 17, 1737. [Google Scholar] [CrossRef]

- Timsit, R. +Fretting wear: A phenomological approach. Tribol. Int. 2024, 195, 109572. [Google Scholar] [CrossRef]

- Yin, J.; Yue, Z.; Fan, X.; Zhuang, W.; Zhu, M. Study on the effect of counter ball materials on fretting wear behavior of solid lubricating films. Wear 2023, 526–527, 204957. [Google Scholar] [CrossRef]

- Zhang, M.; Zhu, C.; Zhao, X.; Huang, Y.; Wang, S. The oil lubricated fretting wear behavior under different sliding displacements and frequencies of Ti6Al4V titanium alloy as affected by micro-shot peening. Wear 2024, 548–549, 205386. [Google Scholar] [CrossRef]

- Kowalski, S.; Cieślikowski, B.; Barta, D.; Dižo, J.; Dittrich, A. Analysis of the Operational Wear of the Combustion Engine Piston Pin. Lubricants 2023, 11, 100. [Google Scholar] [CrossRef]

- Kowalski, S.; Pexa, M.; Aleš, Z.; Čedík, J. Failure analysis and the evaluation of forced-in joint reliability for selected operation conditions. Coatings 2021, 11, 1305. [Google Scholar] [CrossRef]

- Kowalski, S. Application of dimensional analysis in the fretting wear studies. J. Balk. Tribol. Assoc. 2016, 22, 3823–3835. [Google Scholar]

| C | Mn | Si | P | S | Cr | V |

|---|---|---|---|---|---|---|

| 0.40 | 0.63 | 0.33 | 0.028 | 0.031 | 0.17 | 0.24 |

| Yield Point [MPa] | Tensile Strength [MPa] | Relative Elongation [%] | Relative Reduction [%] |

|---|---|---|---|

| 315 | 530 | 20 | 45 |

| Parameter | Shaft | Sleeve |

|---|---|---|

| Top layer condition | without extra finish treatment | without extra finish treatment |

| Surface hardness, HB | 160 | 158 |

| Surface roughness | ||

| Ra [µm] | 1.63 | 1.8 |

| Rz [µm] | 7.59 | 11.5 |

| Parameter | Unit | MoS2 Grease | Whitmore Grease |

|---|---|---|---|

| Viscosity (at 40 °C) | mm2/s | 220 | 220 |

| Density (at 20 °C) | g/cm3 | 0.93 | 0.72 |

| Max operating temperature | °C | 180 | 200 |

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Load force | Q | N | 400 |

| Number of revolutions | N | Rev/min | 1380 |

| Number of fatigue cycles | n | - | 106 |

| Number of samples tested | - | - | 18 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barta, D.; Kowalski, S.; Dižo, J.; Dittrich, A. The Influence of a Lubricant Medium on the Development of Fretting Wear in an Interference Fit Connection. Lubricants 2024, 12, 327. https://doi.org/10.3390/lubricants12090327

Barta D, Kowalski S, Dižo J, Dittrich A. The Influence of a Lubricant Medium on the Development of Fretting Wear in an Interference Fit Connection. Lubricants. 2024; 12(9):327. https://doi.org/10.3390/lubricants12090327

Chicago/Turabian StyleBarta, Dalibor, Sławomir Kowalski, Ján Dižo, and Aleš Dittrich. 2024. "The Influence of a Lubricant Medium on the Development of Fretting Wear in an Interference Fit Connection" Lubricants 12, no. 9: 327. https://doi.org/10.3390/lubricants12090327

APA StyleBarta, D., Kowalski, S., Dižo, J., & Dittrich, A. (2024). The Influence of a Lubricant Medium on the Development of Fretting Wear in an Interference Fit Connection. Lubricants, 12(9), 327. https://doi.org/10.3390/lubricants12090327