Effect of Electroplastic-Assisted Grinding on Surface Quality of Ductile Iron

Abstract

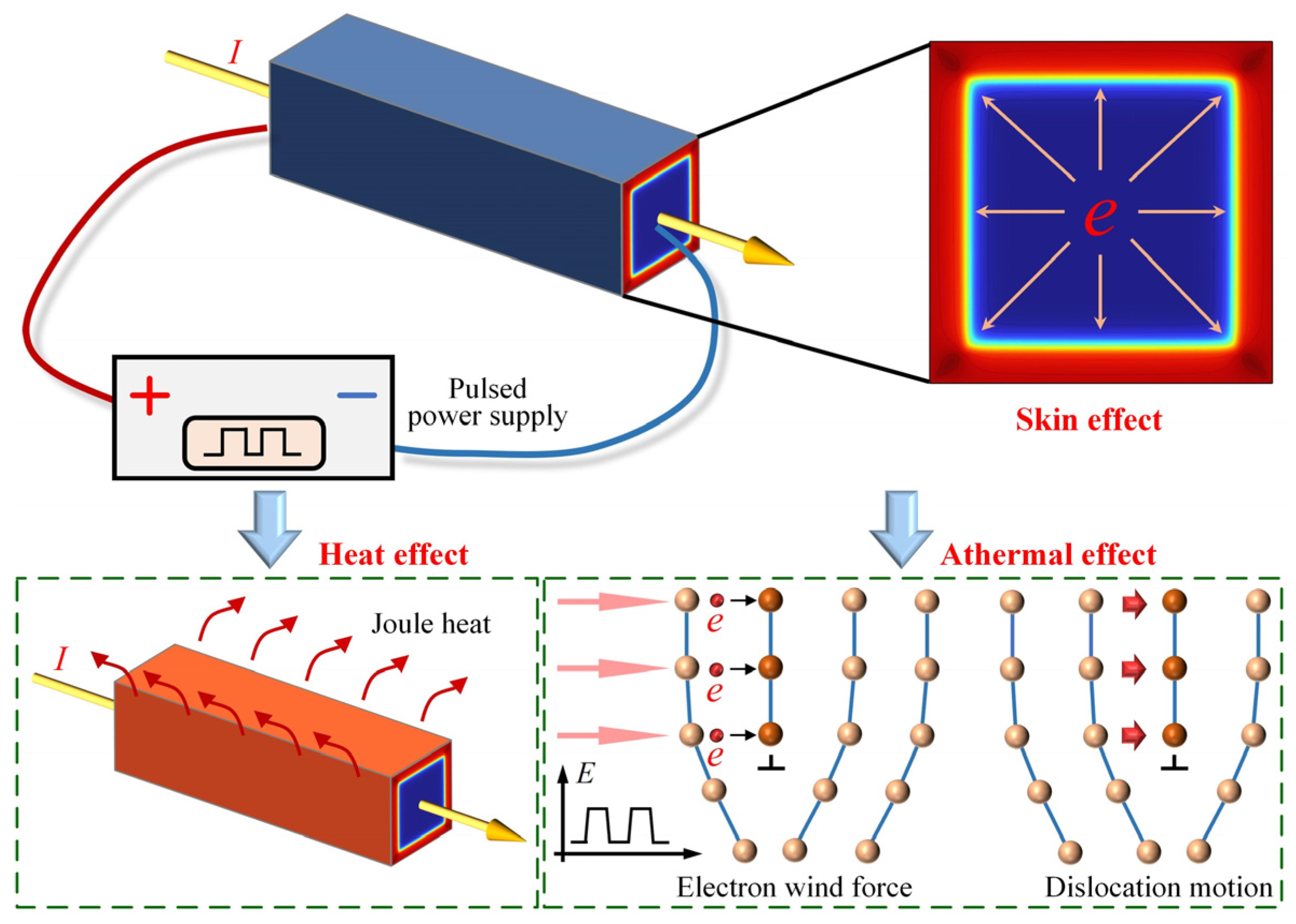

1. Introduction

2. Materials and Methods

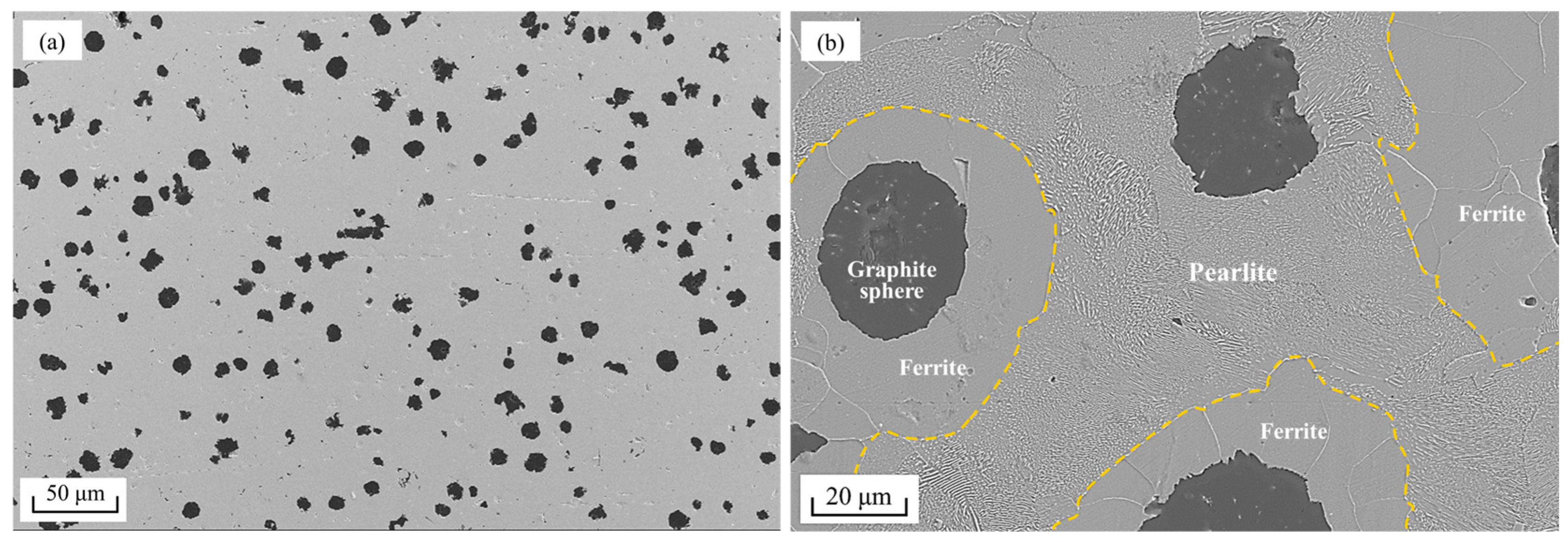

2.1. Materials

2.2. Experimental Setup

2.3. Experimental Design

3. Results and Discussion

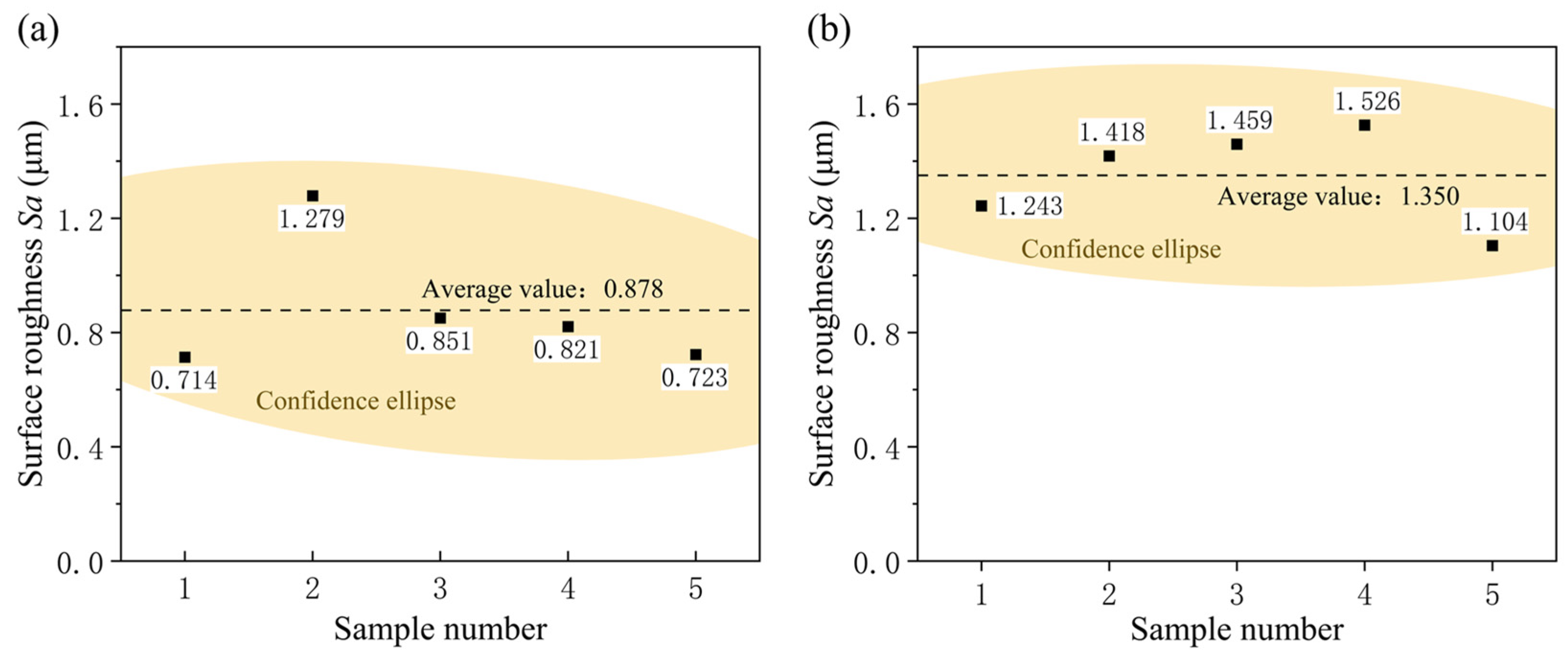

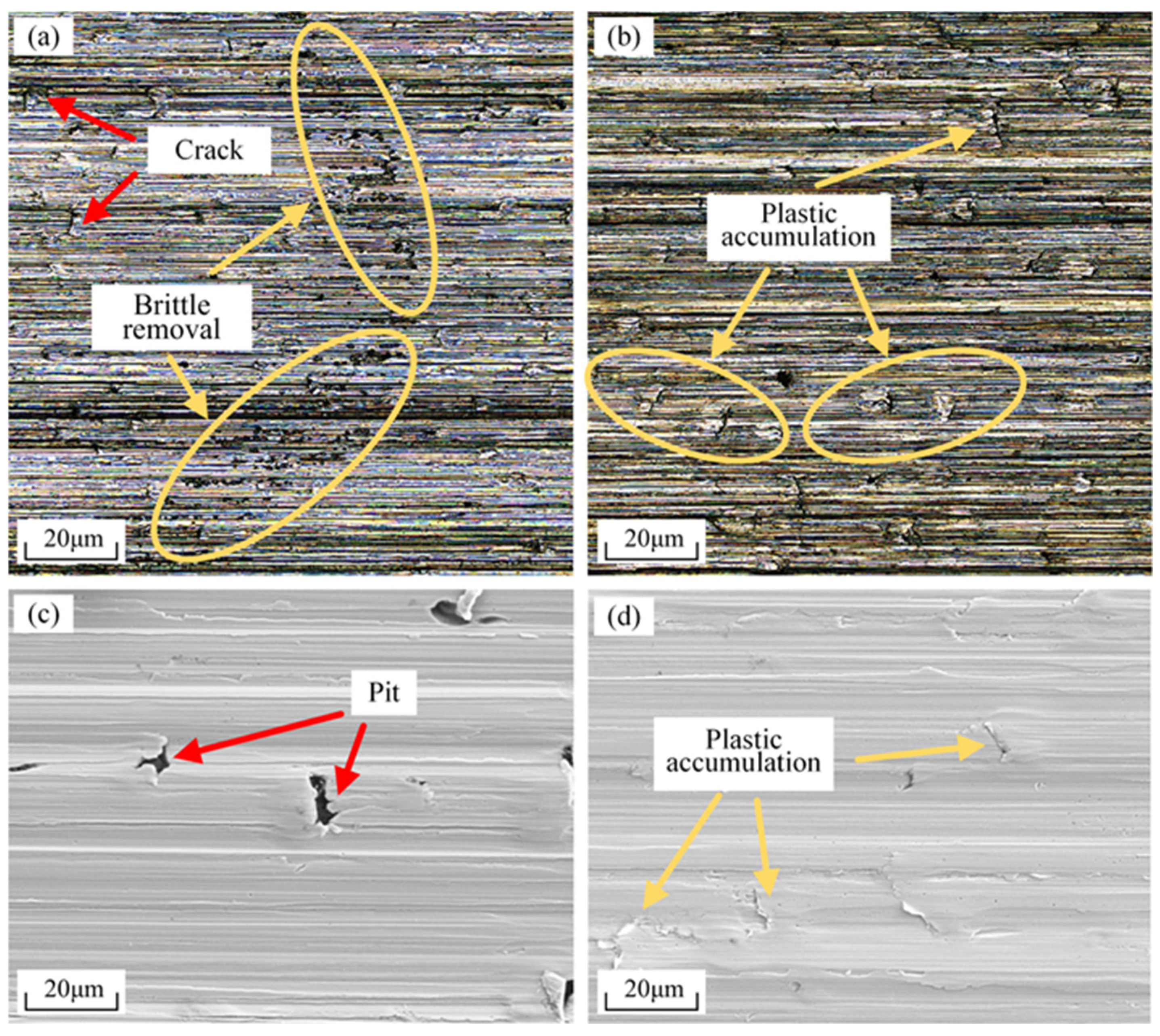

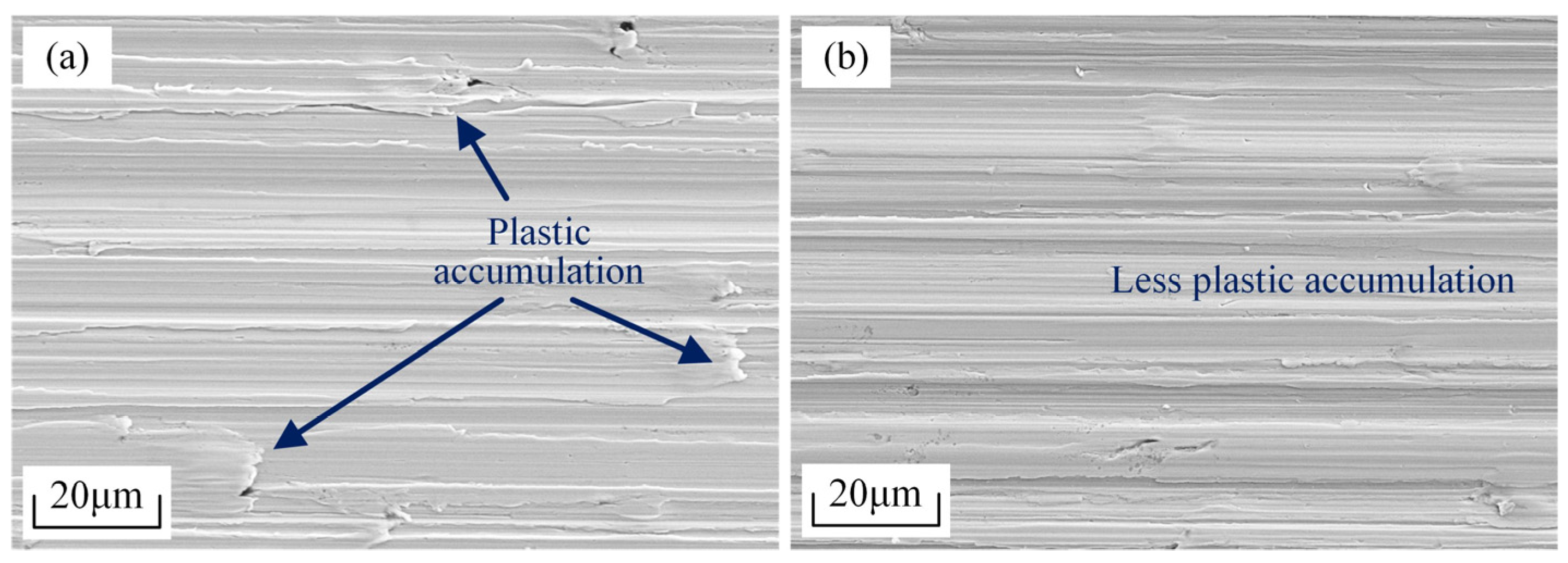

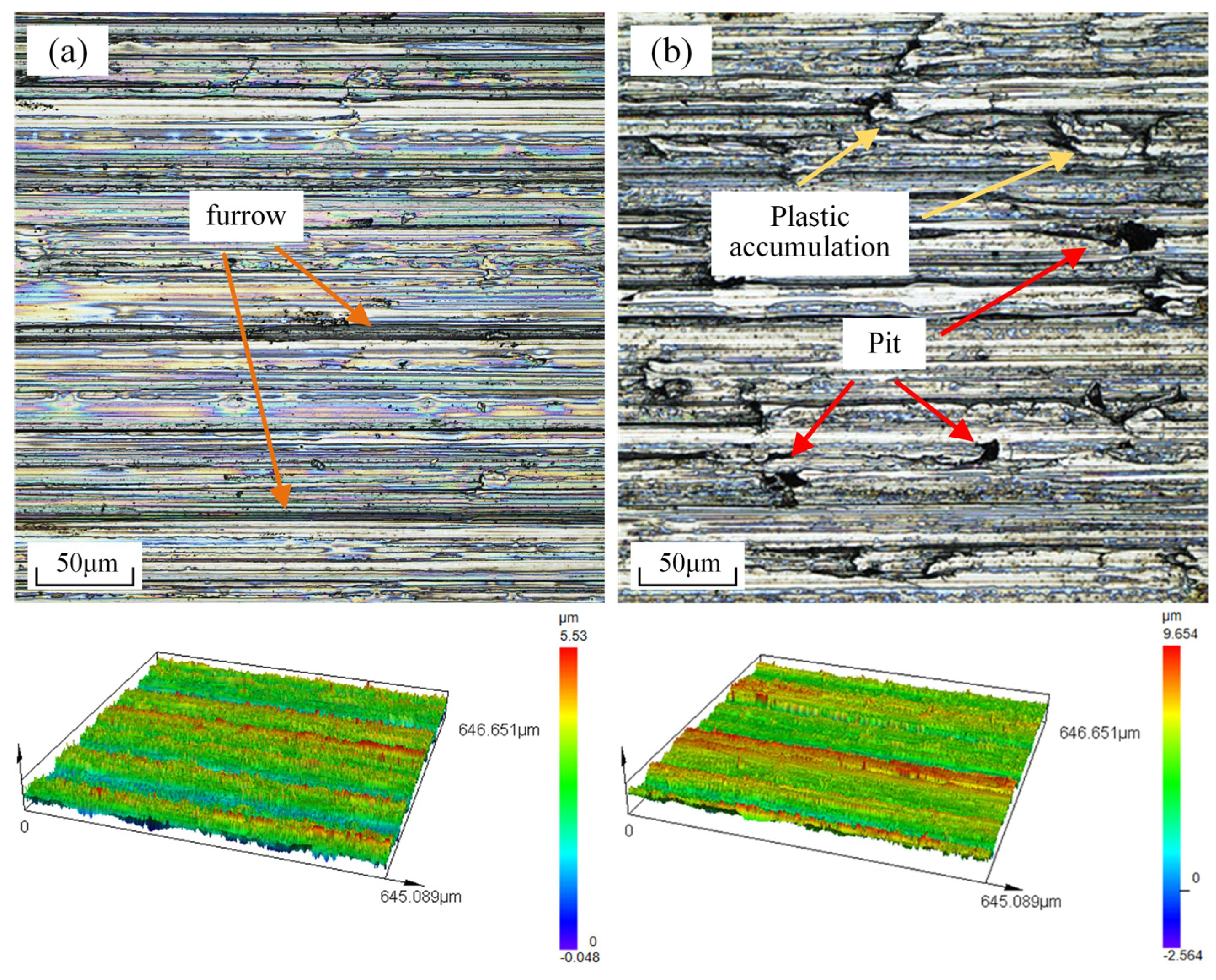

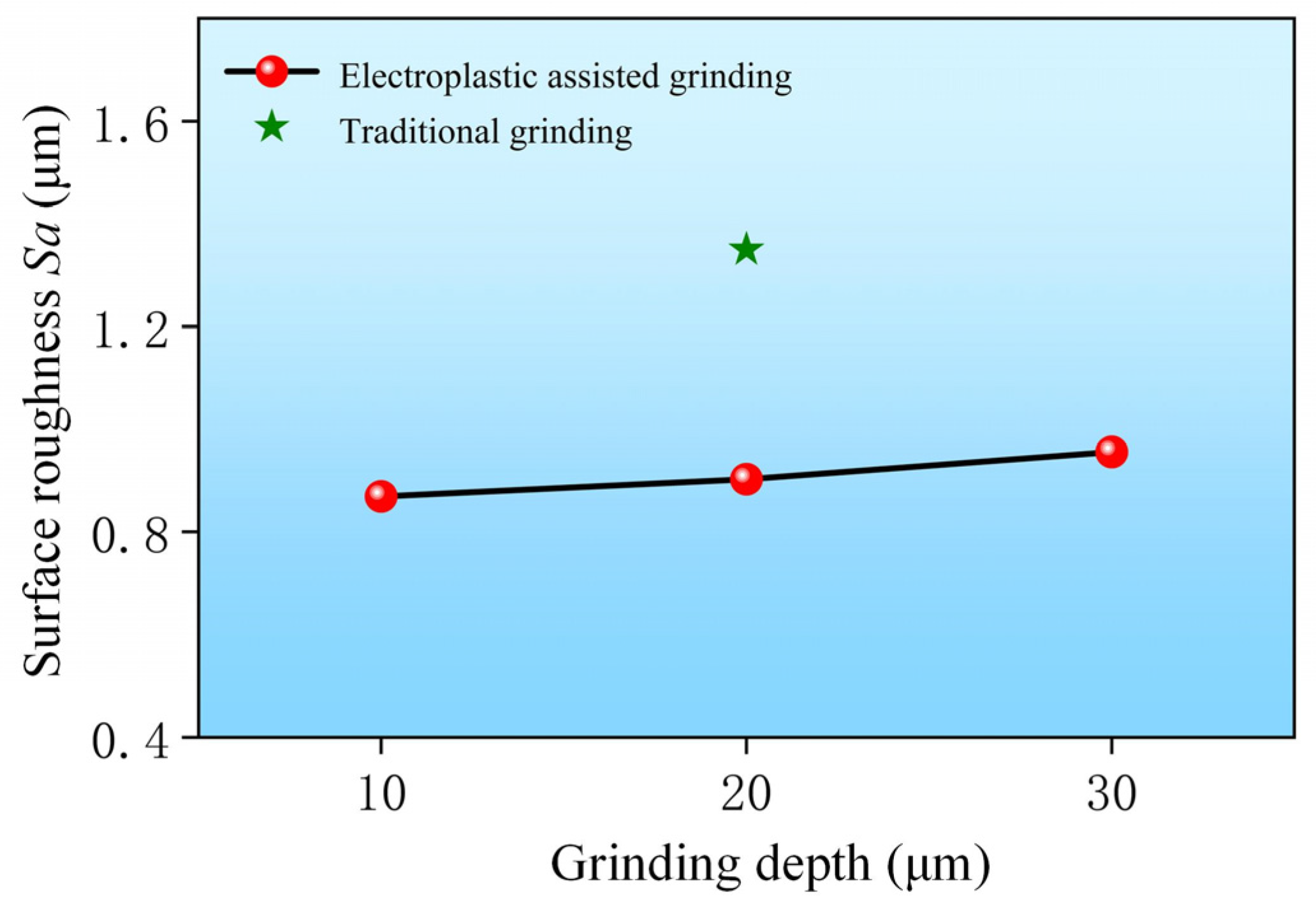

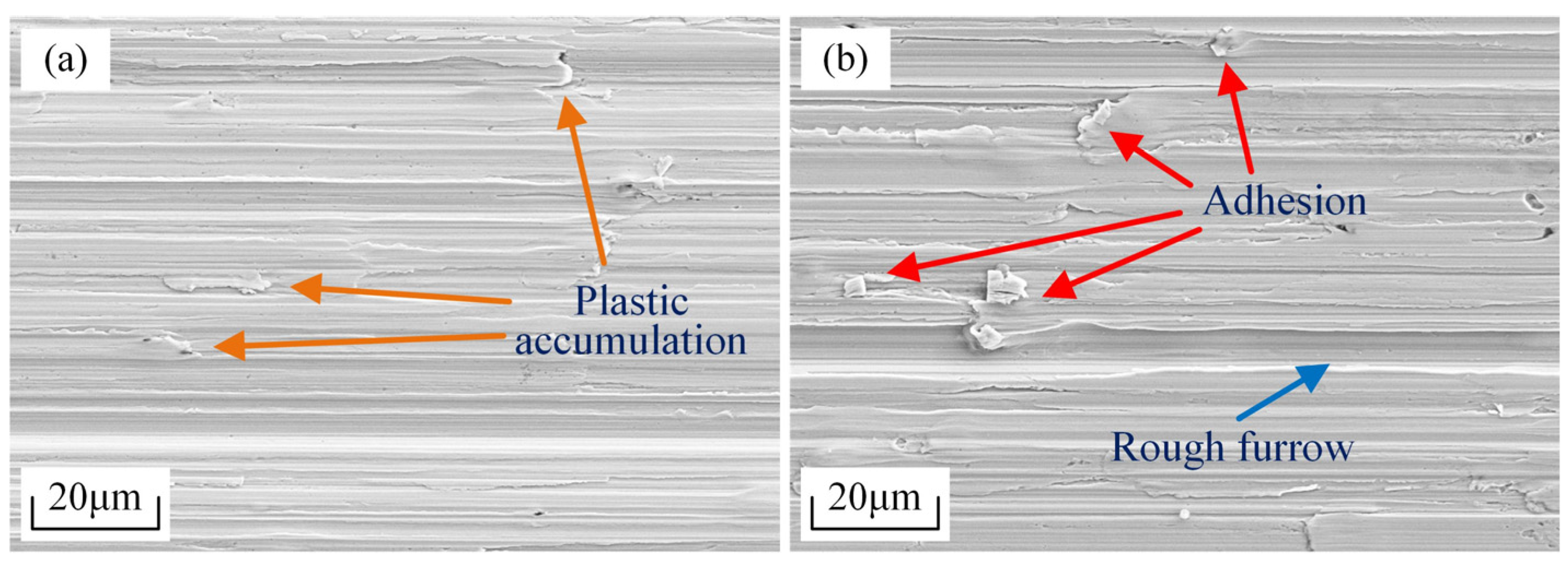

3.1. Surface Quality Optimization Verification of Electroplastic-Assisted Grinding

3.2. Optimization of Electroplastic-Assisted Grinding Process Parameters

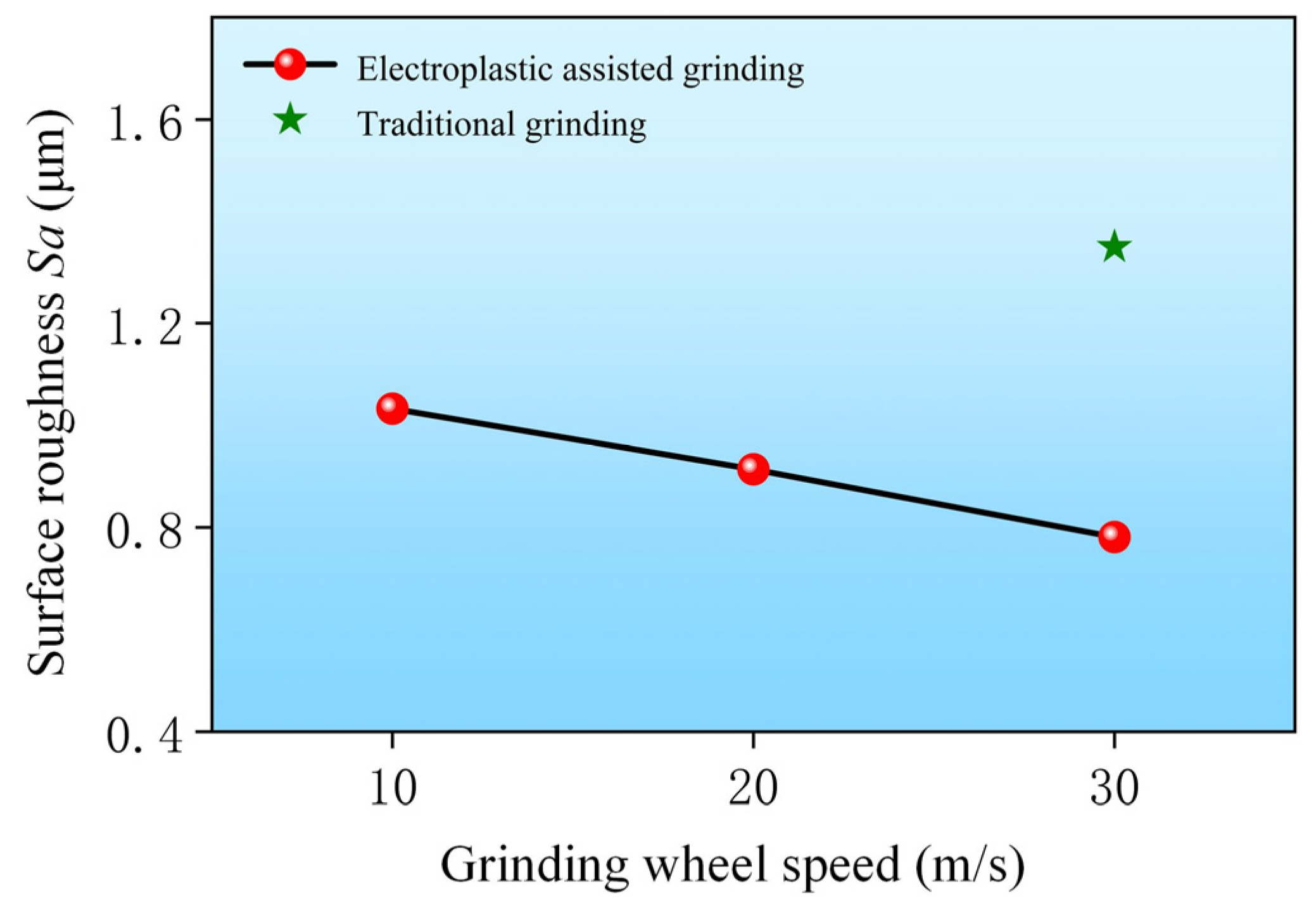

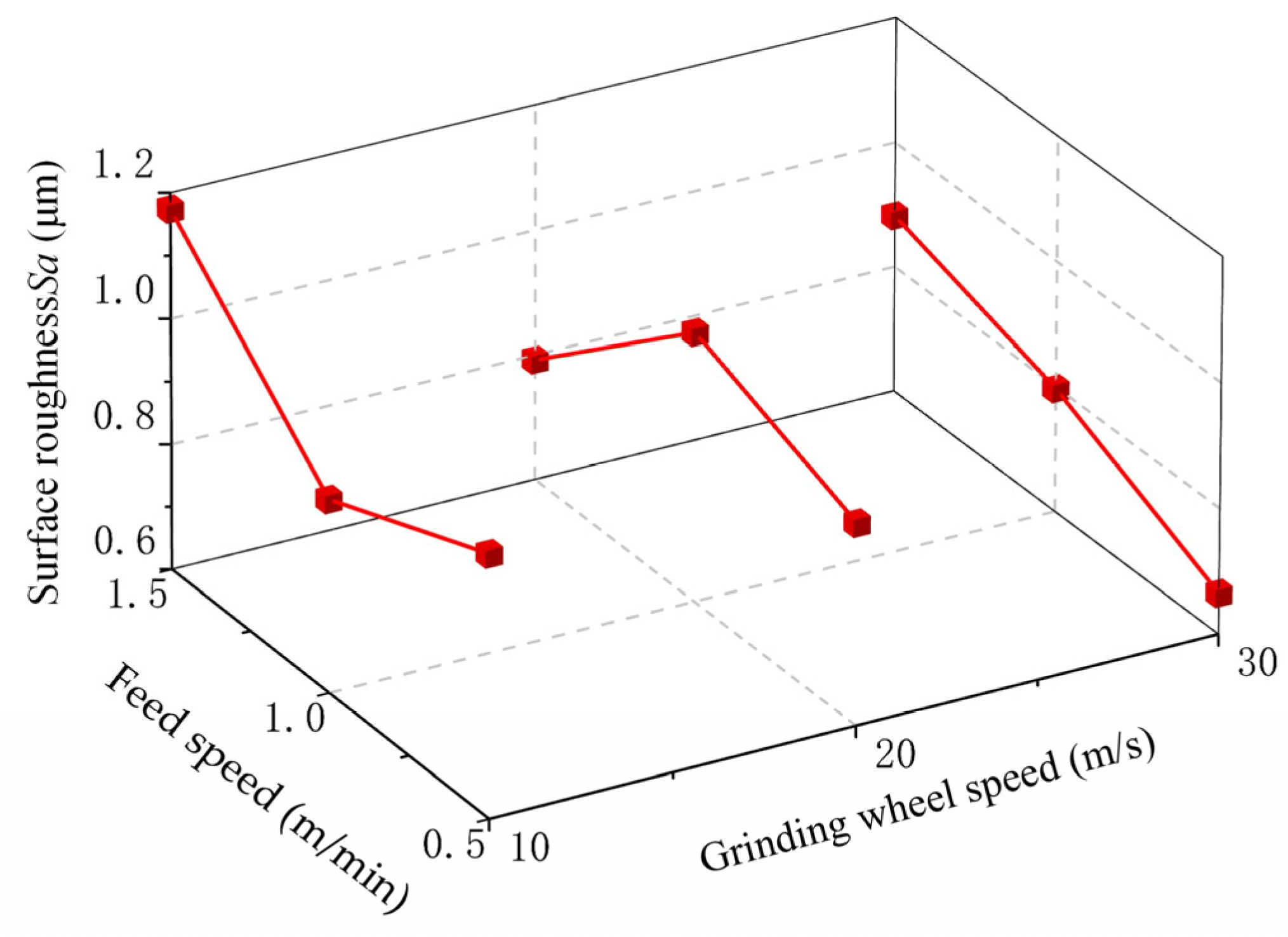

3.2.1. Influence of Grinding Wheel Speed

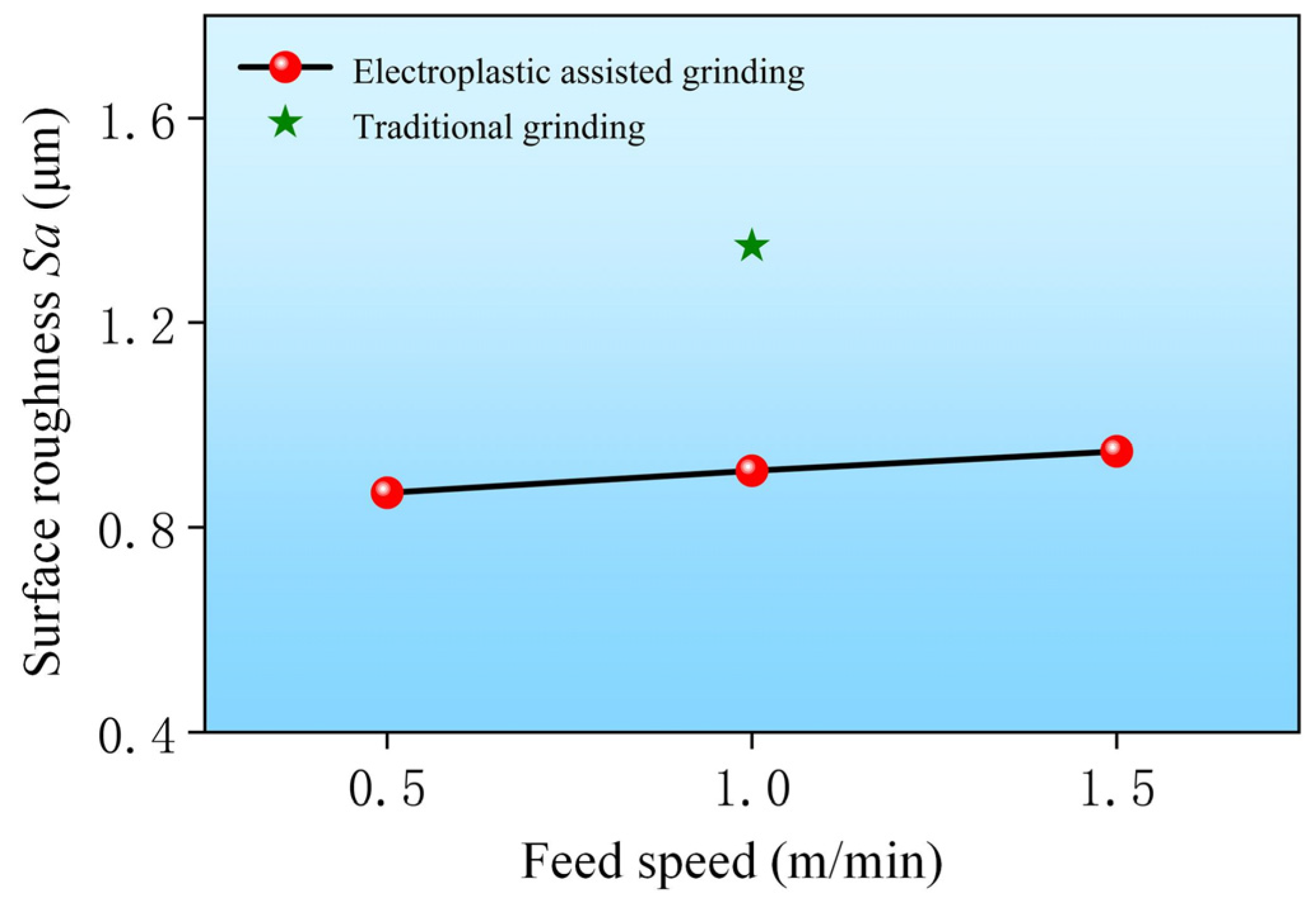

3.2.2. Influence of Feed Rate

3.2.3. Influence of Grinding Depth

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Wang, X.; Liu, W.; Huang, W.; Wu, M.; Xue, M.; Li, L. Influence of distribution and size of graphite particle on the machinability of nodular cast iron. Eng. Fract. Mech. 2024, 297, 109882. [Google Scholar] [CrossRef]

- Fragassa, C. Investigating the material properties of nodular cast iron from a data mining perspective. Metals 2022, 12, 1493. [Google Scholar] [CrossRef]

- Torshizian, M.R.; Aliakbari, K.; Ghonchegi, M. Failure analysis of ductile iron differential housing spline in 4WD passenger car. Int. J. Met. 2021, 15, 587–601. [Google Scholar] [CrossRef]

- Colin, G.E.; Cruz, R.A.; Reyes, C.G.; Tellez, R.J.; Magana, H.A. Microstructural and mechanical assessment of camshafts produced by ductile cast iron low alloyed with vanadium. Metals 2021, 11, 146. [Google Scholar] [CrossRef]

- Hou, N.; Ding, N.; Qu, S. Failure modes, mechanisms and causes of shafts in mechanical equipment. Eng. Fail. Anal. 2022, 136, 106216. [Google Scholar] [CrossRef]

- Tkaya, M.B.; Mezlini, S.; El, M.M. On some tribological effects of graphite nodules in wear mechanism of SG cast iron: Finite element and experimental analysis. Wear 2009, 267, 535–539. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Lusuardi, D. Effect of graphite morphology on the fatigue and fracture resistance of ferritic ductile cast iron. Eng. Fract. Mech. 2019, 206, 427–441. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z. The different electroplastic effects of cutting directions during the turning process of Ti-6Al-4V titanium alloy. Int. J. Mater. Prod. Technol. 2023, 67, 155–165. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, G.; Liu, J.; Wei, H.; Huang, J. Effect of pulse current parameters on electroplastically assisted dry cutting performance of W93NiFe alloy. Int. J. Adv. Manuf. Technol. 2023, 131, 2123–2131. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Grimm, T.; Ragai, I.; Mears, L.; Roth, J.T. A review of electrically-assisted manufacturing with emphasis on modeling and understanding of the electroplastic effect. J. Manuf. Sci. Eng. 2017, 139, 110801. [Google Scholar] [CrossRef]

- Li, H.; Peng, L.F.; Meng, B.; Xu, Z.T.; Wang, L.L.; Ngaile, G.; Fu, M.W. Energy field assisted metal forming: Current status, challenges and prospects. Int. J. Mach. Tools Manuf. 2023, 192, 104075. [Google Scholar] [CrossRef]

- Peng, L.; Mai, J.; Jiang, T.; Lai, X.; Lin, Z. Experimental investigation of tensile properties of SS316L and fabrication of micro/mesochannel features by electrical-assisted embossing process. J. Micro Nano-Manuf. 2014, 2, 021002. [Google Scholar] [CrossRef]

- Dai, Z.; Jin, K.; Kou, Y. An electroplastic constitutive model of fcc metals and their alloys under high current density. Mech. Mater. 2024, 189, 104878. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, T.; Huang, J. Electroplasticity in electrically-assisted forming: Process phenomena, performances and modelling. Int. J. Mach. Tools Manuf. 2022, 175, 103871. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, J.; Liu, B. Experimental and simulated investigation of the deformation behavior and microstructural evolution of Ti6554 titanium alloy during an electropulsing-assisted microtension process. Mater. Sci. Eng. A 2022, 838, 142745. [Google Scholar] [CrossRef]

- Liu, J.; Jia, D.; Fu, Y.; Kong, X.; Lv, Z.; Zeng, E.; Gao, Q. Electroplasticity effects: From mechanism to application. Int. J. Adv. Manuf. Technol. 2023, 131, 3267–3286. [Google Scholar] [CrossRef]

- Xiang, S.; Zhang, X. Dislocation structure evolution under electroplastic effect. Mater. Sci. Eng. A 2019, 761, 138026. [Google Scholar] [CrossRef]

- Fan, Y.; Fan, H.; Hao, Z. Effect of pulsed current on plastic deformation of Inconel 718 under high strain rate and high temperature conditions. J. Alloys Compd. 2023, 943, 169150. [Google Scholar] [CrossRef]

- Sprecher, A.F.; Mannan, S.L.; Conrad, H. Overview no. 49: On the mechanisms for the electroplastic effect in metals. Acta Metall. 1986, 34, 1145–1162. [Google Scholar] [CrossRef]

- Dimitrov, N.K.; Liu, Y.; Horstemeyer, M.F. Electroplasticity: A review of mechanisms in electro-mechanical coupling of ductile metals. Mech. Adv. Mater. Struct. 2022, 29, 705–716. [Google Scholar] [CrossRef]

- Egea, A.J.S.; Rojas, H.A.G.; Montaña, C.A.M.; Echeverri, V.K. Effect of electroplastic cutting on the manufacturing process and surface properties. J. Mater. Process. Technol. 2015, 222, 327–334. [Google Scholar] [CrossRef]

- Hameed, S.; Gonzalez Rojas, H.A.; Sánchez Egea, A.J.; Alberro, A.N. Electroplastic cutting influence on power consumption during drilling process. Int. J. Adv. Manuf. Technol. 2016, 87, 1835–1841. [Google Scholar] [CrossRef]

- Kinsey, B.; Cullen, G.; Jordan, A.; Mates, S. Investigation of electroplastic effect at high deformation rates for 304SS and Ti–6Al–4V. CIRP Ann. 2013, 62, 279–282. [Google Scholar] [CrossRef]

- Zhu, R.; Tang, G.; Shi, S.; Fu, M. Effect of electroplastic rolling on deformability and oxidation of NiTiNb shape memory alloy. J. Mater. Process. Technol. 2013, 213, 30–35. [Google Scholar] [CrossRef]

- Troitskiy, O.A.; Stashenko, V.I. Electroplastic wire drawing: A promising method of production of lightweight wire and cable. J. Mach. Manuf. Reliab. 2015, 44, 758–765. [Google Scholar] [CrossRef]

- Qian, L.; Zhan, L.; Zhou, B.; Zhang, X.; Liu, S.; Lv, Z. Effects of electroplastic rolling on mechanical properties and microstructure of low-carbon martensitic steel. Mater. Sci. Eng. A 2021, 812, 141144. [Google Scholar] [CrossRef]

- Wang, H.; Chen, L.; Liu, D.; Song, G.; Tang, G. Study on electropulsing assisted turning process for AISI 304 stainless steel. Mater. Sci. Technol. 2015, 31, 1564–1571. [Google Scholar] [CrossRef]

- Yuan, M.; Wang, J.; Wang, M.; Huang, K.; Wang, L.; Tian, Y. Enhanced carbide tool life by the electromagnetic coupling field for sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2020, 108, 3905–3914. [Google Scholar] [CrossRef]

- Zhao, G.; Zhao, B.; Ding, W.; Xin, L.; Nian, Z.; Peng, J.; Xu, J. Nonconventional energy-assisted mechanical machining of difficult-to-cut materials and components in aerospace community: A comparative analysis. Int. J. Extrem. Manuf. 2024, 6, 022007. [Google Scholar] [CrossRef]

- Shao, Z.; Li, G.; Liu, W.; Wu, X.; Ma, G.; Wang, F. Advance in the research of electric pulse-assisted cutting. Int. J. Adv. Manuf. Technol. 2023, 127, 2107–2123. [Google Scholar] [CrossRef]

- Da Silva, R.B.; Lima, M.L.S.; Pereira, M.F.; Abrão, B.S.; Da Silva, L.R.R.; Bianchi, E.C.; Machado, A.R. A surface and sub-surface quality evaluation of three cast iron grades after grinding under various cutting conditions. Int. J. Adv. Manuf. Technol. 2018, 99, 1839–1852. [Google Scholar] [CrossRef]

- Furno, M.E.; Sosa, A.D. Surface integrity analysis of grinding on ductile iron. Int. J. Adv. Manuf. Technol. 2020, 110, 2067–2078. [Google Scholar] [CrossRef]

- Liu, J.H. Experimental Study on Electroplastic-Assisted Grinding of Ductile Iron; Liaoning University of Technology: Jinzhou, China, 2024. [Google Scholar]

- Rosentritt, M.; Schneider-Feyrer, S.; Kurzendorfer, L. Comparison of surface roughness parameters Ra/Sa and Rz/Sz with different measuring devices. J. Mech. Behav. Biomed. Mater. 2024, 150, 106349. [Google Scholar] [CrossRef]

- Nwaogu, U.C.; Tiedje, N.S.; Hansen, H.N. A non-contact 3D method to characterize the surface roughness of castings. J. Mater. Process. Technol. 2013, 213, 59–68. [Google Scholar] [CrossRef]

- Li, Q.; Li, R.; Chang, G.; Zhai, Q. Research of microstructure of spherical graphite iron by electropulsing annealing. J. Mater. Process. Technol. 2009, 209, 2015–2020. [Google Scholar] [CrossRef]

- Sheng, Y.; Hua, Y.; Wang, X.; Zhao, X.; Chen, L.; Zhou, H.; Li, W. Application of high-density electropulsing to improve the performance of metallic materials: Mechanisms, microstructure and properties. Materials 2018, 11, 185. [Google Scholar] [CrossRef]

- Yang, M.; Kong, M.; Li, C.; Long, Y.; Zhang, Y.; Sharma, S.; Yang, Y. Temperature field model in surface grinding: A comparative assessment. Int. J. Extrem. Manuf. 2023, 5, 042011. [Google Scholar] [CrossRef]

- Li, Y.; Chen, J.; Wang, J.; Shi, X.; Chen, L. Study on the effect of residual stresses on fatigue crack initiation in rails. Int. J. Fatigue 2020, 139, 105750. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | S | Mg | Re |

|---|---|---|---|---|---|---|

| Content | 3.55–3.85 | 2.34–2.86 | ≤0.6 | ≤0.025 | 0.02–0.04 | 0.03–0.05 |

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| QT500-7 | ≥500 | ≥320 | ≥7 | 170–230 |

| Factor | Symbol | Level | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Grinding wheel tangential speed (m/s) | A | 10 | 20 | 30 |

| Feed speed (m/min) | B | 0.5 | 1.0 | 1.5 |

| Grinding depth (μm) | C | 10 | 20 | 30 |

| Process Parameters | Value Ranges |

|---|---|

| Impulse current (A) | 600 |

| Pulse frequency (Hz) | 200 |

| Duty ratio (%) | 50 |

| Grinding wheel speed (m/s) | 10–30 |

| Feed speed (m/min) | 0.5–1.5 |

| Grinding depth (μm) | 10–30 |

| Experiment No. | Grinding Wheel Speed (m/s) | Feed Speed (m/min) | Grinding Depth (μm) | Surface Roughness Sa (μm) |

|---|---|---|---|---|

| 1 | 10 | 0.5 | 10 | 1.017 ± 0.27 |

| 2 | 10 | 1.0 | 20 | 0.907 ± 0.26 |

| 3 | 10 | 1.5 | 30 | 1.174 ± 0.12 |

| 4 | 20 | 0.5 | 20 | 0.921 ± 0.16 |

| 5 | 20 | 1.0 | 30 | 1.029 ± 0.28 |

| 6 | 20 | 1.5 | 10 | 0.792 ± 0.23 |

| 7 | 30 | 0.5 | 30 | 0.665 ± 0.31 |

| 8 | 30 | 1.0 | 10 | 0.797 ± 0.32 |

| 9 | 30 | 1.5 | 20 | 0.882 ± 0.24 |

| Level | Grinding Wheel Speed (m/s) | Feed Speed (m/min) | Grinding Depth (μm) |

|---|---|---|---|

| 1 | −0.2306 | 1.3707 | 1.2833 |

| 2 | 0.8307 | 0.8568 | 0.8844 |

| 3 | 2.2017 | 0.5743 | 0.6340 |

| Project | Result | Grinding Wheel Speed (m/s) | Feed Speed (m/min) | Grinding Depth (μm) |

|---|---|---|---|---|

| Surface roughness Sa (μm) | K1 | 1.033 | 0.868 | 0.869 |

| K2 | 0.914 | 0.911 | 0.903 | |

| K3 | 0.781 | 0.949 | 0.956 | |

| R | 0.252 | 0.081 | 0.087 | |

| Order | 1 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, S.; Jia, D.; Zhang, Y.; Wu, X.; Guo, E.; Xue, R.; Gong, T.; Yang, H.; Li, X.; Jiang, X. Effect of Electroplastic-Assisted Grinding on Surface Quality of Ductile Iron. Lubricants 2024, 12, 266. https://doi.org/10.3390/lubricants12080266

Feng S, Jia D, Zhang Y, Wu X, Guo E, Xue R, Gong T, Yang H, Li X, Jiang X. Effect of Electroplastic-Assisted Grinding on Surface Quality of Ductile Iron. Lubricants. 2024; 12(8):266. https://doi.org/10.3390/lubricants12080266

Chicago/Turabian StyleFeng, Shuo, Dongzhou Jia, Yanbin Zhang, Xiaoqiang Wu, Erkuo Guo, Rui Xue, Taiyan Gong, Haijun Yang, Xiaoxue Li, and Xin Jiang. 2024. "Effect of Electroplastic-Assisted Grinding on Surface Quality of Ductile Iron" Lubricants 12, no. 8: 266. https://doi.org/10.3390/lubricants12080266

APA StyleFeng, S., Jia, D., Zhang, Y., Wu, X., Guo, E., Xue, R., Gong, T., Yang, H., Li, X., & Jiang, X. (2024). Effect of Electroplastic-Assisted Grinding on Surface Quality of Ductile Iron. Lubricants, 12(8), 266. https://doi.org/10.3390/lubricants12080266