Improved Tribological Properties of Epoxy Cement Reinforced with Impact-Resistant Core-Shell Structured Polymer Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Core–Shell Structured Nanoparticles (CSP)

2.3. Preparation Procedure of Core-Shell Epoxy Cement (CSEC)

2.4. Tribological Property Tests

2.5. Characterization

3. Results and Discussion

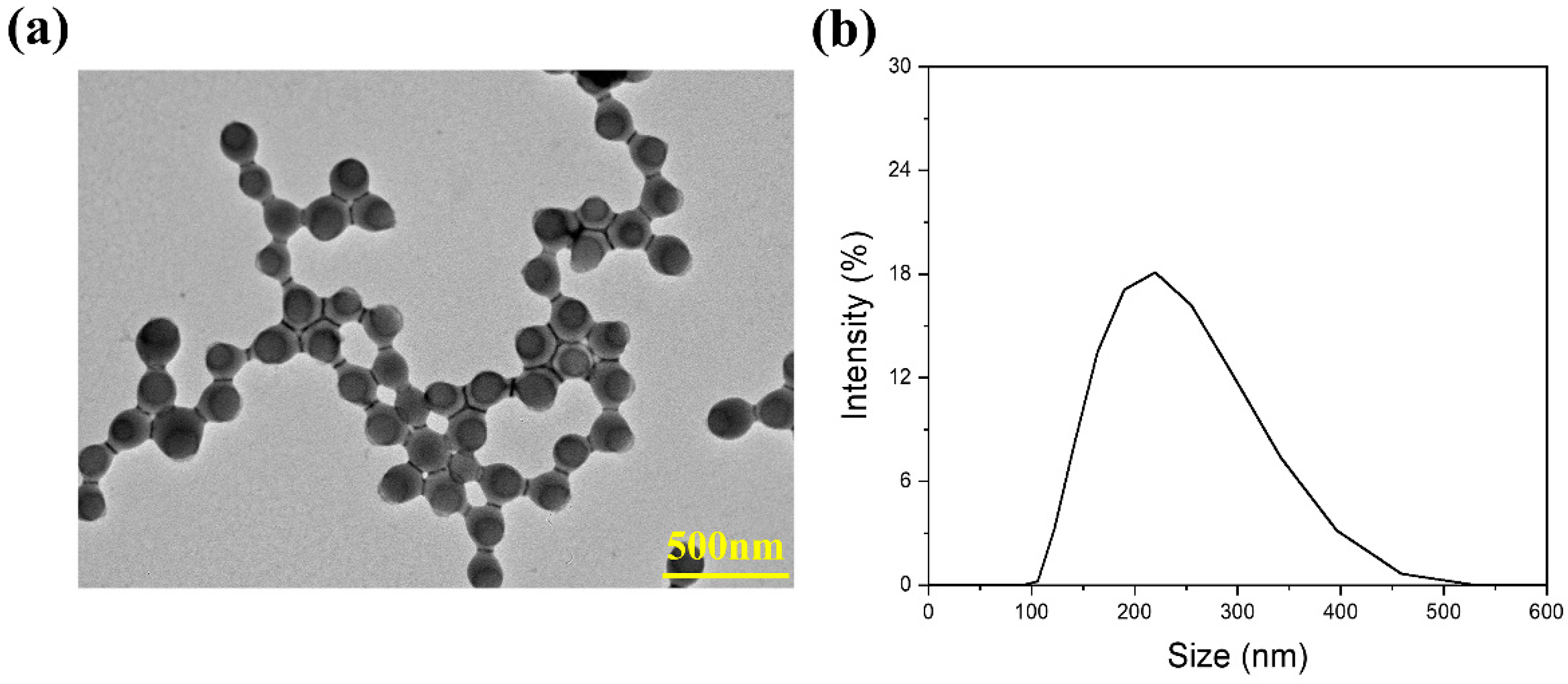

3.1. The Characterization of CSP

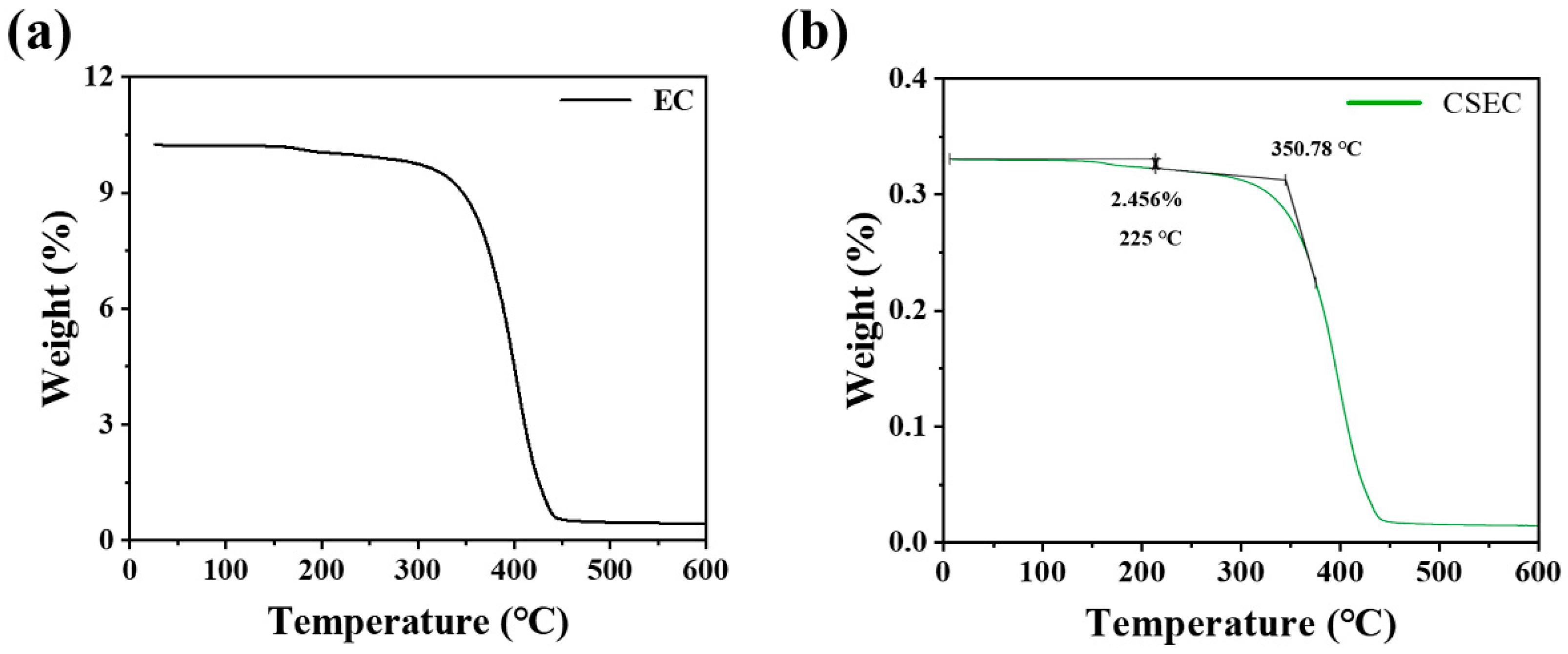

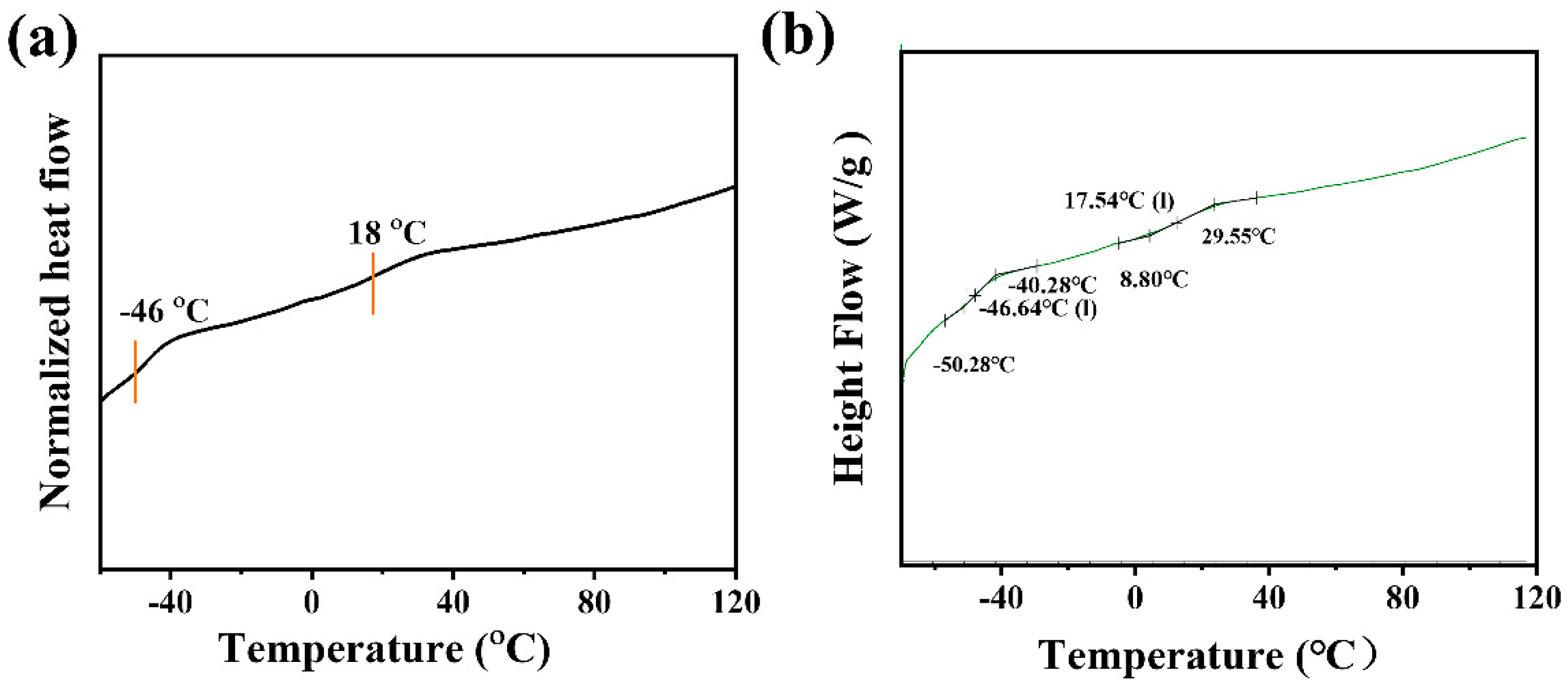

3.2. Thermogravimetric Analysis TGA and Differential Scanning Calorimetry DSC Tests

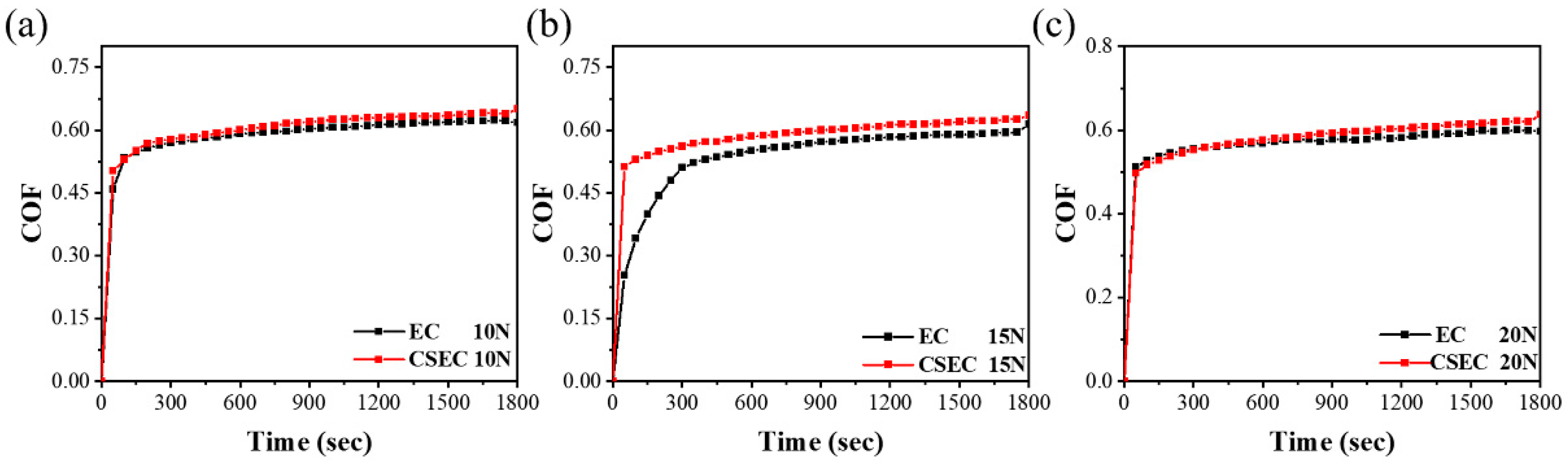

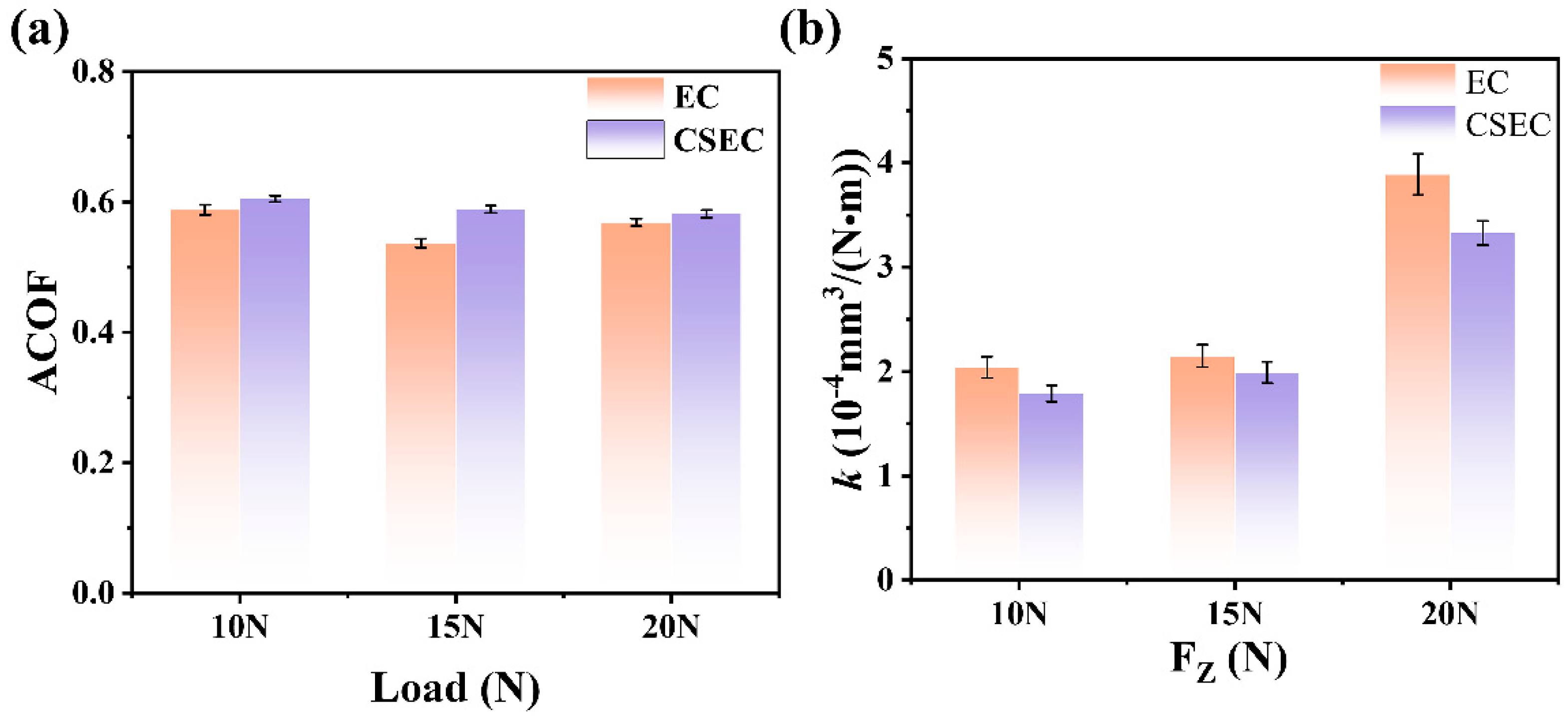

3.3. Frictional Performance Testing

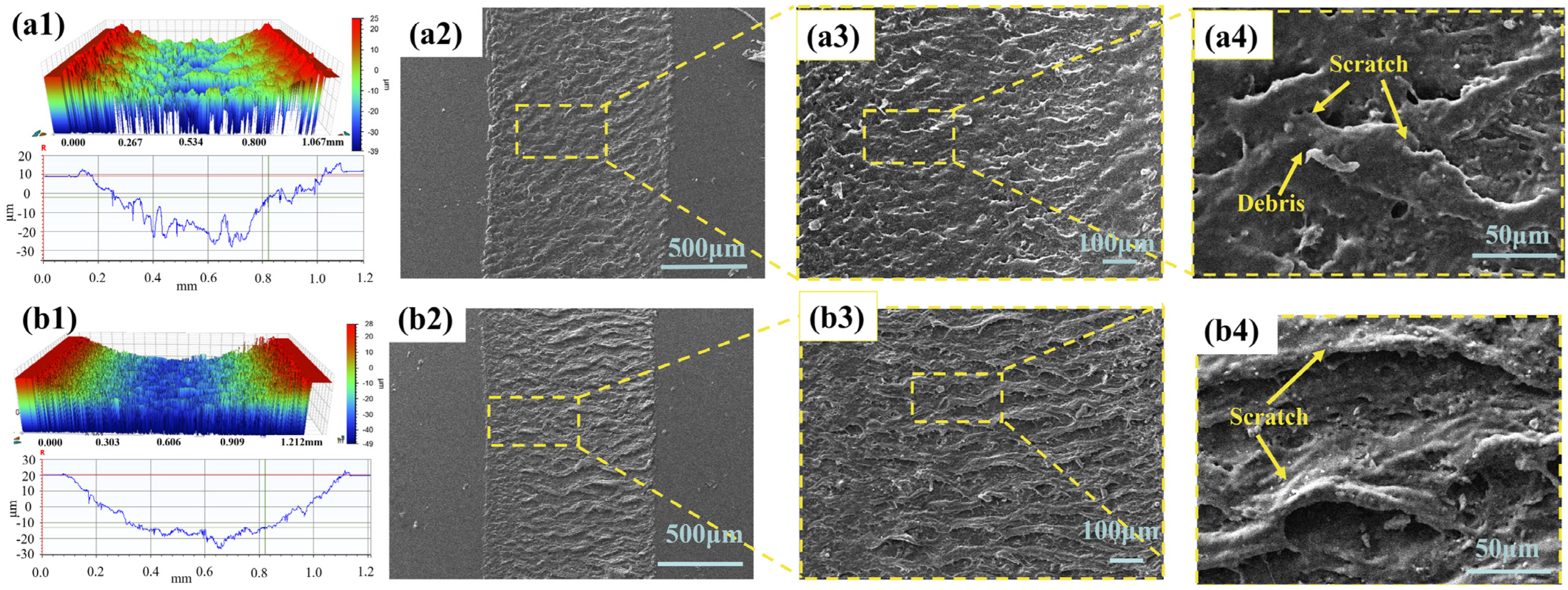

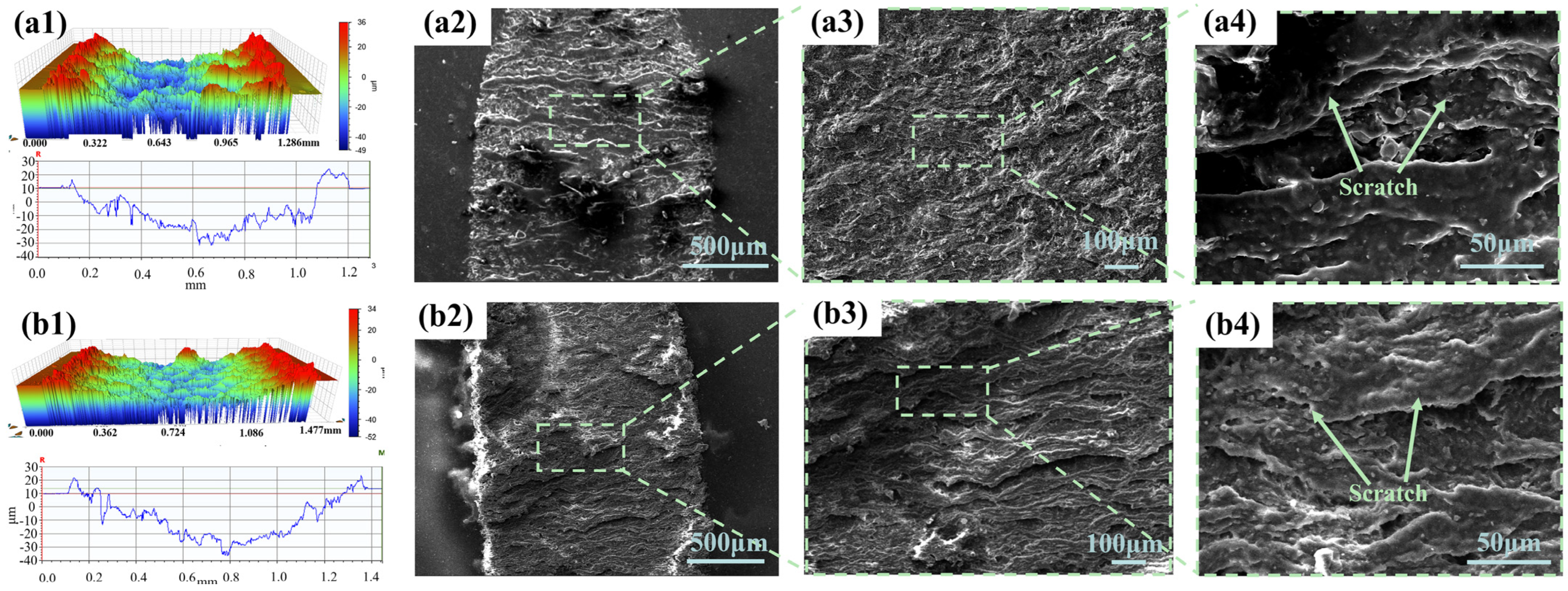

3.4. The Analysis of Wear Surface

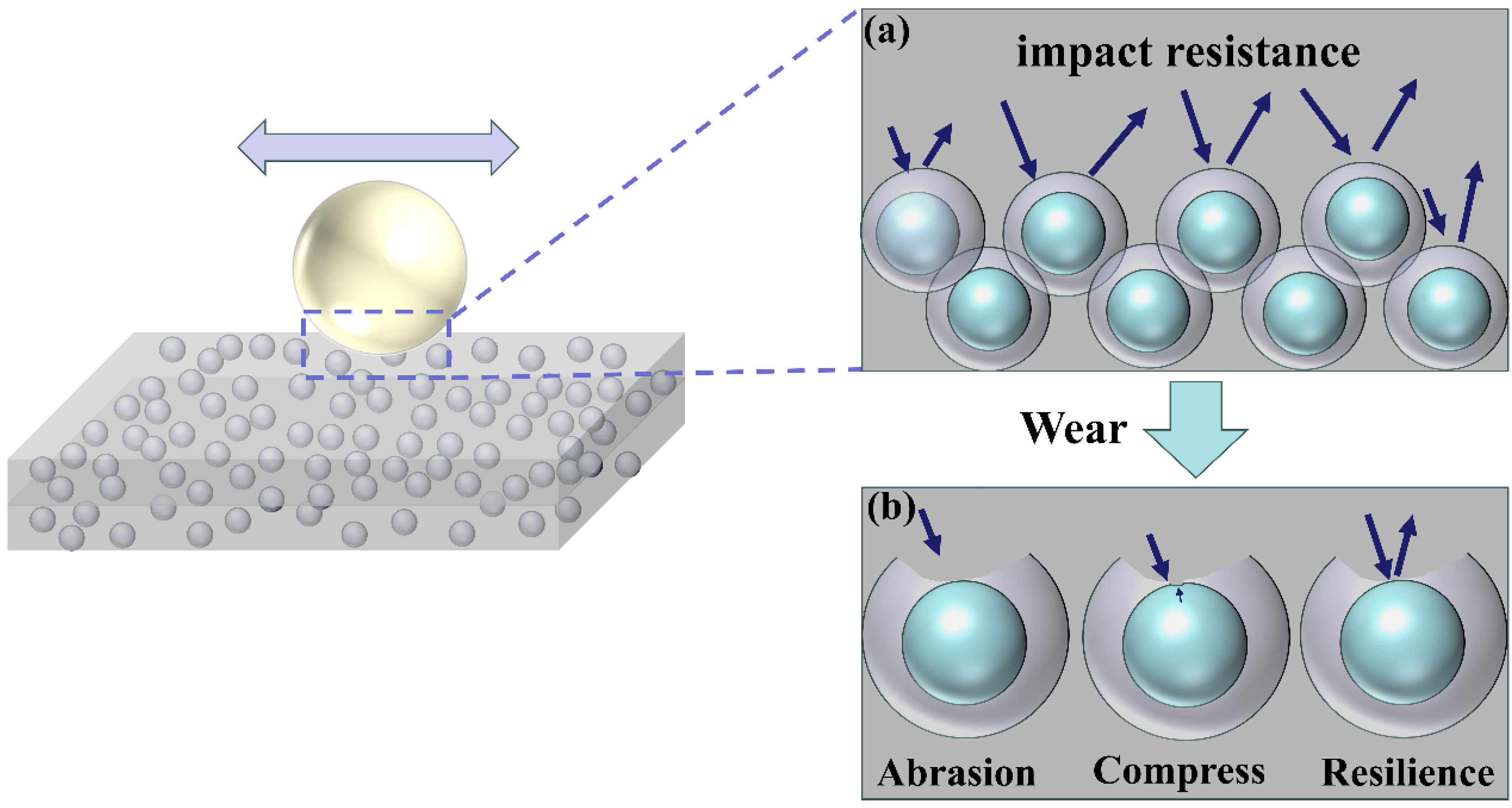

4. Friction Mechanism Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Liu, Q. Investigation on fundamental properties and chemical characterization of water-soluble epoxy resin modified cement grout. Constr. Build. Mater. 2021, 299, 123877. [Google Scholar] [CrossRef]

- Gujar, P.; Hirshikesh, H.; Annabattula, R.K.; Ghosh, P. Structural to interfacial fracture transition in epoxy coated hydrating cement. Constr. Build. Mater. 2021, 310, 125128. [Google Scholar] [CrossRef]

- Jiao, B.; Pan, B.; Liu, F.; Yin, P.; Li, Z. Evaluating the interfacial properties between crumb rubber modified asphalt and aggregates using molecular dynamics simulation methods. Constr. Build. Mater. 2023, 400, 132809. [Google Scholar] [CrossRef]

- Turk, J.; Pranjić, A.M.; Mladenovič, A.; Cotič, Z.; Jurjavčič, P. Environmental comparison of two alternative road pavement rehabilitation techniques: Cold-in-place-recycling versus traditional reconstruction. J. Clean. Prod. 2016, 121, 45–55. [Google Scholar] [CrossRef]

- Wang, H.; Qian, J.; Zhang, H.; Nan, X.; Chen, G.; Li, X. Exploring skid resistance over time: Steel slag as a pavement aggregate—Comparative study and morphological analysis. J. Clean. Prod. 2024, 464, 142779. [Google Scholar] [CrossRef]

- Wang, M.; Yang, X.; Zheng, K.; Chen, R. Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material. Buildings 2024, 14, 1439. [Google Scholar] [CrossRef]

- Liu, F.; Pan, B.; Zhou, C.; Nie, J. Repair interface crack resistance mechanism: A case of magnesium phosphate cement overlay repair cement concrete pavement surface. Dev. Built Environ. 2024, 17, 100355. [Google Scholar] [CrossRef]

- Pineda, P.; García-Martínez, A.; Castizo-Morales, D. Environmental and structural analysis of cement-based vs. natural material-based grouting mortars. Results from the assessment of strengthening works. Constr. Build. Mater. 2017, 138, 528–547. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.; Jia, Z.; Cao, R.; Xiong, Y.; Chen, C.; Zhang, Y. Thermal properties of amino-functionalized multi-walled carbon nanotubes reinforced epoxy-based transducers embedded in concrete. Cem. Concr. Compos. 2022, 127, 104411. [Google Scholar] [CrossRef]

- Wu, X.; Yu, Y.; Zhao, J.; Zhang, C.; He, M.; Li, M. Study on water-based epoxy resin cementing fluid system. J. Dispers. Sci. Technol. 2024, 45, 780–789. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, Z.; Feng, Q.; Zheng, Y. Effect of CTBN and Nano-SiO2 modified epoxy resin powder on the mechanical properties of cement-based composites. J. Build. Eng. 2024, 83, 108456. [Google Scholar] [CrossRef]

- Al-kawaz, A.E.; Al-Mutairi, N.H.; Alobad, Z.K.M. Tribological behavior of epoxy/nano-clay nanocomposites used as a floor coating. J. Adhes. Sci. Technol. 2024, 1–17. [Google Scholar] [CrossRef]

- Abdelrhman, Y.; Omar, M.; Hassab-Allah, I.M.; Shewakh, W.M.; Khierldeen, W.M.; Hedaya, M.; Omar, R.; Younes, M.F. Mechanical properties and damping characteristics of Egyptian granite-epoxy composite material. Mater. Res. Express 2024, 11, 066501. [Google Scholar] [CrossRef]

- Du, J.; Bu, Y.; Shen, Z. Interfacial properties and nanostructural characteristics of epoxy resin in cement matrix. Constr. Build. Mater. 2018, 164, 103–112. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Hailatihan, B.; Mi, L.; Baheti, Y.; Yan, Y. Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers 2022, 14, 1087. [Google Scholar] [CrossRef]

- Heng, Y.; Qi, X.; Xu, L.; Yan, Y.; Ni, Q. Development of high-strength carbon fiber/thermoplastic epoxy resin composites and it’s recyclability. Polym. Compos. 2024, 45, 8657–9619. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, S. Thermal, mechanical properties and morphology of epoxy resins modified with light pyrolysis natural rubber. Adv. Polym. Technol. 2018, 37, 2541–2551. [Google Scholar] [CrossRef]

- Yu, P.; He, H.; Jiang, C.; Wang, D.; Jia, Y.; Zhou, L.; Jia, D.M. Reinforcing styrene butadiene rubber with lignin-novolac epoxy resin networks. Express Polym. Lett. EBSCOhost 2015, 9, 36. [Google Scholar] [CrossRef]

- Wolk, A.; Rosenthal, M.; Weiß, J.; Voigt, M.; Wesendahl, J.-N.; Hartmann, M.; Grundmeier, G.; Wilhelm, R.; Meschut, G.; Tiemann, M.; et al. Graphene oxide as flexibilizer for epoxy amine resins. Prog. Org. Coat. 2018, 122, 280–289. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Z.; Pang, J.; Su, L. Preparation of carbon fibre-reinforced composite panels from epoxy resin matrix of nano lignin polyol particles. J. Clean. Prod. 2023, 428, 139170. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Z.; Pang, J.; Su, L. Study on the preparation of epoxy resin materials from nano-lignin polyols. Ind. Crops Prod. 2022, 185, 115158. [Google Scholar] [CrossRef]

- Peng, Z.; Zeng, W.; Feng, Q.; Zheng, Y. Study on Improving the Toughness of Silicate Cement Stone by Modified Epoxy Resin. Silicon 2023, 15, 3137–3148. [Google Scholar] [CrossRef]

- Zhang, N.; Qu, C.; Li, S.; Wang, C.; Xu, M.; Yang, Z.; Zhang, X.; Wang, T.; Wang, Q. Significantly enhanced tribology and thermal management by dual-network graphene/epoxy composites. Tribol. Int. 2021, 164, 107239. [Google Scholar] [CrossRef]

- Kurien, R.A.; Selvaraj, D.P.; Sekar, M.; Koshy, C.P.; Praveen, K.M.; Mechanical, C. Tribological and Morphological Properties of Epoxy Resin Composites Reinforced with Multi-Walled Carbon Nanotubes. Arab. J. Sci. Eng. 2022, 47, 8059–8067. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, Y.L.; Peng, S.G.; Guo, D.; Wen, S.Z. Core-shell nanospheres to achieve ultralow friction polymer nanocomposites with superior mechanical properties. Nanoscale 2019, 11, 8237–8246. [Google Scholar] [CrossRef]

- Nanda, T.; Singh, K.; Shelly, D.; Mehta, R. Advancements in multi-scale filler reinforced epoxy nanocomposites for improved impact strength: A review. Crit. Rev. Solid State Mater. Sci. 2021, 4, 281–329. [Google Scholar] [CrossRef]

- Zanurin, A.; Johari, N.A.; Alias, J.; Ayu, H.M.; Redzuan, N.; Izman, S. Research progress of sol-gel ceramic coating: A review. ScienceDirect 2022, 48, 1849–1854. [Google Scholar] [CrossRef]

- Zhao, G.; Li, J.; Wang, H.; Chen, S.; Li, Z.; Lv, B.; Liu, W.; Gao, G.; Ren, J.; Yang, D. Improved tribological performance of epoxy composites containing core–shell PE wax@SiO2 nanoparticles. Polym. Eng. Sci. 2022, 62, 2863–2877. [Google Scholar] [CrossRef]

- Li, H.; Ma, Y.; Li, Z.; Ji, J.; Zhu, Y.; Wang, H. High temperature resistant polysulfone/silica double-wall microcapsules and their application in self-lubricating polypropylene. RSC Adv. 2017, 7, 50328–50335. [Google Scholar] [CrossRef]

- Tang, Z.; Guo, L.; Xu, M.; Ruan, H.; Yang, G.; Wang, T.; Zhang, J.; Wang, Q.; Zhang, Y. Tribological behavior of shape memory cyanate ester materials and their tunable friction mechanism. Friction 2023, 11, 1794–1803. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, G.; Li, Z.; Zeng, X.; Xu, Y.; Zhao, S.; Hu, H.; Zhang, Y.; Ren, T. Tribological behavior of Ti-6Al-4V against cortical bone in different biolubricants. J. Mech. Behav. Biomed. Mater. 2019, 90, 460–471. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, L.; Wang, Y.; Kong, X.; Li, Y.; Cao, S.; Hu, W.; Zhang, G.; Wang, C. Improved Tribological Properties of Epoxy Cement Reinforced with Impact-Resistant Core-Shell Structured Polymer Nanoparticles. Lubricants 2024, 12, 267. https://doi.org/10.3390/lubricants12080267

Qiu L, Wang Y, Kong X, Li Y, Cao S, Hu W, Zhang G, Wang C. Improved Tribological Properties of Epoxy Cement Reinforced with Impact-Resistant Core-Shell Structured Polymer Nanoparticles. Lubricants. 2024; 12(8):267. https://doi.org/10.3390/lubricants12080267

Chicago/Turabian StyleQiu, Ling, Yuan Wang, Xiaolan Kong, Yanan Li, Shiyu Cao, Wenbin Hu, Gangqiang Zhang, and Chenchen Wang. 2024. "Improved Tribological Properties of Epoxy Cement Reinforced with Impact-Resistant Core-Shell Structured Polymer Nanoparticles" Lubricants 12, no. 8: 267. https://doi.org/10.3390/lubricants12080267

APA StyleQiu, L., Wang, Y., Kong, X., Li, Y., Cao, S., Hu, W., Zhang, G., & Wang, C. (2024). Improved Tribological Properties of Epoxy Cement Reinforced with Impact-Resistant Core-Shell Structured Polymer Nanoparticles. Lubricants, 12(8), 267. https://doi.org/10.3390/lubricants12080267