Friction and Wear Mechanisms of Ti3SiC2/Cu Composites under the Synergistic Effect of Velocity–Load Field at 800 °C

Abstract

1. Introduction

2. Experiment

2.1. Sample Preparation

2.2. Friction and Wear Test

2.3. Characterization

3. Results and Discussion

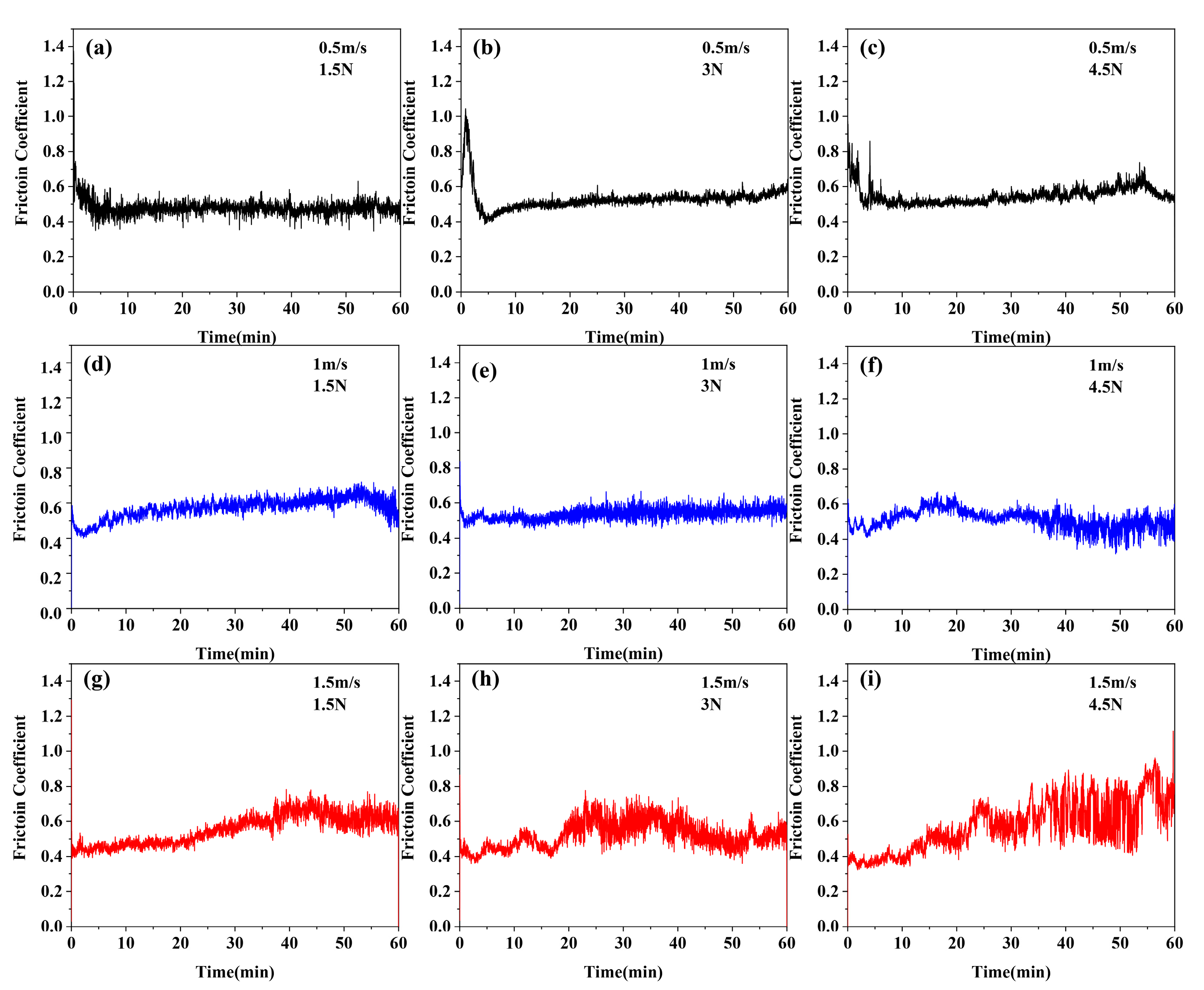

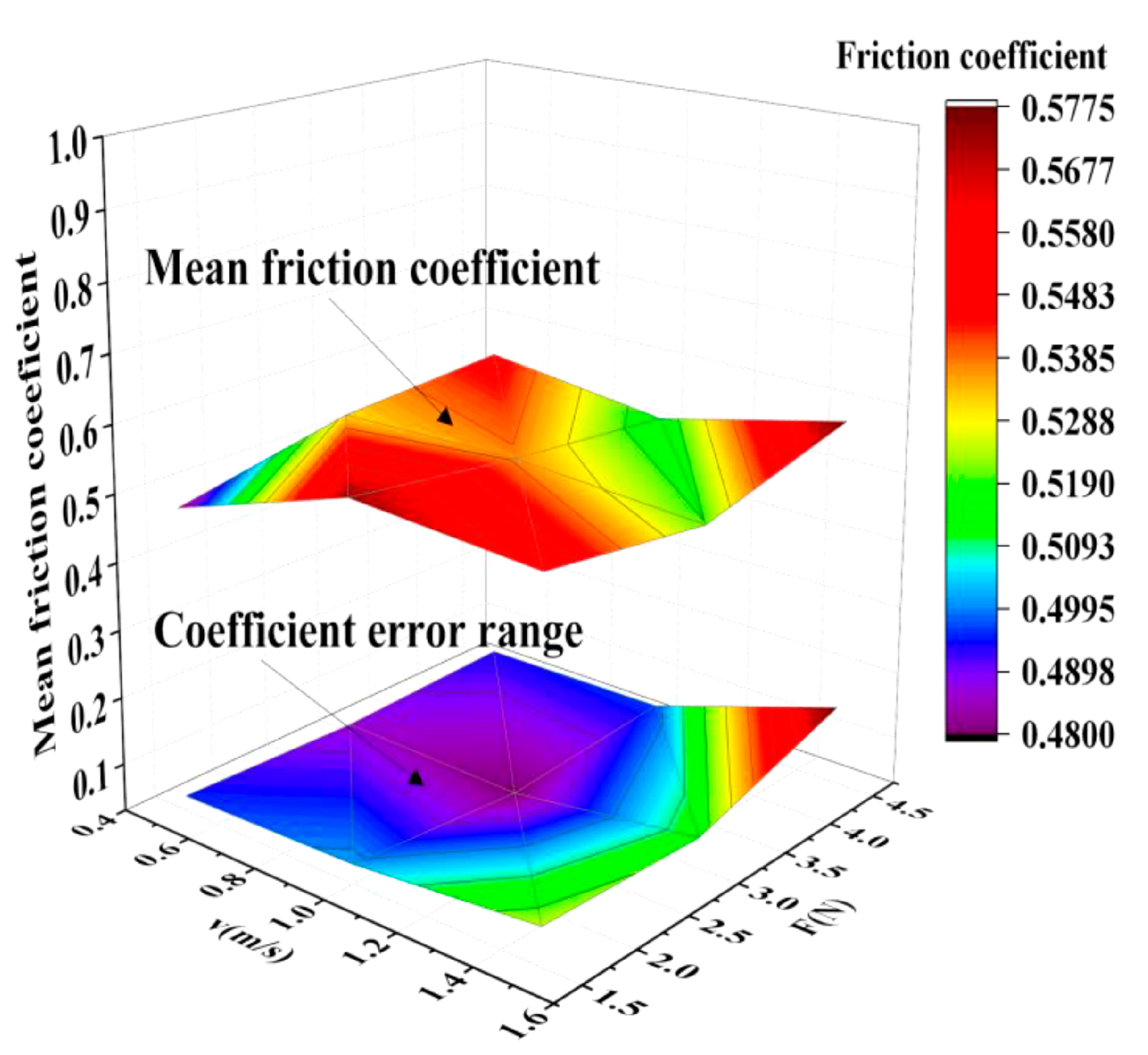

3.1. Friction Coefficients and Wear Rates

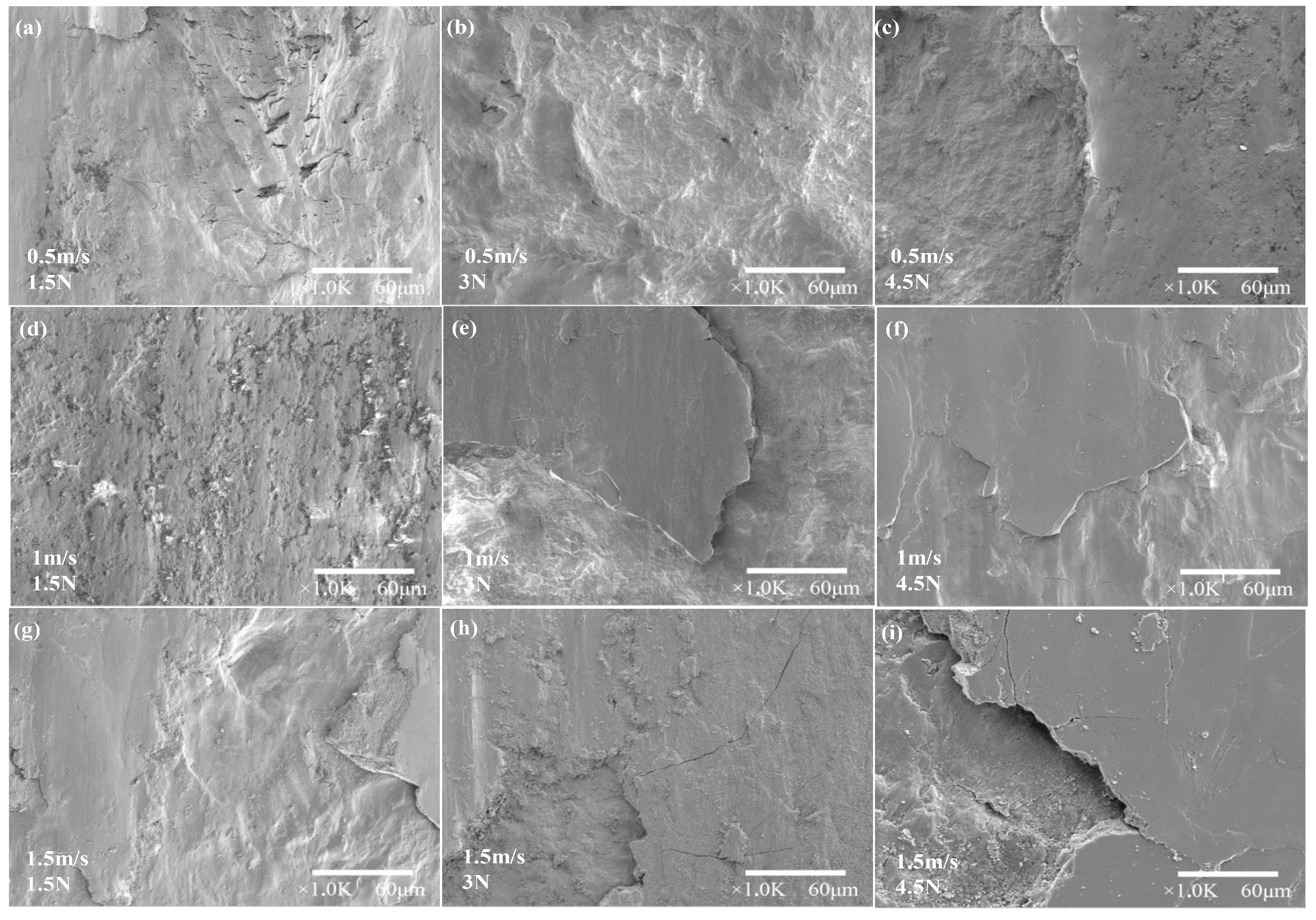

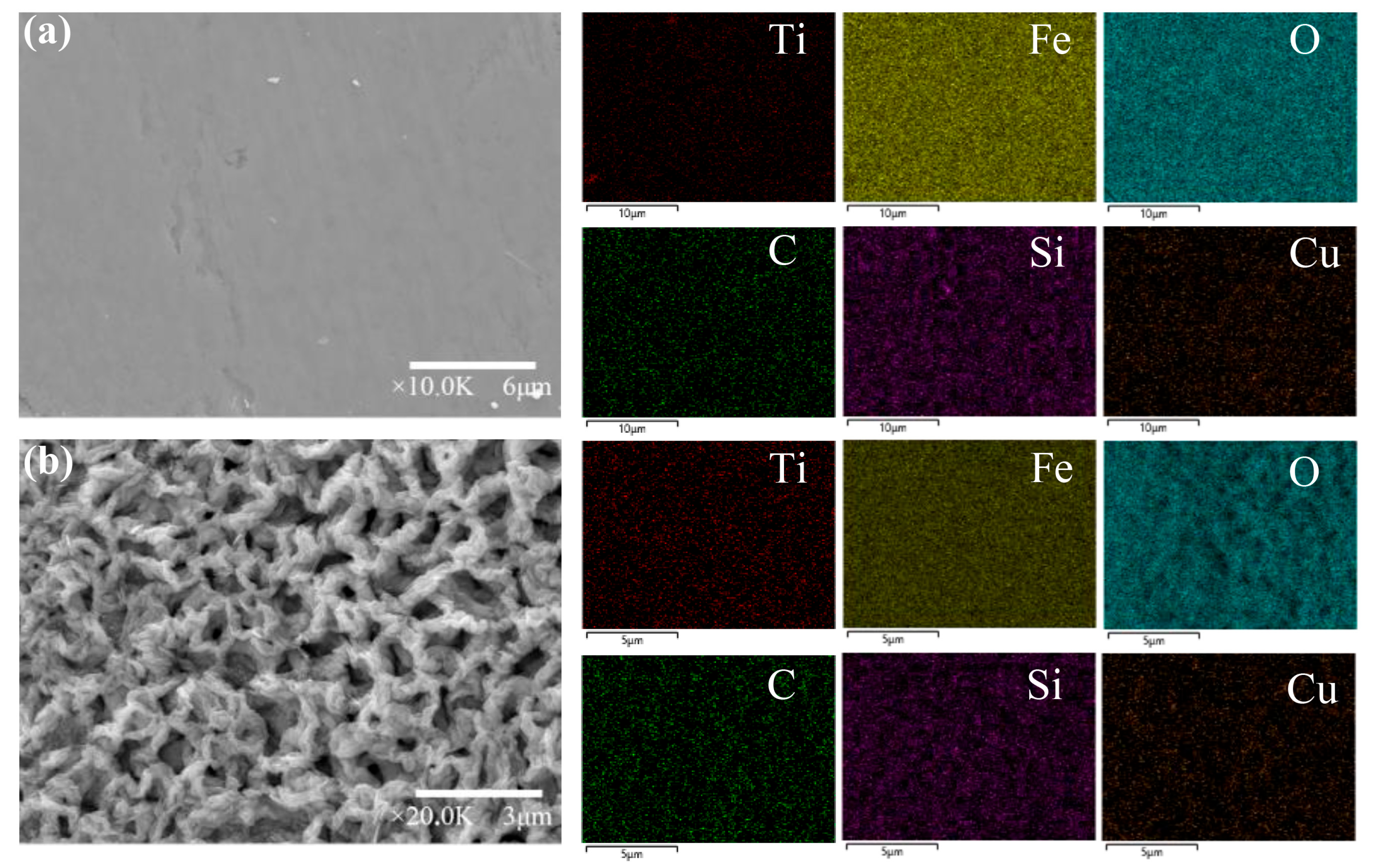

3.2. Morphology and Composition of Worn Surfaces

3.3. Friction Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, X.; Zou, H.; Diao, Q.; Wang, C.; Wang, Y.; Li, H.; Sui, T.; Lin, B.; Yan, S. Surface modification technologies for enhancing the tribological properties of cemented carbides: A review. Tribol. Int. 2023, 180, 108257. [Google Scholar] [CrossRef]

- Xue, Y.; Ye, Y.; Guo, J.; Qian, W.; Jin, Z.; Dai, F.; Hua, Y.; Cai, J. Microstructural evolution and high-temperature oxidation resistance of NiCoCrAlYSiHf coatings after surface thermal modification with millisecond laser. Appl. Surf. Sci. 2024, 644, 158697. [Google Scholar] [CrossRef]

- Ye, W.; Shi, Y.; Zhou, Q.; Xie, M.; Wang, H.; Bou-Saïd, B.; Liu, W. Recent advances in self-lubricating metal matrix nanocomposites reinforced by carbonous materials: A review. Nano Mater. Sci. 2024, in press. [Google Scholar] [CrossRef]

- Silvestroni, L.; Melandri, C.; Gonzalez-Julian, J. Exploring processing, reactivity and performance of novel MAX phase/ultra-high temperature ceramic composites: The case study of Ti3SiC2. J. Eur. Ceram. Soc. 2021, 41, 6064–6069. [Google Scholar] [CrossRef]

- Singh, J.; Wani, M.F. Fretting wear of spark plasma sintered Ti3SiC2/GNP ceramic composite against Si3N4. Ceram. Int. 2021, 47, 5648–5655. [Google Scholar] [CrossRef]

- Wang, J.; Ge, Y.; Ma, Y.; Qu, C.; Li, X.; Qu, S. Synergistic effect of the combined surface modification technology on rotational bending fatigue of low carbon alloy steel. Vacuum 2023, 212, 111993. [Google Scholar] [CrossRef]

- Azina, C.; Poll, M.; Holzapfel, D.M.; Tailleur, E.; Zuber, A.; Dubois, S.; Eklund, P.; Gonzalez-Julian, J. Microstructural and compositional design of Cr2AlC MAX phases and their impact on oxidation resistance. J. Eur. Ceram. Soc. 2024, 44, 4895–4904. [Google Scholar] [CrossRef]

- Vatanpour, V.; Mehrabani, S.A.N.; Dehqan, A.; Arefi-Oskoui, S.; Orooji, Y.; Khataee, A.; Koyuncu, I. Performance improvement of polyethersulfone membranes with Ti3AlCN MAX phase in the treatment of organic and inorganic pollutants. Chemosphere 2024, 362, 142583. [Google Scholar] [CrossRef] [PubMed]

- Cygan, T.; Wozniak, J.; Broniszewski, K.; Kulikowski, K.; Moszczyńska, D.; Adamczyk-Cieślak, B.; Kurkowska, M.; Olszyna, A. Analysis of microstructure and mechanical properties of alumina composites reinforced with Ti2AlN MAX phases. Int. J. Refract. Met. Hard Mater. 2024, 122, 106725. [Google Scholar] [CrossRef]

- Wei, X.; Li, L.; Liu, F.; Fan, L.; Wu, Y. Synthesis, microstructure, and mechanical properties of MAX phase Ti2GaC ceramics with V doping. Ceram. Int. 2024, 50, 15806–15820. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, W.; Jin, Y.; Wu, S.; Hu, T.; Li, Y.; Xiao, X. Study of the interfacial reaction between Ti3SiC2 particles and Al matrix. J. Alloys Compd. 2018, 738, 1–9. [Google Scholar] [CrossRef]

- Wang, L.; Tong, Y.G.; Zhou, C.; Li, Y.J.; Liu, J.; Cai, Z.H.; Wang, H.D.; Hu, Y.L. Self-lubricating Ti3SiC2 strengthening Cu composites with electrical conductivity and wear resistance trade off. Tribol. Int. 2023, 187, 108724. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, J.; Qian, Y.; Liu, H.; Zuo, J.; Ma, K.; Li, M. Electrical conductivities and mechanical properties of Ti3SiC2 reinforced Cu-based composites prepared by cold spray. J. Alloys Compd. 2023, 946, 169473. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Lei, Q.; Xiao, S.; Jiang, Y. Effect of Ti3SiC2 replacing graphite on the microstructure and properties of Cu-Sn matrix composites. Tribol. Int. 2024, 194, 109540. [Google Scholar] [CrossRef]

- Shu, R.; Jiang, X.; Liu, W.; Shao, Z.; Song, T.; Luo, Z. Synergetic effect of nano-carbon and HBN on microstructure and mechanical properties of Cu/Ti3SiC2/C nanocomposites. Mater. Sci. Eng. A 2019, 755, 128–137. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, R.; Liu, F.Y.; Wu, C.L.; Zhang, H.M.; Sun, M.; Tulugan, K. Effect of full melt temperature sintering and semi-melt heat preservation sintering on microstructure and mechanical properties of Ti3SiC2/Cu composites. Mater. Res. Express 2024, 11, 13. [Google Scholar] [CrossRef]

- Magnus, C. Sliding wear of MAX phase composites Ti3SiC2–TiC and Ti3SiC2–Ti2AlC at 400 °C and the influence of counterface material (steel, Al2O3, and Si3N4) on wear behaviour. Wear 2023, 516–517, 204588. [Google Scholar] [CrossRef]

- Wang, Q.; Peng, Y.; Jiang, W.; Xu, H.; Hai, W.; Shao, Q.; Li, A. Effect of high temperature oxidation on mechanical and electromagnetic interference shielding effectiveness of Ti3SiC2 modified SiCf/BN/SiBCN composites. Ceram. Int. 2024, 50, 20167–20175. [Google Scholar] [CrossRef]

- Gou, R.; Luo, X. Friction behavior and wear mechanism of the PDC-CR in comparison with different friction pairs at high temperatures. Ceram. Int. 2024, 50, 8132–8140. [Google Scholar] [CrossRef]

- Liu, G.-L.; Sun, X.-X.; Cai, Y.-Y.; Li, Z.-Q.; Xu, F.-H.; Cao, Y.-H.; Liu, H.-X.; Zhou, J.-Z.; Cheng, X.-N. High-temperature dry sliding friction and wear behavior of Ni60A coating on the 20CrNiMo alloy surface treated by laser shock peening and its bonding zone. J. Mater. Res. Technol. 2024, 29, 2902–2911. [Google Scholar] [CrossRef]

- Meng, X.; Cui, Z.; Huang, L.; Xia, C.; Lei, Q. Effects of loads and speeds on friction and wear properties of Cu–Ti alloys processed by combination aging treatments. J. Mater. Res. Technol. 2023, 26, 948–960. [Google Scholar] [CrossRef]

- Kandasamy, K.P.J. Effect of load and sliding velocity on wear behaviour of magnesium AZ91D composites reinforced with Ca2SiO4 at ambient temperature. Tribol. Int. 2024, 192, 109314. [Google Scholar]

| Velocity/m·s−1 | 0.5 | 1 | 1.5 | ||

|---|---|---|---|---|---|

| No. | |||||

| Load/N | |||||

| 1.5 | a | d | g | ||

| 3 | b | e | h | ||

| 4.5 | c | f | i | ||

| Position | Sample | Velocity (m/s) | Load (g) | Atomic Percentage |

|---|---|---|---|---|

| Figure 4a | pin | 0.5 | 150 | 7.65% Ti, 0.56% Si, 5.69% C, 0.55% Cu, 31.88% Fe, 53.67% O |

| Figure 4b | pin | 0.5 | 300 | 0.33% Ti, 0.29% Si, 7.2% C, 0.08% Cu, 38.22% Fe, 53.88% O |

| Figure 4c | pin | 0.5 | 450 | 0.46% Ti, 0.29% Si, 9.65% C, 0.55% Cu, 33.19% Fe, 55.85% O |

| Figure 4d | pin | 1 | 150 | 0.21% Ti, 0.23% Si, 18.52% C, 0.75% Cu, 25.91% Fe, 54.38% O |

| Figure 4e | pin | 1 | 300 | 0.18% Ti, 0.26% Si, 7.35% C, 0% Cu, 38.65% Fe, 53.56% O |

| Figure 4f | pin | 1 | 450 | 0.29% Ti, 0.34% Si, 5.65% C, 0.59% Cu, 43.1% Fe, 50.03% O |

| Figure 4g | pin | 1.5 | 150 | 1.49% Ti, 0.59% Si, 8.31% C, 1.28% Cu, 30.83% Fe, 57.5% O |

| Figure 4h | pin | 1.5 | 300 | 0.52% Ti, 0.23% Si, 7.25% C, 0.4% Cu, 39.64% Fe, 51.97% O |

| Figure 4i | pin | 1.5 | 450 | 1.35% Ti, 0.53% Si, 8.45% C, 1.09% Cu, 43.89% Fe, 44.69% O |

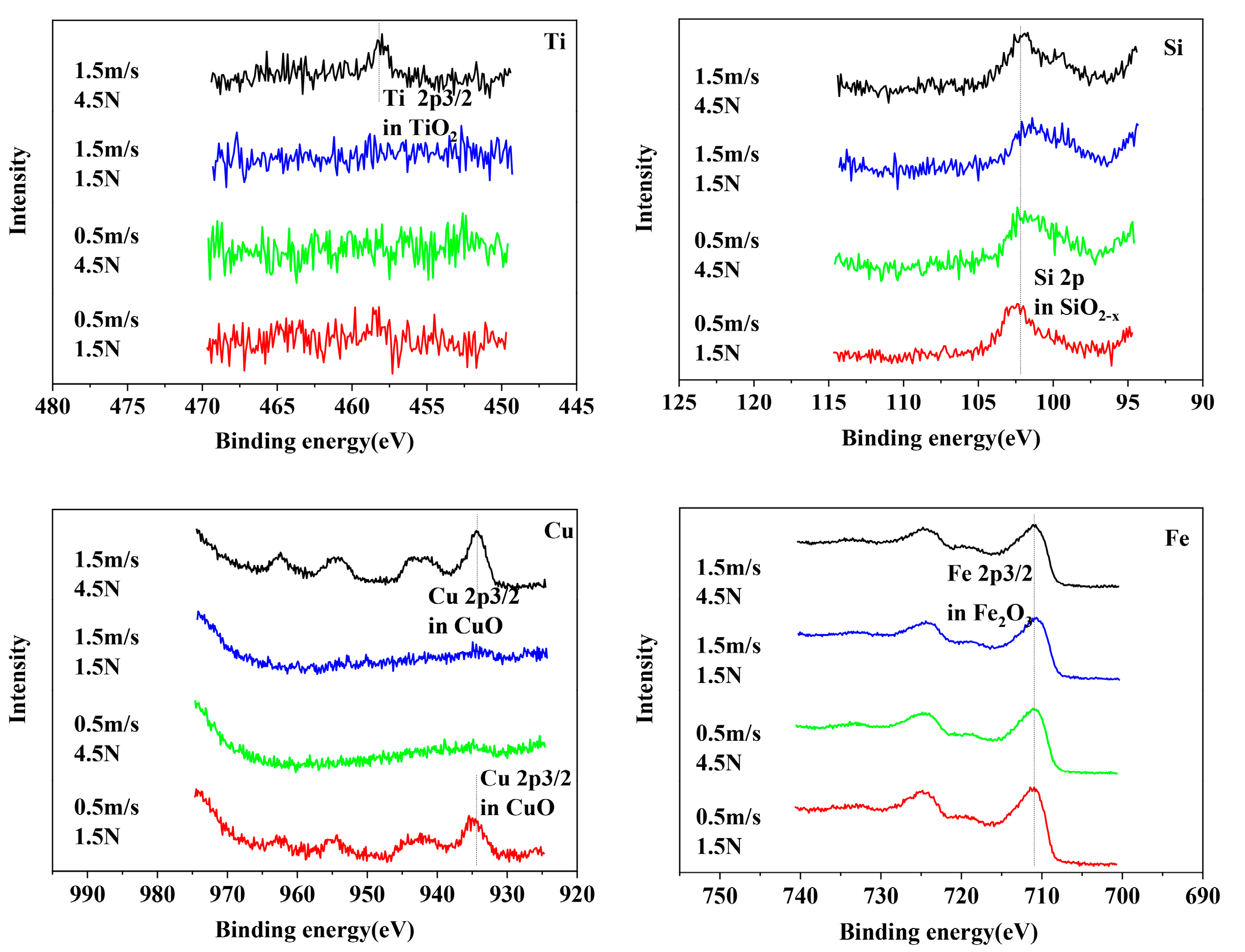

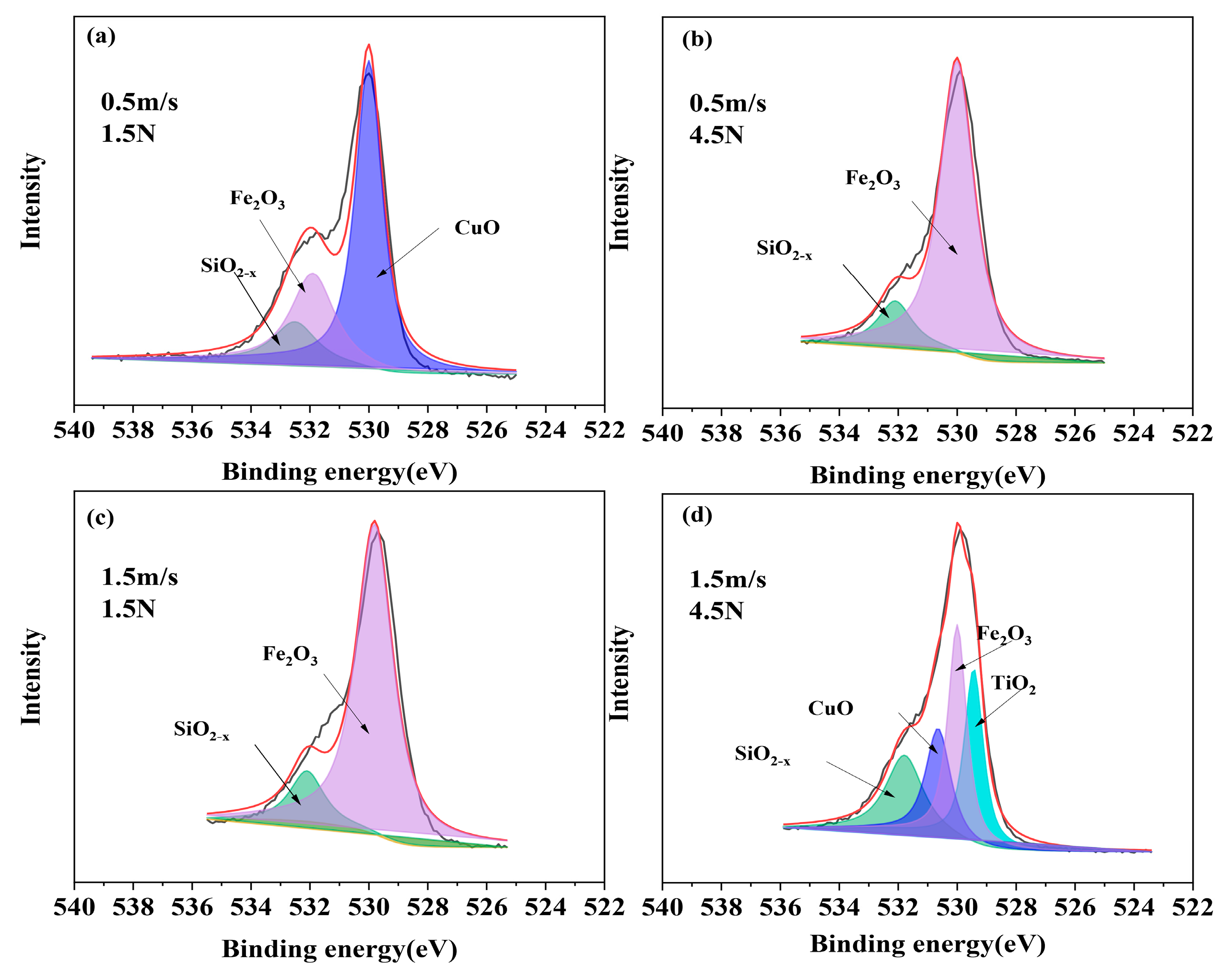

| Oxide | Relative Peak Area (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Oxides of Ti | Oxides of Si | Oxides of Cu | Oxides of Fe | Oxides of Ti | Oxides of Si | Oxides of Cu | Oxides of Fe | |

| a | / | SiO2−x | CuO | Fe2O3 | / | 13.4 | 27.6 | 59.0 |

| b | / | SiO2−x | / | Fe2O3 | / | 11.7 | / | 88.3 |

| c | / | SiO2−x | / | Fe2O3 | / | 13.5 | / | 86.5 |

| d | TiO2 | SiO2−x | CuO | Fe2O3 | 27.2 | 19.4 | 20.2 | 33.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Lei, B.; Chen, B.; Liu, F. Friction and Wear Mechanisms of Ti3SiC2/Cu Composites under the Synergistic Effect of Velocity–Load Field at 800 °C. Lubricants 2024, 12, 265. https://doi.org/10.3390/lubricants12080265

Zhang R, Lei B, Chen B, Liu F. Friction and Wear Mechanisms of Ti3SiC2/Cu Composites under the Synergistic Effect of Velocity–Load Field at 800 °C. Lubricants. 2024; 12(8):265. https://doi.org/10.3390/lubricants12080265

Chicago/Turabian StyleZhang, Rui, Bo Lei, Biao Chen, and Fuyan Liu. 2024. "Friction and Wear Mechanisms of Ti3SiC2/Cu Composites under the Synergistic Effect of Velocity–Load Field at 800 °C" Lubricants 12, no. 8: 265. https://doi.org/10.3390/lubricants12080265

APA StyleZhang, R., Lei, B., Chen, B., & Liu, F. (2024). Friction and Wear Mechanisms of Ti3SiC2/Cu Composites under the Synergistic Effect of Velocity–Load Field at 800 °C. Lubricants, 12(8), 265. https://doi.org/10.3390/lubricants12080265