Assessing the Potential of Bio-Based Friction Modifiers for Food-Grade Lubrication

Abstract

1. Introduction

2. Materials and Methods

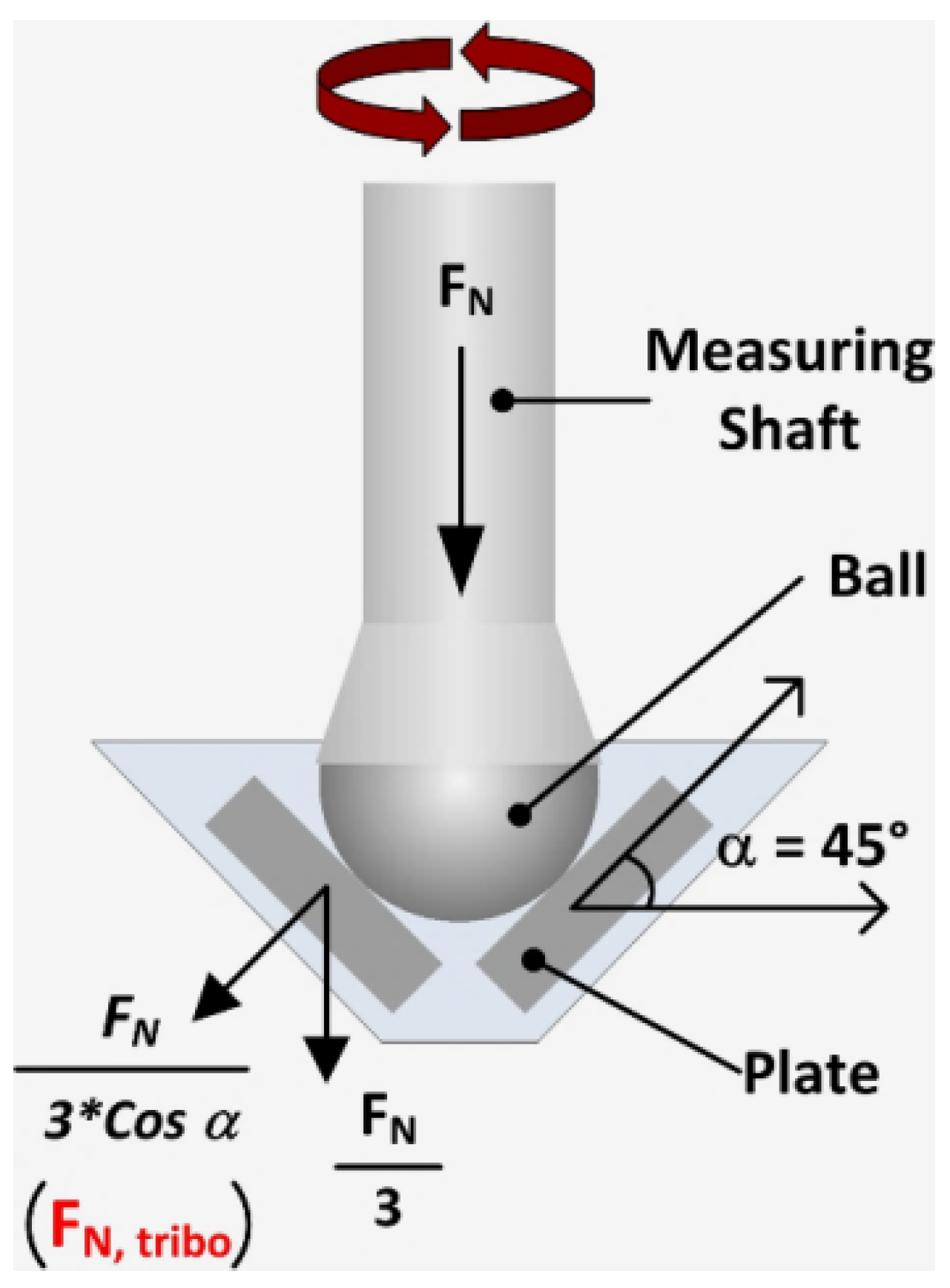

2.1. Tribological Tests

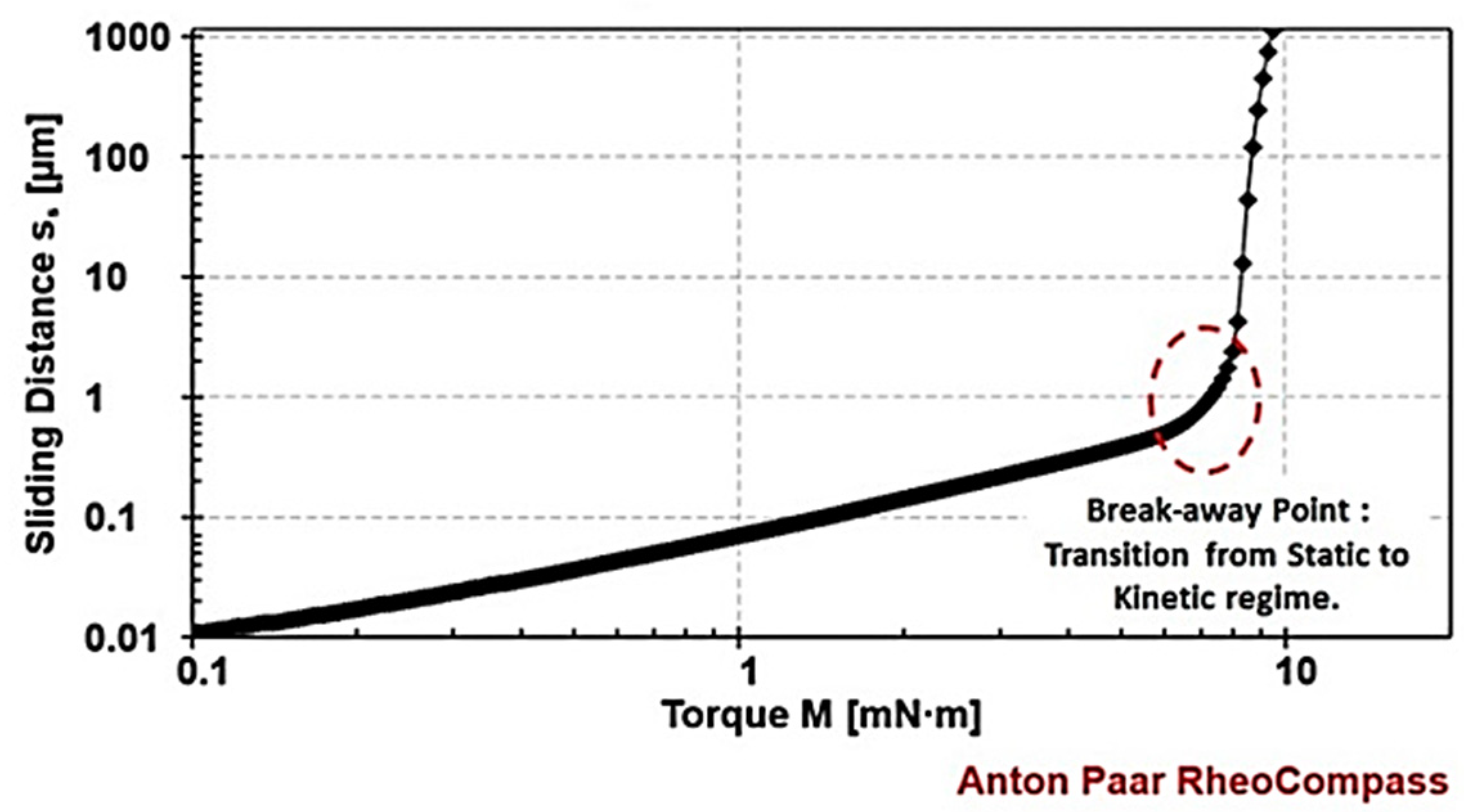

2.1.1. Breakaway Torque

2.1.2. Use Case 1—Cold Extrusion

2.1.3. Use Case 2—Warm Extrusion

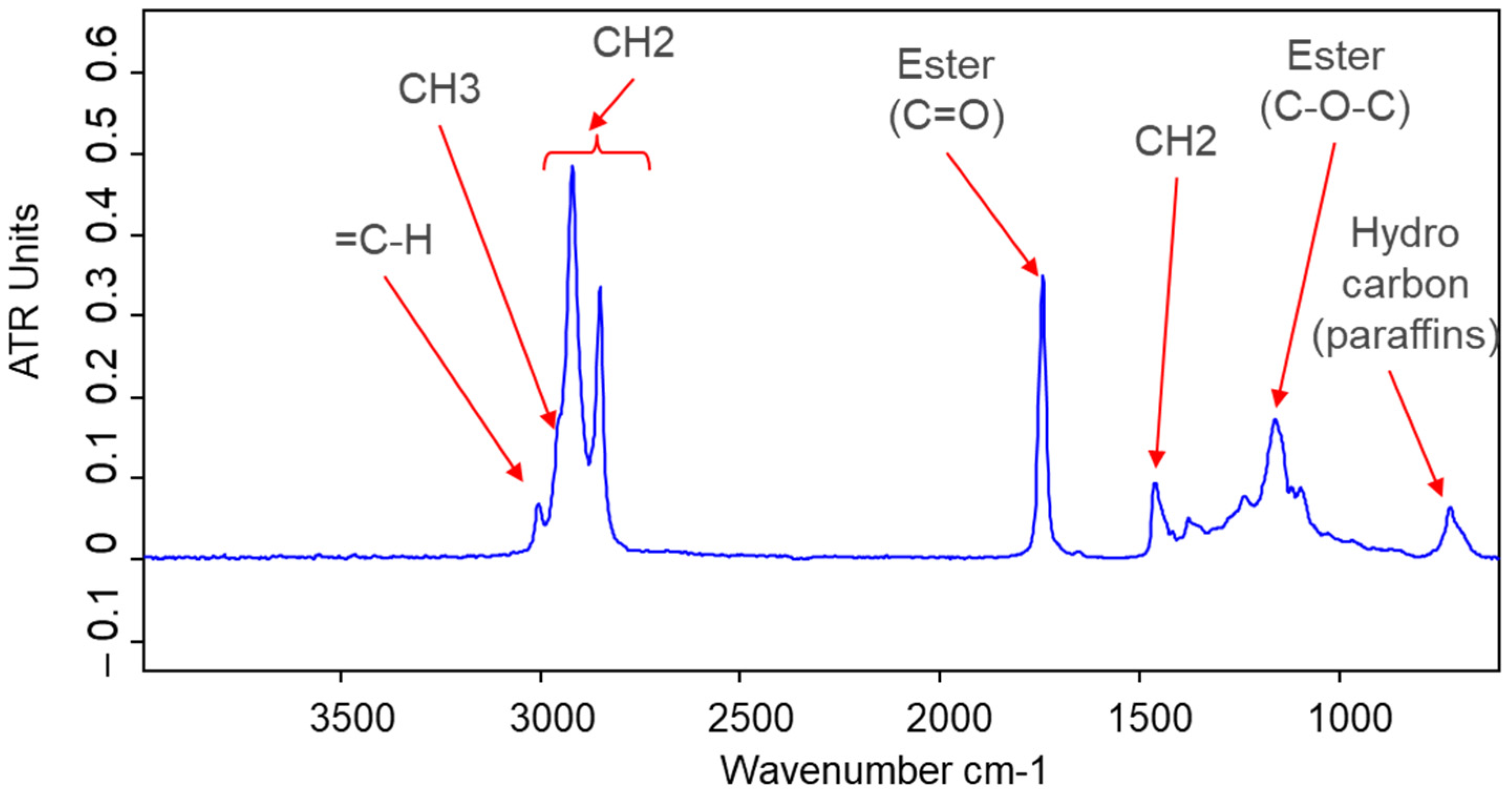

2.2. Sample Characterization

3. Results and Discussion

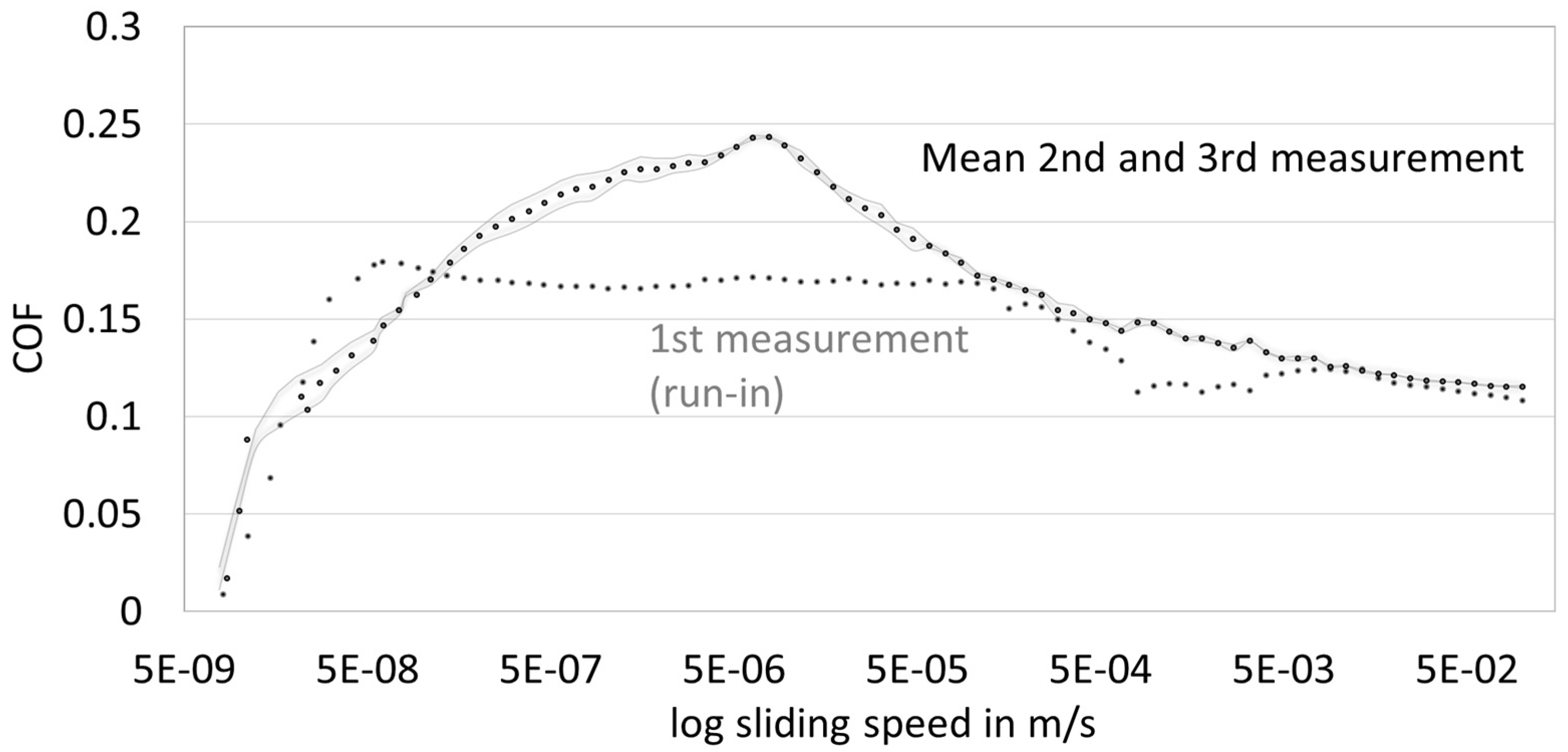

3.1. Tribological Tests

3.1.1. Breakaway Torque

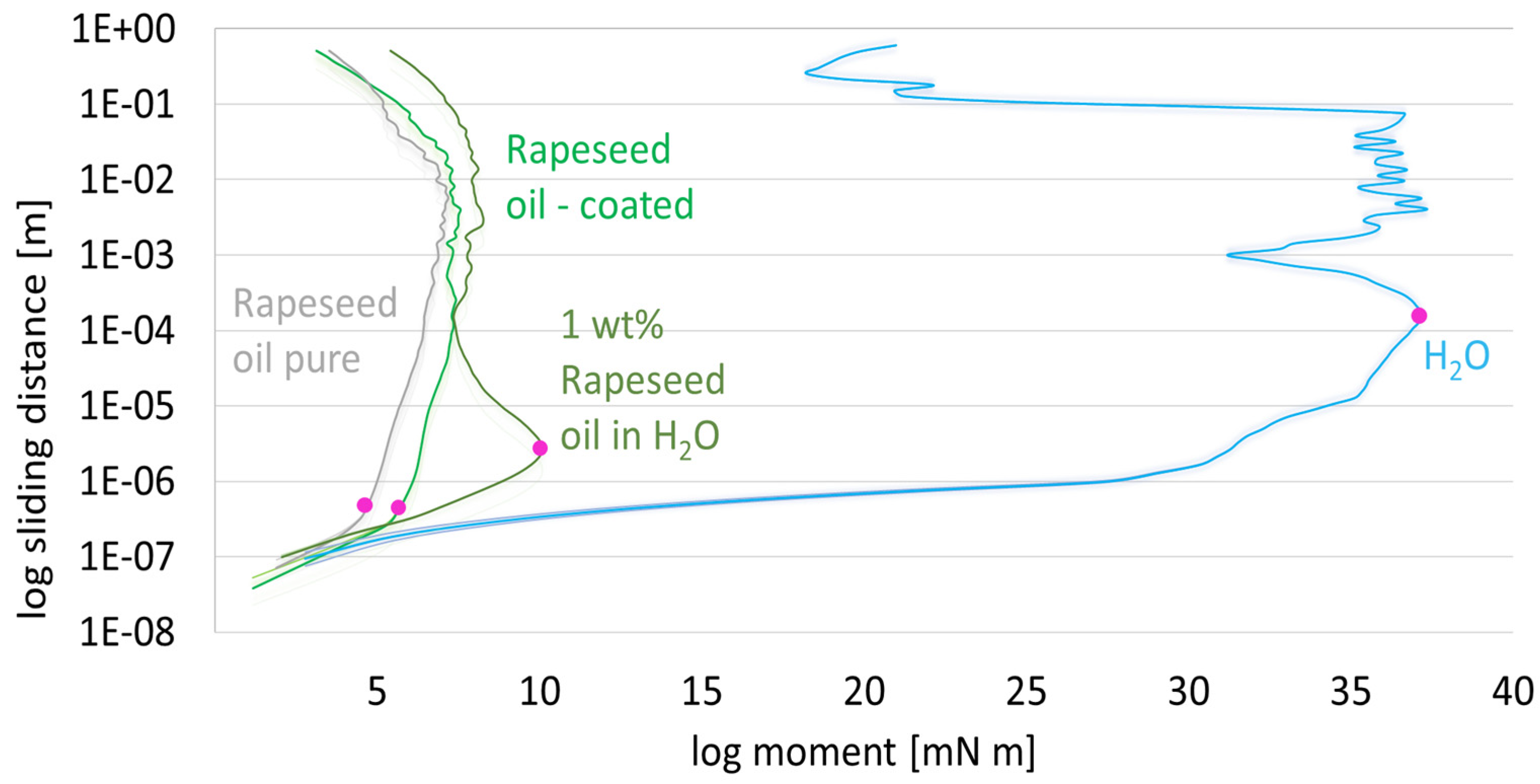

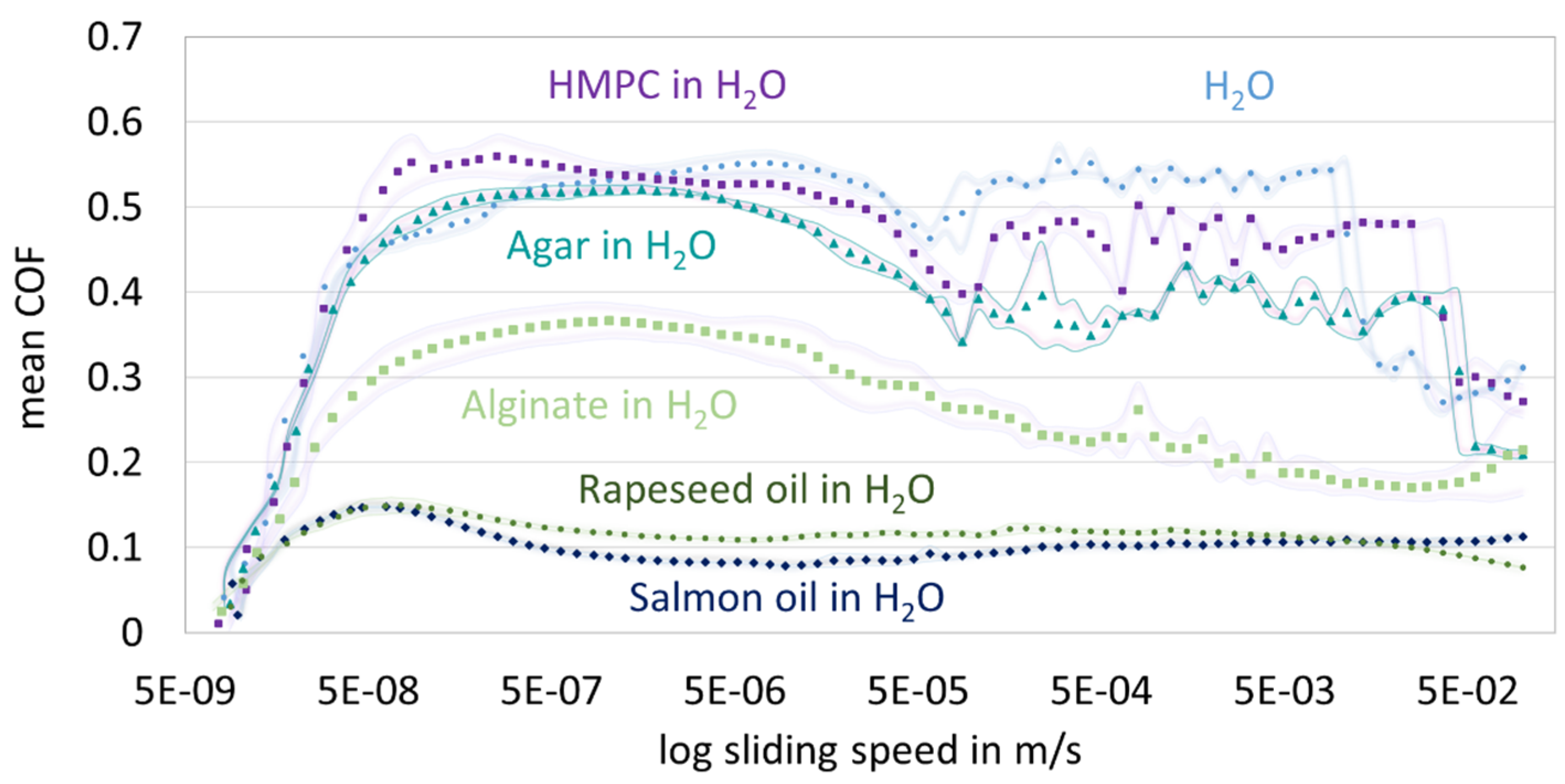

3.1.2. Use Case 1—Cold Extrusion

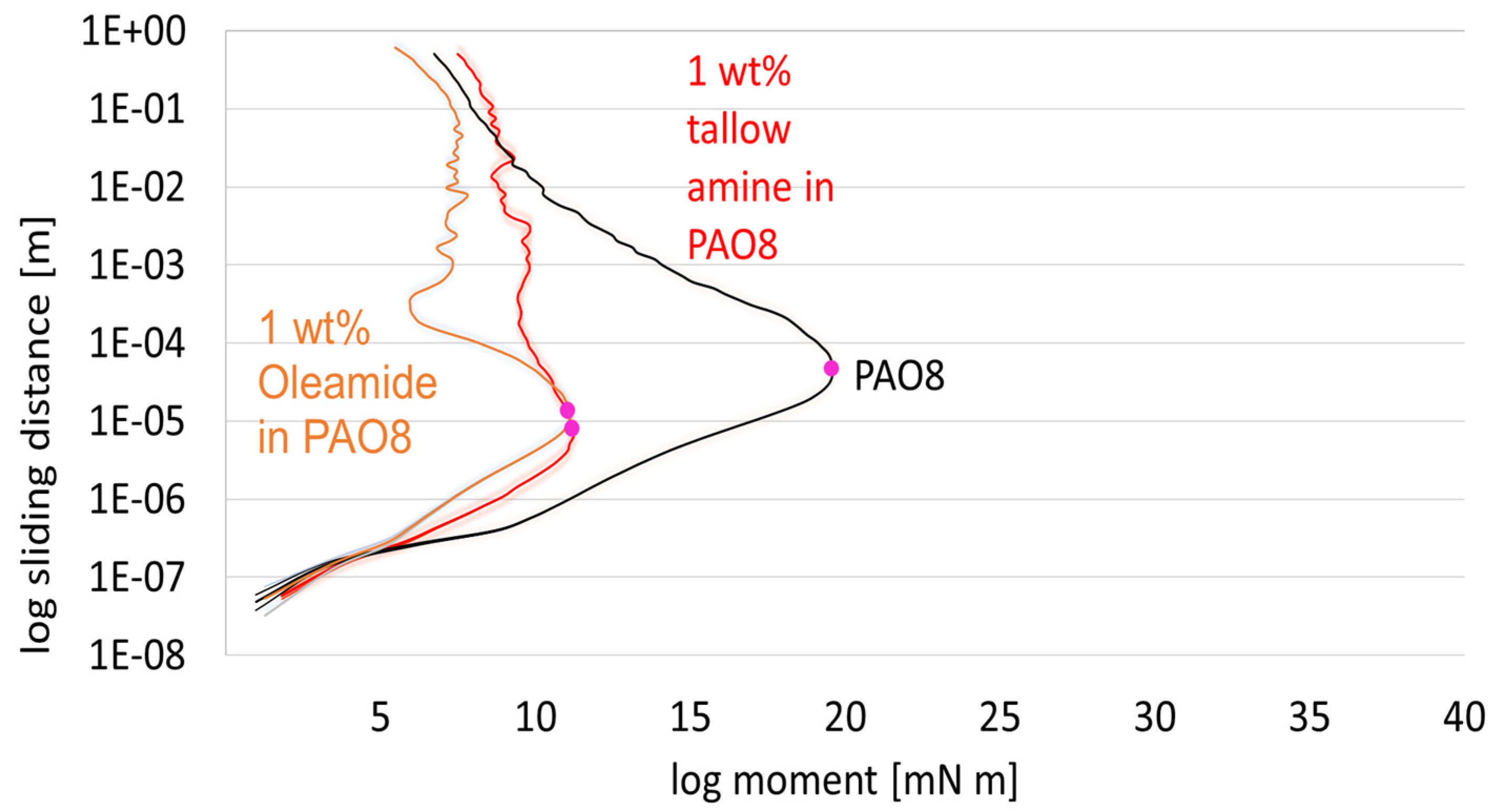

3.1.3. Use Case 2—Warm Extrusion

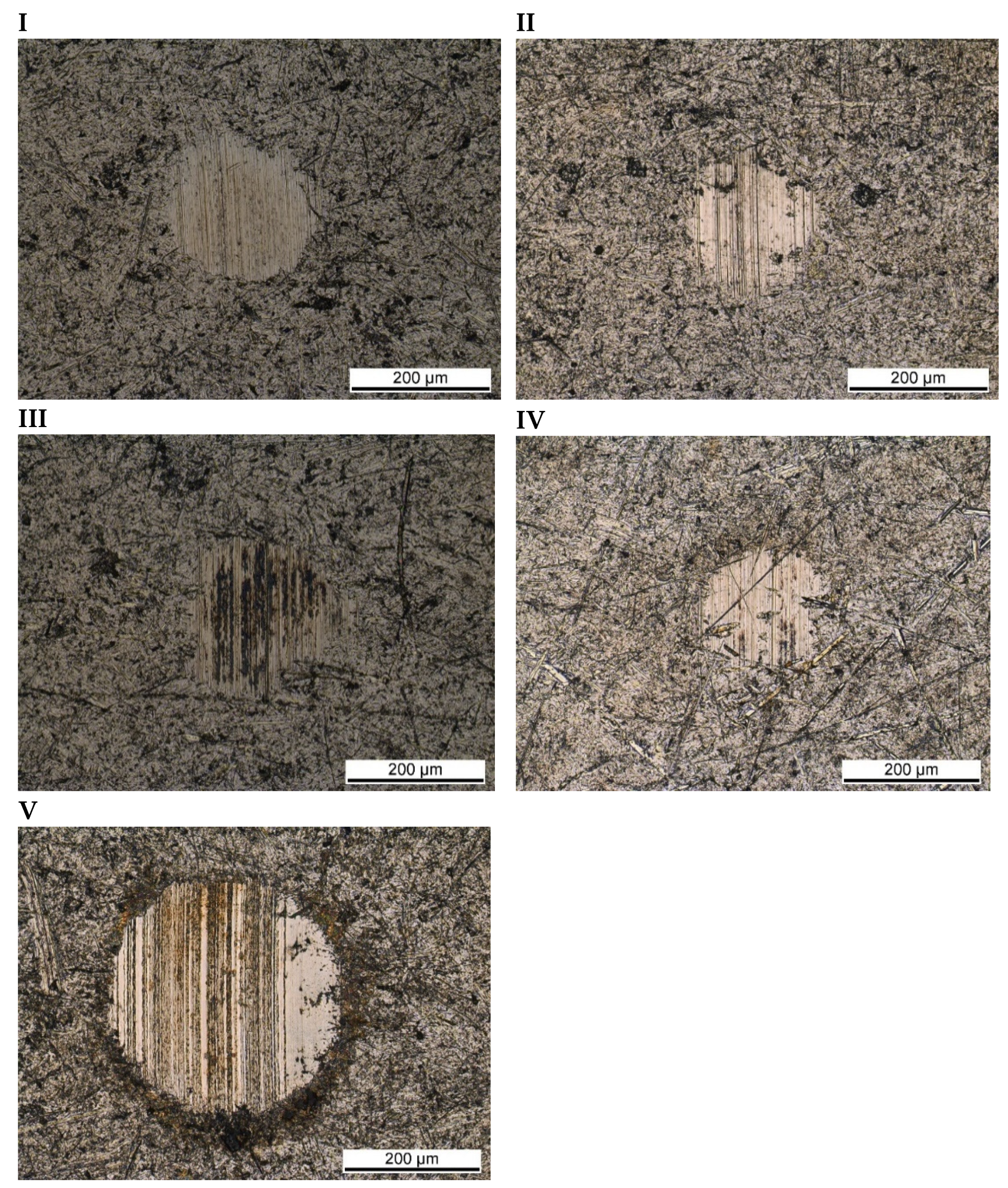

3.2. Characterization of Samples after Tribological Tests

4. Conclusions

- The performed tests of all the conventional FMs in oil mixtures and the best-performing bio-based FMs in both oil and water mixtures underline the working range of FMs, namely in the boundary and/or mixed lubrication regimes.

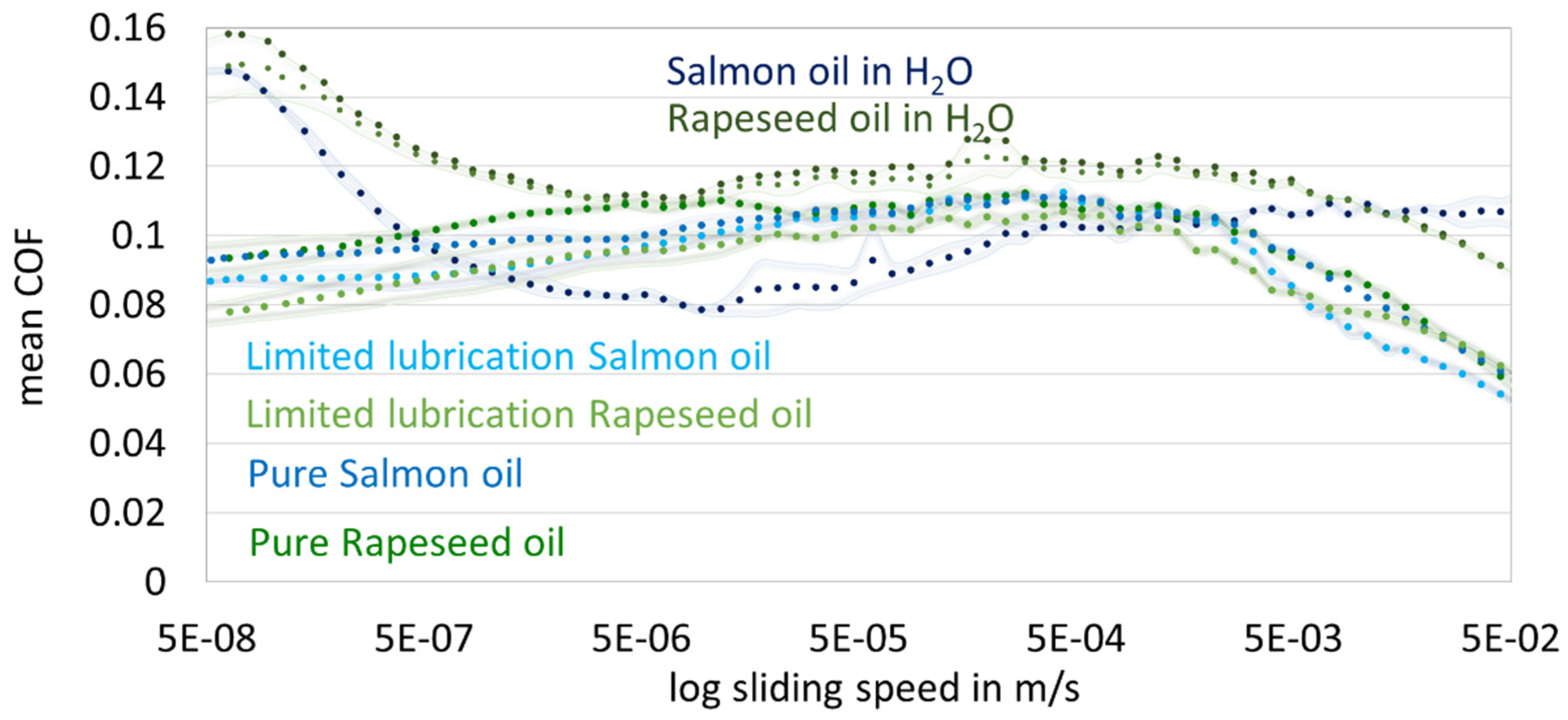

- The worst performer (distilled water at 30 °C) and the best performers (pure and limited lubrication of the rapeseed and salmon oil in water at 30 °C) depict wear formation, indicating the initial boundary lubrication.

- The friction and wear characteristics of the best-performing bio-based FMs (salmon oil and rapeseed oil) in 1 wt% water mixtures and in pure lubrication (without water) are comparable. Thus, the 1 wt% bio-based FM water mixtures should be considered from a sustainable point of view. However, relubrication must be considered since the minimal concentration of oil could lead to a reduced service life of the machine.

- The best bio-based FMs (salmon oil and rapeseed oil) in PAO8 possess the frictional characteristics to replace the best conventional FM (tallow amine) in PAO8.

- By interpreting the breakaway torque results, both the bio-based (distilled water) and the conventional (PAO8) references need substantially more torque than the mixtures with the bio-based and conventional FMs to reach the end of the elastic/plastic deformation and the onset of macroscopic motion. Therefore, the usage of the bio-based FMs (1 wt%) in distilled water and of the conventional FMs (1 wt%) in PAO8 can significantly reduce energy consumption in applications such as extruders and two-role presses.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B. The ICP-OES Results for the Conventional and Bio-Based FMs; Elements below 10 ppm Were Excluded (Co, Cr, Cu, Li, Mn, Mo, Ni, Sb, Sn, Ti, V, W, Zn); Both Modified Accordingly [13]

| Name | Al | B | Ba | Ca | Fe | K |

|---|---|---|---|---|---|---|

| Hydroxypropyl methylcelullose | 5 | <5 | <1 | 11 | 14 | <10 |

| Agar | 11 | 144 | 1 | 3100 | 22 | 286 |

| Alginic acid calcium salt from brown algae | 154 | <5 | 30 | >14,500 | 147 | 250 |

| Salmon oil | <5 | <5 | <1 | <5 | <1 | <10 |

| Rapeseed oil | <5 | <5 | <1 | 5 | <1 | <10 |

| Borate ester | 26 | >12,600 | <1 | 16 | <1 | <10 |

| Tallow amine | <5 | <10 | <1 | 10 | <1 | <10 |

| Oleamide | <5 | <5 | <1 | 30 | <1 | <10 |

| Methyl ricinoleate | <5 | <5 | <1 | <5 | <1 | <10 |

| Name | Mg | Na | P | Pb | S | Si |

|---|---|---|---|---|---|---|

| Hydroxypropyl methylcelullose | 2 | 3330 | <10 | <10 | 16 | 10 |

| Agar | 992 | 5000 | 49 | <10 | 5290 | 33 |

| Alginic acid calcium salt from brown algae | 827 | 2040 | 75 | <10 | 316 | 140 |

| Salmon oil | <1 | <10 | <10 | <10 | <10 | <10 |

| Rapeseed oil | <1 | <10 | <10 | <10 | <10 | <10 |

| Borate ester | 2 | 65 | <10 | <10 | <10 | <10 |

| Tallow amine | <1 | <10 | <10 | <10 | <10 | <10 |

| Oleamide | 1 | <10 | <10 | <10 | <25 | <10 |

| Methyl ricinoleate | <1 | <10 | <10 | <10 | 50 | <10 |

References

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. A Review on Biolubricants Based on Vegetable Oils through Transesterification and the Role of Catalysts: Current Status and Future Trends. Catalysts 2023, 13, 1299. [Google Scholar] [CrossRef]

- Circular Economy. Available online: https://environment.ec.europa.eu/topics/circular-economy (accessed on 13 May 2024).

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 1–26. [Google Scholar] [CrossRef]

- Karmakar, G.; Ghosh, P. Soybean Oil as a Biocompatible Multifunctional Additive for Lubricating Oil. ACS Sustain. Chem. Eng. 2015, 3, 19–25. [Google Scholar] [CrossRef]

- Dörr, N. Condition Monitoring—Der Schmierstoff Als Informationsträger. 2019. Available online: https://tiss.tuwien.ac.at/course/courseDetails.xhtml?dswid=7175&dsrid=676&courseNr=164346&semester=2019S (accessed on 13 May 2024).

- Singh, A.; Verma, N.; Mamatha, T.; Kumar, A.; Singh, S.; Kumar, K. Properties, functions and applications of commonly used lubricant additives: A review. Mater. Today Proc. 2020, 44, 5018–5022. [Google Scholar] [CrossRef]

- Dresel, W.; Mang, T. (Eds.) Lubricants and Lubrication; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Guegan, J.; Southby, M.; Spikes, H. Friction Modifier Additives, Synergies and Antagonisms. Tribol. Lett. 2019, 67, 83. [Google Scholar] [CrossRef]

- Fry, B.M.; Moody, G.; Spikes, H.A.; Wong, J.S.S. Adsorption of Organic Friction Modifier Additives. Langmuir 2020, 36, 1147–1155. [Google Scholar] [CrossRef] [PubMed]

- Soltanahmadi, S.; Esfahani, E.A.; Nedelcu, I.; Morina, A.; van Eijk, M.C.P.; Neville, A. Surface Reaction Films from Amine-Based Organic Friction Modifiers and Their Influence on Surface Fatigue and Friction. Tribol. Lett. 2019, 67, 80. [Google Scholar] [CrossRef]

- Cyriac, F.; Yi, T.X.; Poornachary, S.K.; Chow, P.S. Behavior and interaction of boundary lubricating additives on steel and DLC-coated steel surfaces. Tribol. Int. 2021, 164, 107199. [Google Scholar] [CrossRef]

- ECHA. Available online: https://echa.europa.eu/de/substance-information/-/substanceinfo/100.005.550 (accessed on 3 May 2024).

- Eder, R.M. Potential of Bio-Based Friction Modifiers for Safe Use in Food-Grade Lubrication. Master’s Thesis, Universität für Bodenkultur Wien, Vienna, Austria, 2021. [Google Scholar]

- ECHA. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.004.063 (accessed on 6 May 2024).

- Richard, S.; Moslemi, S.; Sipahutar, H.; Benachour, N.; Seralini, G.-E. Differential Effects of Glyphosate and Roundup on Human Placental Cells and Aromatase. Environ. Health Perspect. 2005, 113, 716–720. [Google Scholar] [CrossRef]

- Yang, M.; Fan, S.; Huang, H.; Zhang, Y.; Huang, Z.; Hu, H.; Liang, J. In-situ synthesis of calcium borate/cellulose acetate-laurate nanocomposite as efficient extreme pressure and anti-wear lubricant additives. Int. J. Biol. Macromol. 2020, 156, 280–288. [Google Scholar] [CrossRef]

- Pichler, J.; Eder, R.M.; Besser, C.; Pisarova, L.; Dörr, N.; Marchetti-Deschmann, M.; Frauscher, M. A comprehensive review of sustainable approaches for synthetic lubricant components. Green Chem. Lett. Rev. 2023, 16, 2185547. [Google Scholar] [CrossRef]

- DIN EN 16807:2016-12; Liquid Petroleum Products—Bio-Lubricants—Criteria and Requirements of Bio-Lubricants and Bio-Based Lubricants; German Version EN 16807:2016 2016;12. European Committee for Standardization: Brussels, Belgium, 2016.

- Syahir, A.Z.; Zulkifli, N.W.M.; Masuki, H.H.; Kalam, M.A.; Alabdulkarem, A.; Gulzar, M.; Khuong, L.S.; Harith, M.H. A review on bio-based lubricants and their applications. J. Clean. Prod. 2017, 168, 997–1016. [Google Scholar] [CrossRef]

- Kurre, S.K.; Yadav, J. A review on bio-based feedstock, synthesis, and chemical modification to enhance tribological properties of biolubricants. Ind. Crops Prod. 2023, 193, 116122. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, Y.; Negi, P. A review on the characterization of bio based lubricants from vegetable oils and role of nanoparticles as additives. Mater. Today Proc. 2021, 46, 10513–10517. [Google Scholar] [CrossRef]

- Rustan, A.C.; Drevon, C.A. Fatty Acids: Structures and Properties; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Sarma, R.N.; Vinu, R. Current Status and Future Prospects of Biolubricants: Properties and Applications. Lubricants 2022, 10, 70. [Google Scholar] [CrossRef]

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Xie, Z.; Rao, Z.-S.; Na, T.; Liu, L.; Chen, R. Theoretical and experimental research on the friction coefficient of water lubricated bearing with consideration of wall slip effects. Mech. Ind. 2016, 17, 106. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems Used in Machining Processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Salih, N.; Salimon, J. A Review on New Trends, Challenges and Prospects of Ecofriendly Friendly Green Food-Grade Biolubricants. Biointerface Res. Appl. Chem. 2021, 12, 1185–1207. [Google Scholar] [CrossRef]

- Oyinbo, S.T.; Ikumapayi, O.M.; Jen, T.-C.; Ismail, S.O. Experimental and numerical prediction of extrusion load at different lubricating conditions of aluminium 6063 alloy in backward cup extrusion. Eng. Solid Mech. 2020, 8, 119–130. [Google Scholar] [CrossRef]

- Kozdrach, R. The tribological properties of lubricating greases produced on vegetable base and modified of polytetrafluoroethylene. Tribol. Finn. J. Tribol. 2020, 37, 4–14. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Díaz, M.J.; Franco, J.M. Gel-like Dispersions of HMDI-Cross-Linked Lignocellulosic Materials in Castor Oil: Toward Completely Renewable Lubricating Grease Formulations. ACS Sustain. Chem. Eng. 2015, 3, 2130–2141. [Google Scholar] [CrossRef]

- Su, F.-H.; Zhang, Z.-Z.; Liu, W.-M. Study on the friction and wear properties of glass fabric composites filled with nano- and micro-particles under different conditions. Mater. Sci. Eng. A 2005, 392, 359–365. [Google Scholar] [CrossRef]

- Hou, X.; Deem, P.T.; Choy, K.-L. Hydrophobicity study of polytetrafluoroethylene nanocomposite films. Thin Solid Films 2012, 520, 4916–4920. [Google Scholar] [CrossRef]

- Mu, L.; Shi, Y.; Hua, J.; Zhuang, W.; Zhu, J. Engineering Hydrogen Bonding Interaction and Charge Separation in Bio-Polymers for Green Lubrication. J. Phys. Chem. B 2017, 121, 5669–5678. [Google Scholar] [CrossRef]

- Ermakov, C.F.; Chmykhova, T.G.; Timoshenko, A.V.; Shershnev, E.B. Tribological Features of Environmentally Safe Lubricant Compositions Based on Rapeseed Oil. J. Frict. Wear 2019, 40, 194–199. [Google Scholar] [CrossRef]

- El Kossori, R.L.; Sanchez, C.; El Boustani, E.-S.; Maucourt, M.N.; Sauvaire, Y.; Méjean, L.; Villaume, C. Comparison of effects of prickly pear (Opuntia ficus indica sp.) fruit, arabic gum, carrageenan, alginic acid, locust bean gum and citrus pectin on viscosity and in vitro digestibility of casein 2000. J. Sci. Food Agric. 2000, 80, 359–364. [Google Scholar] [CrossRef]

- Tang, D.Y.Y.; Khoo, K.S.; Chew, K.W.; Tao, Y.; Ho, S.-H.; Show, P.L. Potential utilization of bioproducts from microalgae for the quality enhancement of natural products. Bioresour. Technol. 2020, 304, 122997. [Google Scholar] [CrossRef]

- Thirugnanasambantham, R.; Elango, T.; Elangovan, K. Wear and friction characterization of chlorella sp. microalgae oil based blended lubricant on pin on disc tribometer. Mater. Today Proc. 2020, 33, 3063–3067. [Google Scholar] [CrossRef]

- Cheah, M.Y.; Ong, H.C.; Zulkifli, N.W.M.; Masjuki, H.H.; Salleh, A. Physicochemical and tribological properties of microalgae oil as biolubricant for hydrogen-powered engine. Int. J. Hydrogen Energy 2020, 45, 22364–22381. [Google Scholar] [CrossRef]

- Sanjurjo, C.; Rodríguez, E.; Viesca, J.L.; Battez, A.H. Influence of Molecular Structure on the Physicochemical and Tribological Properties of Biolubricants: A Review. Lubricants 2023, 11, 380. [Google Scholar] [CrossRef]

- Pondicherry, K.; Rummel, F.; Läuger, J. Extended Stribeck curves for food samples. Biosurf. Biotribol. 2018, 4, 34–37. [Google Scholar] [CrossRef]

- Hevo Plastics. 2023. Available online: http://www.hevo-plastics.com/html/grundlagen_der_extrusion.html (accessed on 1 May 2024).

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; John Wiley & Sons Ltd.: Chichester, UK, 2006; pp. 10815–10837. [Google Scholar] [CrossRef]

- Farrés, I.F.; Norton, I. The influence of co-solutes on tribology of agar fluid gels. Food Hydrocoll. 2015, 45, 186–195. [Google Scholar] [CrossRef]

| Concentration | Sample | Lubricant | Test Temperature |

|---|---|---|---|

| 1 wt% | Salmon oil | Distilled water | 30 °C |

| Rapeseed oil | |||

| Agar | |||

| Alginate | |||

| Hydroxypropyl methyl-cellulose (HPMC) |

| FMs | Concentration | Sample | Lubricant | Test Temperature |

|---|---|---|---|---|

| Conventional | 1 wt% | Oleamide | PAO8 | 80 °C |

| Borate ester | ||||

| Methyl ricinoleate | ||||

| Tallow amine | ||||

| Bio-based | 1 wt% | Salmon oil | PAO8 | 80 °C |

| Rapeseed oil |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nothnagel, R.M.; Boidi, G.; Franz, R.; Frauscher, M. Assessing the Potential of Bio-Based Friction Modifiers for Food-Grade Lubrication. Lubricants 2024, 12, 247. https://doi.org/10.3390/lubricants12070247

Nothnagel RM, Boidi G, Franz R, Frauscher M. Assessing the Potential of Bio-Based Friction Modifiers for Food-Grade Lubrication. Lubricants. 2024; 12(7):247. https://doi.org/10.3390/lubricants12070247

Chicago/Turabian StyleNothnagel, Rosa Maria, Guido Boidi, Rainer Franz, and Marcella Frauscher. 2024. "Assessing the Potential of Bio-Based Friction Modifiers for Food-Grade Lubrication" Lubricants 12, no. 7: 247. https://doi.org/10.3390/lubricants12070247

APA StyleNothnagel, R. M., Boidi, G., Franz, R., & Frauscher, M. (2024). Assessing the Potential of Bio-Based Friction Modifiers for Food-Grade Lubrication. Lubricants, 12(7), 247. https://doi.org/10.3390/lubricants12070247