Effect of Wear on Alternating Bending Fatigue Life of 20CrNi2Mo Martensitic Steel

Abstract

1. Introduction

2. Methods

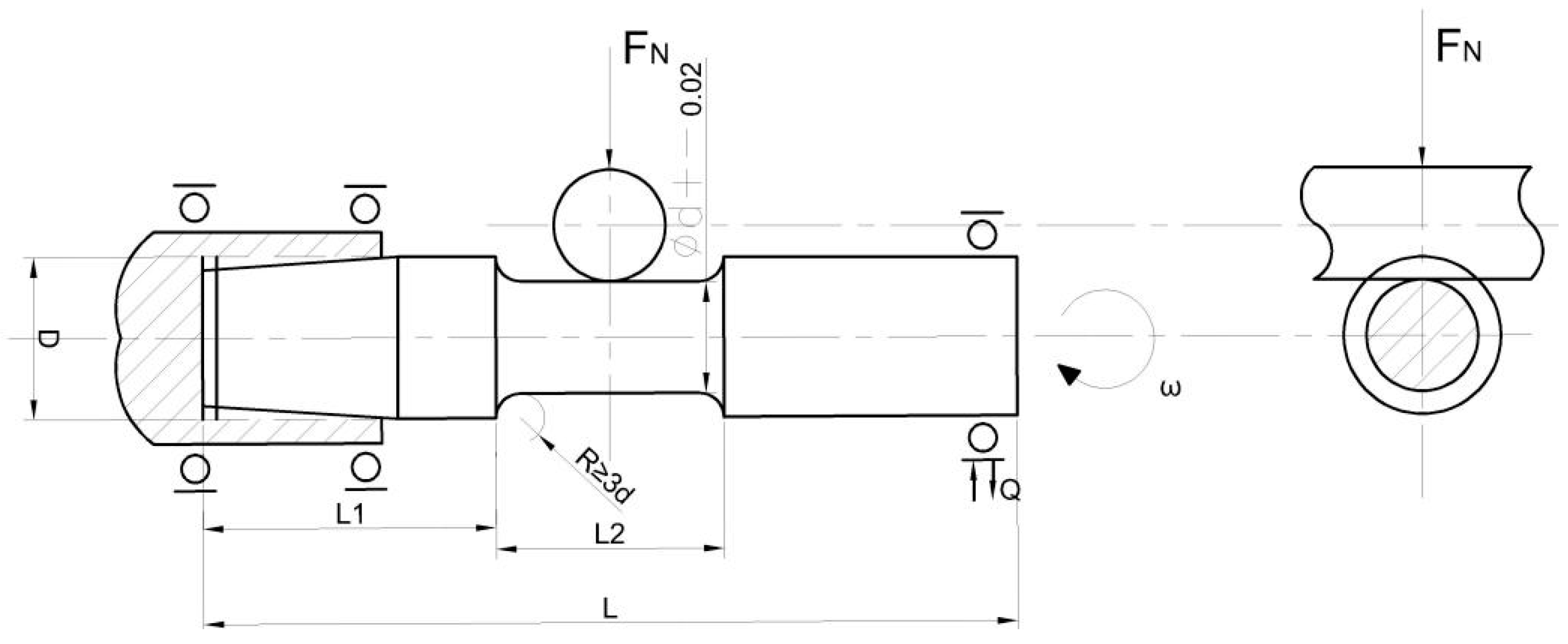

2.1. Wear–Fatigue Behavior Test Device

2.2. Wear–Fatigue Test Samples

2.3. Characterization

3. Results and Discussion

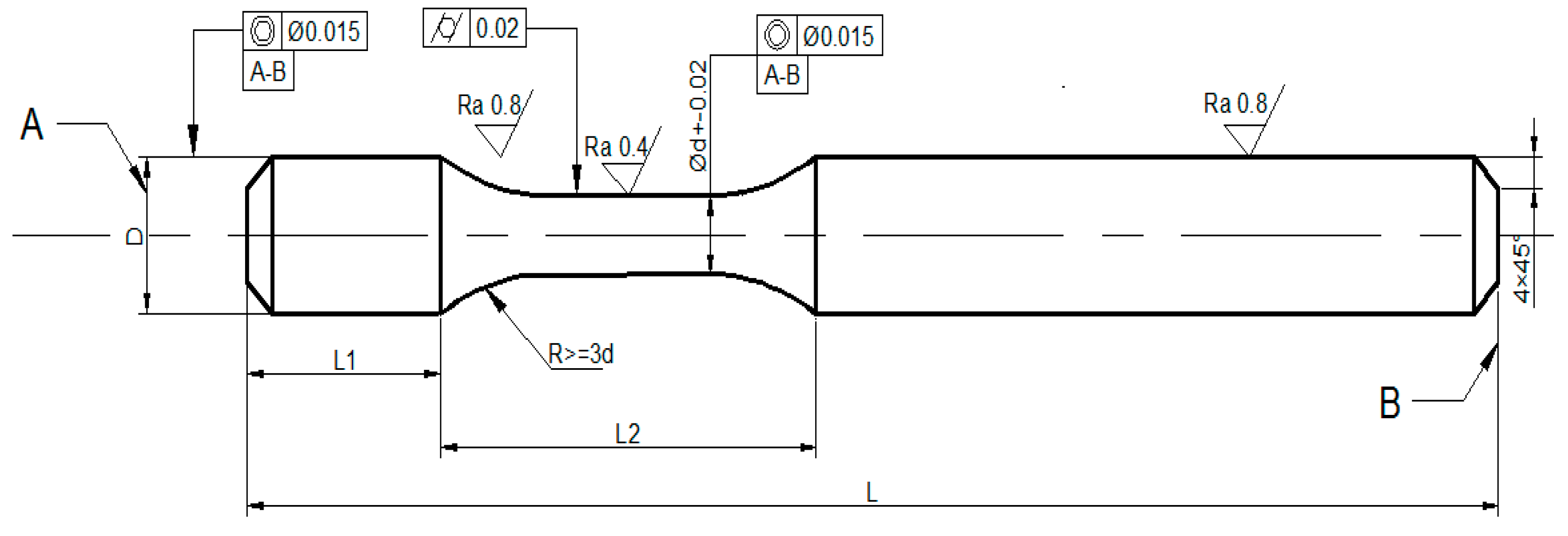

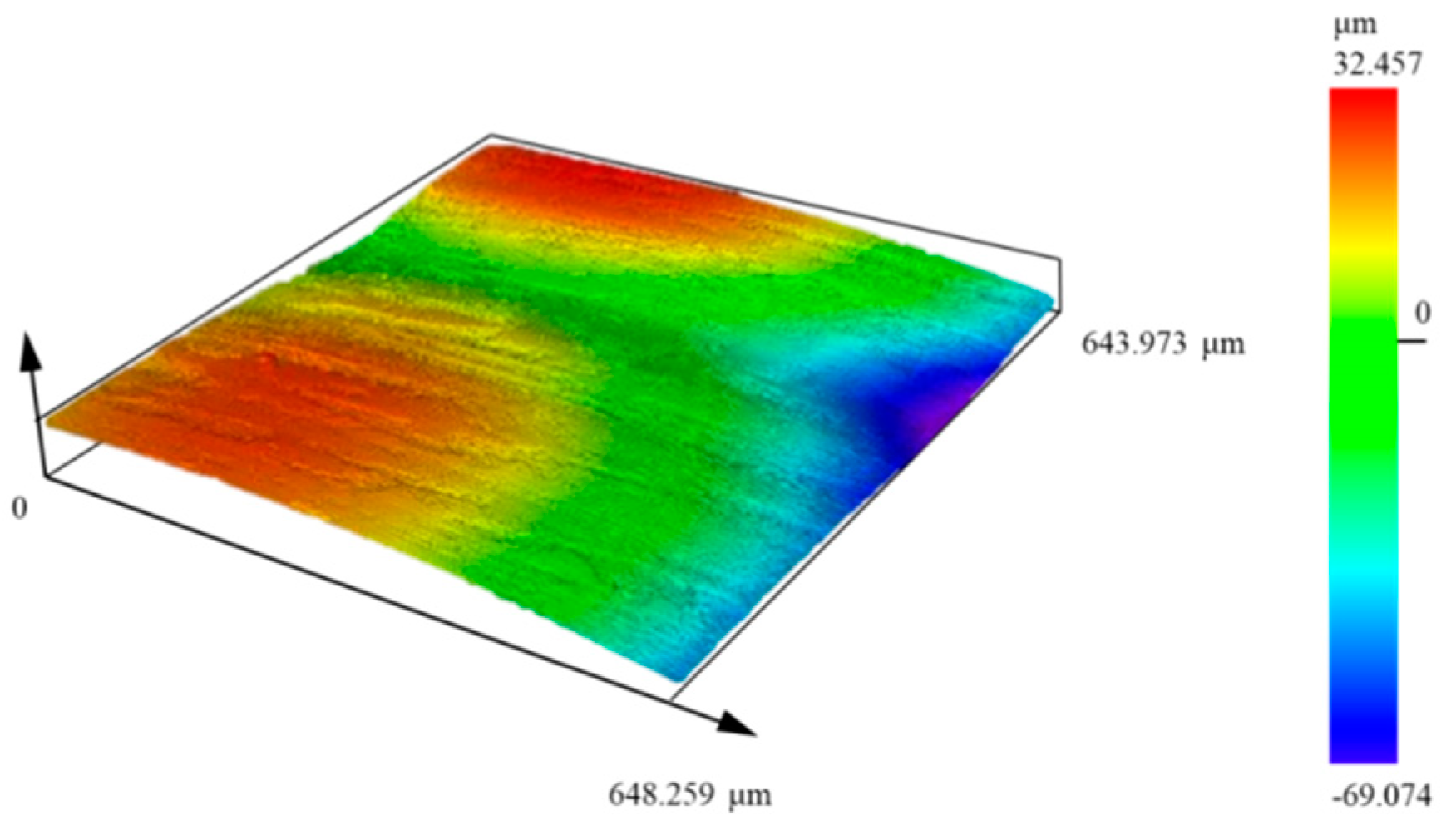

3.1. Wear Effect on Wear–Fatigue Behavior under Low Bending Stress

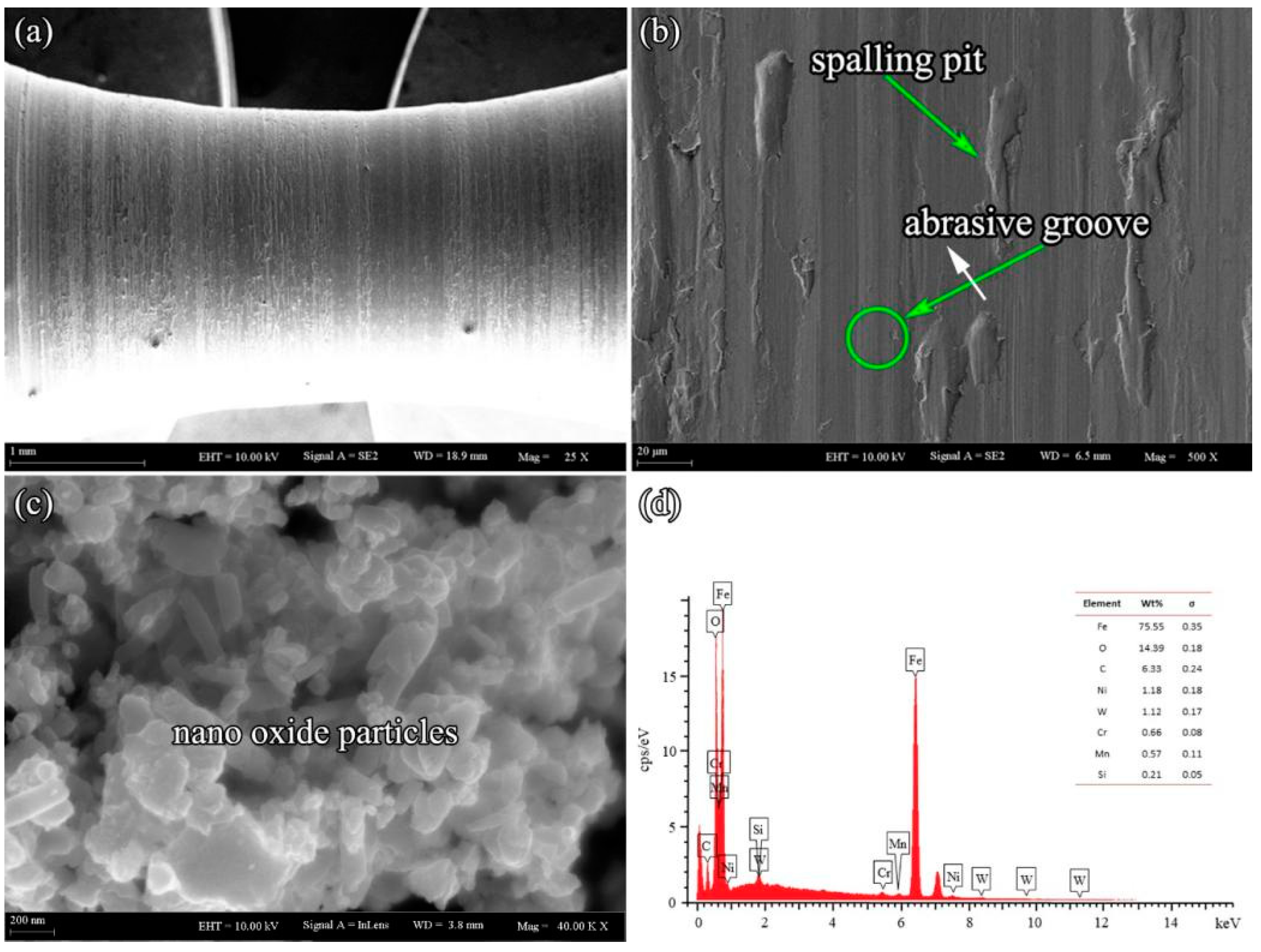

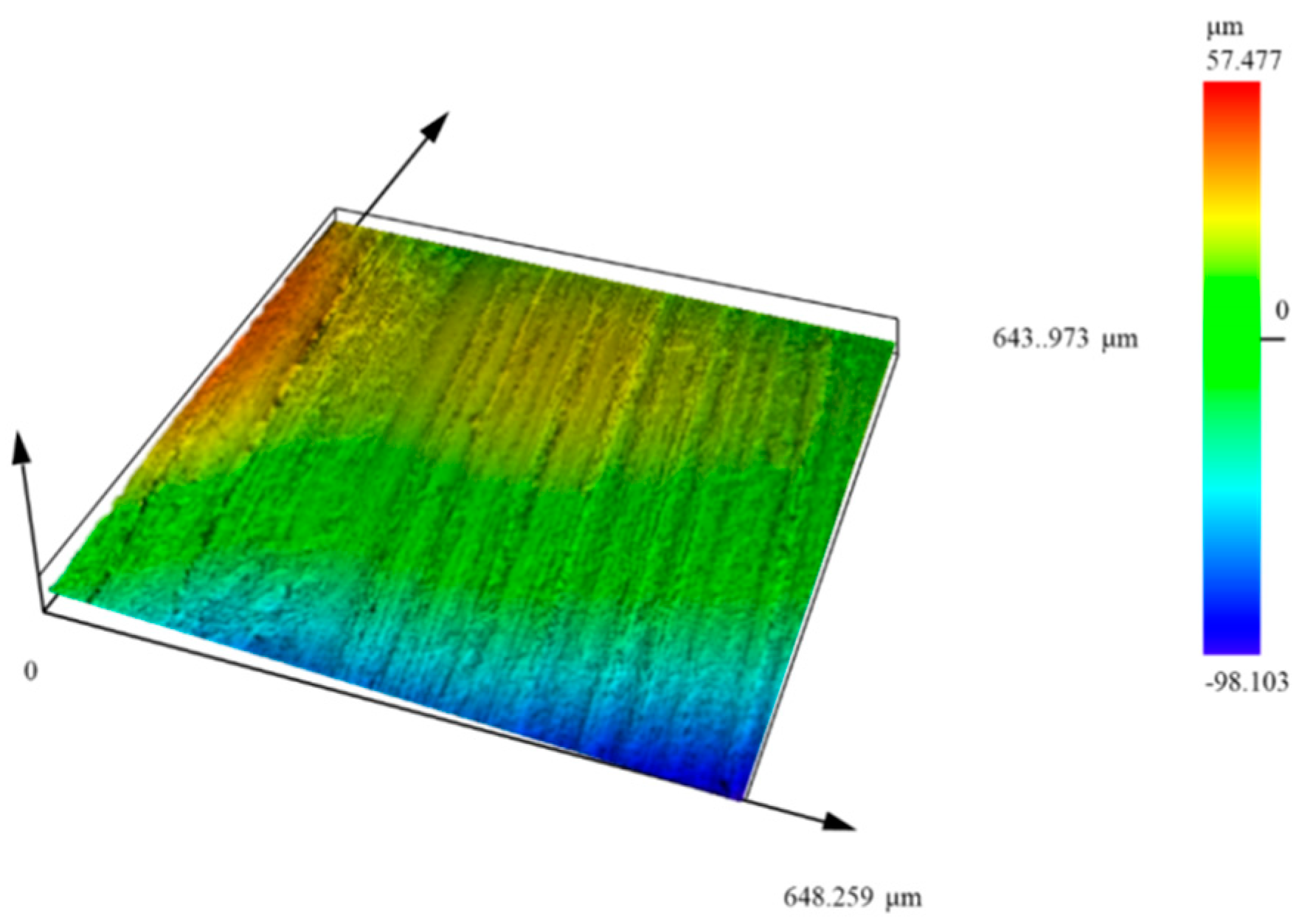

3.2. Wear Effect on Wear–Fatigue Behavior under High Bending Stress

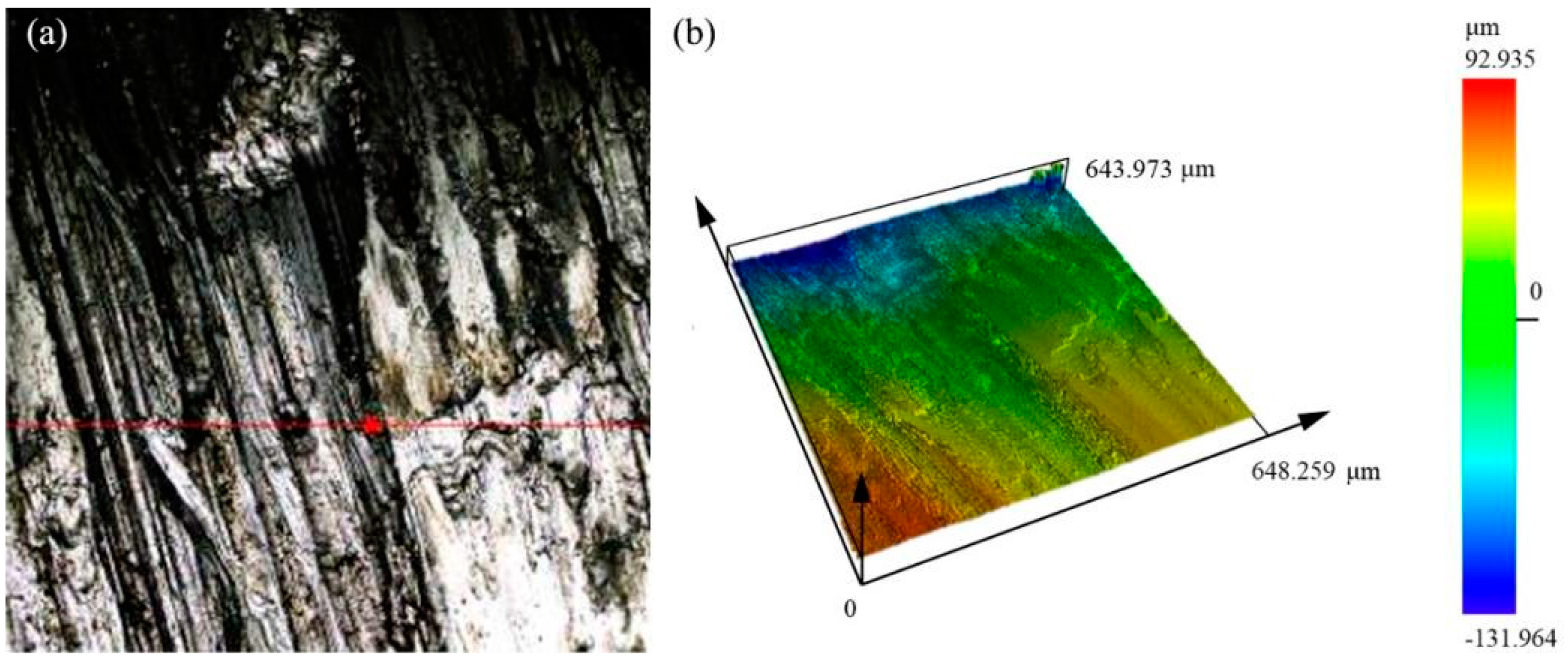

3.3. Rotation Speed Effect on Wear–Fatigue Behavior

4. Conclusions

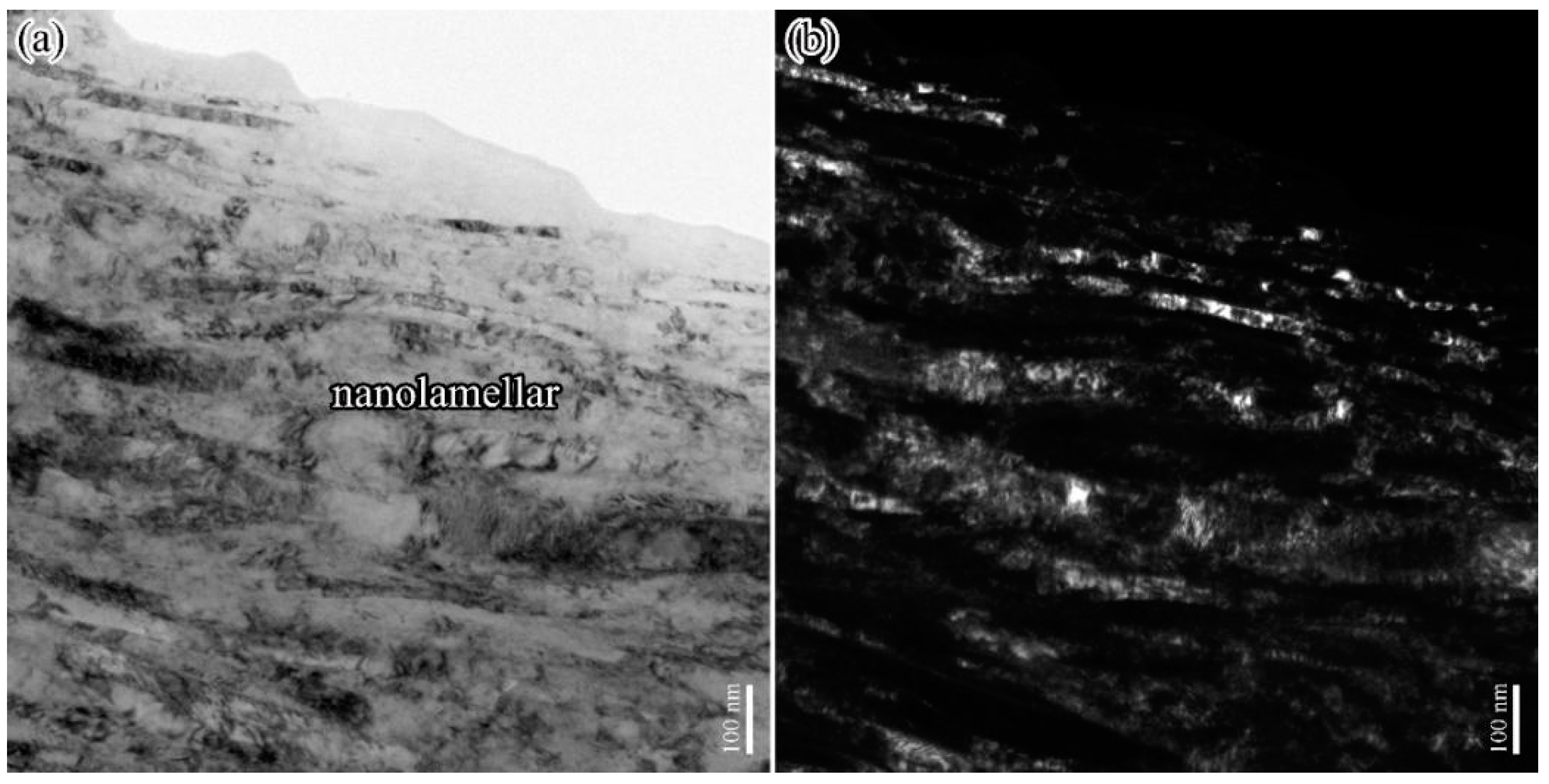

- If the wear mechanism is mainly slight oxidative wear with oxide nanoparticles forming on the contact surface, the fatigue life is long under low bending stress, and substructures in the near-surface areas are almost parallel to the sliding direction.

- If bending stress is high, the wear–bending fatigue life is long under low wear load. On the other hand, an increase in wear load sharply reduced the wear–bending fatigue life.

- If other experimental conditions are fixed, an increase in the sliding speed will lead to a wear mechanism change from oxidative wear and grinding wear to adhesive wear, resulting in a significant decrease in wear–fatigue life.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Madge, J.; Leen, S.; Shipway, P. A combined wear and crack nucleation–propagation methodology for fretting fatigue prediction. Int. J. Fatigue 2008, 30, 1509–1528. [Google Scholar] [CrossRef]

- McCarthy, O.J.; McGarry, J.P.; Leen, S.B. Micro-mechanical modelling of fretting fatigue crack initiation and wear in Ti–6Al–4V. Int. J. Fatigue 2014, 62, 180–193. [Google Scholar] [CrossRef]

- O’Halloran, S.M.; Shipway, P.H.; Connaire, A.D.; Leen, S.B.; Harte, A.M. A combined wear-fatigue design methodology for fretting in the pressure armour layer of flexible marine risers. Tribol. Int. 2017, 108, 7–15. [Google Scholar] [CrossRef]

- Cardoso, R.A.; Doca, T.; Néron, D.; Pommier, S.; Araújo, J.A. Wear numerical assessment for partial slip fretting fatigue conditions. Tribol. Int. 2019, 136, 508–523. [Google Scholar] [CrossRef]

- Lv, J.H.; Wang, W.Z.; Tu, S.T.; Liu, S.W. Failure Cases Analysis in Aerospace Field. Mater. Sci. Forum 2020, 993, 1277–1285. [Google Scholar] [CrossRef]

- Sherbakov, S.S.; Zhuravkov, M.A. Interaction of several bodies as applied to solving tribo-fatigue problems. Acta Mech. 2013, 224, 1541–1553. [Google Scholar] [CrossRef]

- Yan, Y.; Jiang, C.; Li, W. Simulation on coupling effects between surface wear and fatigue in spur gear. Eng. Fail. Anal. 2022, 134, 106055. [Google Scholar] [CrossRef]

- Khan, S.A.; Persson, I.; Lundberg, J.; Stenström, C. Prediction of top-of-rail friction control effects on rail RCF suppressed by wear. Wear 2017, 380–381, 106–114. [Google Scholar] [CrossRef]

- Llavori, I.; Zabala, A.; Mendiguren, J.; Gómez, X. A coupled 3D wear and fatigue numerical procedure: Application to fretting problems in ultra-high strength steel wires. Int. J. Fatigue 2021, 143, 106012. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhu, C.; Tang, J. Study on gear contact fatigue failure competition mechanism considering tooth wear evolution. Tribol. Int. 2020, 147, 106277. [Google Scholar] [CrossRef]

- Roy, M. Failure Analysis of Bearings of Aero-Engine. J. Fail. Anal. Prev. 2019, 19, 1615–1629. [Google Scholar] [CrossRef]

- Kapoor, A.; Fletcher, D.I.; Franklin, F.J. The Role of Wear in Enhancing Rail Life. Tribol. Ser. 2003, 41, 331–340. [Google Scholar]

- Cantini, S.; Cervello, S. The competitive role of wear and RCF: Full scale experimental assessment of artificial and natural defects in railway wheel treads. Wear 2016, 366–367, 325–337. [Google Scholar] [CrossRef]

- Kang, J.-J.; Xu, B.-S.; Wang, H.-D.; Wang, C.-B. Investigation of a novel rolling contact fatigue/wear competitive life test machine faced to surface coating. Tribol. Int. 2013, 66, 249–258. [Google Scholar] [CrossRef]

- Basseville, S.; Cailletaud, G. An evaluation of the competition between wear and crack initiation in fretting conditions for Ti–6Al–4V alloy. Wear 2015, 328–329, 443–455. [Google Scholar] [CrossRef]

- Wang, W.J.; Guo, J.; Liu, Q.Y.; Zhu, M.H.; Zhou, Z.R. Study on relationship between oblique fatigue crack and rail wear in curve track and prevention. Wear 2009, 267, 540–544. [Google Scholar] [CrossRef]

- Zhang, F.T.; Liang, Y.L.; Wu, Y.Z.; Yin, C.H.; Zhang, J.; Yang, S.Y.; Huang, X. Microstructure evolution of a drive shaft spline from an aero-engine fuel pump during fretting wear. Mater. Res. Express 2022, 9, 046513. [Google Scholar] [CrossRef]

- Masoudi Nejad, R.; Shariati, M.; Farhangdoost, K. Effect of wear on rolling contact fatigue crack growth in rails. Tribol. Int. 2016, 94, 118–125. [Google Scholar] [CrossRef]

- Trummer, G.; Marte, C.; Scheriau, S.; Dietmaier, P.; Sommitsch, C.; Six, K. Modeling wear and rolling contact fatigue: Parametric study and experimental results. Wear 2016, 366–367, 71–77. [Google Scholar] [CrossRef]

- Trummer, G.; Marte, C.; Dietmaier, P.; Sommitsch, C.; Six, K. Modeling surface rolling contact fatigue crack initiation taking severe plastic shear deformation into account. Wear 2016, 352–353, 136–145. [Google Scholar] [CrossRef]

- Trummer, G.; Six, K.; Marte, C.; Dietmaier, P.; Sommitsch, C. An approximate model to predict near-surface ratcheting of rails under high traction coefficients. Wear 2014, 314, 28–35. [Google Scholar] [CrossRef]

- Yin, C.; Liang, Y.; Liang, Y.; Li, W.; Yang, M. Formation of a self-lubricating layer by oxidation and solid-state amorphization of nano-lamellar microstructures during dry sliding wear tests. Acta Mater. 2019, 166, 208–220. [Google Scholar] [CrossRef]

- Yin, C.H.; Liang, Y.L.; Jiang, Y.; Yang, M.; Long, S.L. Formation of nano-laminated structures in a dry sliding wear-induced layer under different wear mechanisms of 20CrNi2Mo steel. Appl. Surf. Sci. 2017, 423, 305–313. [Google Scholar] [CrossRef]

- Hohenwarter, A.; Taylor, A.; Stock, R.; Pippan, R. Effect of Large Shear Deformations on the Fracture Behavior of a Fully Pearlitic Steel. Metall. Mater. Trans. A 2010, 42, 1609–1618. [Google Scholar] [CrossRef]

- Zou, J.H.; Liang, Y.L.; Jiang, Y.; Yin, C.H.; Huang, C.W.; Liu, D.; Zhu, Z.L.; Wu, Y.Z. Fretting fatigue mechanism of 40CrNiMoA steel subjected to the ultrasonic surface rolling process: The role of the gradient structure. Int. J. Fatigue 2023, 167, 107383. [Google Scholar] [CrossRef]

- Yin, C.-H.; Yang, C.; Wu, Y.-Z.; Liang, Y.-L.; Zhu, Z.-L. Synergistic effect of cementite amorphization and oxidation on forming a nanocomposite self-lubricating surface during sliding. Compos. Part B-Eng. 2022, 236, 109799. [Google Scholar] [CrossRef]

- Liang, C.; Li, C.; Lv, X.X.; An, J. Correlation between friction-induced microstructural evolution, strain hardening in subsurface and tribological properties of AZ31 magnesium alloy. Wear 2014, 312, 29–39. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, T.; Zhang, S. Influence of oxides on the formation of self-lubricating layer and anti-wear performance during sliding. Tribol. Int. 2023, 179, 108188. [Google Scholar] [CrossRef]

| Bending Stress (MPa) | Wear Load F (N) | Cycle Number (Times) | Fatigue Life |

|---|---|---|---|

| 468 | 5 | 1 × 107+ | pass |

| 10 | 1 × 107+ | pass | |

| 15 | 1 × 107+ | pass | |

| 20 | 1 × 107+ | pass | |

| 25 | 1 × 107+ | pass | |

| 30 | 1 × 107+ | pass |

| Bending Stress (MPa) | Wear Load (N) | Cycles | Fatigue Life |

|---|---|---|---|

| 550 | 5 | 1.0 × 107+ | pass |

| 10 | 5.36 × 106 | failure | |

| 15 | 3.21 × 106 | failure | |

| 20 | 2.61 × 106 | failure | |

| 25 | 2.14 × 106 | failure | |

| 30 | 2.34 × 106 | failure |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, X.; Liu, X.; Huang, H.; Yin, C. Effect of Wear on Alternating Bending Fatigue Life of 20CrNi2Mo Martensitic Steel. Lubricants 2024, 12, 157. https://doi.org/10.3390/lubricants12050157

Qin X, Liu X, Huang H, Yin C. Effect of Wear on Alternating Bending Fatigue Life of 20CrNi2Mo Martensitic Steel. Lubricants. 2024; 12(5):157. https://doi.org/10.3390/lubricants12050157

Chicago/Turabian StyleQin, Xinmao, Xixia Liu, Huaze Huang, and Cunhong Yin. 2024. "Effect of Wear on Alternating Bending Fatigue Life of 20CrNi2Mo Martensitic Steel" Lubricants 12, no. 5: 157. https://doi.org/10.3390/lubricants12050157

APA StyleQin, X., Liu, X., Huang, H., & Yin, C. (2024). Effect of Wear on Alternating Bending Fatigue Life of 20CrNi2Mo Martensitic Steel. Lubricants, 12(5), 157. https://doi.org/10.3390/lubricants12050157