The Effects of the Lubricant Properties and Surface Finish Characteristics on the Tribology of High-Speed Gears for EV Transmissions †

Abstract

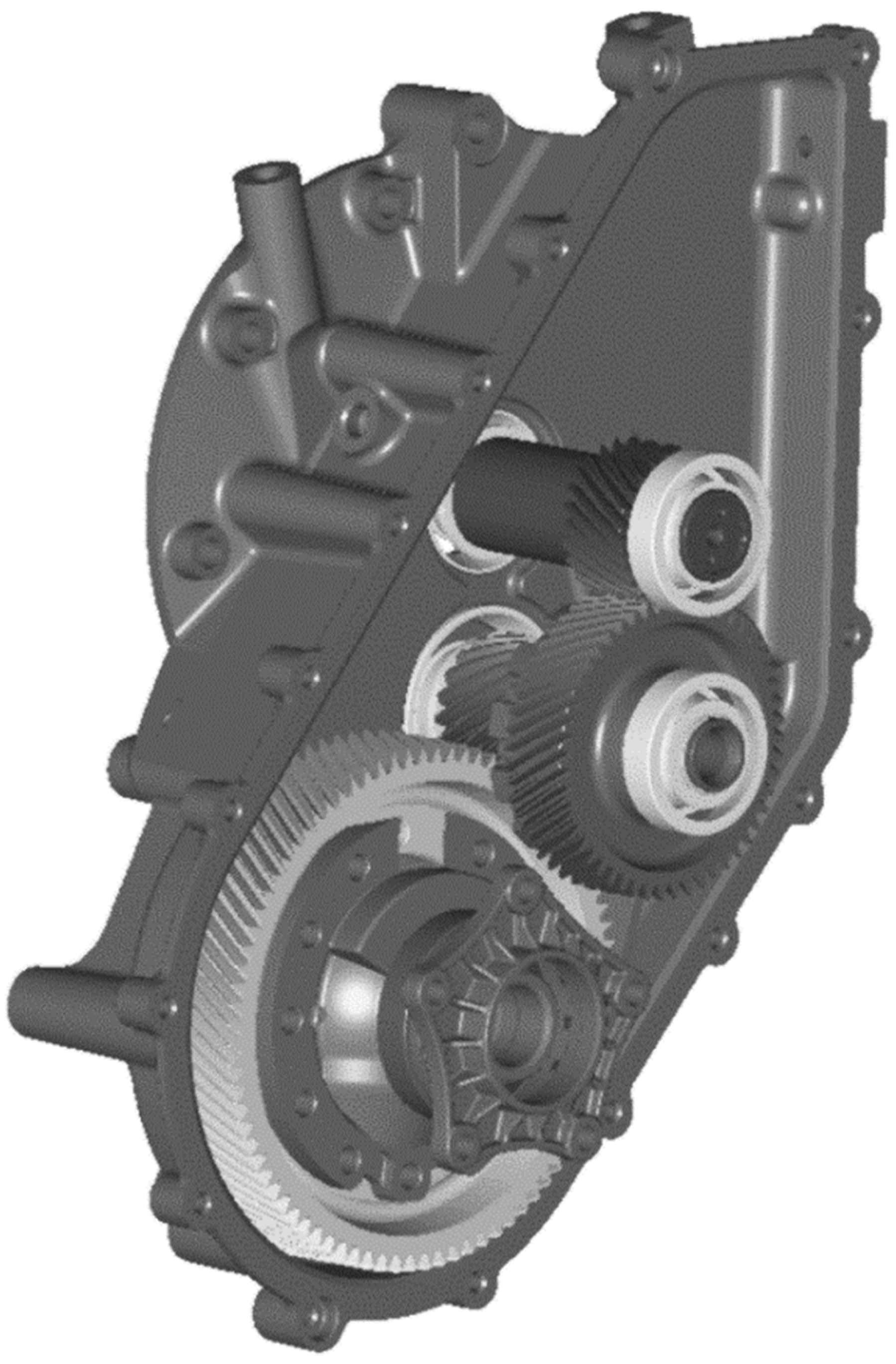

1. Introduction

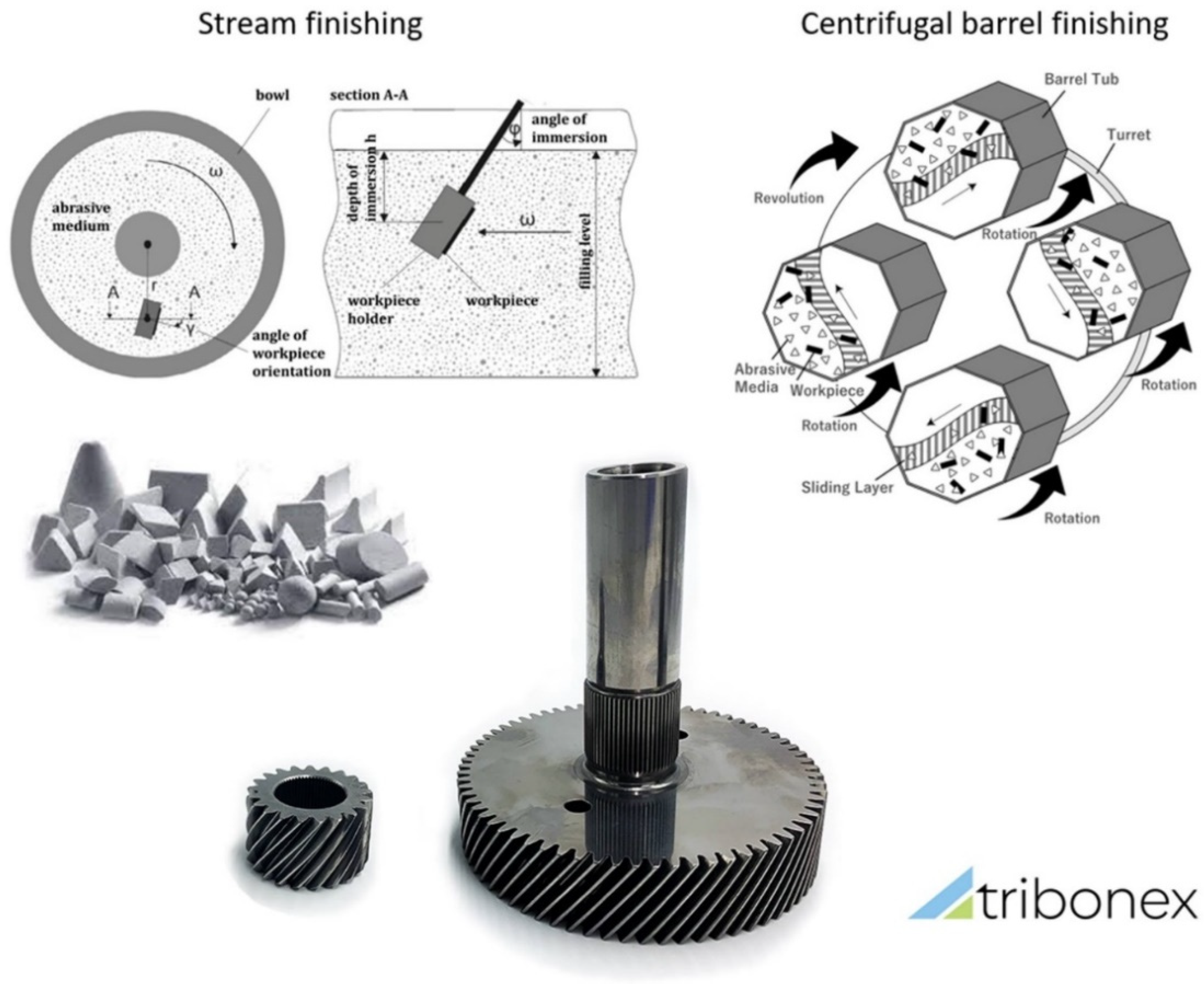

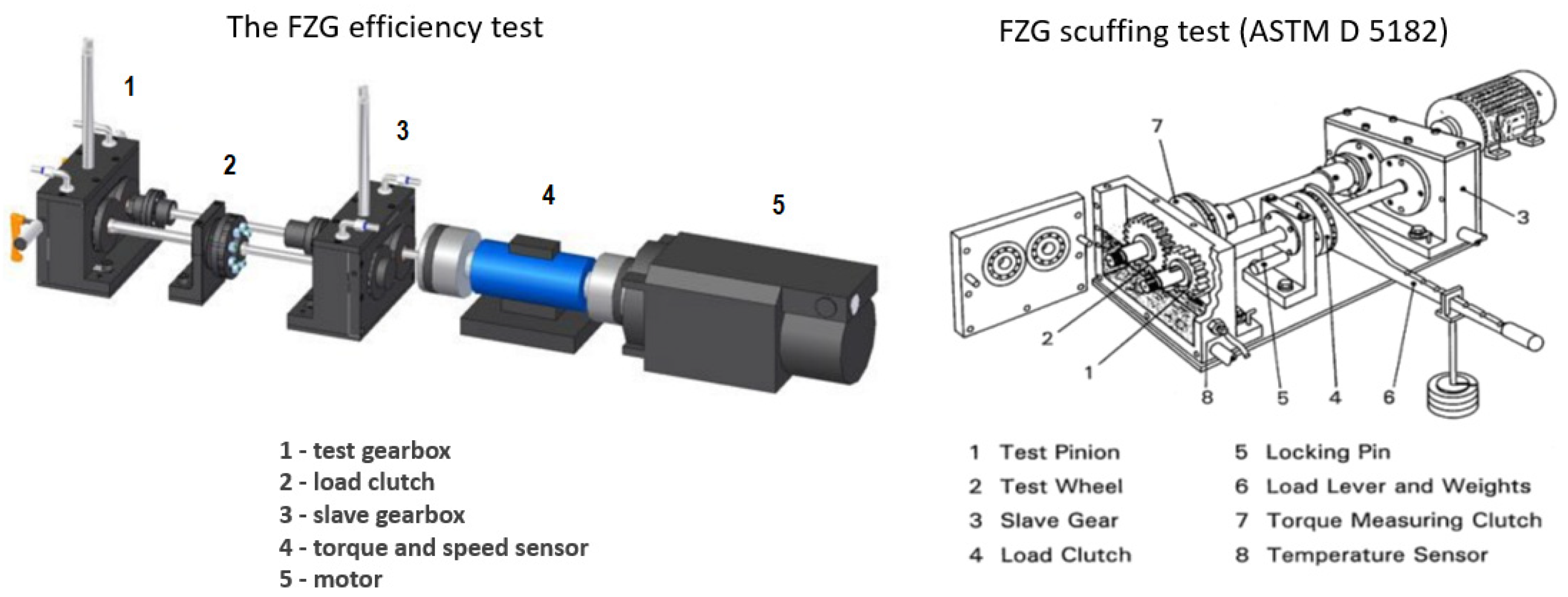

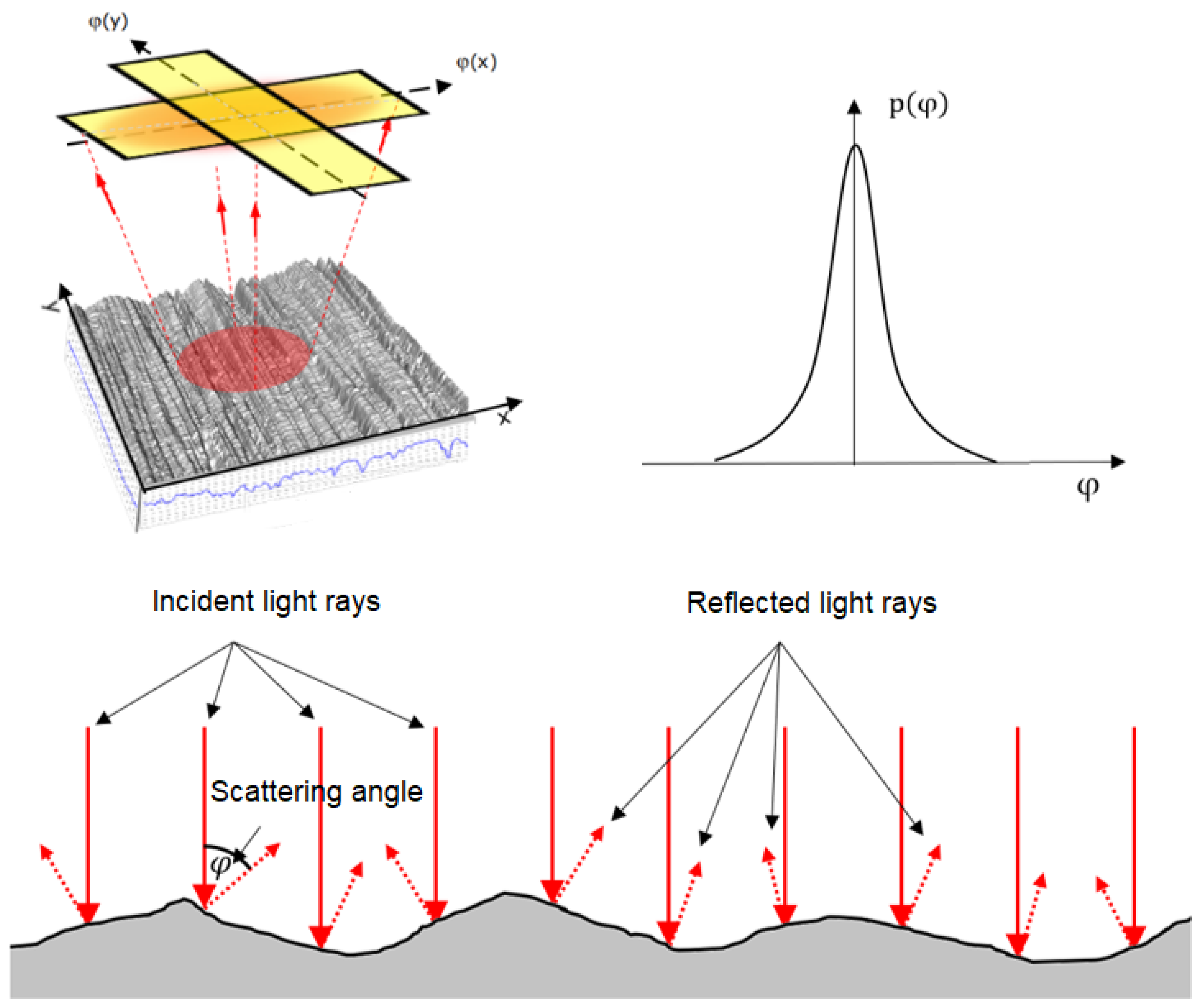

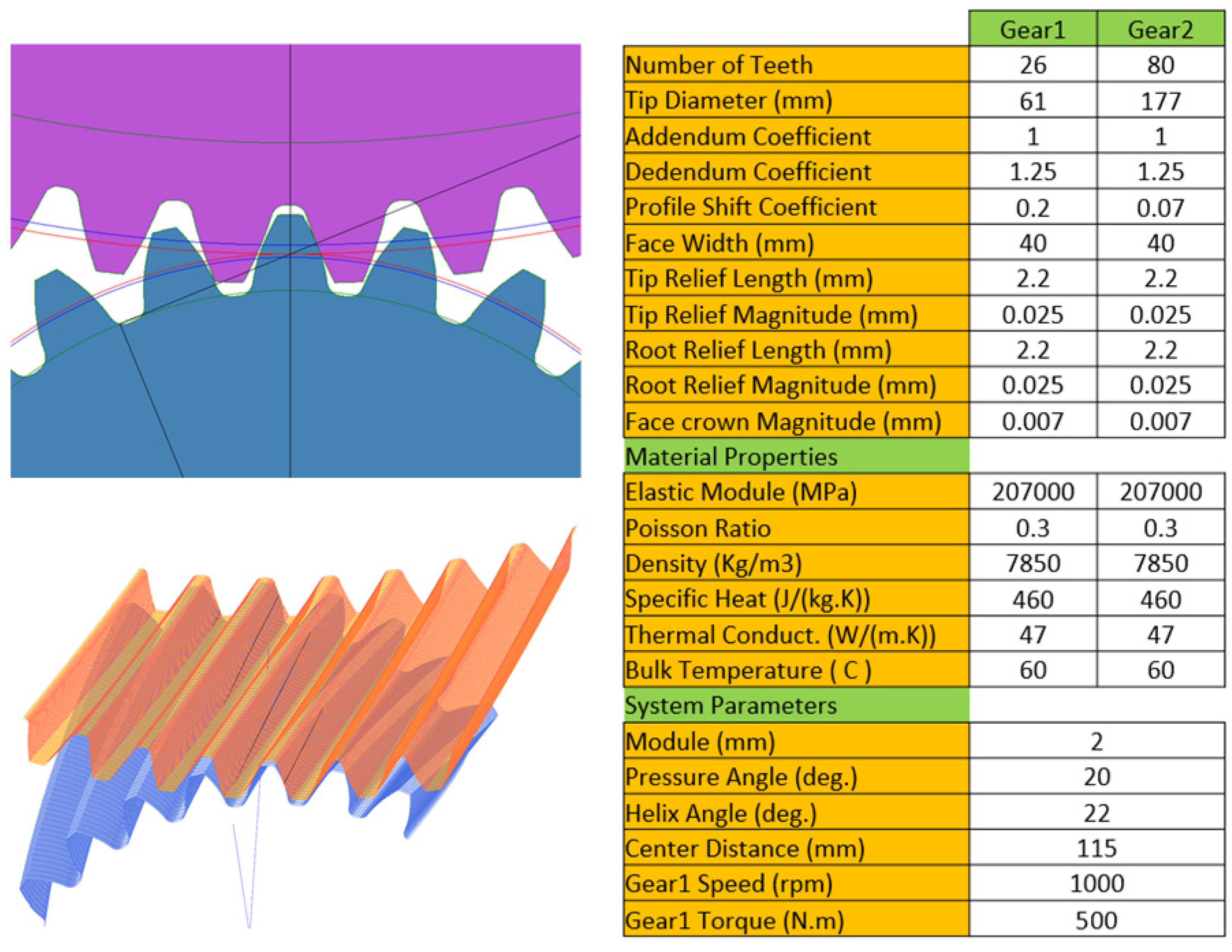

2. Experimental

3. Results and Discussion

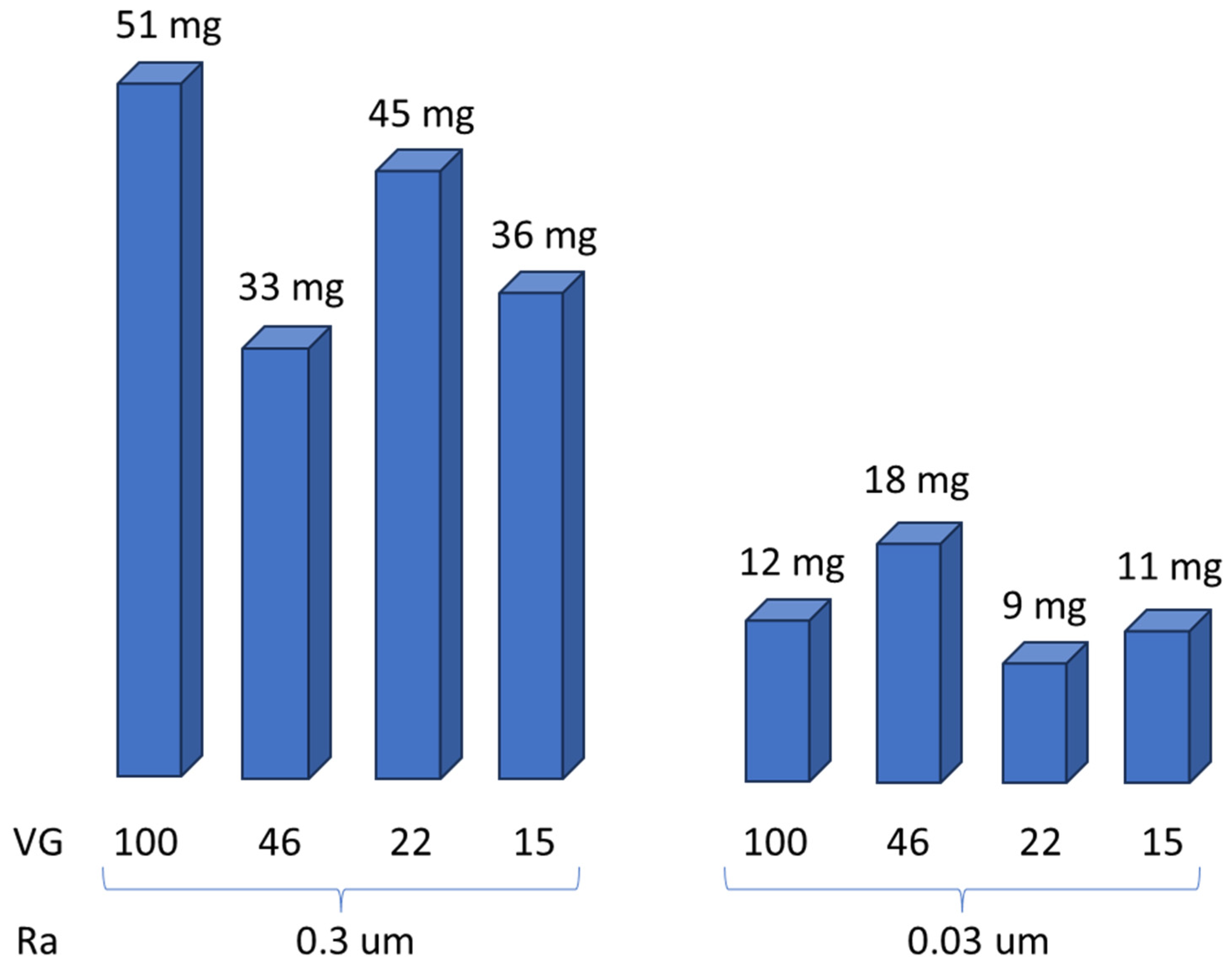

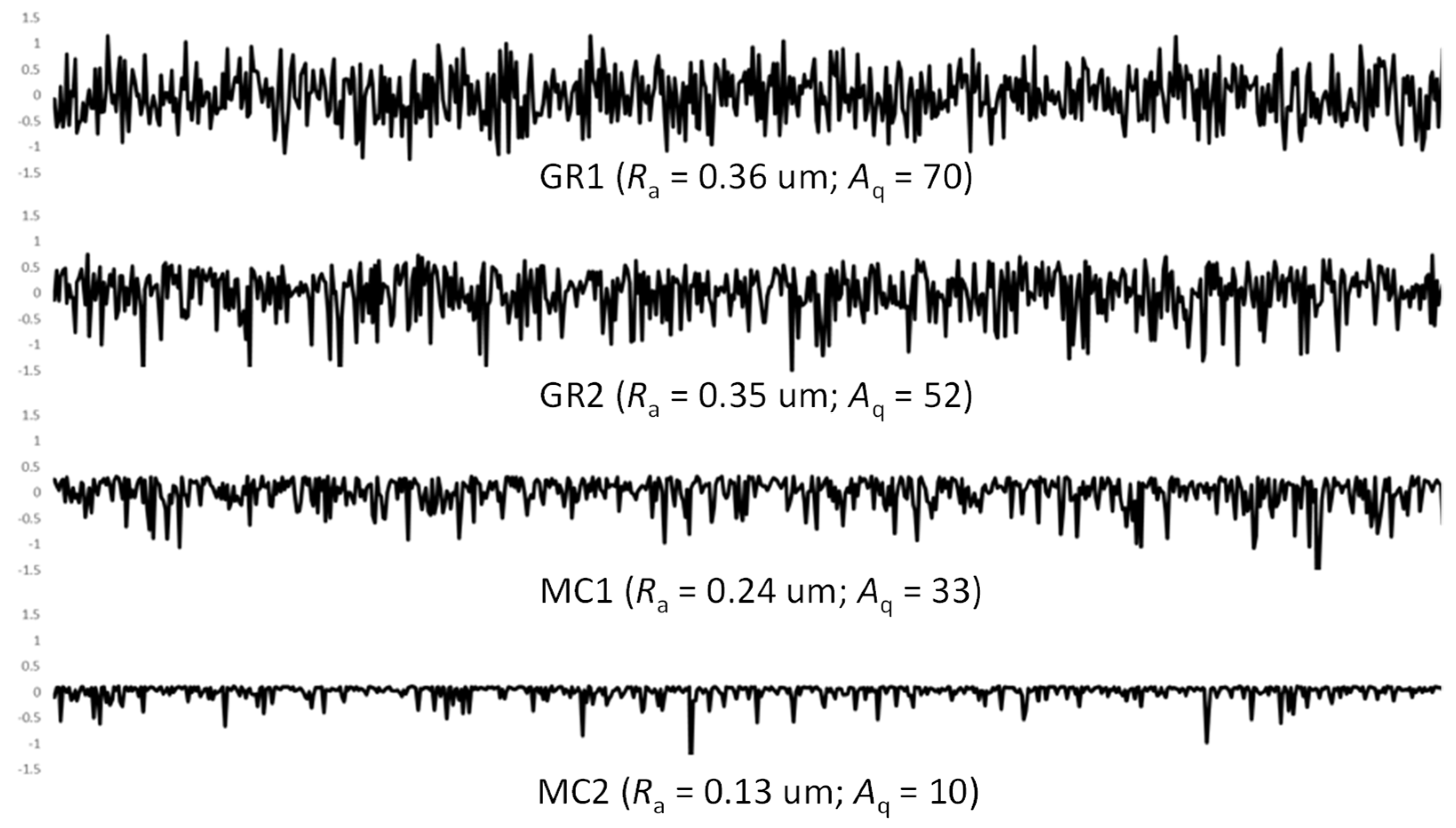

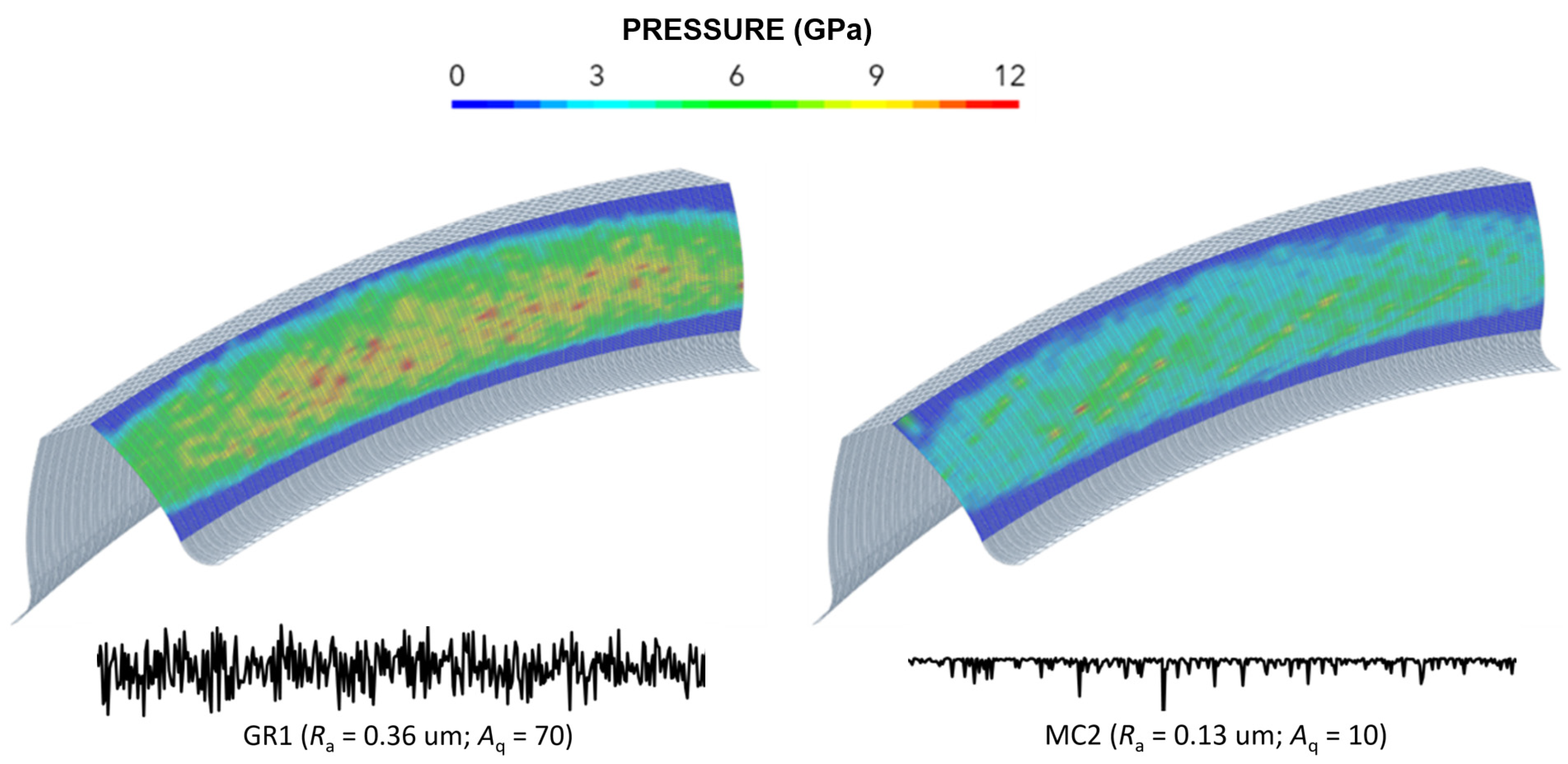

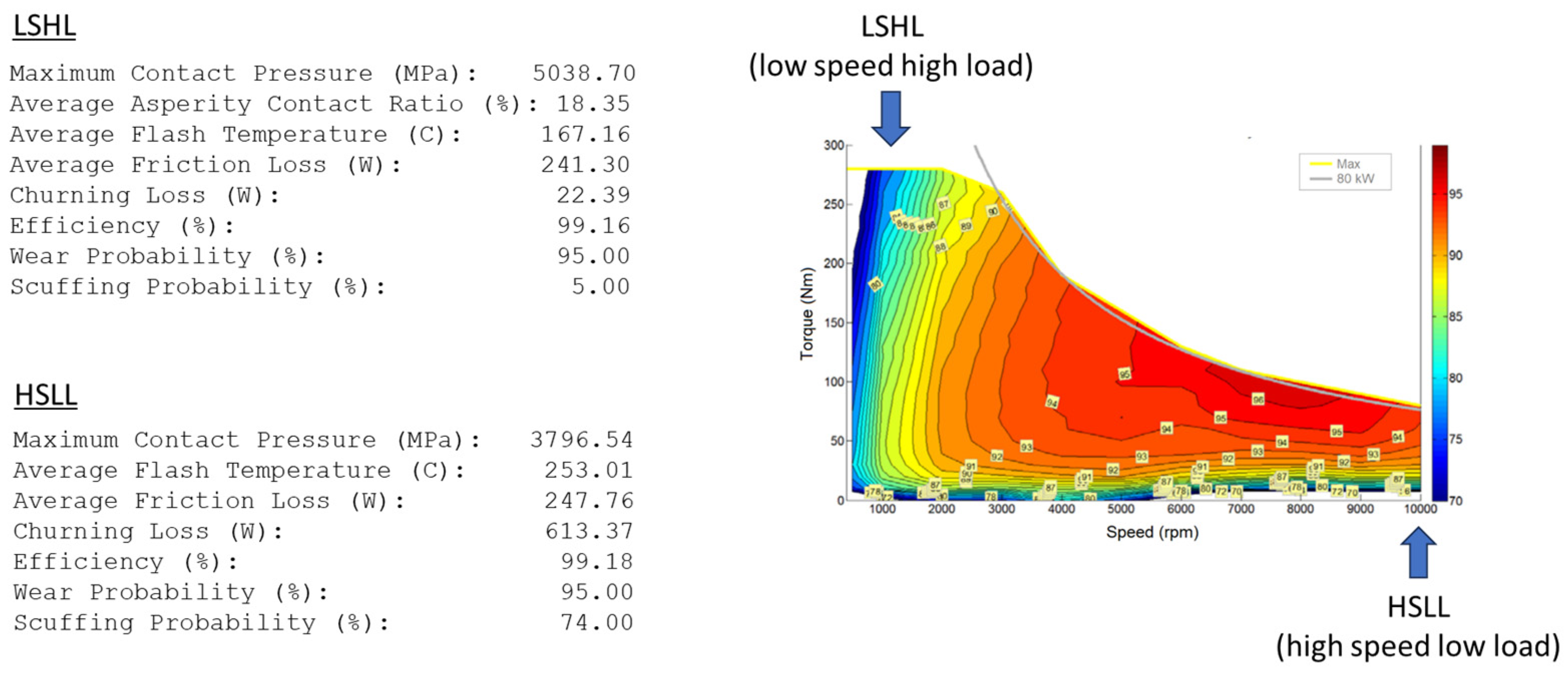

3.1. Scuffing and Wear

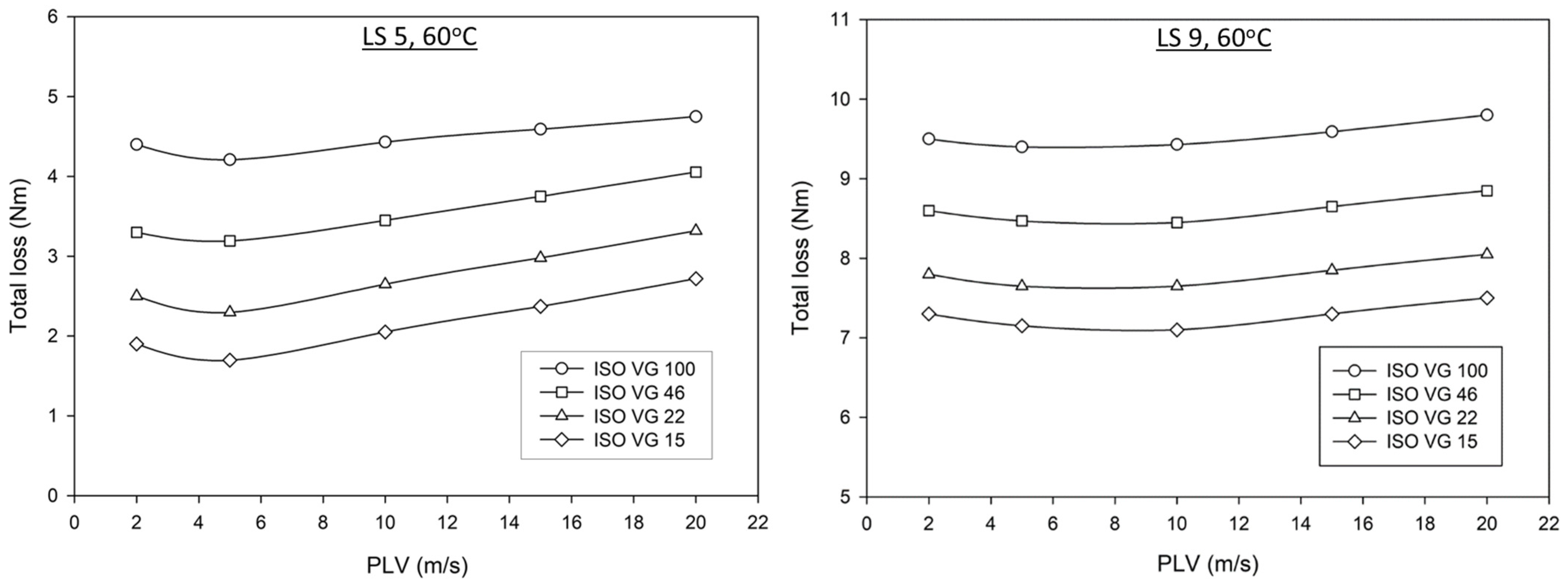

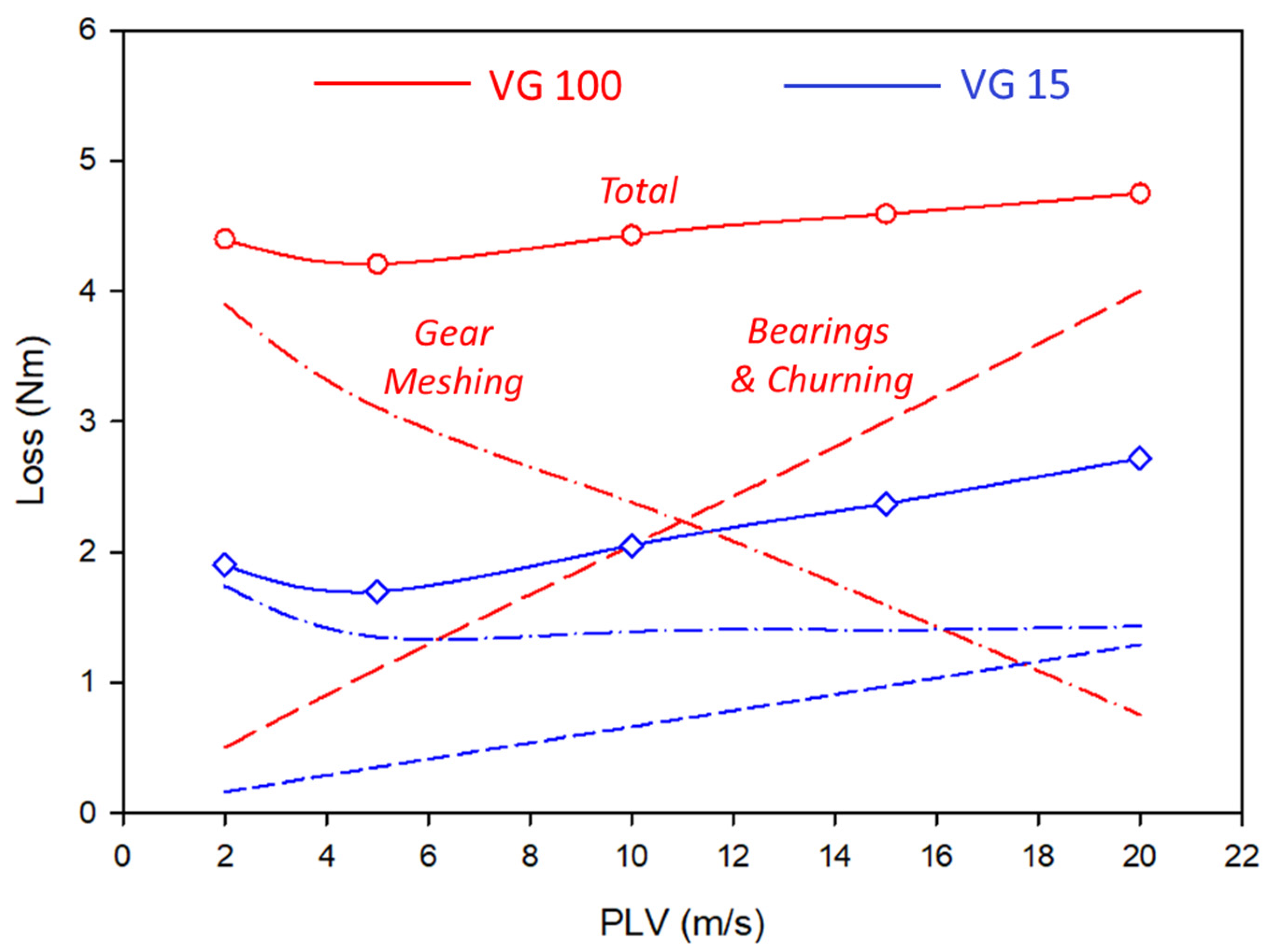

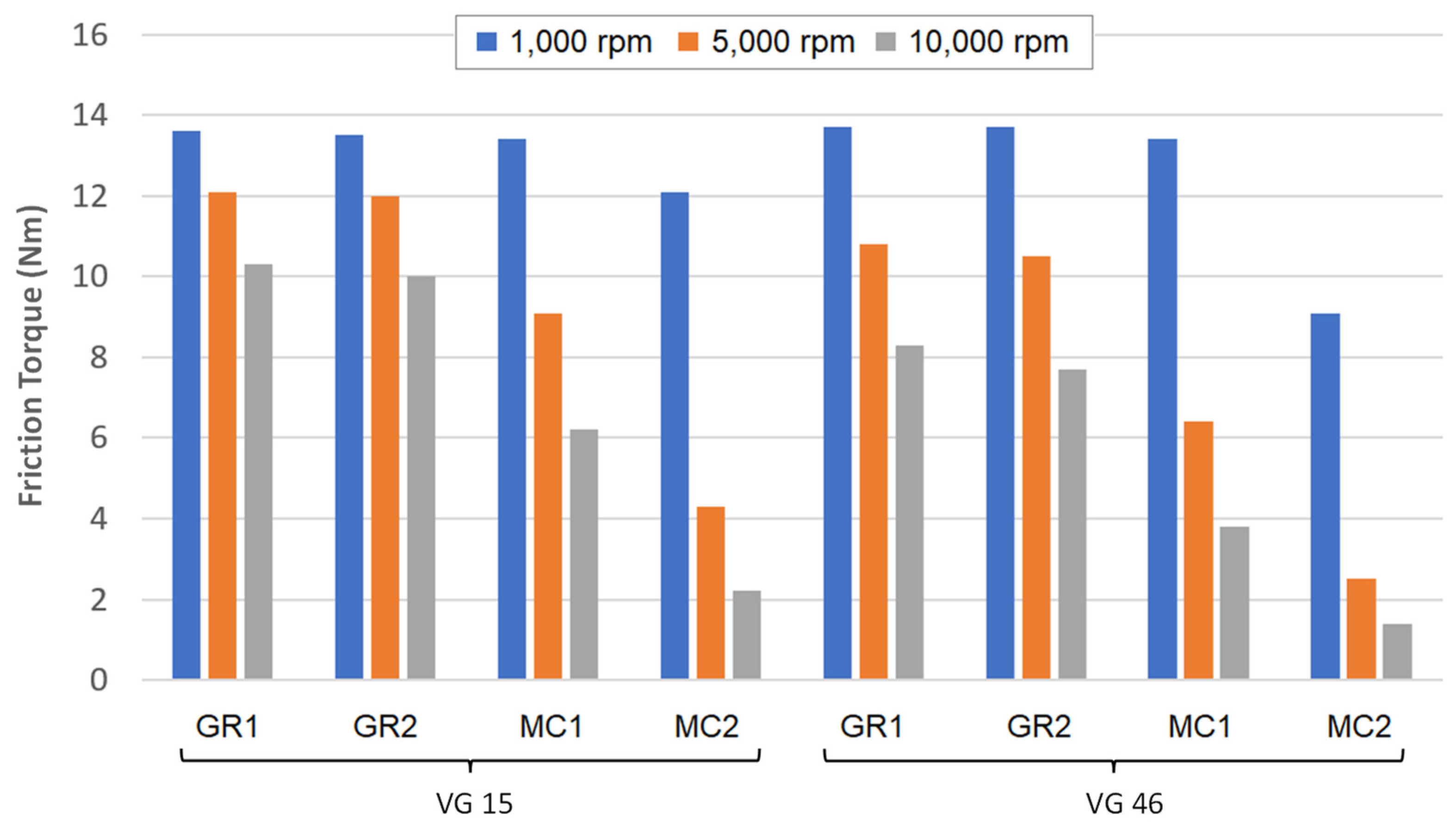

3.2. Power Loss and Efficiency

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burress, T. Benchmarking State-of-the-Art Technologies. In Proceedings of the U.S. DoE Hydrogen and Fuel Cells Program and Vehicle Technologies Program Annual Merit Review and Peer Evaluation Meeting, Arlington, VA, USA, 13–17 May 2013. [Google Scholar]

- Brauer, S. High Speed Electric Vehicle Transmission. Master’s Thesis, Karlstad University, Karlstad, Sweden, 2017. [Google Scholar]

- Michaelis, K.; Hoehn, B.R.; Oster, P. Influence of Lubricant on Gear Failures—Test Methods and Application to Gearboxes in Practice. Tribotest 2004, 11, 43–56. [Google Scholar] [CrossRef]

- Hoehn, B.R.; Stahl, K.; Michaelis, K. Lubricant Influence of Slow Speed Wear in Gears. Goriva Maz. 2012, 1, 5–28. [Google Scholar]

- Zhmud, B.; Najjari, L.M. Everlid, Gear Design and Tribology of EV Transmissions. In Proceedings of the LUBMAT 2023, Preston, UK, 17–19 July 2023. [Google Scholar]

- Taylor, R.I. Energy Efficiency, Emissions, Tribological Challenges and Fluid Requirements of Electrified Passenger Car Vehicles. Lubricants 2021, 9, 66. [Google Scholar] [CrossRef]

- Errichello, R. Friction, Lubrication, and Wear of Gears and Wind-Turbine Components. In ASM Handbook: Volume 18—Friction, Lubrication, and Wear Technology; ASM International: Materials Park, OH, USA, 1992; Volume 18, pp. 535–545. [Google Scholar]

- Michaelis, K.; Hoehn, B.-R.; Hinterstoisser, M. Influence Factors on Gearbox Power Loss. Ind. Lubr. Tribol. 2011, 63, 46. [Google Scholar] [CrossRef]

- Magalhes, L.; Martins, R.; Locateli, C.; Seabra, J. Influence of Tooth Profile and Oil Formulation on Gear Power Loss. Tribol. Int. 2010, 43, 1861. [Google Scholar] [CrossRef]

- Zhmud, B.; Mallipeddi, D.; Krajnik, P. Mechanochemical Surface Treatment of Precision Components. In Proceedings of the CIRP Winter Meeting, Paris, France, 21–23 February 2023. [Google Scholar]

- Everlid, L.; Bengtsson, M.; Najjari, M.; Reinle, F.; Storz, A.; Zhmud, B. Improving the Tribological and NHV Behavior of Gears by Mechanochemical Surface Finishing. In Proceedings of the VDI International Conference on Gears 2022, Garching, Germany, 12–14 September 2022. [Google Scholar]

- Hoehn, B.R.; Oster, P.; Tobie, T.; Michaelis, K. Test Methods for Gear Lubricants. Goriva Maz. 2008, 47, 129. [Google Scholar]

- Yilmaz, M.; Lohner, T.; Michaelis, K.; Stahl, K. Minimizing Gear Friction with Water-Containing Gear Fluids. Forsch Ingenieurwes 2019, 83, 327. [Google Scholar] [CrossRef]

- Li, X.; Olofsson, U. FZG Gear Efficiency and Pin-on-Disc Frictional Study of Sintered and Wrought Steel Gear Materials. Tribol. Lett. 2015, 60, 9. [Google Scholar] [CrossRef][Green Version]

- Ha, T.; Han, N.G.; Kim, M.S.; Rho, K.H.; Kim, D.K. Experimental Study on Behavior of Coolants, Particularly the Oil-Cooling Method, in Electric Vehicle Motors Using Hairpin Winding. Energies 2021, 14, 956. [Google Scholar] [CrossRef]

- Farrenkopf, F.; Schwarz, A.; Lohner, T.; Stahl, K. Analysis of a Low-Loss Gear Geometry Using a Thermal Elastohydrodynamic Simulation including Mixed Lubrication. Lubricants 2022, 10, 200. [Google Scholar] [CrossRef]

- Ziegltrum, A.; Lohner, T.; Stahl, K. TEHL Simulation on the Influence of Lubricants on the Frictional Losses of DLC Coated Gears. Lubricants 2018, 6, 17. [Google Scholar] [CrossRef]

- Najjari, M.; Guilbault, R. Edge Contact Effect on Thermal Elastohydrodynamic Lubrication of Finite Contact Lines. Tribol. Int. 2014, 71, 50. [Google Scholar] [CrossRef]

- Vorburger, T.V.; Silver, R.; Brodmann, R.; Brodmann, B.; Seewig, J. Light Scattering Methods. In Optical Measurement of Surface Topography; Leach, R., Ed.; Springer: Berlin, Germany, 2011. [Google Scholar]

- VDA2009, Geometrische Produktspezifikation, Winkelaufgelöste Streulichtmethode, Definition, Kenngrößen und Anwendung. 07/2010. Available online: https://webshop.vda.de/VDA/de/vda-2009-072010 (accessed on 22 February 2024).

- Hermansson, P.; Forssell, G.; Fagerström, J. A Review of Models for Scattering from Rough Surfaces; Report FOI-R-0988-SE; Totalförsvarets Forskningsinstitut: Linkoping, Sweden, 2003. [Google Scholar]

- Jao, T.C.; Devlin, M.T.; Milner, J.L.; Iyer, R.N.; Hoeprich, M.R. Influence of Surface Roughness on Gear Pitting Behavior. Gear Technol. 2006, 23, 31. [Google Scholar]

- Bergstedt, E.; Lin, J.; Olofsson, U. Influence of Gear Surface Roughness on the Pitting and Micropitting Life. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 4953–4961. [Google Scholar] [CrossRef]

- Ribas, C.J.G. Infuence of Geometry, Surface Roughness, and Operating Conditions on Mild Wear in Lubricated Gear Transmissions. Master’s Thesis, Universidade do Porto, Porto, Portugal, 2016. [Google Scholar]

- Andersson, M.; Sosa, M.; Olofsson, U. The Effect of Running-in on the Efficiency of Superfinished Gears. Tribol. Int. 2016, 93, 71. [Google Scholar] [CrossRef]

- Britton, R.D.; Elcoate, C.D.; Alanou, M.P.; Evans, H.P.; Snidle, R.W. Effect of Surface Finish on Gear Tooth Friction. Trans. ASME 2000, 122, 354. [Google Scholar] [CrossRef]

- Mallipeddi, D.; Norell, M.; Sosa, M.; Nyborg, L. Influence of Running-in on Surface Characteristics of Efficiency Tested Ground Gears. Tribol. Int. 2017, 115, 45. [Google Scholar] [CrossRef]

| Viscosity Grade | KV40, cSt | KV100, cSt | Density, RT, g cm−3 |

|---|---|---|---|

| ISO VG 100 | 98.1 | 11.2 | 0.87 |

| ISO VG 46 | 46.2 | 7.0 | 0.85 |

| ISO VG 22 | 23.4 | 5.0 | 0.83 |

| ISO VG 15 | 14.5 | 3.5 | 0.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhmud, B.; Najjari, M.; Brodmann, B. The Effects of the Lubricant Properties and Surface Finish Characteristics on the Tribology of High-Speed Gears for EV Transmissions. Lubricants 2024, 12, 112. https://doi.org/10.3390/lubricants12040112

Zhmud B, Najjari M, Brodmann B. The Effects of the Lubricant Properties and Surface Finish Characteristics on the Tribology of High-Speed Gears for EV Transmissions. Lubricants. 2024; 12(4):112. https://doi.org/10.3390/lubricants12040112

Chicago/Turabian StyleZhmud, Boris, Morteza Najjari, and Boris Brodmann. 2024. "The Effects of the Lubricant Properties and Surface Finish Characteristics on the Tribology of High-Speed Gears for EV Transmissions" Lubricants 12, no. 4: 112. https://doi.org/10.3390/lubricants12040112

APA StyleZhmud, B., Najjari, M., & Brodmann, B. (2024). The Effects of the Lubricant Properties and Surface Finish Characteristics on the Tribology of High-Speed Gears for EV Transmissions. Lubricants, 12(4), 112. https://doi.org/10.3390/lubricants12040112