Titanium Nitride Coatings on CoCrMo and Ti6Al4V Alloys: Effects on Wear and Ion Release

Abstract

1. Introduction

2. Materials and Methods

2.1. Testing Materials and Substrates

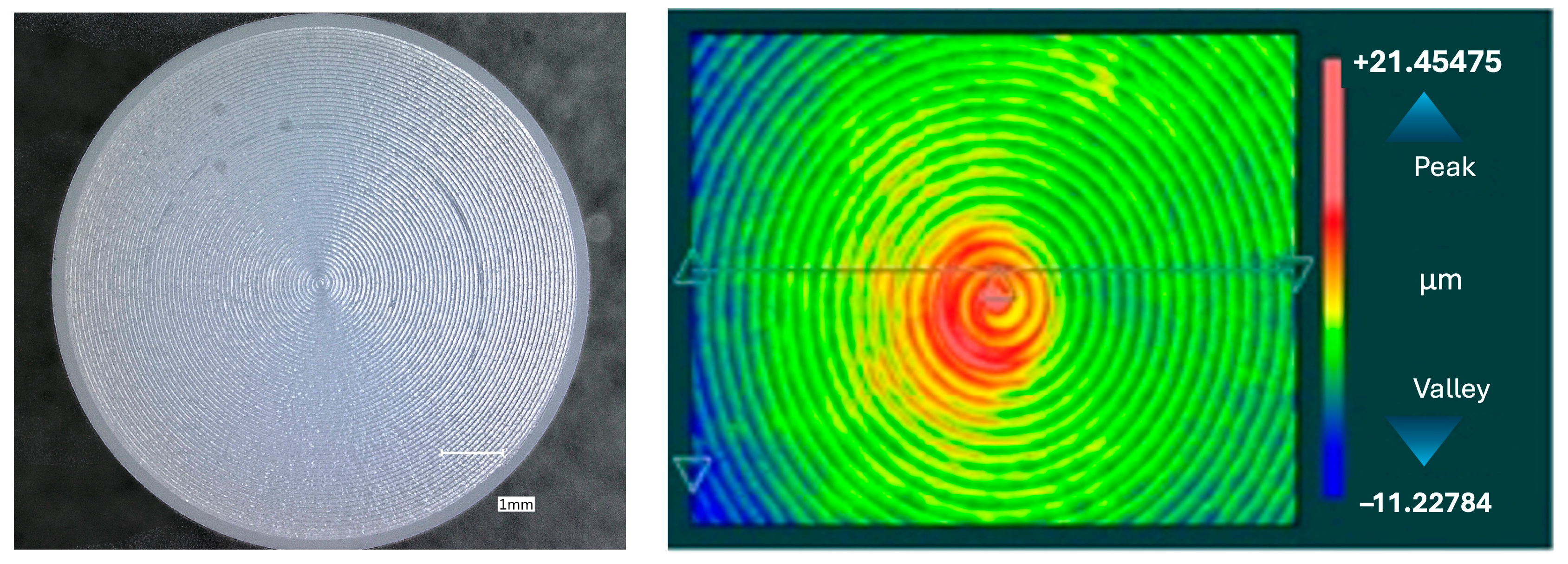

2.2. Coating Deposition and Characterization

2.3. Thickness Evaluation and Coating Hardness

2.4. Wear Testing

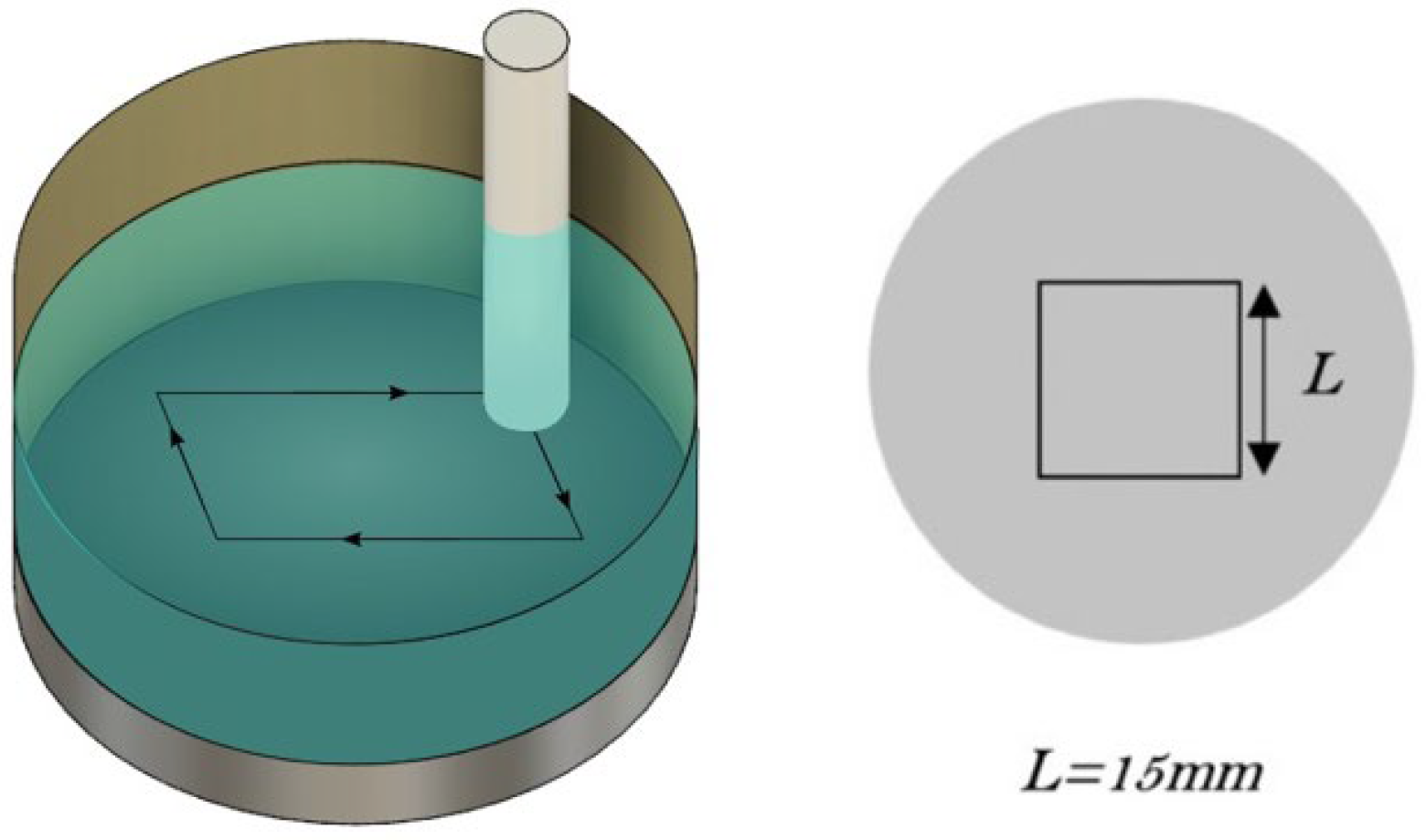

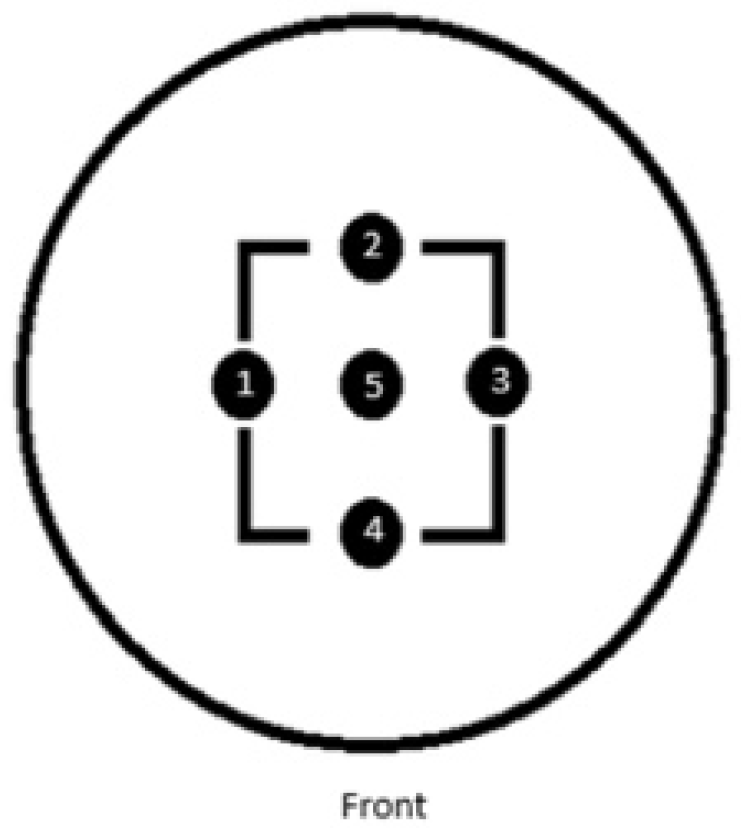

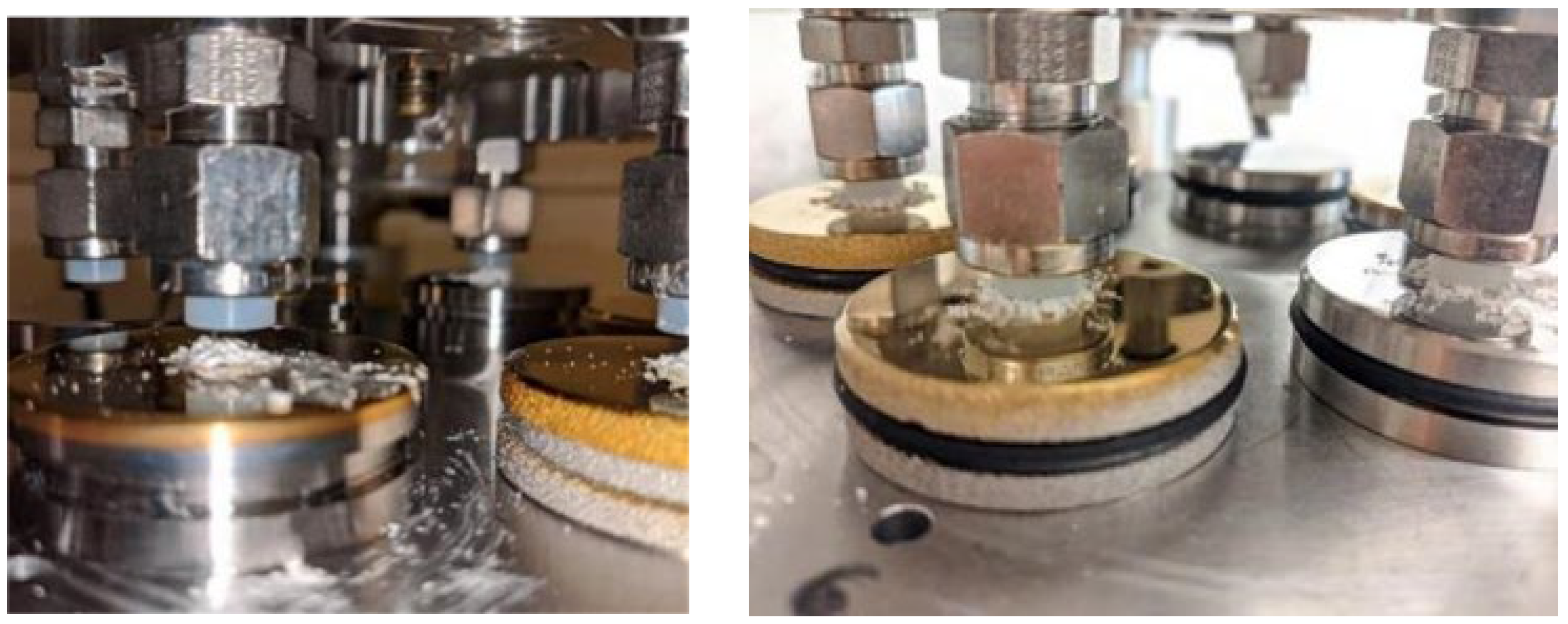

2.4.1. Pin-on-Disc Standard Wear Testing Using Bovine Serum

2.4.2. Pin-on-Disc Wear Test Adding PMMA Bone Cement Particles

2.4.3. Determining Wear Rates

2.5. Imaging and Spectroscopy

2.5.1. Light Microscopy

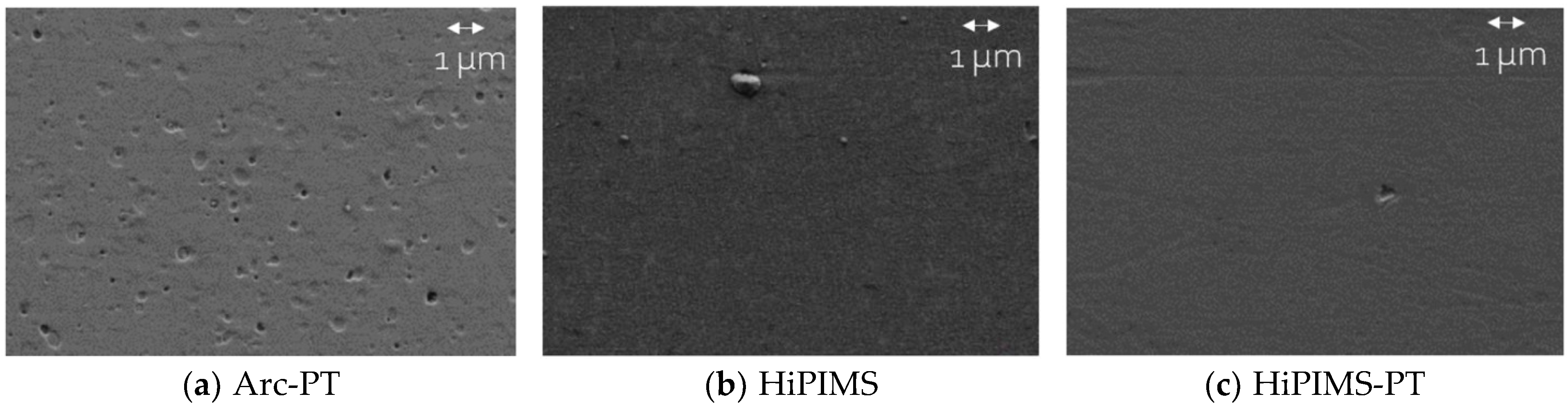

2.5.2. Scanning Electron Microscopy (SEM)

2.5.3. Raman Spectroscopy

2.5.4. Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

2.6. Statistics

3. Results

3.1. Pin-on-Disc Wear Test Using Bovine Serum

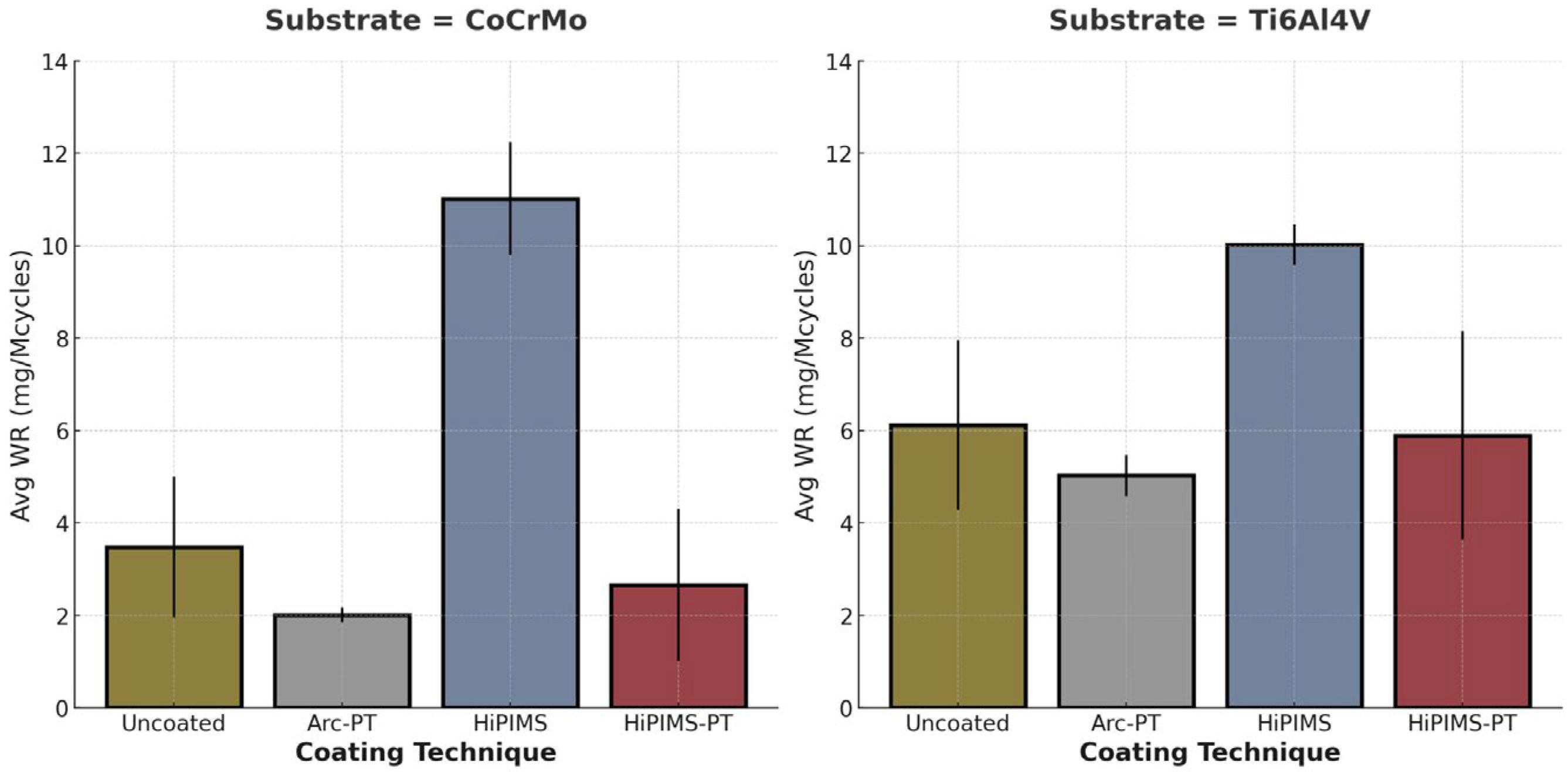

3.1.1. Polyethylene Wear

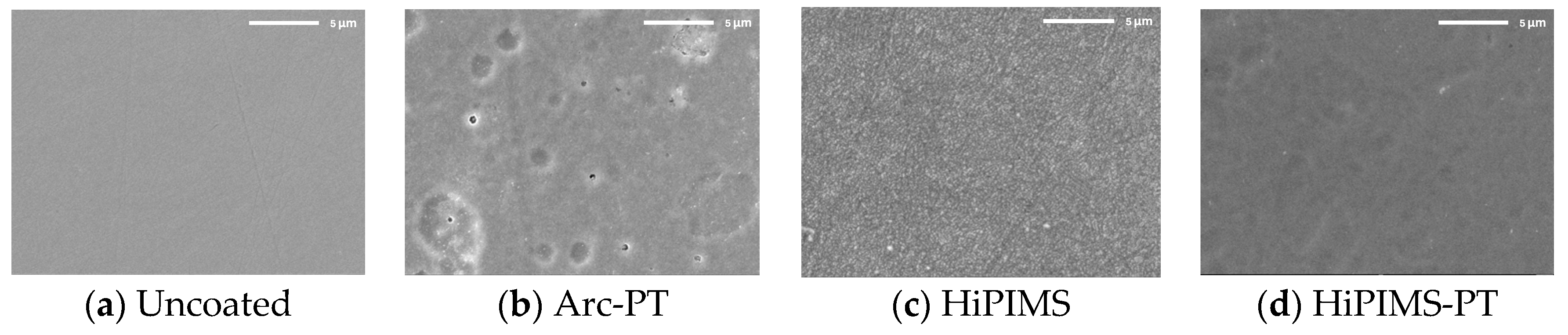

3.1.2. Surface Appearance and Roughness

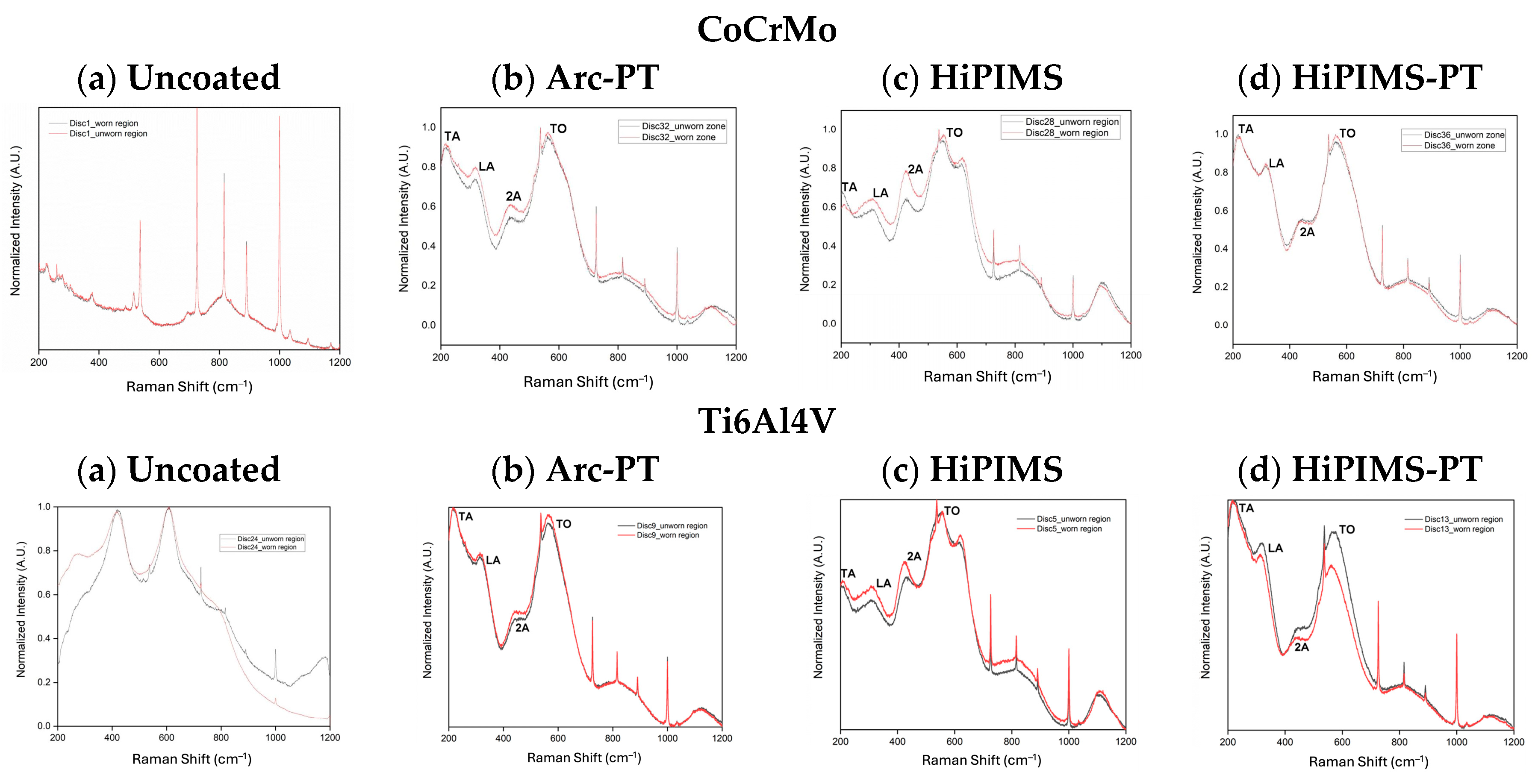

3.1.3. Raman Spectroscopy of Discs

3.2. PMMA Bone Cement Particles Wear Test Results

3.2.1. Polyethylene Wear

3.2.2. Metal Release into Bovine Serum

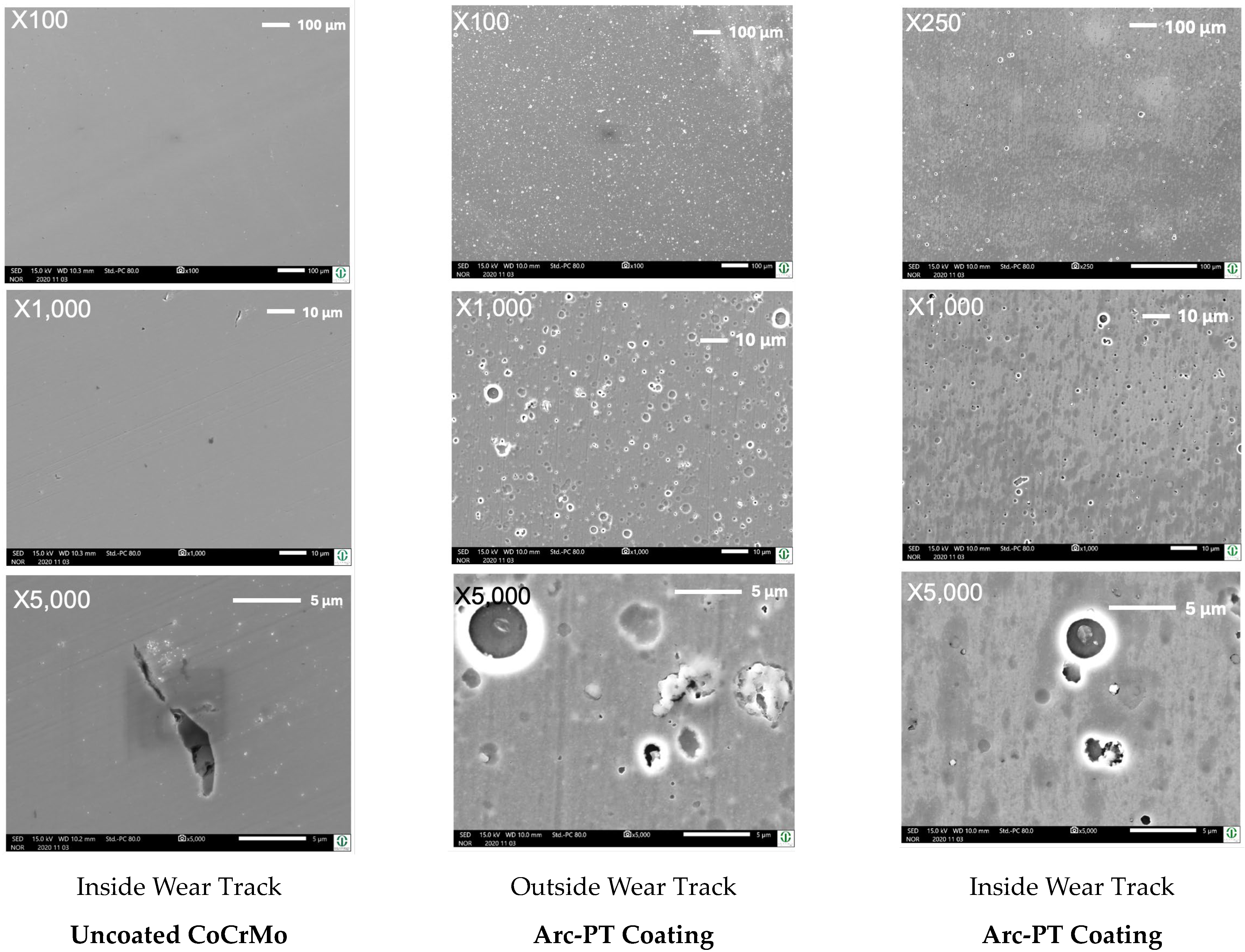

3.2.3. Wear Appearances and Morphology

3.2.4. Roughness Changes after PMMA Particle Challenge

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bitar, D.; Parvizi, J. Biological response to prosthetic debris. World J. Orthop. 2015, 6, 172. [Google Scholar] [CrossRef] [PubMed]

- American Joint Replacement Registry (AJRR): 2023 Annual Report; American Academy of Orthopaedic Surgeons (AAOS): Rosemont, IL, USA, 2023.

- Xie, Y.; Peng, Y.; Fu, G.; Jin, J.; Wang, S.; Li, M.; Zheng, Q.; Lyu, F.J.; Deng, Z.; Ma, Y. Nano wear particles and the periprosthetic microenvironment in aseptic loosening induced osteolysis following joint arthroplasty. Front. Cell. Infect. Microbiol. 2023, 13, 1275086. [Google Scholar] [CrossRef]

- Kandahari, A.M.; Yang, X.; Laroche, K.A.; Dighe, A.S.; Pan, D.; Cui, Q. A review of UHMWPE wear-induced osteolysis: The role for early detection of the immune response. Bone Res. 2016, 4, 16014. [Google Scholar] [CrossRef] [PubMed]

- Abu-Amer, Y.; Darwech, I.; Clohisy, J.C. Aseptic loosening of total joint replacements: Mechanisms underlying osteolysis and potential therapies. Arthritis Res. Ther. 2007, 9, S6. [Google Scholar] [CrossRef] [PubMed]

- Zivic, F.; Babic, M.; Grujovic, N.; Mitrovic, S.; Adamovic, D. Influence of loose PMMA bone cement particles on the corrosion assisted wear of the orthopedic AISI 316LVM stainless steel during reciprocating sliding. Wear 2013, 300, 65–77. [Google Scholar] [CrossRef]

- Rani Bijukumar, D.; Segu, A.; Souza, J.C.; Li, X.; Barba, M.; Mercuri, L.G.; Jacobs, J.J.; Thoppil Mathew, M. Systemic and local toxicity of metal debris released from hip prostheses: A review of experimental approaches. Nanomed. Nanotechnol. Biol. Med. 2018, 14, 951–963. [Google Scholar] [CrossRef]

- Chang, B.S.; Brown, P.R.; Sieber, A.; Valdevit, A.; Tateno, K.; Kostuik, J.P. Evaluation of the biological response of wear debris. Spine J. 2004, 4, S239–S244. [Google Scholar] [CrossRef]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On Coating Techniques for Surface Protection: A Review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef]

- Knight, S.R.; Aujla, R.; Biswas, S.P. Total Hip Arthroplasty—Over 100 years of operative history. Orthop. Rev. 2011, 3, e16. [Google Scholar] [CrossRef]

- Purdue, P.E.; Koulouvaris, P.; Nestor, B.J.; Sculco, T.P. The Central Role of Wear Debris in Periprosthetic Osteolysis. HSS J. 2006, 2, 102. [Google Scholar] [CrossRef]

- Bi, Y.; Seabold, J.M.; Kaar, S.G.; Ragab, A.A.; Goldberg, V.M.; Anderson, J.M.; Greenfield, E.M. Adherent endotoxin on orthopedic wear particles stimulates cytokine production and osteoclast differentiation. J. Bone Miner. Res. 2001, 16, 2082–2091. [Google Scholar] [CrossRef]

- Swaminathan, V.; Gilbert, J.L. Fretting corrosion of CoCrMo and Ti6Al4V interfaces. Biomaterials 2012, 33, 5487–5503. [Google Scholar] [CrossRef]

- Van Hove, R.P.; Sierevelt, I.N.; Van Royen, B.J.; Nolte, P.A. Titanium-Nitride Coating of Orthopaedic Implants: A Review of the Literature. BioMed Res. Int. 2015, 2015, 485975. [Google Scholar] [CrossRef]

- Quinn, J.; McFadden, R.; Chan, C.W.; Carson, L. Titanium for Orthopedic Applications: An Overview of Surface Modification to Improve Biocompatibility and Prevent Bacterial Biofilm Formation. iScience 2020, 23, 101745. [Google Scholar] [CrossRef]

- Łapaj, Ł.; Wendland, J.; Markuszewski, J.; Mróz, A.; Wiśniewski, T. Retrieval analysis of titanium nitride (TiN) coated prosthetic femoral heads articulating with polyethylene. J. Mech. Behav. Biomed. Mater. 2016, 55, 127–139. [Google Scholar] [CrossRef]

- Ming, X.; Wu, Y.; Zhang, Z.; Li, Y. Micro-Arc Oxidation in Titanium and Its Alloys: Development and Potential of Implants. Coatings 2023, 13, 2064. [Google Scholar] [CrossRef]

- Liu, Y.C.; Hsiao, S.N.; Chen, Y.H.; Hsieh, P.Y.; He, J.L. High-Power Impulse Magnetron Sputter-Deposited Chromium-Based Coatings for Corrosion Protection. Coatings 2023, 13, 2101. [Google Scholar] [CrossRef]

- Qureshi, M.W.; Ma, X.; Tang, G.; Miao, B.; Niu, J. Fabrication and Mechanical Properties of Cr2AlC MAX Phase Coatings on TiBw/Ti6Al4V Composite Prepared by HiPIMS. Materials 2021, 14, 826. [Google Scholar] [CrossRef] [PubMed]

- Revolutionary Novel Nanostructured HIPIMS Coatings for Orthopaedic Implant Applications | Sheffield Hallam University. Available online: https://www.shu.ac.uk/research/specialisms/materials-and-engineering-research-institute/what-we-do/thin-films-research-centre/the-national-hipims-technology-centre/case-studies/medical-implants (accessed on 14 February 2024).

- Lofaj, F.; Tanaka, H.; Bureš, R.; Kabátová, M.; Sawae, Y. Tribochemistry of Transfer Layer Evolution during Friction in HiPIMS W-C and W-C:H Coatings in Humid Oxidizing and Dry Inert Atmospheres. Coatings 2022, 12, 493. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Sedelnikova, M.B.; Tolkacheva, T.V.; Shcheglova, N.A.; Panchenko, A.A.; Krasovsky, I.B.; Solomatina, M.V.; Efimenko, M.V.; Pavlov, V.V.; Cherdantseva, L.A.; et al. Micro-Arc Zn- and Ag-Containing Coatings for Implants with Complex Porous Architecture Obtained by 3D Printing Method from Titanium Alloy. Traumatol. Orthop. Russ. 2020, 26, 109–119. [Google Scholar] [CrossRef]

- Hussain, M.; Askari Rizvi, S.H.; Abbas, N.; Sajjad, U.; Shad, M.R.; Badshah, M.A.; Malik, A.I. Recent Developments in Coatings for Orthopedic Metallic Implants. Coatings 2021, 11, 791. [Google Scholar] [CrossRef]

- Mavrogenis, A.F.; Papagelopoulos, P.J.; Babis, G.C. Osseointegration of cobalt-chrome alloy implants. J. Long-Term Eff. Med. Implants 2011, 21, 349–358. [Google Scholar] [CrossRef] [PubMed]

- Park, J.Y.; Shin, D.H.; Choi, J.S.; Kim, K.H. Metallic discoloration on the right shin caused by titanium alloy prostheses in a patient with right total knee replacement. Ann. Dermatol. 2013, 25, 356–359. [Google Scholar] [CrossRef] [PubMed]

- Hall, D.J.; Pourzal, R.; Jacobs, J.J. What Surgeons Need to Know About Adverse Local Tissue Reaction in Total Hip Arthroplasty. J. Arthroplast. 2020, 35, S55–S59. [Google Scholar] [CrossRef] [PubMed]

- Kozelskaya, A.I.; Rutkowski, S.; Frueh, J.; Gogolev, A.S.; Chistyakov, S.G.; Gnedenkov, S.V.; Sinebryukhov, S.L.; Frueh, A.; Egorkin, V.S.; Choynzonov, E.L.; et al. Surface Modification of Additively Fabricated Titanium-Based Implants by Means of Bioactive Micro-Arc Oxidation Coatings for Bone Replacement. J. Funct. Biomater. 2022, 13, 285. [Google Scholar] [CrossRef]

- Lohberger, B.; Stuendl, N.; Glaenzer, D.; Rinner, B.; Donohue, N.; Lichtenegger, H.C.; Ploszczanski, L.; Leithner, A. CoCrMo surface modifications affect biocompatibility, adhesion, and inflammation in human osteoblasts. Sci. Rep. 2020, 10, 1682. [Google Scholar] [CrossRef] [PubMed]

- Lawson, T.R.; Catledge, S.A.; Vohra, Y.K. Nanostructured Diamond Coated CoCrMo Alloys for Use in Biomedical Implants. Key Eng. Mater. 2005, 284–286, 1015–1018. [Google Scholar] [CrossRef]

- Logan, N.; Sherif, A.; Cross, A.J.; Collins, S.N.; Traynor, A.; Bozec, L.; Parkin, I.P.; Brett, P. TiO2-coated CoCrMo: Improving the osteogenic differentiation and adhesion of mesenchymal stem cells in vitro. J. Biomed. Mater. Res. A 2015, 103, 1208–1217. [Google Scholar] [CrossRef]

- Yue, T.; Huang, K. Laser cladding of Cu 0.5 NiAlCoCrFeSi high entropy alloy on AZ91D magnesium substrates for improving wear and corrosion resistance. World J. Eng. 2012, 9, 119–124. [Google Scholar] [CrossRef]

- Cooke, K.; Alhubaida, A. Microstructural response and wear behaviour of Ti-6Al-4V impregnated with Ni/Al2O3 + TiO2 nanostructured coating using an electric arc. Sci. Rep. 2022, 12, 21978. [Google Scholar] [CrossRef]

- Lundin, D.; Sarakinos, K. An introduction to thin film processing using high-power impulse magnetron sputtering. J. Mater. Res. 2012, 27, 780–792. [Google Scholar] [CrossRef]

- Escudeiro, A.; Wimmer, M.A.; Polcar, T.; Cavaleiro, A. Tribological behavior of uncoated and DLC-coated CoCr and Ti-alloys in contact with UHMWPE and PEEK counterbodies. Tribol. Int. 2015, 89, 97–104. [Google Scholar] [CrossRef]

- ASTM F1537-20; Standard Specification for Wrought Cobalt-28Chromium-6Molybdenum Alloys for Surgical Implants. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM F1108-21; Standard Specification for Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical Implants. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM F2924-14(2021); Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 26423:2009; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Coating Thickness by Crater-Grinding Method. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- Fullam, S.; He, J.; Scholl, C.S.; Schmid, T.M.; Wimmer, M.A. Competitive Binding of Bilirubin and Fatty Acid on Serum Albumin Affects Wear of UHMWPE. Lubricants 2020, 8, 53. [Google Scholar] [CrossRef]

- Schwenke, T.; Wimmer, M.A. Cross-shear in metal-on-polyethylene articulation of orthopaedic implants and its relationship to wear. Wear 2013, 301, 168–174. [Google Scholar] [CrossRef][Green Version]

- Kunze, J.; Wimmer, M.A.; Koelling, S.; Schneider, E. Determination of titanium and zirconium wear debris in blood serum by means of HNO3/HF pressurized digestion using ICP-optical emission spectrometry. Fresenius J. Anal. Chem. 1998, 361, 496–499. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Tay, B.K.; Lau, S.P.; Kupfer, H.; Richter, F. Substrate bias dependence of Raman spectra for TiN films deposited by filtered cathodic vacuum arc. J. Appl. Phys. 2002, 92, 1845–1849. [Google Scholar] [CrossRef]

- Mohammadtaheri, M.; Yang, Q.; Li, Y.; Corona-Gomez, J. The Effect of Deposition Parameters on the Structure and Mechanical Properties of Chromium Oxide Coatings Deposited by Reactive Magnetron Sputtering. Coatings 2018, 8, 111. [Google Scholar] [CrossRef]

- Ponon, N.K.; Appleby, D.J.R.; Arac, E.; King, P.J.; Ganti, S.; Kwa, K.S.K.; O’Neill, A. Effect of deposition conditions and post deposition anneal on reactively sputtered titanium nitride thin films. Thin Solid Films 2015, 578, 31–37. [Google Scholar] [CrossRef]

- Cowie, R.M.; Jennings, L.M. Third body damage and wear in arthroplasty bearing materials: A review of laboratory methods. Biomater. Biosyst. 2021, 4, 100028. [Google Scholar] [CrossRef]

- WK80293 New Test Method for Third-Body Adverse Hip Simulator Wear Testing of Metal-on-Polymer Articulations. Available online: https://www.astm.org/products-services/standards-and-publications/standards/workitem-wk80293 (accessed on 8 February 2024).

| Substrate | Coating Technique | Ra ± SD (nm) |

|---|---|---|

| CoCrMo | Uncoated | 4.16 ± 0.35 |

| Arc-PT 1 | 35.24 ± 7.35 | |

| HiPIMS 2 | 5.36 ± 3.92 | |

| HiPIMS-PT 3 | 14.92 ± 1.28 | |

| Ti6Al4V | Uncoated | 17.23 ± 3.64 |

| Arc-PT | 42.50 ± 4.33 | |

| HiPIMS | 30.40 ± 5.76 | |

| HiPIMS-PT | 27.95 ± 2.83 |

| Coating | Thickness (µm) | Hardness ± SD (GPa) |

|---|---|---|

| Arc-PT | 4 | 30.3 ± 1.3 |

| HiPIMS | 5 | 33.5 ± 1.8 |

| HiPIMS-PT | 5 | 32 ± 0.8 |

| Coating | Substrate | Ra ± SD (nm) Pre | Ra ± SD (nm) Post | p Value |

|---|---|---|---|---|

| Uncoated | CoCrMo | 4.16 ± 0.58 | 4.70 ± 0.29 | 0.309 |

| Ti6Al4V | 17.23 ± 0.20 | 25.18 ± 8.56 | 0.256 | |

| Arc-PT | CoCrMo | 35.24 ± 7.24 | 27.97 ± 3.91 | 0.073 |

| Ti6Al4V | 42.50 ± 4.59 | 43.75 ± 8.52 | 0.637 | |

| HiPIMS | CoCrMo | 15.36 ± 0.80 | 17.94 ± 0.96 | 0.124 |

| Ti6Al4V | 30.40 ± 0.91 | 34.41 ± 6.27 | 0.421 | |

| HiPIMS-PT | CoCrMo | 14.92 ± 1.38 | 12.61 ± 0.92 | 0.044 |

| Ti6Al4V | 27.95 ± 5.50 | 35.52 ± 5.61 | 0.046 |

| Coating | Substrate | WR ± SD (mg/MC) Pre | WR ± SD (mg/MC) Post | p Value |

|---|---|---|---|---|

| Uncoated | CoCrMo | 3.47 ± 1.51 | 14.6 ± 2.99 | 0.049 |

| Arc-PT | CoCrMo | 2.0 ± 0.16 | 7.77 ± 1.05 | 0.014 |

| Ti6Al4V | 5.02 ± 0.44 | 7.02 ± 0.65 | 0.108 | |

| HiPIMS-PT | CoCrMo | 2.65 ± 1.64 | 11.91 ± 5.23 | 0.115 |

| Ti6Al4V | 5.88 ± 2.25 | 10.22 ±1.52 | 0.018 |

| Coating | Substrate | Co | Mo | Cr | Ti |

|---|---|---|---|---|---|

| Uncoated | CoCrMo | 5.947 ± 1.862 | 0.527 ± 0.174 | 2.563 ± 0.766 | ND |

| Arc-PT | CoCrMo | ND | ND | ND | 2.733 ± 1.124 |

| Ti6Al4V | ND | ND | ND | 2.133 ± 1.106 | |

| HiPIMS-PT | CoCrMo | ND | ND | ND | 3.333 ± 3.784 |

| Ti6Al4V | ND | ND | ND | 2.266 ± 2.532 |

| Coating | Substrate | Ra ± SD (nm) Pre | Ra ± SD (nm) Post | p Value |

|---|---|---|---|---|

| Uncoated | CoCrMo | 4.707 ± 1.335 | 5.652 ± 0.600 | 0.295 |

| Arc-PT | CoCrMo | 27.967 ± 1.3.998 | 22.445 ± 2.834 | 0.087 |

| Ti6Al4V | 43.748 ± 17.387 | 31.473 ± 4.715 | 0.120 | |

| HiPIMS-PT | CoCrMo | 12.613 ± 3.550 | 9.991 ± 0.700 | 0.053 |

| Ti6Al4V | 32.524 ± 3.647 | 21.346 ± 5.365 | 0.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AbuAlia, M.; Fullam, S.; Cinotti, F.; Manninen, N.; Wimmer, M.A. Titanium Nitride Coatings on CoCrMo and Ti6Al4V Alloys: Effects on Wear and Ion Release. Lubricants 2024, 12, 96. https://doi.org/10.3390/lubricants12030096

AbuAlia M, Fullam S, Cinotti F, Manninen N, Wimmer MA. Titanium Nitride Coatings on CoCrMo and Ti6Al4V Alloys: Effects on Wear and Ion Release. Lubricants. 2024; 12(3):96. https://doi.org/10.3390/lubricants12030096

Chicago/Turabian StyleAbuAlia, Mohammed, Spencer Fullam, Filippo Cinotti, Noora Manninen, and Markus A. Wimmer. 2024. "Titanium Nitride Coatings on CoCrMo and Ti6Al4V Alloys: Effects on Wear and Ion Release" Lubricants 12, no. 3: 96. https://doi.org/10.3390/lubricants12030096

APA StyleAbuAlia, M., Fullam, S., Cinotti, F., Manninen, N., & Wimmer, M. A. (2024). Titanium Nitride Coatings on CoCrMo and Ti6Al4V Alloys: Effects on Wear and Ion Release. Lubricants, 12(3), 96. https://doi.org/10.3390/lubricants12030096