1. Introduction

Bio-lubricants are future lubricants that will replace mineral and synthetic oils due to environmental concerns because they have some advantages, including being biodegradable and non-toxic [

1]. Although mineral and synthetic oils have superior performance and are widely used as lubricants in the automotive industry, they are not environmentally friendly. Meanwhile, bio-based oil has good lubricant properties but has one disadvantage, which is low thermal-oxidative stability [

2]. It contains unsaturated fatty acids that actively react with oxygen to form peroxides, which affect the viscosity and performance of the lubricant [

3]. Therefore, bio-based oil is not widely used in industry. Many researchers are currently focusing on improving the weaknesses of bio-based oil so that it can be used in industry.

To improve thermal-oxidative stability in bio-based oils, a chemical modification process such as transesterification is used, which eliminates the hydrogen molecule at the beta carbon position by substituting glycerol with polyols that do not contain beta hydrogen [

3]. Another way to eliminate the disadvantages of bio-based oils is by adding additives to improve their lubricant performances significantly [

4]. Organic compounds [

5], ionic liquids [

6], and nanomaterials [

7] have been adopted and studied as lubricant additives. Organic compounds are a form of oil additive that is environmentally friendly and improves not only the physical but also the tribological properties of lubricant oils [

5]. Furthermore, ionic liquids not only enhance the inherent tribological performance of the lubricant bio-based oils but also enhance physiochemical properties and subdue undesirable properties [

6]. Moreover, nanomaterials can significantly reduce wear and friction through self-repair and the formation of a lubricating film [

7] due to their atomic size and surface effect.

Nowadays, due to the growing environmental and ecological concerns associated with using synthetic polymers, cellulose compounds are often used as additives in lubricant oils to increase the performance of lubricant oil [

8]. Cellulose is an alluring material as a matrix and substrate for the preparation of multifunctional composites because of its convenient water processability, good biodegradability, mechanical strength, biocompatibility, natural abundance, and sustainability [

9]. Carboxymethyl cellulose (CMC) is a cellulose derivative that is widely used in industry. CMC is a linear polysaccharide of anhydro-glucose that is used to enhance viscosity, control the rheology of a solution, avoid the separation of water from a suspension, and improve surface or barrier properties [

8]. CMC acts both as a film-forming agent and as a stabilizer and emulsifier for an aqueous system. Research conducted by Opia et al. recently showed that adding CMC to rapeseed oil can reduce the friction coefficient and wear by 44.8% [

10].

MXenes are a class of two-dimensional (2D) inorganic compounds notable for their distinctive physical and chemical properties that combine aspects of both metals and ceramics [

11]. Due to the unique mechanical properties of MXenes, they have received extensive attention in the field of tribology as an additive [

12]. As a result, MXenes have been revealed to be an excellent lubricant candidate due to their low friction and wear rate in various tribological applications [

13]. The properties can be applied in tribology due to weak interlayer interactions and a highly specific surface, which makes them readily slide between interlayers under pressure and easily form lubrication [

14,

15]. Since MXenes were first discovered in 2011, their application has grown not only in liquid lubrication but also in solid lubrication. Some investigators [

16,

17,

18] have demonstrated that the addition of MXenes enhances the tribological performance of the base oil, where, as an additive, MXenes contribute to the formation of a uniform and continuous tribofilm on the contact surface.

The potential problem of solid–liquid lubricants is agglomeration. It is associated with the high surface energy of nanoparticles and their ability to adsorb large amounts of oxygen, nitrogen, and moisture from the environment. To prevent agglomeration in liquid media, surfactants are used to stabilize the dispersion in lubricant for a long period of time [

19]. The selection of an appropriate surfactant is crucial to achieving the desired friction-reduction and anti-wear properties. In several studies, surfactants have been known as anti-wear or anti-friction additives for their superior performance in lubricating oil, consisting of nano or colloidal particles [

20].

The use of MXene/CMC as a water-based lubricant was investigated by Rahmadiawan et al., and the result shows that the addition of MXene and CMC with 0.4% and 0.7% wt, respectively, in water can decrease the coefficient of friction by around 25% compared to water [

21]. In this study, crude palm oil (CPO), which grows in tropical countries like Indonesia, will be used as a lubricant base oil. This oil has good properties as a biobased lubricant because it has a high viscosity index, is a biodegradable lubricant, and has good lubricity [

22,

23,

24]. However, this oil still has some drawbacks as a candidate bio-lubricant. Therefore, it is necessary to improve its physicochemical and tribological properties by adding some additives. In this research, a composite of CMC/MXene will be added as an additive to CPO to increase its performance as a bio-lubricant. To prevent agglomeration of the solution between MXene and CPO, Span 60 will be added as a surfactant in the solution. The characteristics of the physicochemical and tribological properties of the bio-lubricant will be investigated.

5. Conclusions

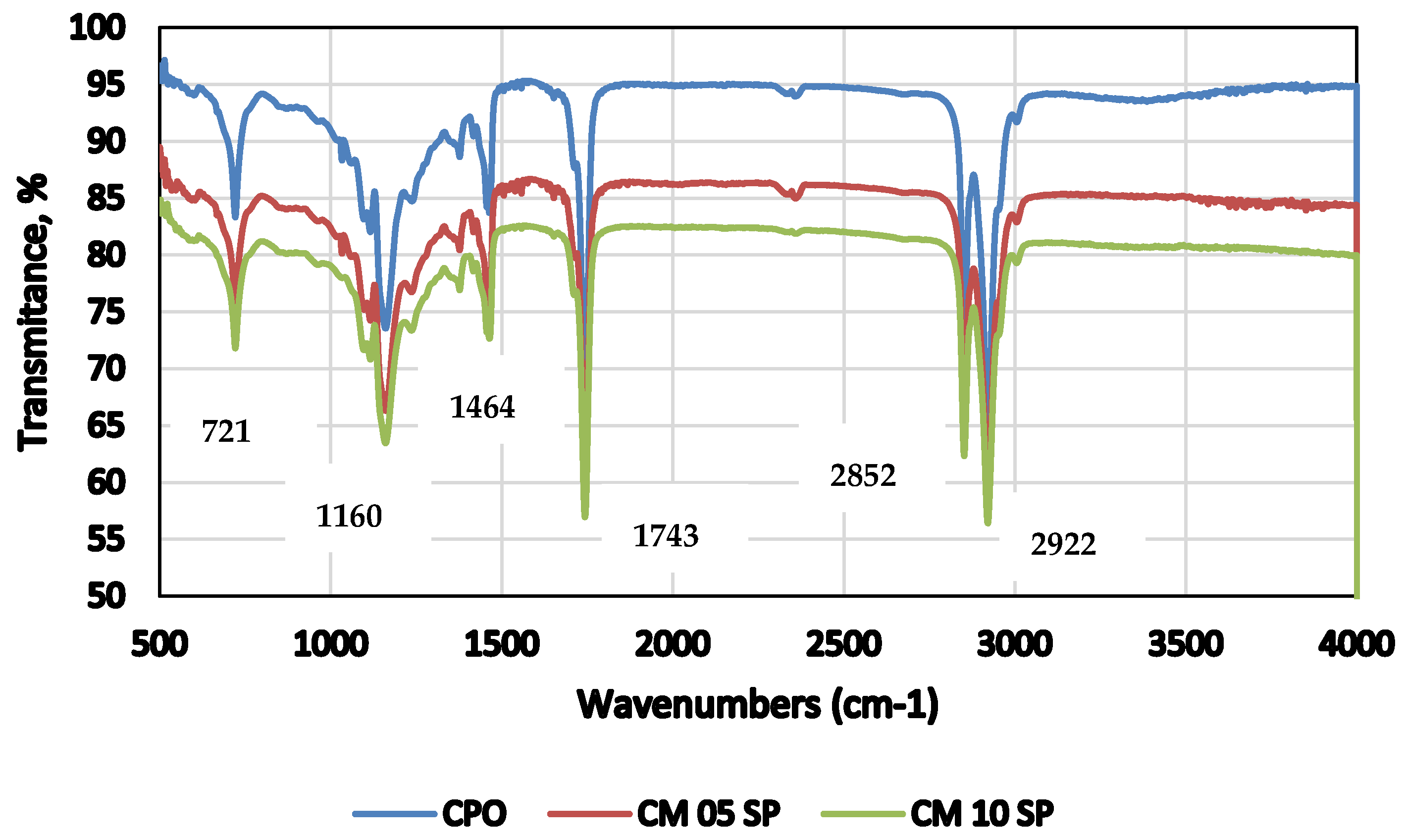

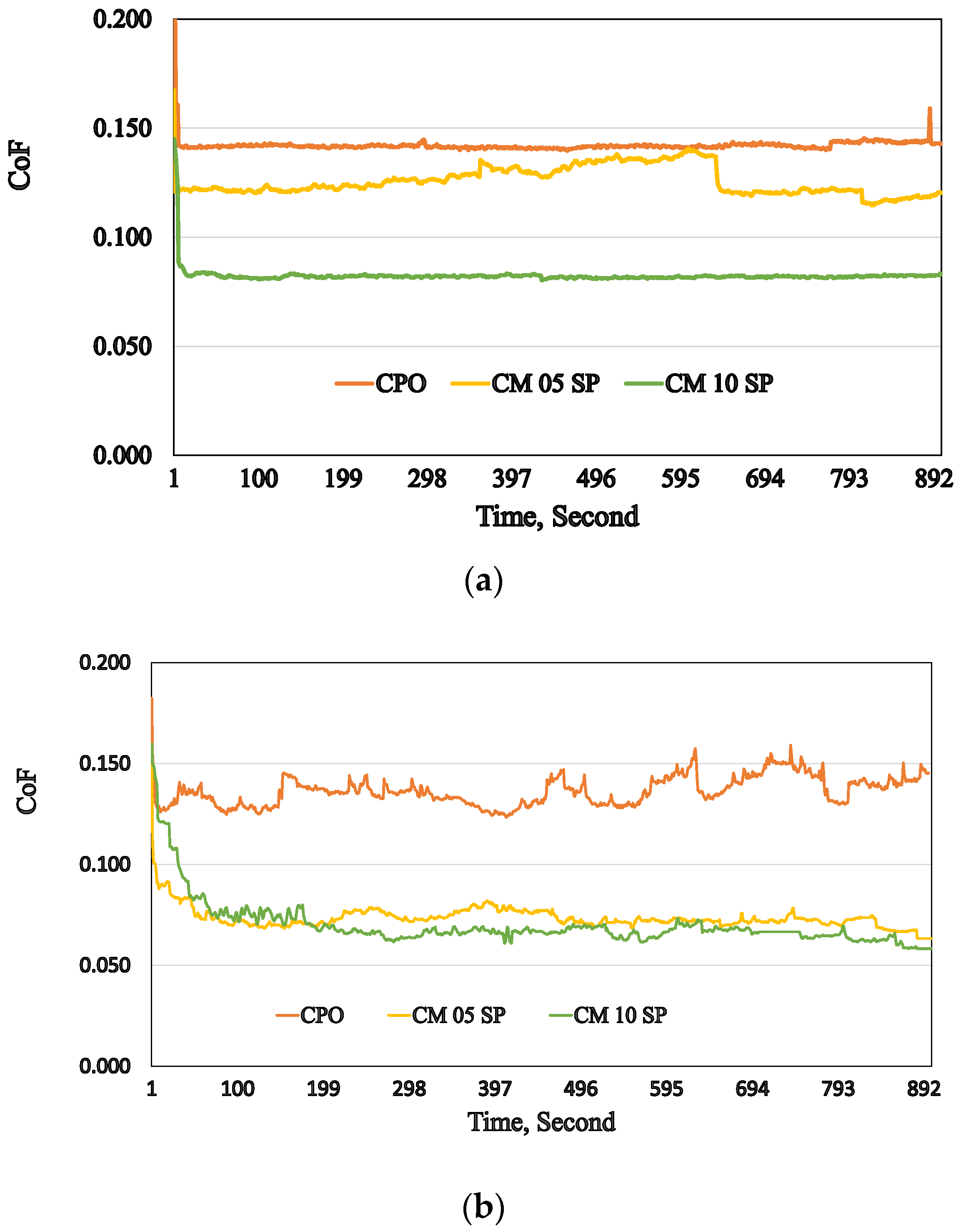

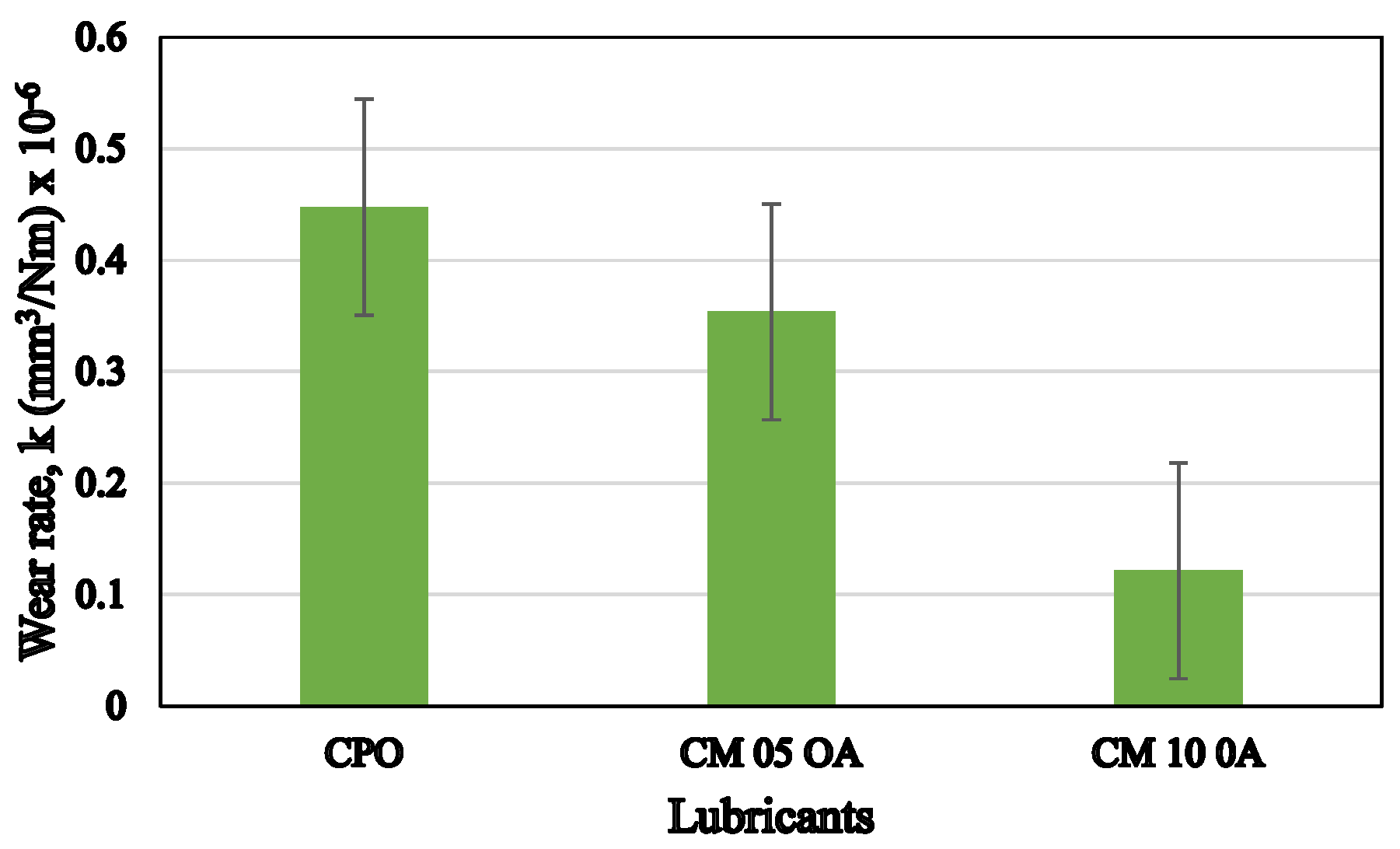

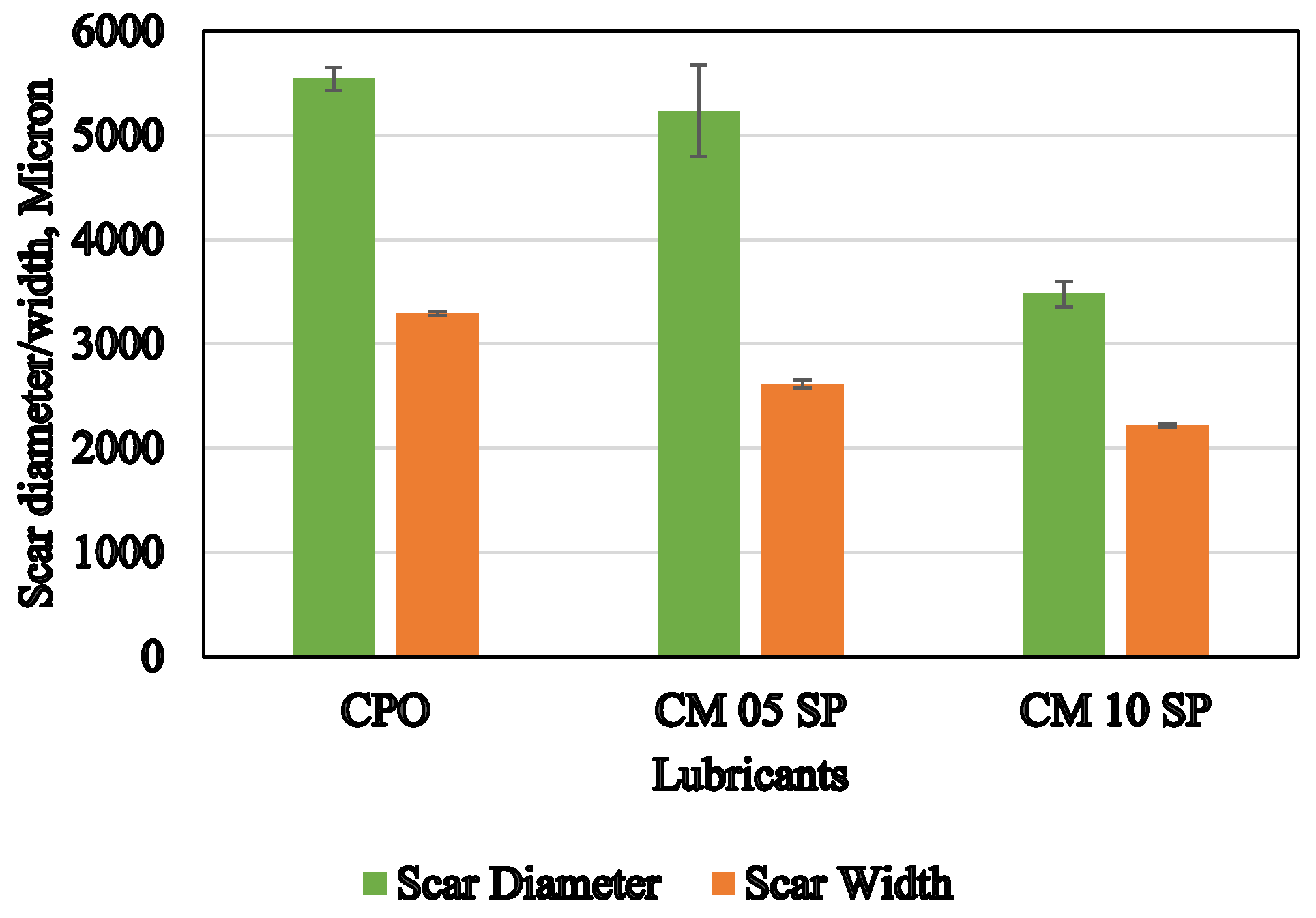

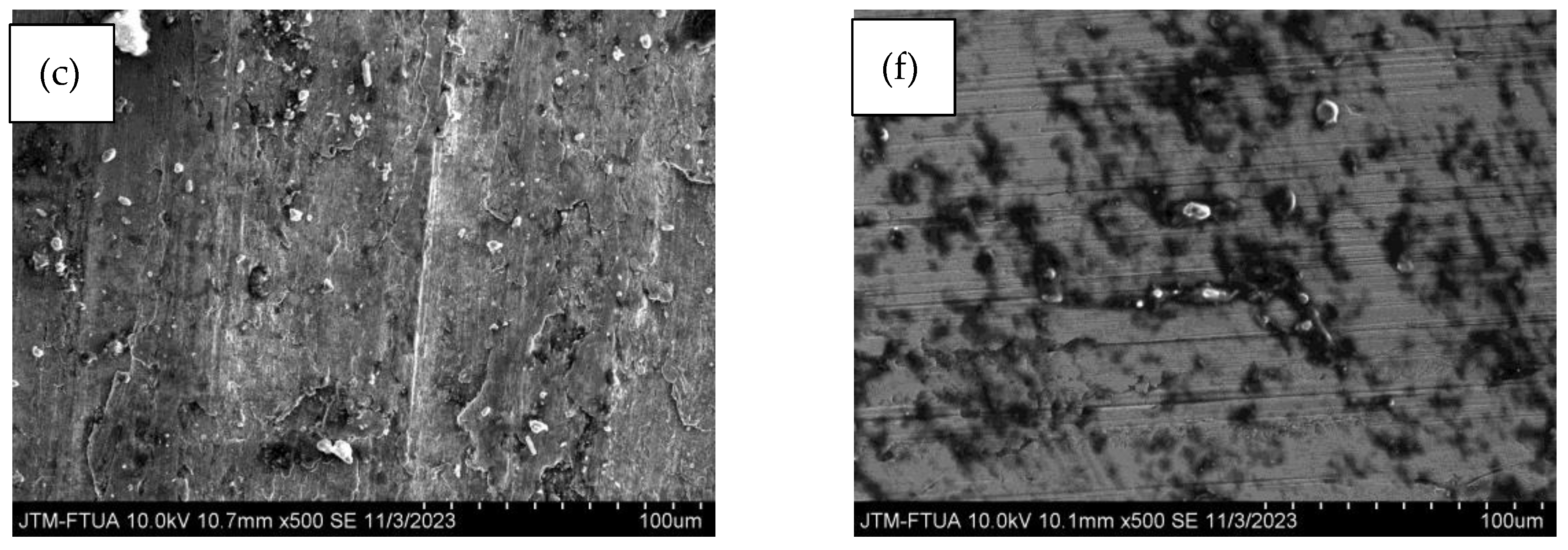

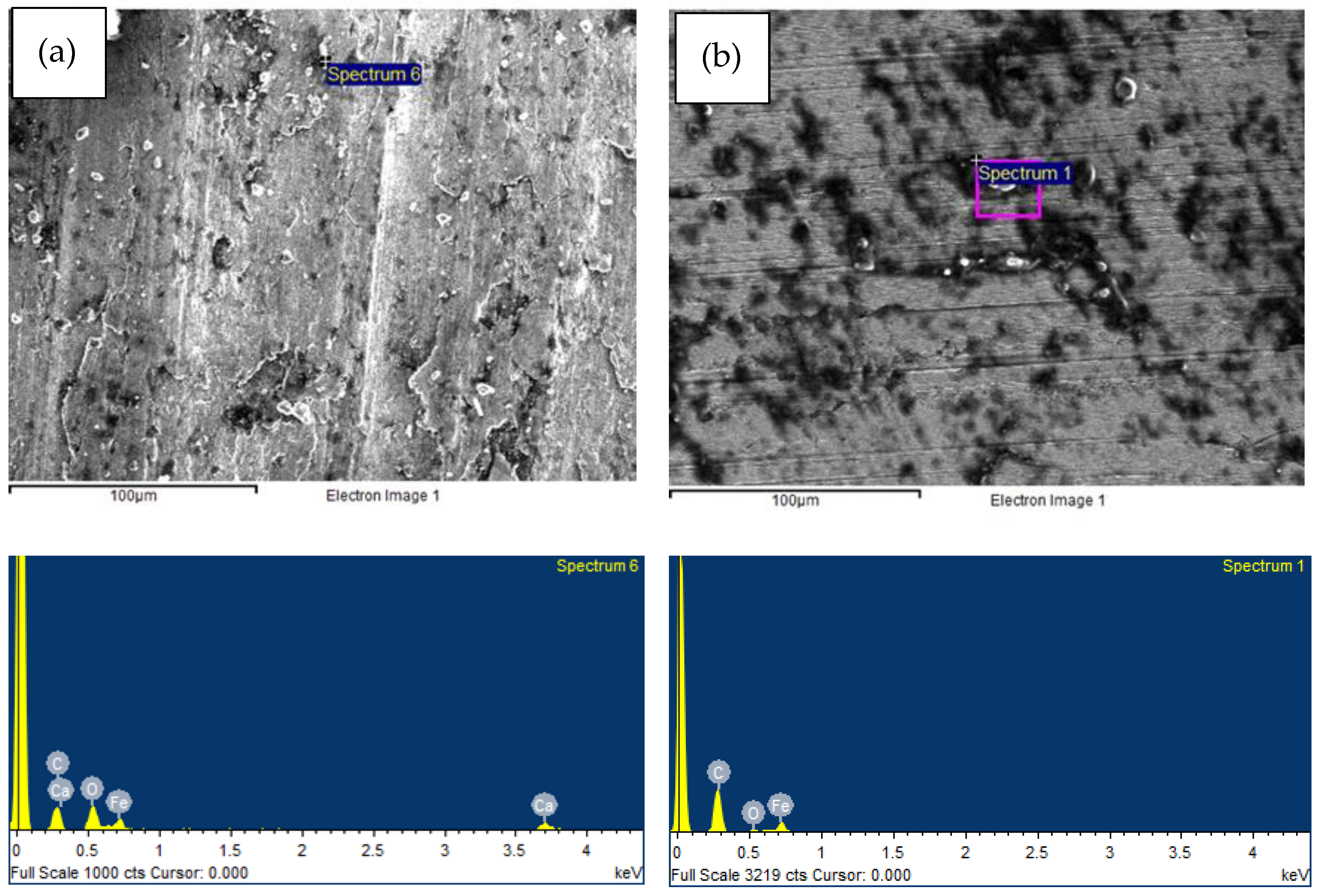

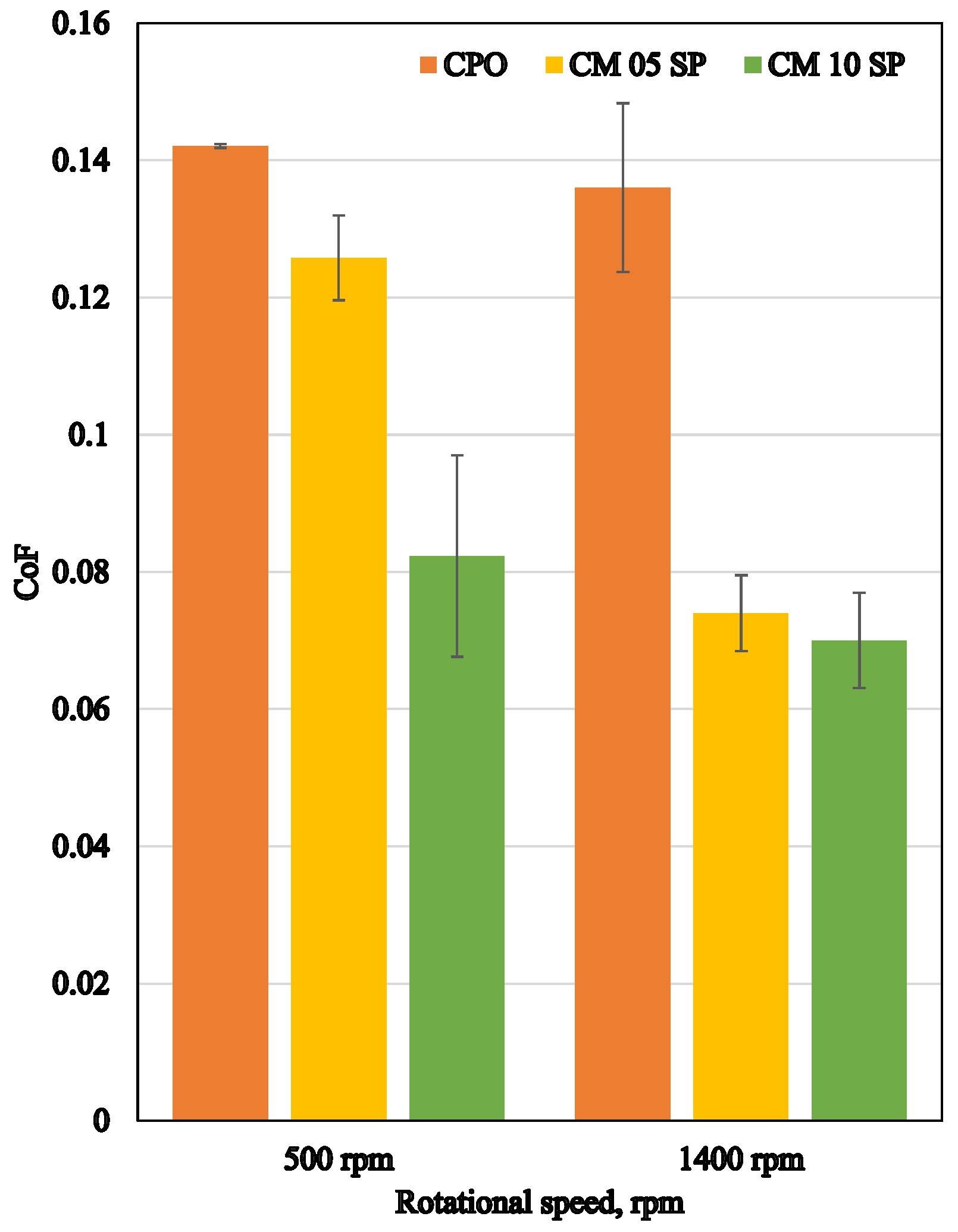

The interaction of additives in base oils can result in a positive, negative, or neutral effect on lubricant performance, including its tribological and physicochemical properties. In this research, the addition of a composite of CMC/MXene and Span 60 with different concentrations in CPO increased the tribological and physicochemical properties of CPO. The physicochemical properties of addition additives in CPO changed, including kinematic viscosity, TAN, thermal conductivity, and fatty acids, which had a positive impact on lubrication performance in terms of reducing oxidation processes and increasing thermal conductivity. Tribo-improver of composites of CMC/MXene and Span 60 in CPO protected surface contact from wear and friction, where the CoF and wear rate were reduced by 49% and 70%, respectively, at a rotational speed of 1400 rpm. Meanwhile, composites of CMC/MXene and Span 60 as additives in CPO formed a surface layer coating the contact surface, which prevents direct contact between two rubbing surfaces.