Evaluating the Tribological Behaviour in Cutting Operations Using a Modified Ball-on-Disc Open Tribotester

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Characterisation

2.2. FTIR Anaylsis

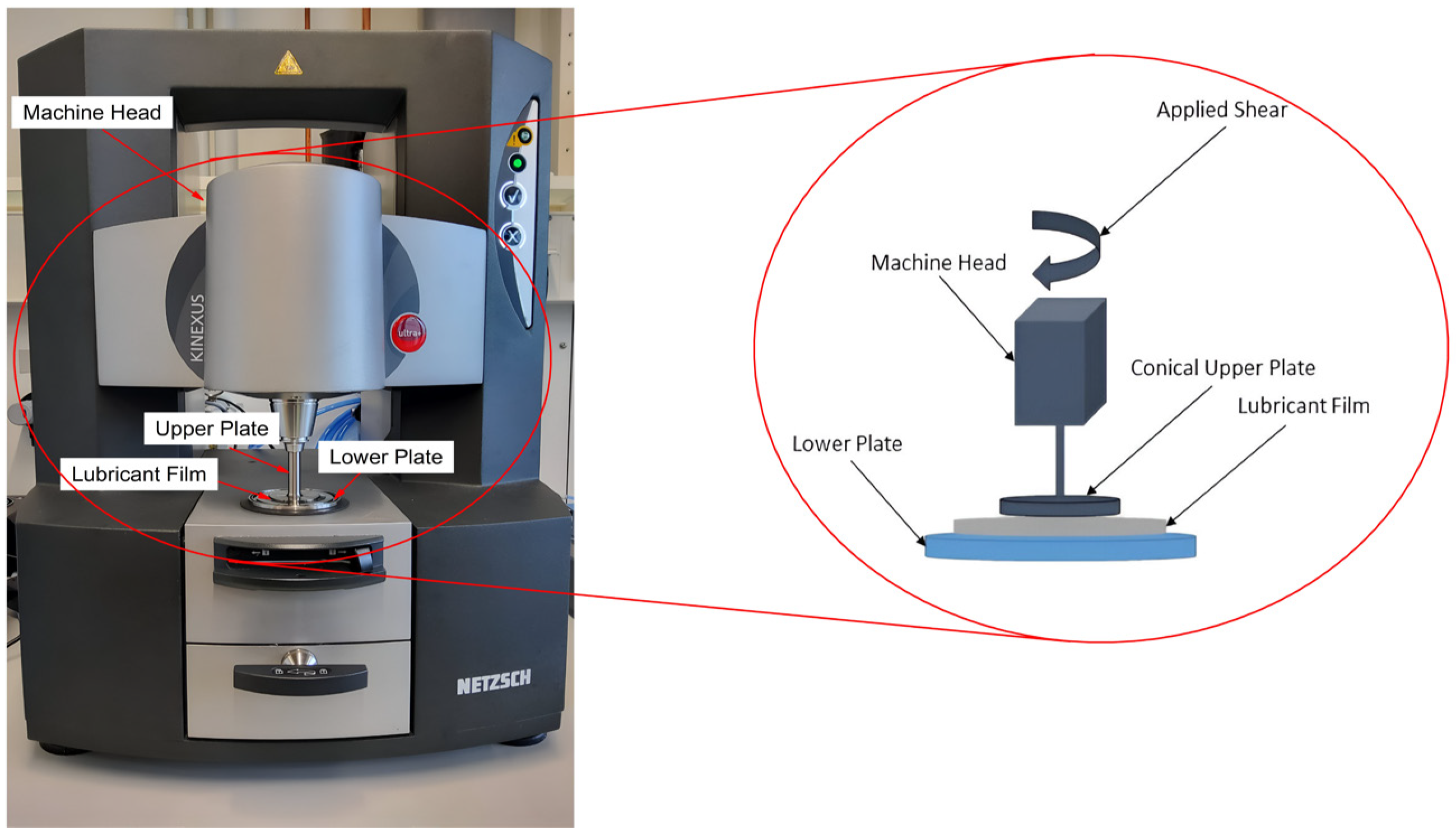

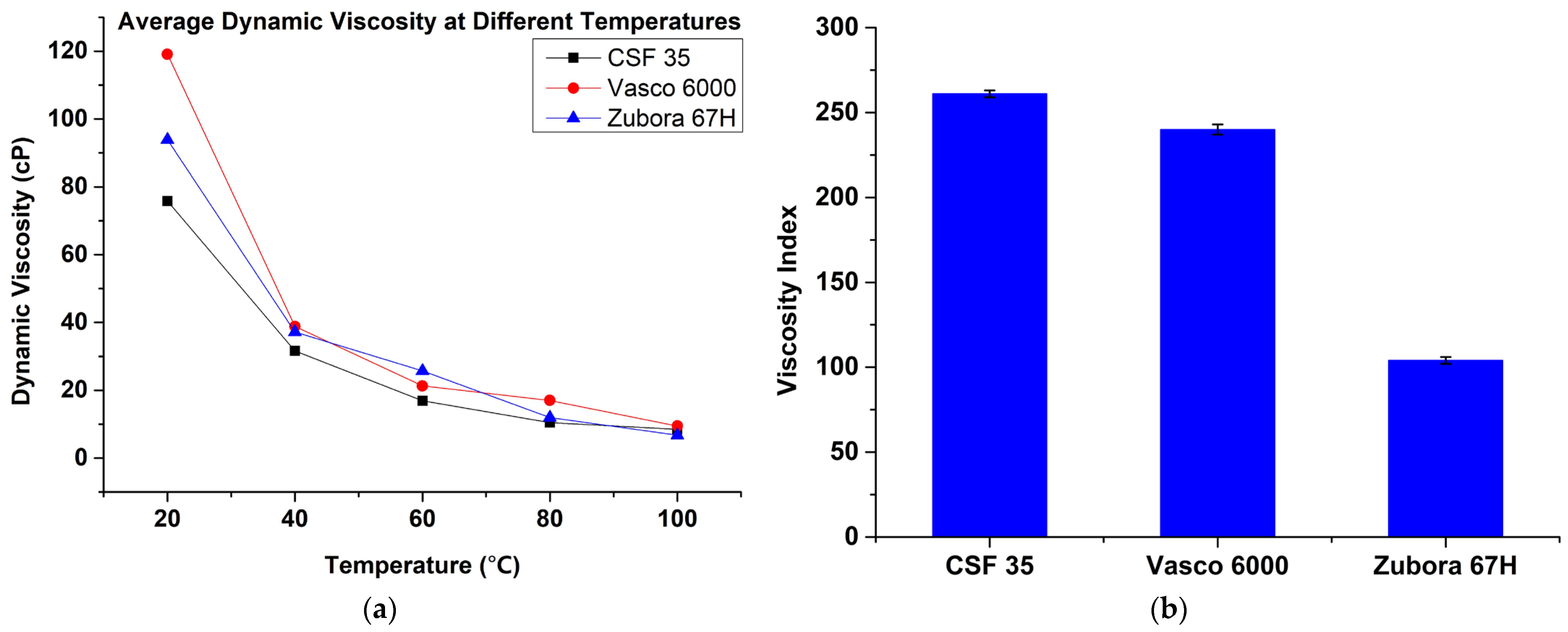

2.3. Rheological Behavior

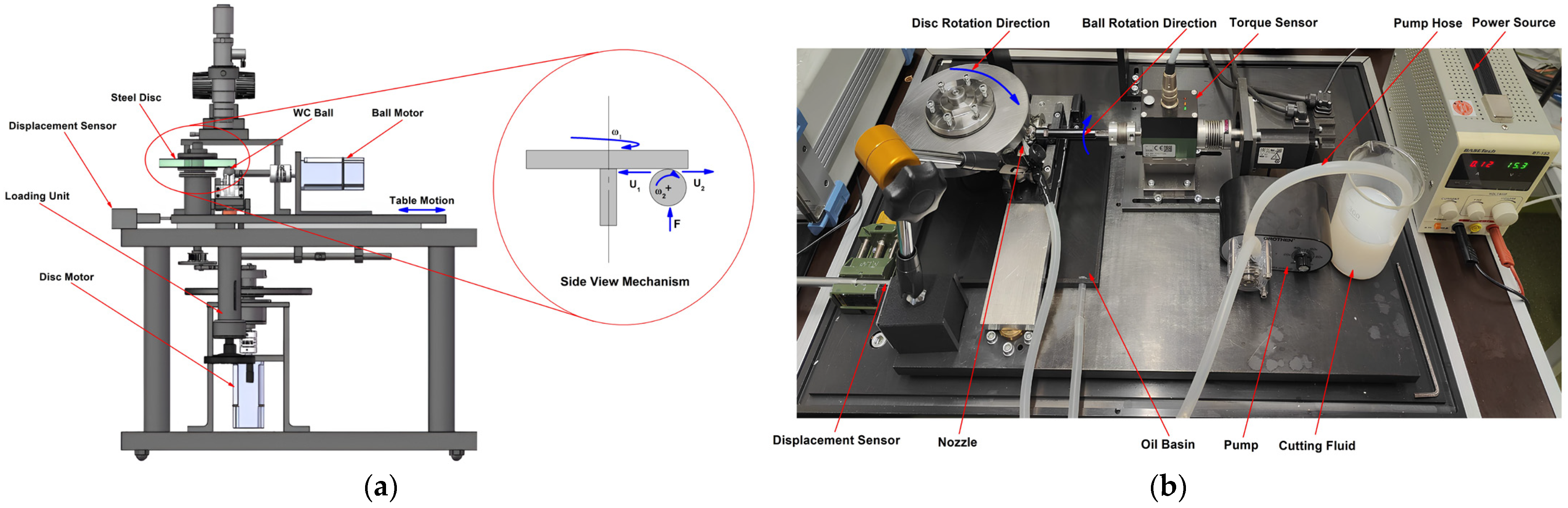

2.4. Ball-on-Disc Open Tribometer

2.5. Wettability Analysis

2.6. Orthogonal Cutting

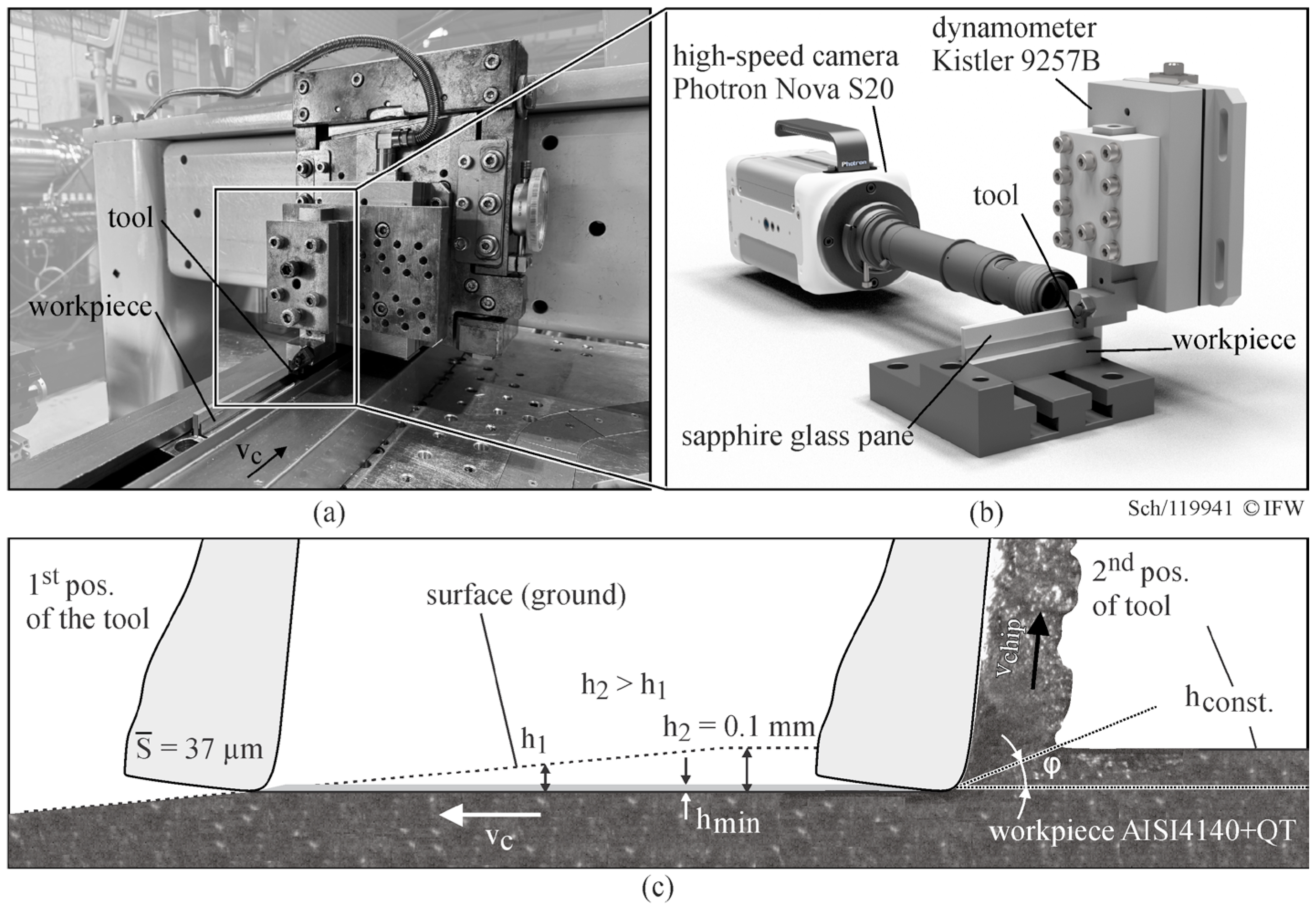

3. Results and Discussion

3.1. FTIR Results

3.2. Rheological Behavior

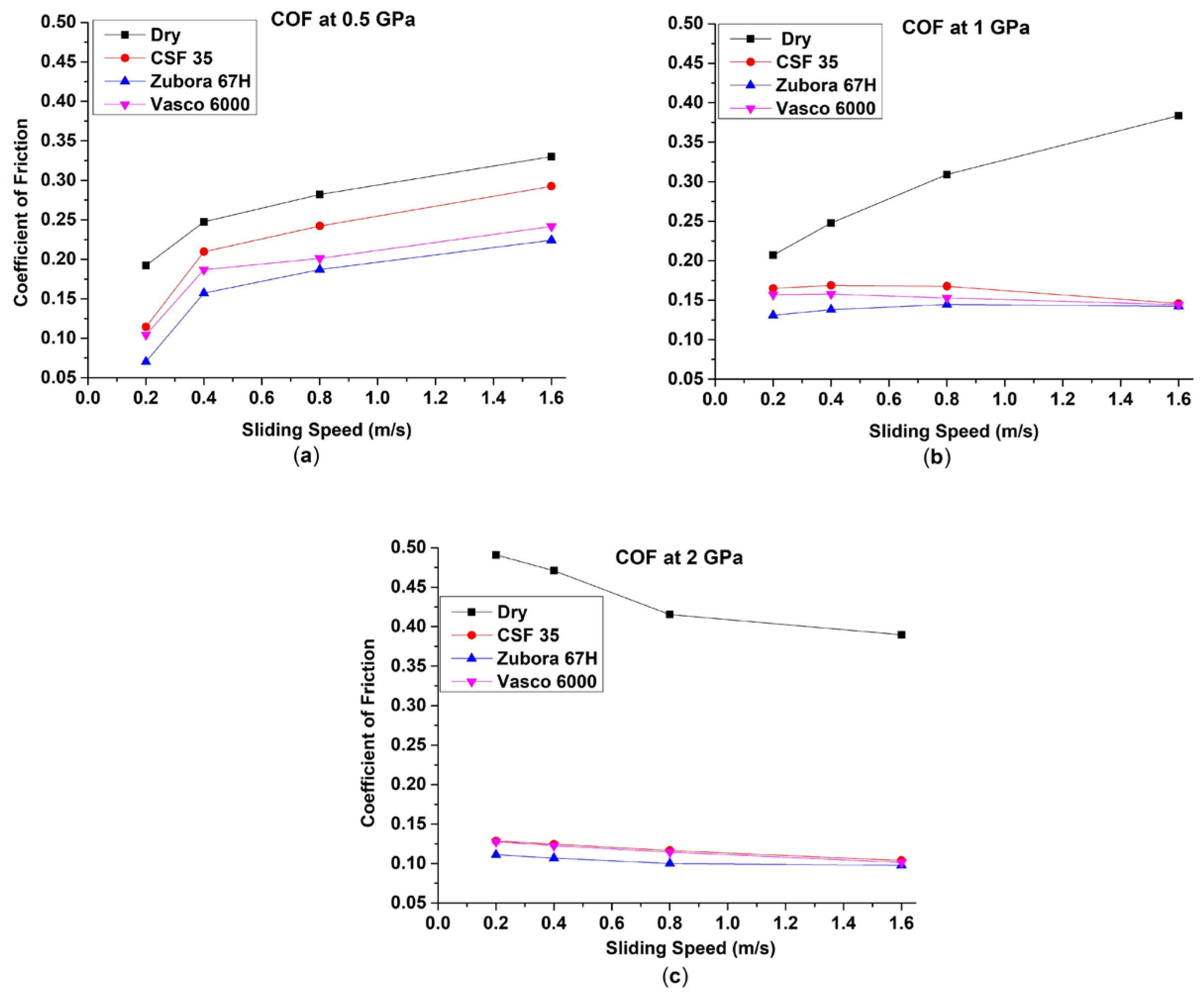

3.3. Frictional Characteristics

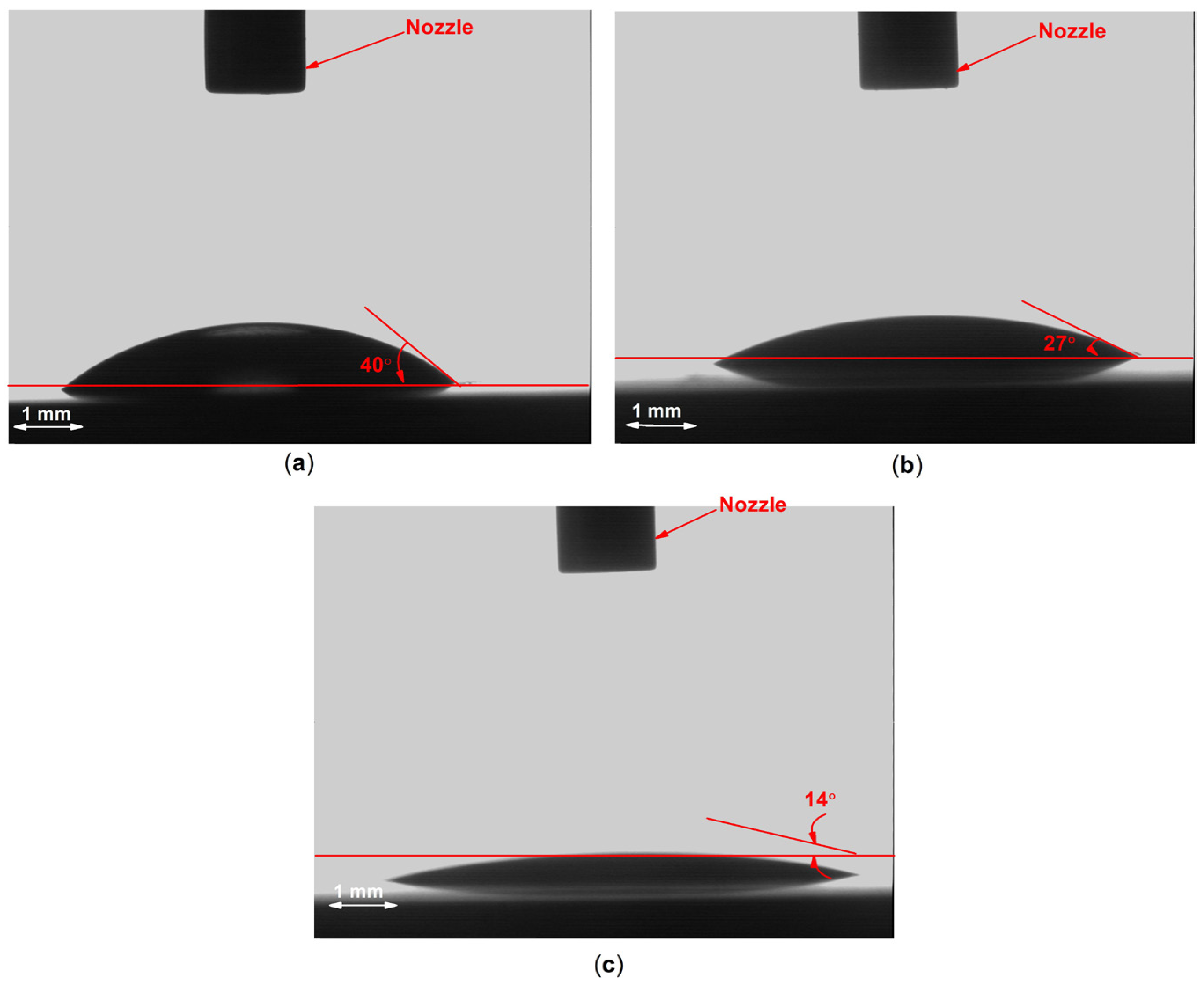

3.4. Wettability Analysis

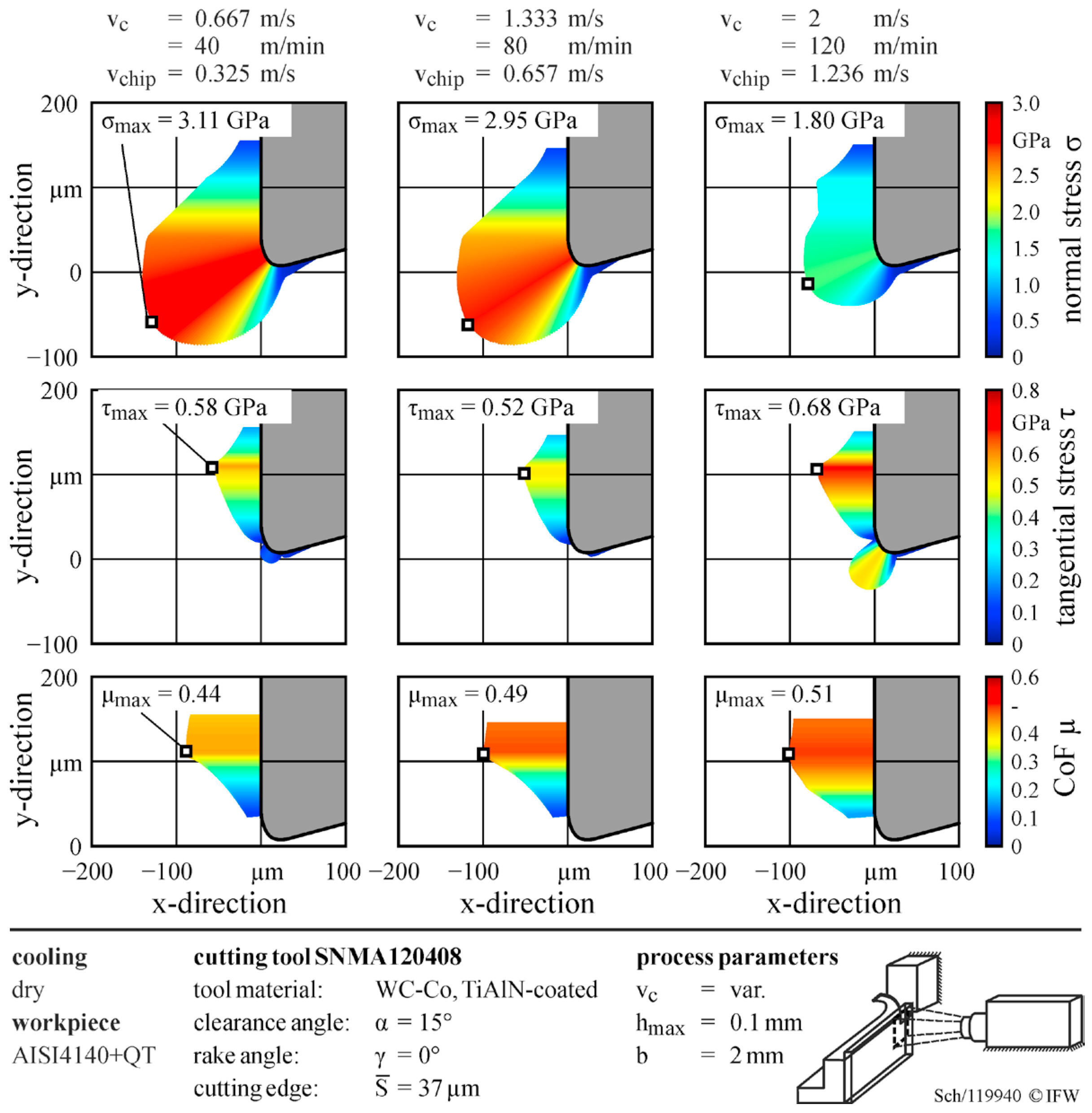

3.5. Comparison with In Situ Measured Coefficient of Friction during Orthogonal Cutting

4. Conclusions

- All applied cutting fluids experienced Newtonian attitude at up to 40 ℃. At 60 ℃, the emulsion-based oils started showing shear thinning behaviour, and this phenomenon significantly increased, especially for Zubora 67H, as the temperature increased further.

- CSF 35 displayed the lowest dynamic viscosity, attributed to the absence of certain polar additives found in emulsions. However, it can sustain viscosity at higher temperatures, thanks to its highest viscosity index.

- The COF obtained from tribometer testing in dry conditions showcased a noteworthy increase at contact pressures of up to 1 GPa. However, at 2 GPa, the COF trend exhibited a marked decrease. This reversal could potentially be ascribed to three factors: increased heat dissipation at higher speeds, a reduced impact of surface irregularities on the friction coefficient, and thermal softening resulting from increased pressure.

- COF values under lubricated conditions highlighted the capability of emulsion-based oils, particularly Zubora 67H, to achieve a reduction of up to 78%. This reduction was attributed to the influence of polar additives enhancing frictional behaviour.

- The physical characteristics of the applied MWFs were evaluated by measuring the contact angle with the steel surface. Emulsions, especially Zubora 67H, demonstrated a significant improvement in wettability characteristics, evidenced by a 65% reduction in the contact angle compared to CSF 35.

- The local coefficient of friction in the secondary shear zone of the rake face can be calculated due to high-speed recordings and measurements of the process forces.

- The in situ-measured COFs in cutting showed the same trend as the measured COFs on the open tribometer regarding an increase in the relative velocity. However, there was a difference in the absolute values due to the high temperature and high temperature gradients in the cutting processes which were not present at the open tribometer.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shashidhara, Y.; Jayaram, S. Vegetable oils as a potential cutting fluid—An evolution. Tribol. Int. 2010, 43, 1073–1081. [Google Scholar] [CrossRef]

- Khan, M.A.A.; Hussain, M.; Lodhi, S.K.; Zazoum, B.; Asad, M.; Afzal, A. Green Metalworking Fluids for Sustainable Machining Operations and Other Sustainable Systems: A Review. Metals 2022, 12, 1466. [Google Scholar] [CrossRef]

- Vardhanapu, M.; Chaganti, P.K. A review on testing methods of metalworking fluids for environmental health. Mater. Today Proc. 2020, 26, 2405–2411. [Google Scholar] [CrossRef]

- Ogedengbe, T.S.; Awe, P.; Joseph, O.I. Comparative analysis of machining stainless steel using soluble and vegetable oils as cutting fluids. Int. J. Manu. Mater. Mech. Eng. 2019, 4, 33–40. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Irani, R.; Bauer, R.; Warkentin, A. A review of cutting fluid application in the grinding process. Int. J. Mach. Tools Manuf. 2005, 45, 1696–1705. [Google Scholar] [CrossRef]

- de Eguilaz, E.R.; Rech, J.; Arrazola, P. Characterization of friction coefficient and heat partition coefficient between an AISI4140 steel and a TiN-coated carbide—Influence of (Ca, Mn, S) steel’s inclusions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 1115–1127. [Google Scholar] [CrossRef]

- Zemzemi, F.; Bensalem, W.; Rech, J.; Dogui, A.; Kapsa, P. New tribometer designed for the characterisation of the friction properties at the tool/chip/workpiece interfaces in machining. Lubr. Sci. 2008, 14, 11–25. [Google Scholar] [CrossRef]

- Özel, T. The influence of friction models on finite element simulations of machining. Int. J. Mach. Tools Manuf. 2006, 46, 518–530. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal cutting, (4th edition), “Butterworth-Heinemann”, Boston, 2000. Sci. Sinter. 2004, 36, 446. [Google Scholar] [CrossRef]

- Melkote, S.N.; Grzesik, W.; Outeiro, J.; Rech, J.; Schulze, V.; Attia, H.; Arrazola, P.-J.; M’Saoubi, R.; Saldana, C. Advances in material and friction data for modelling of metal machining. CIRP Ann. Manuf. Technol. 2017, 66, 731–754. [Google Scholar] [CrossRef]

- Grzesik, W.; Rech, J. Development of tribo-testers for predicting metal cutting friction. J. Mach. Eng. 2019, 19, 62–70. [Google Scholar] [CrossRef]

- Wiklund, U.; Wänstrand, O.; Larsson, M.; Hogmark, S. Evaluation of new multilayered physical vapour deposition coatings in sliding contact. Wear 1999, 236, 88–95. [Google Scholar] [CrossRef]

- Hogmark, S.; Hedenqvist, P.; Jacobson, S. Tribological properties of thin hard coatings: Demands and evaluation. Surf. Coat. Technol. 1997, 90, 247–257. [Google Scholar] [CrossRef]

- Pape, F.; Poll, G.; Ellersiek, L.; Denkena, B.; Liu, H. Tribological Effects of Metalworking Fluids in Cutting Processes. Lubricants 2023, 11, 224. [Google Scholar] [CrossRef]

- Liu, H.C.; Pape, F.; Zhao, Y.; Ellersiek, L.; Denkena, B.; Poll, G. On the Elastohydrodynamic Film-Forming Properties of Metalworking Fluids and Oil-in-Water Emulsions. Tribol. Lett. 2022, 71, 10. [Google Scholar] [CrossRef]

- Grzesik, W.; Zalisz, Z.; Nieslony, P. Friction and wear testing of multilayer coatings on carbide substrates for dry machining applications. Surf. Coat. Technol. 2002, 155, 37–45. [Google Scholar] [CrossRef]

- Hedenqvist, P.; Olsson, M. Sliding wear testing of coated cutting tool materials. Tribol. Int. 1991, 24, 143–150. [Google Scholar] [CrossRef]

- Claudin, C.; Mondelin, A.; Rech, J.; Fromentin, G. Effects of a straight oil on friction at the tool–workmaterial interface in machining. Int. J. Mach. Tools Manuf. 2010, 50, 681–688. [Google Scholar] [CrossRef]

- Bonnet, C.; Valiorgue, F.; Rech, J.; Claudin, C.; Hamdi, H.; Bergheau, J.; Gilles, P. Identification of a friction model—Application to the context of dry cutting of an AISI 316L austenitic stainless steel with a TiN coated carbide tool. Int. J. Mach. Tools Manuf. 2008, 48, 1211–1223. [Google Scholar] [CrossRef]

- Rech, J.; Arrazola, P.J.; Claudin, C.; Courbon, C.; Pusavec, F.; Kopac, J. Characterisation of friction and heat partition coefficients at the tool-work material interface in cutting. CIRP Ann. Manuf. Technol. 2013, 62, 79–82. [Google Scholar] [CrossRef]

- Priest, J.; Ghadbeigi, H.; Ayvar-Soberanis, S.; Liljerehn, A.; Way, M. Analysis of the contact mechanics in machining using a novel high-speed tribometer. Procedia CIRP 2022, 108, 123–128. [Google Scholar] [CrossRef]

- Sadowski, P.; Stupkiewicz, S. Friction in lubricated soft-on-hard, hard-on-soft and soft-on-soft sliding contacts. Tribol. Int. 2019, 129, 246–256. [Google Scholar] [CrossRef]

- Randall, N.X. Experimental Methods in Tribology. In Tribology for Scientists and Engineers: From Basics to Advanced Concepts; Menezes, P.L., Nosonovsky, M., Ingole, S.P., Kailas, S.V., Lovell, M.R., Eds.; Springer: New York, NY, USA, 2013; pp. 141–175. [Google Scholar] [CrossRef]

- Wang, L.; Cai, J.; Zhou, J.; Duszczyk, J. Characteristics of the Friction Between Aluminium and Steel at Elevated Temperatures During Ball-on-Disc Tests. Tribol. Lett. 2009, 36, 183–190. [Google Scholar] [CrossRef]

- Peng, B.; Spikes, H.; Kadiric, A. The Development and Application of a Scuffing Test Based on Contra-rotation. Tribol. Lett. 2019, 67, 37. [Google Scholar] [CrossRef]

- Ingram, M.; Hamer, C.; Spikes, H. A new scuffing test using contra-rotation. Wear 2015, 328–329, 229–240. [Google Scholar] [CrossRef][Green Version]

- Lakner, T.; Hardt, M. A Novel Experimental Test Bench to Investigate the Effects of Cutting Fluids on the Frictional Conditions in Metal Cutting. J. Manuf. Mater. Process. 2020, 4, 45. [Google Scholar] [CrossRef]

- Bergmann, B. Grundlagen zur Auslegung von Schneidkantenverrundungen; TEWISS. Ph.D. Thesis, Leibniz University, Hanover, Germany, 2018. [Google Scholar]

- Bair, S.; Vergne, P.; Kumar, P.; Poll, G.; Krupka, I.; Hartl, M.; Habchi, W.; Larsson, R. Comment on “History, origins and prediction of elastohydrodynamic friction” by Spikes and Jie. Tribol. Lett. 2015, 58, 16. [Google Scholar] [CrossRef]

- Yan, Y.D.; Dhont, J.K.G.; Smits, C.; Lekkerkerker, H.N.W. Oscillatory-shear-induced order in nonaqueous dispersions of charged colloidal spheres. Phys. A Stat. Mech. Appl. 1994, 202, 68–80. [Google Scholar] [CrossRef][Green Version]

- Nassef, B.G.; Pape, F.; Poll, G. Enhancing the Performance of Rapeseed Oil Lubricant for Machinery Component Applications through Hybrid Blends of Nanoadditives. Lubricants 2023, 11, 479. [Google Scholar] [CrossRef]

- López-Barrón, C.R.; Wagner, N.J.; Porcar, L. Layering, melting, and recrystallization of a close-packed micellar crystal under steady and large-amplitude oscillatory shear flows. J. Rheol. 2015, 59, 793–820. [Google Scholar] [CrossRef]

- Fagundes, F.M.; Santos, N.B.; Damasceno, J.J.R.; Arouca, F.O. Study on the stability of a shear-thinning suspension used in oil well drilling. Oil Gas Sci. Technol. 2018, 73, 10. [Google Scholar] [CrossRef]

- Sjöblom, J.; Stenius, P.; Simon, S.; Grimes, B.A. Emulsion Stabilization. In Encyclopedia of Colloid and Interface Science; Tadros, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 415–454. [Google Scholar] [CrossRef]

- Yaghi, B.M.; Al-Bemani, A. Heavy Crude Oil Viscosity Reduction for Pipeline Transportation. Energy Sources 2002, 24, 93–102. [Google Scholar] [CrossRef]

- Souas, F.; Safri, A.; Benmounah, A. A review on the rheology of heavy crude oil for pipeline transportation. Pet. Res. 2021, 6, 116–136. [Google Scholar] [CrossRef]

- Jamaluddin, N.A.; Talib, N.; Sani, A.S.A. Tribological assessment of modified Jatropha oil with hBN and graphene nanoparticles as a new preference for the metalworking fluid. Int. J. Eng. Adv. Technol. 2020, 9, 3144–3149. [Google Scholar] [CrossRef]

- Yang, K.Z.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Shankar, S.; Dixit, S.; Kumar, K.; Ivanovich Vatin, N. Application of coolants during tool-based machining—A review. Ain Shams Eng. J. 2023, 14, 101830. [Google Scholar] [CrossRef]

- Rech, J. A multiview approach to the tribological characterisation of cutting tool coatings for steels in high-speed dry turning. Int. J. Mach. Mach. Mater. 2006, 1, 27–44. [Google Scholar] [CrossRef]

- Oshio, T. Anti-Wear Properties and Mechanisms of Dialkyl Phosphonates in Ester Base Oils. Ph.D. Thesis, Ecole Centrale de Lyon, Écully, France, 2023. (In English). [Google Scholar]

- Beltzer, M.; Jahanmir, S. Effect of additive molecular structure on friction. Lubr. Sci. 1988, 1, 3–26. [Google Scholar] [CrossRef]

- Minami, I.; Mori, S. Concept of molecular design towards additive technology for advanced lubricants. Lubr. Sci. 2007, 19, 127–149. [Google Scholar] [CrossRef]

- Tang, Z.; Li, S. A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr. Opin. Solid State Mater. Sci. 2014, 18, 119–139. [Google Scholar] [CrossRef]

- Ma, J.; Mohammadi, J.; Zhou, Y.; Larsh, J.; Januszkiewicz, K.; Evans, R.; Zhao, Y.; Gali, O.A.; Riahi, R.A. An investigation into cutting fluid additives performance during machining processing of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2021, 112, 977–987. [Google Scholar] [CrossRef]

- Sterle, L.; Pušavec, F.; Kalin, M. Determination of friction coefficient in cutting processes: Comparison between open and closed tribometers. Procedia CIRP 2019, 82, 101–106. [Google Scholar] [CrossRef]

- Iowa Waste Reduction Center. Cutting Fluid Management: Small Machining Operations; Iowa Waste Reduction Center: Cedar Falls, IA, USA, 2003. [Google Scholar]

- Bienkowski, K. Coolants and Lubricants: The Truth; Manufacturing Engineering: Oakland, CA, USA, 1993; pp. 90–92. [Google Scholar]

- Wang, S.-H.; Yue, J.; Dong, W.; Zuo, T.-T.; Li, J.-Y.; Liu, X.; Zhang, X.-D.; Liu, L.; Shi, J.-L.; Yin, Y.-X. Tuning wettability of molten lithium via a chemical strategy for lithium metal anodes. Nat. Commun. 2019, 10, 4930. [Google Scholar] [CrossRef] [PubMed]

- Pu, D.; Xiong, Y.-c.; Feng, R.-s.; Guo, Y.-j.; Lin, L.; Xu, C.-j.; Yu, W.-k. Study on the Adaptability of Alkanolamide (LDEA) Lowering Oil/Water Interfacial Tension to Different Crude Oils. J. Surfactants Deterg. 2020, 23, 1145–1157. [Google Scholar] [CrossRef]

- Li, Y.; Duan, Y.-Z.; Zhang, K. Effect of Alkanolamide on Interfacial Tension and Loss of Petroleum Sulfonates for Enhanced Oil Recovery. J. Dispers. Sci. Technol. 2010, 31, 722–726. [Google Scholar] [CrossRef]

- Aguilar-Mendoza, J.A.; Rosales-Leal, J.I.; Rodríguez-Valverde, M.A.; Cabrerizo-Vílchez, M.A. Effect of acid etching on dentin wettability and roughness: Self-etching primers versus phosphoric acid. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 84B, 277–285. [Google Scholar] [CrossRef] [PubMed]

- Wakabayashi, T. Cutting Fluid. In CIRP Encyclopedia of Production Engineering; Laperrière, L., Reinhart, G., Eds.; Springer: Berlin, Germany, 2014; pp. 311–315. [Google Scholar] [CrossRef]

- Denkena, B.; Bergmann, B.; Picker, T.; Kraeft, M. Modeling of stresses at the cutting wedge in the interrupted cut for the design of the cutting edge microgeometry. Procedia CIRP 2023, 117, 299–304. [Google Scholar] [CrossRef]

- Denkena, B.; Liu, H.C.; Pape, F.; Bergmann, B.; Poll, G.; Schenzel, J.; Ellersiek, L. Simulation of local contact conditions in the secondary shear zone in dry and wet metal cutting. Procedia CIRP 2023, 117, 293–298. [Google Scholar] [CrossRef]

- Bergmann, B.; Denkena, B.; Beblein, S.; Picker, T. FE-Simulation Based Design of Wear-Optimized Cutting Edge Roundings. J. Manuf. Mater. Process. 2021, 5, 126. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the Metal Cutting Process. I. Orthogonal Cutting and a Type 2 Chip. J. Appl. Phys. 2004, 16, 267–275. [Google Scholar] [CrossRef]

- Zorev, N. Inter-relationship between shear processes occurring along tool face and shear plane in metal cutting. Proc. Int. Prod. Eng. Res. 1963, 49, 143–152. [Google Scholar]

| Item | Vascomill CSF 35 Oil | Blaser Vasco 6000 | Zeller + Gmelin Zubora 67H Extra |

|---|---|---|---|

| Viscosity at 40 °C | 35 mm2/s | 42 mm2/s | 39 mm2/s |

| Density at 20 °C | 0.90 g/cm3 | 0.99 g/cm3 | 0.98 g/cm3 |

| Structure | Ester-based oil | Fully synthetic emulsion based on 10% ester-oil and 90% deionized water | Semi-synthetic emulsion based on 10% mineral-oil and 90% deionized water |

| Flash point °C | 310 | 129 | >100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nassef, B.G.; Pape, F.; Poll, G.; Schenzel, J.; Bergmann, B.; Denkena, B. Evaluating the Tribological Behaviour in Cutting Operations Using a Modified Ball-on-Disc Open Tribotester. Lubricants 2024, 12, 77. https://doi.org/10.3390/lubricants12030077

Nassef BG, Pape F, Poll G, Schenzel J, Bergmann B, Denkena B. Evaluating the Tribological Behaviour in Cutting Operations Using a Modified Ball-on-Disc Open Tribotester. Lubricants. 2024; 12(3):77. https://doi.org/10.3390/lubricants12030077

Chicago/Turabian StyleNassef, Belal G, Florian Pape, Gerhard Poll, Jan Schenzel, Benjamin Bergmann, and Berend Denkena. 2024. "Evaluating the Tribological Behaviour in Cutting Operations Using a Modified Ball-on-Disc Open Tribotester" Lubricants 12, no. 3: 77. https://doi.org/10.3390/lubricants12030077

APA StyleNassef, B. G., Pape, F., Poll, G., Schenzel, J., Bergmann, B., & Denkena, B. (2024). Evaluating the Tribological Behaviour in Cutting Operations Using a Modified Ball-on-Disc Open Tribotester. Lubricants, 12(3), 77. https://doi.org/10.3390/lubricants12030077