Lubrication-Enhanced Mechanisms of Bentonite Grease Using 2D MoS2 with Narrow Lateral Size and Thickness Distributions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

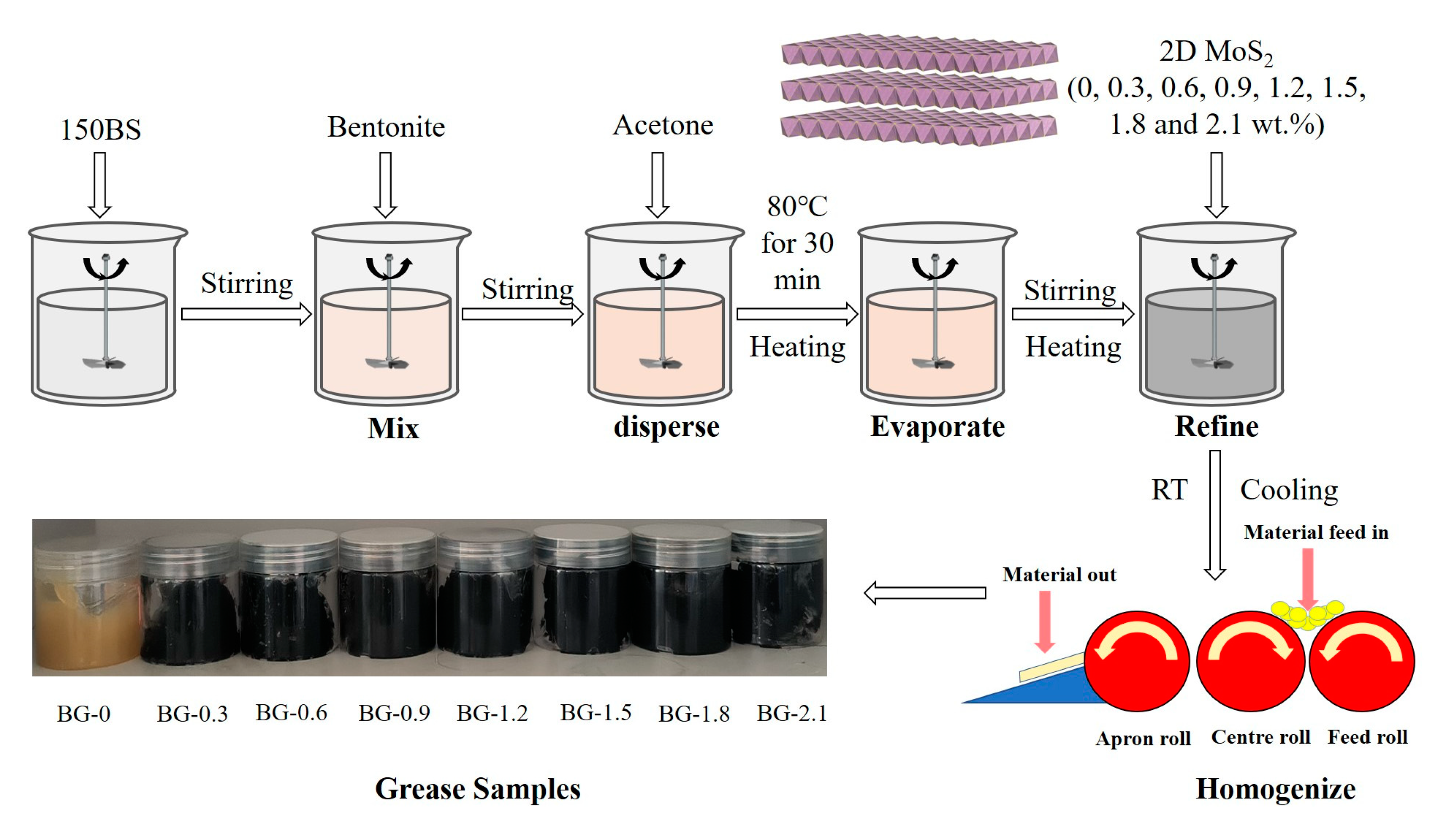

2.2. Preparation and Characterization of Bentonite Grease with 2D MoS2

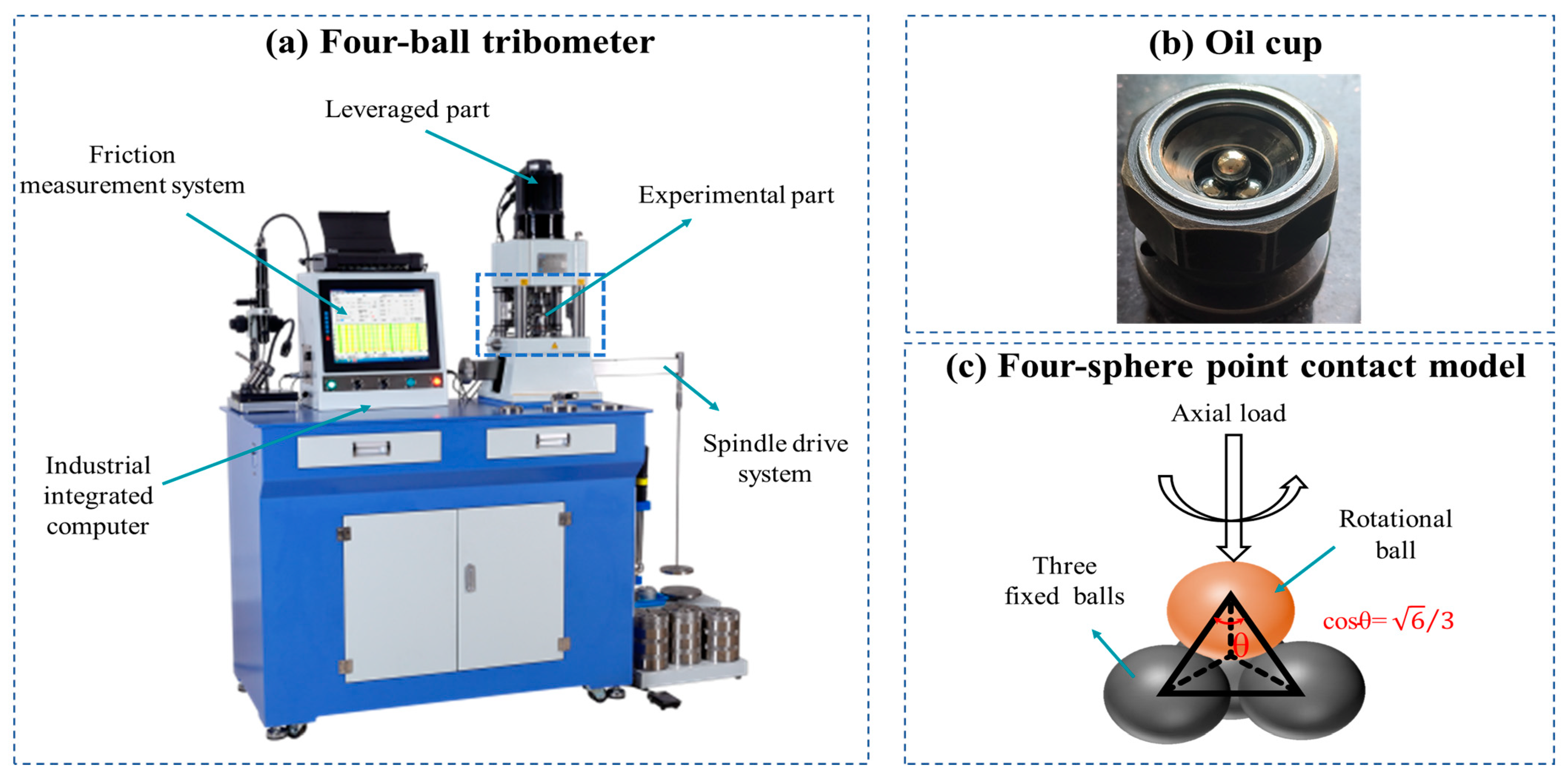

2.3. Tribology Tests and Analysis

3. Results and Discussion

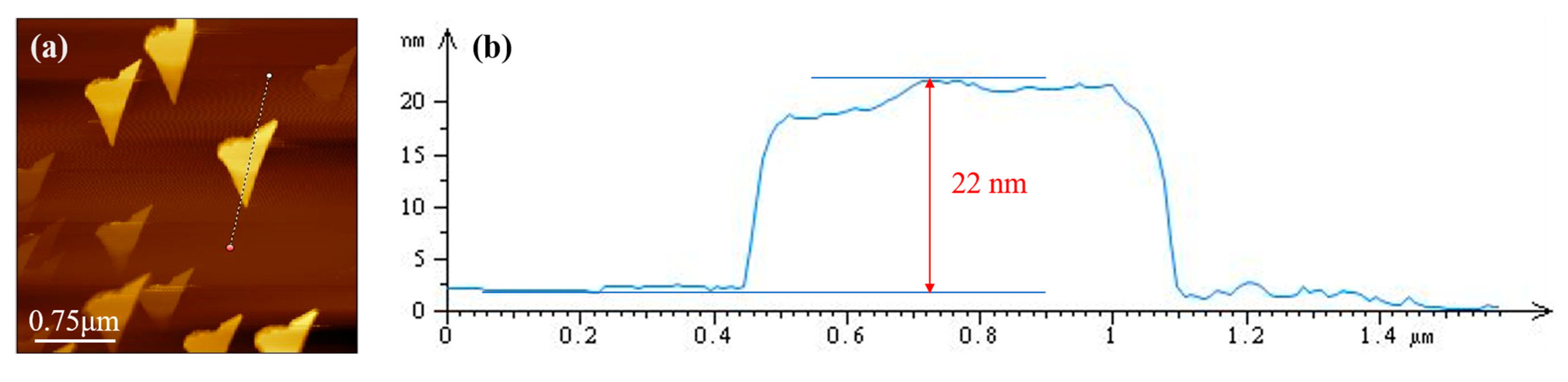

3.1. Physico-Chemical Properties

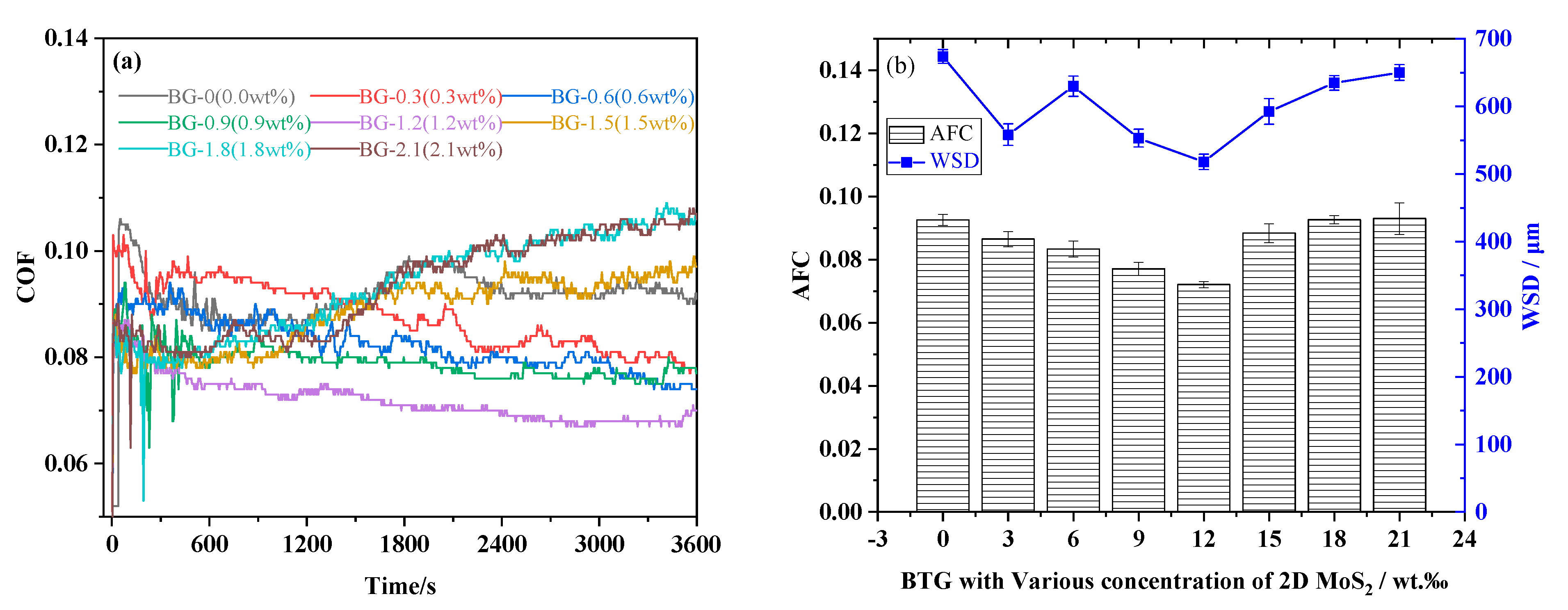

3.2. Friction and Wear Performance

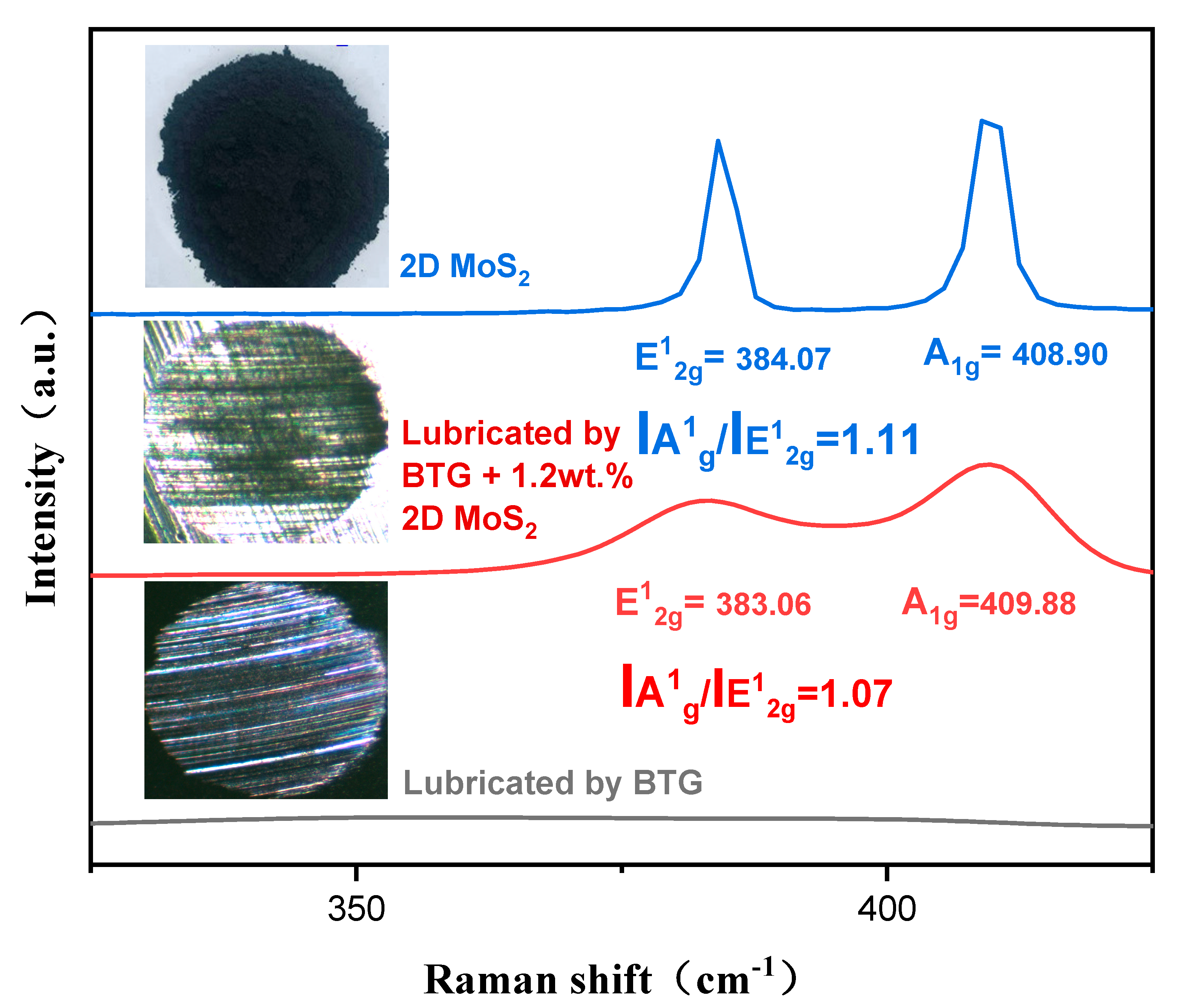

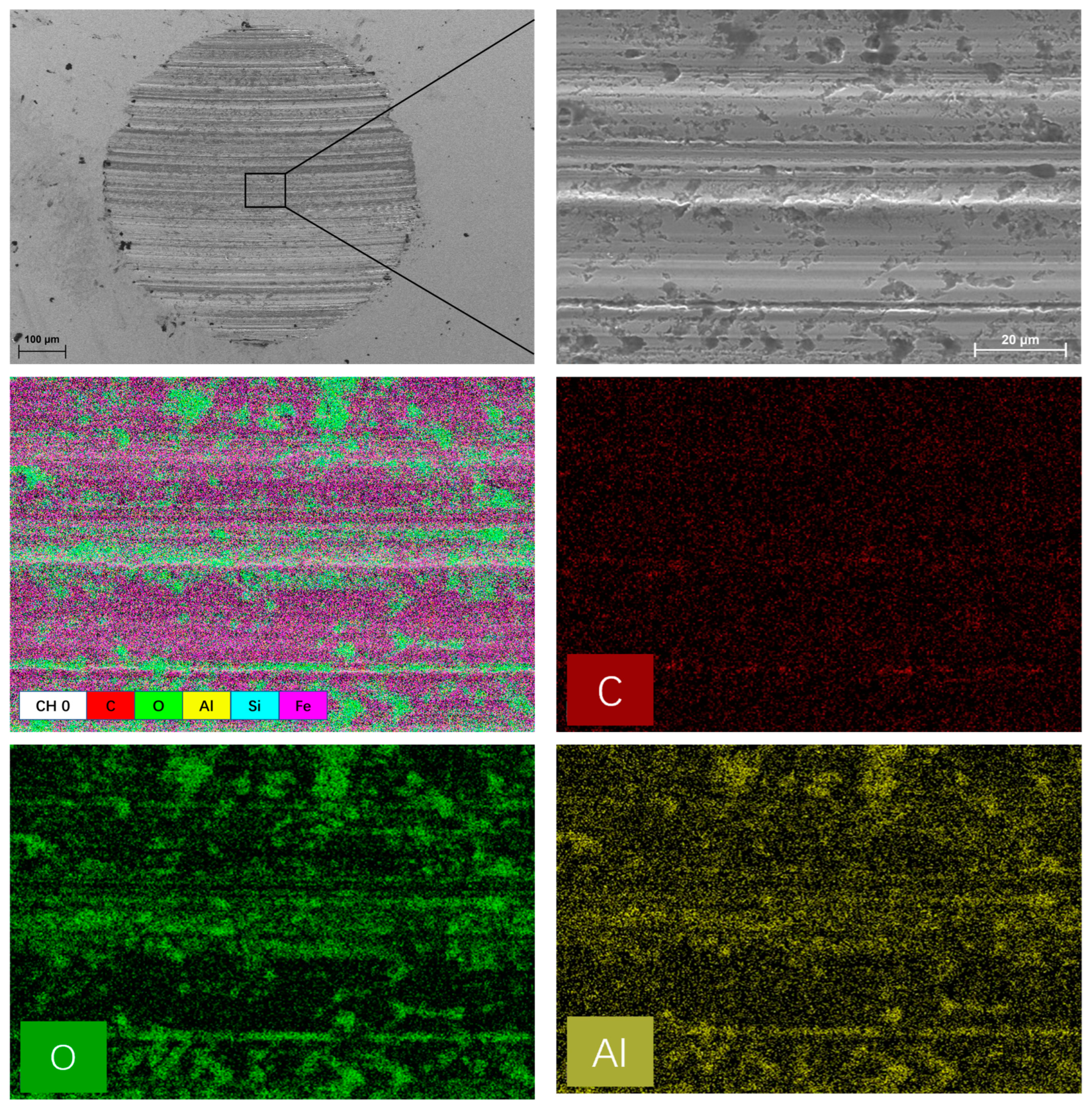

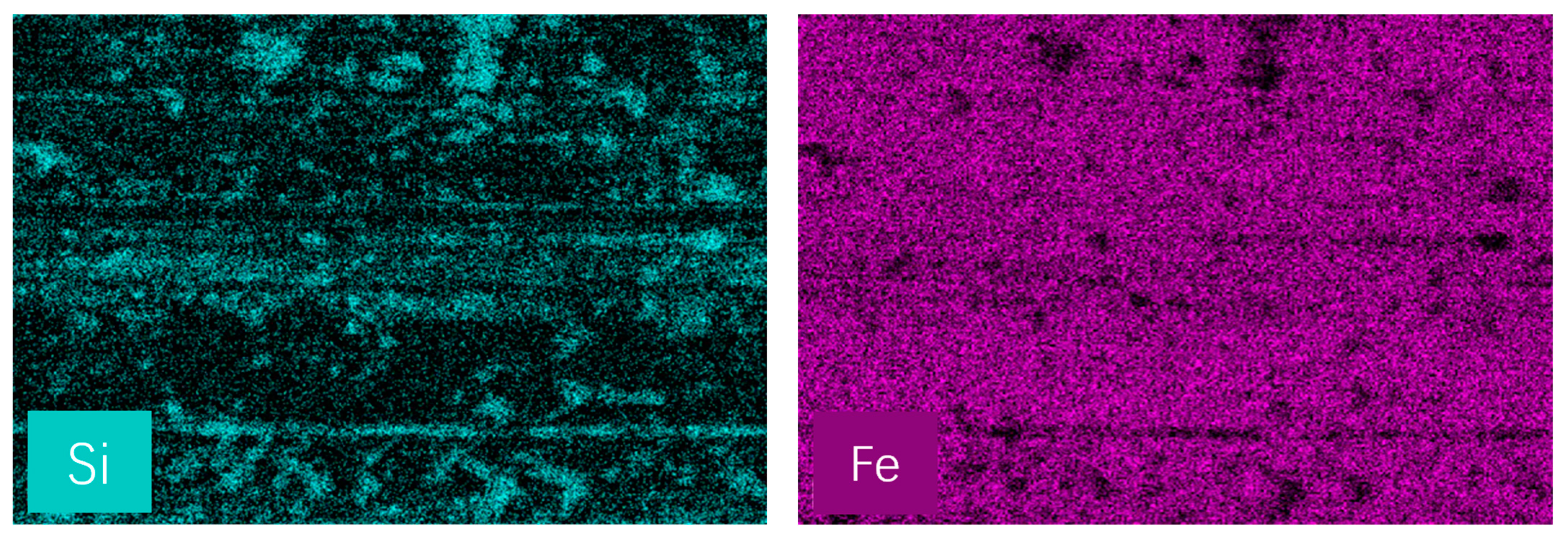

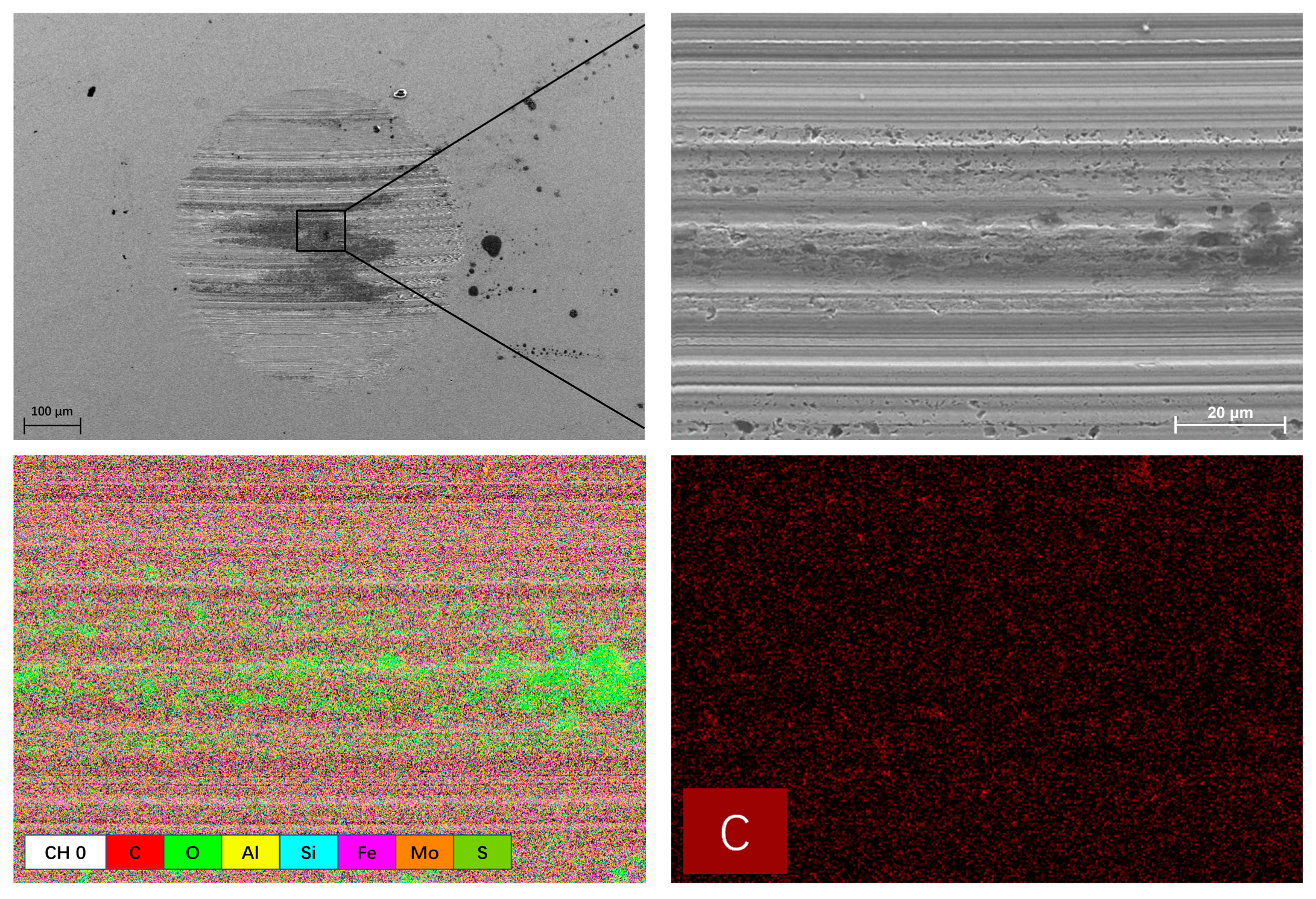

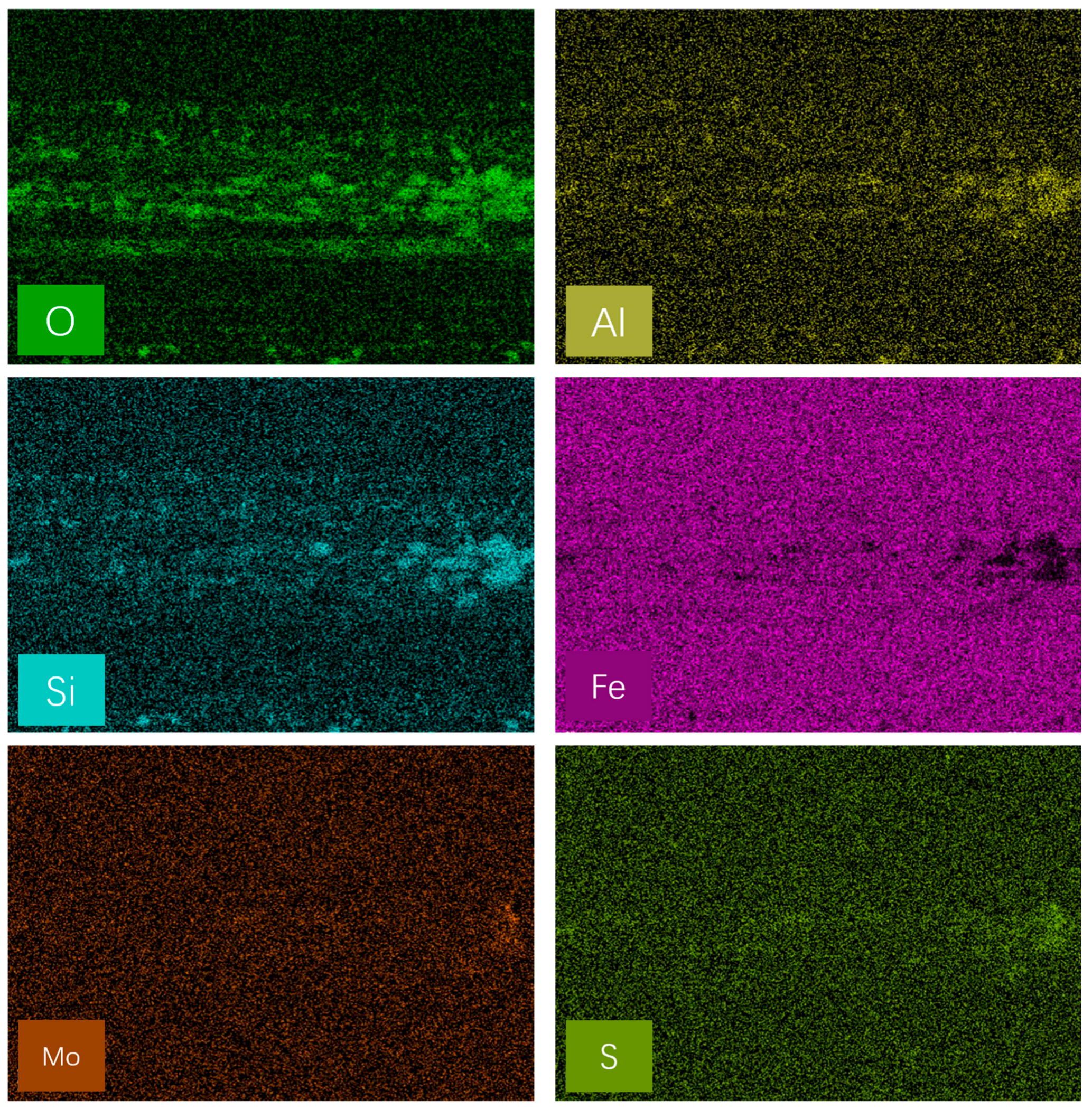

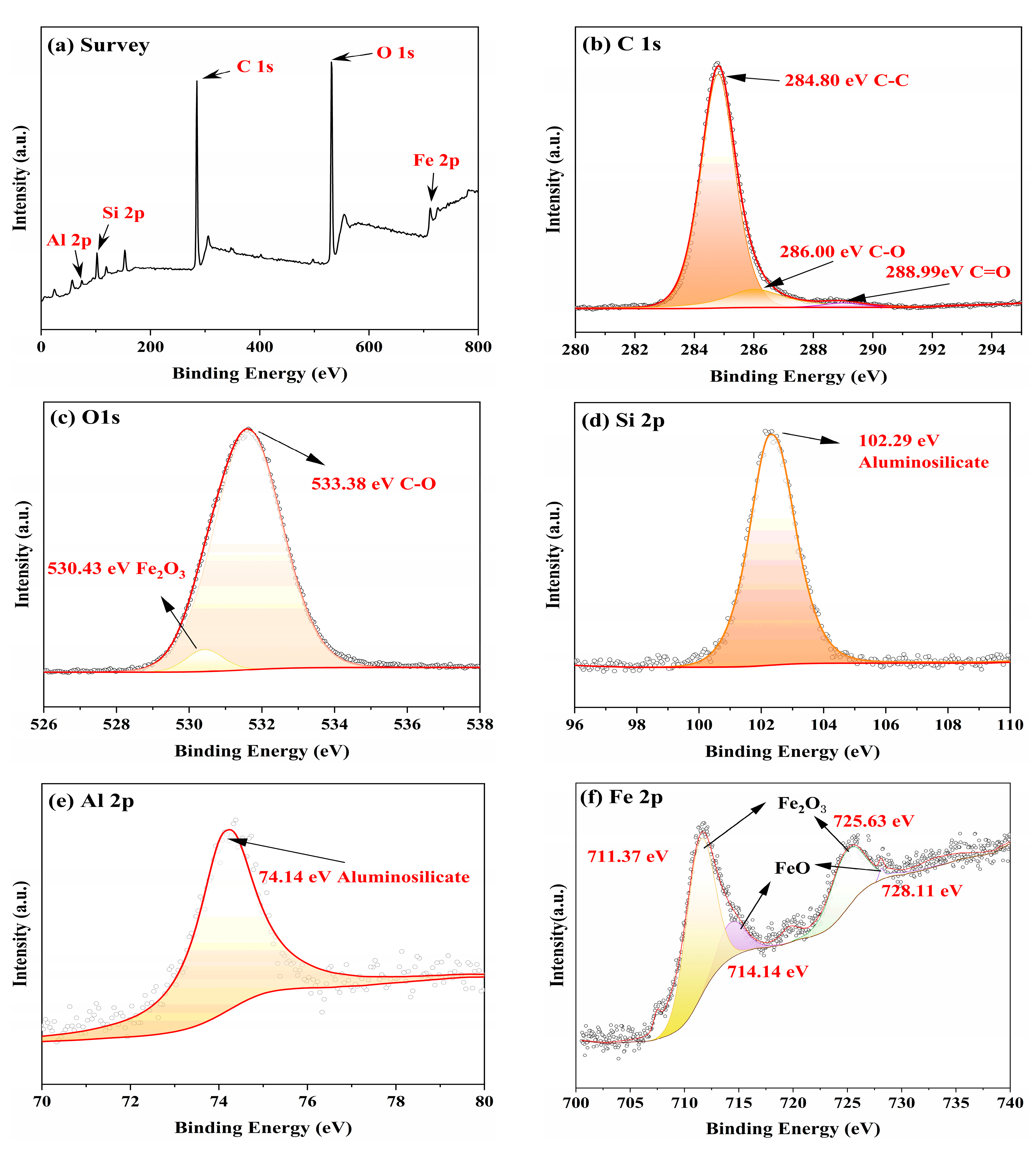

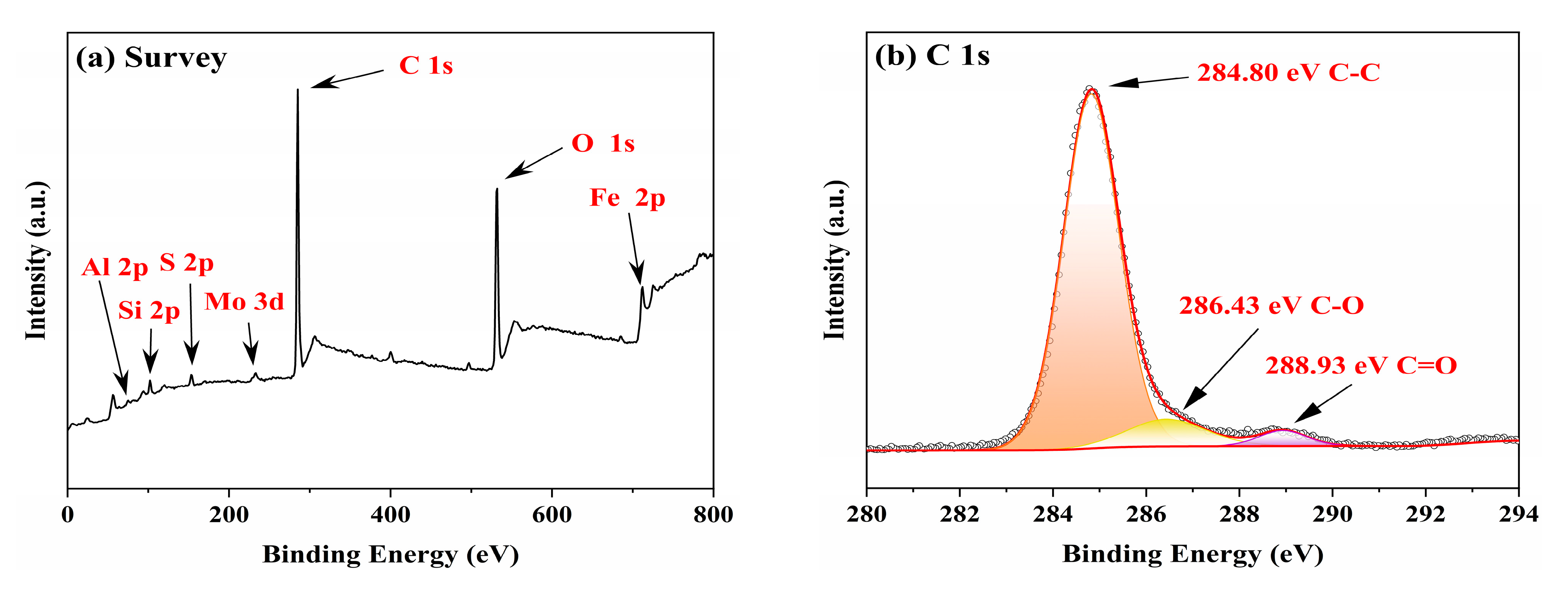

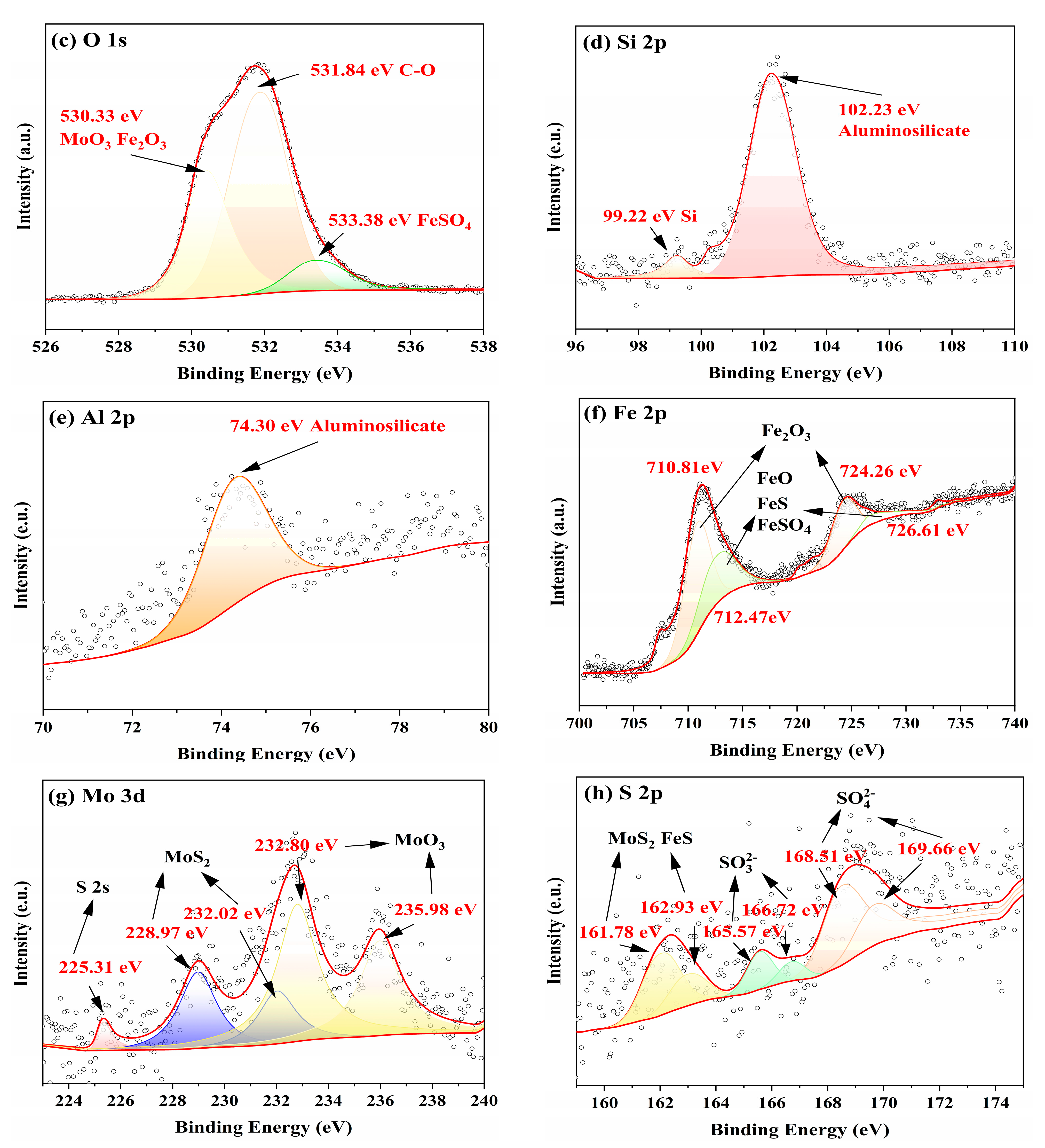

3.3. Worn Surface Analysis

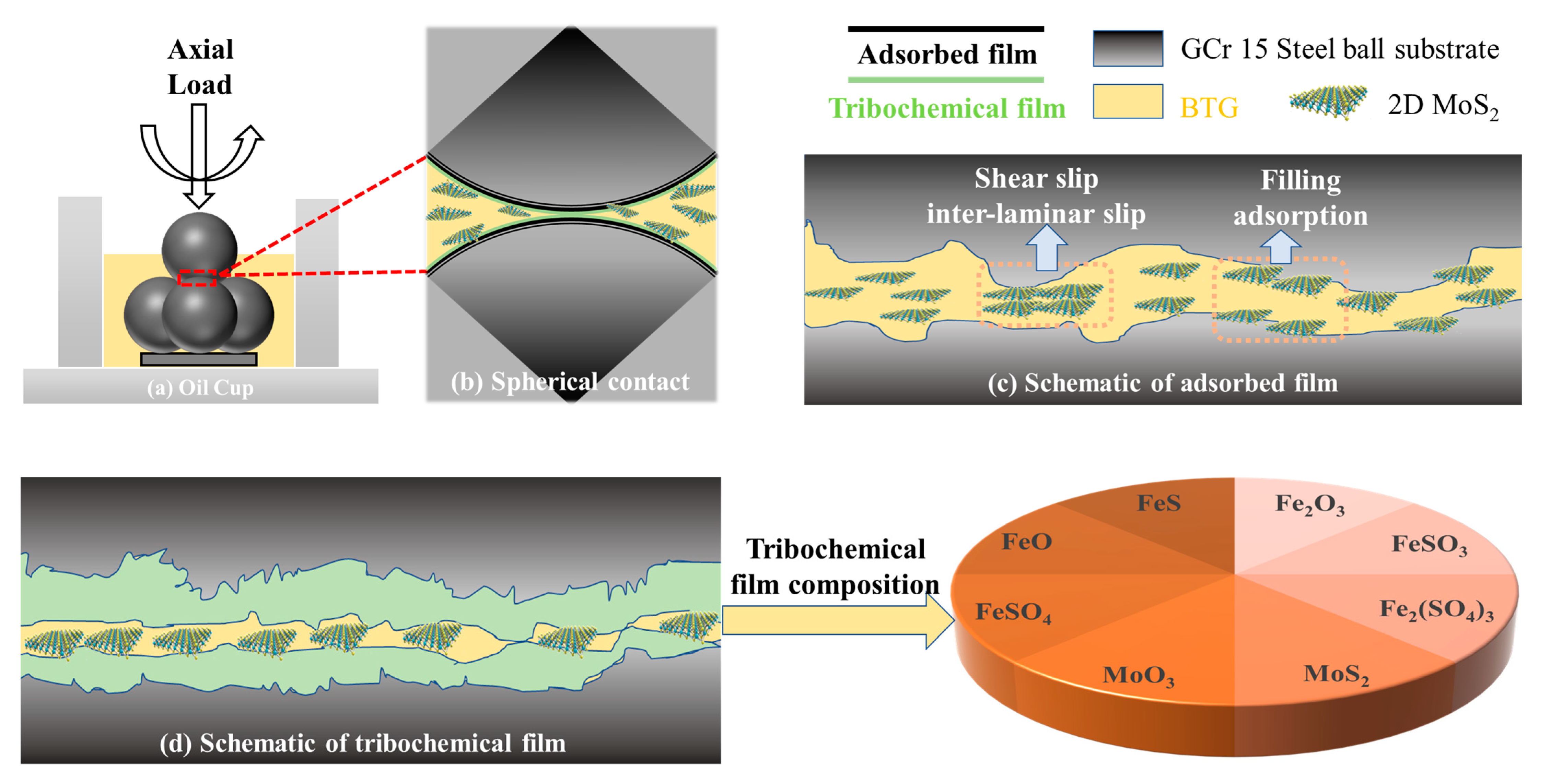

3.4. Lubrication Mechanism of 2D MoS2

4. Conclusions

- a

- The 2D MoS2 as lubricating additives utilized in the bentonite grease have significant effects on its penetration, dropping point, oil separation, evaporation, copper corrosion and friction-reducing and antiwear properties.

- b

- The COF, WSD, surface roughness and wear scar depth of BG + 1.2 wt.% 2D MoS2 were effectively reduced by approximately 22.15%, 23.14%, 55.15%, and 82.64%, respectilvely, in comparison with that of BG. In addition, the contact region was firmly in a state of boundary lubrication under the four-ball tribometer according to the calculation of the Dowson and Hamrock minimum film thickness formula.

- c

- Raman, EDS and XPS results collectively showed that a stable adsorption film and a robust tribochemical composed of Fe2O3, FeSO4, Fe2(SO4)3,FeSO3, FeS, FeO, and MoO3, which is typically more ductile than the GCr15 bearing steel substrate and protect the GCr15 bearing steel/GCr15 bearing steel substrate from severe wear by avoiding direct metal-to-metal contact.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, J.; Min, L.; Ma, L. Origin of friction and the new frictionless technology—Superlubricity: Advancements and future outlook. Nano Energy 2021, 86, 106092. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Tang, Q.; Xu, H.; Tang, M.; Li, X.; Liu, L.; Dong, J. Tribological and rheological performance of lithium grease with poly-α-olefin and alkyl-tetralin as base oils. Chin. J. Chem. Eng. 2023, 56, 180–192. [Google Scholar] [CrossRef]

- Zhou, C.; Ren, G.; Fan, X.; Lv, Y. Probing the effect of thickener microstructure on rheological and tribological properties of grease. J. Ind. Eng. Chem. 2022, 111, 51–63. [Google Scholar] [CrossRef]

- Calderon Salmeron, G.; Leckner, J.; Schwack, F.; Westbroek, R.; Glavatskih, S. Greases for electric vehicle motors: Thickener effect and energy saving potential. Tribol. Int. 2022, 167, 107400. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Extreme pressure and antiwear additives for lubricant: Academic insights and perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 1–27. [Google Scholar] [CrossRef]

- Vetter, W.; Sprengel, J.; Krätschmer, K. Chlorinated paraffins—A historical consideration including remarks on their complexity. Chemosphere 2022, 287, 132032. [Google Scholar] [CrossRef]

- Niu, W.; Yuan, M.; Wang, P.; Shi, Q.; Xu, H.; Dong, J. One-pot synthesis of SIB@ZIF-8 with enhanced anti-corrosion properties and excellent lubrication properties. Tribol. Int. 2020, 151, 106491. [Google Scholar] [CrossRef]

- Acharya, B.; Pardue, T.N.; Avva, K.S.; Krim, J. In situ, real time studies of thermal reaction film formation temperatures for iron and 304SS surfaces immersed in 5% tricresyl phosphate in base oil. Tribol. Int. 2018, 126, 106–115. [Google Scholar] [CrossRef]

- Mistry, K.K.; Morina, A.; Erdemir, A.; Neville, A. Tribological Performance of EP Lubricants with Phosphorus-Based Additives. Tribol. Trans. 2013, 56, 645–651. [Google Scholar] [CrossRef]

- Sato, K.; Watanabe, S.; Sasaki, S. High Friction Mechanism of ZDDP Tribofilm Based on in situ AFM Observation of Nano-Friction and Adhesion Properties. Tribol. Lett. 2022, 70, 94. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Li, C.; Zhao, G.; Wang, X. A study of 2,5-dimercapto-1,3,4-thiadiazole derivatives as multifunctional additives in water-based hydraulic fluid. Ind. Lubr. Tribol. 2014, 66, 402–410. [Google Scholar] [CrossRef]

- Guegan, J.; Southby, M.; Spikes, H. Friction Modifier Additives, Synergies and Antagonisms. Tribol. Lett. 2019, 67, 83. [Google Scholar] [CrossRef]

- Liu, S.; Yu, T.; Lich, L.V.; Yin, S.; Bui, T.Q. Size and surface effects on mechanical behavior of thin nanoplates incorporating microstructures using isogeometric analysis. Comput. Struct. 2019, 212, 173–187. [Google Scholar] [CrossRef]

- Baig, N. Two-dimensional nanomaterials: A critical review of recent progress, properties, applications, and future directions. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107362. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, T.; Li, Y.; He, Y.; Shi, Y. Two-dimensional (2D) graphene nanosheets as advanced lubricant additives: A critical review and prospect. Mater. Today Commun. 2021, 29, 102755. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.; Li, J.; Xiao, Y.; Mu, W.; Wang, Z.; Song, L.; Yu, J. Flame Retardancy of Epoxy Resins Modified with Few-Layer Black Phosphorus. Polymers 2023, 15, 1655. [Google Scholar] [CrossRef]

- Zang, C.; Yang, M.; Liu, E.; Qian, Q.; Zhao, J.; Zhen, J.; Zhang, R.; Jia, Z.; Han, W. Synthesis, characterization and tribological behaviors of hexagonal boron nitride/copper nanocomposites as lubricant additives. Tribol. Int. 2022, 165, 107312. [Google Scholar] [CrossRef]

- Yang, J.; Xu, X.; Liu, L. Plasma-assisted friction control of 2D MoS2 made by atomic layer deposition. Nanotechnology 2020, 31, 395711. [Google Scholar] [CrossRef]

- Yi, S.; Guo, Y.; Li, J.; Zhang, Y.; Zhou, A.; Luo, J. Two-dimensional molybdenum carbide (MXene) as an efficient nanoadditive for achieving superlubricity under ultrahigh pressure. Friction 2023, 11, 369–382. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Liu, Y.; Zhao, J.; Li, J.; Wang, Q.; Luo, J. Tribological behavior of layered double hydroxides with various chemical compositions and morphologies as grease additives. Friction 2021, 9, 952–962. [Google Scholar] [CrossRef]

- Kang, J.; Sangwan, V.K.; Wood, J.D.; Hersam, M.C. Solution-based processing of monodisperse two-dimensional nanomaterials. Acc. Chem. Res. 2017, 50, 943–951. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Wang, Z.; Zhang, M.; Yu, C.; Wang, G.; Dong, Y.; Liu, S.; Wang, Y.; Qiu, J. Sustainable synthesis and assembly of biomass-derived B/N co-doped carbon nanosheets with ultrahigh aspect ratio for high-performance supercapacitors. Adv. Funct. Mater. 2016, 26, 111–119. [Google Scholar] [CrossRef]

- He, Q.; Zeng, Z.; Yin, Z.; Li, H.; Wu, S.; Huang, X.; Zhang, H. Fabrication of flexible MoS2 thin-film transistor arrays for practical gas-sensing applications. Small 2012, 8, 2994–2999. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Xie, Y.; Liu, Z.; Wang, X.; Chai, Y.; Yan, F. Two-dimensional material membranes: An emerging platform for controllable mass transport applications. Small 2014, 10, 4521–4542. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Tang, L.; Khan, U.; Yu, Q.; Cheng, H.-M.; Zou, X.; Liu, B. Morphology and surface chemistry engineering toward pH-universal catalysts for hydrogen evolution at high current density. Nat. Commun. 2019, 10, 269. [Google Scholar] [CrossRef]

- Lu, P.; Xiang, S.; Xu, S.; Chen, H.; Wang, H.; Wang, J.; Zhang, G. Tribological study on preparation of two-dimensional MoS2 as grease additive by ultrasonic liquid phase stripping. J. Mater. Eng. 2023, 51, 160–168. [Google Scholar]

- Ren, S.; Yu, Q.; Yu, X.; Rong, P.; Jiang, L.; Jiang, J. Graphene-supported metal single-atom catalysts: A concise review. Sci. China Mater. 2020, 63, 903–920. [Google Scholar] [CrossRef]

- Sun, X.; Liu, Z.; Welsher, K.; Robinson, J.T.; Goodwin, A.; Zaric, S.; Dai, H. Nano-graphene oxide for cellular imaging and drug delivery. Nano Res. 2008, 1, 203–212. [Google Scholar] [CrossRef]

- O’Neill, A.; Khan, U.; Coleman, J.N. Preparation of high concentration dispersions of exfoliated MoS2 with increased flake size. Chem. Mater. 2012, 24, 2414–2421. [Google Scholar] [CrossRef]

- Chaurasia, A.; Verma, A.; Parashar, A.; Mulik, R.S. Experimental and computational studies to analyze the effect of h-BN nanosheets on mechanical behavior of h-BN/polyethylene nanocomposites. J. Phys. Chem. C 2019, 123, 20059–20070. [Google Scholar] [CrossRef]

- Peng, L.; Zhu, Y.; Li, H.; Yu, G. Chemically integrated inorganicgraphene two-dimensional hybrid materials for flexible energy storage devices. Small 2016, 12, 6183–6199. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, J.; Li, J.; Yi, S.; Ge, X.; Zhang, X.; Luo, J. Shear-Induced Interfacial Structural Conversion Triggers Macroscale Su-perlubricity: From Black Phosphorus Nanoflakes to Phosphorus Oxide. ACS Appl. Mater. Interfaces 2021, 13, 31947–31956. [Google Scholar] [CrossRef] [PubMed]

- Hamrock, B.J.; Dowson, D.C. Isothermal Elastohydrodynamic Lubrication of Point Contacts: Part III—Fully Flooded Results. J. Lubr. Technol. 1976, 99, 264–275. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, P.; Ji, L.; Liu, X.; Wan, H.; Chen, L.; Li, H.; Jin, Z. Tribological properties of MoS2 coating for ultra-long wear-life and low coefficient of friction combined with additive g-C3N4 in air. Friction 2021, 9, 789–801. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, D.; Guo, Y.; Feng, D.; Shi, L. Influence of Competitive Adsorption on Lubricating Property of Phosphonate Ionic Liquid Additives in PEG. Tribol. Lett. 2016, 64, 22. [Google Scholar] [CrossRef]

- Lu, Z.; Cao, Z.; Hu, E.; Hu, K.; Hu, X. Preparation and tribological properties of WS2 and WS2/TiO2 nanoparticles. Tribol. Int. 2019, 130, 308–316. [Google Scholar] [CrossRef]

- Rabaso, P.; Dassenoy, F.; Ville, F.; Diaby, M.; Vacher, B.; Le Mogne, T.; Belin, M.; Cavoret, J. An Investigation on the Reduced Ability of IF-MoS2 Nanoparticles to Reduce Friction and Wear in the Presence of Dispersants. Tribol. Lett. 2014, 55, 503–516. [Google Scholar] [CrossRef]

- Geng, S.; Yang, W.; Liu, Y.; Yu, Y. Engineering sulfur vacancies in basal plane of MoS2 for enhanced hydrogen evolution reaction. J. Catal. 2020, 391, 91–97. [Google Scholar] [CrossRef]

- Hu, H.; He, Y.; Wang, Q.; Tao, L. In-situ research on formation mechanisms of transfer films of a Polyimide-MoS2 composite in vacuum. Tribol. Int. 2023, 180, 108211. [Google Scholar] [CrossRef]

- Wei, X.; Li, W.; Fan, X.; Zhu, M. MoS2-functionalized attapulgite hybrid toward high-performance thickener of lubricating grease. Tribol. Int. 2023, 179, 108135. [Google Scholar] [CrossRef]

| Test Description | Result | Method |

|---|---|---|

| Kinematic viscosity (mm2/s) (40 °C) | 490.7 | ASTM D445 |

| Kinematic viscosity (mm2/s) (100 °C) | 31.75 | ASTM D445 |

| Viscosity Index | 95 | ASTM D2270 |

| Appearance | Clear to bright | Visual |

| Colour (ASTM) (Quantitative) | L2.0 | ASTM D1500 |

| Density (kg/m3) (15 °C) | 0.9012 | ASTM D4052 |

| Density (kg/m3) (30 °C) | 0.8917 | ASTM D4052 |

| Refractive index (20 °C) | 1.46 | ASTM D1218 |

| Pour point (°C) | −6 | ASTM D5950 |

| Flash point (°C) (PMcc) | 316 | ASTM D92 |

| Specific Gravity (60/60 °F) | 0.9017 | ASTM D4052 |

| Total acid number (mgKOH/g) | 0.01 | ASTM D664 |

| Cartxon residue (micro method) (wt.%) | 0.41 | ASTM D4530 |

| Sulphur content (wt.%) | 0.536 | ASTM D4294 |

| Water content (vol.%) | Nill | ASTM D95 |

| Parameter | BG-0 | BG-0.3 | BG-0.6 | BG-0.9 | BG-1.2 | BG-1.5 | BG-1.8 | BG-2.1 |

|---|---|---|---|---|---|---|---|---|

| Speed | 1200 rpm | |||||||

| Load | 392 N | |||||||

| Temerature | 75 °C | |||||||

| Test Duration | 60 min | |||||||

| Component | Elastic modulus (MPa) | Poisson ratio | Diameter | Rockwell harness (HR) | Surface roughness (Ra) | |||

| GCr15 | 2.085 × 105 | 0.3 | 12.7 mm | 60 ± 1 | 0.256 µm | |||

| Parameter | BG-0 | BG-0.3 | BG-0.6 | BG-0.9 | BG-1.2 | BG-1.5 | BG-1.8 | BG-2.1 | Method |

|---|---|---|---|---|---|---|---|---|---|

| Penetration/0.1 mm | 285 | 244 | 261 | 292 | 297 | 301 | 306 | 310 | GB/T 269 |

| Dropping point | 278 | 292 | 290 | 285 | 286 | 287 | 287 | 291 | GB/T 3498 |

| Oil separation | 0.93 | 0.54 | 1.46 | 1.22 | 0.92 | 0.91 | 1.42 | 1.64 | NB/SH/T 0324 |

| Evaporation loss | 0.20 | 0.41 | 0.47 | 0.40 | 0.39 | 0.43 | 0.45 | 0.52 | SH/T 0661 |

| Copper corrosion | 1a | 1a | 1a | 1a | 1a | 1a | 1a | 1a | GB 7326 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, S.; Xiang, S.; Yang, X.; Yang, X.; Bao, H.; He, H.; Du, X.; Zhang, Q.; Zhang, J.; Ma, K.; et al. Lubrication-Enhanced Mechanisms of Bentonite Grease Using 2D MoS2 with Narrow Lateral Size and Thickness Distributions. Lubricants 2024, 12, 447. https://doi.org/10.3390/lubricants12120447

Zhu S, Xiang S, Yang X, Yang X, Bao H, He H, Du X, Zhang Q, Zhang J, Ma K, et al. Lubrication-Enhanced Mechanisms of Bentonite Grease Using 2D MoS2 with Narrow Lateral Size and Thickness Distributions. Lubricants. 2024; 12(12):447. https://doi.org/10.3390/lubricants12120447

Chicago/Turabian StyleZhu, Shaoyicheng, Shuo Xiang, Xue Yang, Xin Yang, Hebin Bao, Hao He, Xin Du, Qinhui Zhang, Junjie Zhang, Kai Ma, and et al. 2024. "Lubrication-Enhanced Mechanisms of Bentonite Grease Using 2D MoS2 with Narrow Lateral Size and Thickness Distributions" Lubricants 12, no. 12: 447. https://doi.org/10.3390/lubricants12120447

APA StyleZhu, S., Xiang, S., Yang, X., Yang, X., Bao, H., He, H., Du, X., Zhang, Q., Zhang, J., Ma, K., Cao, Y., Liu, Y., Peng, L., Li, Z., & Fan, Y. (2024). Lubrication-Enhanced Mechanisms of Bentonite Grease Using 2D MoS2 with Narrow Lateral Size and Thickness Distributions. Lubricants, 12(12), 447. https://doi.org/10.3390/lubricants12120447