Influence of Molybdenum Addition on the Structure, Mechanical Properties, and Cutting Performance of AlTiN Coatings

Abstract

:1. Introduction

2. Materials and Methods

3. Result and Discussion

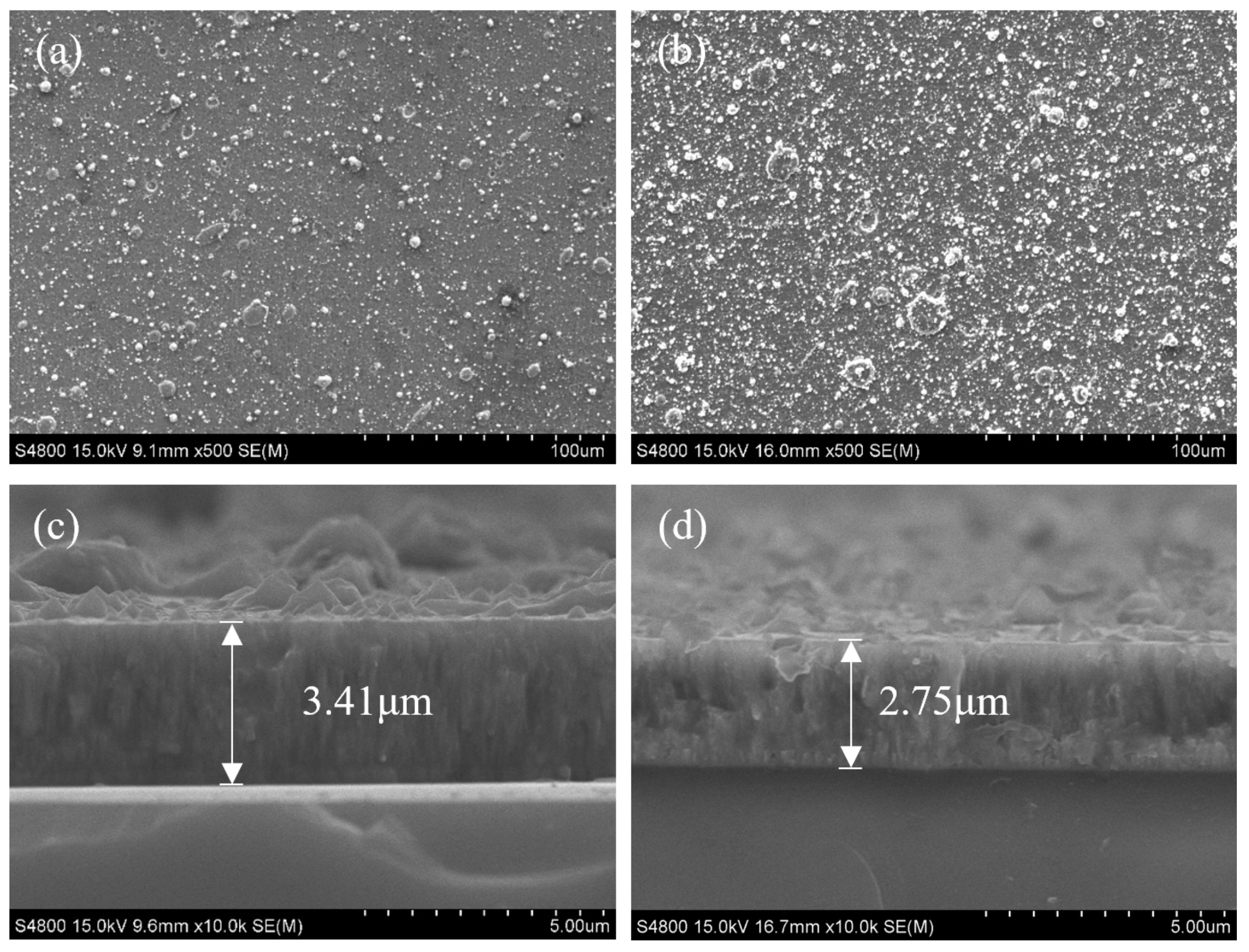

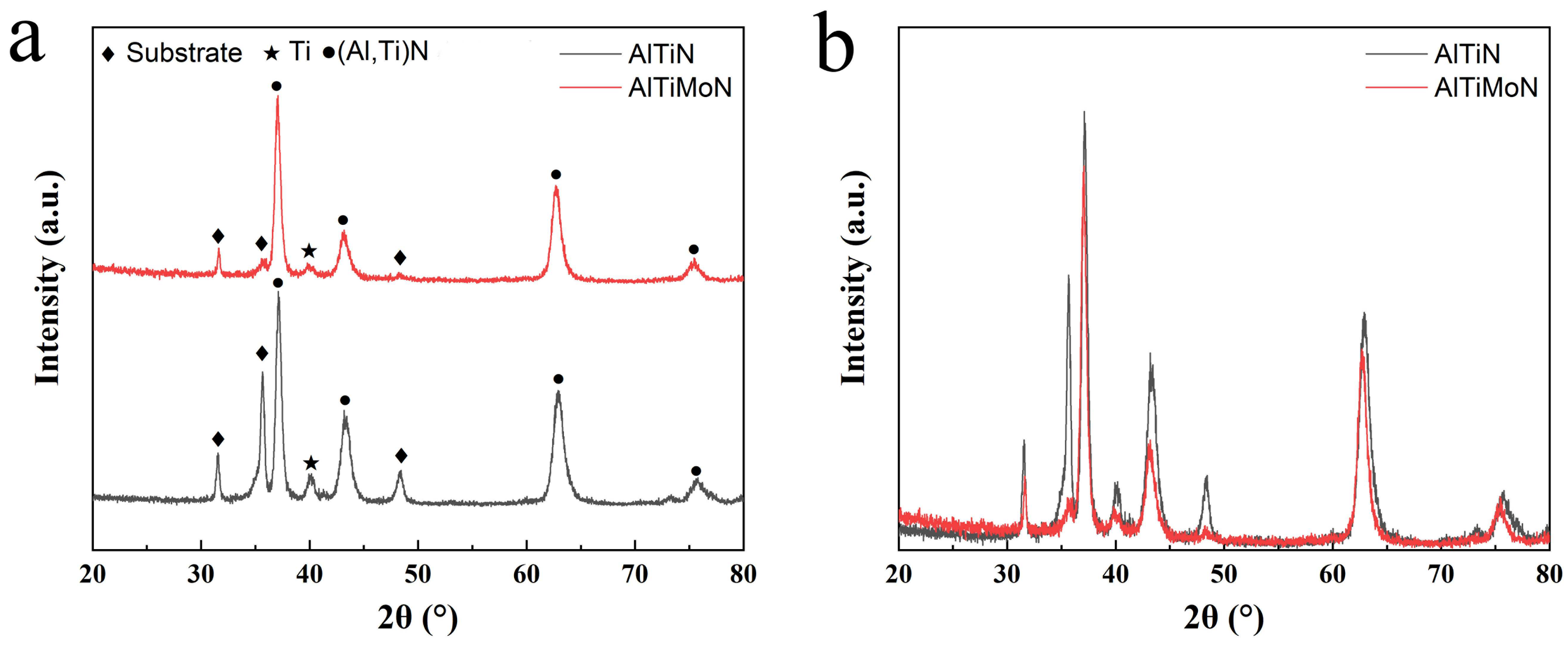

3.1. Structural Characterization of the AlTiN and AlTiMoN Coatings

3.2. Mechanical Properties of the AlTiN and AlTiMoN Coatings

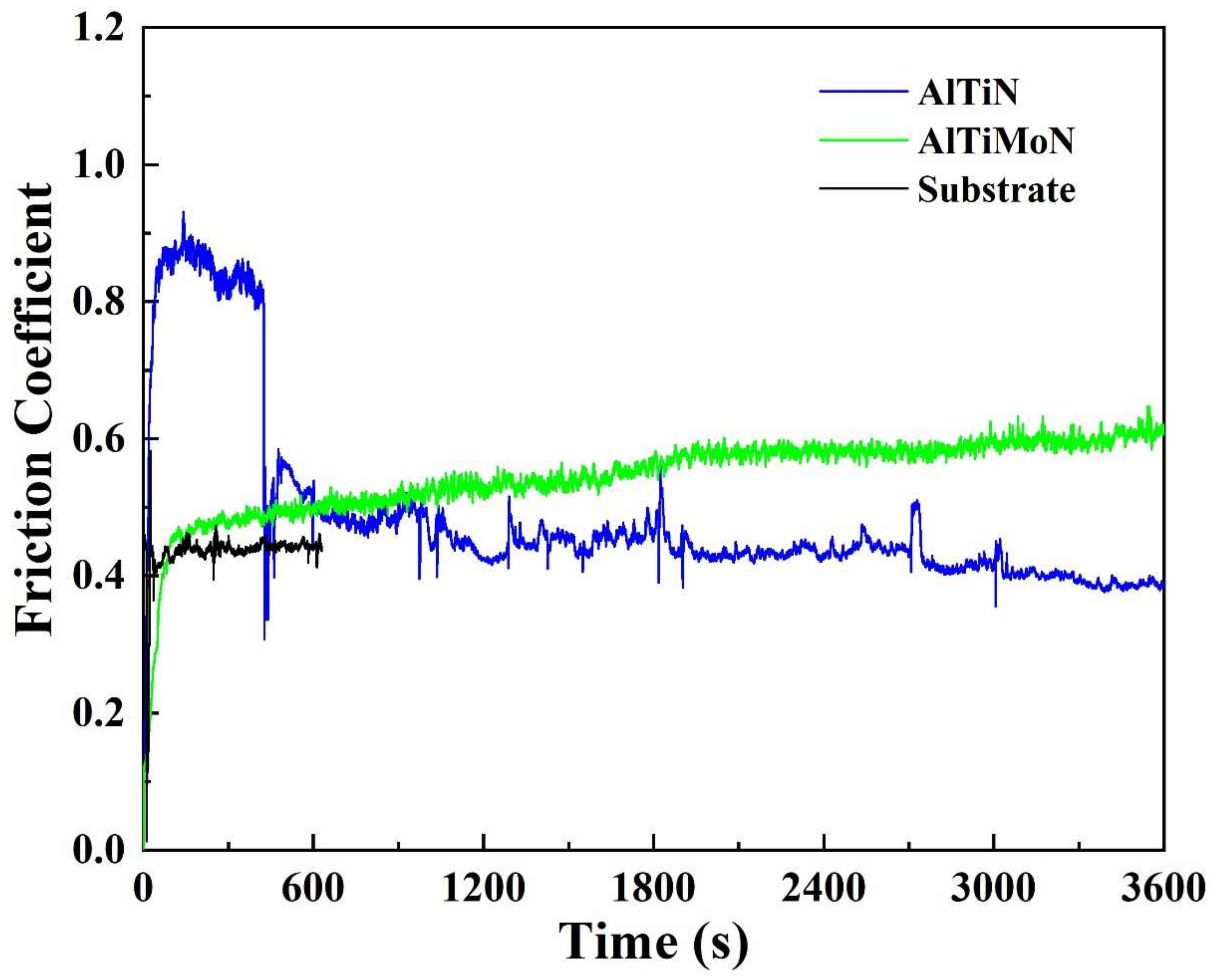

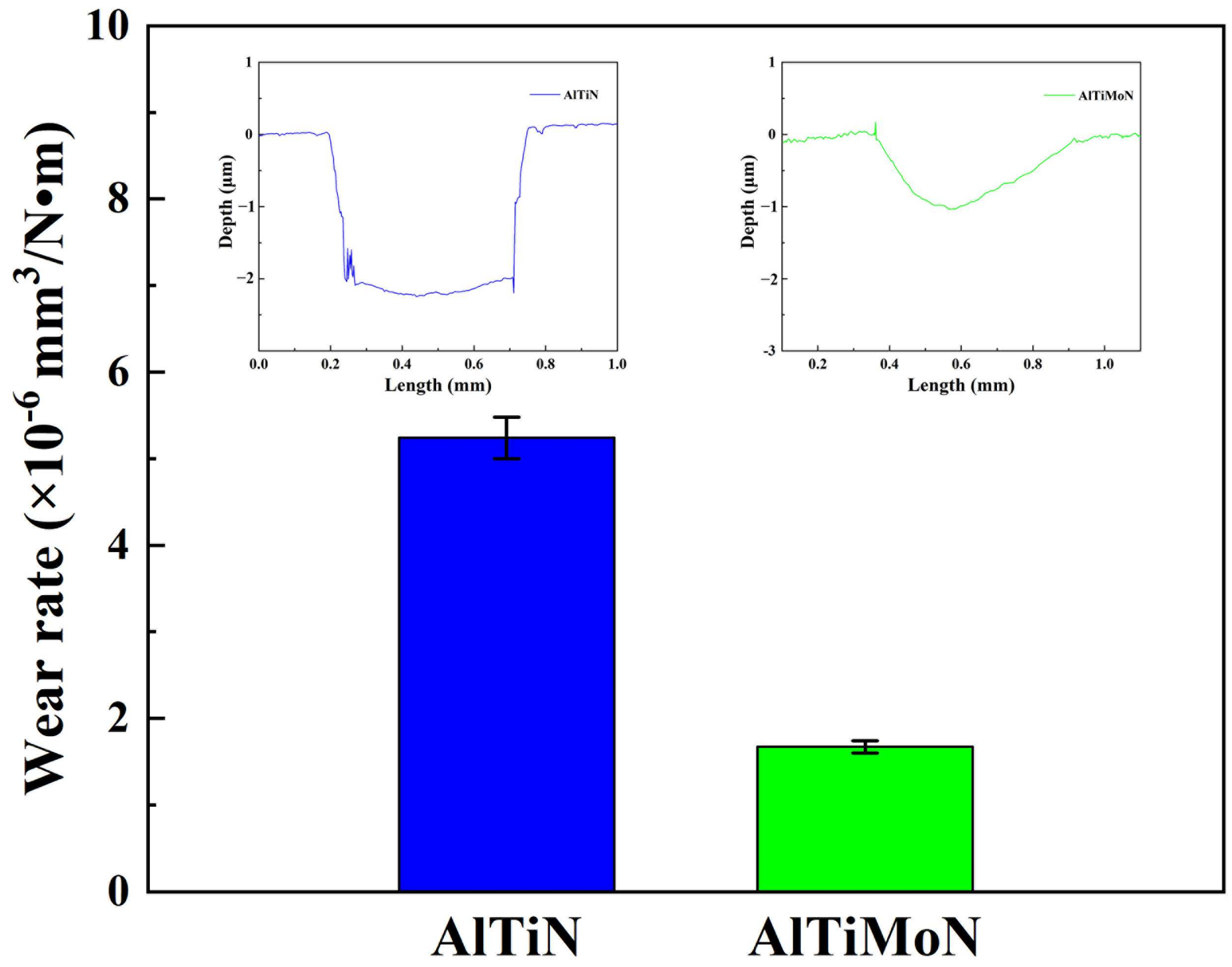

3.3. Tribological Properties of the AlTiN and AlTiMoN Coatings

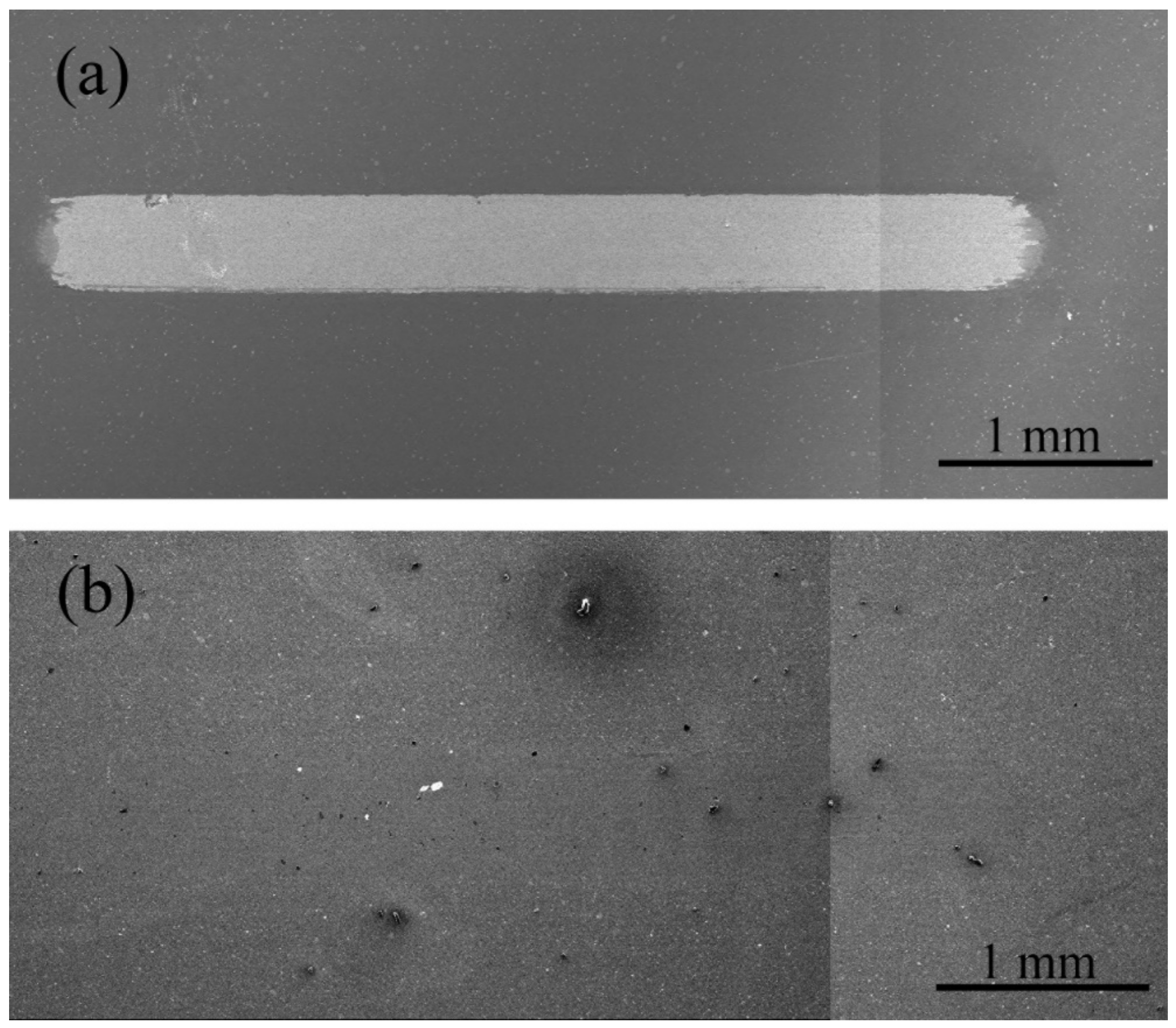

3.4. Cutting Performance of the AlTiN and AlTiMoN Coatings

4. Conclusions

- Spherical droplets formed on the surfaces of both coatings, with the AlTiMoN coating exhibiting more surface defects than the AlTiN coating. The GIXRD results for the AlTiN and AlTiMoN coatings showed that an (Al,Ti)N phase was formed. Doping of the AlTiMoN coating with Mo slightly reduced the grain size.

- Both coatings exhibited excellent adhesion to the substrate. The hardness, elastic modulus, and H/E and H3/E2 ratios of the AlTiMoN coating were higher than those of the AlTiN coating. The improvement in the mechanical properties can be attributed to grain refinement and solution strengthening.

- The tribological properties and cutting performance of the AlTiN coating improved with the Mo doping, which can be attributed to the formation of MoO3 as a solid lubricant.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Avila, R.F.; Mancosu, R.D.; Machado, A.R.; Vecchio, S.D.; Silva, R.B.d.; Vieira, J.M. Comparative analysis of wear on PVD TiN and (Ti1−xAlx)N coatings in machining process. Wear 2013, 302, 1192–1200. [Google Scholar] [CrossRef]

- Chauhan, K.V.; Rawal, S.K. A review paper on tribological and mechanical properties of ternary nitride based coatings. Procedia Technol. 2014, 14, 430–437. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Musil, J.; Hrubý, H. Superhard nanocomposite Ti1−xAlxN films prepared by magnetron sputtering. Thin Solid Films 2000, 365, 104–109. [Google Scholar] [CrossRef]

- Kale, A.N.; Ravindranath, K.; Kothari, D.C.; Raole, P.M. Tribological properties of (Ti,Al) N coatings deposited at different bias voltages using the cathodic arc technique. Surf. Coat. Technol. 2001, 145, 60–70. [Google Scholar] [CrossRef]

- Richthofen, A.; Cremer, R.; Witthaut, M.; Domnick, R.; Neuschütz, D. Composition, binding states, structure, and morphology of the corrosion layer of an oxidized Ti0.46Al0.54N film. Thin Solid Films 1998, 312, 190–194. [Google Scholar] [CrossRef]

- Hardell, J.; Prakash, B. Tribological performance of surface engineered tool steel at elevated temperatures. Int. J. Refract. Met. Hard Mater. 2010, 28, 106–114. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.D.; Pinto, G.F.; Baptista, A. Characteristics and wear mechanisms of TiAlN-based coatings for machining applications: A comprehensive review. Metals 2021, 11, 260. [Google Scholar] [CrossRef]

- He, J.; Liu, G.; Ren, H.X.; Liu, J.; Wang, H.; Qiu, L.S.; Hu, X.G. Investigations on the structure, mechanical property, wear and oxidation resistances of TiAlSiN coatings by tailoring Al/(Al + Ti) ratios. Adv. Eng. Mater. 2024, 26, 2400625. [Google Scholar] [CrossRef]

- Gao, T.; Yu, L.H.; Lu, G.Y.; Ju, H.B.; Xu, J.H. Influence of Mo content on properties of Ti-Al-Mo-N films. Surf. Eng. 2021, 37, 519–526. [Google Scholar] [CrossRef]

- Sergevnin, V.S.; Blinkov, I.V.; Belov, D.S.; Volkhonskii, A.O.; Krupin, A.Y.; Chernogor, A.V. Hardness, adhesion strength, and tribological properties of adaptive nanostructured ion-plasma vacuum-arc coatings (Ti,Al)N-Mo2N. Russ. J. Non-Ferr. Met. 2016, 57, 572–579. [Google Scholar] [CrossRef]

- Yang, K.; Xian, G.; Zhao, H.B.; Fan, H.Y.; Wang, J.; Wamg, H.; Du, H. Effect of Mo content on the structure and mechanical properties of TiAlMoN films deposited on WC-Co cemented carbide substrate by magnetron sputtering. Int. J. Refract. Met. Hard Mater. 2015, 52, 29–35. [Google Scholar] [CrossRef]

- Sergevnin, V.S.; Blinkov, I.V.; Belov, D.S.; Smirnov, N.I.; Volkhonskii, A.O.; Kuptsov, K.A. Wear and erosion of arc-PVD multilayer Ti-Al-Mo-N coatings under various conditions of friction and loading. Int. J. Adv. Manuf. Technol. 2018, 98, 593–601. [Google Scholar] [CrossRef]

- Sangiovanni, D.G.; Chirita, V.; Hultman, L. Toughness enhancement in TiAlN-based quarternary alloys. Thin Solid Films 2012, 52, 4080–4088. [Google Scholar] [CrossRef]

- Gassner, G.; Mayrhofer, P.H.; Kutschej, K.; Mitterer, C.; Mitterer, M. Magnéli phase formation of PVD Mo-N and W-N coatings. Surf. Coat. Technol. 2006, 201, 3335–3341. [Google Scholar] [CrossRef]

- Tomaszewski, Ł.; Gulbinski, W.; Urbanowicz, A.; Suszko, T.; Lewandowski, A.; Gulbinskin, W. TiAlN based wear resistant coatings modified by molybdenum addition. Vacuum 2015, 121, 223–229. [Google Scholar] [CrossRef]

- Sergevnin, V.S.; Blinkov, I.V.; Volkhonskii, A.O.; Belov, D.S.; Kuznetsov, D.V.; Gorshenkov, M.V.; Skryleva, E.A. Wear behaviour of wear-resistant adaptive nano-multilayered Ti-Al-Mo-N coatings. Appl. Surf. Sci. 2016, 388, 13–23. [Google Scholar] [CrossRef]

- Yousaf, M.I.; Pelenovich, V.O.; Yang, B.; Liu, C.S.; Fu, D.J. Effect of bilayer period on structural and mechanical properties of nanocomposite TiAlN/MoN multilayer films synthesized by cathodic arc ion-plating. Surf. Coat. Technol. 2015, 282, 94–102. [Google Scholar] [CrossRef]

- Tavares, C.J.; Rebouta, L.; Alves, E.; Cavaleiro, A.; Goudeau, P.; Riviere, J.P.; Declemy, A. A structural and mechanical analysis on PVD-grown (Ti,Al)N/Mo multilayers. Thin Solid Film. 2000, 377–378, 425–429. [Google Scholar] [CrossRef]

- Tavares, C.J.; Rebouta, L.; Riviere, J.P.; Pacaud, J.; Garem, H.; Pischow, K.; Wang, Z. Microstructure of superhard (Ti,Al)N/Mo multilayers. Thin Solid Film. 2001, 398–399, 397–404. [Google Scholar] [CrossRef]

- Tavares, C.J.; Rebouta, L.; Andritschky, M.; Guimarães, F.; Cavaleiro, A. Mechanical and surface analysis of Ti0.4Al0.6N/Mo multilayers. Vacuum 2001, 60, 339–346. [Google Scholar] [CrossRef]

- Tavares, C.J.; Rebouta, L.; Alves, E.; Barradas, N.P.; Pacaud, J.; Riviere, J.P. Study of roughness in Ti0.4Al0.6N/Mo multilayer structures. Nucl. Instrum. Methods Phys. Res. B 2002, 188, 90–95. [Google Scholar] [CrossRef]

- Tavares, C.J.; Rebouta, L.; Riviere, J.P.; Girardeau, T.; Goudeau, P.; Alves, E.; Barradas, N.P. Atomic environment and interfacial structural order of TiAlN/Mo multilayers. Surf. Coat. Technol. 2004, 187, 393–398. [Google Scholar] [CrossRef]

- Tavares, C.J.; Vidrago, C.; Rebouta, L.; Riviere, J.P.; Bourhis, E.L.; Denanot, M.F. Optimization and thermal stability of TiAlN/Mo multilayers. Surf. Coat. Technol. 2005, 200, 288–292. [Google Scholar] [CrossRef]

- Sergevnin, V.S.; Blinkov, I.V.; Belov, D.S.; Volkhonskii, A.O.; Skryleva, E.A.; Chernogor, A.V. Phase formation in the Ti-Al-Mo-N system during the growth of adaptive wear-resistant coatings by arc PVD. Inorg. Mater. 2016, 52, 735–742. [Google Scholar] [CrossRef]

- Yousaf, M.I.; Abudouwufu, T.; Yang, B.; Tolstoguzov, A.; Fu, D.J. Influence of bilayer thickness on mechanical and tribological properties of (Ti-Al)N/MoN nanostructured hard coatings deposited by cathodic arc ion plating. Coatings 2023, 13, 1654. [Google Scholar] [CrossRef]

- Yousaf, M.I.; Pelenovich, V.O.; Yang, B.; Liu, C.S.; Fu, D.J. Influence of substrate rotation speed on the structure and mechanical properties of nanocrystalline AlTiN/MoN coatings synthesized by cathodic arc ion-plating. Surf. Coat. Technol. 2015, 265, 117–124. [Google Scholar] [CrossRef]

- Wang, Z.S.; Tian, C.X.; Tolstogouzov, A.; Liang, F.; Zou, C.W.; Li, S.Q.; Gusev, S.I.; Yousaf, M.I.; Pelenovich, V.; Zuo, W.B.; et al. Microstructure and Rutherford backscattering spectrometry of hard/lubricant Mo-Ti-Al-N multilayered coatings prepared by multi-arc ion plating at low substrate rotation. Coatings 2020, 10, 101. [Google Scholar] [CrossRef]

- Jirón-Lazos, U.; Rodil, S.E.; Mazón-Montijo, D.A.; Pérez-Higareda, J.R.; Torres, D.; Garay-Tapia, A.M.; Montiel-González, Z. Microstructural behavior of the Ti-Al-Mo-N system controlled by Mo content: Impact on the performance as hard coatings. J. Mater. Sci. 2023, 58, 11771–11787. [Google Scholar] [CrossRef]

- Belgroune, A.; Aissani, L.; Alhussein, A.; Zaabat, M.; Obrosov, A.; Rtimi, S. In vitro corrosion and wear investigation of multifunctional TiAlMoN sputtered coatings on cold-sprayed SS316L. ACS Appl. Eng. Mater. 2024, 2, 345–359. [Google Scholar] [CrossRef]

- Glatz, S.A.; Moraes, V.; Koller, C.M.; Riedl, H.; Bolvardi, H.; Kolozsvári, S.; Mayrhofer, P.H. Effect of Mo on the thermal stability, oxidation resistance, and tribo-mechanical properties of arc evaporated Ti-Al-N coatings. J. Vac. Sci. Technol. A 2017, 35, 061515. [Google Scholar] [CrossRef]

- Glatz, S.A.; Koller, C.M.; Bolvardi, H.; Kolozsvári, S.; Riedl, H.; Mayrhofer, P.H. Influence of Mo on the structure and the tribomechanical properties of arc evaporated Ti-Al-N. Surf. Coat. Technol. 2017, 311, 330–336. [Google Scholar] [CrossRef]

- Moreno, M.; Andersson, J.M.; Johansson-Jöesaar, M.P.; Friedrich, B.E.; Boyd, R.; Schramm, I.C.; Johnson, L.J.S.; Odén, M.; Rogström, L. Wear of Mo- and W-alloyed TiAlN coatings during high-speed turning of stainless steel. Surf. Coat. Technol. 2022, 446, 128786. [Google Scholar] [CrossRef]

- Demirov, A.P.; Blinkov, I.V.; Sergevnin, V.S.; Volkhonskii, A.O.; Chernogor, A.V.; Shchetinin, I.V. Thermal stability and electrochemical behavior of nanostructured Ti-Al (∼1%(at.))-Mo-N coatings deposited using the Arc-PVD method. J. Alloys Compd. 2022, 929, 167269. [Google Scholar] [CrossRef]

- ISO 14577; Metallic Materials-Instrumented Indentation Test for Hardness and Materials Parameters. ISO Central Secretariat: Geneva, Switzerland, 2002.

- Wang, H.M.; Shi, P.J.; Yu, H.L.; Zhang, W.; Xu, B.S. Applications of nanoindentation techniques in the field of surface coatings. Key Eng. Mater. 2008, 373–374, 802–805. [Google Scholar] [CrossRef]

- ASTM G137; Standard Test Method for Ranking Resistance of Plastic Materials to Sliding Wear Using a Block-on-Ring Configuration. ASTM International: West Conshohocken, PA, USA, 2017.

- Ying, P.Y.; Sun, H.Y.; Zhang, P.; Lin, C.H.; Yang, T.; Wu, J.B.; Huang, M.; Wang, T.L.; Lian, Z.B.; Levchenko, V. Preparation and tribological properties of WS2 solid lubricating coating with dense structure using HiPIMS. J. Mater. Res. Technol. 2024, 32, 530–540. [Google Scholar] [CrossRef]

- JB/T 11442-2013; Coated Solid-Carbide Tools. Detection Methods. Machinery Industry Press: Beijing, China, 2013.

- GB/T 16461-2016; Tool-Life Testing with Single-Point Turning Tools. China Standards Press: Beijing, China, 2016.

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Sotova, C.; Sadov, I. Investigation of the influence of microdroplets on the coatings nanolayer structure. Coatings 2020, 10, 1204. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.H.; Chen, Z.; Li, J.L.; Li, M.X. Influence of deposition parameters on hard Cr-Al-N coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Ju, H.B.; Yu, L.H.; Yu, D.; Asempah, I.; Xu, J.H. Microstructure, mechanical and tribological properties of TiN-Ag films deposited by reactive magnetron sputtering. Vacuum 2017, 141, 82–88. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks. Mater. Res. Soc. Symp. Proc. 1995, 383, 447. [Google Scholar] [CrossRef]

- Erdemir, A. A crystal chemical approach to the formulation of self-lubricating nanocomposite coatings. Surf. Coat. Technol. 2005, 200, 1792–1796. [Google Scholar] [CrossRef]

- Yang, Q. Wear resistance and solid lubricity of molybdenum-containing nitride coatings deposited by cathodic arc evaporation. Surf. Coat. Technol. 2017, 322, 283–295. [Google Scholar] [CrossRef]

- Biksa, A.; Yamamoto, K.; Dosbaeva, G.; Veldhuis, S.C.; Fox-Rabinovich, G.S.; Elfizy, A.; Wagg, T.; Shuster, L.S. Wear behavior of adaptive nano-multilayered AlTiN/MexN PVD coatings during machining of aerospace alloys. Tribol. Int. 2010, 43, 1491–1499. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Deng, J.X.; Li, S.P.; Yue, H.Z.; Meng, R.; Gao, P. Cutting performance and wear characteristics of Al2O3/TiC ceramic cutting tools with WS2/Zr soft-coatings and nano-textures in dry cutting. Wear 2014, 318, 12–26. [Google Scholar] [CrossRef]

- Li, X.M.; Deng, J.X.; Lu, Y.; Duan, R.; Ge, D.L. Machinability investigation and sustainability assessment of dry cutting AISI1045 steel using tools configured with shark-skin-inspired structures and WS2/C coatings. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 83–106. [Google Scholar] [CrossRef]

| Al | Ti | Mo | N | |

|---|---|---|---|---|

| AlTiN | 27.4 ± 0.9 | 15.8 ± 0.7 | — | 56.8 ± 1.5 |

| AlTiMoN | 24.9 ± 1.0 | 14.2 ± 0.9 | 5.1 ± 0.6 | 55.8 ± 1.2 |

| Coating | Hardness (GPa) | Elastic Moduli (GPa) | H/E | H3/E2 |

|---|---|---|---|---|

| AlTiN | 26 ± 2 | 318 ± 9 | 0.082 | 0.174 |

| AlTiMoN | 30 ± 3 | 341 ± 12 | 0.088 | 0.232 |

| Al | Ti | Mo | N | W | C | Co | |

|---|---|---|---|---|---|---|---|

| AlTiN | — | — | — | — | 36.1 ± 0.8 | 61.3 ± 1.3 | 2.6 ± 0.7 |

| AlTiMoN | 23.1 ± 0.6 | 14.8 ± 0.5 | 5.1 ± 0.5 | 57.0 ± 1.2 | — | — | — |

| Highest Temperature During Cutting (°C) | Average Temperature at Which Cutting Is Stable (°C) | |

|---|---|---|

| AlTiN | 611 | 596 |

| AlTiMoN | 577 | 560 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.; Yin, J.; Ying, P.; Lin, C.; Zhang, P.; Wu, J.; Kovalev, A.; Huang, M.; Wang, T.; Grigoriev, A.Y.; et al. Influence of Molybdenum Addition on the Structure, Mechanical Properties, and Cutting Performance of AlTiN Coatings. Lubricants 2024, 12, 429. https://doi.org/10.3390/lubricants12120429

Yang T, Yin J, Ying P, Lin C, Zhang P, Wu J, Kovalev A, Huang M, Wang T, Grigoriev AY, et al. Influence of Molybdenum Addition on the Structure, Mechanical Properties, and Cutting Performance of AlTiN Coatings. Lubricants. 2024; 12(12):429. https://doi.org/10.3390/lubricants12120429

Chicago/Turabian StyleYang, Tao, Jun Yin, Puyou Ying, Changhong Lin, Ping Zhang, Jianbo Wu, Alexander Kovalev, Min Huang, Tianle Wang, Andrei Y. Grigoriev, and et al. 2024. "Influence of Molybdenum Addition on the Structure, Mechanical Properties, and Cutting Performance of AlTiN Coatings" Lubricants 12, no. 12: 429. https://doi.org/10.3390/lubricants12120429

APA StyleYang, T., Yin, J., Ying, P., Lin, C., Zhang, P., Wu, J., Kovalev, A., Huang, M., Wang, T., Grigoriev, A. Y., Gutsev, D. M., & Levchenko, V. (2024). Influence of Molybdenum Addition on the Structure, Mechanical Properties, and Cutting Performance of AlTiN Coatings. Lubricants, 12(12), 429. https://doi.org/10.3390/lubricants12120429