Carbon Nanotubes Decorated with Nickel or Copper as Anti-Wear and Extreme-Pressure Additives for Greases

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

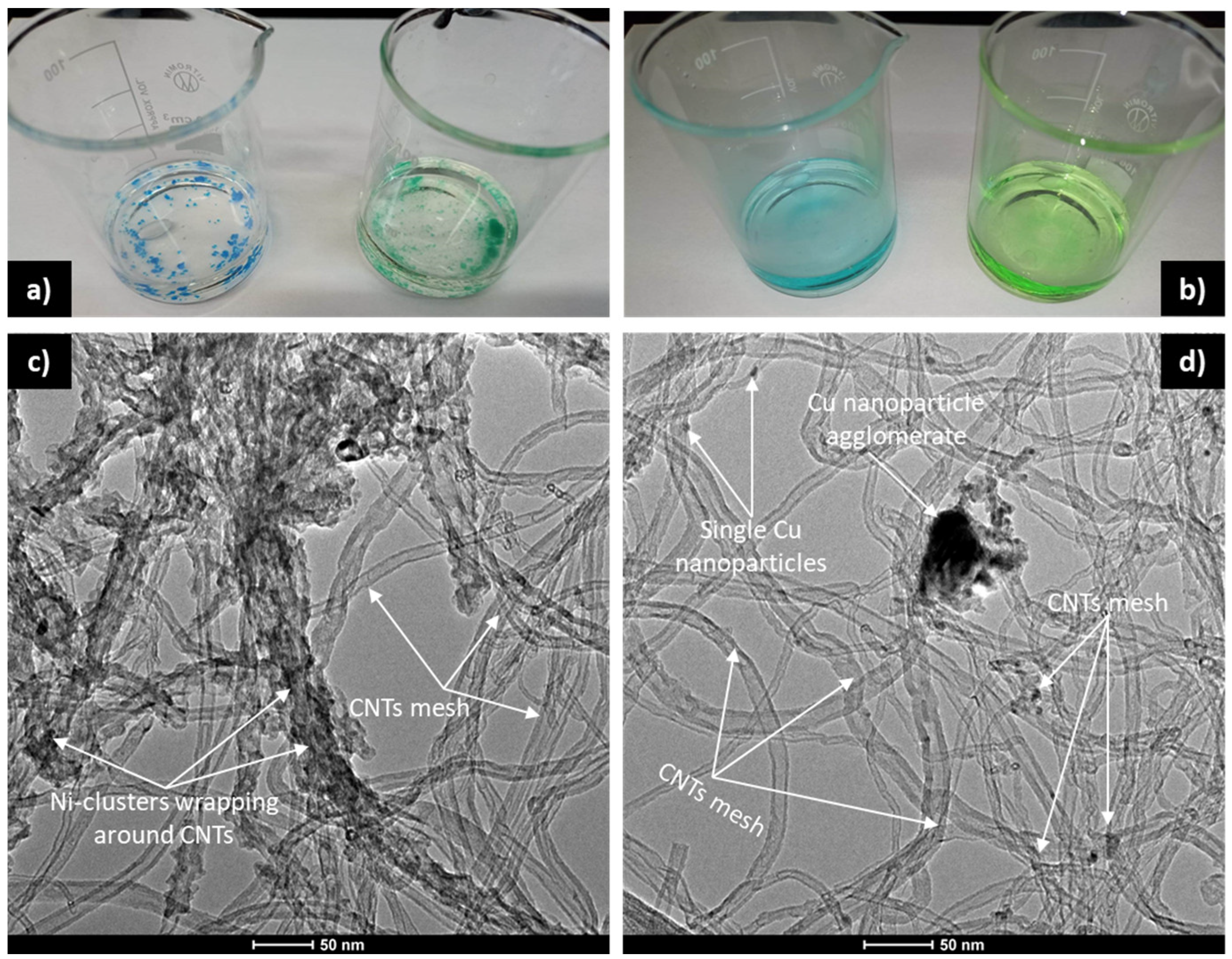

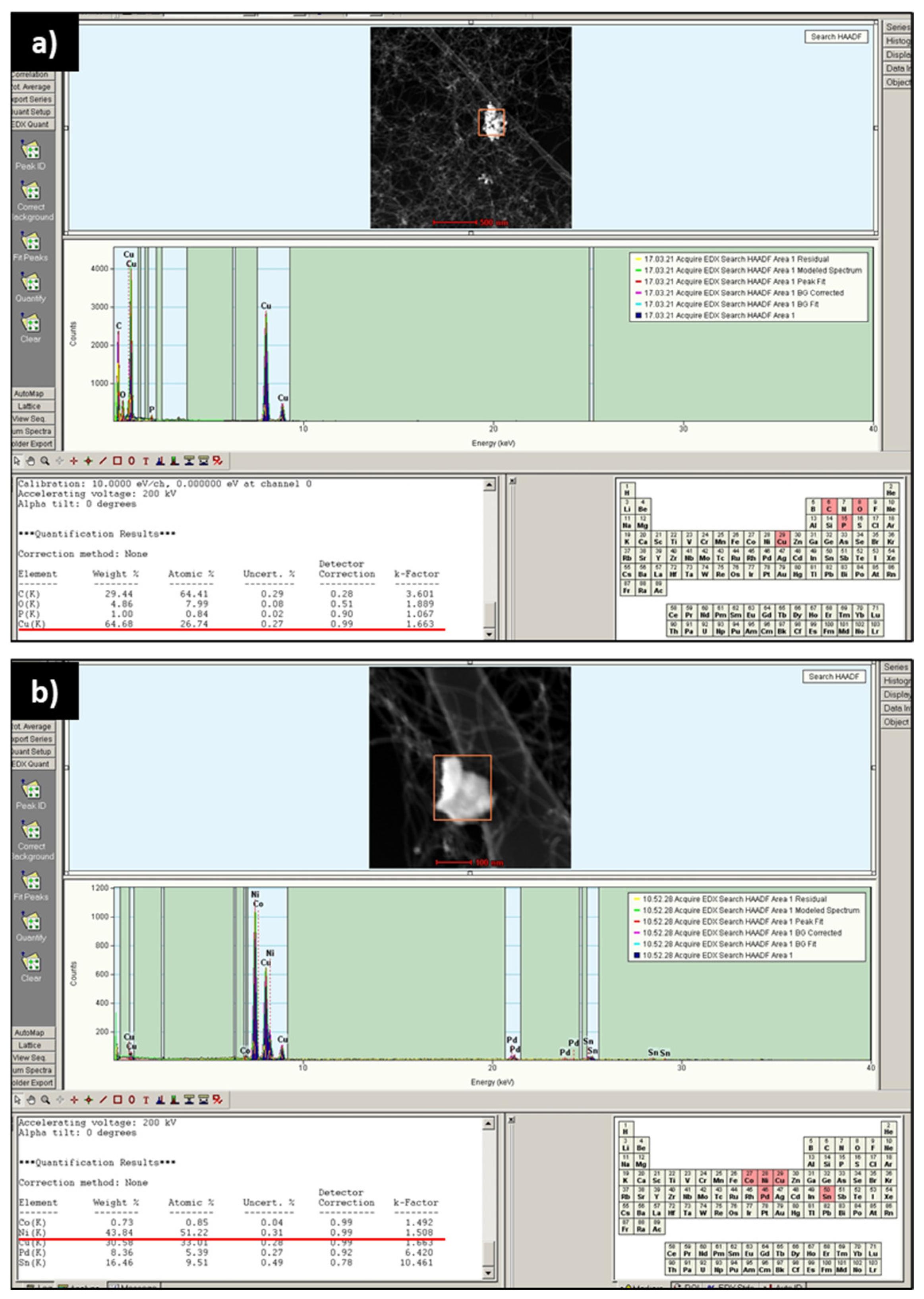

3.1. Material Characterisation

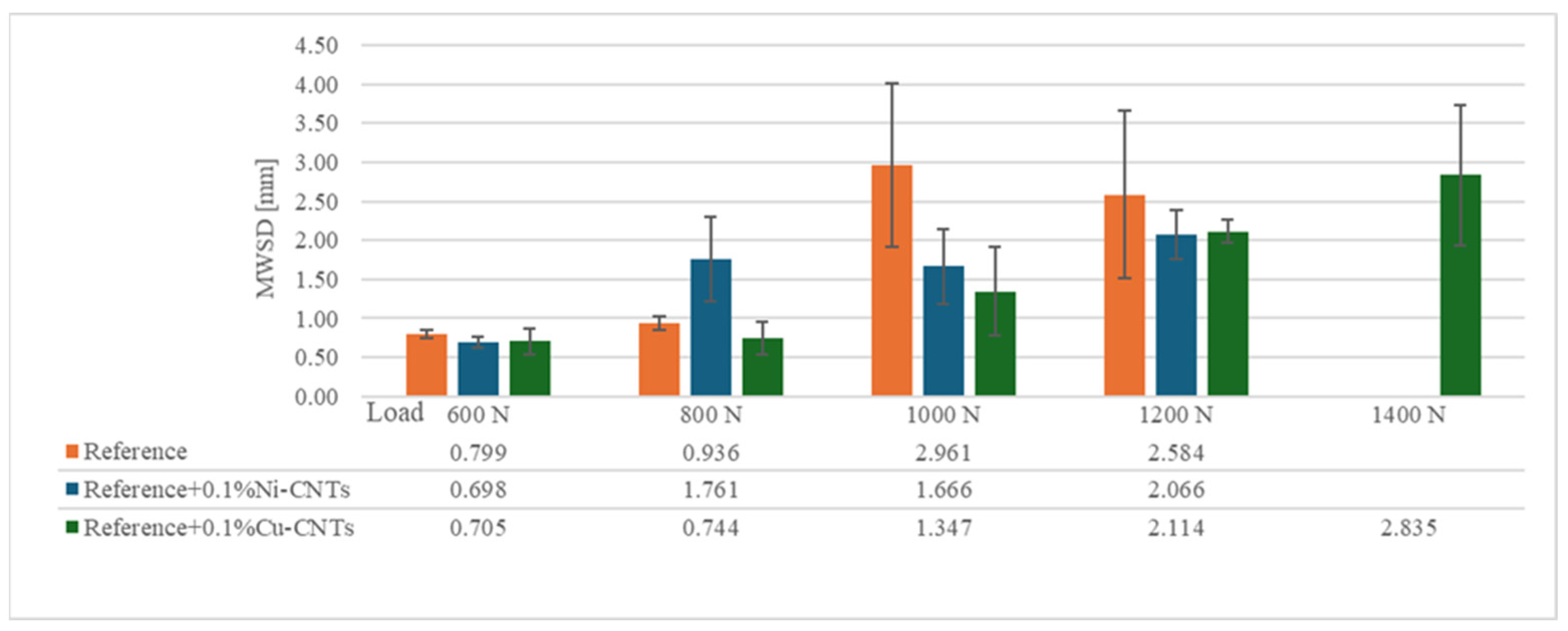

3.2. Four-Ball Test

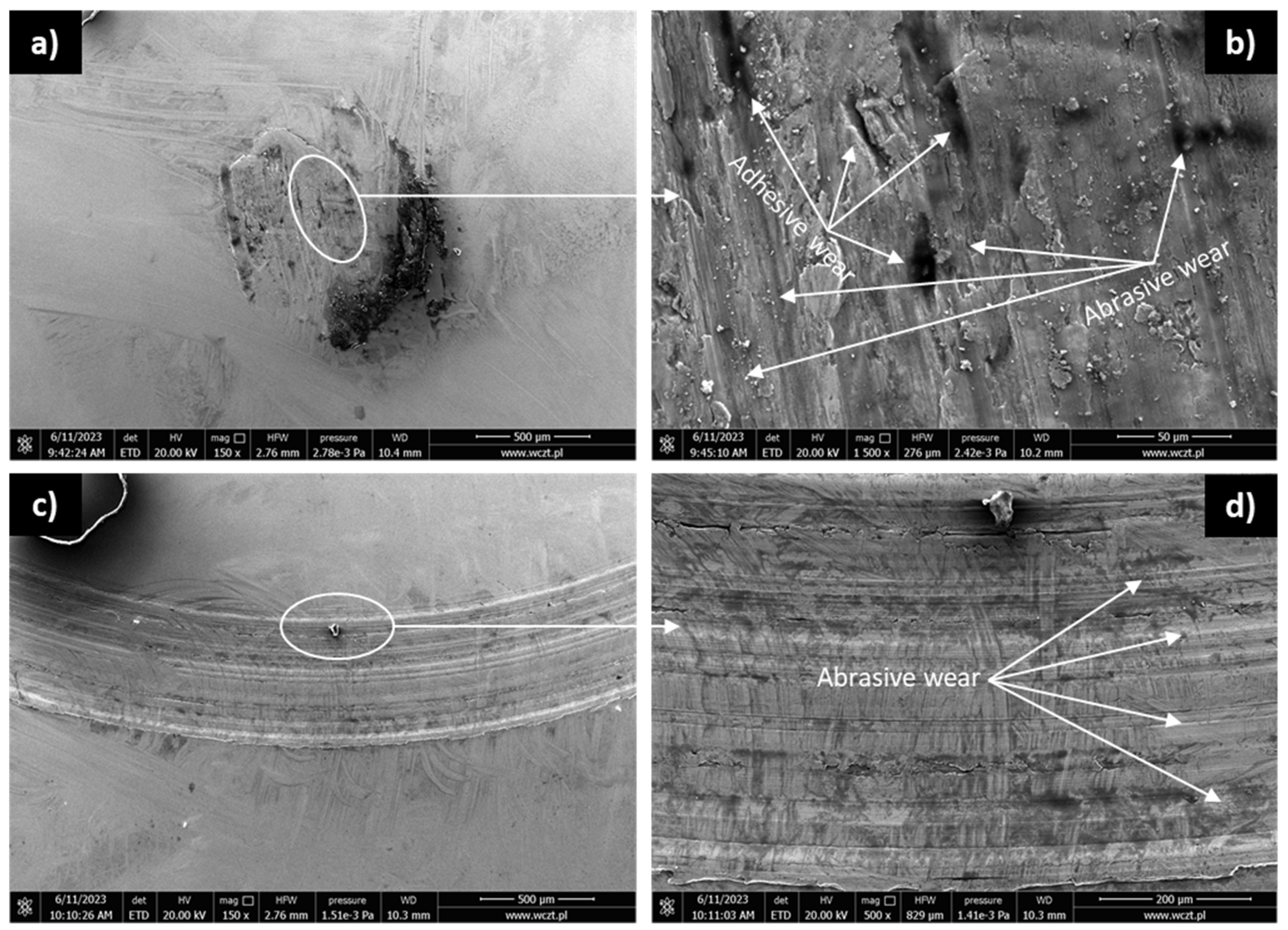

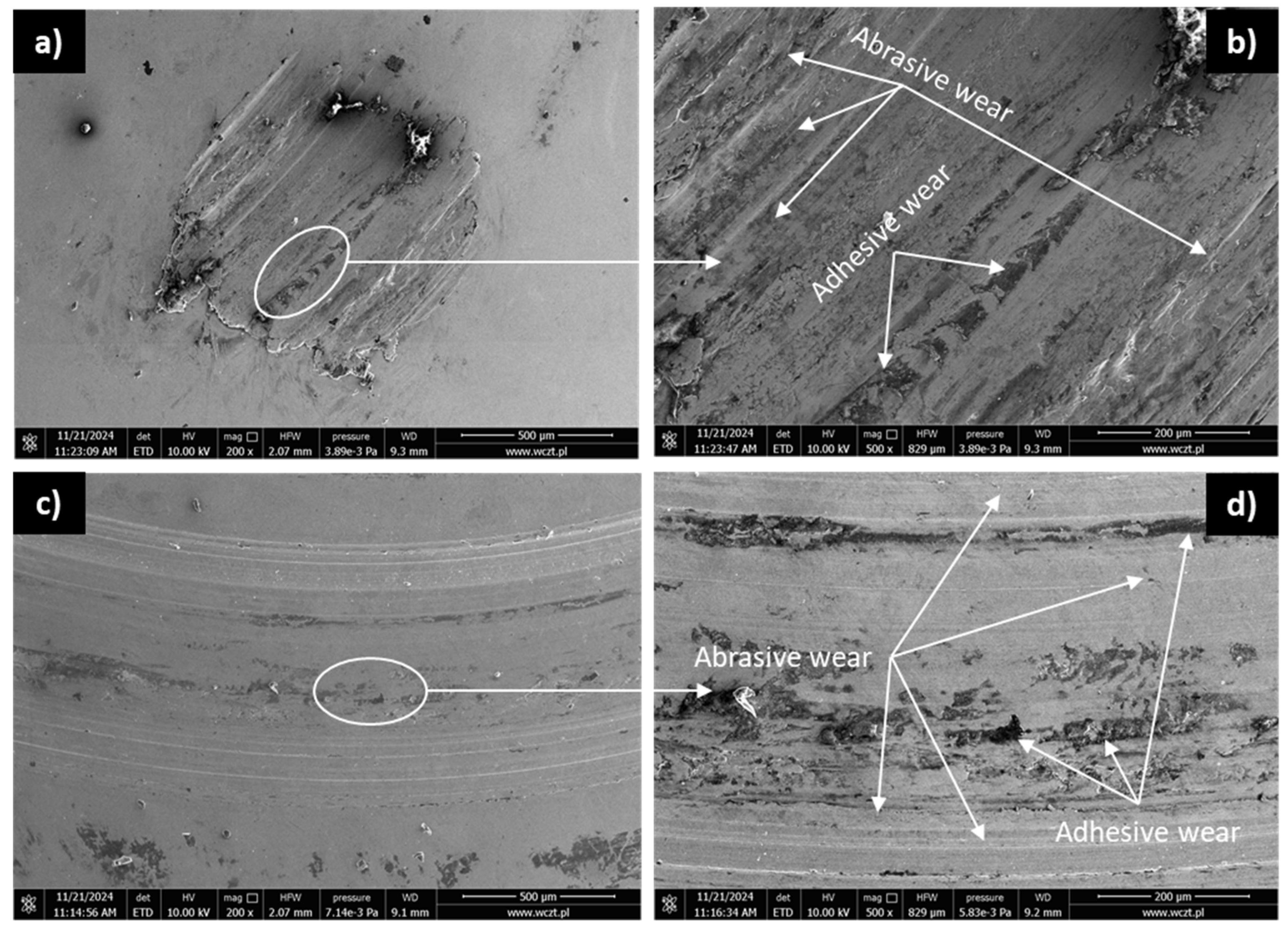

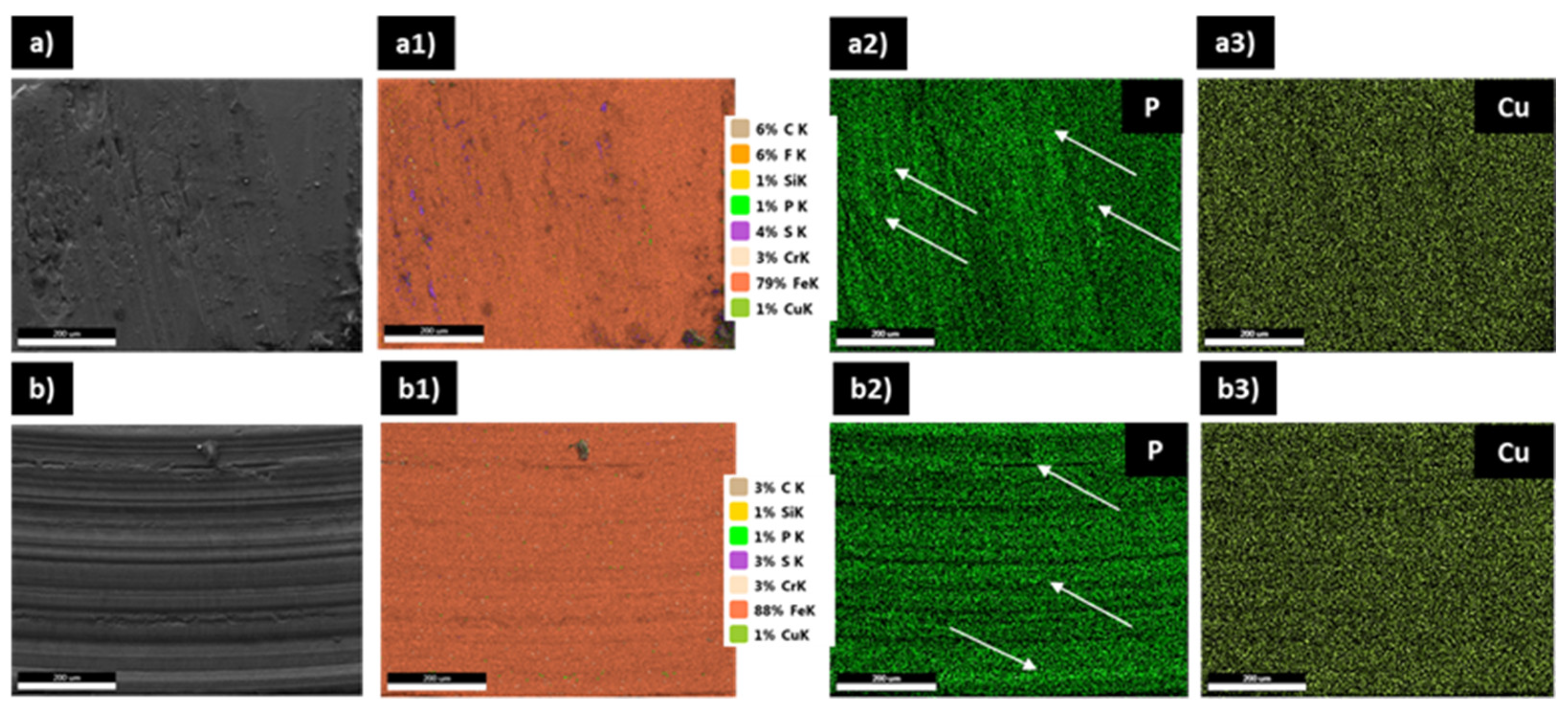

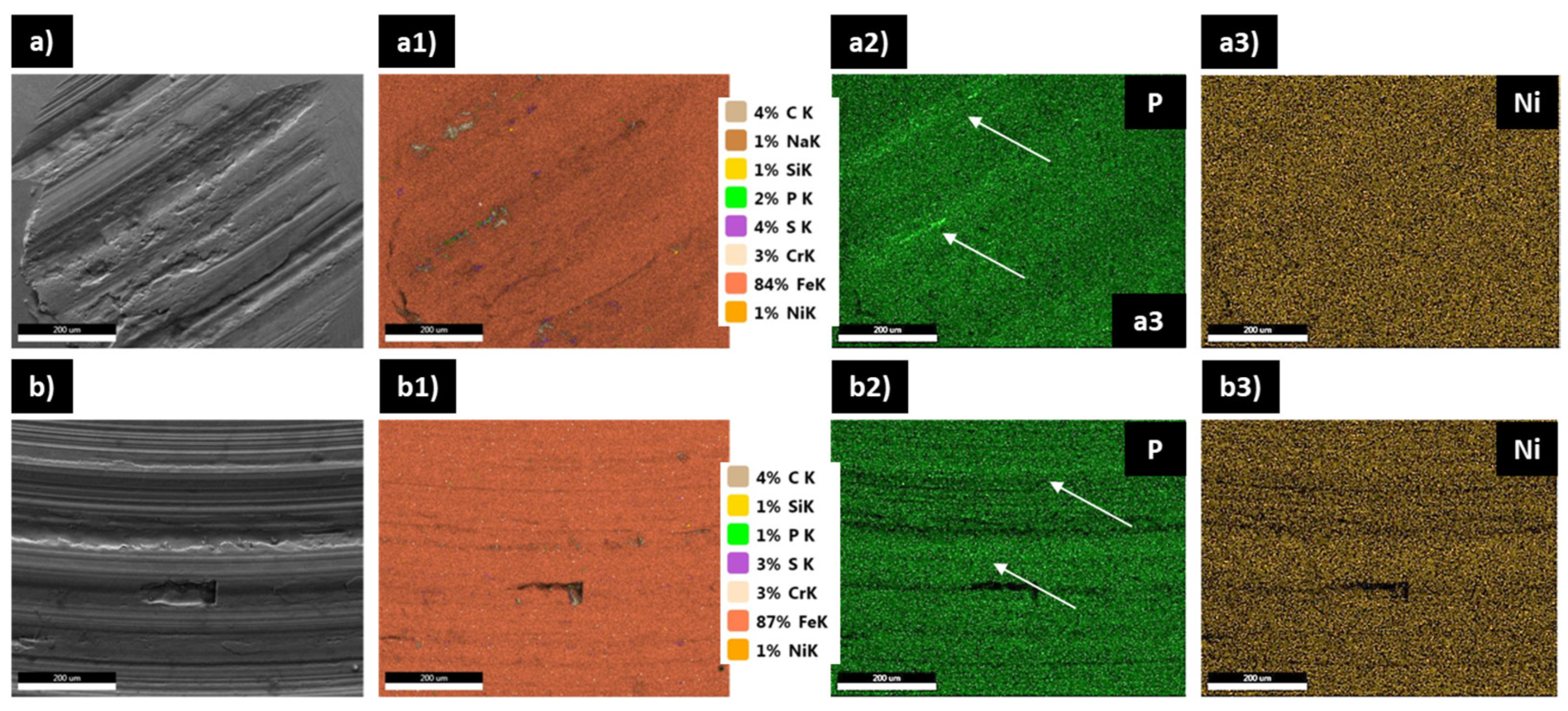

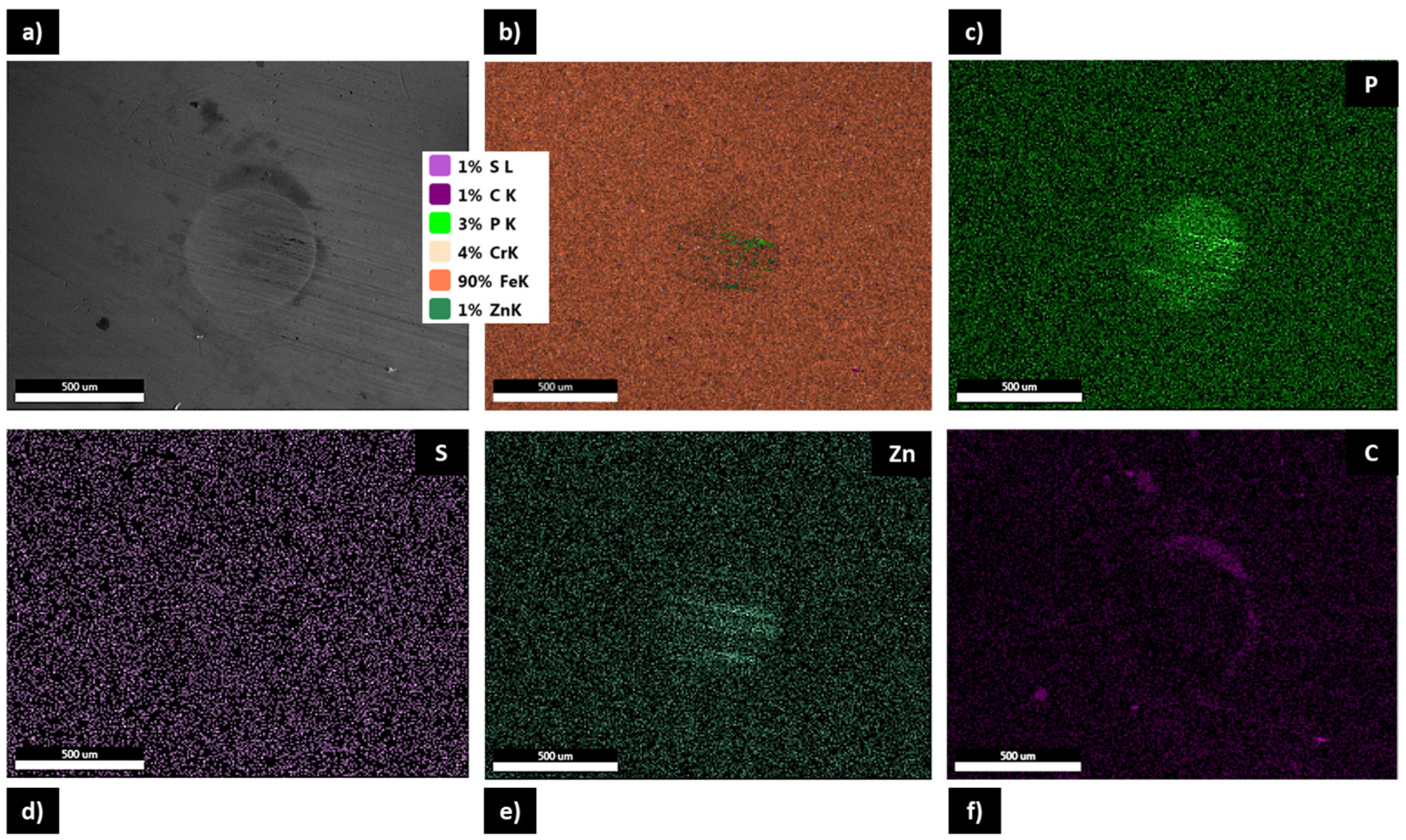

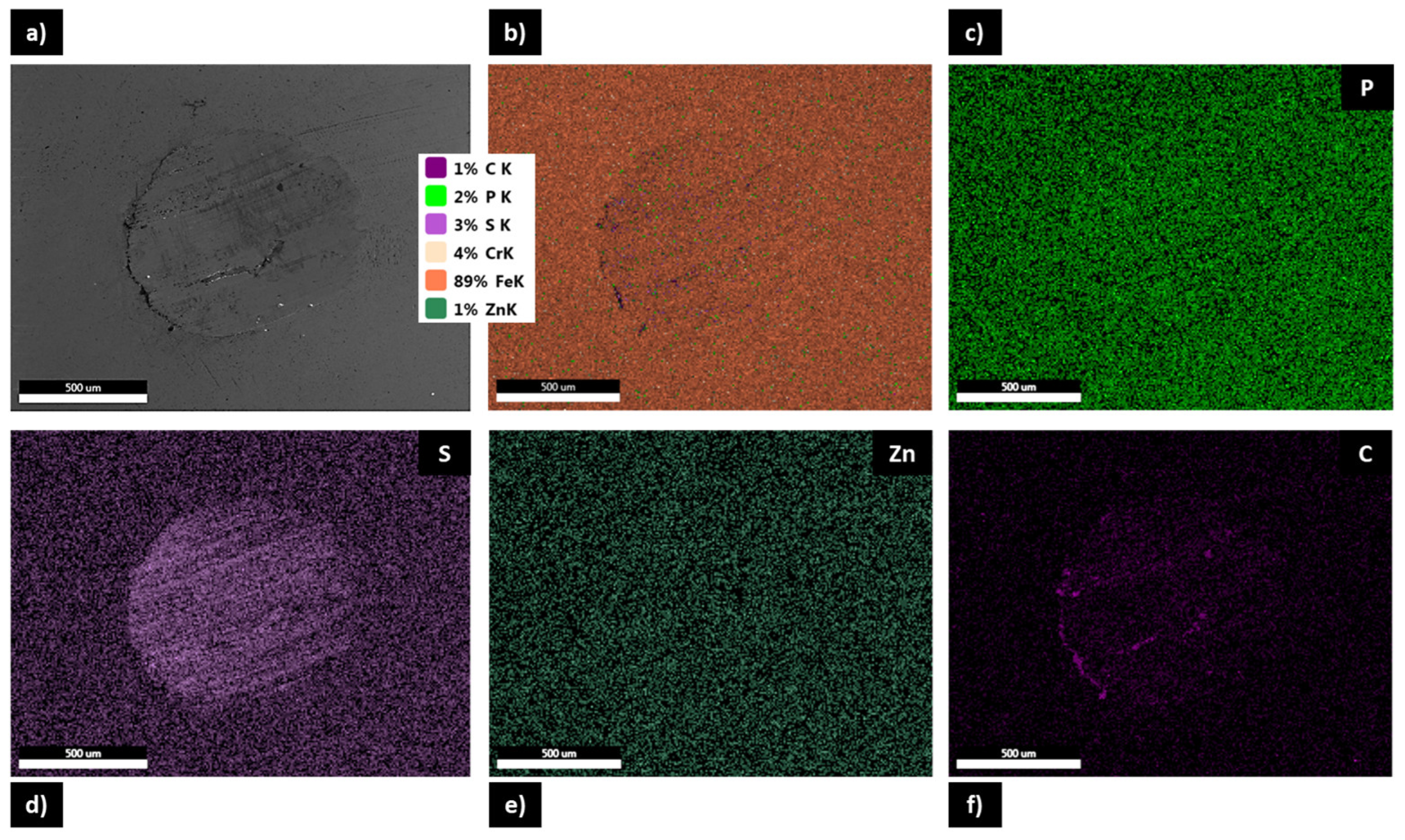

3.3. SEM/EDS Investigations—Wear Mechanisms

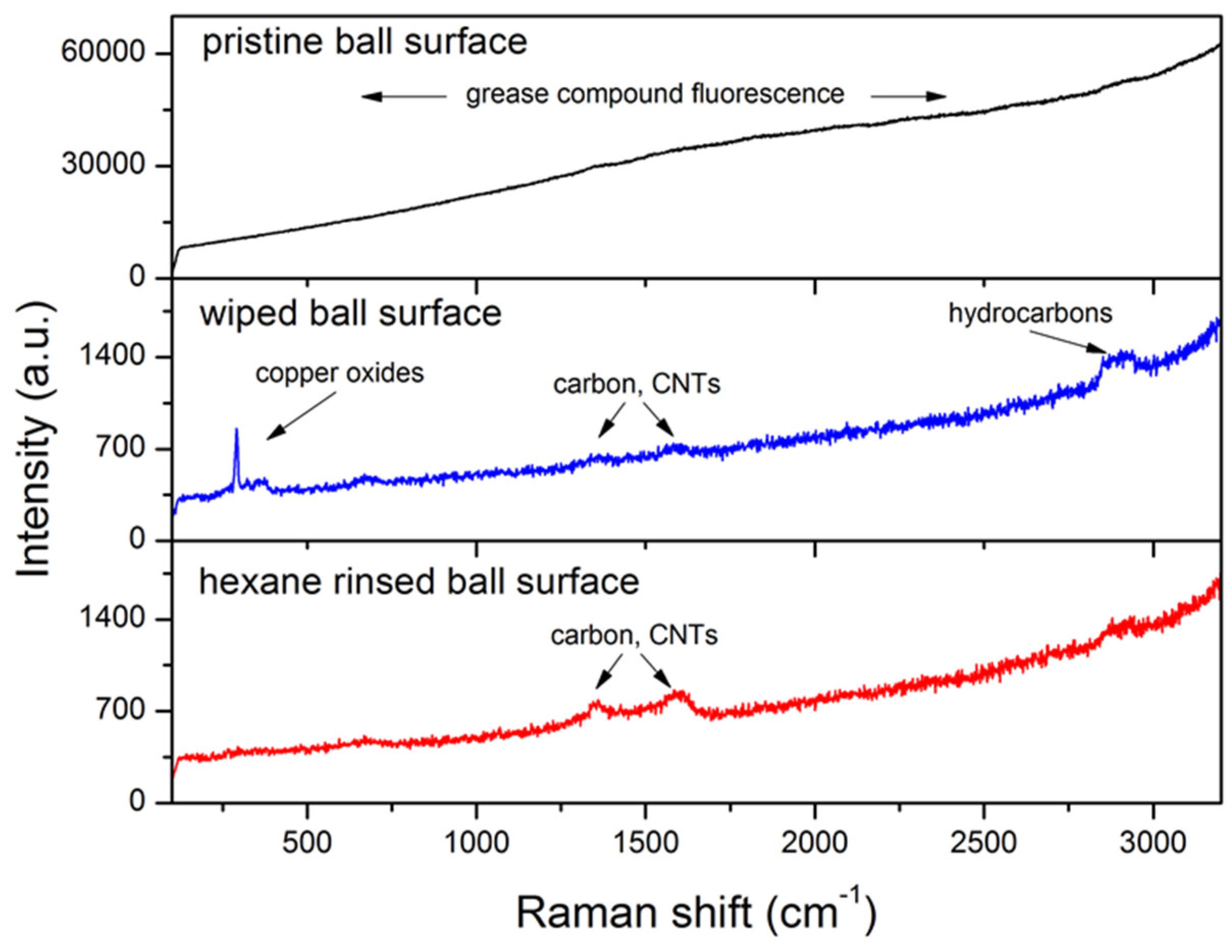

3.4. Raman Spectroscopy

4. Conclusions

5. Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nosonovsky, M.; Bushan, B. Green tribology: Principles, research areas and challenges. Philos. Trans. R. Soc. A 2010, 368, 4677–4694. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Zhang, S.; Zhang, C. Unlocking the secrets behind liquid superlubricity: A state-of-the-art review on phenomena and mechanisms. Friction 2022, 10, 1137–1165. [Google Scholar] [CrossRef]

- Ayyagari, A.; Alam, K.I.; Berma, D.; Erdemir, A. Progress in superlubricity across different media and material systems—A review. Front. Mech. Eng. 2022, 8, 908497. [Google Scholar] [CrossRef]

- Wojciechowski, Ł.; Kubiak, K.J.; Boncel, S.; Marek, A.; Gapiński, B.; Runka, T.; Jędrysiak, R.; Ruczka, S.; Błaszkiewicz, P.; Mathia, T.G. Towards the superlubricity of polymer–steel interfaces with ionic liquids and carbon nanotubes. Tribol. Int. 2024, 191, 109203. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Rashidi, A.; Ahmadi, H.; Mohtasebi, S.S.; Pourkhalil, M. Thermal and rheological properties of oil-based nanofluids from different carbon nanostructures. Int. Commun. Heat Mass Transf. 2013, 48, 178–182. [Google Scholar] [CrossRef]

- Mohamed, A.; Tirth, V.; Kamel, B.M. Tribological characterization and rheology of hybrid calcium grease with graphene nanosheets and multi-walled carbon nanotubes as additives. J. Mater. Res. Technol. 2015, 137, 6178–6185. [Google Scholar] [CrossRef]

- Nyholm, N.; Espallargas, N. Functionalized carbon nanostructures as lubricant additives. Carbon 2023, 201, 1200–1228. [Google Scholar] [CrossRef]

- Karousis, N.; Tagmatarchis, N.; Tasis, D. Current progress on the chemical modification of carbon nanotubes. Chem. Rev. 2010, 110, 5366–5397. [Google Scholar] [CrossRef]

- Dobrzańska-Danikiewicz, A.D.; Łukowiec, D.; Cichocki, D.; Wolany, W. Carbon nanotubes decorating methods. Arch. Mater. Sci. Eng. 2013, 61, 53–61. [Google Scholar]

- Cursaru, D.L.; Andronescu, C.; Pirvu, C.; Ripeanu, R. The efficiency of Co-based single-wall carbon nanotubes (SWNTs) as an AW/EP additive for mineral base oils. Wear 2012, 290–291, 133–139. [Google Scholar] [CrossRef]

- Kałużny, J.; Kulczycki, A.; Dzięgielewski, W.; Piasecki, A.; Gapiński, B.; Mendak, M.; Runka, T.; Łukawski, D.; Stepanenko, O.; Merkisz, J.; et al. The indirect tribological role of carbon nanotubes stimulating zinc dithiophosphate anti-wear film formation. Nanomaterials 2020, 10, 1330. [Google Scholar] [CrossRef] [PubMed]

- Salah, N.; Abdel-wahab, M.S.; Alshahrie, A.; Alharbi, N.D.; Khan, Z.H. Carbon nanotubes of oil fly ash as lubricant additives for different base oils and their tribology performance. RSC Adv. 2017, 7, 40295–40302. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Dassenoy, F.; Vacher, B.; Martin, J.M.; Mieno, T. Ultralow friction and wear behaviour of Ni/Y-based single wall carbon nanotubes (SWNTs). Tribol. Int. 2004, 37, 1013–1018. [Google Scholar] [CrossRef]

- Sultan, J.N.; Karash, E.T.; Abdulrazzaq, T.K.; Kassim, M.T.E. The effect of multi-walled carbon nanotubes additives on the tribological properties of austempered AISI 4340 Steel. J. Eur. Des Systèmes Autom. 2022, 55, 387–396. [Google Scholar] [CrossRef]

- Ye, X.; Songfeng, E.; Fan, M. The influences of functionalized carbon nanotubes as lubricating additives: Length and diameter. Diam. Relat. Mater. 2019, 100, 107548. [Google Scholar] [CrossRef]

- Boncel, S.; Kałużny, J.; Różański, J.; Strzemiecka, B.; Runka, T.; Wojciechowski, Ł.; Kujawa, J.; Korczeniewski, E.; Terzyk, A.P.; Błaszkiewicz, P.; et al. Carbon nanotubes as fast-thickening agents in polyalphaolefin greases: Partial crystallinity and intertube joints toward multifunctionality. J. Mol. Liq. 2023, 391 Pt A, 123215. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Hu, W.; Li, J. Tribological properties and lubrication mechanism of nickel nanoparticles as an additive in lithium grease. Nanomaterials 2022, 12, 2287. [Google Scholar] [CrossRef]

- Peng, F.; Fan, S.; Song, N.; Gao, C.; Zhang, S.; Zhang, Y. Effect of nickel acetyl acetonate as lubricant additive in base oils with different molecular structure on in-situ formation and tribomechanism of carbon-based tribofilms of steel-steel sliding pair. Tribol. Lett. 2024, 72, 56. [Google Scholar] [CrossRef]

- Wang, X.L.; Yin, Y.L.; Zhang, G.N.; Wang, W.Y.; Zhao, K.K. Study on antiwear and repairing performances about mass of nano-copper lubricating additives to 45 steel. Phys. Procedia 2013, 50, 466–472. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Wang, J.; Gao, C.; Zhang, S.; Zhang, P.; Zhang, Z. Interactions of Cu nanoparticles with conventional lubricant additives on tribological performance and some physicochemical properties of an ester base oil. Tribol. Int. 2020, 141, 105941. [Google Scholar] [CrossRef]

- Shen, Y.; Lua, A.C. Synthesis of Ni and Ni–Cu supported on carbon nanotubes for hydrogen and carbon production by catalytic decomposition of methane. Appl. Catal. B Environ. 2015, 164, 61–69. [Google Scholar] [CrossRef]

- ISO-20623:2017; Petroleum and Related Products—Determination of the Extreme-Pressure and Anti-Wear Properties of Lubricants—Four-Ball Method. ISO: Geneva, Switzerland, 2017.

- Padgurskas, J.; Snitka, V.; Jankauskas, V.; Andriušis, A. Selective transfer phenomenon in lubricated sliding surfaces with copper and its alloy coatings made by electro-pulse spraying. Wear 2006, 260, 652–661. [Google Scholar] [CrossRef]

- Chen, J.; Chen, L.; Zhang, Z.; Li, J.; Wang, L.; Jiang, W. Graphene layers produced from carbon nanotubes by friction. Carbon 2012, 50, 1934–1941. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, G.; Geng, Z.; Tian, P.; Ren, K.; Wu, W.; Gong, Z. Ultra low friction of conductive carbon nanotube films and their structural evolution during sliding. Diam. Relat. Mater. 2021, 120, 108617. [Google Scholar] [CrossRef]

- Chou, R.; Hernandez Battez, A.; Cabello, J.J.; Viesca, J.L.; Osorio, A.; Sagastume, A. Tribological behavior of polyalphaolefin with the addition of nickel nanoparticles. Tribol. Int. 2010, 43, 2327–2332. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Zhang, S.; Yu, L.; Zhang, P.; Zhang, Z. Preparation of nickel-based nanolubricants via a facile in situ one-step route and investigation of their tribological properties. Tribol. Lett. 2013, 51, 73–83. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Nickel/multi-walled carbon Nanotube nanocomposite synthesized in supercritical fluid as efficient lubricant additive for mineral oil. Tribol. Lett. 2018, 66, 134. [Google Scholar] [CrossRef]

- Willermet, P.A.; Dailey, D.P.; Carter, R.O., III; Schmitz, P.J.; Zhu, W. Mechanism of formation of antiwear films from zinc dialkyldithiophosphates. Tribol. Int. 1995, 28, 177–187. [Google Scholar] [CrossRef]

- Martin, J.M. Antiwear mechanisms of zinc dithiophosphate: A chemical hardness approach. Tribol. Lett. 1999, 6, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrzypek, M.; Wojciechowski, Ł.; Kałużny, J.; Boncel, S.; Marek, A.A.; Runka, T.; Nowicki, M.; Jędrysiak, R.; Ruczka, S.; Błaszkiewicz, P. Carbon Nanotubes Decorated with Nickel or Copper as Anti-Wear and Extreme-Pressure Additives for Greases. Lubricants 2024, 12, 448. https://doi.org/10.3390/lubricants12120448

Skrzypek M, Wojciechowski Ł, Kałużny J, Boncel S, Marek AA, Runka T, Nowicki M, Jędrysiak R, Ruczka S, Błaszkiewicz P. Carbon Nanotubes Decorated with Nickel or Copper as Anti-Wear and Extreme-Pressure Additives for Greases. Lubricants. 2024; 12(12):448. https://doi.org/10.3390/lubricants12120448

Chicago/Turabian StyleSkrzypek, Magdalena, Łukasz Wojciechowski, Jarosław Kałużny, Sławomir Boncel, Adam A. Marek, Tomasz Runka, Marek Nowicki, Rafał Jędrysiak, Szymon Ruczka, and Paulina Błaszkiewicz. 2024. "Carbon Nanotubes Decorated with Nickel or Copper as Anti-Wear and Extreme-Pressure Additives for Greases" Lubricants 12, no. 12: 448. https://doi.org/10.3390/lubricants12120448

APA StyleSkrzypek, M., Wojciechowski, Ł., Kałużny, J., Boncel, S., Marek, A. A., Runka, T., Nowicki, M., Jędrysiak, R., Ruczka, S., & Błaszkiewicz, P. (2024). Carbon Nanotubes Decorated with Nickel or Copper as Anti-Wear and Extreme-Pressure Additives for Greases. Lubricants, 12(12), 448. https://doi.org/10.3390/lubricants12120448