Response Modeling and Optimization of Process Parameters in Turning Medium Carbon Steel Under Minimum Quantity Lubrication (MQL) with Vegetable Oil and Oil Blends

Abstract

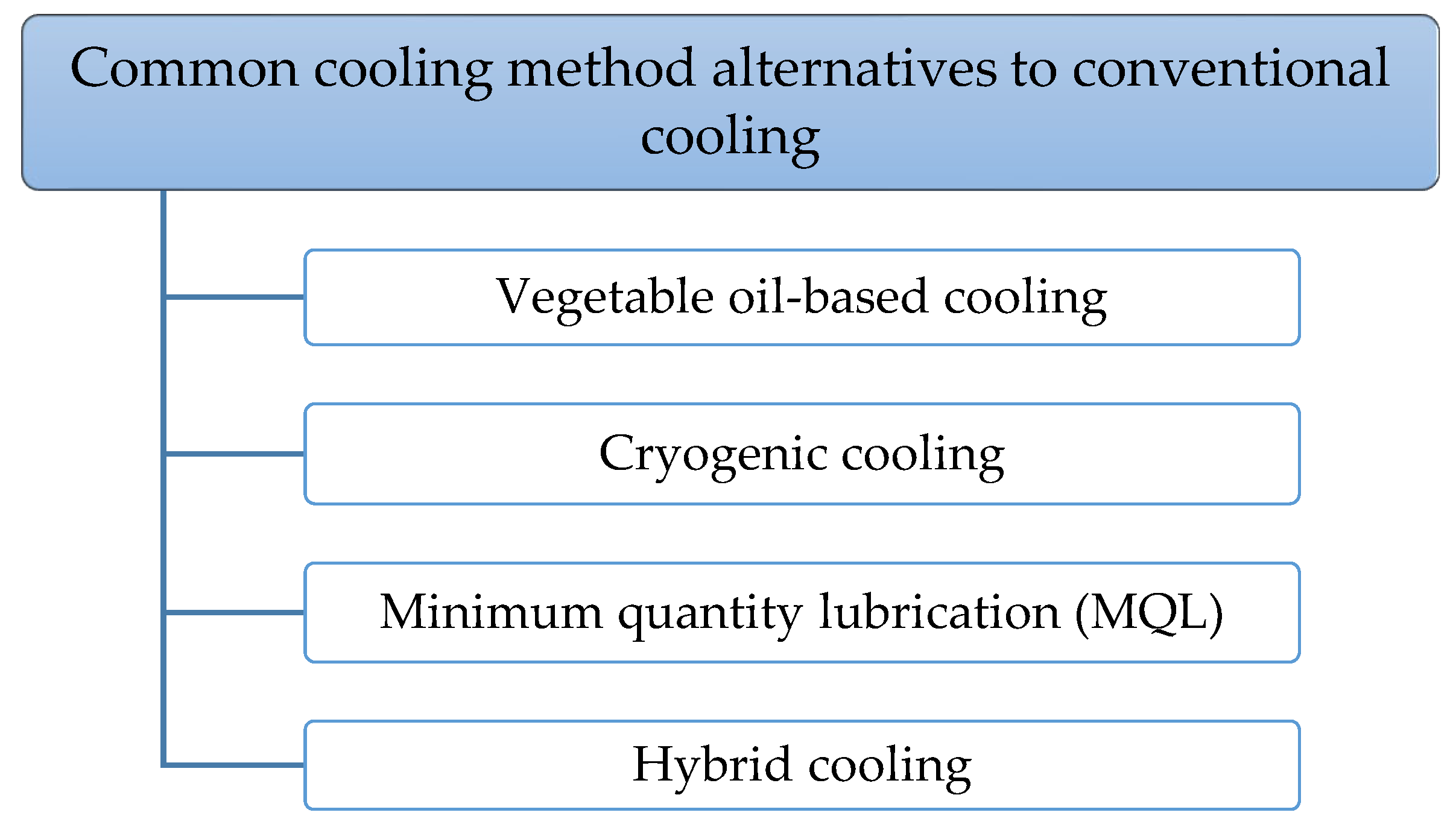

1. Introduction

2. Materials and Methods

2.1. Workpiece and Cutting Tool Material

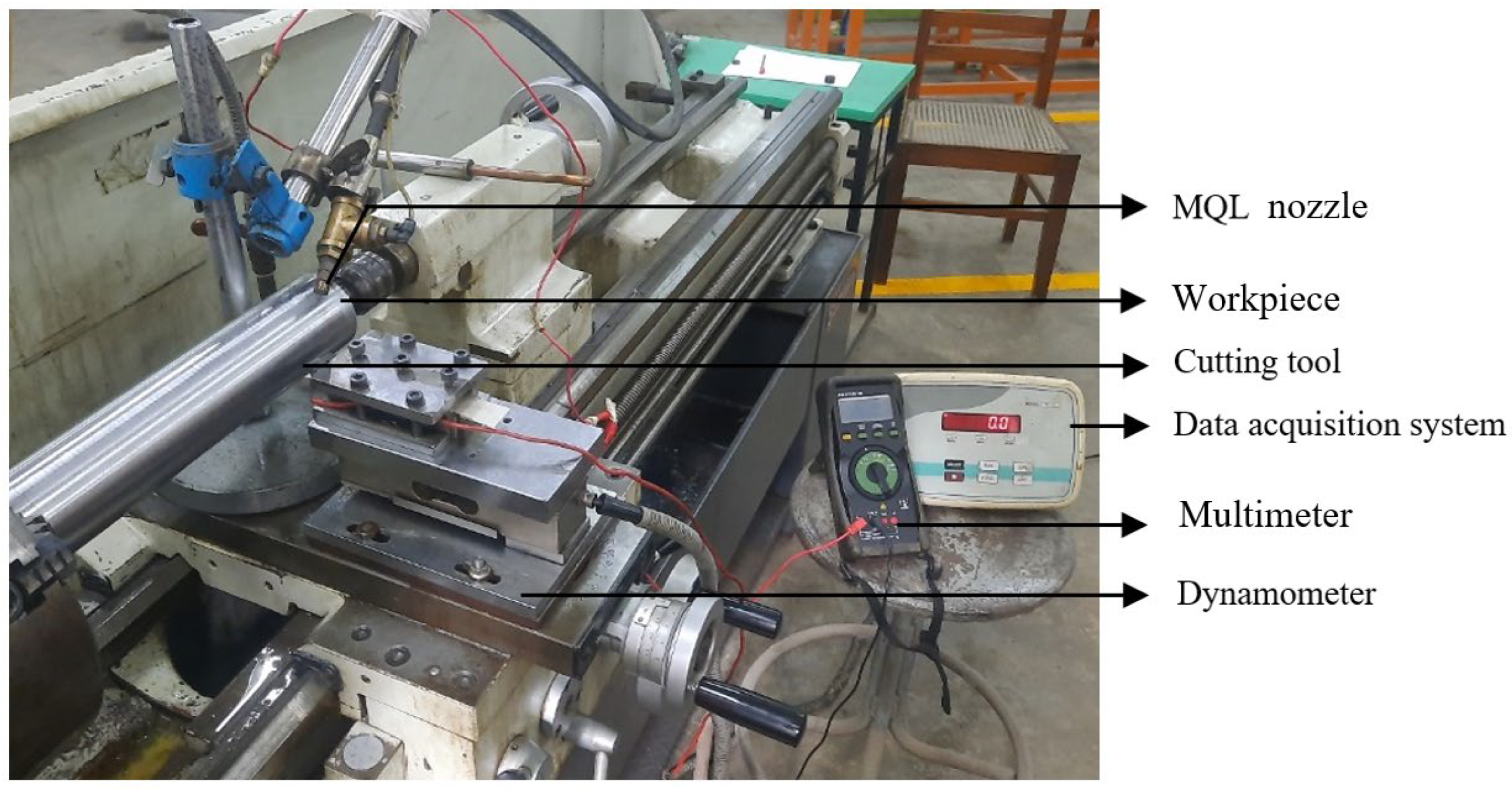

2.2. Machine Tool and Experimental Conditions

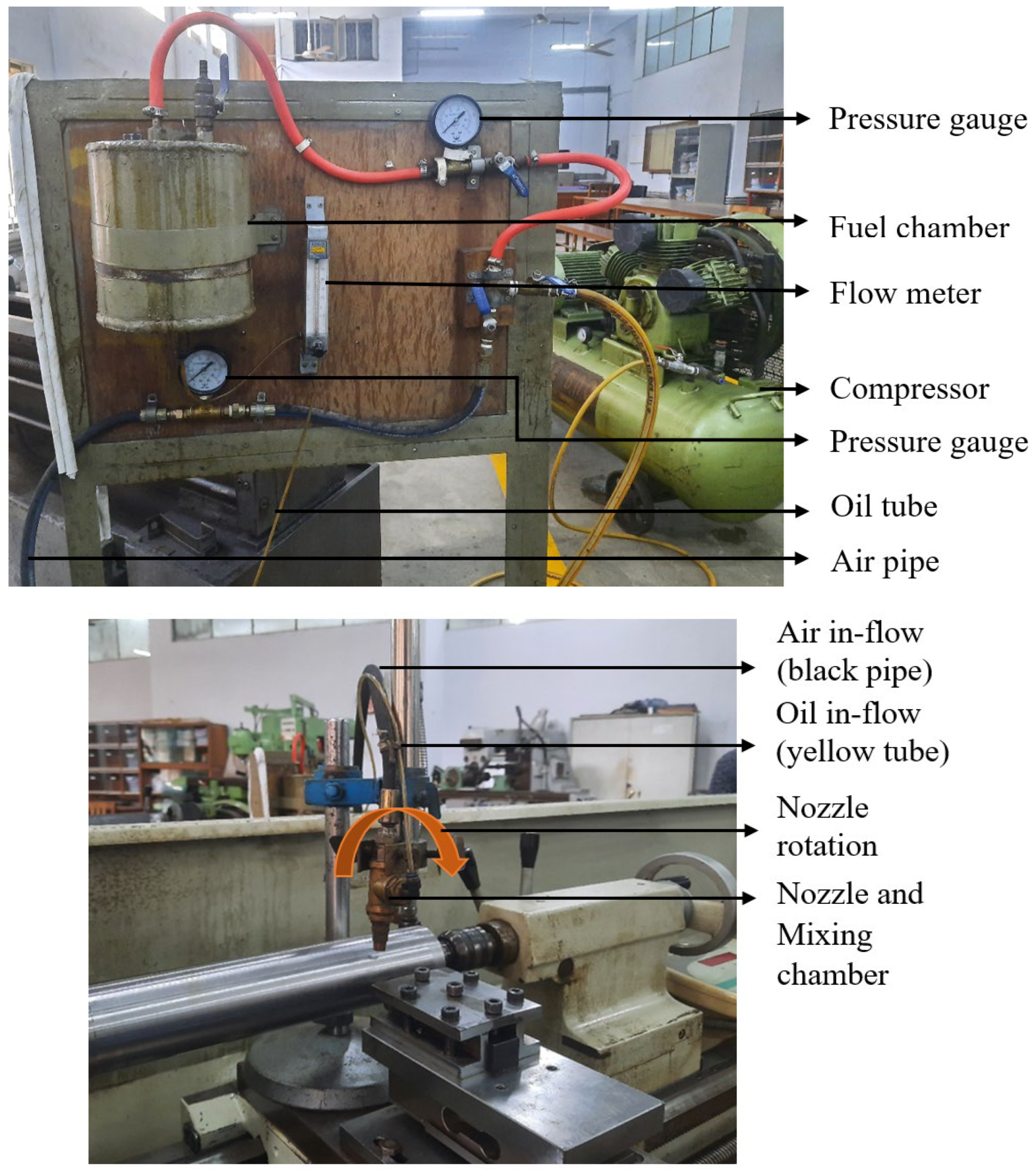

2.3. MQL Setup and Oil Preparation

2.4. Preparation of Cutting Oil Blends

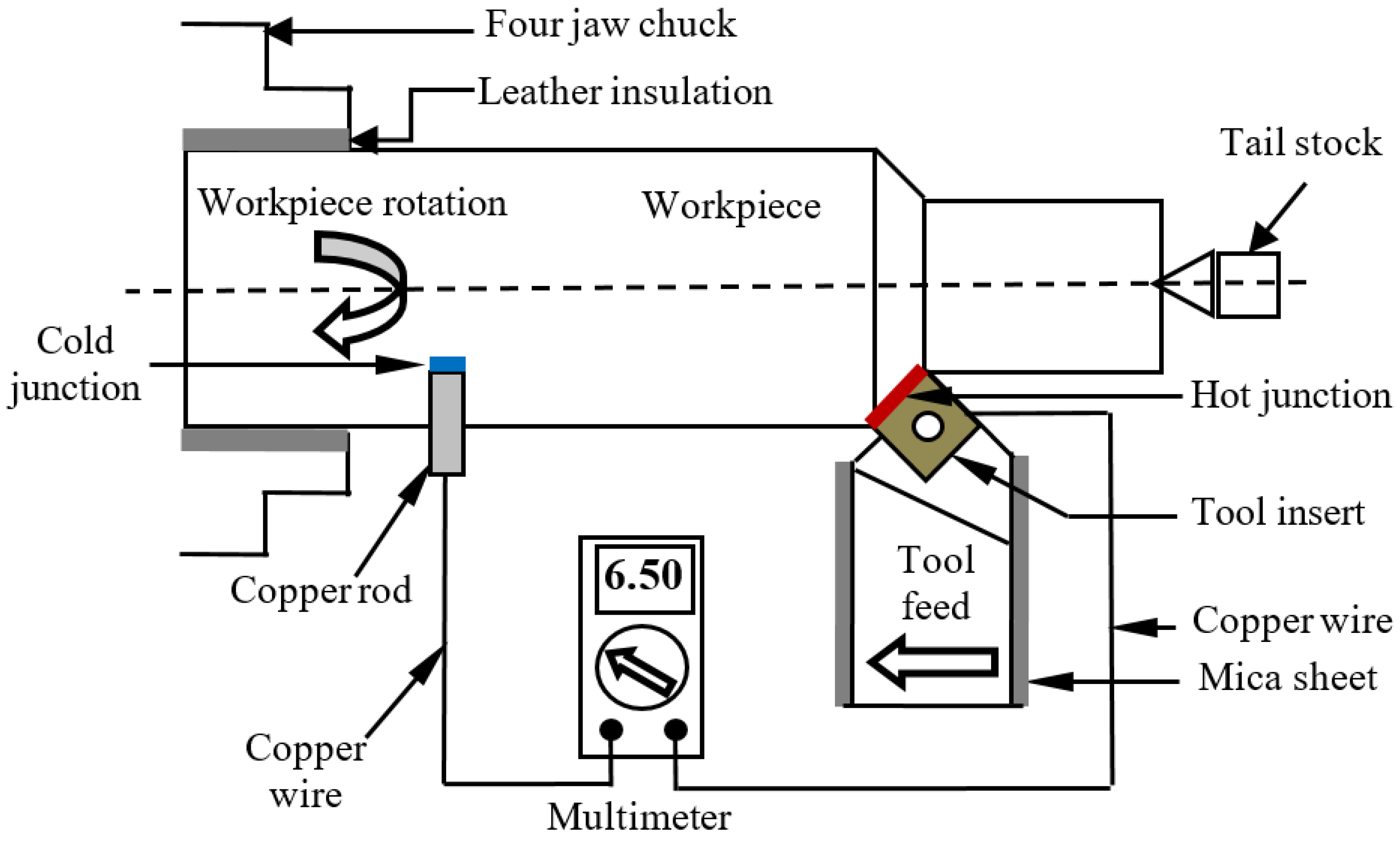

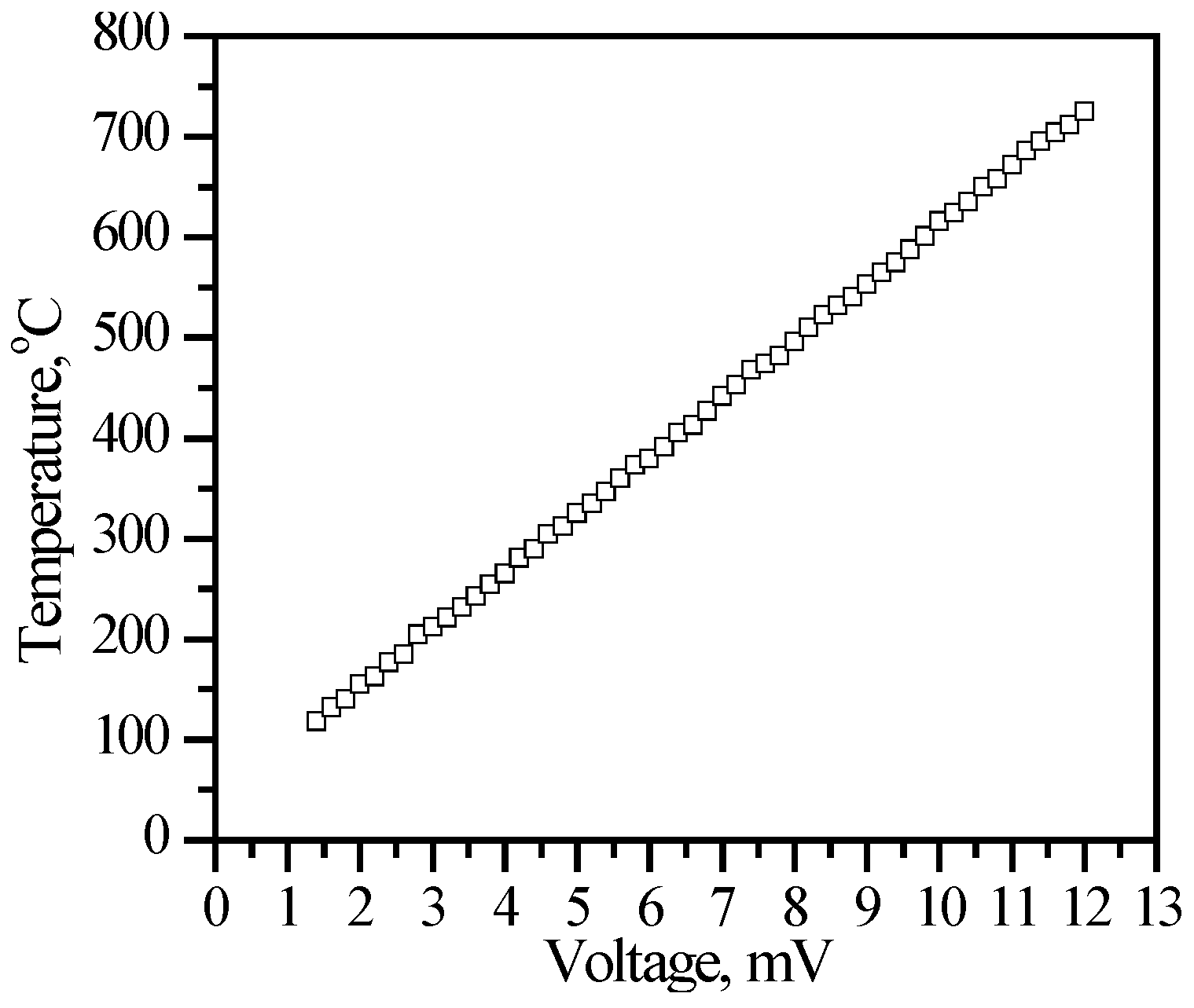

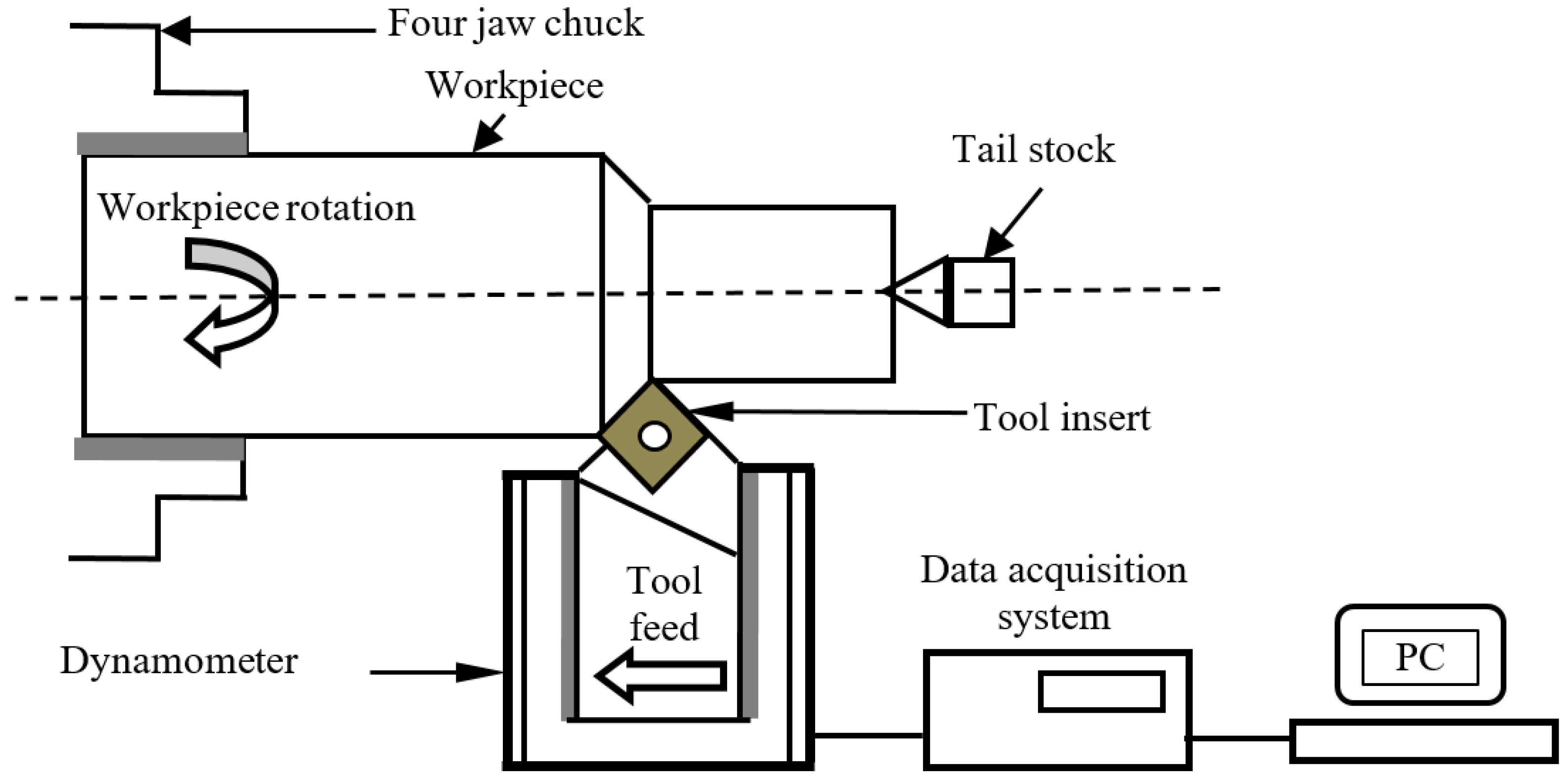

2.5. Measurement of Responses

2.6. RSM-Based Approach for Process Optimization

3. Results and Discussions

3.1. Design of Experiment (DOE) and Data Collection

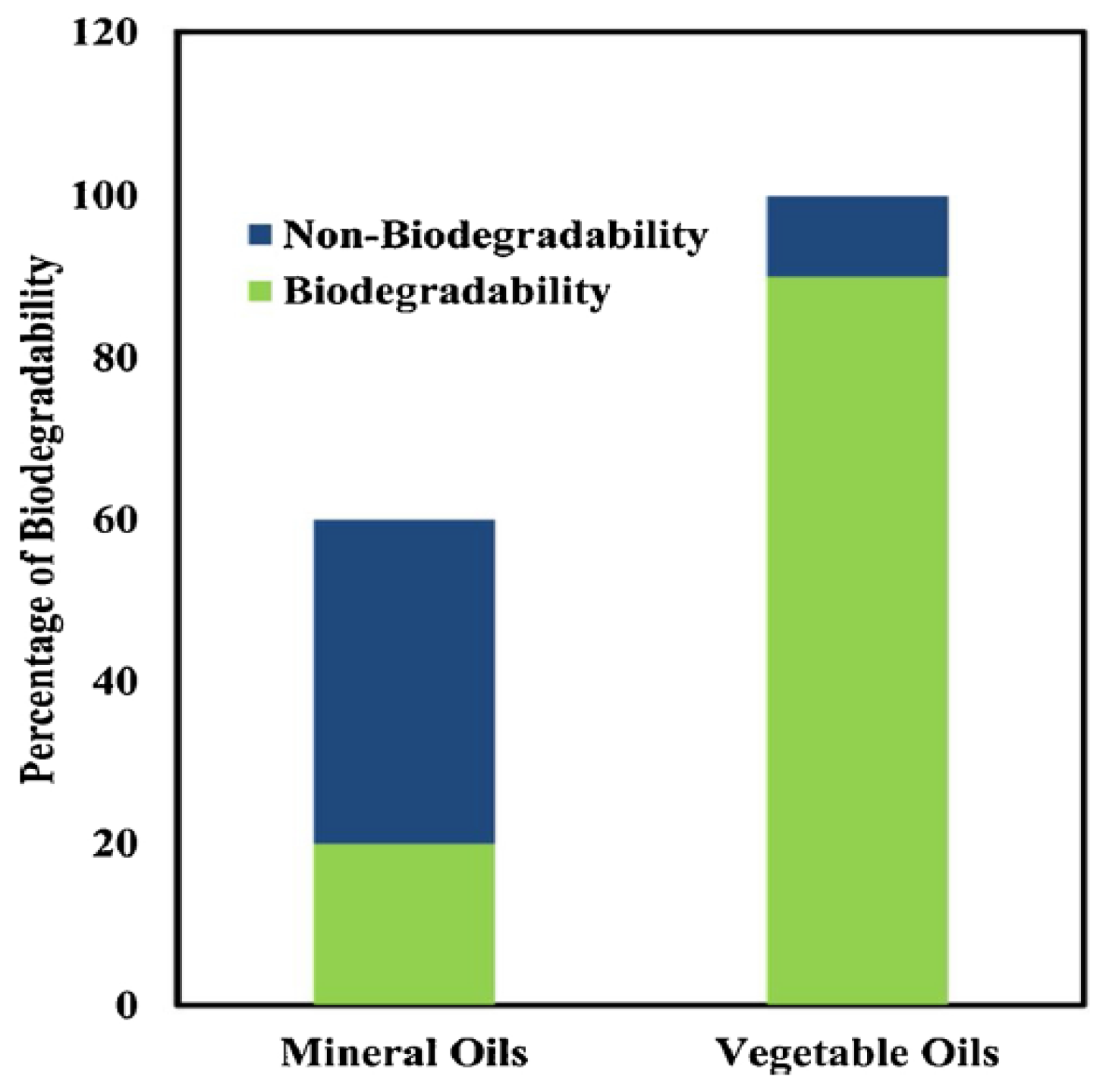

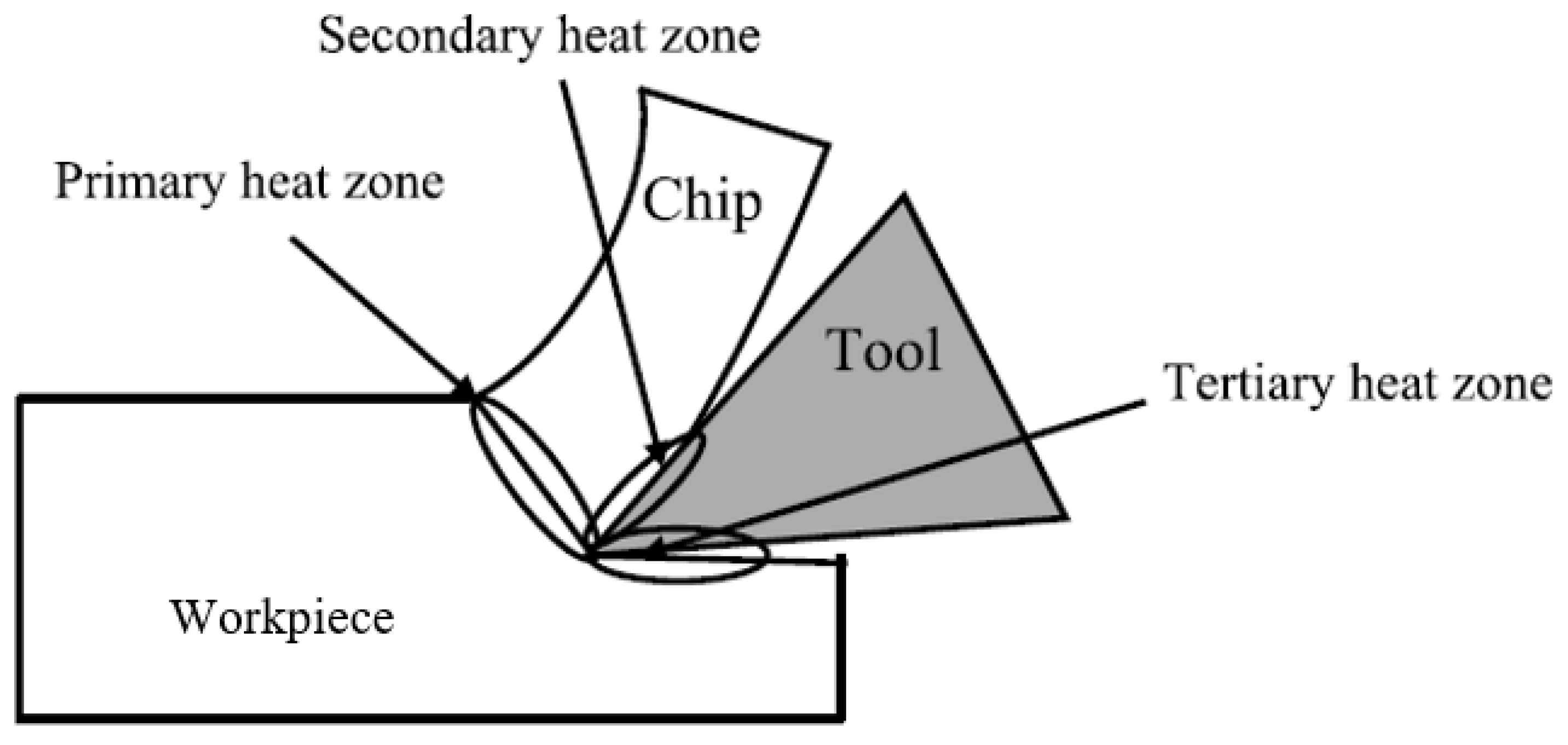

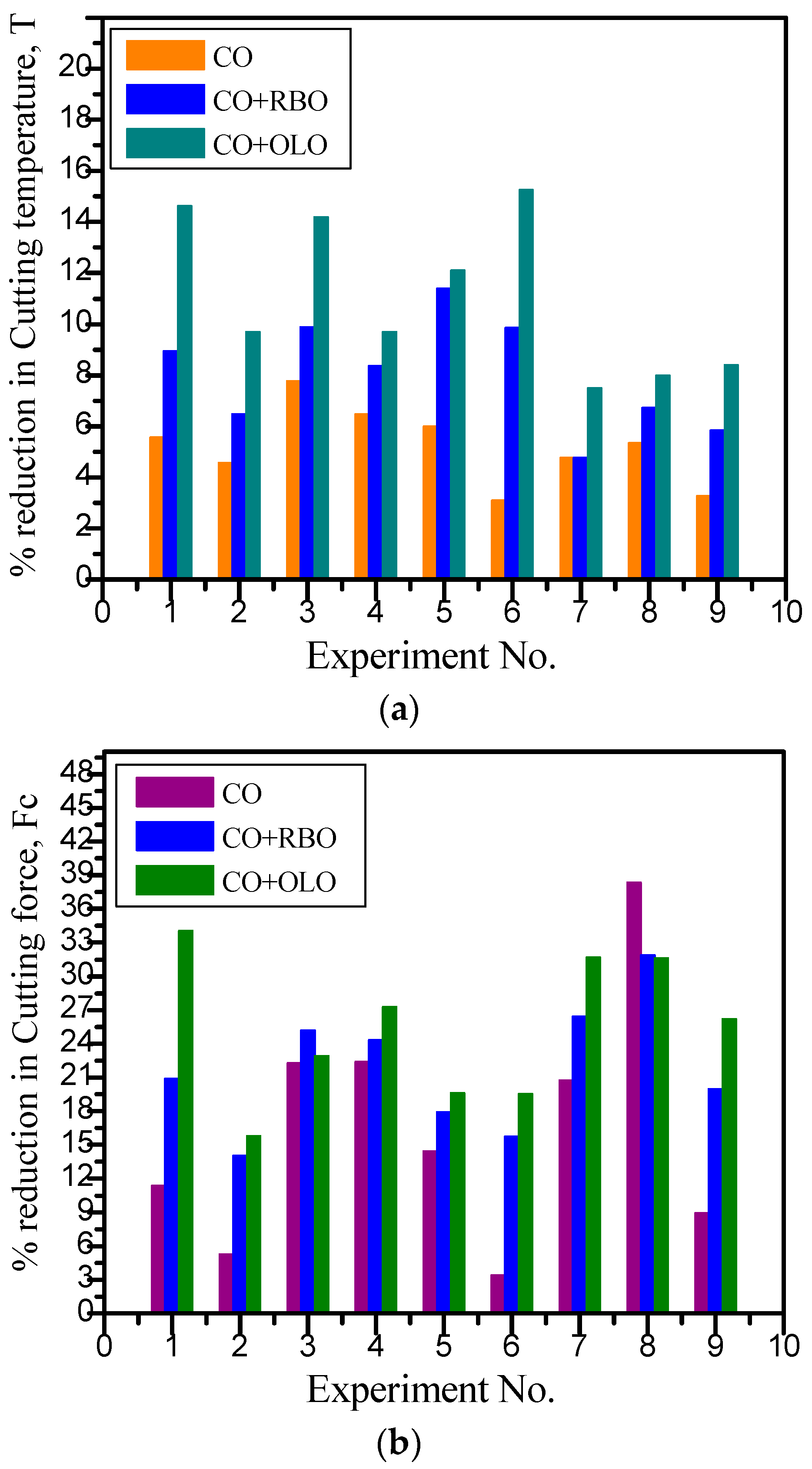

3.2. Effect of Vegetable-Based Oil Compared to Mineral Oil

3.3. Response Surface Modeling (RSM)

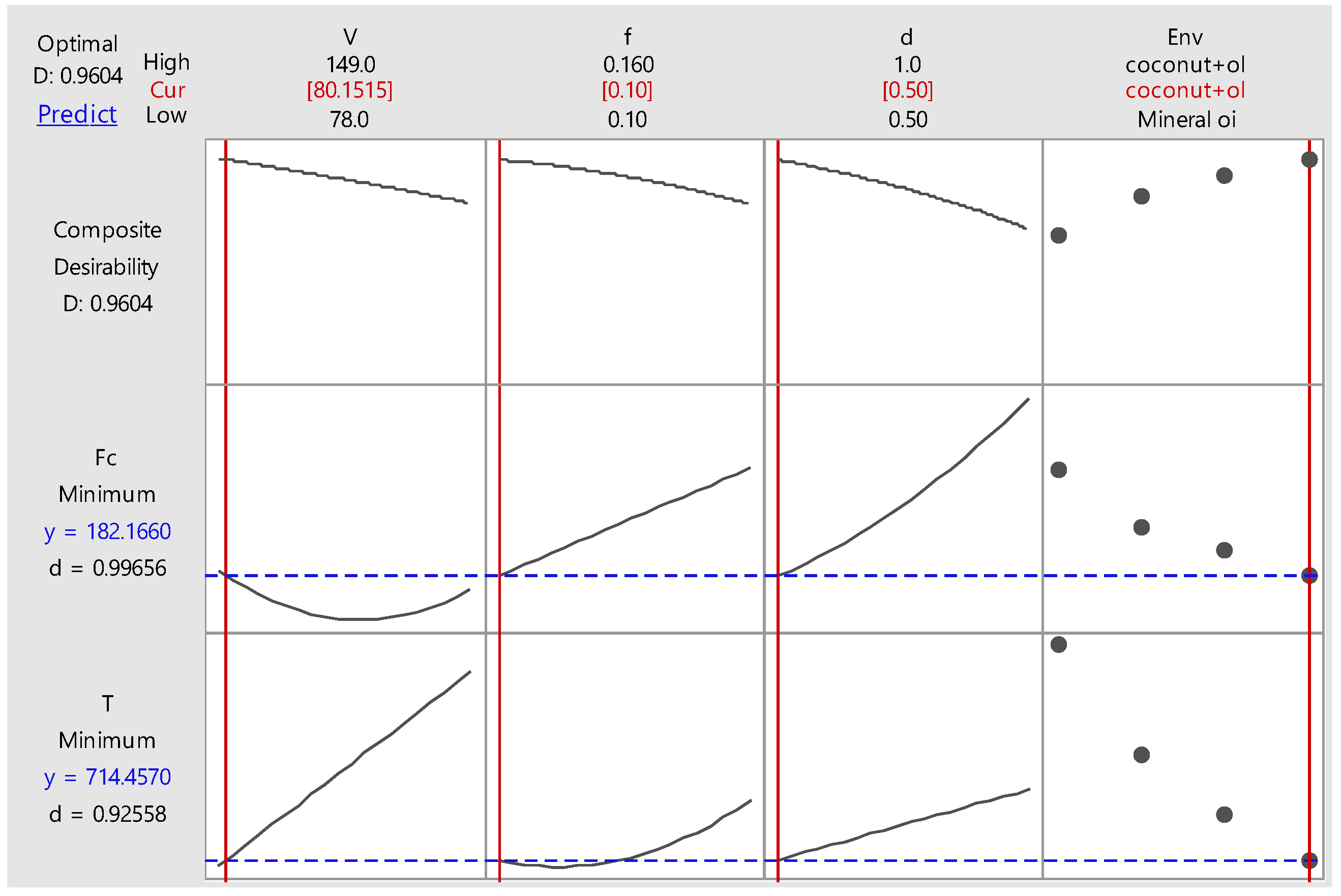

3.4. Optimum Process Parameters Selection by Response Optimizer

4. Conclusions

- Performance of three vegetable oil-based cutting fluids were compared with mineral oil under MQL conditions. Due to the long fatty acid structure and higher viscosity index of vegetable oils, they performed better compared with mineral oils concerning cutting temperature and cutting force.

- Among the three oils, both oil blends performed better than pure coconut oil because, blending can improve the properties of oil as cutting fluids. In addition, between the two oil blends, the coconut + olive oil blend outperformed the other blend (coconut + rice bran oil).

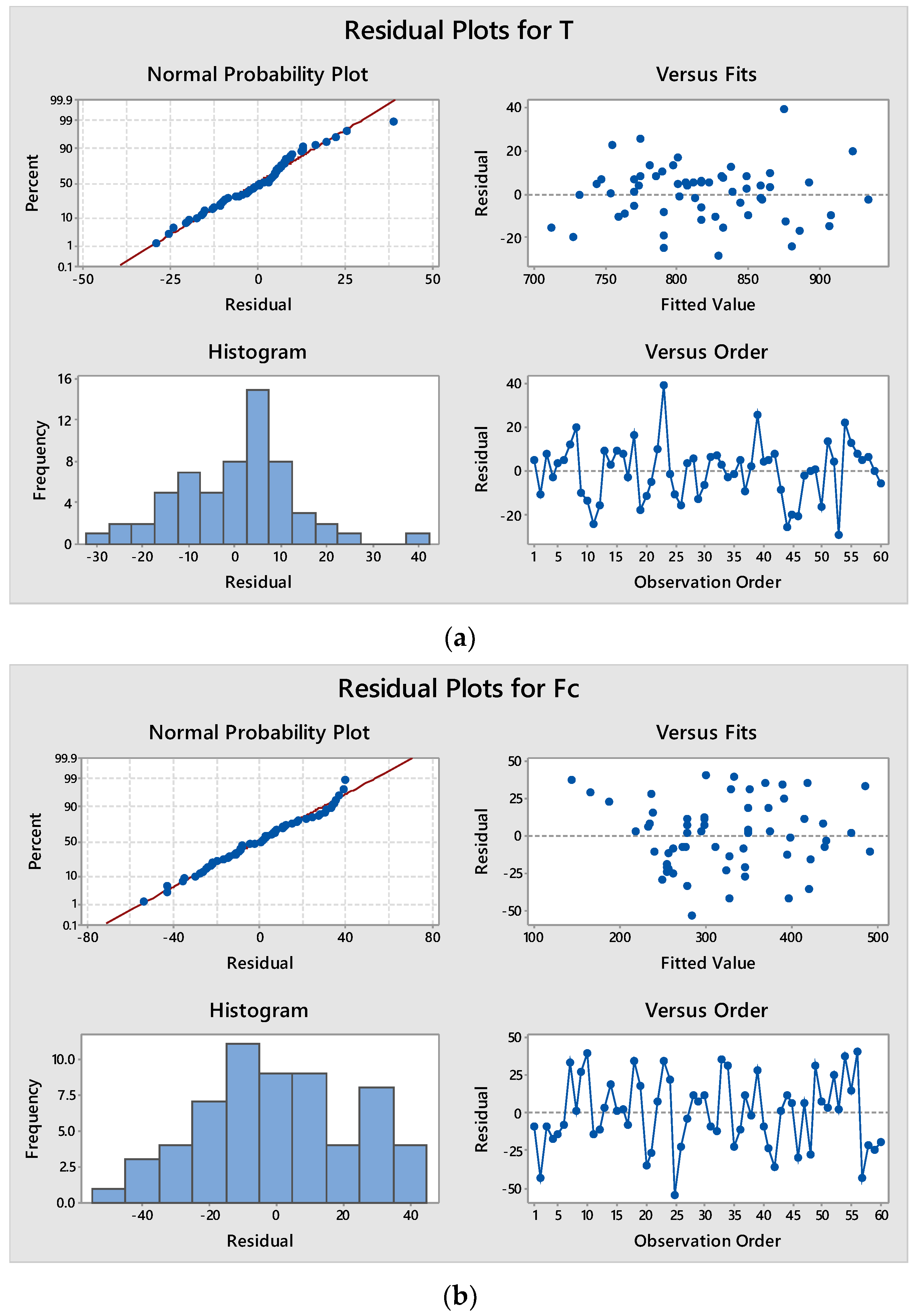

- Based on the experimental data, predictive models for cutting temperature and cutting force were developed. Both of the models preserved over 92% accuracy (R2 value). This accuracy value indicated that the regression models explained more than 92% of the variability in the response data.

- For both of the models, very little differences between the adjusted R2 and predicted R2 values confirmed the adequacy of the model. These models can accurately predict the responses within the range of process parameters used in the experimentation.

- By using residual plots, the normality and randomness of the residuals for both regression models were also well established. Additionally, the residuals also showed constant variance and were correlated to each other. These confirmed the reliability of the regression models and data.

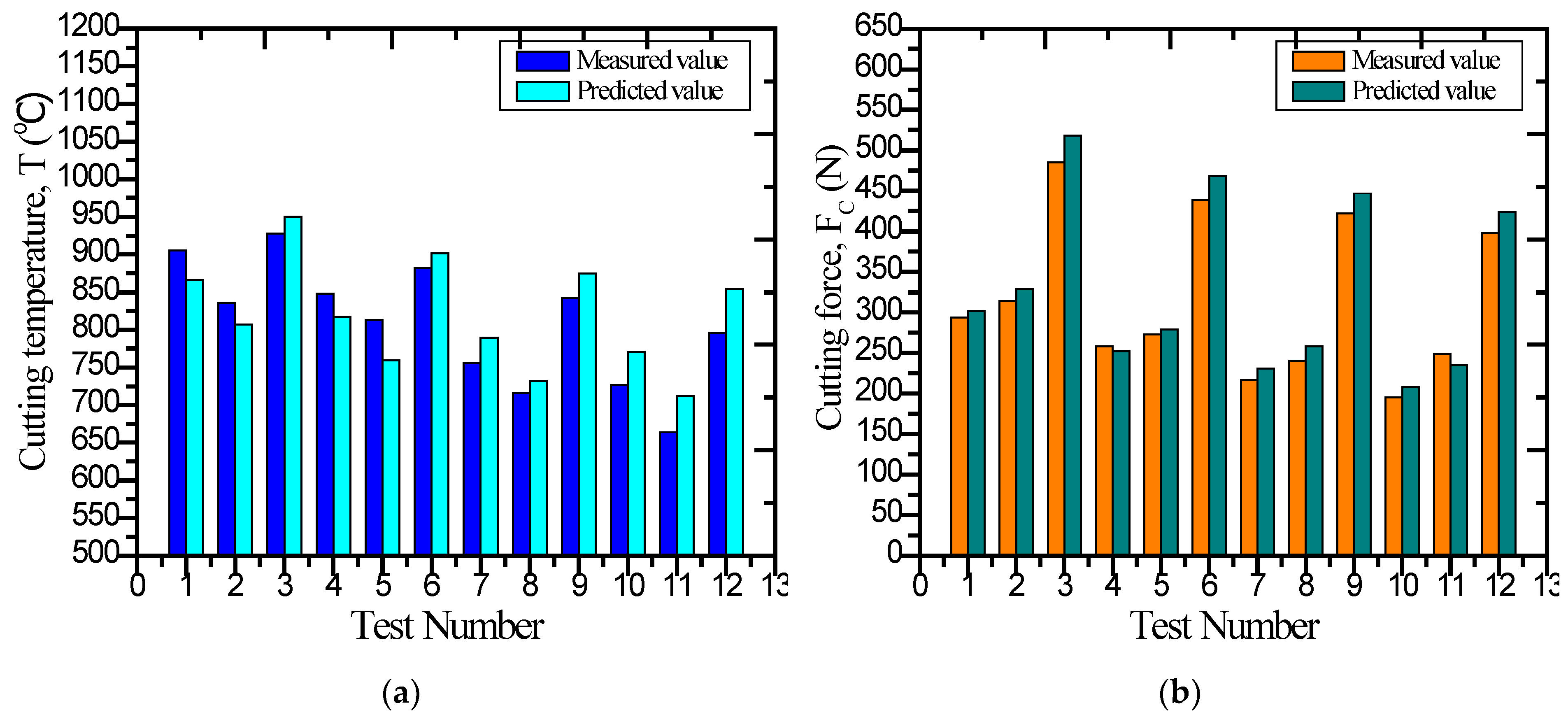

- The regression models were verified with new observation data where the MAPE values were less than 10% for both responses.

- By using a composite desirability-based response optimizer, input parameters for this experiment were optimized for minimum cutting temperature and force simultaneously. Optimum process parameters were found as cutting speed at 80.15 m/min, feed rate at 0.1 mm/rev, and depth of cut at 0.5 mm under the coconut + olive oil blend-based MQL. A high composite desirability value (0.96) of the optimum process parameter settings indicated that this could achieve satisfactory results for all the responses.

- The optimum result was validated and found reasonable improvement of the responses in these settings compared with the initial settings. This optimal setting was proved to be more effective for minimizing the cutting force compared with the cutting temperature. This result was aligned with the individual desirability values of the responses (Force-0.99 and T-0.92).

5. Future Recommendations

- Different vegetable oils can be studied for new blending. Also, the mixing ratio can be varied in further investigation to reveal the effect.

- Due to limited resources, this work only addresses two response parameters (temperature and force), but additional response parameters, such as tool wear, surface roughness, material removal rate (MRR), etc., can be experimentally analyzed.

- The addition of nanoparticles in vegetable oil blends can be considered for advanced analysis.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhatt, Y.; Ghuman, K.; Dhir, A. Sustainable manufacturing. Bibliometrics and content analysis. J. Clean. Prod. 2020, 260, 120988. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Sustainable Manufacturing Performance Evaluation: Integrating Product and Process Metrics for Systems Level Assessment. Procedia Manuf. 2017, 8, 563–570. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. A systematic literature review to map literature focus of sustainable manufacturing. J. Clean. Prod. 2020, 256, 120345. [Google Scholar] [CrossRef]

- Singh, G.; Singh, S.; Singh, M.; Kumar, A. Experimental investigations of vegetable & mineral oil performance during machining of EN-31 steel with minimum quantity lubrication. Int. J. Res. Eng. Technol. 2013, 2, 1030–1037. [Google Scholar] [CrossRef]

- Girsang, I.P.; Dhupia, J.S. Machine Tools for Machining. In Handbook of Manufacturing Engineering and Technology; Springer: London, UK, 2014; pp. 1–48. [Google Scholar]

- Jaspers, S.P.F.C.; Dautzenberg, J.H. Material behaviour in metal cutting: Strains, strain rates and temperatures in chip formation. J. Mater. Process Technol. 2002, 121, 123–135. [Google Scholar] [CrossRef]

- Li, A.; Zhao, J.; Luo, H.; Pei, Z.; Wang, Z. Progressive tool failure in high-speed dry milling of Ti-6Al-4V alloy with coated carbide tools. Int. J. Adv. Manuf. Technol. 2012, 58, 465–478. [Google Scholar] [CrossRef]

- Ranjan Das, S.; Panda, A.; Dhupal, D. Hard turning of AISI 4340 steel using coated carbide insert: Surface roughness, tool wear, chip morphology and cost estimation. Mater. Today Proc. 2018, 5, 6560–6569. [Google Scholar] [CrossRef]

- Revuru, R.S.; Zhang, J.Z.; Posinasetti, N.R.; Kidd, T. Optimization of titanium alloys turning operation in varied cutting fluid conditions with multiple machining performance characteristics. Int. J. Adv. Manuf. Technol. 2018, 95, 1451–1463. [Google Scholar] [CrossRef]

- Vipindas, K.; Mathew, J. Wear behavior of TiAlN coated WC tool during micro end milling of Ti-6Al-4V and analysis of surface roughness. Wear 2019, 424–425, 165–182. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining—Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Sultana, N.; Dhar, N.R. A critical review on the progress of MQL in machining hardened steels. Adv. Mater. Process. Technol. 2022, 8, 3834–3858. [Google Scholar] [CrossRef]

- Lee, C.M.; Choi, Y.H.; Ha, J.H.; Woo, W.S. Eco-friendly technology for recycling of cutting fluids and metal chips: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 457–468. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Li, R.; Hou, Y.; Cao, H.; Wang, J. Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions. Ceram. Int. 2019, 45, 14908–14920. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Biological Stability of Water-Based Cutting Fluids: Progress and Application. Chin. J. Mech. Eng. En. Ed. 2022, 35, 3. [Google Scholar] [CrossRef]

- Anton, S.; Andreas, S.; Friedrich, B. Heat dissipation in turning operations by means of internal cooling. Procedia Eng. 2015, 100, 1116–1123. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B.; Demirbas, E. Environmentally Friendly Machining: Vegetable Based Cutting Fluids. In Green Manufacturing Processes and Systems; Springer: Berlin/Heidelberg, Germany, 2013; pp. 23–47. [Google Scholar]

- Heisel, U.; Lutz, D.; Wassmer, S. The minimum quantity lubricant technique and its application in cutting process. Mach. Met. Mag. 1998, 386, 22–38. [Google Scholar]

- Dhar, N.R.; Paul, S.; Chattopadhyay, A.B. Role of cryogenic cooling on cutting temperature turning steel. J. Manuf. Sci. Eng. Trans. ASME 2002, 124, 146–154. [Google Scholar] [CrossRef]

- Salur, E.; Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y. The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel. Metals 2021, 11, 1674. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A.; Darras, B. Sustainable cooling and lubrication strategies in machining processes: A comparative study. Procedia Manuf. 2019, 33, 786–793. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Adediran, A.A.; Aliyu, S.J.; Akinlabi, S.A.; Jen, T.C.; Akinlabi, E.T. Advances in the Application of Vegetable-Oil-Based Cutting Fluids to Sustainable Machining Operations—A Review. Lubricants 2022, 10, 69. [Google Scholar] [CrossRef]

- Greaves, I.A.; Eisen, E.A.; Smith, T.J.; Pothier, L.J.; Kriebel, D.; Woskie, S.R.; Kennedy, S.M.; Shalat, S.; Monson, R.R. Respiratory health of automobile workers exposed to metal-working fluid aerosols: Respiratory symptoms. Am. J. Ind. Med. 1997, 32, 450–459. [Google Scholar] [CrossRef]

- Krahenbuhl, B.U. Vegetable oil-based coolants improve cutting performance. J. Cut. Fluids 2002, 68, 34–35. [Google Scholar]

- Sancho-Madriz, M.F. Encyclopedia of Food Sciences and Nutrition; Elsevier: Amsterdam, The Netherlands, 2003; ISBN 9780122270550. [Google Scholar]

- Singh, A.K.; Gupta, A.K. Metal working fluids from vegetable fluids. J. Synth. Lubr. 2006, 123, 167–176. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants—A review of oxidation. Tribol. Int. 2017, 40, 1035–1046. [Google Scholar] [CrossRef]

- Mahadi, M.A.; Choudhury, I.A.; Azuddin, M.; Yusoff, N.; Yazid, A.A.; Norhafizan, A. Vegetable Oil-Based Lubrication in Machining: Issues and Challenges. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2019; Volume 530. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Hashempour-Baltork, F.; Torbati, M.; Azadmard-Damirchi, S.; Savage, G.P. Vegetable oil blending: A review of physicochemical, nutritional and health effects. Trends Food Sci. Technol. 2016, 57, 52–58. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Rajesh, J.H.N.; Senthil Kumar, J.; Krolczyk, G.M. A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Gupta, M.K.; Song, Q. Tool wear and hole quality evaluation in cryogenic Drilling of Inconel 718 superalloy. Tribol. Int. 2020, 143, 106084. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Palanisamy, S.; Dargusch, M.S. Effect of cryogenic compressed air on the evolution of cutting force and tool wear during machining of Ti-6Al-4V alloy. J. Mater. Process. Technol. 2015, 221, 243–254. [Google Scholar] [CrossRef]

- Karkade, H.B.; Patil, N.G. Comparative investigations into high speed machining of A-B titanium alloy (Ti-6al-4v) under dry and compressed Co2 gas cooling environment. AIP Conf. Proc. 2018, 2018, 020009. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; Khan, A.M.; Dhar, N.R. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Revuru, R.S.; Posinasetti, N.R.; Vsn, V.R.; Amrita, M. Application of cutting fluids in machining of titanium alloys—A review. Int. J. Adv. Manuf. Technol. 2017, 91, 2477–2498. [Google Scholar] [CrossRef]

- Liew, P.J.; Shaaroni, A.; Sidik, N.A.C.; Yan, J. An overview of current status of cutting fluids and cooling techniques of turning hard steel. Int. J. Heat Mass Transf. 2017, 114, 380–394. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Elmunafi, M.H.S.; Kurniawan, D.; Noordin, M.Y. Use of Castor Oil as Cutting Fluid in Machining of Hardened Stainless Steel with Minimum Quantity of Lubricant. Procedia CIRP 2015, 26, 408–411. [Google Scholar] [CrossRef]

- Anuja Beatrice, B.; Kirubakaran, E.; Ranjit Jeba Thangaiah, P.; Leo Dev Wins, K. Surface roughness prediction using artificial neural network in hard turning of AISI H13 steel with minimal cutting fluid application. Procedia Eng. 2014, 97, 205–211. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Dhar, N.R.; Kamruzzaman, M.; Ahmed, M. Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. J. Mater. Process. Technol. 2006, 172, 299–304. [Google Scholar] [CrossRef]

- Tasdelen, B.; Wikblom, T.; Ekered, S. Studies on minimum quantity lubrication (MQL) and air cooling at drilling. J. Mater. Process. Technol. 2008, 200, 339–346. [Google Scholar] [CrossRef]

- Silva, L.R.; Corrêa, E.C.S.; Brandão, J.R.; de Ávila, R.F. Environmentally friendly manufacturing: Behavior analysis of minimum quantity of lubricant-MQL in grinding process. J. Clean. Prod. 2020, 256, 103287. [Google Scholar] [CrossRef]

- Mulyadi, I.H.; Balogun, V.A.; Mativenga, P.T. Environmental performance evaluation of different cutting environments when milling H13 tool steel. J. Clean. Prod. 2015, 108, 110–120. [Google Scholar] [CrossRef]

- Iruj, M.; Yaqoob, S.; Ghani, J.A.; Jaber, H.; Saibani, N.; Alkhedher, M. State-of-the-art hybrid lubrication (Cryo-MQL) supply systems, performance evaluation, and optimization studies in various machining processes. Results Eng. 2024, 22, 102090. [Google Scholar] [CrossRef]

- Tuan, N.M.; Duc, T.M.; Long, T.T.; Hoang, V.L.; Ngoc, T.B. Investigation of Machining Performance of MQL and MQCL Hard Turning Using Nano Cutting Fluids. Fluids 2022, 7, 143. [Google Scholar] [CrossRef]

- Ajay Vardhaman, B.S.; Amarnath, M.; Jhodkar, D.; Ramkumar, J.; Chelladurai, H.; Roy, M.K. Influence of coconut oil on tribological behavior of carbide cutting tool insert during turning operation. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 450. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Dhar, N.R. Performance evaluation of minimum quantity lubrication by vegetable oil in terms of cutting force, cutting zone temperature, tool wear, job dimension and surface finish in turning AISI-1060 steel. J. Zhejiang Univ. Sci. 2006, 7, 1790–1799. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Mithu, M.A.H.; Dhar, N.R. Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Process. Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Susmitha, M.; Sharan, P.; Jyothi, P.N. Influence of non-edible vegetable based oil as cutting fluid on chip, surface roughness and cutting force during drilling operation of Mild Steel. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2016; Volume 149. [Google Scholar]

- Zaman, P.B.; Tusar, M.I.H.; Dhar, N.R. Selection of appropriate process inputs for turning Ti-6Al-4V alloy under hybrid Al2O3-MWCNT nano-fluid based MQL. Adv. Mater. Process. Technol. 2022, 8, 380–400. [Google Scholar] [CrossRef]

- Panda, D.; Kumari, K.; Dalai, N. Performance of Minimum Quantity Lubrication (MQL) and its effect on Dry Machining with the addition of Nano-particle with the biodegradable base fluids: A review. Mater. Today Proc. 2022, 56, 1298–1301. [Google Scholar] [CrossRef]

- Xiong, Y.; Wu, J.; Deng, C.; Wang, Y. Machining process parameters optimization for heavy-duty CNC machine tools in sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2016, 87, 1237–1246. [Google Scholar] [CrossRef]

- Sristi, N.A.; Zaman, P.B.; Dhar, N.R. Multi-response optimization of hard turning parameters: A comparison between different hybrid Taguchi-based MCDM methods. Int. J. Interact. Des. Manuf. 2022, 16, 1779–1795. [Google Scholar] [CrossRef]

- Zaman, P.B.; Dhar, N.R. Multi-objective Optimization of Double-Jet MQL System Parameters Meant for Enhancing the Turning Performance of Ti–6Al–4V Alloy. Arab. J. Sci. Eng. 2020, 45, 9505–9526. [Google Scholar] [CrossRef]

- Muthuram, N.; Frank, F.C. Optimization of machining parameters using artificial Intelligence techniques. Mater. Today Proc. 2021, 46, 8097–8102. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S. Effect of Process Parameters on Tool Wear and Surface Roughness during Turning of Hardened Steel with Coated Ceramic Tool. Procedia Mater. Sci. 2014, 5, 1450–1459. [Google Scholar] [CrossRef]

- Mia, M.; Khan, M.A.; Dhar, N.R. Study of surface roughness and cutting forces using ANN, RSM, and ANOVA in turning of Ti-6Al-4V under cryogenic jets applied at flank and rake faces of coated WC tool. Int. J. Adv. Manuf. Technol. 2017, 93, 975–991. [Google Scholar] [CrossRef]

- Bartarya, G.; Choudhury, S.K. Effect of cutting parameters on cutting force and surface roughness during finish hard turning aisi52100 grade steel. Procedia CIRP 2012, 1, 651–656. [Google Scholar] [CrossRef]

- Zahia, H.; Athmane, Y.M.; Lakhdar, B.; Tarek, M. On the application of response surface methodology for predicting and optimizing surface roughness and cutting forces in hard turning by PVD coated insert. Int. J. Ind. Eng. Comput. 2015, 6, 267–284. [Google Scholar] [CrossRef]

- Zaman, P.; Dhar, N. Multi-criteria Process Optimization for better machinability in Turning Medium Carbon Steel using Composite Desirability Approach. Int. J. Manuf. Res. 2021, 16, 280–308. [Google Scholar] [CrossRef]

- Bousnina, K.; Hamza, A.; Ben Yahia, N. A combination of PSO-ANN hybrid algorithm and genetic algorithm to optimize technological parameters during milling 2017A alloy. J. Ind. Prod. Eng. 2023, 40, 554–571. [Google Scholar] [CrossRef]

- Javid, H.; Jahanzaib, M.; Jawad, M.; Ali, M.A.; Farooq, M.U.; Pruncu, C.I.; Hussain, S. Parametric analysis of turning HSLA steel under minimum quantity lubrication (MQL) and nanofluids-based minimum quantity lubrication (NF-MQL): A concept of one-step sustainable machining. Int. J. Adv. Manuf. Technol. 2021, 117, 1915–1934. [Google Scholar] [CrossRef]

- Amini, M.; Djazayery, A.; Majdzadeh, R.; Taghdisi, M.H.; Jazayeri, S. Effect of school-based interventions to control childhood obesity: A review of reviews. Int. J. Prev. Med. 2015, 6, 68. [Google Scholar] [CrossRef] [PubMed]

- Dureja, J.S.; Singh, R.; Singh, T.; Singh, P.; Dogra, M.; Bhatti, M.S. Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 123–129. [Google Scholar] [CrossRef]

- Amiril, S.A.S.; Rahim, E.A.; Hishamudin, A.Z. Effect of nozzle distance and cutting parameters on MQL machining of AISI 1045. J. Phys. Conf. Ser. 2019, 1150, 012045. [Google Scholar] [CrossRef]

- Zaman, P.B.; Dhar, N.R. Design and evaluation of an embedded double jet nozzle for MQL delivery intending machinability improvement in turning operation. J. Manuf. Process. 2019, 44, 179–196. [Google Scholar] [CrossRef]

- Goethals, P.L.; Cho, B.R. Experimental analysis of estimator functions in response surface designs. In IIE Annual Conference Proceedings; Institute of Industrial Engineers: Norcross, GA, USA, 2010. [Google Scholar]

- Boyaci, I.H. A new approach for determination of enzyme kinetic constants using response surface methodology. Biochem. Eng. J. 2005, 25, 55–62. [Google Scholar] [CrossRef]

- Manohar, T.S.M.; Joseph, J. Application of Box Behnken design to optimize the parameters for turning Inconel 718 using coated carbide tools. Int. J. Sci. Eng. Res. 2013, 4, 620–642. [Google Scholar]

- Beg, S.; Akhter, S. Box–Behnken Designs and Their Applications in Pharmaceutical Product Development. In Design of Experiments for Pharmaceutical Product Development Volume I: Basics and Fundamental Principles; Springer: Singapore, 2021; Volume 1, pp. 77–85. [Google Scholar]

- Singh, J.; Gill, S.S.; Dogra, M.; Singh, R. A review on cutting fluids used in machining processes. Eng. Res. Express 2021, 3, 012002. [Google Scholar] [CrossRef]

- Majumder, H.; Paul, T.R.; Dey, V.; Dutta, P.; Saha, A. Use of PCA-grey analysis and RSM to model cutting time and surface finish of Inconel 800 during wire electro discharge cutting. Meas. J. Int. Meas. Confed. 2017, 107, 19–30. [Google Scholar] [CrossRef]

- Koç, B.; Kaymak-Ertekin, F. Response Surface Methodology and Food Processing Applications. Gida 2010, 35, 63–70. [Google Scholar]

- de Myttenaere, A.; Golden, B.; Le Grand, B.; Rossi, F. Mean Absolute Percentage Error for regression models. Neurocomputing 2016, 192, 38–48. [Google Scholar] [CrossRef]

- Zaman, P.B. Experimental and Numerical Investigations of Minimum Quantity Lubrication with Hybrid Nano-Fluid on Machinability of Titanium Alloy. Ph.D. Thesis, Bangladesh University of Engineering and Technology, Dhaka, Bangladesh, 2021. [Google Scholar]

- Xiao, M.; Shen, X.; Ma, Y.; Yang, F.; Gao, N.; Wei, W.; Wu, D. Prediction of Surface Roughness and Optimization of Cutting Parameters of Stainless Steel Turning Based on RSM. Math. Probl. Eng. 2018, 2018, 9051084. [Google Scholar] [CrossRef]

- Pant, P.; Chatterjee, D. Prediction of clad characteristics using ANN and combined PSO-ANN algorithms in laser metal deposition process. Surf. Interfaces 2020, 21, 100699. [Google Scholar] [CrossRef]

- Jumare, A.I.; Abou-El-Hossein, K.; Abdulkadir, L.N.; Liman, M.M. Predictive modeling and multiobjective optimization of diamond turning process of single-crystal silicon using RSM and desirability function approach. Int. J. Adv. Manuf. Technol. 2019, 103, 4205–4220. [Google Scholar] [CrossRef]

- Adalarasan, R.; Santhanakumar, M. Response surface methodology and desirability analysis for optimizingμwedmparameters for Al6351/20%Al2O3 composite. Int. J. ChemTech Res. 2015, 7, 2625–2631. [Google Scholar]

| Machine Tool | : Lathe Machine (KL-3280C/2000), spindle power 7.5 KW |

| Work Material | : Medium Carbon Steel |

| Tool Material | : Uncoated Tungsten Carbide |

| Cooling Condition | : MQL |

| MQL Supply Parameters: | |

| Air Pressure | : 23 bar |

| Oil Pressure | : 25 bar |

| Oil Quantity | : 150 mL/h |

| Nozzle Diameter | : 1 mm |

| MQL Coolants: | |

| i. Mineral Oil (VG 68 Cutting Fluid) | |

| ii. Coconut Oil | |

| iii. Coconut + Rice Bran Oil | |

| iv. Coconut + Olive Oil | |

| Process Parameters: | |

| Cutting Speed (V) | : 78, 113.5, 149 m/min |

| Feed Rate (f) | : 0.1, 0.13, 0.16 mm/rev |

| Depth of Cut (d) | : 0.5, 0.75, 1 mm |

| Oil Sample | Vegetable Oil | Oil Quantity | Blend Ratio |

|---|---|---|---|

| Oil blend 1 | Coconut oil | 500 mL | 1:1 |

| Rice bran oil | 500 mL | ||

| Oil blend 2 | Coconut oil | 500 mL | 1:1 |

| Olive oil | 500 mL |

| Sl. No | Variable | Symbols | Unit | Lower Level | Upper Level | ||

|---|---|---|---|---|---|---|---|

| 1 | Cutting Speed | V | m/min | 78 | 149 | ||

| 2 | Feed Rate | f | mm/rev | 0.10 | 0.16 | ||

| 3 | Depth of Cut | d | mm | 0.5 | 1 | ||

| 4 | Cooling Environment | CE | Categorical | MO | CO | CO + RBO | CO + OLO |

| Exp No. | V (m/min) | f (mm/rev) | d (mm) | CE | T | Fc |

|---|---|---|---|---|---|---|

| 1 | 78 | 0.1 | 0.75 | MO | 828 | 335 |

| 2 | 149 | 0.1 | 0.75 | MO | 898 | 285 |

| 3 | 78 | 0.16 | 0.75 | MO | 857 | 432 |

| 4 | 149 | 0.16 | 0.75 | MO | 932 | 407 |

| 5 | 78 | 0.13 | 0.5 | MO | 811 | 314 |

| 6 | 149 | 0.13 | 0.5 | MO | 898 | 304 |

| 7 | 78 | 0.13 | 1 | MO | 851 | 520 |

| 8 | 149 | 0.13 | 1 | MO | 944 | 471 |

| 9 | 113.5 | 0.1 | 0.5 | MO | 840 | 265 |

| 10 | 113.5 | 0.16 | 0.5 | MO | 863 | 373 |

| 11 | 113.5 | 0.1 | 1 | MO | 857 | 382 |

| 12 | 113.5 | 0.16 | 1 | MO | 892 | 481 |

| 13 | 113.5 | 0.13 | 0.75 | MO | 875 | 353 |

| 14 | 113.5 | 0.13 | 0.75 | MO | 869 | 368 |

| 15 | 113.5 | 0.13 | 0.75 | MO | 875 | 351 |

| 16 | 78 | 0.1 | 0.75 | CO | 782 | 297 |

| 17 | 149 | 0.1 | 0.75 | CO | 857 | 270 |

| 18 | 78 | 0.16 | 0.75 | CO | 817 | 425 |

| 19 | 149 | 0.16 | 0.75 | CO | 869 | 392 |

| 20 | 78 | 0.13 | 0.5 | CO | 748 | 244 |

| 21 | 149 | 0.13 | 0.5 | CO | 840 | 236 |

| 22 | 78 | 0.13 | 1 | CO | 800 | 445 |

| 23 | 149 | 0.13 | 1 | CO | 915 | 455 |

| 24 | 113.5 | 0.1 | 0.5 | CO | 800 | 210 |

| 25 | 113.5 | 0.16 | 0.5 | CO | 817 | 230 |

| 26 | 113.5 | 0.1 | 1 | CO | 817 | 324 |

| 27 | 113.5 | 0.16 | 1 | CO | 863 | 438 |

| 28 | 113.5 | 0.13 | 0.75 | CO | 823 | 312 |

| 29 | 113.5 | 0.13 | 0.75 | CO | 805 | 307 |

| 30 | 113.5 | 0.13 | 0.75 | CO | 811 | 311 |

| 31 | 78 | 0.1 | 0.75 | CO + RBO | 754 | 265 |

| 32 | 149 | 0.1 | 0.75 | CO + RBO | 840 | 245 |

| 33 | 78 | 0.16 | 0.75 | CO + RBO | 777 | 405 |

| 34 | 149 | 0.16 | 0.75 | CO + RBO | 857 | 384 |

| 35 | 78 | 0.13 | 0.5 | CO + RBO | 731 | 235 |

| 36 | 149 | 0.13 | 0.5 | CO + RBO | 823 | 230 |

| 37 | 78 | 0.13 | 1 | CO + RBO | 754 | 427 |

| 38 | 149 | 0.13 | 1 | CO + RBO | 851 | 397 |

| 39 | 113.5 | 0.1 | 0.5 | CO + RBO | 800 | 195 |

| 40 | 113.5 | 0.16 | 0.5 | CO + RBO | 805 | 254 |

| 41 | 113.5 | 0.1 | 1 | CO + RBO | 811 | 301 |

| 42 | 113.5 | 0.16 | 1 | CO + RBO | 840 | 385 |

| 43 | 113.5 | 0.13 | 0.75 | CO + RBO | 782 | 280 |

| 44 | 113.5 | 0.13 | 0.75 | CO + RBO | 765 | 290 |

| 45 | 113.5 | 0.13 | 0.75 | CO + RBO | 771 | 285 |

| 46 | 78 | 0.1 | 0.75 | CO + OLO | 707 | 221 |

| 47 | 149 | 0.1 | 0.75 | CO + OLO | 811 | 240 |

| 48 | 78 | 0.16 | 0.75 | CO + OLO | 754 | 319 |

| 49 | 149 | 0.16 | 0.75 | CO + OLO | 840 | 361 |

| 50 | 78 | 0.13 | 0.5 | CO + OLO | 696 | 242 |

| 51 | 149 | 0.13 | 0.5 | CO + OLO | 811 | 221 |

| 52 | 78 | 0.13 | 1 | CO + OLO | 748 | 418 |

| 53 | 149 | 0.13 | 1 | CO + OLO | 800 | 379 |

| 54 | 113.5 | 0.1 | 0.5 | CO + OLO | 777 | 181 |

| 55 | 113.5 | 0.16 | 0.5 | CO + OLO | 794 | 255 |

| 56 | 113.5 | 0.1 | 1 | CO + OLO | 794 | 342 |

| 57 | 113.5 | 0.16 | 1 | CO + OLO | 817 | 355 |

| 58 | 113.5 | 0.13 | 0.75 | CO + OLO | 777 | 234 |

| 59 | 113.5 | 0.13 | 0.75 | CO + OLO | 771 | 231 |

| 60 | 113.5 | 0.13 | 0.75 | CO + OLO | 765 | 236 |

| Sl. No. | V m/min | F mm/rev | D mm | CO % Reduction | CO + RBO % Reduction | CO + OLO % Reduction | |||

|---|---|---|---|---|---|---|---|---|---|

| T | Fc | T | Fc | T | Fc | ||||

| 1 | 78 | 0.1 | 0.75 | 5.56 | 11.35 | 8.94 | 20.9 | 14.62 | 34.03 |

| 2 | 149 | 0.1 | 0.75 | 4.57 | 5.27 | 6.46 | 14.04 | 9.69 | 15.79 |

| 3 | 78 | 0.13 | 0.5 | 7.77 | 22.30 | 9.87 | 25.16 | 14.19 | 22.93 |

| 4 | 149 | 0.13 | 0.5 | 6.46 | 22.37 | 8.36 | 24.35 | 9.69 | 27.31 |

| 5 | 78 | 0.13 | 1 | 6.00 | 14.43 | 11.4 | 17.89 | 12.11 | 19.62 |

| 6 | 149 | 0.13 | 1 | 3.08 | 3.40 | 9.86 | 15.72 | 15.26 | 19.54 |

| 7 | 113.5 | 0.1 | 0.5 | 4.77 | 20.76 | 4.77 | 26.42 | 7.50 | 31.70 |

| 8 | 113.5 | 0.16 | 0.5 | 5.34 | 38.34 | 6.73 | 31.91 | 8.00 | 31.64 |

| 9 | 113.5 | 0.16 | 1 | 3.26 | 8.94 | 5.83 | 19.96 | 8.41 | 26.20 |

| AVG | 5.20 | 16.35 | 8.02 | 21.82 | 11.05 | 25.42 | |||

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 150,999 | 21,571.3 | 115.55 | 0.000 |

| Linear | 6 | 148,515 | 24,752.6 | 132.59 | 0.000 |

| V | 1 | 58,739 | 58,738.8 | 314.64 | 0.063 |

| f | 1 | 5539 | 5538.8 | 29.67 | 0.000 |

| d | 1 | 7813 | 7812.5 | 41.85 | 0.000 |

| Env | 3 | 76,425 | 25,475.1 | 136.46 | 0.000 |

| Square | 1 | 2484 | 2484.0 | 13.31 | 0.001 |

| V*V | 1 | 2484 | 2484.0 | 13.31 | 0.001 |

| Error | 52 | 9709 | 186.7 | ||

| Lack-of-Fit | 44 | 9295 | 211.2 | 4.10 | 0.020 |

| Pure Error | 8 | 413 | 51.6 | ||

| Total | 59 | 160,707 | |||

| Model Summary | |||||

| S | R-sq | R-sq (adj) | R-sq (pred) | ||

| 13.6632 | 93.96% | 93.15% | 91.89% | ||

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 368,502 | 46,063 | 74.45 | 0.000 |

| Linear | 6 | 348,293 | 58,049 | 93.83 | 0.000 |

| V | 1 | 2228 | 2228 | 3.60 | 0.063 |

| f | 1 | 73,920 | 73,920 | 119.48 | 0.000 |

| d | 1 | 200,186 | 200,186 | 323.57 | 0.000 |

| Env | 3 | 71,959 | 23,986 | 38.77 | 0.000 |

| Square | 2 | 20,209 | 10,105 | 16.33 | 0.000 |

| V*V | 1 | 17,817 | 17,817 | 28.80 | 0.000 |

| d*d | 1 | 3401 | 3401 | 5.50 | 0.023 |

| Error | 51 | 31,553 | 619 | ||

| Lack-of-Fit | 43 | 31,304 | 728 | 23.36 | 0.000 |

| Pure Error | 8 | 249 | 31 | ||

| Total | 59 | 400,055 | |||

| Model Summary | |||||

| S | R-sq | R-sq (adj) | R-sq (pred) | ||

| 24.8734 | 92.11% | 90.88% | 88.90% | ||

| Run | Input Parameters | Experimental Output | Predicted Output | APE | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| V (m/min) | f (mm/rev) | D (mm) | CE | T (°C) | Fc (N) | T (°C) | Fc (N) | T (%) | Fc (%) | |

| 1 | 113.5 | 0.1 | 0.75 | MO | 905 | 294 | 866 | 302 | 4.36 | 2.56 |

| 2 | 78 | 0.13 | 0.5 | 836 | 314 | 807 | 329 | 3.43 | 4.65 | |

| 3 | 149 | 0.16 | 1 | 928 | 485 | 950 | 518 | 2.41 | 6.84 | |

| 4 | 113.5 | 0.1 | 0.75 | CO | 848 | 258 | 817 | 252 | 3.64 | 2.39 |

| 5 | 78 | 0.13 | 0.5 | 813 | 273 | 759 | 279 | 6.65 | 2.16 | |

| 6 | 149 | 0.16 | 1 | 882 | 439 | 902 | 468 | 2.26 | 6.71 | |

| 7 | 113.5 | 0.1 | 0.75 | CO + RBO | 756 | 217 | 790 | 231 | 4.53 | 6.28 |

| 8 | 78 | 0.13 | 0.5 | 716 | 240 | 732 | 258 | 2.24 | 7.37 | |

| 9 | 149 | 0.16 | 1 | 842 | 422 | 875 | 447 | 3.93 | 5.99 | |

| 10 | 113.5 | 0.1 | 0.75 | CO + OLO | 727 | 195 | 770 | 208 | 5.93 | 6.58 |

| 11 | 78 | 0.13 | 0.5 | 664 | 249 | 712 | 235 | 7.25 | 5.67 | |

| 12 | 149 | 0.16 | 1 | 796 | 398 | 855 | 424 | 7.41 | 6.65 | |

| Optimum Parameters | |

|---|---|

| Cutting Speed | 80.15 m/min |

| Feed Rate | 0.10 mm/min |

| Depth of Cut | 0.50 mm |

| Cutting Environment | Coconut + Olive Oil Blend |

| Responses | Initial Settings | RSM Settings | Improvement in Responses | ||

|---|---|---|---|---|---|

| Predicted Value | Experimental Value | Predicted Value | Experimental Value | ||

| Parameter settings (V, f, d, Env) | 78, 0.1, 0.75, MO | 80.15, 0.1, 0.5, CO + OLO | - | ||

| Cutting temperature | 823 | 828 | 714 | 698 | 15.7% |

| Cutting force | 344 | 335 | 182 | 194 | 42% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, I.; Zaman, P.B. Response Modeling and Optimization of Process Parameters in Turning Medium Carbon Steel Under Minimum Quantity Lubrication (MQL) with Vegetable Oil and Oil Blends. Lubricants 2024, 12, 444. https://doi.org/10.3390/lubricants12120444

Das I, Zaman PB. Response Modeling and Optimization of Process Parameters in Turning Medium Carbon Steel Under Minimum Quantity Lubrication (MQL) with Vegetable Oil and Oil Blends. Lubricants. 2024; 12(12):444. https://doi.org/10.3390/lubricants12120444

Chicago/Turabian StyleDas, Indranil, and Prianka Binte Zaman. 2024. "Response Modeling and Optimization of Process Parameters in Turning Medium Carbon Steel Under Minimum Quantity Lubrication (MQL) with Vegetable Oil and Oil Blends" Lubricants 12, no. 12: 444. https://doi.org/10.3390/lubricants12120444

APA StyleDas, I., & Zaman, P. B. (2024). Response Modeling and Optimization of Process Parameters in Turning Medium Carbon Steel Under Minimum Quantity Lubrication (MQL) with Vegetable Oil and Oil Blends. Lubricants, 12(12), 444. https://doi.org/10.3390/lubricants12120444