Study on Performance of Compliant Foil Gas Film Seal Based on Different Texture Bottom Designs

Abstract

1. Introduction

2. Theoretical Model

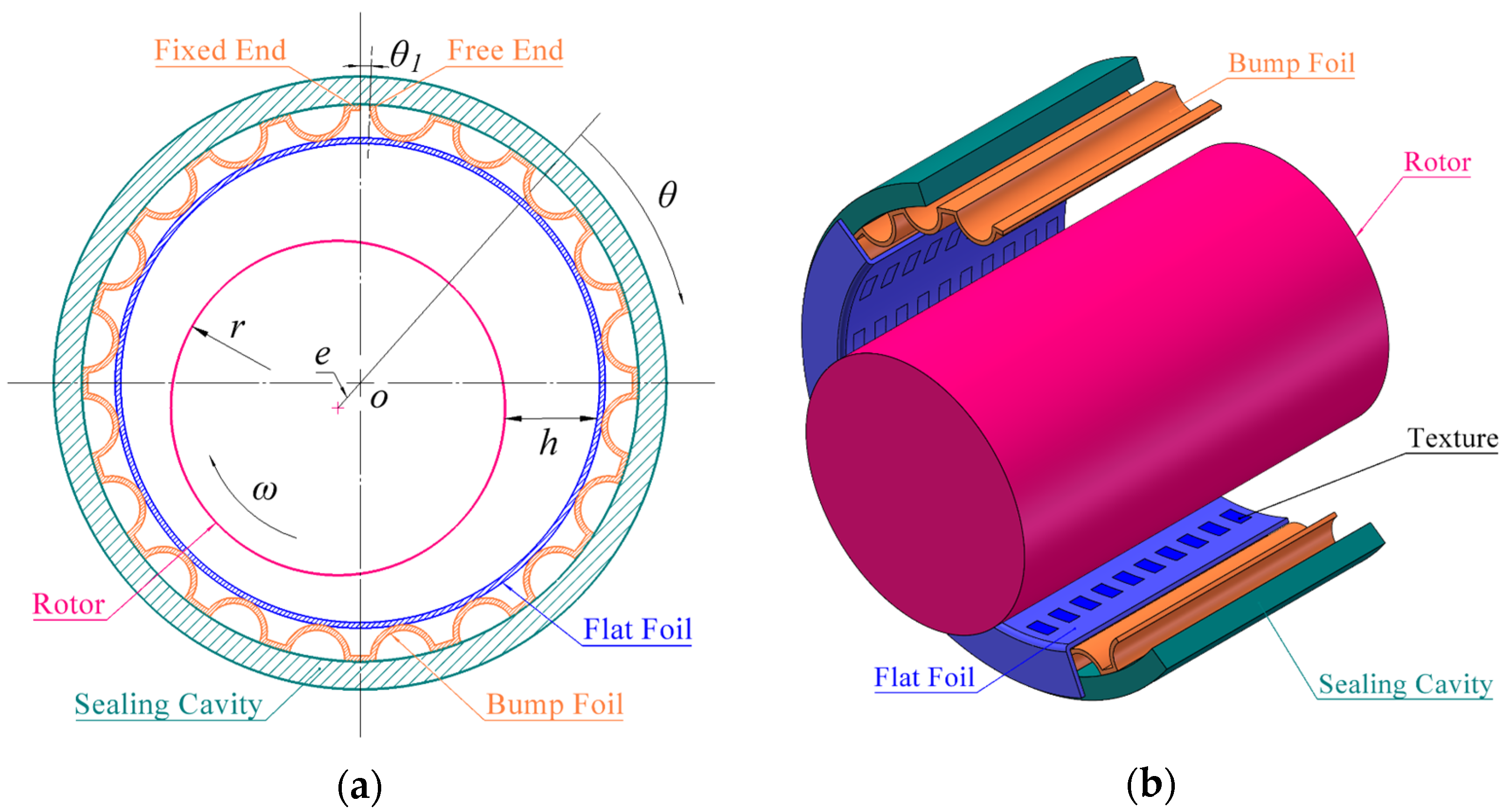

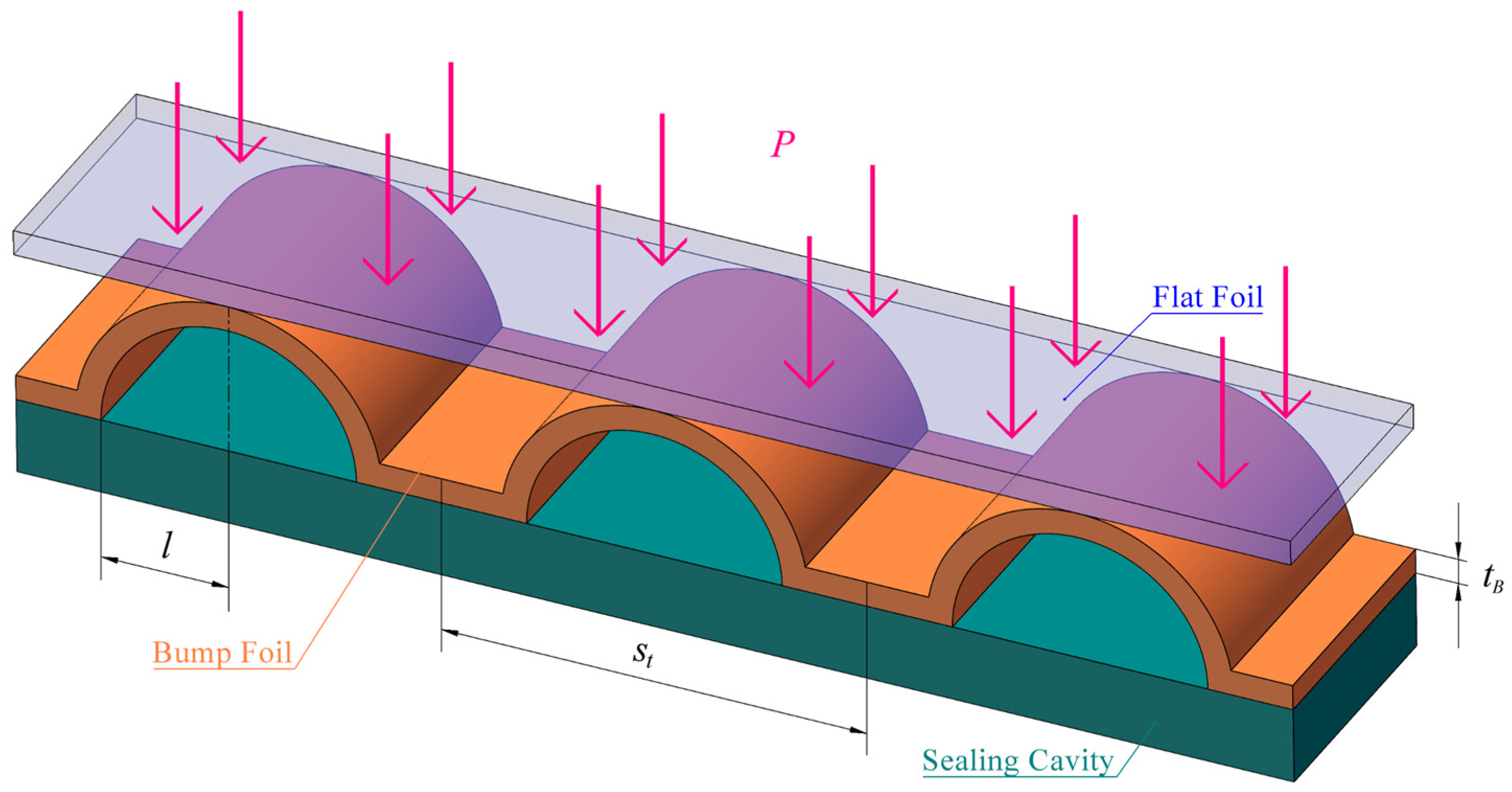

2.1. Geometrical Structure

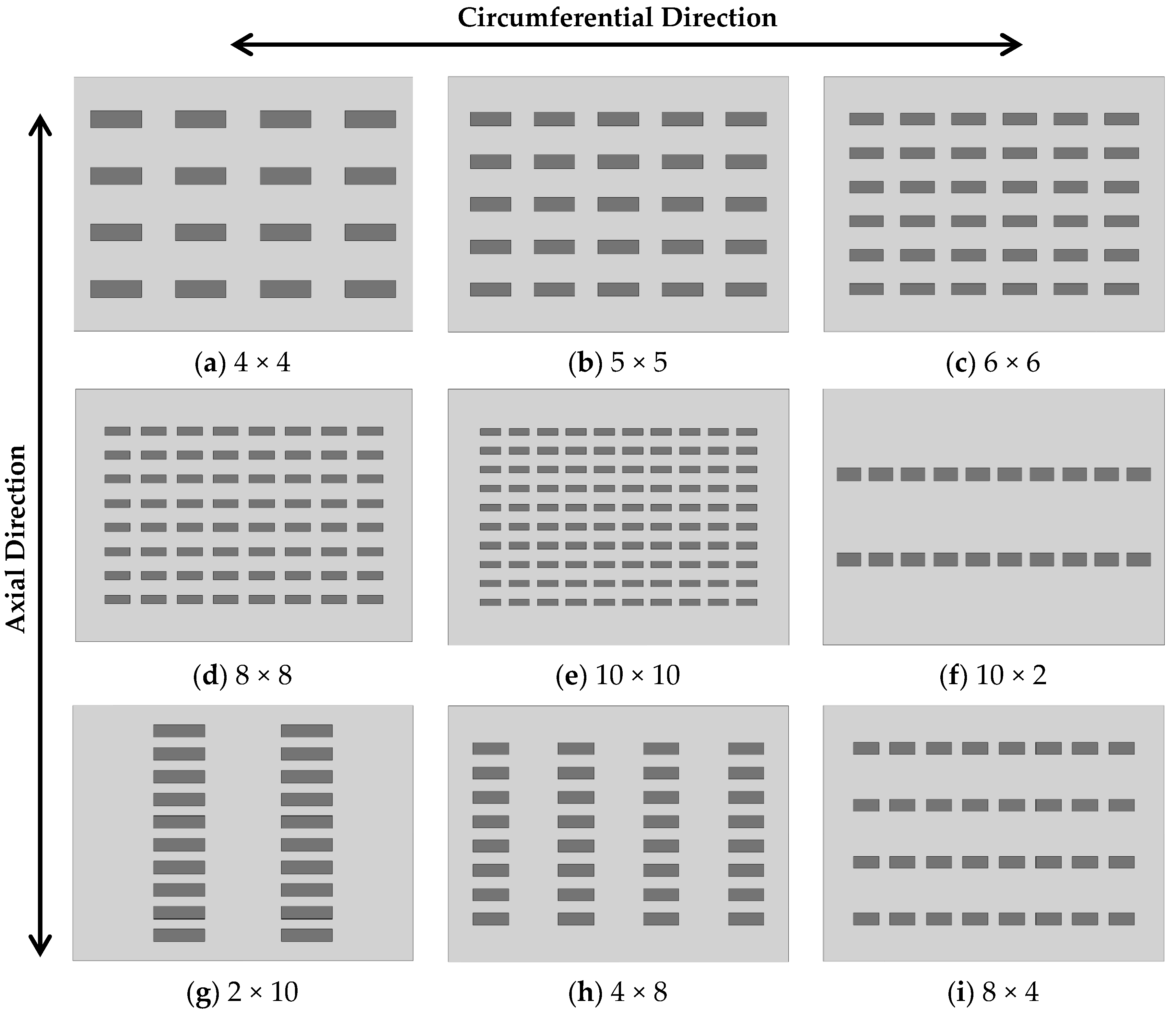

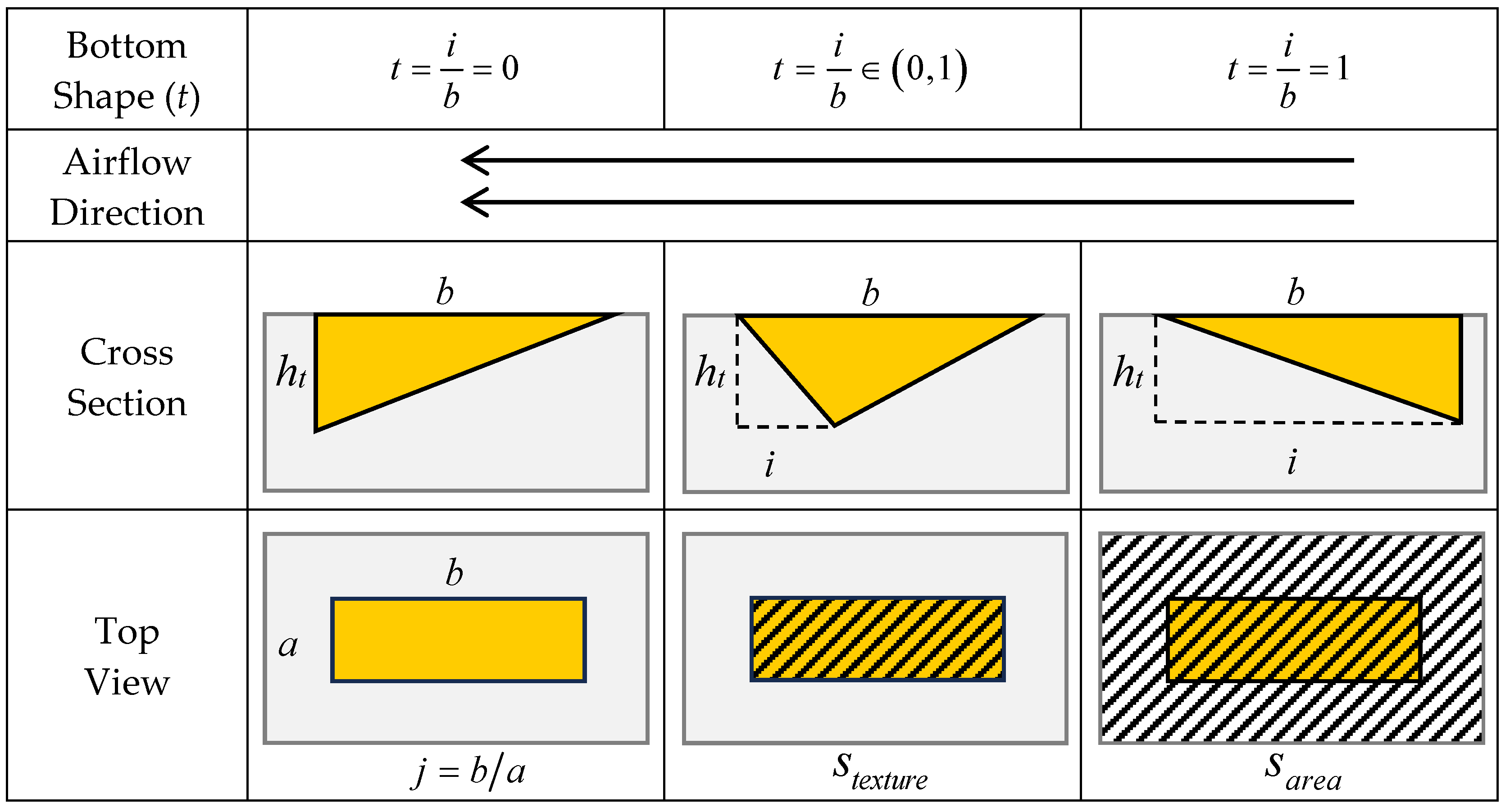

2.2. Texture Design

2.3. Foil Deformation Model

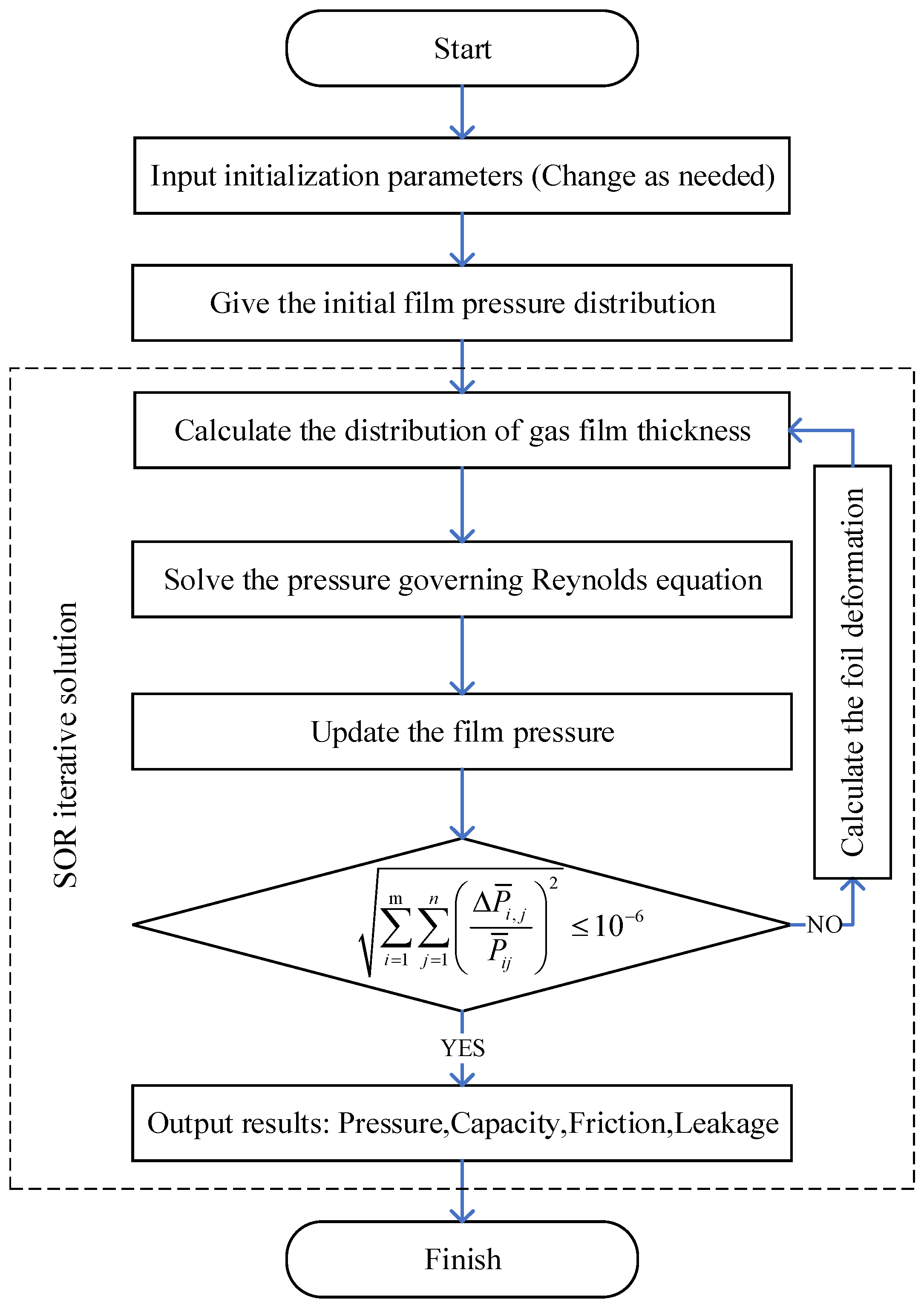

2.4. Solution Method

2.5. Performance Parameter

3. Validation

4. Result and Discussion

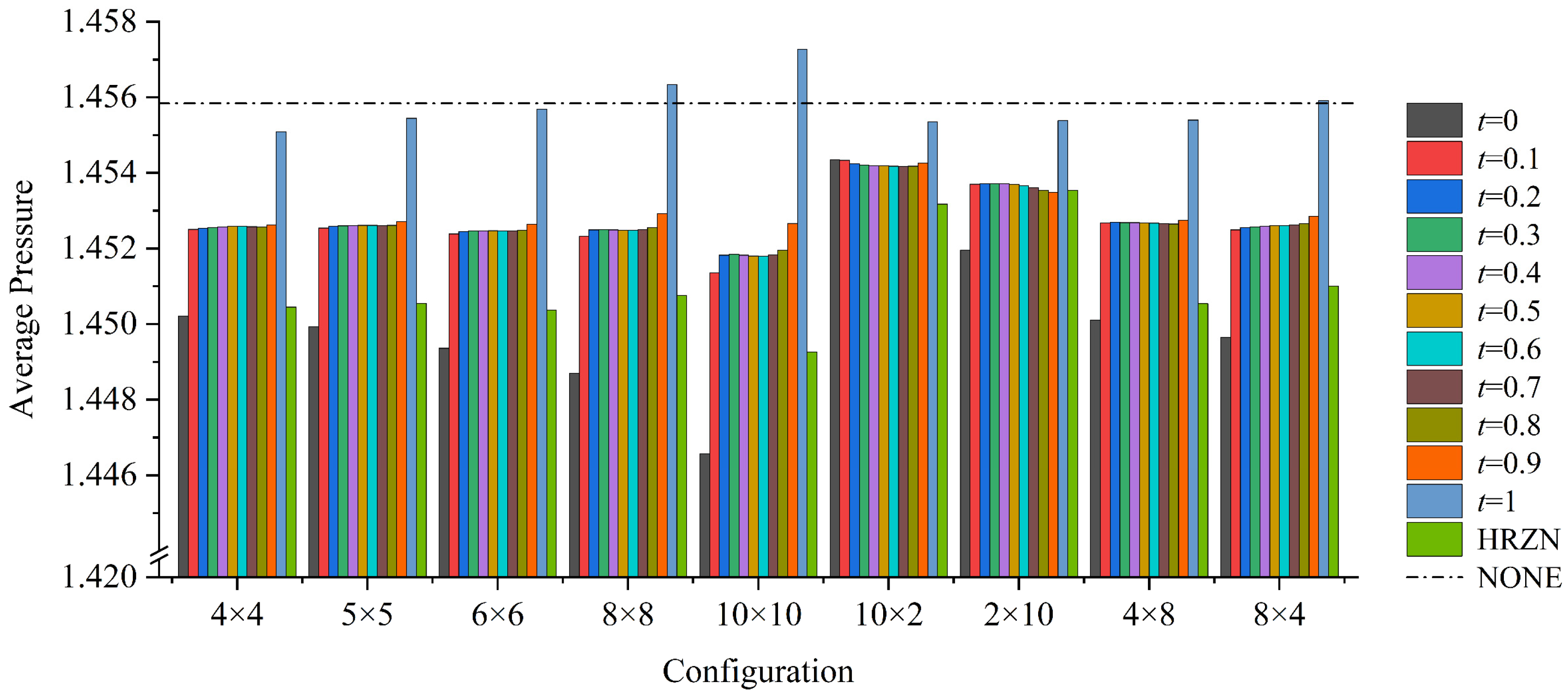

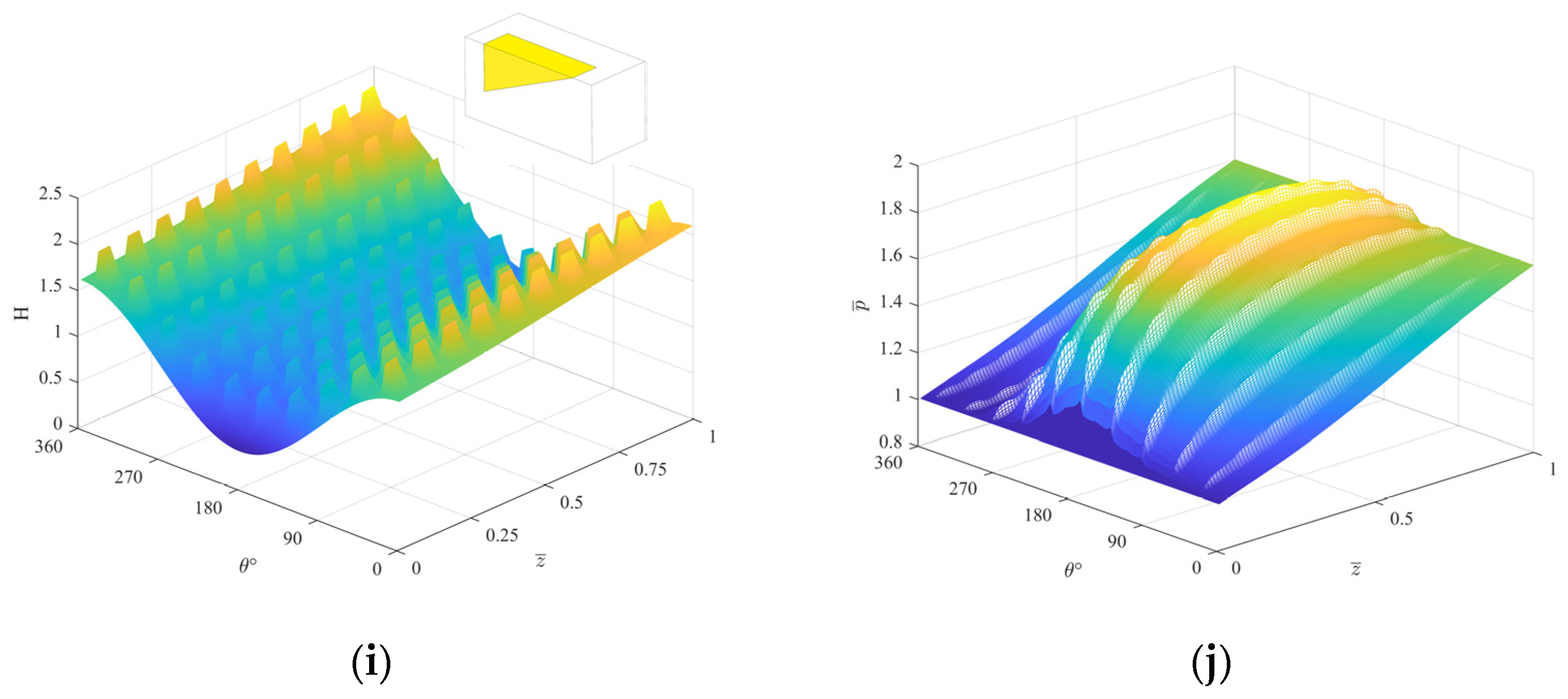

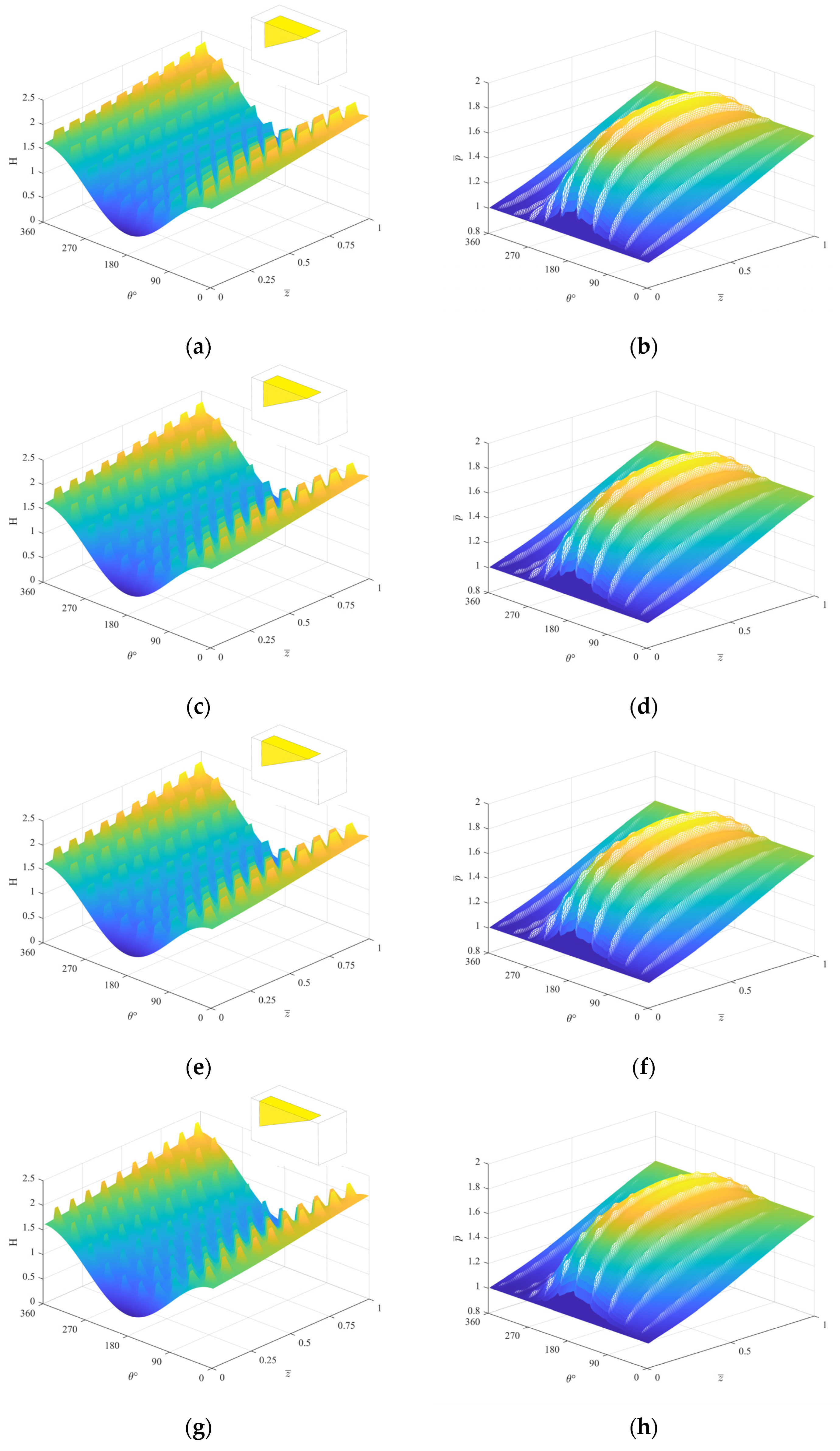

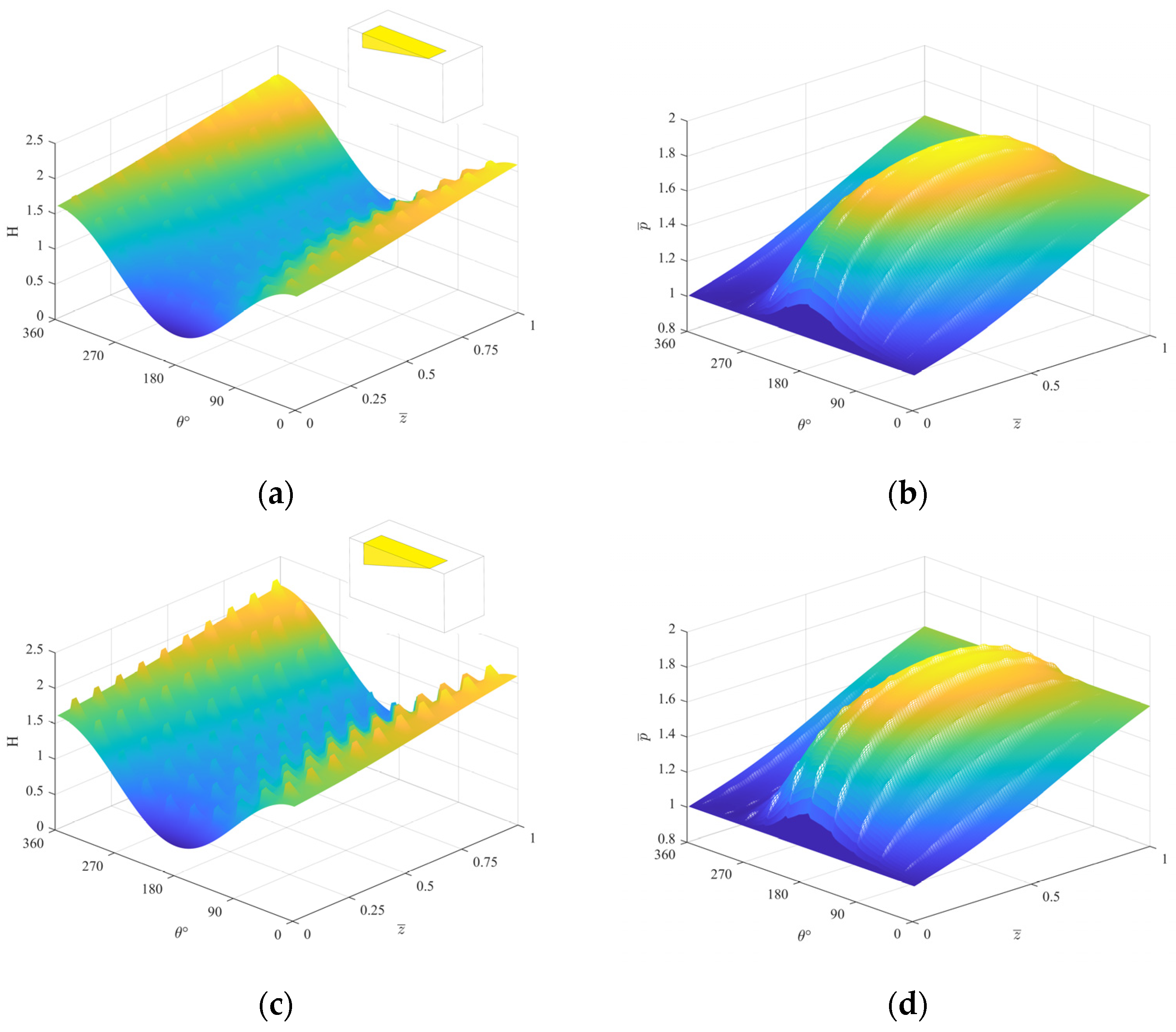

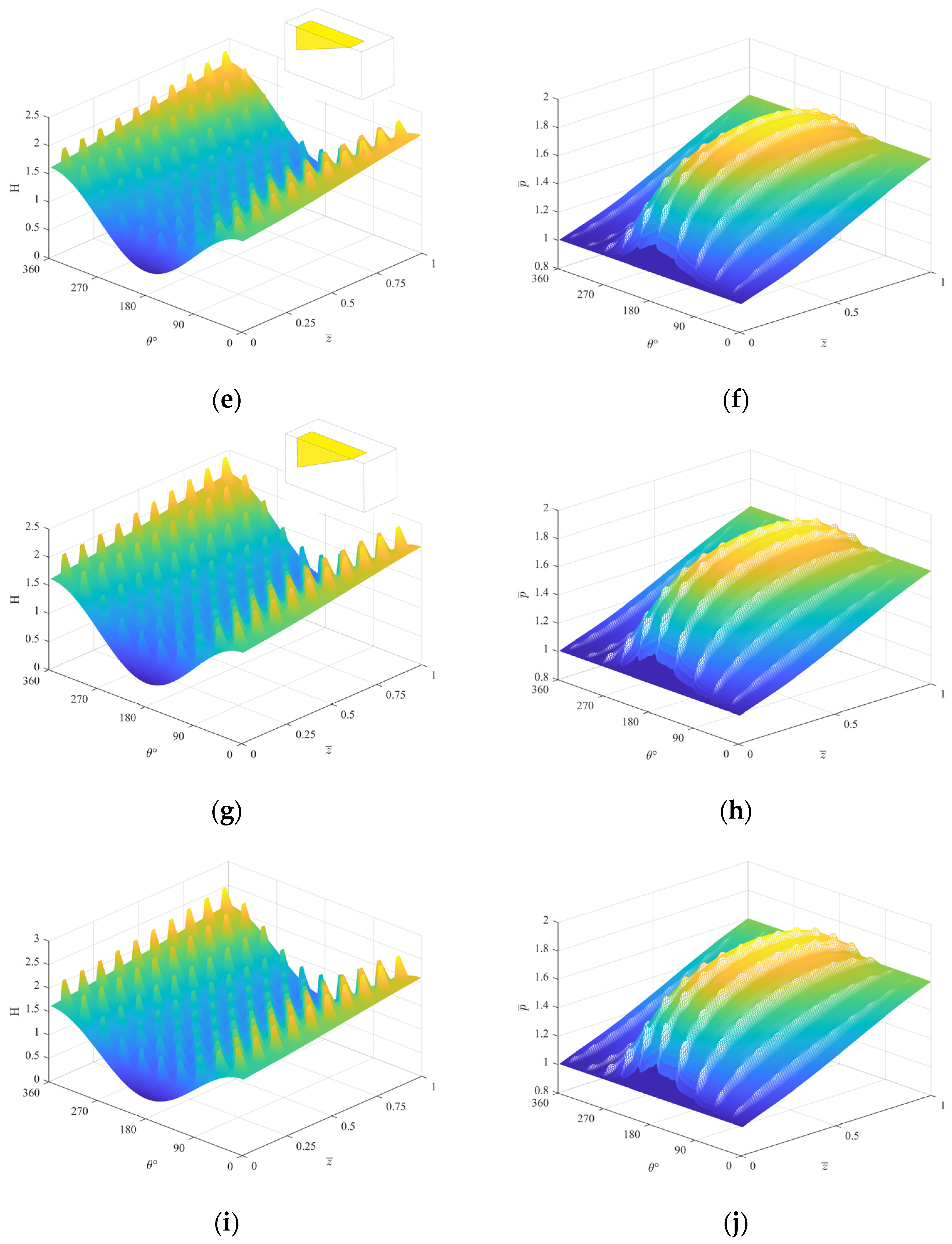

4.1. Effect of Configuration and Bottom Shape

4.2. Effect of Bottom Shape and Ascept Ratio

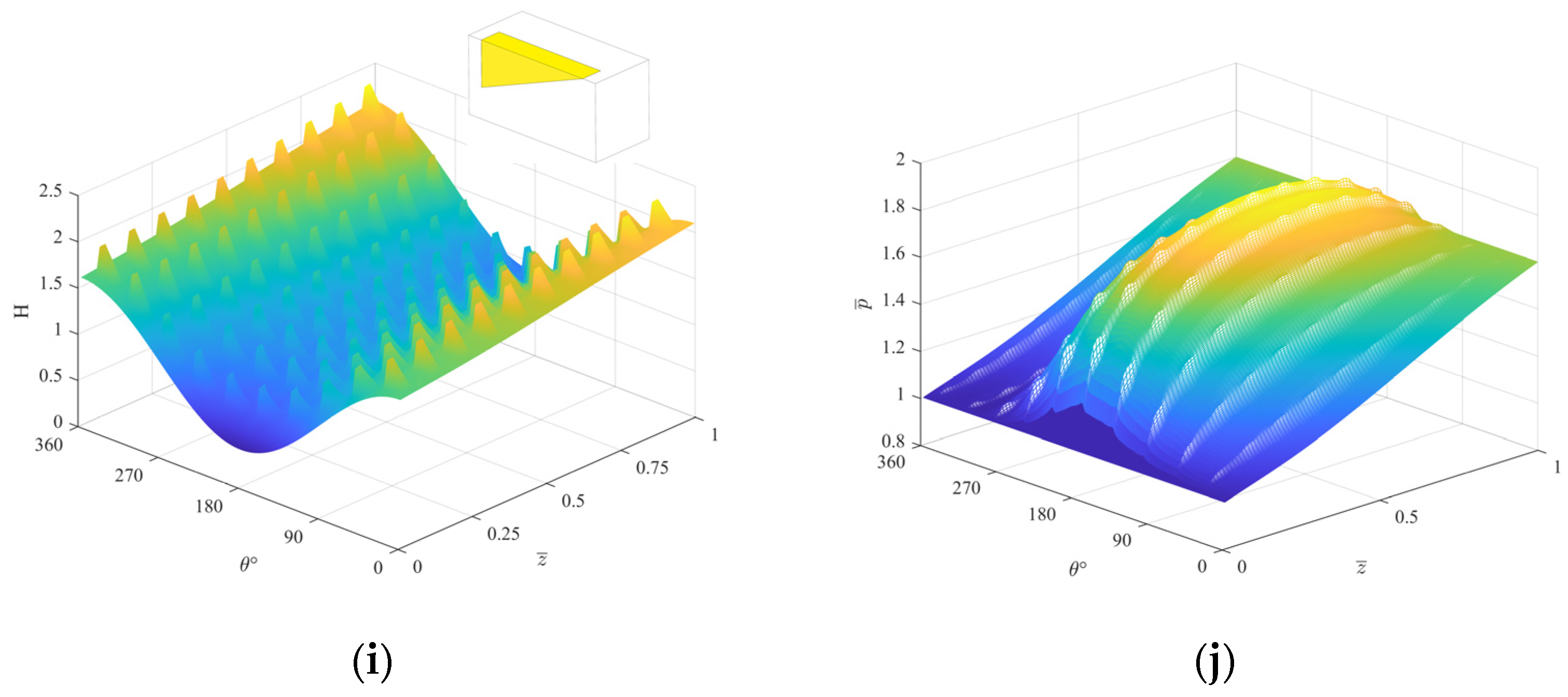

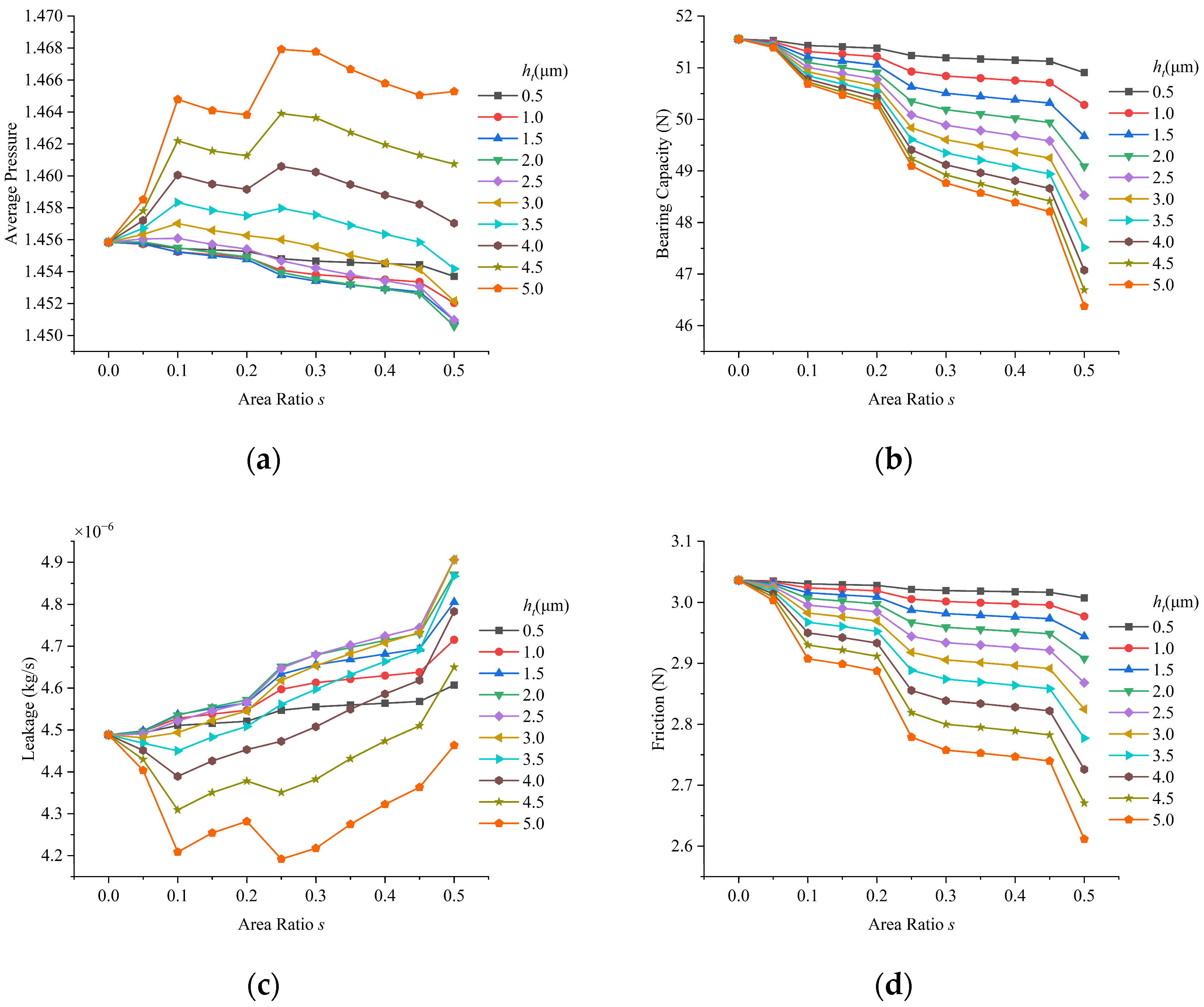

4.3. Effect of Area Ratio and Depth

5. Conclusions

- (1)

- The influence of the change of the bottom shape on the performance of the compliant foil gas film seal is not affected by the configuration of the texture. The dynamic pressure effect of the texture of the convergent right-angle triangular slope (i.e., t = 1) is the best, and when the texture is arranged in the axial and circumferential directions, the average pressure of the compliant foil gas film seal can be increased by 0.55% compared with the horizontal bottom surface morphology. On the contrary, the dynamic pressure effect of the texture on the bottom surface of the diffuse right-angle triangular slope (i.e., t = 0) is the weakest. Under a certain configuration, the sealing performance of the textured compliant foil with a convergent right-angle triangular bevel bottom shape is better than that without texture, and the sealing performance of the textured compliant foil is the best when the texture is arranged in 10 axial and circumferential directions, respectively, which can be improved by 0.10% compared with the average gas film pressure without texture.

- (2)

- The aspect ratio of the texture shows an important influence on the performance of the compliant foil gas film seal. Under the same conditions, when the aspect ratio is smaller within a certain range, the average pressure of the compliant foil gas film seal is higher. In this study, when the aspect ratio of the texture is 2/1, the sealing gas film achieves the maximum gas film pressure and the lowest leakage. It can be found that when the length of the texture in the axial direction of the compliant foil is longer, the dynamic pressure effect is the best.

- (3)

- In the case of different depths, the bearing capacity and friction force generated by the bottom shape of the convergent right-angle triangular slope decrease with the increase in the texture area ratio, and the compliant foil gas film seal shows the minimum bearing capacity and friction force when the texture is 5.0 μm depth and s = 0.5 area ratio. Compared with the bearing capacity and friction force without texture, it can be reduced by 10.04% and 13.99%. In the range of texture depth ht ≤ 2.5 μm, the average gas film pressure and leakage show a monotonically decreasing and monotonically increasing trend with the increase in texture area ratio. When the depth ht = 5.0 μm, the compliant foil gas film seal with the area ratio of s = 0.25 shows the largest gas film pressure and the lowest leakage. The average pressure can be increased by 0.83% compared with the case without texture, and the leakage can be reduced by 6.61% compared with the case without texture.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salehi, M.; Heshmat, H. Performance of a complaint foil seal in a small gas turbine engine simulator employing a hybrid foil/ball bearing support system. Tribol. Trans. 2001, 44, 458–464. [Google Scholar] [CrossRef]

- Salehi, M.; Heshmat, H. Non-contacting compliant foil seal for gas turbine engine. In Proceedings of the 2001 NASA Seal/Secondary Air System Workshop, Cleveland, OH, USA, 30–31 October 2001. [Google Scholar]

- Heshmat, H.; Walton, J. Innovative High-temperature Compliant Surface Foil Face Seal Development. In Proceedings of the AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Hartford, CT, USA, 21–23 July 2008; pp. 1–13. [Google Scholar]

- Xu, H.J.; Liu, Z.S.; Zhang, G.H.; Wang, Y.L. Characteristics of Film Pressure Distribution of Bump Foil Gas Bearings. Bearings 2008, 6, 23–27. [Google Scholar]

- Ma, G.; Ping, X.; Shen, X.; Hu, G. Analysis of quasi-dynamic characteristics of compliant floating ring gas cylinder seal. Aerosp. Power 2010, 25, 1190–1196. [Google Scholar]

- Lee, D.H.; Kim, Y.C.; Kim, K.W. The effect of coulomb friction on the static performance of foil journal bearings. Tribol. Int. 2010, 43, 1065–1072. [Google Scholar] [CrossRef]

- Sun, J.; Liu, M.; Xu, Z.; Liao, T.; Hu, X.; Li, Y.; Wang, J. Coupled fluid–solid numerical simulation for flow field characteristics and supporting performance of flexible support cylindrical gas film seal. Aerospace 2021, 8, 97. [Google Scholar] [CrossRef]

- Jiang, H.; Yu, S.; Ding, X. Parametric Analysis of Compliant End Face Gas Film Seals Considering Slip Flow Effects. Appl. Sci. 2024, 14, 6953. [Google Scholar] [CrossRef]

- Wang, X.; Liu, M.; Kao-Walter, S.; Hu, X. Numerical Evaluation of Rotordynamic Coefficients for Compliant Foil Gas Seal. Appl. Sci. 2020, 10, 3828. [Google Scholar] [CrossRef]

- Wang, X.; Liu, M. The Seal Performance of Compliant Foil Gas Seal Based on Multi-Scale Analysis. Processes 2022, 10, 1123. [Google Scholar] [CrossRef]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A theory of lubrication by micro irregularitiesm. J. Basic Eng. 1966, 88, 177–185. [Google Scholar] [CrossRef]

- Luz, F.K.C.; Profito, F.J.; dos Santos, M.B.; Silva, S.A.; Costa, H.L. Deterministic Simulation of Surface Textures for the Piston Ring/Cylinder Liner System in a Free Piston Linear Engine. Lubricants 2024, 12, 12. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, Y.; Chen, S.; Zhu, W. Comparative research on gas seal performance textured with microgrooves and microdimples. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 280. [Google Scholar] [CrossRef]

- Shi, L.; Wang, X.; Su, X.; Huang, W.; Wang, X. Comparison of the load-carrying performance of mechanical gas seals textured with microgrooves and microdimples. J. Tribol. 2016, 138, 021701. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. The Friction Reducing Effect of Square-Shaped Surface Textures under Lubricated Line-Contacts—An Experimental Study. Lubricants 2016, 4, 26. [Google Scholar] [CrossRef]

- Pei, S.; Xu, H.; Yun, M.; Shi, F.; Hong, J. Effects of surface texture on the lubrication performance of the floating ring bearing. Tribol. Int. 2016, 102, 143–153. [Google Scholar] [CrossRef]

- Zhang, G.; Xu, K.; Han, J.; Huang, Y.; Gong, W.; Guo, Y.; Huang, Z.; Luo, X.; Liang, B. Performance of textured oil journal bearings considering the influence of related texture depth. Process. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 2105–2117. [Google Scholar] [CrossRef]

- Wang, S.; Ding, X.; Li, N.; Ding, J.; Zhang, L. Orientation effect on sealing characteristics of rectangular micro-textured floating ring gas film seal. Beijing Univ. Aeronaut. Astronaut. 2023, 1–18. [Google Scholar]

- Xu, J.; Yi, S.R.; Yang, X.C.; Ding, X.X.; Jiang, H.T. Impact Analysis of Surface Morphology on Floating Foil Film Sealing Performance. Tribology 2023, 43, 1341–1352. [Google Scholar]

- Xu, J. Analysis and Experimental Research on Dynamic Pressure Lubrication Characteristics of Compliant Foil Gas Film Seal. Ph.D. Thesis, Lanzhou University of Technology, Lanzhou, China, 2022. [Google Scholar]

- Vishal, M.; Skylab, P.B. Comparative Study on Tribological Vehavior of Foil Journal Bearings with Micro Pocket. Surf. Topogr. Metrol. Prop. 2024, 12, 015020. [Google Scholar]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. A Novel Surface Texture Shape for Directional Friction Control. Tribol. Lett. 2018, 66, 51. [Google Scholar] [CrossRef]

- Nanbu, T.; Ren, N.; Yasuda, Y.; Zhu, D.; Wang, J. Micro-Textures in Concentrated Conformal-Contact Lubrication: Effects of Texture Bottom Shape and Surface Relative Motion. Tribol. Lett. 2008, 29, 241–252. [Google Scholar] [CrossRef]

- Yan, J. Research on Dynamic Characteristics of Compliant Foil Gas Thrust Bearing-Rotor System. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2012. [Google Scholar]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| R [mm] | 25 | tB [mm] | 0.2016 |

| L [mm] | 26.67 | μ [Pa·s] | 1.8 × 10−5 |

| c [μm] | 10 | Pa [MPa] | 0.101325 |

| e | 0.6 | Phigh [MPa] | 0.16 |

| Eb [GPa] | 2.14 × 1011 | ω [r/min] | 30000 |

| vb | 0.3 | st [mm] | 4.572 |

| l [mm] | 1.778 | μf | 0.10 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Eccentricity | 0.5 | Viscosity [10−5 Pa·s] | 1.932 |

| Clearance [10−6 m] | 10 | Density [kg/m3] | 1.1614 |

| Width of seal [10−3 m] | 40 | Pressure of low side [MPa] | 0.11 |

| Diameter of rotor [10−3 m] | 160 | Pressure of high side [MPa] | 0.11, 0.20 |

| Speed of rotor [r/min] | 25,000 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Zou, Y.; Si, J.; Lei, Z.; Li, N.; Guo, Y. Study on Performance of Compliant Foil Gas Film Seal Based on Different Texture Bottom Designs. Lubricants 2024, 12, 445. https://doi.org/10.3390/lubricants12120445

He Z, Zou Y, Si J, Lei Z, Li N, Guo Y. Study on Performance of Compliant Foil Gas Film Seal Based on Different Texture Bottom Designs. Lubricants. 2024; 12(12):445. https://doi.org/10.3390/lubricants12120445

Chicago/Turabian StyleHe, Zhenpeng, Yuchen Zou, Jiaxin Si, Ziyi Lei, Ning Li, and Yuhang Guo. 2024. "Study on Performance of Compliant Foil Gas Film Seal Based on Different Texture Bottom Designs" Lubricants 12, no. 12: 445. https://doi.org/10.3390/lubricants12120445

APA StyleHe, Z., Zou, Y., Si, J., Lei, Z., Li, N., & Guo, Y. (2024). Study on Performance of Compliant Foil Gas Film Seal Based on Different Texture Bottom Designs. Lubricants, 12(12), 445. https://doi.org/10.3390/lubricants12120445