Effect of Nanodiamonds on Friction Reduction Performance in Presence of Organic and Inorganic Friction Modifiers

Abstract

1. Introduction

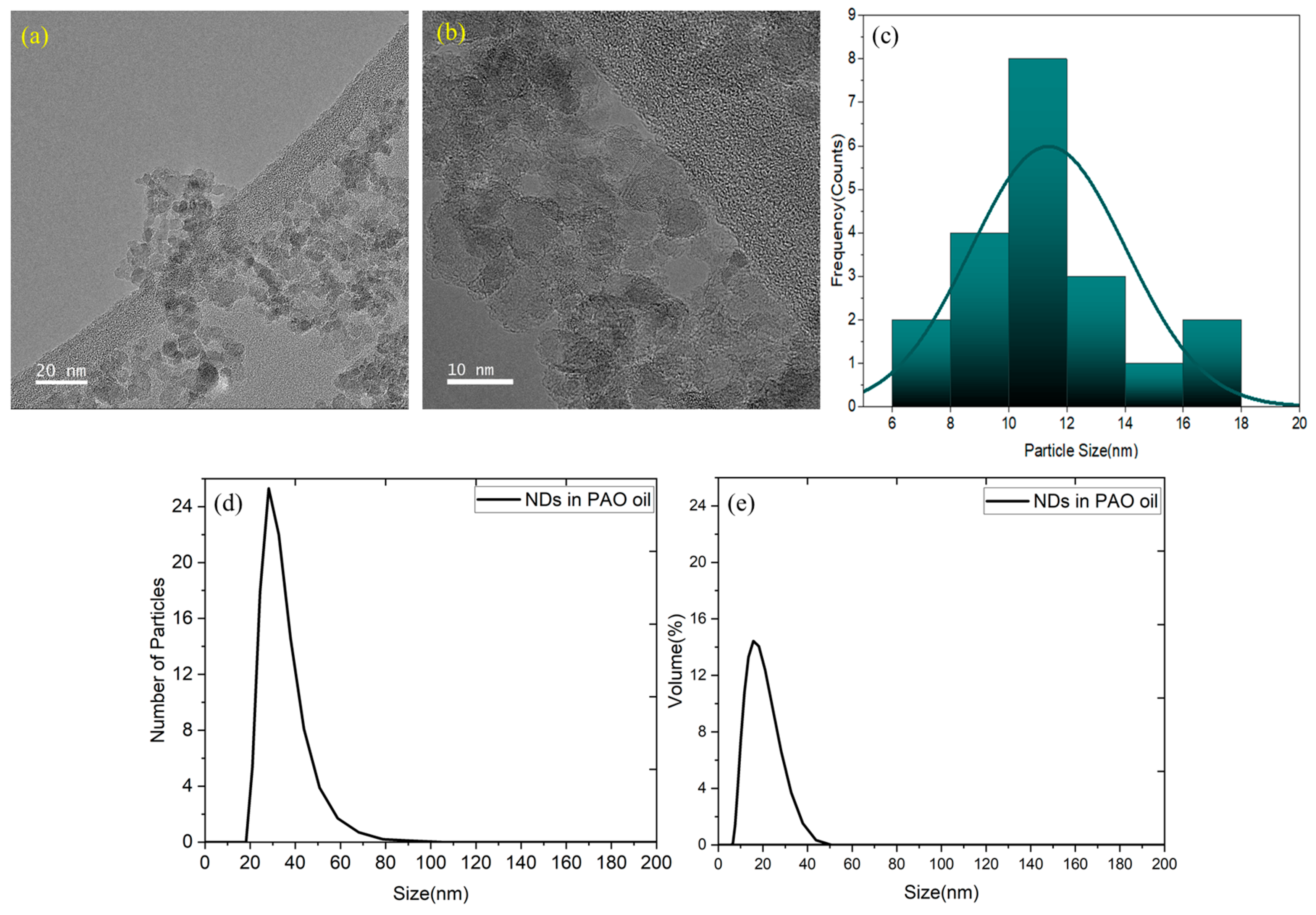

2. Material and Methods

2.1. Lubricant and Specimen Preparation

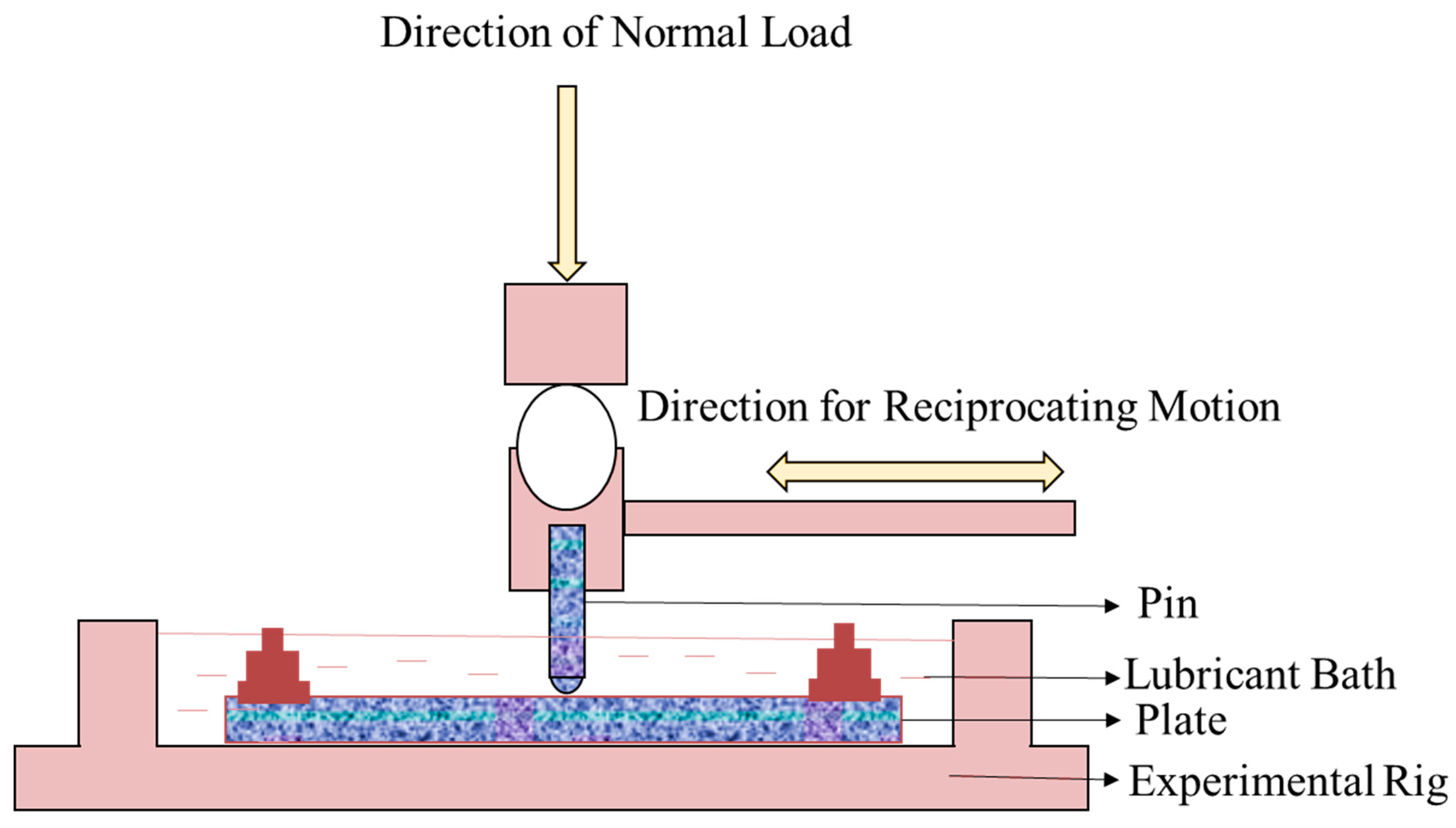

2.2. Tribological Tests

2.3. Wear and Tribofilm Characterisation

3. Results

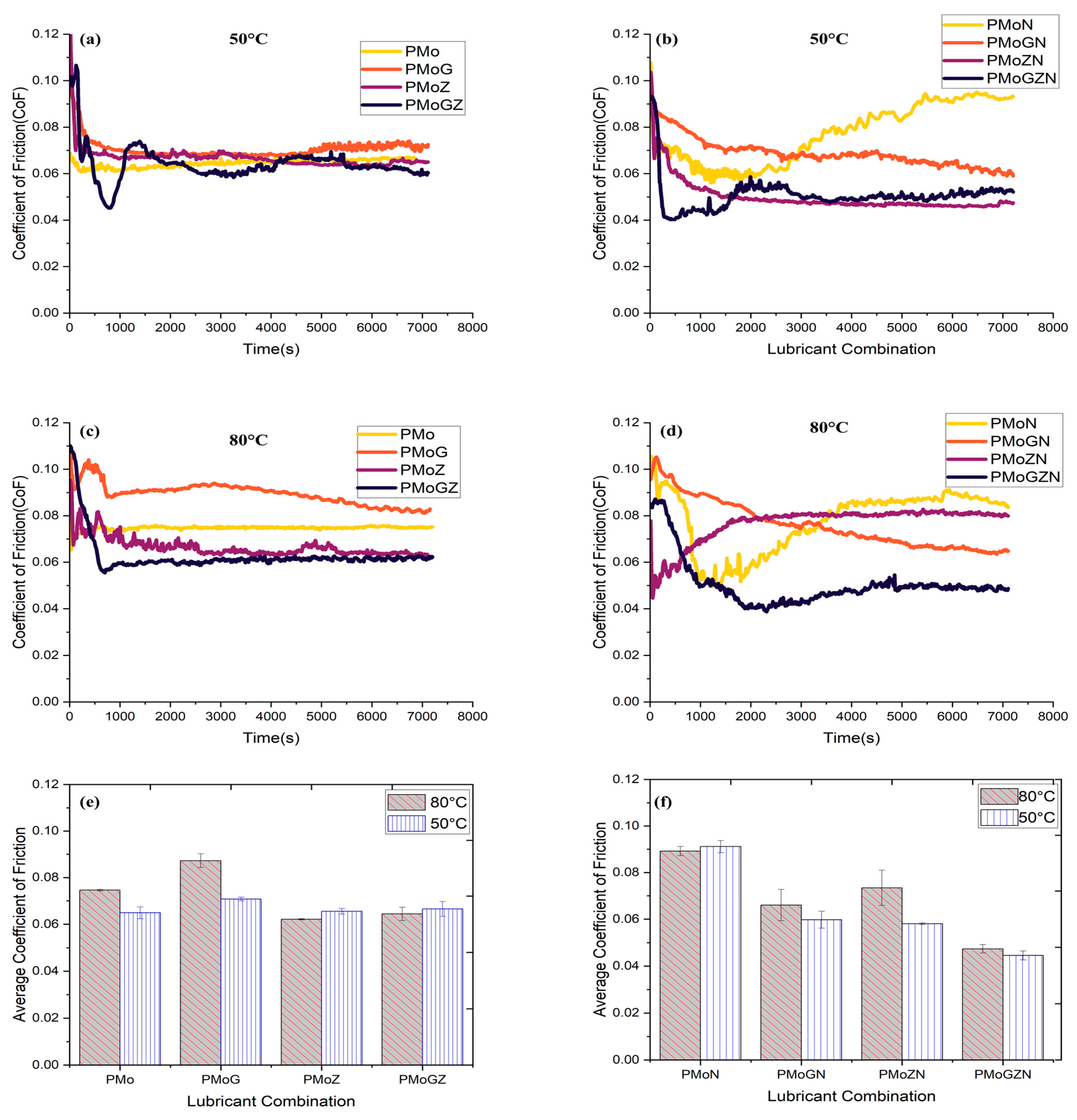

3.1. Tribological Performance

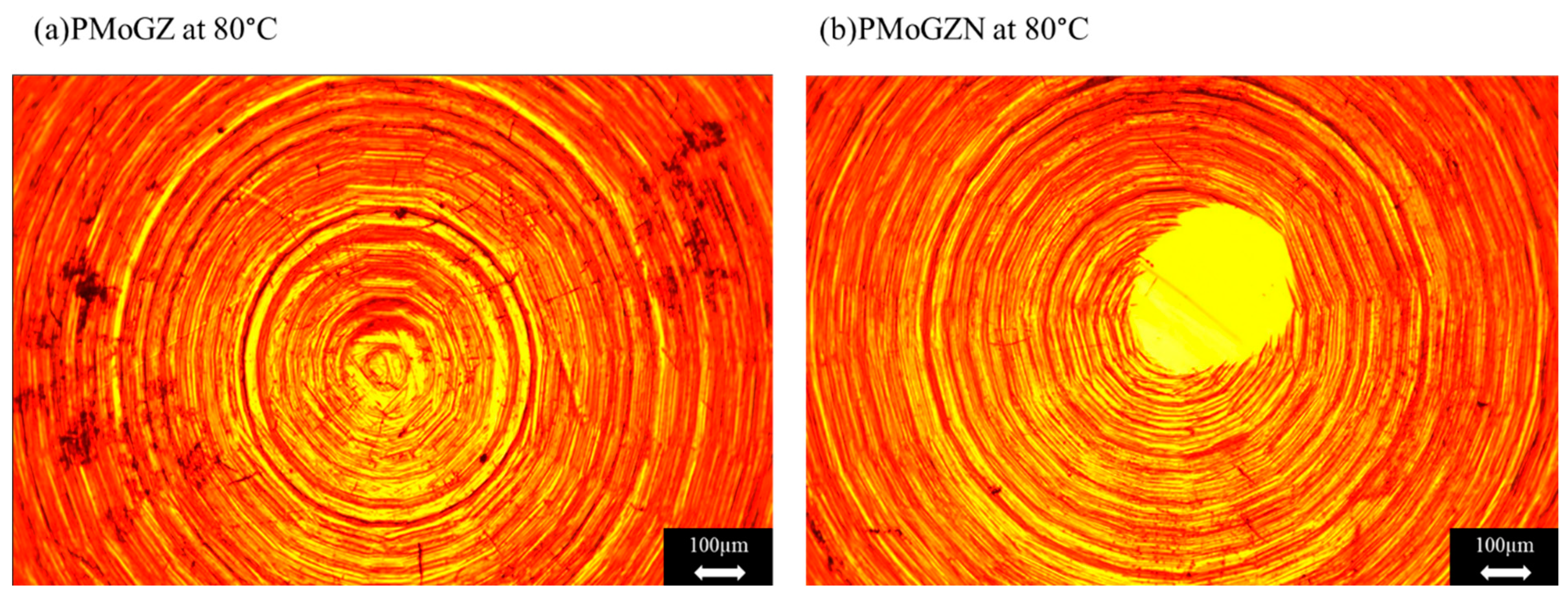

3.2. Wear Surface Analysis

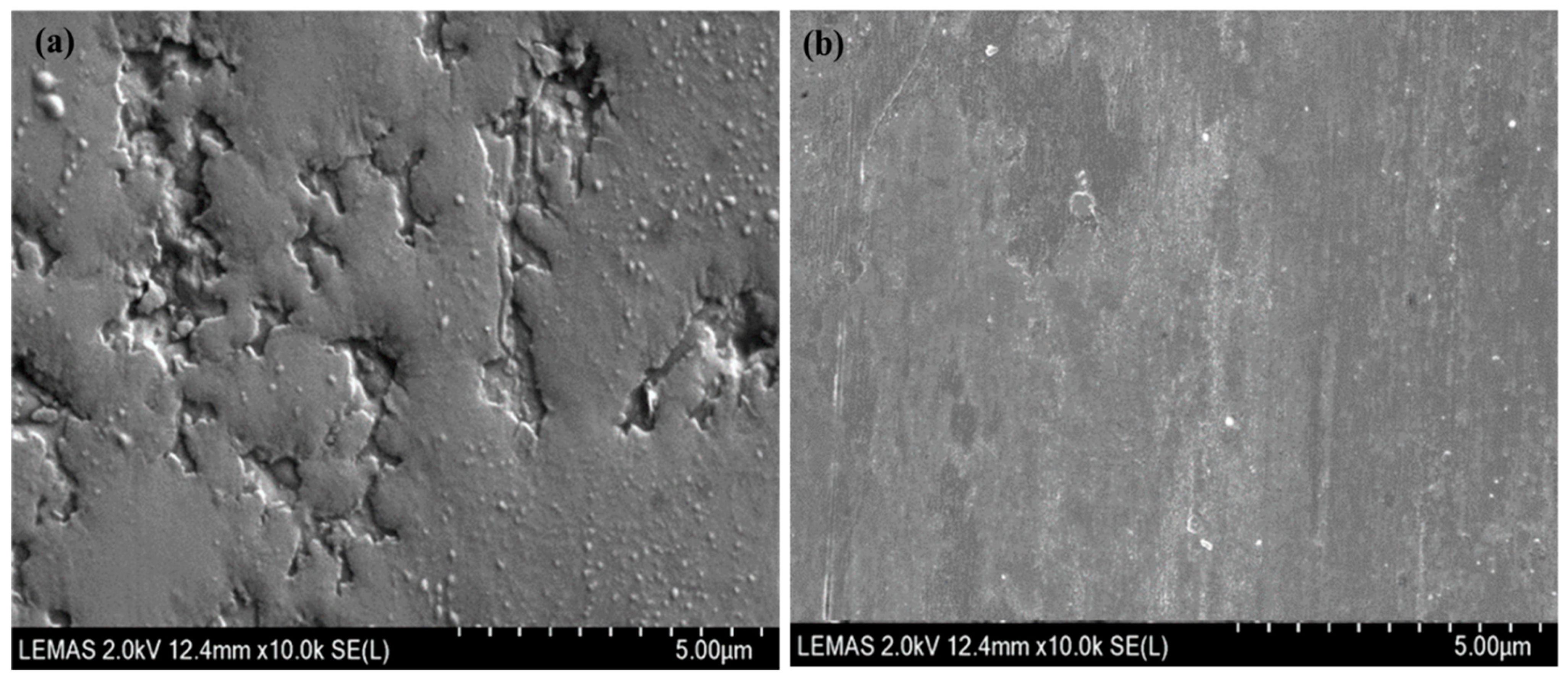

3.3. Changes in Surface Morphology

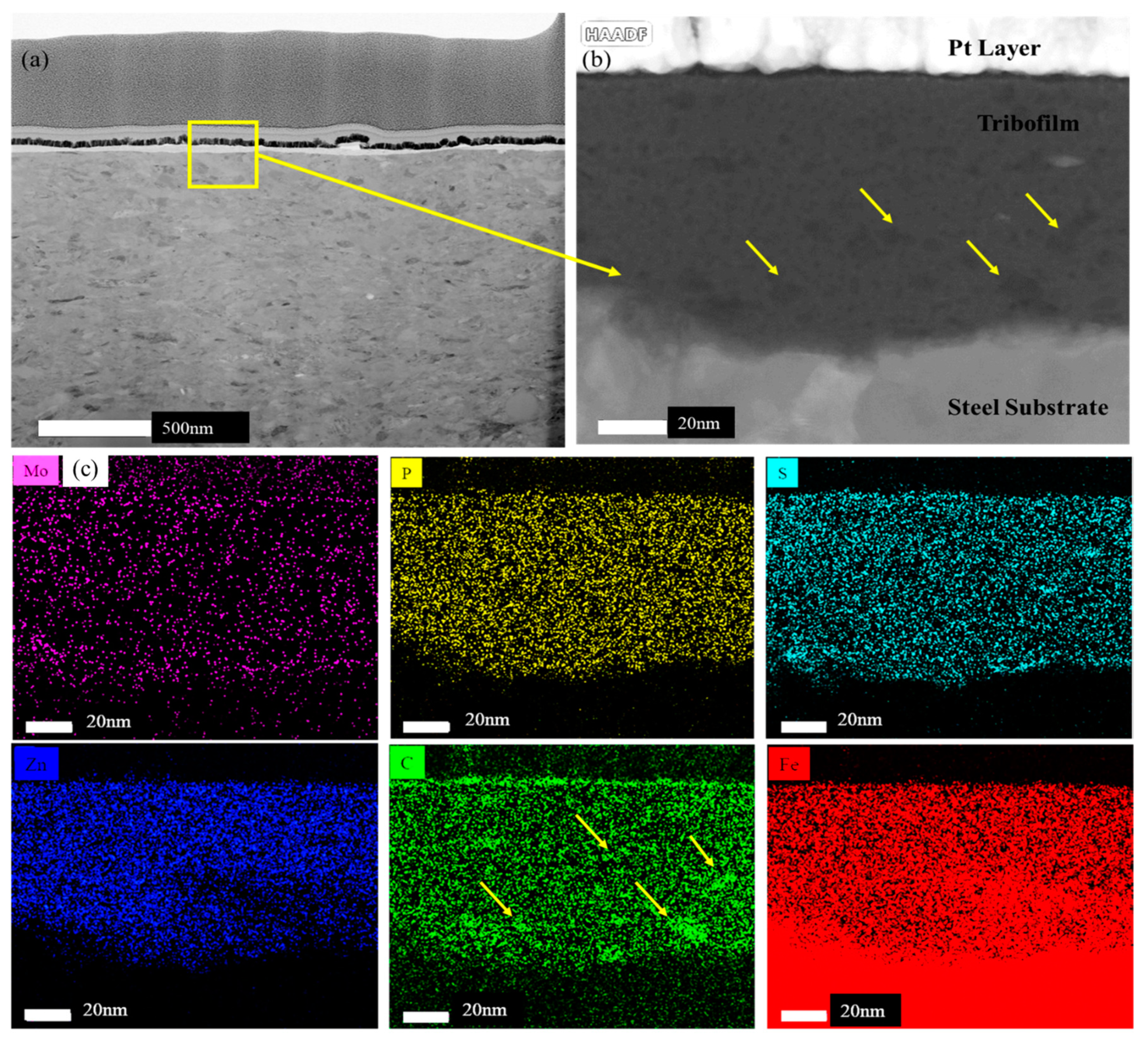

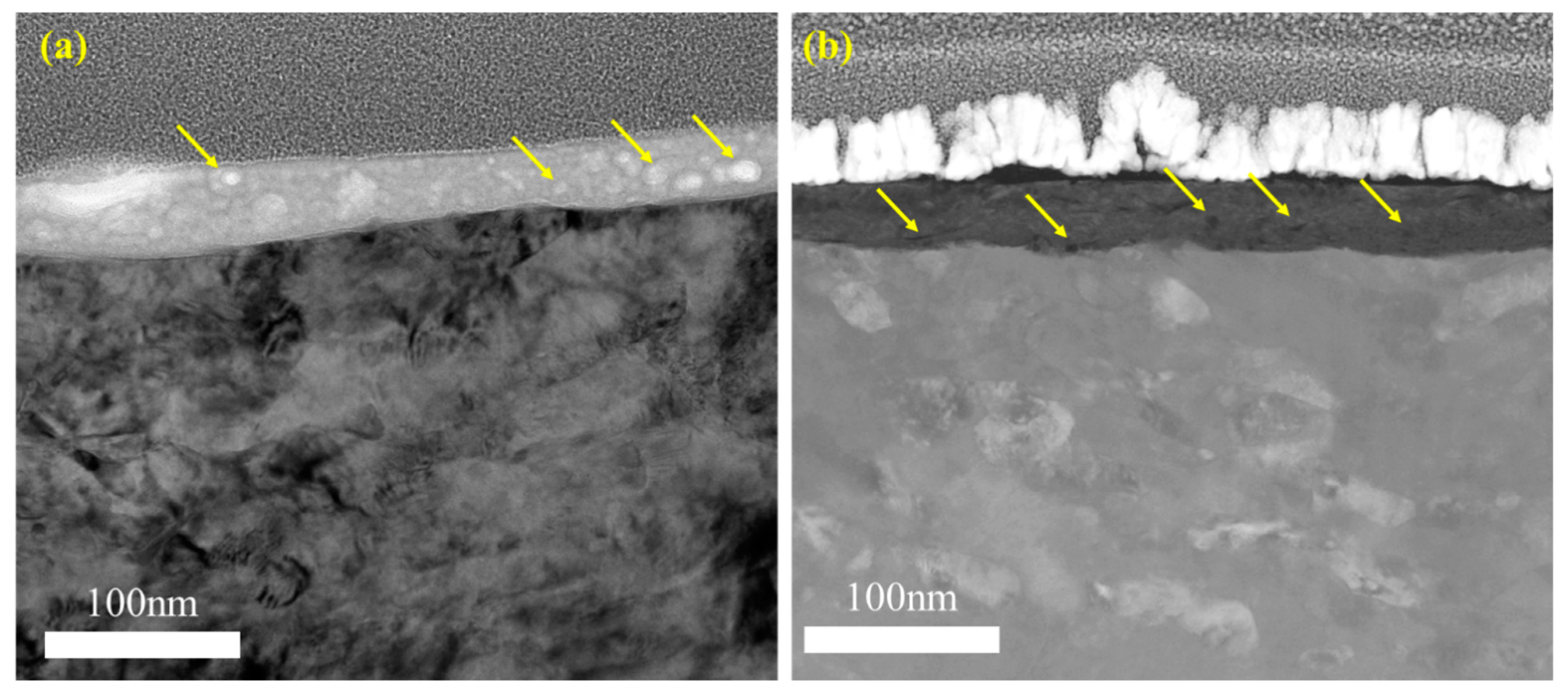

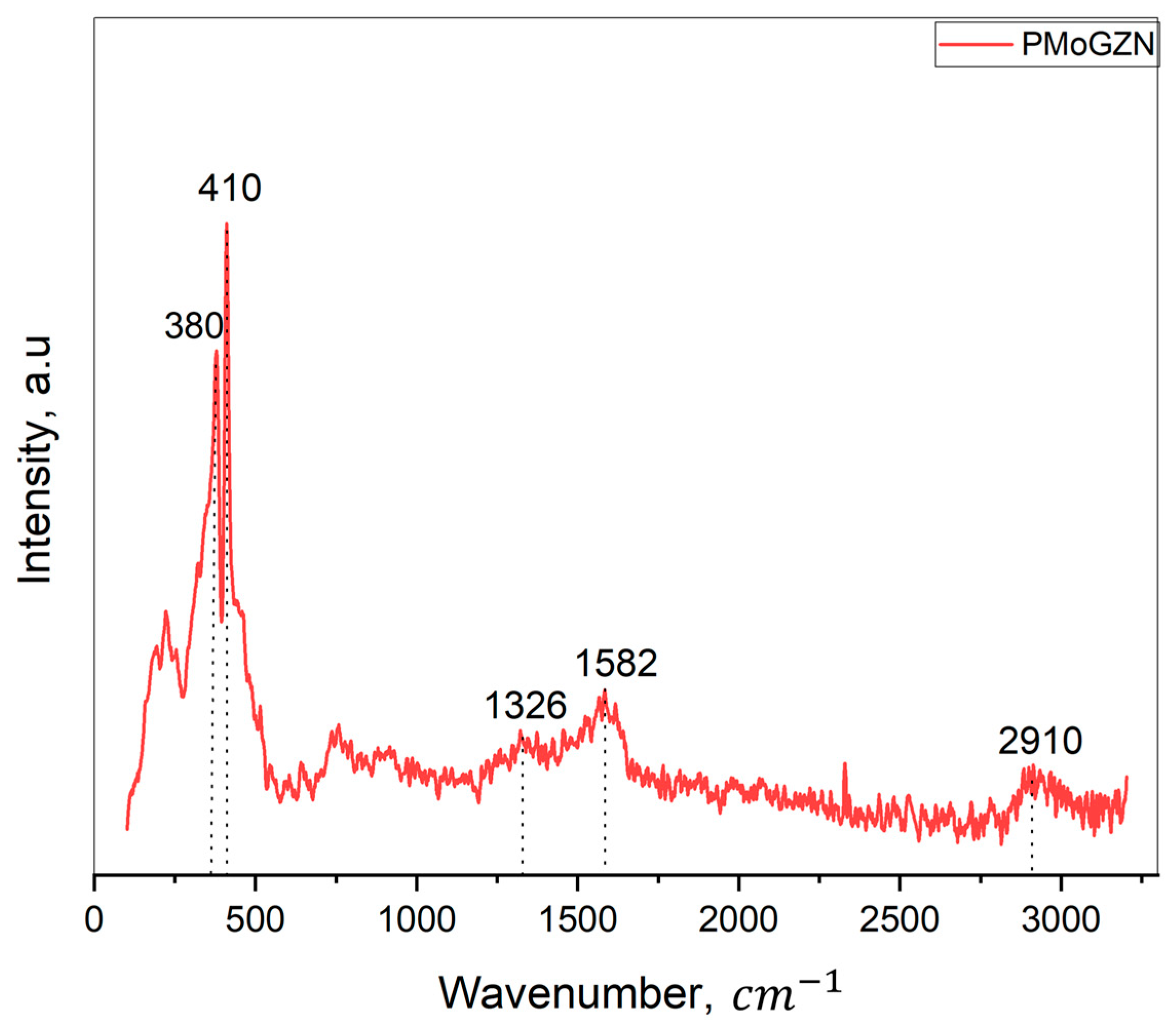

3.4. Characterisation of Tribofilm

4. Discussion

- Friction Performance and Variability

- Abrasive Nature of Nanodiamonds: Due to the hardness of NDs, they could act as abrasive particles in the case of the inappropriate integration of NDs into the tribofilm [45]. A poor dispersion or embedding of the NDs results in increasing surface roughness and, hence, increased friction [46]. The abrasive properties of the NDs can also disrupt the protective films developed by other additives, especially because of interference with MoDTC’s ability to form a uniform MoS2 tribofilm [47];

- Tribofilm Formation Delayed or Incomplete: The efficiency of NDs depends on being incorporated into a stable tribofilm. In formulations like PMoN, friction rose with time, which suggests that tribofilm formation was either delayed or incomplete. Without a stable tribofilm, NDs could have acted abrasively and increased friction due to the inappropriate formation of the protective layers [48];

- Interactions with other Additives: The interaction between NDs and other additives can be inconsistent. In some formulations, such as PMoGZN, the NDs acted synergistically to reduce friction; in other formulations, such as PMoN, they might interfere with the chemical reactions to produce a low-friction tribofilm. In the cases of some of the formulations studied here, a lack of synergy between MoDTC and NDs could have resulted in increased friction by preventing the stable MoS2 layer from being formed [41].

- 2.

- Temperature-Dependent Effects

- 3.

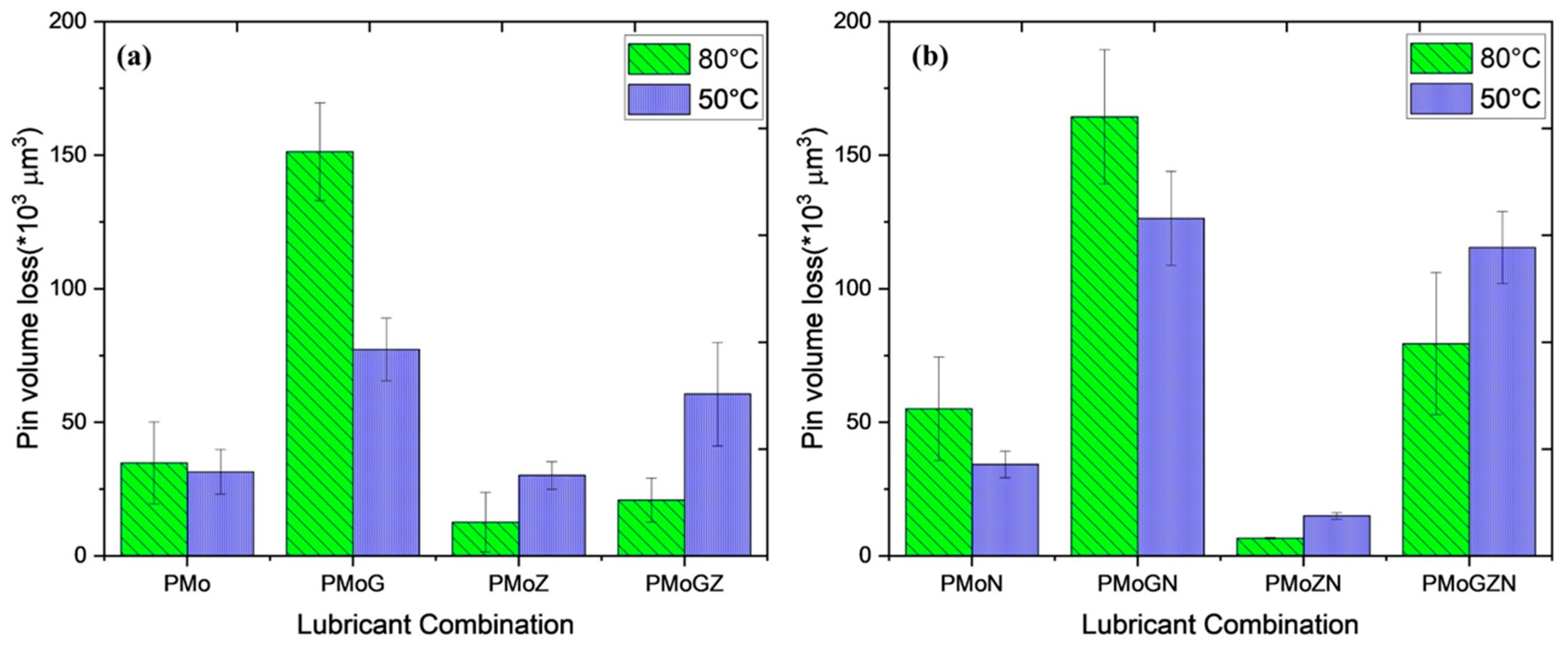

- Wear performance

- 4.

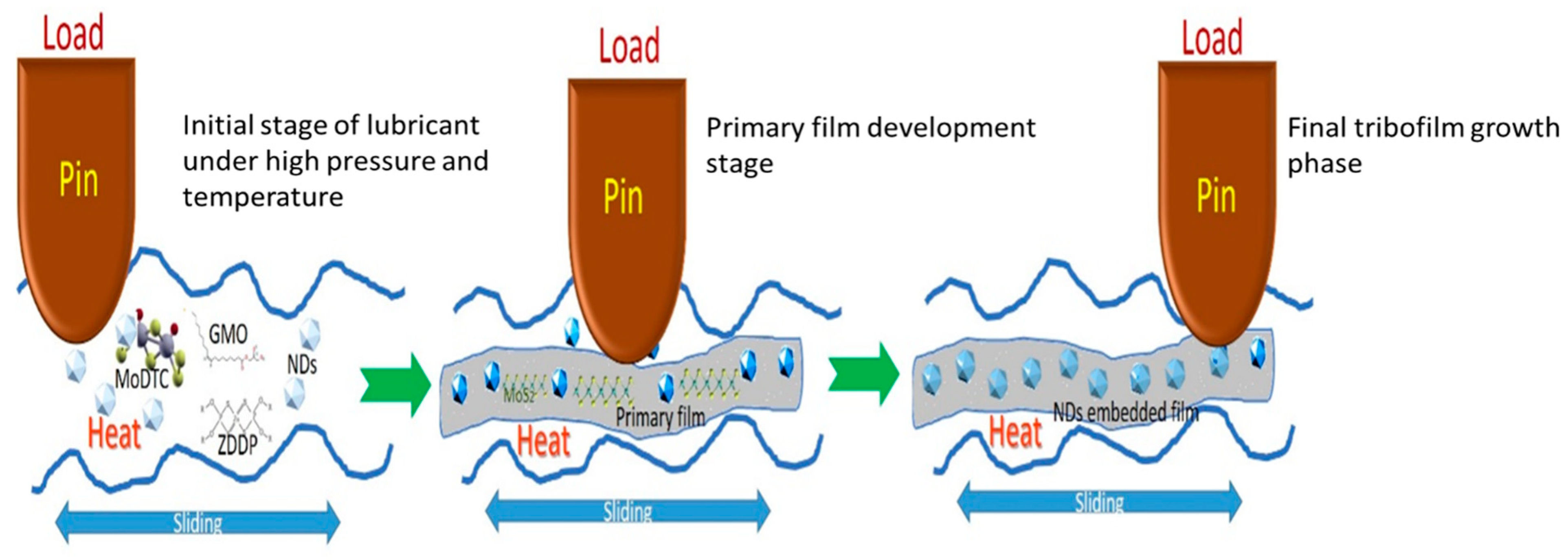

- Tribofilm Formation and Mechanical Interlocking

5. Conclusions

- The addition of NDs with widely used lubricant additives like MoDTC and ZDDP has the potential to reduce the coefficient of friction. Especially, the formulation PMoGZN, which includes MoDTC, GMO, ZDDP and NDs, at both 50 °C and 80 °C exhibited the lowest coefficient of friction, demonstrating the synergy among the additives present in the formulation. However, some exceptional cases were also visible; the PMoN formulation, which includes MoDTC and NDs, showed an antagonistic impact on friction reduction. The reason could be due to incomplete tribofilm formation and the abrasive nature of NDs when they were not integrated properly into the formed film;

- The wear results also showed mixed characteristics. NDs, if not fully embedded inside the tribofilm, could perform as abrasive particles, increasing the wear, as observed in the PMoN and PMoGN formulations. Nevertheless, the appropriate embedment of NDs can form protective tribofilm that will result in reduced wear;

- A robust thick tribofilm was formed for the observed PMoGZN lubricant formulation. The newly developed tribofilm has shown mechanical stability due to the presence of NDs. This thicker tribofilm, and the embedment of NDs inside the tribofilm, could be the reason for lower friction due to smoother sliding between the surfaces.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guegan, J.; Southby, M.; Spikes, H. Friction Modifier Additives, Synergies and Antagonisms. Tribol. Lett. 2019, 67, 83. [Google Scholar] [CrossRef]

- Wang, J.; Huang, X.; Li, Z.; Fu, C.; Wang, C.; Zheng, L.; Ren, T. Tribological behavior of a novel organic molybdenum containing dimercaptothiadiazole as a multifunctional additive in biodegradable base oil. Mater. Des. 2021, 206, 109823. [Google Scholar] [CrossRef]

- Gorbatchev, O.; Bouchet, M.D.B.; Martin, J.; Léonard, D.; Le-Mogne, T.; Iovine, R.; Thiebaut, B.; Héau, C. Friction reduction efficiency of organic Mo-containing FM additives associated to ZDDP for steel and carbon-based contacts. Tribol. Int. 2016, 99, 278–288. [Google Scholar] [CrossRef]

- Ivanov, M.G.; Mahbooba, Z.; Ivanov, D.; Smirnov, S.; Pavlyshko, S.; Osawa, E.; Brenner, D.; Shenderova, O. Nanodiamond-based oil lubricants on steel-steel and stainless steel—Hard alloy high load contact: Investigation of friction surfaces. Nanosyst. Phys. Chem. Math. 2014, 5, 160–166. [Google Scholar]

- Liu, E.; Kouame, S.D. An XPS Study on the Composition of Zinc Dialkyl Dithiophosphate Tribofilms and Their Effect on Camshaft Lobe Wear. Tribol. Trans. 2014, 57, 18–27. [Google Scholar] [CrossRef]

- Taylor, L.; Dratva, A.; Spikes, H.A. Friction and Wear Behavior of Zinc Dialkyldithiophosphate Additive. Tribol. Trans. 2000, 43, 469–479. [Google Scholar] [CrossRef]

- Taylor, L.J.; Spikes, H.A. Friction-Enhancing Properties of ZDDP Antiwear Additive: Part I—Friction and Morphology of ZDDP Reaction Films. Tribol. Trans. 2003, 46, 303–309. [Google Scholar] [CrossRef]

- Dubey, M.K.; Chaudhary, R.; Emmandi, R.; Seth, S.; Mahapatra, R.; Harinarain, A.; Ramakumar, S. Tribological evaluation of passenger car engine oil: Effect of friction modifiers. Results Eng. 2022, 16, 100727. [Google Scholar] [CrossRef]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A.; Priest, M.; Green, J.H. ZDDP and MoDTC interactions in boundary lubrication—The effect of temperature and ZDDP/MoDTC ratio. Tribol. Int. 2006, 39, 1545–1557. [Google Scholar] [CrossRef]

- Du, S.; Yue, W.; Wang, Y.; She, D.; Huang, H.; Fu, Z. Synergistic effects between sulfurized-nanocrystallized 316L steel and MoDTC lubricating oil additive for improvement of tribological performances. Tribol. Int. 2016, 94, 530–540. [Google Scholar] [CrossRef]

- Bovington, C.; Castle, R. Lubricant chemistry including the impact of legislation. In Boundary and Mixed Lubrication; Dowson, D., Priest, M., Dalmaz, G., Lubrecht, A.A., Eds.; Tribology Series; Elsevier: Amsterdam, The Netherlands, 2002; Volume 40, pp. 141–146. [Google Scholar] [CrossRef]

- Kim, D.; Toops, T.J.; Nguyen, K.; Lance, M.J.; Qu, J. Impact of Primary and Secondary ZDDP and Ionic Liquid as Lubricant Oil Additives on the Performance and Physicochemical Properties of Pd-Based Three-Way Catalysts. Catalysts 2021, 11, 878. [Google Scholar] [CrossRef]

- Jiang, S.; Yuan, C.; Wong, J.S.S. Effectiveness of glycerol-monooleate in high-performance polymer tribo-systems. Tribol. Int. 2021, 155, 106753. [Google Scholar] [CrossRef]

- Fry, B.M.; Chui, M.Y.; Moody, G.; Wong, J.S.S. Interactions between organic friction modifier additives. Tribol. Int. 2020, 151, 106438. [Google Scholar] [CrossRef]

- Massoud, T.; De Matos, R.P.; Le Mogne, T.; Belin, M.; Cobian, M.; Thiébaut, B.; Loehlé, S.; Dahlem, F.; Minfray, C. Effect of ZDDP on lubrication mechanisms of linear fatty amines under boundary lubrication conditions. Tribol. Int. 2020, 141, 105954. [Google Scholar] [CrossRef]

- Topolovec-Miklozic, K.; Forbus, T.R.; Spikes, H.A. Performance of Friction Modifiers on ZDDP-Generated Surfaces. In Proceedings of the STLE/ASME 2006 International Joint Tribology Conference, San Antonio, TX, USA, 23–25 October 2006; American Society of Mechanical Engineers Digital Collection. ASME: New York, NY, USA, 2008; pp. 159–167. [Google Scholar] [CrossRef]

- Cyriac, F.; Yi, T.X.; Poornachary, S.K.; Chow, P.S. Effect of temperature on tribological performance of organic friction modifier and anti-wear additive: Insights from friction, surface (ToF-SIMS and EDX) and wear analysis. Tribol. Int. 2021, 157, 106896. [Google Scholar] [CrossRef]

- Zahid, R.; Hassan, M.B.H.; Alabdulkarem, A.; Varman, M.; Mufti, R.A.; Kalam, A.; Zulkifli, N.W.B.M.; Gulzar, M.; Lee, T. Investigation of the tribochemical interactions of a tungsten-doped diamond-like carbon coating (W-DLC) with formulated palm trimethylolpropane ester (TMP) and polyalphaolefin (PAO). RSC Adv. 2017, 7, 26513–26531. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Zou, Q.; Wang, J.; Guo, S.; Yuan, Y.; Jiang, Q. Role of nano-sized materials as lubricant additives in friction and wear reduction: A review. Wear 2022, 490–491, 204206. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A Review of Friction Performance of Lubricants with Nano Additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Chauhan, P.; Mamatha, T.G. A review on tribological performance of lubricants with nanoparticles additives. Mater. Today Proc. 2020, 25, 586–591. [Google Scholar] [CrossRef]

- Chu, H.Y.; Hsu, W.C.; Lin, J.F. The anti-scuffing performance of diamond nano-particles as an oil additive. Wear 2010, 268, 960–967. [Google Scholar] [CrossRef]

- Kim, S.-T.; Woo, J.-Y.; Lee, Y.-Z. Friction, Wear, and Scuffing Characteristics of Marine Engine Lubricants with Nanodiamond Particles. Tribol. Trans. 2016, 59, 1098–1103. [Google Scholar] [CrossRef]

- Marko, M.; Kyle, J.; Branson, B.; Terrell, E. Tribological Improvements of Dispersed Nanodiamond Additives in Lubricating Mineral Oil. J. Tribol. 2014, 137, 011802. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Liu, X.; Zhou, L. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol. Int. 2019, 129, 75–81. [Google Scholar] [CrossRef]

- Chen, S.; Ding, Q.; Gu, Y.; Quan, X.; Ma, Y.; Jia, Y.; Xie, H.; Tang, J. Study of Tribological Properties of Fullerenol and Nanodiamonds as Additives in Water-Based Lubricants for Amorphous Carbon (a-C) Coatings. Nanomaterials 2022, 12, 139. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Wang, Z.; Yuan, X.; Zhang, T.; Ma, S.; Chen, X.; Xu, J. Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring. Nanotechnol. Rev. 2020, 9, 455–464. [Google Scholar] [CrossRef]

- Piya, A.K.; Yang, L.; Omar, A.A.S.; Emami, N.; Morina, A. Synergistic lubrication mechanism of nanodiamonds with organic friction modifier. Carbon 2024, 218, 118742. [Google Scholar] [CrossRef]

- Acharya, B.; Avva, K.S.; Thapa, B.; Pardue, T.N.; Krim, J. Synergistic Effect of Nanodiamond and Phosphate Ester Anti-Wear Additive Blends. Lubricants 2018, 6, 56. [Google Scholar] [CrossRef]

- Espejo, C.; Wang, C.; Thiébaut, B.; Charrin, C.; Neville, A.; Morina, A. The role of MoDTC tribochemistry in engine tribology performance. A Raman microscopy investigation. Tribol. Int. 2020, 150, 106366. [Google Scholar] [CrossRef]

- Wang, W.; Yu, M.; Ma, J.; Jia, Y. Tribological Properties of Nanoparticles in the Presence of MoDTC. Lubricants 2023, 11, 132. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Peng, W.; Zare, Y.; Rhee, K.Y. Effects of Size and Aggregation/Agglomeration of Nanoparticles on the Interfacial/Interphase Properties and Tensile Strength of Polymer Nanocomposites. Nanoscale Res. Lett. 2018, 13, 214. [Google Scholar] [CrossRef]

- Al Sheikh Omar, A.; Salehi, F.M.; Farooq, U.; Morina, A.; Neville, A. Chemical and physical assessment of engine oils degradation and additive depletion by soot. Tribol. Int. 2021, 160, 107054. [Google Scholar] [CrossRef]

- Xu, D.; Wang, C.; Espejo, C.; Wang, J.; Neville, A.; Morina, A. Understanding the Friction Reduction Mechanism Based on Molybdenum Disulfide Tribofilm Formation and Removal. Langmuir 2018, 34, 13523–13533. [Google Scholar] [CrossRef]

- Muraki, M.; Yanagi, Y.; Sakaguchi, K. Synergistic effect on frictional characteristics under rolling-sliding conditions due to a combination of molybdenum dialkyldithiocarbamate and zinc dialkyldithiophosphate. Tribol. Int. 1997, 30, 69–75. [Google Scholar] [CrossRef]

- Kasrai, M.; Cutler, J.N.; Gore, K.; Canning, G.; Bancroft, G.M.; Tan, K.H. The Chemistry of Antiwear Films Generated by the Combination of ZDDP and MoDTC Examined by X-ray Absorption Spectroscopy. Tribol. Trans. 1998, 41, 69–77. [Google Scholar] [CrossRef]

- Hwang, S.-W.; Chang, S.-C.; Zhang, T.; Kim, H.-K. Tribology behavior of a lubricant with nano-diamond particles on steel. Int. J. Eng. Technol. 2017, 9, 169–174. [Google Scholar] [CrossRef]

- Raina, A.; Anand, A. Effect of nanodiamond on friction and wear behavior of metal dichalcogenides in synthetic oil. Appl. Nanosci. 2018, 8, 581–591. [Google Scholar] [CrossRef]

- Shenderova, O.; Vargas, A.; Turner, S.; Ivanov, D.; Ivanov, M. Nanodiamond-Based Nanolubricants: Investigation of Friction Surfaces. Tribol. Trans. 2014, 57, 1051–1057. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Z.; Song, Q.; Zhang, X.; Jiao, S.; Xu, Y.; Xu, Q.; Sheng, D. Tribological performance of organic molybdenum in the presence of organic friction modifier. PLoS ONE 2021, 16, e0252203. [Google Scholar] [CrossRef]

- Tomala, A.; Vengudusamy, B.; Rodríguez Ripoll, M.; Naveira Suarez, A.; Remškar, M.; Rosentsveig, R. “Interaction Between Selected MoS2 Nanoparticles and ZDDP Tribofilms. Tribol. Lett. 2015, 59, 26. [Google Scholar] [CrossRef]

- Topolovec Miklozic, K.; Graham, J.; Spikes, H. Chemical and Physical Analysis of Reaction Films Formed by Molybdenum Dialkyl-Dithiocarbamate Friction Modifier Additive Using Raman and Atomic Force Microscopy. Tribol. Lett. 2001, 11, 71–81. [Google Scholar] [CrossRef]

- Mermoux, M.; Chang, S.; Girard, H.A.; Arnault, J.-C. Raman spectroscopy study of detonation nanodiamond. Diam. Relat. Mater. 2018, 87, 248–260. [Google Scholar] [CrossRef]

- Zhao, W.; Duan, F. Friction properties of carbon nanoparticles (nanodiamond and nanoscroll) confined between DLC and a-SiO2 surfaces. Tribol. Int. 2020, 145, 106153. [Google Scholar] [CrossRef]

- Ivanov, M.; Shenderova, O. Nanodiamond-based nanolubricants for motor oils. Curr. Opin. Solid State Mater. Sci. 2017, 21, 17–24. [Google Scholar] [CrossRef]

- Rai, Y.; Neville, A.; Morina, A. Transient processes of MoS2 tribofilm formation under boundary lubrication. Lubr. Sci. 2016, 28, 449–471. [Google Scholar] [CrossRef]

- Tsai, A.E.; Komvopoulos, K. Dynamics of Tribofilm Formation in Boundary Lubrication Investigated Using In Situ Measurements of the Friction Force and Contact Voltage. Materials 2024, 17, 1335. [Google Scholar] [CrossRef] [PubMed]

- Garcia, C.E.; Ueda, M.; Spikes, H.; Wong, J.S.S. Temperature dependence of molybdenum dialkyl dithiocarbamate (MoDTC) tribofilms via time-resolved Raman spectroscopy. Sci. Rep. 2021, 11, 3621. [Google Scholar] [CrossRef] [PubMed]

- Kano, M.; Yasuda, Y.; Ye, J.P. The effect of ZDDP and MoDTC additives in engine oil on the friction properties of DLC-coated and steel cam followers. Lubr. Sci. 2004, 17, 95–103. [Google Scholar] [CrossRef]

- Acharya, B.; Seed, C.M.; Krim, J. Shear activation of ZDDP reaction films in the presence and absence of nanodiamonds. Appl. Surf. Sci. Adv. 2022, 7, 100214. [Google Scholar] [CrossRef]

- Peeters, S.; Restuccia, P.; Loehlé, S.; Thiebaut, B.; Righi, M.C. Tribochemical Reactions of MoDTC Lubricant Additives with Iron by Quantum Mechanics/Molecular Mechanics Simulations. J. Phys. Chem. C 2020, 124, 13688–13694. [Google Scholar] [CrossRef]

| No. | Lubricant ID | PAO Oil (P) wt% | GMO (G) wt% | ZDDP (Z) wt% | Nanodiamonds (N) wt% | MoDTC (Mo) wt% |

|---|---|---|---|---|---|---|

| 1 | PMo | 99 | 0 | 0 | 0 | 1 |

| 2 | PMoG | 98 | 1 | 0 | 0 | 1 |

| 3 | PMoZ | 98.8 | 0 | 0.2 | 0 | 1 |

| 4 | PMoGZ | 97.8 | 1 | 0.2 | 0 | 1 |

| 5 | PMoN | 98.95 | 0 | 0 | 0.05 | 1 |

| 6 | PMoGN | 97.95 | 1 | 0 | 0.05 | 1 |

| 7 | PMoZN | 98.75 | 0 | 0.2 | 0.05 | 1 |

| 8 | PMoGZN | 97.75 | 1 | 0.2 | 0.05 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piya, A.K.; Yang, L.; Emami, N.; Morina, A. Effect of Nanodiamonds on Friction Reduction Performance in Presence of Organic and Inorganic Friction Modifiers. Lubricants 2025, 13, 1. https://doi.org/10.3390/lubricants13010001

Piya AK, Yang L, Emami N, Morina A. Effect of Nanodiamonds on Friction Reduction Performance in Presence of Organic and Inorganic Friction Modifiers. Lubricants. 2025; 13(1):1. https://doi.org/10.3390/lubricants13010001

Chicago/Turabian StylePiya, A. K., L. Yang, N. Emami, and A. Morina. 2025. "Effect of Nanodiamonds on Friction Reduction Performance in Presence of Organic and Inorganic Friction Modifiers" Lubricants 13, no. 1: 1. https://doi.org/10.3390/lubricants13010001

APA StylePiya, A. K., Yang, L., Emami, N., & Morina, A. (2025). Effect of Nanodiamonds on Friction Reduction Performance in Presence of Organic and Inorganic Friction Modifiers. Lubricants, 13(1), 1. https://doi.org/10.3390/lubricants13010001