Abstract

The demand for an improvement in the tribological properties of lubricants used in various industrial plants, the automotive industry, and other power transmissions has resulted in the development of a whole family of improved lubricants based on nanotechnology. Especially important are nanotube additives, which significantly improve the tribological properties of lubricants, primarily by reducing the friction coefficient and wear of the coupled elements but also by reducing the temperature load and increasing the stability of the oil film between the lubricated surfaces. The properties of nanotube-based additives were further improved using elements such as metal oxides and compounds based on titanium, molybdenum, aluminum, etc. This paper presents the results obtained in the field of research and application of nanocomposite lubricant additives. It also gives a partial comparative analysis of the research conducted in this field. The primary goal of this paper is to analyze the research results in the field of the application of nanotubes in lubricants and to indicate the importance of their application, such as improving the tribological properties of machines and reducing power losses. Furthermore, this paper shows the negative impact of nanoparticles on the environment and human health and the costs of applying some types of nanoparticles.

1. Introduction

Oils used in vehicles, machine systems, and the industry are often subjected to heavy loads, leading to high temperatures and pressures. This results in higher friction and surface damage, which, in turn, can cause more frequent failure, deformation, and damage. In order to prevent failure, conventional engine and gear oils disperse extreme pressure and anti-wear additives, which react with metal surfaces, forming an easily sheared layer, thus preventing severe wear and the stoppage of a specific assembly or unit.

Many researchers have tried to improve the tribological properties of lubricants by reducing the coefficients of friction and wear in mechanical systems. Various types of additives are added to the base mineral oil, such as phosphorus, sulfur, nitrogen, and chlorine compounds, to improve anti-wear and extreme pressure. Recently, nanoparticles have emerged as a new type of additive due to their size, shape, and other properties. A significant number of researchers have pointed out that the addition of nanoparticles to the lubricant is effective in reducing wear and friction.

Polymer composites have been increasingly used in tribological applications to replace metallic materials due to their ease of fabrication and excellent wear resistance [1].

Allotropic carbon modifications, such as graphite, fullerenes, carbon nanotubes, and graphene, have attracted the interest of many scientists and researchers primarily because of their exceptional properties. Carbon nanotubes (CNTs), some types of fullerenes similar to graphite, and some types of carbon nanotube composites possess probably the strongest bonds in solid materials. CNTs are expected to exhibit excellent lubricating performance because they reduce the wear of lubricated elements as a result of lower coefficients of friction and wear [1,2].

Since the discovery of carbon nanotubes in 1991, there has been a great interest in their application due to their exceptional mechanical, thermal, electrical, chemical, and optical properties. Due to their excellent mechanical properties, carbon nanotubes have been studied primarily for tribological systems as oil additives for various lubrication purposes [3].

Since the development of nanotechnology, it has been possible to add nanoparticles to lubricants because of their excellent tribological properties. Due to the nanometers’ size, they can easily enter the contact zone between the surfaces they lubricate, thus significantly improving the tribological properties of the lubricant. Compared to organic additives, nanoparticles are thermally stable at elevated high temperatures, and they do not need an induction period to obtain tribological properties [4]. A large number of nanoparticles have been used as additives for lubricants, including metals [5], metal oxides [6,7,8], metal sulfides [9,10,11], carbon materials [12], and rare compounds in nature [13].

The significance of this paper lies in the fact that it reviews and presents the results of investigations conducted in the area of application of nanotube-based lubricant additives with a different percentage of additives, aiming to improve the tribological properties of the lubricant, improve efficiency, and reduce friction and temperature.

2. Tribological Application of Carbon Nanotubes in Oils

The application of CNTs as an antiwear additive to improve the tribological properties of lubricants is a very emerging topic of research and has been extensively studied by many researchers [14,15,16,17,18,19,20,21,22,23].

The application of carbon nanotubes as a motor oil additive is particularly important, and it was the subject of a patent [24]. The liquid oil additive that contains CNT is commercially available.

Because of the need to lower tribologically induced CO2 emissions, the viscosity of engine oil has been extremely reduced in recent years. The next step is to replace the standard lubricating oil with suitable oils containing CNT-based additives [24]. A detailed computer simulation and tribological studies of such engine lubricant additives have shown their impressive potential in reducing engine assembly friction [25].

The addition of micro- and nanoparticles of elements such as copper, tungsten, molybdenum, and molybdenum disulfide to lubricating oil has proven to be an effective method of reducing engine friction. It was experimentally shown that the deposition of these particles on the surface of elements in contact reduces friction and surface wear [26,27,28].

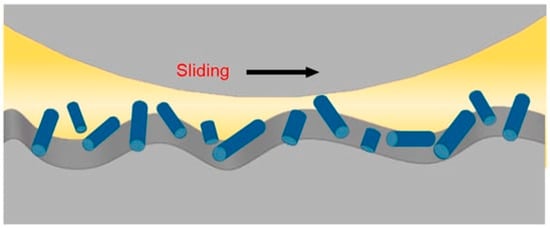

When considering the positive effects of nanotube additives in oils, the lubrication mechanism during their application must be considered. Their lubrication mechanism is similar to the principle of the operation of rolling bearings, which is shown schematically in Figure 1 [27].

Figure 1.

The “rolling bearing” effect of nanomaterials [27].

In study [28], when single-walled carbon nanotubes (SWCNTs) were added to lubricating oil, a reduction in friction between the contacting metal surfaces was observed. With 1% of CNTs studied under different pressures, the lowest friction coefficient achieved was 0.08. Based on the published results [28] of friction tests in tribometers, it can be concluded that the optimal mass fraction of CNTs is 1%, and a higher concentration is ineffective. Nevertheless, the change in the friction coefficient, recorded for the mass concentration of nanotubes limited to 0.5%, shows a significant reduction in frictional forces only after a large number of test cycles. Based on similar tests [29], the friction coefficient was found to be 0.087 when the mass fraction of CNTs in the oil was 0.5%. The test results [28] clearly indicate that the CNT-based additives reduce friction better than graphite-based ones or the additives based on C60 fullerene. On the other hand, some other studies [29] show that oils with added nanotubes yield a higher friction coefficient than oils with additives with spherical nanoparticles. This was explained in paper [29], which proved the hypothesis given in paper [30] that nanoparticles act as rolling (nanotubes) or ball bearing (spherical nanoparticles).

Furthermore, researchers have concluded that the lubrication performance improves with the reduction in size of the particle suspended in the mineral oil [31]. Yet, when the average size of suspended particles in the oil exceeded a few micrometers, the lubrication was poorer compared to mineral oils without additives [19,32].

Given the conditions in the engine, the fact that there is a dramatic increase in the oil film thickness at low speeds of the elements in contact is especially important for the selection of additives in oils [19,32]. This effect was observed for lubricants with CNT concentrations in the range of 0.01% to 0.1%. Bearing in mind the intense internal friction in oils, it is vital to study the influence of CNTs on the oil rheological parameters, both for those with nanotubes and those with spherical nanoparticles [33]. The improvement in thermal conductivity in engines, as a result of the addition of CNTs to oil, is very significant [33,34]. The addition of other nanoparticles, such as molybdenum disulfide, to CNTs, has positive effects on increasing thermal conductivity, which makes the lubricating oil even more effective [35,36].

Carbon nanotubes and other nanomaterials [37] are characterized by a strong tendency towards agglomeration, i.e., the deposition of particles in the fluid, that form the tribological properties of lubricants. A large surface area containing carbon nanotubes causes strong attraction forces which form visible agglomerates (deposited material) several tens or hundreds of microns in size. The available literature shows that lubricants with huge CNT agglomerates have weaker tribological properties compared to oils with well-dispersed CNTs [19,30,32]. While some tribometric studies of CNT agglomeration show that lubricants with CNTs are less effective in reducing friction and wear, the impact of using lubricants with CNTs on conventional engines needs to be studied more comprehensively. The oil film agglomerate (with furrows of several tens of micrometers in diameter) temporarily blocks the positive effects of CNTs so that the added CNTs cease to fulfill their function in the oil [14].

The remaining agglomerates probably block the flow in small-diameter oil supply tubes, such as the ones leading to turbochargers or timing control valves. This can damage some engine parts or even destroy the whole engine. Therefore, achieving the effective dispersion of CNTs in lubricants is essential for reducing friction losses in internal combustion engines [14]. Ethylene glycol and ethyl alcohol are hydrocarbons that help achieve the good dispersion of CNTs in oils relatively easily.

Single-walled carbon nanotube (SWCNT) additives form “bundles” out of adjacent, parallel CNT sidewalls. Multi-walled carbon nanotubes (MWCNTs) are entangled in chaotically bonded cross fibers, forming a mesh-like structure [19,38,39]. The number of contacts that can be formed between neighboring MWCNTs increases dramatically with the length of the CNTs. Therefore, the binding of the clustered network of long MWCNTs is very strong, and each contact acts as a crosslink of the network [39].

Based on paper [14], the following conclusions can be drawn:

- The use of oil with MWCNTs at a concentration of about 0.5% leads to a significant decrease in frictional losses.

- No-engine tribological tests show that adding CNTs to oil can reduce friction both in the boundary lubrication regime and in the elastohydrodynamic regime [19]. Favorable results in terms of reducing friction and fuel consumption obtained at low engine speeds suggest the positive effects of using CNTs in the boundary lubrication regime.

- Adding CNT to engine oil can significantly decrease engine friction losses. The high thermal conductivity of the lubricant [19,34] plays a crucial role in cooling the vital parts of the engine, such as the pistons [40,41,42].

Research has shown [1,43] that beads in MWCNT additives can form stable suspensions and improve anti-wear and anti-friction properties in machine assemblies, especially engines. Several researchers have investigated engine oils with dispersed nanoparticles with the aim of improving tribological properties [43].

Testing mineral oil with dispersed graphite and MWCNTs in a concentration from 0.1 to 0.6% using a pin-on-disc tribometer and a four-ball tester, it was determined that MWCNTs are better than graphite, i.e., that wear decreased by 70–75%, while the load bearing capacity increased by 20% [44]. Using Paraffin oil dispersed with stearic acid-modified MWCNTs in 0.45 wt% and the ring-on-plate apparatus, it was noticed that the friction coefficient decreased by 10% and the wear decreased by 30–40%. It was shown that the friction reduction depended both on the type of nanomaterials in the oil and their stability [45]. In an experiment with oil and water suspensions with SWCNTs and MWCNTs in concentrations from 0.01 to 0.05 wt% using a twin-disk machine for measurements in rolling and sliding contacts, the measured friction coefficients and the wear losses were lower both for the oil and water dispersed with nanotubes, with the friction coefficient values as low as 0.063. It was concluded that the decrease in friction and high-wear resistance was due to the formation of an amorphous carbon film transferred from the CNT to the surface it was in contact with [46]. In the tests with mineral base oil with CuO (9 nm) in concentrations from 0.5 to 2 wt% using the disc-on-disc friction and wear test, the results showed that the friction coefficient decreased by 14% and 23% for the CuO nanoparticles in concentrations of 1% and 2%, respectively. It was shown that reducing the real contact area due to nanomaterials dispersed in the lubricant meant it was possible to achieve a significant reduction in the friction force [6]. In the tests with poly-alpha-olefin (PAO6) dispersed with CuO, ZnO, and ZrO2 in a concentration from 0.5% to 2% wt, using a four-ball tester, the results indicated that, in the conditions of extreme pressure, the behavior of the lubricant with nanoparticles depended on the size and hardness of the nanoparticles [47]. When testing water dispersed with dodecyl sulfate and modified by oxidized MWCNTs at a concentration of 0.1 wt%, using a four-ball tester, it was determined that the oxidation of MWCNTs produced a deficiency on the surface, which led to the formation of better suspensions. A significant improvement in tribological properties was obtained with surfactant-modified MWCNTs, compared to unmodified MWCNTs, which suggests the strong influence of suspension stability [48]. In tests with poly-alpha-olefin fluid dispersed with a carbon nanoarc and graphite powder at 0.1% using a pin-on-flat tribometer, it was determined that carbon onions displayed better tribological properties than graphite powder. It was also found that the tribofilm formed by the carbon onions converted the wear particles into ultrafine lubricious iron oxides; therefore, it prevented further abrasive wear process [49]. Using Mobil gear 627 and paraffin mineral oil in 0.1% to 2 wt% on a four-ball tribotester, a 50% reduction in friction and an increase in the weld load by up to 100% was observed when MWCNTs were used as a lubricant additive. The deposition of MWCNT nanoparticles on the worn surface leads to a decrease in shear stresses, thus improving tribological properties [3]. In the tests involving raw mineral oil (Sun Oil, Japan) dispersed with fullerenes in 0.01 wt% to 0.05 wt% on a disk-on-disk tribotester, the results showed that fullerene reduced friction between metal surfaces by 30%. It was further determined that the volume fraction was the key factor to control the friction and wear [50]. The results obtained in the tests with commercial transmission oil were dispersed with nanographite (55 nm) in 0.1 wt% to 0.5 wt% and Alkyl aryl sulfonate as a dispersant, performed on a disk-on-disk tribotester, showed that the dispersion of nanographite in the lubricant boosted the lubrication characteristics. It can be concluded that the possible reason for an improvement in the tribological properties is the fact that nanoparticles act as ball-bearing spacers between the friction surfaces, reducing the contact between the plates [51].

In the experiments with four types of oils dispersed with TiO2, Al2O3, CuO, and MWCNTs in 0.01 wt% to 0.1 wt% on a four-ball T-02U tribotester, it was determined that all the nanomaterials improved the tribological properties, with MWCNT additives yielding the best results. The tribosintering of nanomaterials on contact surfaces is considered to be the main reason for improving the tribological properties [52]. Testing commercial oils dispersed with surface-modified nanodiamonds in 0.01 wt% using a block-on-ring test setup, it was established that nanodiamond additives in oils improved the anti-wear properties and decreased the oil temperature under load compared to mineral oils. The good anti-wear properties of nanodiamond additives are attributed to the formation of a hard and porous layer between the contact surfaces [53]. When testing engine oil dispersed with Cu and TiO2 nanoprticles in 0.025 wt% to 0.1 wt%, using a pin-on-disk tester and engine test rig, it was determined that the copper nanoparticle-dispersed lubricant were given the best results, primarily due to the increase in the thermal efficiency of the engine [54]. In the tests with an EP 140 transmission of oil dispersed with WS2 and MoS2 nanomaterials in 0.5 wt% using a four-ball tester, it was determined that lubricant dispersed with WS2 nanoparticles managed to withstand a higher load, and it had given a higher load wear index compared to the lubricant dispersed with MoS2 nanoparticles. The reason for the better performance of WS2 nanoparticles is attributed to their lower hardness, resulting in better deposition on the contact surfaces under load [55]. In the tests with engine oil dispersed with long MWCNT particles using a four-ball tester, it was found that the added additives improved the stability of the oil, thereby significantly reducing the friction and wear of engine parts [56]. It is especially important to point out the fact that when choosing a lubricating oil, one must take into account the lubricant viscosity because an increase in the lubricant viscosity increases the temperature, friction resistance, and the losses in gear transmissions, as shown in the experiments [57].

The tests with polyalphaolefin (PAO6) lubricating fluids dispersed with carbon-coated nanoparticles in 0.5 to 2 wt%, using a block on-ring tribometer and four-ball tester, showed that carbon nanoparticles with copper decreased wear and increased the load-carrying capacity of polyalphaolefins in the lubricant between the contact surfaces [58].

Scientific studies suggest that it is desirable to determine the optimal CNT content in engine and transmission oils. The relatively good stability of CNT-based oil additives can be taken as a starting point for further research of these substances for applications beyond vehicle engines and transmissions.

Lubricants with additives based on carbon nanoparticles have found a wide application in various industrial plants, primarily as oils with excellent characteristics in terms of reducing the coefficient of friction. They are used in transmission systems of working, mining, and energy machines and vehicles. They are especially used in machines that operate in difficult conditions in terms of high pressures and temperatures and are exposed to harmful influences in aggressive environments. Due to their unique physical and mechanical characteristics, lubricants based on carbon nanotubes have a lot of potential applications, mainly in improving lubrication. Lubricants with nanotubes have proven to be extremely useful in microtribological and biotribological applications. These lubricants have proven to be very useful in planetary, worm, and cycloid power transmission systems, but also as engine oils in power units [59].

3. Tribological Application of Titanium Oxide Nanotubes in Oils

Metal oxides are commonly added to the base lubricants as additives with the main purpose of reducing the friction and wear of elements in contact [59].

Titanium oxide TiO2, in combination with Cu, is one of the most frequently applied additives for nanotubes in lubricating oils. It has been shown that adding two different particles to the lubricant has the strongest effect on the reduction in friction [60]. Nanotubes with TiO2 additives are considered to be an effective heterogeneous catalyst for the ring-opening of epoxides [17]. It has been proven that even after several cycles of reactions, the catalyst remains weakened. Nanotubes with added TiO2 particles for engine and transmission oils significantly reduce friction and increase wear protection [60].

The researchers studied the effect of nanoparticles on the tribological behavior of chemically modified vegetables, so they chemically modified crude rapeseed oil via epoxidation, hydroxylation, and esterification in order to improve oxidation stability and cold flow behavior. It was concluded that the addition of TiO2 nanoparticles improved the lubrication properties (the friction coefficient was reduced by 15.2%) of rapeseed oil compared to the use of metal oxide microparticles in mineral oil (the friction coefficient was reduced by 6.9%). This is attributed to the fact that spherical TiO2 particles have a lower aspect ratio. In addition, when chemically modified rapeseed oil with TiO2 particles was used as an additive, the wear was reduced by 6.1%. Furthermore, since TiO2 nanoparticles are highly soluble in rapeseed oil, they did not deposit even after 80 h [17].

Several studies have shown that using additives based on TiO2 nanoparticles in 0.25 wt% further reduces and stabilizes the coefficient of friction. The addition of TiO2 nanoparticles yields better results in the reduction and stabilization of the friction coefficient compared to the addition of P25 particles, which can be due to the formation of TiO2 films on the sliding surfaces [61,62].

Compared to amorphous TiO2, the anatase form of TiO2 (a form of the titanium oxide mineral) exhibits better thermal stability and, hence, outstanding tribological behavior. For further research in this field, it is necessary to synthesize highly pure monodisperse anatase TiO2 nanoparticles. That is why the anatase nanoparticles are modified with stearic acid when used as an additive in liquid paraffin [63].

It is very important to study the effect of adding low-volume fractions of titanium oxide to nanoparticles in the mineral oil lubricant. The main goal is to measure the performance coefficient, which is the ratio of the heat transfer rate at the evaporator to the power input to the compressor of the refrigeration system. When small amounts of titanium oxide nanoparticles are added to the lubricant, the performance coefficient is significantly improved. As the content of nanoparticles increased, the coefficient of friction decreased. However, this trend was only evident for 0.01% of titanium oxide nanoparticles in the oil. The addition of TiO2 beyond 0.01% increased the friction coefficient [64]. So far, various kinds of physical and chemical techniques, such as the addition of stabilizing agents, ultrasonic agitation, surface modifications, and mechanical stirring, have been used to prepare the stable nanolubricants needed for excellent lubrication performance [65,66,67]. TiO2 nanoparticles are one of the additives that have been highly valued for their application in lubricating oils because of their unique attributes, such as wear resistance, environmental compatibility, a high specific surface area, the ability to withstand high loads, and a reduction in friction coefficient [68].

In one of the studies [69], a sliding tester with a piston was used to test the wear and friction when base oils and nanolubricants were applied. It was concluded that the value of the coefficient of friction achieved for the nanolubricant was less than the one obtained for the base oil. It was also concluded that nanoparticles provided surface repair (the filling of the formed furrows) and improved the lubricant rolling function. Therefore, spherical TiO2 nanoparticles are a good choice for application in lubricating oils in the mechanical industry [69]. Further studies have also shown the impact of TiO2 nanoadditives on the tribological properties of mineral lubricants. Their results suggest that by increasing the mass fraction of TiO2, the viscosity of the nanolubricant also increases, which reduces the coefficient of friction [64]. Other researchers used the TiO2 nanoadditive to improve the tribological performance of the oil and found that increasing the nanoadditive significantly reduced the coefficient of friction. Namely, they demonstrated that increasing nanoadditives to more than 2 wt% reduces the stability of the nanoparticles, resulting in their greater deposition and an increase in the coefficient of friction [62].

There have also been some studies on the effect of using a combination of TiO2 and Al2O3 nanoparticles on the tribological characteristics of engine oil. The results have shown that adding nanoparticles such as nanolubricant additives to the base fluid leads to a decrease in wear, power losses, and the coefficient of friction. It has also been found that adding nanoparticles can improve fuel consumption and reduce energy consumption in automotive engines [70]. Investigations into the improvement of the tribological performance of nanolubricants containing TiO2 and carbon nanoparticles are also very important. It has been shown that the nanolubricant containing 0.2 wt% of graphene and 0.4 wt% of TiO2 provided the best performance with a reduction in the specific wear rate coefficient (15.78%) and the friction coefficient (38.83%) [71].

There have been some investigations in the field of the lubrication and dispersion performance of TiO2 nanoparticles modified with polyphenol derivatives and unmodified nanoparticles in two base oils—commercial engine oil and polyalphaolefin. The results showed that surface modifications of nanoparticles by creating a thick tribofilm or strengthening the mechanical properties of the surface, significantly contributed to a reduction in the coefficient of friction [72]. Other researchers also noted that TiO2 nanoadditives could provide lower friction coefficients and wear reduction when used as nanoadditives in pure lubricants [73].

The tribological and thermophysical performance of turbine meter oil, which contains MWCNT and TiO2 nanoparticles as additives, have also been studied. The results show that the tribological and thermophysical properties of nanofluids were significantly improved compared to pure mineral oil [74,75].

Particularly interesting is the study and application of different nanoadditives in turbine gas flow meters. The primary goal of this study was the numerical and experimental evaluation of the impact of MWCNT and TiO2 nanoadditives on the tribological and thermophysical properties of turbine oil. To achieve this goal, the first nanolubricants containing MWCNTs and TiO2 nanoparticles in different mass fractions (0.05 wt%, 0.1 wt%, 0.2 wt%, 0.3 wt%, and 0.4 wt%) were synthesized using a two-step method. The effect of the nanoparticle concentration on thermophysical and tribological characteristics, including the pressure drop, average friction coefficient, pour point, flash point, kinematic viscosity, relative viscosity, viscosity index, and wear coefficient, was then studied [74,75].

The effects of nanolubricants based on MWCNTs and TiO2 in turbine meter oil, with different mass fractions of MWCNTs and TiO2 (0.05 wt% – 0.4 wt%) and a temperature measurement range from 30 °C to 100 °C, on the average coefficient of friction, drop pressure, pour point, flash point, relative viscosity, kinematic viscosity, viscosity index and mean coefficient of friction were also investigated. Furthermore, the pressure drop and the average coefficient of friction inside the copper tube were simulated and compared with the experimental results. The following conclusions were reached based on the experiment and simulation results [67]:

- With the addition of MWCNT and TiO2 nanoadditives to the pure lubricant, the kinematic viscosity of the nanolubricant, in different percentages of nanoadditives, improves in a given temperature range compared to the pure lubricant.

- The precipitation of additives began after 3 days for TiO2 nanolubricants with 0.05 wt% and after 2 days for TiO2 nanolubricants with 0.4 wt% in oil. However, for MWCNT nanolubricants at 0.05 wt% and 0.4 wt%, precipitation began after 8 h, respectively.

- According to these results, the wear depth increases more with the increase in MWCNT than with the increase in the TiO2 nanoadditive in the base lubricant.

- The average coefficient of friction inside a copper tube when MWCNTs are used as a working fluid in the turbine meter oil is slightly higher than the average coefficient of friction inside a copper tube when TiO2 is used.

- Nanolubricants with 0.4 wt% TiO2 and 0.3 wt% MWCNTs in the oil demonstrated the maximum percentage increase in the average coefficient of friction with an increase of 6.14% and 9.36% compared to the base oil.

Significant progress in the development of lubrication and cooling techniques has been presented through several papers, where the minimum amount of lubrication (minimum quantity lubricant—MQL), cryogenic cooling, compressed air cooling, dry processing, and nanocutting in the lubricating liquid are mainly described [76,77,78].

Several previously involved elements made of alloyed steel Č. 4140 (JUS) rotate at a high speed with a multilayer carbon insert coated with a TiO2-based additive. They were conducted using small-quantity lubrication (SQL) technology. Significant benefits were seen using additives with 3% Al2O3 and 1% MWCNTs in the nanofluid instead of standard soluble oil. These benefits included a significant reduction in the cutting force and a reduction in residual tensile stress [78]. However, in terms of the reduction in residual tensile stresses, as well as other negative indicators for the operation of gear transmissions, when lubricants with the above additives were used, it was necessary to take into account other factors, such as the rotational speed of the transmission elements, load, and temperature [79].

Some papers describe methods for the synthesis and preparation of TiO2/CNT additives for use in nanocomposites. These include direct in situ growth, in situ CVD synthesis, the high-intensity ultrasound method, the assembly of pre-synthesized metal oxide nanoparticles as building blocks in CNT fluid, the spontaneous formation of metal oxide nanoparticles on CNTs, hydrothermal crystallization and chemical deposition [80,81,82,83,84].

The effects of TiO2 additives on the friction coefficient and wear behavior of bearings made of E52100 steel were investigated using a point wedge tribometer, where it was confirmed that the addition of TiO2 nanoparticles reduced the variability of friction losses and stabilized the value of the friction coefficient [62]. Titanium borate in the particle size of 10–70 nm significantly reduced friction and affected the reduction in wear of the surfaces in contact [85].

Nanolubricants offer improved tribological properties in many applications, such as machinery and engines. The presence of nanoparticles in lubricating oil affects its wear, friction, thermal, chemical, and physical properties in many ways. Titanium dioxide (TiO2) is a promising lubricant additive for improved engine efficiency. The positive effect of TiO2 nanoparticles dispersed in the 10W-30 engine oil has especially been pointed out. Tests were performed for four different volume concentrations (of 0.01%, 0.025%, 0.05%, and 0.075%) of TiO2 nanoparticles in a mineral lubricating oil. Tribological tests were conducted on a four-ball tribometer at an ambient temperature of 75 °C [86]. The worn surfaces were analyzed using an electron microscope and an Alicona Inginite Focus G5 microscope. The results show that surface-modified TiO2 nanoparticles can significantly improve the load-carrying capacity and reduce friction and wear. The diameter of the wear trace and the coefficient of friction were analyzed for nanolubricants with different volume concentrations and the mass fractions of nanoparticles. It was found that the diameter of the wear track and the coefficient of friction increased with the increase in the volume concentration of TiO2 nanoparticles in the oil. It was shown that the wear of ball samples decreased with an increase in the mass fraction of the TiO2 additive in the oil. Based on the higher value of the ignition temperature parameter, it was concluded that the concentration of TiO2 at 0.075% improved the performance of the oil compared to the pure lubricant. The average lowest friction coefficient of 0.01 was obtained with the oil sample with 0.075 wt% of TiO2 at a temperature of 75 °C. The average coefficient of friction dropped from 0.112 to 0.05 for concentrations of TiO2 in the range of 0.01% to 0.075%, which indicates that the addition of nanoparticles to the oil reduces friction when stabilizing the amount of additives below 0.025 wt% of TiO2. On the other hand, at 75 °C, the average friction coefficient clearly dropped from 0.095 to 0.015 in the range of 0.01 wt% to 0.075 wt% TiO2. The lowest coefficient of friction was obtained for the oil with 0.075 wt% of TiO2, which decreased by approximately 60% compared to pure mineral oil at room temperature and by approximately 80% at a temperature of 75 °C. Furthermore, the surface contact time clearly decreased with increasing TiO2 concentrations. A physical examination of the worn surfaces of the samples revealed that nano-oil with 0.075 wt% of TiO2 acts as an anti-wear oil additive. Photomicrographs showed that the surfaces in contact were much smoother when using a nano-oil with 0.075 wt% of TiO2. Titanium oxide has a special role in improving the tribological performance of the oil. The spherical shape of TiO2 particles has a positive effect on the lubrication of ball bearings during the friction process. Due to the exceptional characteristics of TiO2, the optimal concentration of TiO2 nanoparticles additionally helps the film to be formed faster and last longer than when additives are not used [86].

Analyzing the influence of TiO2 nanoparticles in lubricating oils, we found that the load capacity was approximately 35% higher when the lubricants with TiO2 nanoparticles were used [61,69]. The experiments that followed showed that the presence of the TiO2 additive in the oil reduced the mean surface roughness value by 80.84%. The average diameter of the TiO2 particles was 50 nm, and the particle concentration was 5 wt%. Even low concentrations of TiO2 nanoparticles were able to improve the tribological characteristics, with the friction coefficient reduced by approximately 15.2% and the surface wear reduced by approximately 11% [87].

Research on the application of TiO2 nanoparticle additives in oils is becoming more and more important [62,88,89,90,91]. The size of the TiO2 particles affects the degree of wear of the composite material [92]. It was found that the TiO2 microparticles damaged the surfaces in contact as a result of severe adhesion and abrasion. Several researchers have conducted tests with TiO2 nanoparticles as a material for surface coating [92,93,94,95] or reinforcement in composites [69] for better tribological performance [62].

Friction coefficients were experimentally determined for commercial oils under different conditions, e.g., for oil SAE20W40, µ = 0.102 with test parameters of 200 rpm, 392 N, 75 °C, and 3600 s; for mineral oil, µ = 0.104 with test parameters of 20 Hz, 10 N, 3600 s. The effects of different concentrations, i.e., the mass fractions of TiO2 additive particles in the oil from 0.5% to 1%, have also been studied. An improvement in viscosity was observed with an increase in the concentration of nanoparticles [94]. Furthermore, it has been noticed that the viscosity of hybrid lubricants containing these additives improves at higher temperatures.

The effect of TiO2 nanoparticle additives in non-standard oils, such as refined canola oil, has also been studied. Tribological parameters were studied at different mass concentrations of TiO2 nanoparticles, of 0.25%, 0.50%, and 1%. The tests were performed on a four-ball tribometer in the laboratory of the University of Galat in Romania. Tests were performed at loads of 100 N, 200 N, and 300 N and rotational speeds of 1000 rpm, 1400 rpm, and 1800 rpm. TiO2 particles have an average size of 21 ± 5 nm. It was found that the tested ranges of parameters and the addition of TiO2 nanoparticles do not improve the friction coefficient or reduce the wear rate. Rapeseed oils with the TiO2 nanoparticle did not improve the coefficient of friction or reduce wear for the tested load, and at the given speed ranges, it was even less efficient compared to pure rapeseed oil. However, it was noticed that the coefficient of friction and the wear parameter depended less on the test regime (load and rotational speed) for a concentration of 1 wt% of TiO2 nanoparticles [96].

When the Al2O3/TiO2 mixture was also tested as an additive for five different concentrations, 0 wt%, 0.05 wt%, 0.1 wt%, 0.5 wt%, and 1 wt%, it was found that the friction coefficient and the diameter of wear trace were reduced compared to the results obtained for oils without additives [97]. Other researchers managed to minimize the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoadditives [98]. There were also some tests carried out to evaluate the load capacity of the oil-lubricated journal bearing with TiO2 nanoparticles as lubricant additives, and it was found that they significantly improved the lubricant performance [99]. The influence of TiO2 as a nanoadditive in oils (rutile and anatase phases) was also studied, with the base oil being a mineral [100]. At all concentrations of these additives, there was an increase in the coefficient of friction, but the variability was reduced, and the behavior of the lubricant was stabilized.

The nanoparticles of titanium oxide used as additives in lubricants have a significant effect on the wear, friction coefficient, pressure, and temperature between the elements in contact. Lubricants containing TiO2 nanoparticles are especially effective when used in power transmission systems for a long uninterrupted operation in extremely demanding field conditions because they reduce the wear of the most heavily loaded elements. They are equally used in transmission and motor drives [101].

4. Tribological Application of Nanotubes of Molybdenum and Other Metals and Non-Metals in Oils

MoS2 nano additives as oil additives have attracted considerable interest because of their wide range of possible applications [102]. One of the main challenges of using nanoparticles as additives is their dispersion in lubricating oils.

One of the earliest studies involved the tribological behavior of surface-capped MoS3 nanoparticles in hydrocarbon oil at test temperatures in the range of 100–160 °C, with a mass fraction of additives in the oil at 0–1.0%. This combination of additives was shown to exhibit high wear resistance and a high ability to reduce friction, especially at high temperatures. In the test conditions, the best tribological properties were exhibited by oils containing 500 ppm MoS3, i.e., 0.1 wt% of MoS3 [102,103].

The studies that explain the tribological behavior of lamellar MoS3 as a lubricant additive, tested at different concentrations, particle sizes, load sizes, speeds, and temperatures, are of great importance today. These tests involving the coefficient of friction and the intensity of wear were carried out using a tribometer and the reciprocating movement of the contact surfaces. The results show that the friction-reducing ability and anti-wear properties of the base oil can be effectively improved by the addition of lamellar MoS3. The MoS3 concentrations of 0.5 wt% and 0.1 wt% in the oil gave the best anti-friction and anti-wear effects. The friction was reduced by 19.8%, and the wear was reduced by 55.9% compared to the base oil. Furthermore, the MoS3 additive can significantly reduce friction under high rotation speeds and a normal load and ensure operation even at higher operating temperatures. The smaller the size of the MoS3 nanoparticles, the better the friction reduction effect [104].

Based on several papers, it can be concluded that MoO3 lamellar additives also have the ability to reduce friction and wear when used as nanoparticles in lubricating oils. The layered additive MoO3 has already shown a significant application in various fields of optics, electrochemistry, electronics, and the sensor industry [105,106,107,108].

In an experiment with MoS2/GO (graphene oxide) as an additive performed on an MS-T3000 ball-on-disk tribometer, the following coefficients of friction (μ) were obtained: for pure oil without additives μ = 0.0915, for oil with 1.0 wt% of MoS2, μ = 0.0685 and for oil with 1.0 wt% of MoS2/GO μ = 0.0557. The wear track widths [μm] in the material were obtained as follows: at 0.5 wt% of MoS2, 202.33 μm, at 0.5 wt% of MoS2/GO, 190.28 μm, at 1.0 wt% of MoS2, 187.57 μm, at 1.0 wt% of MoS2/GO, 132.32 μm, at 2.0 wt% of MoS2, 219.33 μm and at 2.0 wt% of MoS2/GO, 182.83 μm [108].

Due to its outstanding tribological properties, the MoS2 additive is widely considered to be an important lubricant additive in the future. Four different types of fullerenes (C60), similar to MoS2, were synthesized and tested, and it was found that all these types of additives possessed a high tendency to reduce friction coefficients under strong boundary lubrication conditions [109]. However, the tribological performance of C60-MoS2 varied depending on the internal structure. A high load-carrying capacity is obtained using perfectly spherical and crystallized C60-MoS2 particles. Outstanding tribological properties were observed when crystalline C60-MoS2 nanoparticles were used because they could be easily assembled layer upon layer, thereby ensuring the formation of a quality tribofilm. Similarly, the presence of point defects and hollow structures in the particles facilitated the formation of tribofilm layers [110]. This also demonstrated the different tribological characteristics of MoS2 sheets and particles.

MoS2 with an embedded S–Mo–S nanostructure has attracted considerable attention. As already mentioned, MoS2 can be synthesized into various nano-forms, such as nanoparticles, similar to S60, nanotubes, and nanosheets. MoS2 nanosheets possess better tribological properties compared to nanotubes as a result of their ability to form a linear tribo-film more easily [111].

Like graphite (another lamellar material), MoS2 can be used as a dry lubricant by itself, as an additive in oils or greases, or as a single component of a composite coating [112,113]. Unlike graphite, MoS2 does not require a wet environment to perform well, and its lubricating properties have been shown to improve drastically under oxygen-deficient conditions [114]. Combined with its ability to operate reliably over a wide range of temperatures (from cryogenic to several hundreds of degrees Celsius), its ability to function effectively in a vacuum makes MoS2 a particularly attractive lubricant additive for aerospace applications. Currently, there is active research on understanding and improving the lubricating properties of MoS2, which has recently focused on its application in the field of nanocomposite coatings and additives [115,116].

The dependence of the tribological properties of MoS2 on temperature has been the subject of several scientific studies [117,118,119,120,121,122,123,124,125,126], where it has generally been shown that friction and wear when using MoS2 additives vary with temperature. Some scientific studies [121,122] show a uniform increase in the coefficient of friction with a decrease in temperature, while other studies [119,120,123,124] suggest that a decrease in temperature below a certain level does not lead to an increase in the coefficients of friction.

At moderate temperatures (up to about 200 °C), friction in a thermally activated process decreases monotonically as the temperature increases. Since the wear rate increases with the increase in the temperature, the wear rate of the MoS2 coating doubles as the temperature increases from −100 °C to 100 °C [119].

Due to a growing interest in the use of MoS2 in aerospace applications, where operation is expected in a wide range of temperatures (from cryogenic to several hundreds of degrees Celsius), the temperature dependence of the tribological properties of MoS2 is the subject of many studies. In general, in the absence of wear, friction decreases when the temperature increases. However, the degree of wear increases as the temperature increases. Despite many studies highlighting observations on the tribological behavior of MoS2 in different temperature ranges, a systematic study of the mechanisms underlying these observations still provides opportunities for improvement [112].

The nanoparticles of titanium oxide, when used as additives in lubricants, have a significant effect on the wear, friction coefficient, pressure, and temperature between the elements in contact. Lubricants containing TiO2 nanoparticles are especially effective when used in power transmission systems for long, uninterrupted operations in extremely demanding field conditions because they reduce the wear of the most heavily loaded elements. They are equally used in transmission and motor drives [113].

A detailed overview of characteristic research in the field of application of different types and proportions of nanoadditives in lubricants and their influence on tribological characteristics are shown in Table 1. Based on the analyzed research, it can be established that the most commonly used type of additive is CNT, which is just behind gold in terms of its price on the market. The reason for the large use of CNT additives in oils is confirmed by research results in terms of reducing the friction coefficient and wear contact, increasing the load capacity, and improving thermal conductivity. The most commonly used content of CNT additives in oils (Table 1) is from 0.1 to 0.5% [29,30,31,34,35,40,45], but there are studies that have also used content of 1% [28] and 2% nanoadditives [3]. Researchers also examined the influence of additives with below 0.1% of nanoadditives [32,34,46]. It was established that the viscosity of the oil could be increased [34] and that the friction coefficient was reduced [46] using a small content of nanoadditives.

Table 1.

Summary of a recent study in the field of oil-based nanofluids.

According to the analysis of the research results, depending on the application and up-use of oils and additives, different types and contents of additives in oils can be combined in practice in order to achieve certain required properties, i.e., better working characteristics and longer lifetime of the assembly or aggregate.

5. Impact of Nanoparticles on the Environment, Human Health, Economic and Cost–Benefit Analysis

5.1. Impact of Nanoparticles on the Environment and Human Health

The application of nanoparticles in various areas of industry, transport, medicine, pharmacies, etc., is gaining momentum due to many of their beneficial and positive effects. However, the application of nanoparticles also has a negative impact on human health and the environment. Due to their extremely small size, nanoparticles have the ability to react more quickly and efficiently with both living and non-living organisms in the environment. Nanoparticles have been found to cause the degradation of the environment and severe environmental pollution, primarily in water but also in the soil and air. Nanoparticles affect the living world through the degradation of the environment, both in the short term when released into water, soil, or air after an industrial accident and in the long term by maintaining a high concentration of nanoparticles in the air, water, and soil. The penetration of particles through different environments and living organisms largely depends on their size. Since nanoparticles are extremely small in size, their toxicity is much higher compared to larger particles. It has been found that particles smaller than 35 nm can penetrate the blood and brain barrier, and particles smaller than 40 nm can enter the nuclei of cells, while those smaller than 100 nm can enter cells by passing through the cell membrane [127,128].

Nanoparticle’s toxicity strongly depends on their shape. Thus, for example, ZnO nanoparticles in the form of rods are more toxic to human lungs than spherical ZnO nanoparticles [129]. On the other hand, spherical gold nanoparticles are more toxic to the human bloodstream than rod-shaped ones [130]. Furthermore, the type of the basic element or the compound used for the production of nanoparticles affects their toxicity. Thus, Ag nanoparticles are more toxic than Au nanoparticles of the same size and shape [131]. One of the main properties of nanoparticles compared to other particles used as additives is their high level of reactivity. Highly reactive nanoparticles start a catalytic reaction inside cells that results in the creation of reactive oxides, which are extremely toxic [132]. This kind of environment favors the creation of free radicals, which have a very destructive effect on the cells of organisms. The mobility of nanoparticles affects their toxicity because the more mobile nanoparticles are, the faster they penetrate through different environments, especially living organisms.

When considering the toxicity of nanoparticles in lubricants and other solutions, it is particularly important to point out their directly harmful effect on humans. Nanoparticles have a negative impact on the human organism from several aspects. They can come into contact with human skin. This happens to professional workers who handle these types of solutions, but it can also happen to other people who unintentionally or accidentally come into contact with nanoparticles, for example, during packaging, transport, or disposal processes. The toxicity of nanoparticles depends on the concentration of the particles, the time of exposure, the size and mobility of the particles, and the type of material they are made from. Nanoparticles cause strong oxidation reactions on the skin, reducing its vitality and regeneration ability and leading to the death of skin cells [133]. Nanoparticles can cause various reactions on the skin, starting from irritation and allergies to cellular and intercellular damage caused by violent chemical reactions and oxidation processes.

Another very frequent way for nanoparticles to enter the human body is through the respiratory system. Since solutions with nanoparticle additives are volatile at elevated temperatures, they can easily enter the lungs and other parts of the human respiratory system through evaporation. In this case, the toxicity of nanoparticles depends on their aerodynamics, physical and chemical characteristics, and the state of health of an individual exposed to the fumes [134]. When nanoparticles enter the body through the respiratory system, they spread throughout the body much faster and reach the blood, brain, and other vital organs very quickly, causing changes and diseases first at the cellular level and then beyond it.

Another common way of introducing nanoparticles into the human body is by swallowing solutions containing nanoparticles. Nanoparticles introduced into the human body directly or indirectly through food, drink, hands, or in another way, enter into the human digestive tract and cause various negative reactions. Due to the high level of their toxicity, nanoparticles first cause nausea and irritation of the digestive system and then more severe diseases. Long-term exposure to the negative effects of nanoparticles can lead to chronic and autoimmune diseases and even to a fatal outcome.

5.2. Cost Analysis of the Use of Nanoparticles

The production, storage, manipulation, and disposal of nanoparticles are extremely complex, demanding and expensive. It is associated with various limiting factors and challenges in terms of stability and safety [135]. In the test phase, only small amounts of solutions with nanoparticles are usually used, so the costs are not very high at this stage. However, during the introduction and the mass production phase, the costs are significantly higher, depending on the type of nano additive, their concentration in fluids, their useful life, transport, storage, use, etc. The typical and average prices of nanoparticles depend on the current demand and availability of raw materials [136].

Based on the available data on the evaluation of additives that can be used as nanoparticles in oils, it is concluded that the most expensive additives are gold (Au) with a price of USD 55/g, followed by carbon nanotubes with a price rate of USD 9.3 to 12.5/g, and USD 5/g for copper (Cu) nanoparticles.

Additives of a lower price rate are as follows: silver (Ag) with a price of USD 4/g, aluminum (Al) at USD 3.8/g, titanium dioxide (TiO2) at USD 0.8/g, copper oxide (CuO) at USD 0.75/g and aluminum oxide (Al2O3) with a price of USD 0.7/g [136].

When applying certain types of nanoadditives, it is certain that in addition to the tribological characteristics of the additive as dominant, the price of each individual additive is also of great importance.

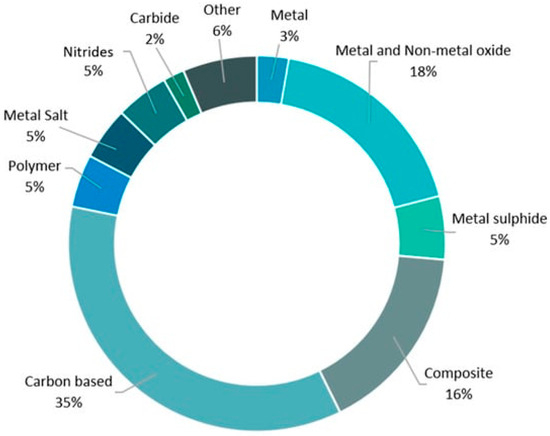

When considering the costs of applying nanoadditives in oils, and in order to see the overall costs, it is necessary to take into account the percentage of the application of certain types of additives. Figure 2 shows a diagram with the percentage of application of individual nanoadditives over the past ten years [137].

Figure 2.

Statistics of nanomaterials used as nanoadditives in water over the past decade [137].

One of the typical characteristics of nanoparticles is their tendency to agglomerate or precipitate in solutions. The level and speed of nanoparticle agglomeration depend on several factors, such as their size, shape, type, charge, concentration, temperature, etc. It has been observed that nanoparticles behave differently from other types of dispersed particles in solutions. In this regard, the agglomeration has negative effects on lubricant properties because the concentration of nanoparticles in the lubricant is not even close to being constant at low speeds of friction elements or when they are still. Furthermore, the agglomeration of nanoparticles does not only affect the lubricant’s characteristics, but it also increases the toxicity of lubricants due to increased interaction with the cells of living organisms [127,138].

6. Conclusions

The use of nanomaterials as additives in lubricants is of great importance for saving energy, reducing the emissions of harmful substances, and protecting the environment. Based on the types of nanoparticles used, lubricant nanoadditives can be divided into the following three categories: nanometal-based, nanocarbon-based, and nanocomposite-based additives. They are all discussed systematically in this review. A stable dispersion of nanoadditives in lubricants can be obtained using physical and/or chemical dispersion methods.

It is necessary to conduct further research in order to improve the methods of dispersion of additives in lubricants. In particular, dispersion methods that do not need special modifiers and indicators and that exhibit good dispersion stability should be further developed. Furthermore, the accumulation and deposition of nanoparticles dispersed in the lubricant have not been studied extensively in the field of toothed gears. This is because the study methods of dispersion stability are mainly limited to passive processes such as observation using optical microscopes and ultraviolet spectrophotometry, which cannot reveal the real state of nanoparticles in the lubricant.

For these above reasons, research in the field of new lubricants with additives that provide high tribological performance, especially under extreme conditions (temperature, pressure, and speed), should be the focus of basic and applied research in the future.

Further research should improve the characteristics of nanoadditives in lubricants and make their effects less harmful to the environment and to human health, primarily by choosing less harmful elements and compounds and using them at lower concentrations. There is also a place for improvement in the field of application of nanoparticles in commercial oils for various purposes in the automotive and transport industry since they are the largest consumers of engine and transmission oils.

This paper is an exceptional starting point for further research in the field of the application of nanotubes in lubricants because, although in brief, it gives a systematic review of all the achievements accomplished in this field so far, it will certainly be very helpful in setting directions for further research and the further improvement of the tribological properties of lubricants.

Author Contributions

Conceptualisation, B.S.; methodology, S.S., M.B. and B.S.; validation, S.G. and A.S.; investigation, S.S., A.A., S.G. and A.S.; writing—original draft preparation, M.B. and S.G.; writing—review and editing, M.B. and S.G.; funding acquisition, A.A. and B.S. All authors have read and agreed to the published version of the manuscript.

Funding

This paper has been performed as a part of activities within the project TR 35021, supported by the Republic of Serbia, Ministry of Science, Technological Development and Innovation and its financial help is gratefully acknowledged.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chebattina, K.R.R.; Srinivas, V.; Rao, N.M. Effect of Size of Multiwalled Carbon Nanotubes Dispersed in Gear Oils for Improvement of Tribological Properties. Adv. Tribol. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Hao, L.; Li, P.; Aljabri, A.; Li, H.; Liu, G.; Xie, Z.; Li, T. Investigation on the tribological performance of functionalized nanoscale silica as an amphiphilic lubricant additive. J. Mater. Res. Technol. 2021, 15, 5507–5515. [Google Scholar] [CrossRef]

- Khalil, W.; Mohamed, A.; Bayoumi, M.; Osman, T.A. Tribological properties of dispersed carbon nanotubes in lubricant. Fullerenes. Nanotub. Carbon Nanostructures 2016, 24, 479–485. [Google Scholar] [CrossRef]

- Мartin, J.M.; Ohmae, N. Nanolubricants, 1st ed.; John Wiley & Sons: New York, NY, USA, 2008; pp. 93–96. [Google Scholar]

- Guzman Borda, F.L.; Ribeiro de Oliveira, S.J.; Seabra Monteiro Lazaro, L.M.; Kalab Leiroz, A.J. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Ghaednia, H.; Jackson, R.L.; Khodadadi, J.M. Experimental analysis of stable CuO nanoparticle enhanced lubricants. J. Exp. Nanosci. 2013, 10, 1–18. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and wear characteristics of oil-based ZnO nanofluids. Tribol. Trans. 2013, 56, 236–244. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and wear characteristics of waterbased ZnO and Al2O3 nanofluids. Tribol. Trans. 2012, 55, 345–350. [Google Scholar] [CrossRef]

- Wu, H.; Johnson, B.; Wang, L.; Dong, G.; Yang, S.; Zhang, J. Highefficiency preparation of oil-dispersible MoS2 nanosheets with superior anti-wear property in ultralow concentration. J. Nanoparticle Res. 2017, 19, 339–349. [Google Scholar] [CrossRef]

- Aralihalli, S.; Biswas, S.K. Grafting of dispersants on MoS2 nanoparticles in base oil lubrication of steel. Tribol. Lett. 2013, 49, 61–76. [Google Scholar] [CrossRef]

- Aldana, P.U.; Vacher, B.; Le Mogne, T.; Belin, M.; Thiebaut, B.; Dassenoy, F. Action mechanism of WS2 nanoparticles with ZDDP additive in boundary lubrication regime. Tribol. Lett. 2014, 56, 249–258. [Google Scholar] [CrossRef]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, L.; Liu, W.; Xue, Q. The effect of LaF3 nanocluster modified with succinimide on the lubricating performance of liquid paraffin for steel-on-steel system. Tribol. Int. 2001, 34, 83–88. [Google Scholar] [CrossRef]

- Kałużny, J.; Merkisz-Guranowska, A.; Giersig, M.; Kempa, K. Lubricating preformance of carbon nanotubes in inernal cobustion engines–engine test results for CNT enriched oil. Int. J. Automot. Technol. 2017, 18, 1047–1059. [Google Scholar] [CrossRef]

- Baughman, R.H.; Zakhidov, A.A.; de Heer, W.A. Carbon Nanotubes—The route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [PubMed]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Miao, J.; Yang, Z.; Xiao, F.X.; Yang, H.B.; Liu, B.; Yang, Y. Carbon nanotube catalysts: Recent advances in synthesis, characterization and applications. Chem. Soc. Rev. 2015, 44, 3295–3346. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, B. Springer Handbook of Nanotechnology, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 23–32. [Google Scholar]

- Chauveau, V. Le Pouvoir Lubrifiant des Nanotubes de Carbonne. Ph.D. Thesis, L’Ecole Centrale de Lyon, Lyon, France, 2010. [Google Scholar]

- Servantir, J.; Gaspard, P. Rotational dynamics and friction in double-walled carbon nanotubes. Phys. Rev. Lett. 2006, 18, 4–7. [Google Scholar]

- Vander Wall, R.L.; Miyoshi, K.; Street, K.W.; Tomasek, A.J.; Peng, H.; Liu, Y.; Margrave, J.L.; Khabashesku, V.N. Friction properties of surface-fluorinated carbon nanotubes. Wear 2005, 259, 738–743. [Google Scholar] [CrossRef]

- Lucas, M.; Palaci, I.; Riedo, E.; Zhang, X.; Tosatti, E. Hindered rolling and friction anisotropy in supported carbon nanotubes. Nat. Mater. 2009, 8, 876–881. [Google Scholar] [CrossRef]

- Cook, E.H.; Buehler, M.J.; Spakovszky, Z.S. Mechanism of friction in rotating carbon nanotube bearings. J. Mech. Phys. Solids 2013, 61, 652–673. [Google Scholar] [CrossRef]

- Habeeb, J.J.; Bogovic, C.N. Reduced Friction Lubricating Oils Containing Functionalized Nanomaterials. U.S. Patent No. 8435931 B2, 7 May 2013. [Google Scholar]

- Santos, N.D.S.A.; Roso, V.R.; Faria, M.T.C. Review of engine journal bearing tribology in start-stop applications. Eng. Fail. Anal. 2020, 108, 104344. [Google Scholar] [CrossRef]

- Kotnarowski, A. Generation of Protective Low-Friction Layers in Tribological Processes. Solid State Phenom. 2013, 199, 607–612. [Google Scholar] [CrossRef]

- Liu, W.; Qiao, X.; Liu, S.; Chen, P. A Review of Nanomaterials with Different Dimensions as Lubricant Additives. Nanomaterials 2022, 12, 3780. [Google Scholar] [CrossRef] [PubMed]

- Pottuz, L.J.; Dassenoy, F.; Vacher, B.; Martin, J.M.; Mieno, T. Ultralow friction and wear behavior of Ni/Y-based single wall carbon nanotubes (SWNTs). Tribol. Int. 2004, 37, 1013–1018. [Google Scholar] [CrossRef]

- Cursaru, D.L.; Andronescu, C.; Pirvu, C.; Ripeanu, R. The efficiency of Co-based single-wall carbon nanotubes (SWNTs) as an AW/EP additive for mineral base oils. Wear 2012, 290–291, 133–139. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, C.; Choi, Y.; Cheong, S.; Kim, D.; Lee, K.; Lee, J.; Kim, H. Effect of size and morphology of particles dispersed in nano-oil on friction performance between rotating discs. J. Mech. Sci. Technol. 2011, 25, 2853–2857. [Google Scholar] [CrossRef]

- Tao, X.; Jiazheng, Z.; Kang, X. The ball-bearing effect of diamond nanoparticles as an oil additive. J. Phys. D Appl. Phys. 1996, 29, 2932–2937. [Google Scholar] [CrossRef]

- Chaveau, V.; Mazuyer, D.; Dassenoy, F.; Cayer-Barrioz, J. In situ film-forming and friction-reduction mechanisms for carbon-nanotube dispersions in lubrication. Tribol. Lett. 2012, 47, 467–480. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Ahmadi, H.; Rashidi, A.; Nouralishahi, A.; Mohtasebi, S.S. Preparation and properties of oil-based nanofluid from multi-walled carbon nanotubes and engine oil as nano—Lubricant. Int. Commun. Heat Mass Transf. 2013, 46, 142–1058. [Google Scholar] [CrossRef]

- Phan, N.M.; Bui, H.T.; Nguyen, M.H.; Phan, H.K. Carbon-nanotube-based liquids: A new class of nanomaterials and their applicatilubricons. Adv. Nat. Sci. Nanosci. Nanotechnol. 2014, 5, 015014. [Google Scholar] [CrossRef]

- Kogovšek, J.; Remškar, M.; Mrzel, A.; Kalin, M. Influence of surface roughness and running-in on the lubrication of steel surfaces with oil containing MoS2 nanotubes in all lubrication regimes. Tribol. Int. 2013, 61, 40–44. [Google Scholar] [CrossRef]

- Kalin, M.; Kogovsek, J.; Remskar, M. Mechanisms and improvements in the friction and wear behavior using MoS2 nanotubes as potential oil additives. Wear 2012, 280–281, 36–45. [Google Scholar] [CrossRef]

- Espinel Blanco, E.; Vázquez-Fletes, R.C.; Rudas, J.S.; Ardila Marín, M.I.; Hoyos-Palacio, L.M.; Carlos Cornelio, J.A. Effect of the concentration of carbon nanotubes (CNTs) on the rheological behavior in a lubricating oil of plant-derived lubricant. J. Dispers. Sci. Technol. 2023, 1–11. [Google Scholar] [CrossRef]

- Xie, H.; Lee, H.; Youn, W.; Choi, M. Nanofluid containing multiwalled carbon nanotubes and their enhanced thermal conductivities. J. Appl. Phys. 2003, 94, 4967–4971. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef]

- Dörnenburg, F.; Lades, K.; Kenningley, S. Neue Technik für Höhere Warmfestigkeit von Aluminiumkolben. MTZ—Mot. Z. 2010, 71, 246–249. [Google Scholar] [CrossRef]

- Backhaus, R. Kolben aus Stahl für PkwDieselmotoren. MTZ—Mot. Z. 2009, 70, 902–906. [Google Scholar] [CrossRef]

- Ottliczky, E.; Voigt, M.; Weimar, H.J.; Weiss, E. Stahlkolben für PKW-Dieselmotoren. MTZ—Mot. Z. 2011, 72, 728–735. [Google Scholar] [CrossRef]

- Yijun, S.; Liwen, M.; Xin, F.; Xiaohua, L. Tribological behavior of carbon nanotube and polytetrafluoroethylene filled polyimide composites under different lubricated conditions. J. Appl. Polym. Sci. 2011, 121, 1574–1578. [Google Scholar] [CrossRef]

- Bhaumik, S.; Prabhu, S.; Singh, K.J. Analysis of tribological behavior of carbon nanotube based industrial mineral gear oil 250 cSt viscosity. Adv. Tribol. 2014, 2014, 341365. [Google Scholar] [CrossRef]

- Chuan-Sheng, C.; Xiao-hua, C.; Jing, H.; Hua, Z.; Wen-hua, L.; Long-shan, X.; Zhi, Y. Effect of multi-walled carbon nanotubes on tribological properties of lubricant. Trans. Nonferrous Met. Soc. China 2005, 15, 300–305. [Google Scholar]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel-rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef]

- Battez, A.H.; González, R.; Felgueroso, D.; Fernández, J.E.; del Rocío Fernández, M.; García, M.A.; Penuelas, I. Wear prevention behaviour of nanoparticle suspension under extreme pressure conditions. Wear 2007, 263, 1568–1574. [Google Scholar] [CrossRef]

- Hu, Y.; Peng, Y.; Wang, H. Tribological behaviors of surfactant-functionalized carbon nanotubes as lubricant additive in water. Tribol. Lett. 2006, 25, 247–253. [Google Scholar]

- Joly- Pottuz, L.J.; Vacher, B.; Ohmae, N.; Martin, J.M.; Epicier, T. Anti-wear and friction reducing mechanisms of carbon nanoonions as lubricant additives. Tribol. Lett. 2008, 30, 69–80. [Google Scholar] [CrossRef]

- Lee, J.; Cho, S.; Hwang, Y.; Lee, C.; Kim, S.H. Enhancement of lubrication properties of nano-oil by controlling the amount of fullerene nanoparticle additives. Tribol. Lett. 2007, 28, 203–208. [Google Scholar] [CrossRef]

- Lee, C.; Hwang, Y.; Choi, Y.; Lee, J.; Choi, C.; Oh, J. A study on the tribological characteristics of graphite nano lubricants. Int. J. Precis. Eng. Manuf. 2009, 10, 85–90. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; García, A.; Maldonado, D.; González, J.A.; Molina, D.; Palacios, E.; Cantú, P. Antiwear and extreme pressure properties of nanofluids for industrial applications. Tribol. Trans. 2014, 57, 1072–1076. [Google Scholar] [CrossRef]

- Puzyr, A.P.; Burov, A.E.; Selyutin, G.E.; Voroshilov, V.A.; Bondar, V.S. Modified nanodiamonds as antiwear additives to commercial oils. Tribol. Trans. 2012, 55, 149–154. [Google Scholar] [CrossRef]

- Sarma, P.K.; Srinivas, V.; Rao, V.D.; Kumar, A.K. Experimental study and analysis of lubricants dispersed with nano Cu and TiO2 in a four-stroke two wheeler. Nanoscale Res. Lett. 2011, 6, 233–243. [Google Scholar] [CrossRef]

- Srinivas, V.; Thakur, R.N.; Jain, A.K.; Saratchandra Babu, M. Tribological studies of transmission oil dispersed with molybdenum disulfide and tungsten disulfide nanoparticles. J. Tribol. 2017, 139, 041301–041306. [Google Scholar] [CrossRef]

- Srinivas, V.; Kodanda, R.R.; Mohan Rao, C.N. Lubricating and physico-chemical properties of CI-4plus engine oil dispersed with surface modified multi-walled carbon nanotubes. Tribol. Mater. Surf. Interfaces 2018, 12, 107–114. [Google Scholar] [CrossRef]

- Skulic, A.; Milojevic, S.; Marić, D.; Ivanović, L.; Krstić, B.; Radojković, M.; Stojanović, B. The Impact of Lubricant Viscosity and Materials on Power Losses and Efficiency of Worm Gearbox. Teh. Vjesn. 2022, 29, 1853–1860. [Google Scholar]

- Shahnazar, S.; Bagheri, S.; Hamid, S.B.A. Enhancing lubricant properties by nanoparticle additives, Review Article, Nanotechnology & Catalysis Research Centre (NANOCAT), IPS Building. Int. J. Hydrog. 2016, 41, 3153–3170. [Google Scholar]

- Sun, J.; Du, S. Application of graphene derivatives and their nanocomposites in tribology and lubrication: A review. RSC Adv. 2019, 9, 40642–40661. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G. Preliminary study of nano- and microscale TiO2 additives on tribological behavior of chemically modified rapeseed oil. Tribol. Trans. 2013, 56, 797–805. [Google Scholar] [CrossRef]

- Ingole, S.; Charanpahari, A.; Kakade, A.; Umare, S.S.; Bhatt, D.V.; Menghani, J. Tribological behavior of nano TiO2 as an additive in base oil. Wear 2013, 301, 776–785. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Wan, H.; Chen, J.; Zhou, H. Synthesis and tribological properties of stearic acid-modified anatase (TiO2) Nanoparticles. Tribol. Lett. 2011, 41, 409–416. [Google Scholar] [CrossRef]

- Sabareesh, R.K.; Gobinath, N.; Sajith, V.; Das, S.; Sobhan, C.B. Application of TiO2 nanoparticles as a lubricant-additive for vapor compression refrigeration systems e an experimental investigation. Int. J. Refrig. 2012, 35, 1989–1996. [Google Scholar] [CrossRef]

- Ghadimi, A.; Metselaar, I.H. The influence of surfactant and ultrasonic processing on improvement of stability, thermal conductivity and viscosity of titania nanofluid. Exp. Therm. Fluid Sci. 2013, 51, 1–9. [Google Scholar] [CrossRef]

- Kumar, R.S.; Sharma, T. Stability and rheological properties of nanofluids stabilized by SiO2 nanoparticles and SiO2-TiO2 nanocomposites for oilfield applications. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 171–183. [Google Scholar] [CrossRef]

- Han, Z.; Yang, B.; Qi, Y.; Cumings, J. Synthesis of low-melting-point metallic nanoparticles with an ultrasonic nanoemulsion method. Ultrasonics 2011, 51, 485–488. [Google Scholar] [CrossRef] [PubMed]

- Pourpasha, H.; Heris, S.Z.; Mohammadfam, Y. Comparison between multi-walled carbon nanotubes and titanium dioxide nanoparticles as additives on performance of turbine meter oil nano lubricant. Sci. Rep. 2021, 11, 11064. [Google Scholar] [CrossRef] [PubMed]

- Кao, M.J.; Lin, C.R. Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieces of cast iron. J. Alloys Compd. 2009, 483, 456–459. [Google Scholar] [CrossRef]

- Ali, M.K.A. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Alghani, W.; Ab Karim, M.S.; Bagheri, S.; Amran, N.A.M.; Gulzar, M. Enhancing the tribological behavior of lubricating oil by adding TiO2, graphene, and TiO2/graphene nanoparticles. Tribol. Trans. 2019, 62, 452–463. [Google Scholar] [CrossRef]

- Hong, F.T.; Schneider, A.; Sarathy, S.M. Enhanced lubrication by core-shell TiO2 nanoparticles modified with gallic acid ester. Tribol. Int. 2020, 146, 106263. [Google Scholar] [CrossRef]

- Sharma, V.; Timmons, R.B.; Erdemir, A.; Aswath, P.B. Interaction of plasma functionalized TiO2 nanoparticles and ZDDP on friction and wear under boundary lubrication. Appl. Surf. Sci. 2019, 489, 372–383. [Google Scholar] [CrossRef]

- Pourpasha, H.; Heris, S.Z.; Mahian, O.; Wongwises, S. The effect of multi-wall carbon nanotubes/turbine meter oil nanofluid concentration on the thermophysical properties of lubricants. Powder Technol. 2020, 367, 133–142. [Google Scholar] [CrossRef]

- Pourpasha, H.; Heris, S.Z.; Asadi, A. Experimental investigation of nano-TiO2/turbine meter oil nanofluid. J. Therm. Anal. Calorim. 2019, 138, 57–67. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dogra, M.; Suri, N. Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 2009, 49, 435–445. [Google Scholar] [CrossRef]

- Krishna, P.V.; Srikant, R.R.; Padmini, R.; Viswaditya, J.L.P.P. Application of Nanomaterials as Coolants/Lubricants in Machining. In Proceedings of the Advanced Nanomaterials and Emerging Engineering Technologies (ICANMEET), 2013 International Conference on IEEE, Chennai, India, 24–26 July 2013. [Google Scholar]

- Krajnik, P.; Pusavec, F.; Rashid, A. Nanofluids: Properties, applications and sustainability aspects in materials processing technologies. In Advances in Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 107–113. [Google Scholar]

- Skulic, A.; Krsmanovic, D.; Radosavljevic, S.; Ivanović, L.; Stojanović, B. Power Losses of Worm Gear Pairs. Acta Tech. Corviniensis-Bull. Eng. 2017, 10, 39–45. [Google Scholar]

- Li, Z.; Gao, B.; Chen, G.Z.; Mokaya, R.; Sotiropoulos, S.; Li Puma, G. Carbon nanotube/titanium dioxide (CNT/TiO2) core-shell nanocomposites with tailored shell thickness, CNT content and photocatalytic/photoelectrocatalytic properties. Appl. Catal. B Environ. 2011, 110, 50–57. [Google Scholar] [CrossRef]

- Saleh, T.A.; Gondal, M.A.; Drmosh, Q.A.; Yamani, Z.H.; AL-yamani, A. Enhancement in photocatalytic activity for acetaldehyde removal by embedding ZnO nano particles on multiwall carbon nanotubes. Chem. Eng. J. 2011, 166, 407–412. [Google Scholar] [CrossRef]

- An, G.; Ma, W.; Sun, Z. Preparation of titania/carbon nanotube composites using supercritical ethanol and their photocatalytic activity for phenol degradation under visible light irradiation. Carbon 2007, 45, 1795–1801. [Google Scholar] [CrossRef]

- Saleh, T.A.; Agarwal, S.; Gupta, V.K. Functionalization of tungsten oxide into MWCNT and its application for sunlightinduced degradation of rhodamine B. J. Colloid Interface Sci. 2011, 362, 337–344. [Google Scholar] [CrossRef]

- Saleh, T.A.; Siddiqui, М.N.; Al-Arfaj, A.A. Synthesis of Multiwalled Carbon Nanotubes-Titania Nanomaterial for Desulfurization of Model Fuel. Hindawi Publ. Corp. J. Nanomater. 2014, 2014, 940639. [Google Scholar] [CrossRef]

- Xue, Q.; Liu, W.; Zhang, Z. Friction and wear properties of a surface-modified TiO2 nanoparticle as an additive in liquid paraffin. Wear 1997, 213, 29–32. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Cioaza, M.; Molea, A.; Popa, F.; Contiu, G. Effect of TiO2 nanoparticles on the tribological properties of lubricating oil: An experimental investigation. Sci. Rep. 2022, 12, 7–14. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, T.; Guo, L.; Jiang, B. Fretting wear behaviour of microarcoxidation coatings formed on titanium alloy against steel in unlubrication and oil lubrication. Appl. Surf. Sci. 2006, 252, 8113–8120. [Google Scholar] [CrossRef]

- Gupta, G.; Ul Haq, M.I.; Raina, A.; Shafi, W.K. Rheological and tribological behavior of sunflower oil: Effect of chemical modification and tungsten disulfide nanoparticles. J. Bio-Tribo-Corros. 2021, 7, 2–6. [Google Scholar] [CrossRef]

- Raina, A.; Irfan Ul Haq, M.; Anand, A.; Mohan, S.; Kumar, R.; Jayalakshmi, S.; Arvind Singh, R. Nanodiamond particles as secondary additive for polyalphaolefin oil lubrication of steel-aluminium contact. Nanomaterials 2021, 11, 1438. [Google Scholar] [CrossRef] [PubMed]

- Anand, R.; Raina, A.; Irfan Ul Haq, M.; Mir, M.J.; Gulzar, O.; Wani, M.F. Synergism of TiO2 and graphene as nano-additives in bio-based cutting fluid—An experimental investigation. Tribol. Trans. 2021, 64, 350–366. [Google Scholar] [CrossRef]

- Kerni, L.; Raina, A.; Ul Haq, M.I. Friction and wear performance of olive oil containing nanoparticles in boundary and mixed lubrication regimes. Wear 2019, 426–427, 819–827. [Google Scholar] [CrossRef]

- Abdullah, M.I.H.C.; Abdollah, M.F.B.; Amiruddin, H.; Tamaldin, N.; Nuri, N.R.M. The potential of hBN nanoparticles as friction modifier and antiwear additive in engine oil. Mech. Ind. 2016, 17, 104. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Ashraful, A.M.; Habib, M.A.; Mobarak, H.M. Effect of biolubricant on tribological characteristics of steel. Procedia Eng. 2014, 90, 740–745. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Turkson, R.F.; Peng, Z.; Chen, X. Enhancing the thermophysical properties and tribological behaviour of engine oils using nanolubricant additives. RSC Adv. 2016, 6, 77913–77924. [Google Scholar]

- Masjuki, H.H.; Saifullah, M.G.; Husnawan, M.; Faizul, M.S.; Shaaban, M.G. Flash Temperature Parameter Number Prediction Model by Design of Tribological Experiments for Basestock Mineral Oil Containing Palm Olein and Aminephosphate Additives. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005. [Google Scholar]

- Cristea, G.C.; Cazamir, D.; Dima, D.; Georgescu, C.; Deleanu, L. Influence of TiO2 as Nano Additive in Rapeseed Oil. In The 8th International Conference on Advanced Concepts in Mechanical Engineering; Institute of Physics Conference Series: Materials Science and Engineering; Institute of Physics Publishing Ltd.: Bristol, UK, 2018; Volume 444, p. 022011. [Google Scholar]