Influence of 1-Ethyl-3-methylimidazolium Diethylphosphate Ionic Liquid on the Performance of Eu- and Gd-Doped Diamond-like Carbon Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparing Samples

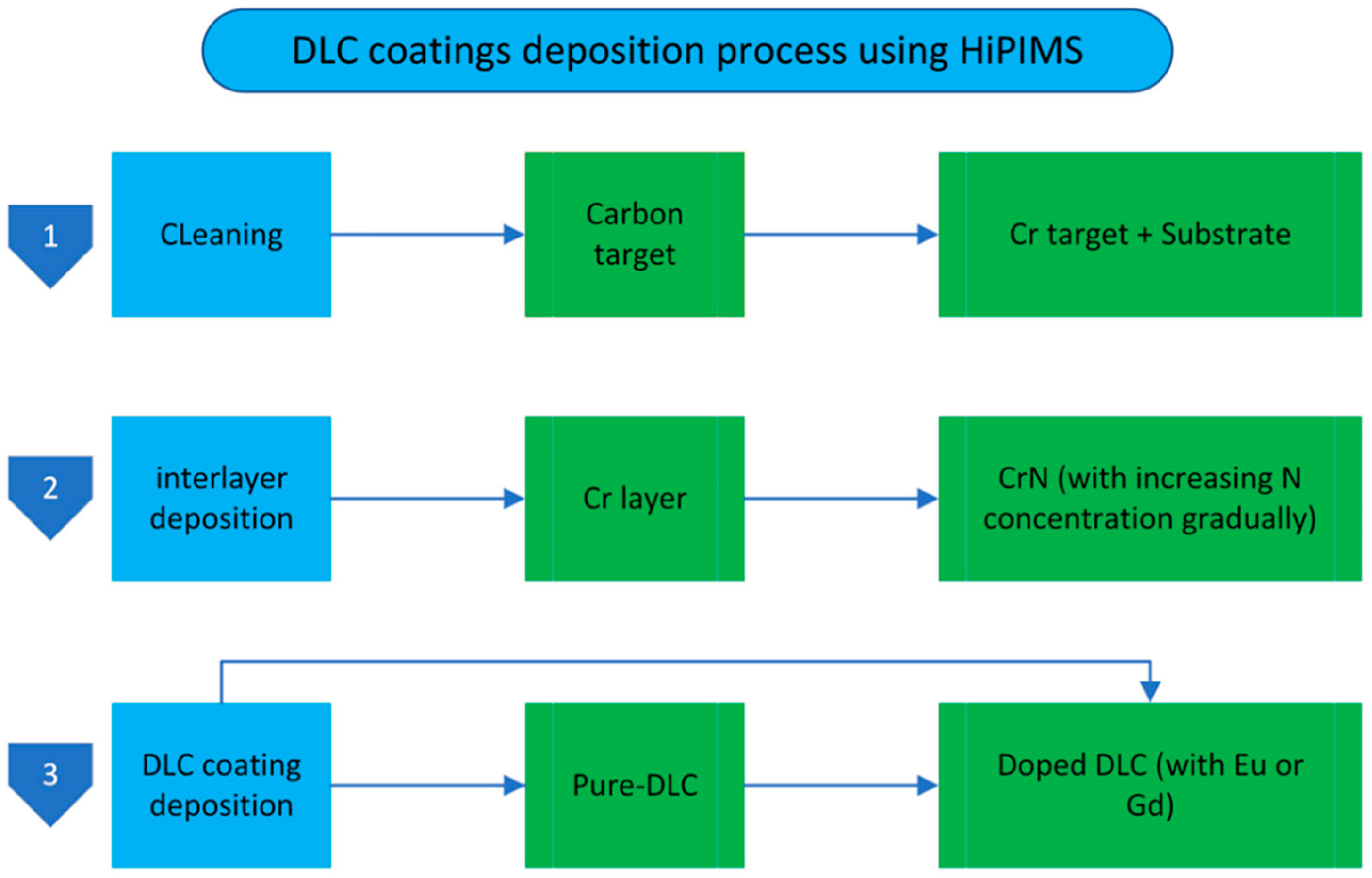

2.2. Coatings Deposition

- Etching process: Cleaning of the C target involved applying a HiPIMS charging voltage of 400 V at a working pressure of 4.0 × 10−1 Pa for a duration of 10 min. A similar cleaning procedure was carried out on the Cr target, using a DC power of 250 W at a working pressure of 3.5 × 10−1 Pa. Simultaneously, the substrates were subjected to pulsed power (120 kHz, 1616 ns) for 60 min.

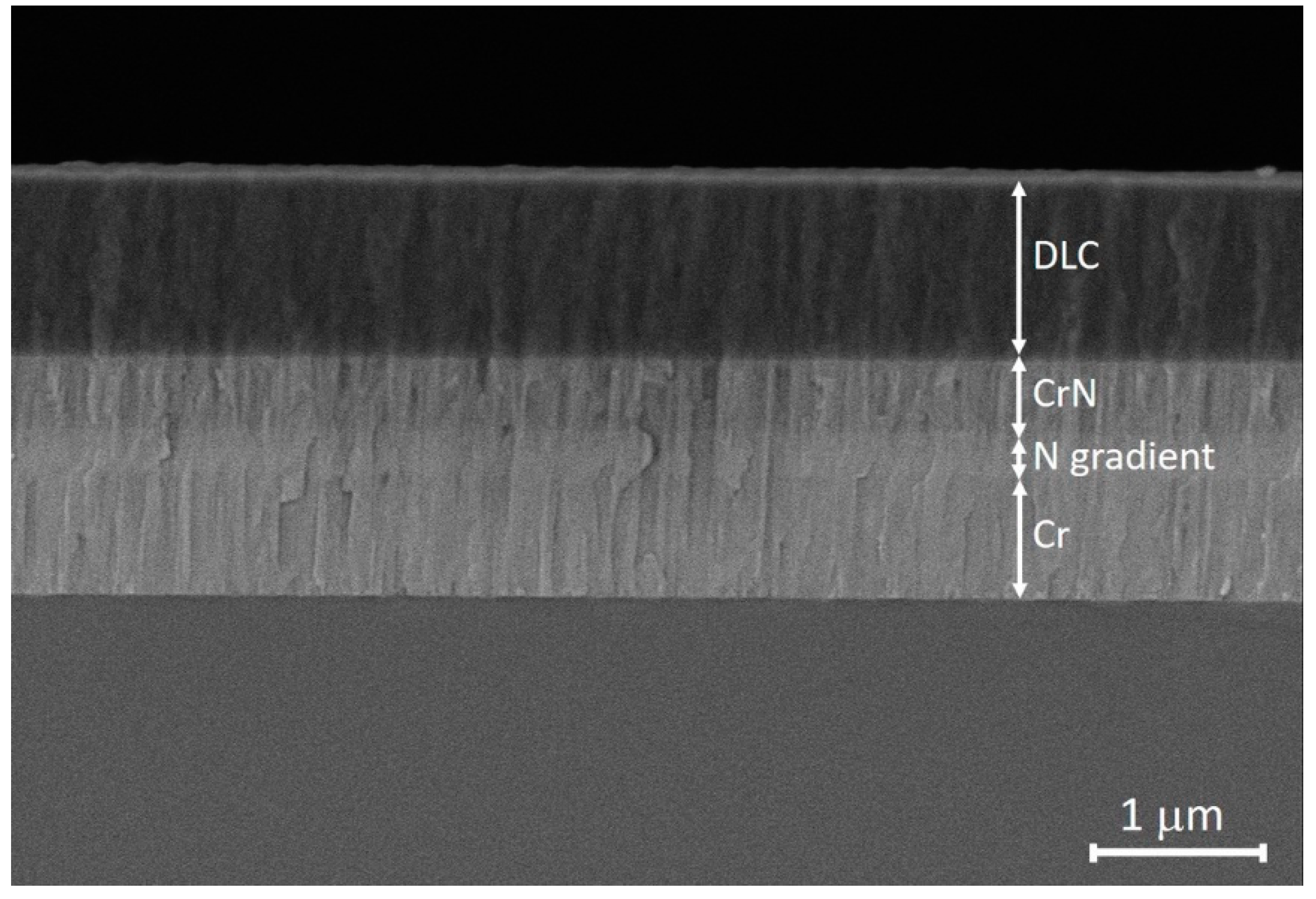

- Interlayer deposition: The chromium (Cr) interlayer was deposited at a working pressure of 3.0 × 10−1 Pa, with a bias of −60 V and a DC power of 1200 W applied to the Cr target. This step lasted for ten minutes. The gas composition was gradually adjusted by increasing the percentage of nitrogen (N2) and reducing the percentage of argon (Ar) to facilitate the deposition of the CrN layer. Both interlayers had a thickness of approximately 400 nm.

- DLC coating deposition: The final step involved depositing the DLC coating for 60 min at a pressure of 4 × 10−1 Pa. The deposition procedure utilized micro-pulsing with a duration of 6 μs for each micro-pulse, separated by intervals of 150 μs. The entire pulse cycle spanned 1800 μs. A substrate voltage bias of −80 V was applied, and the average power was maintained at 600 W. Figure 1 presents an overview of the deposition procedure [2].

2.3. Lubricants

2.4. Characterization Methods

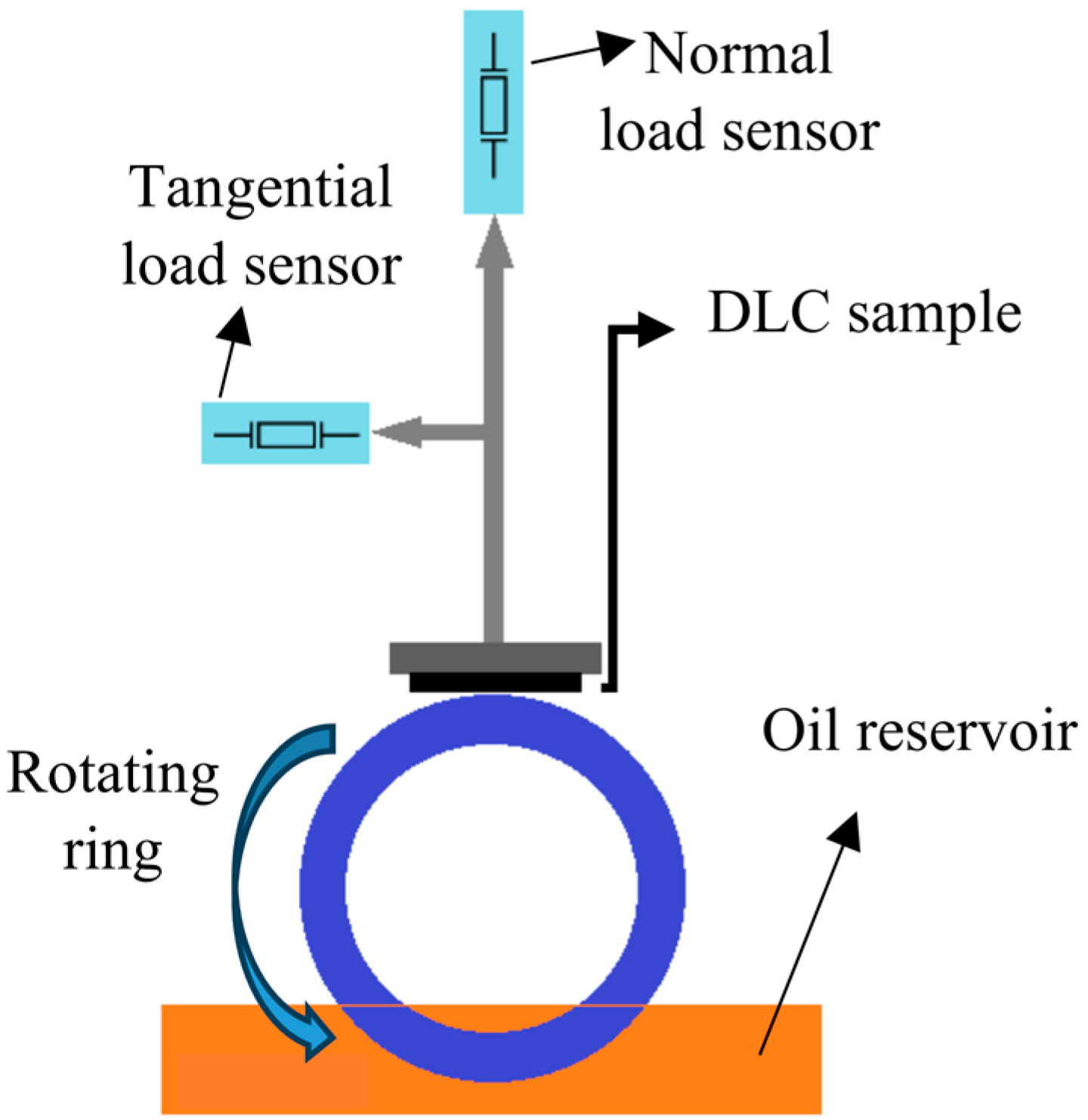

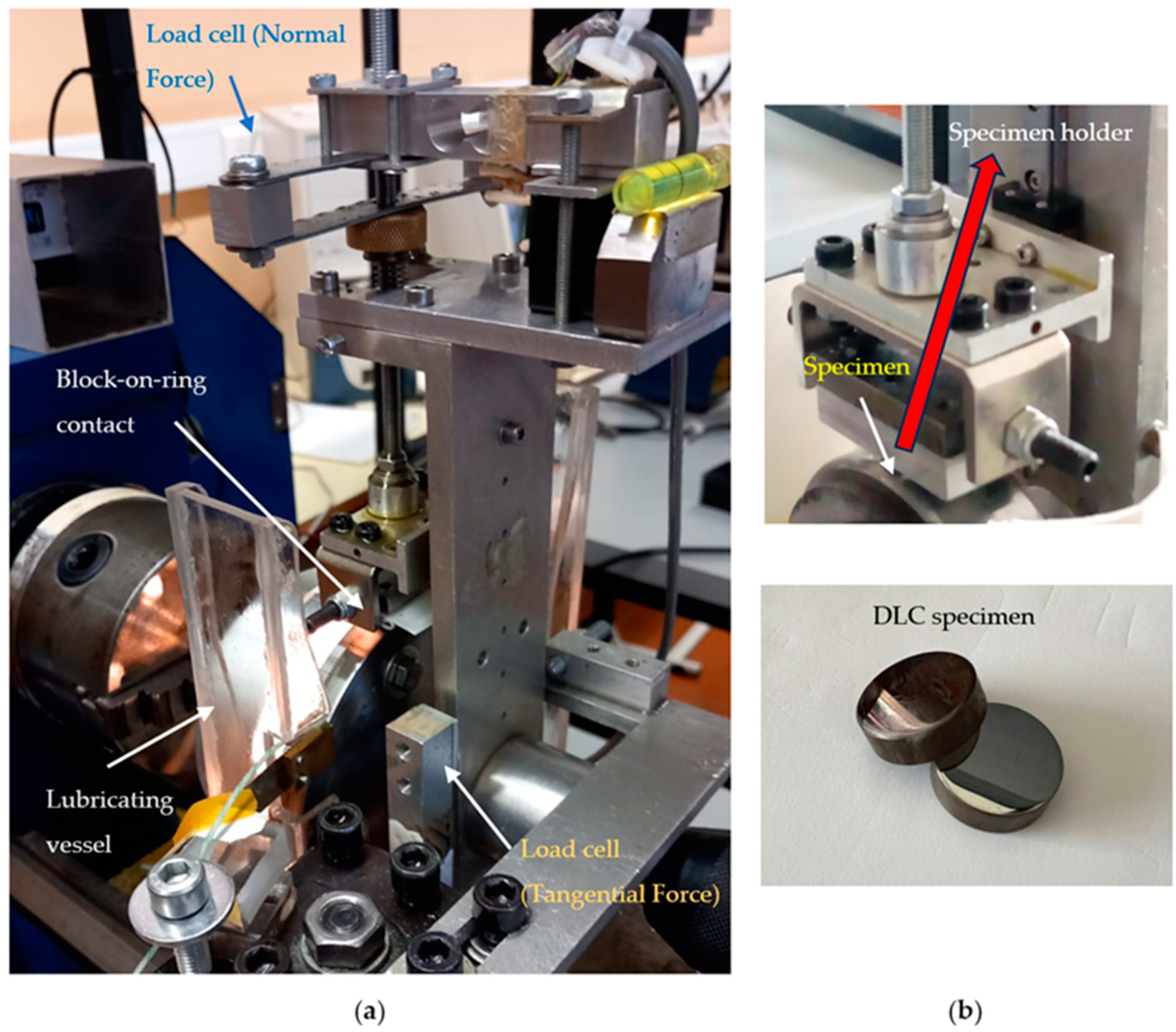

2.5. Tribotest

3. Results and Discussion

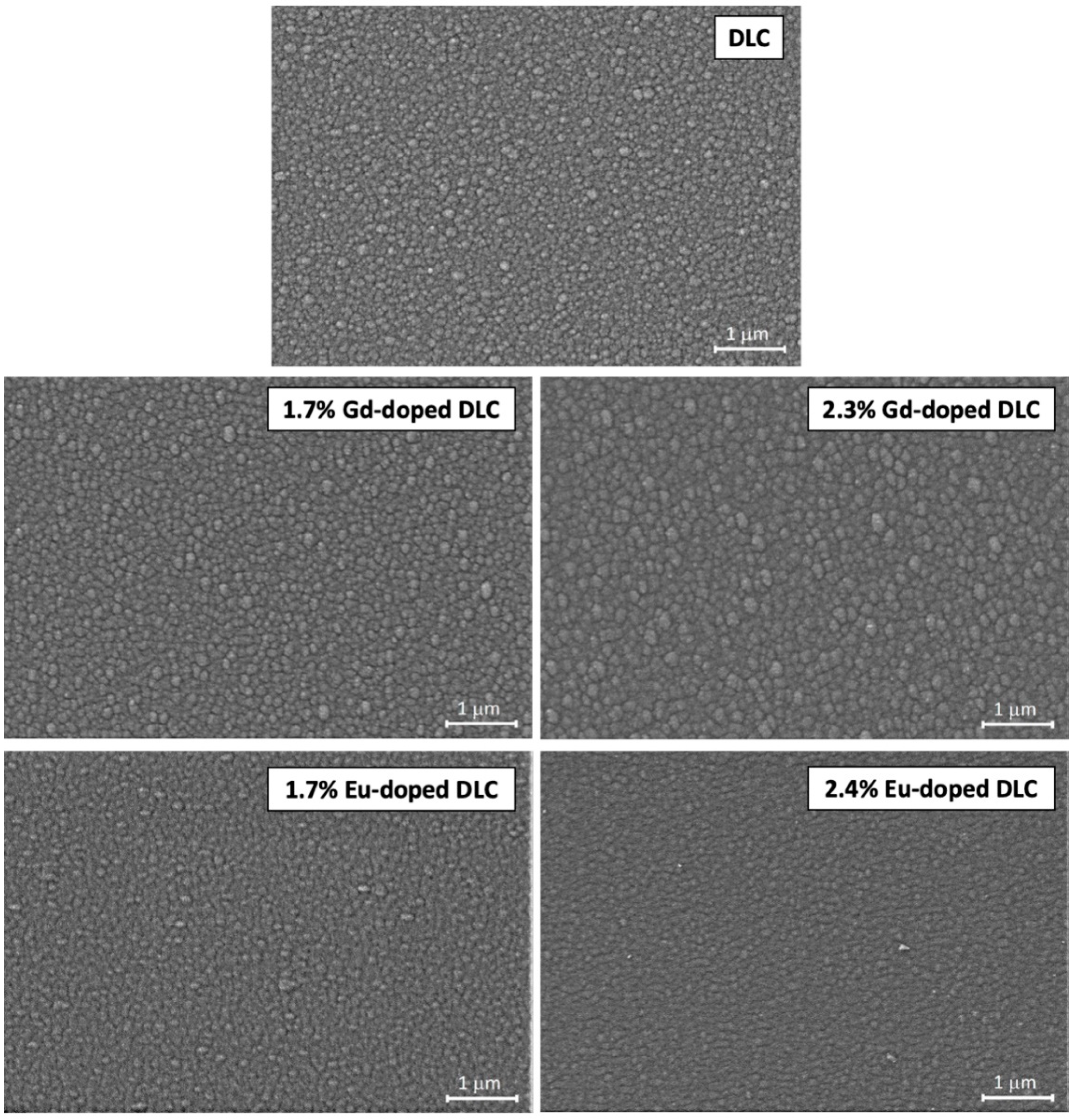

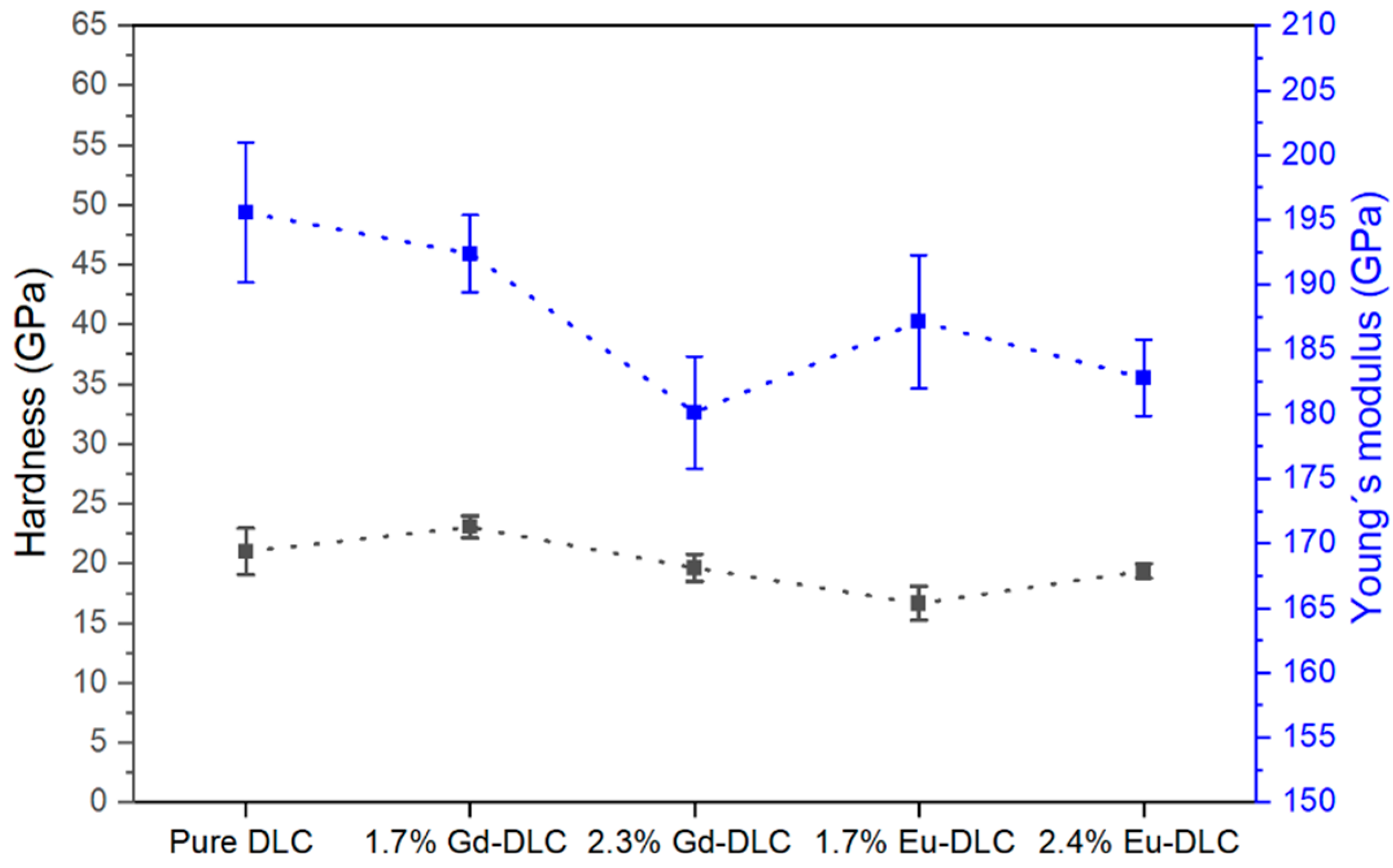

3.1. Chemical Composition, Structure, Hardness, and Reduced Young’s Modulus of Thin Films

3.2. Lubricant Viscosity

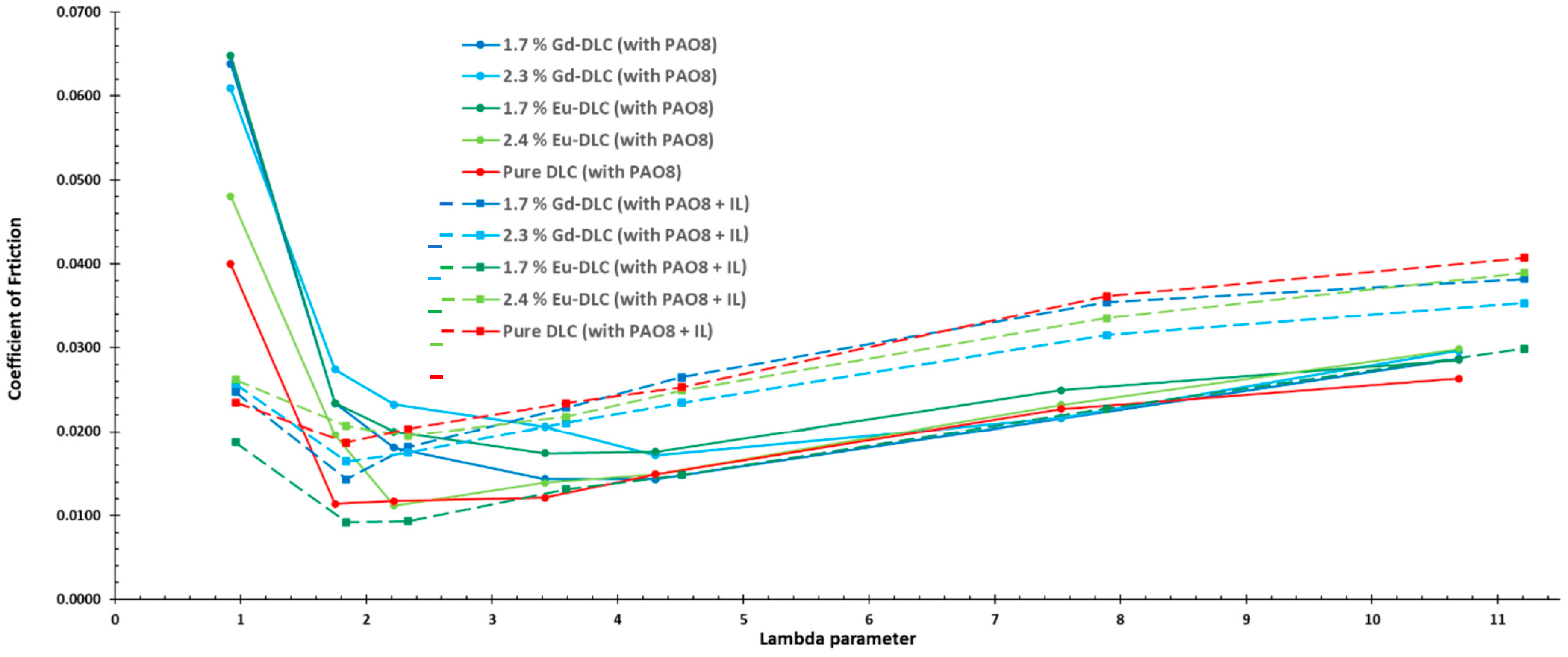

3.3. Stribeck Curves

3.4. Wear Track Analysis

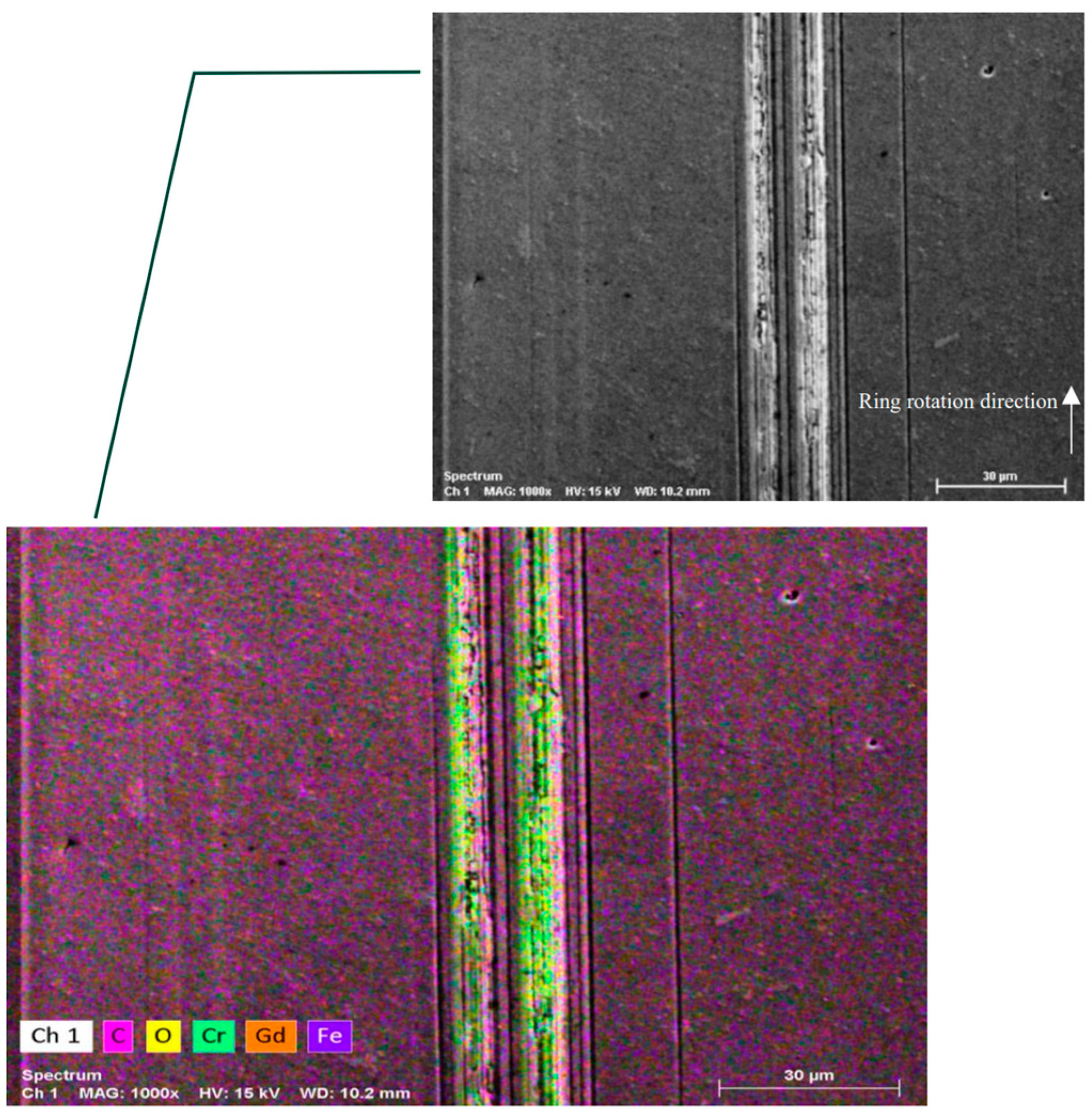

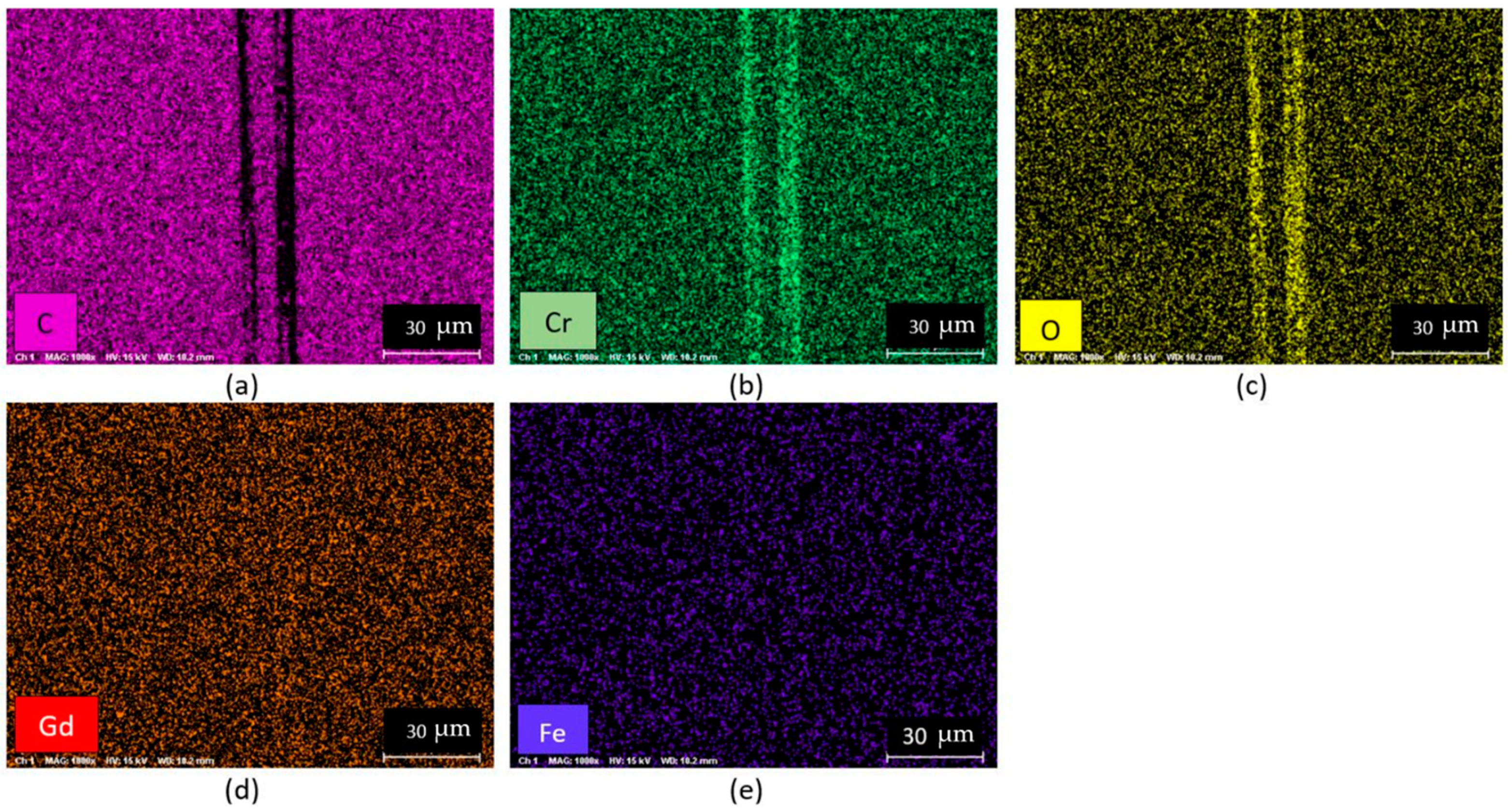

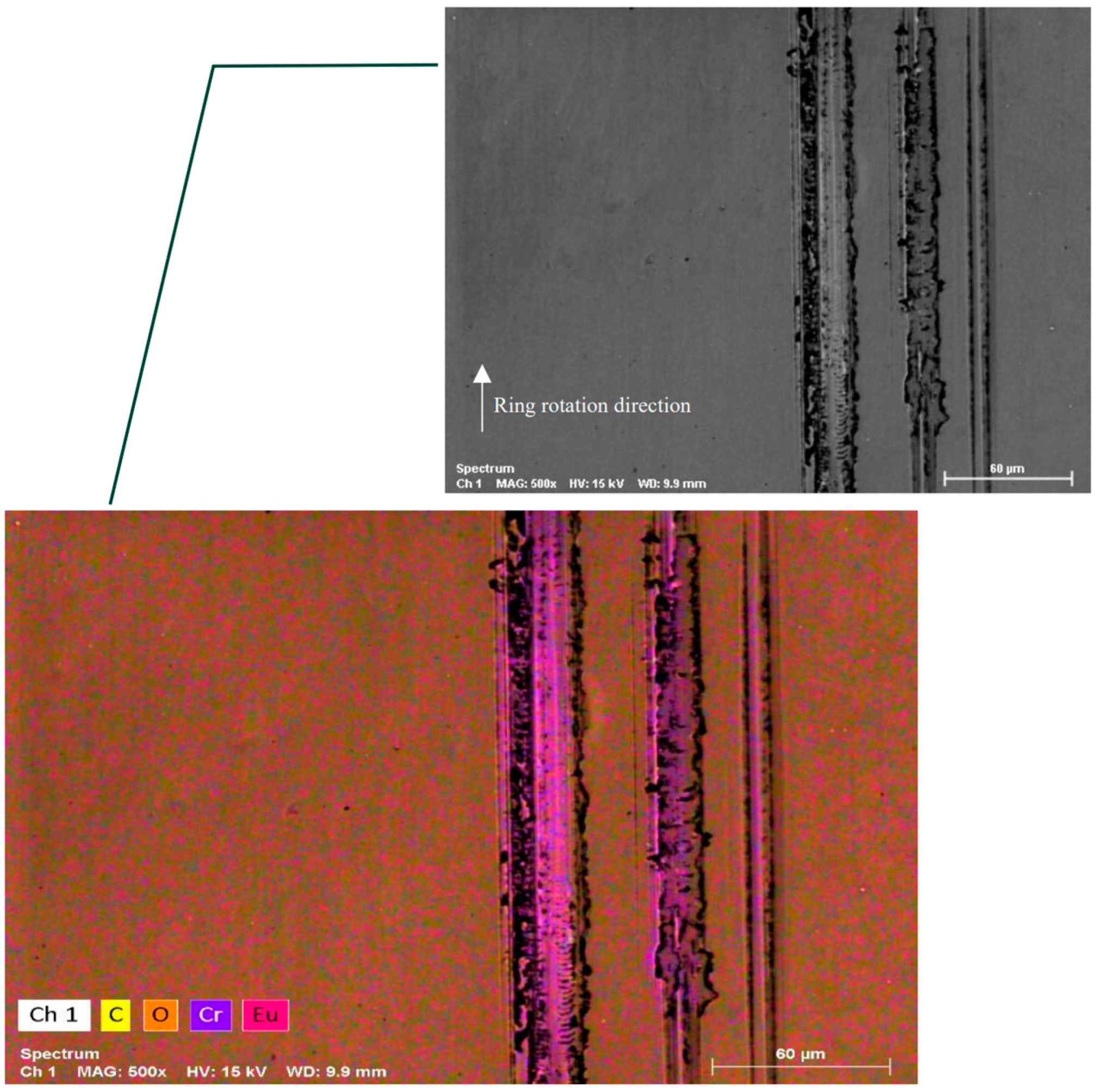

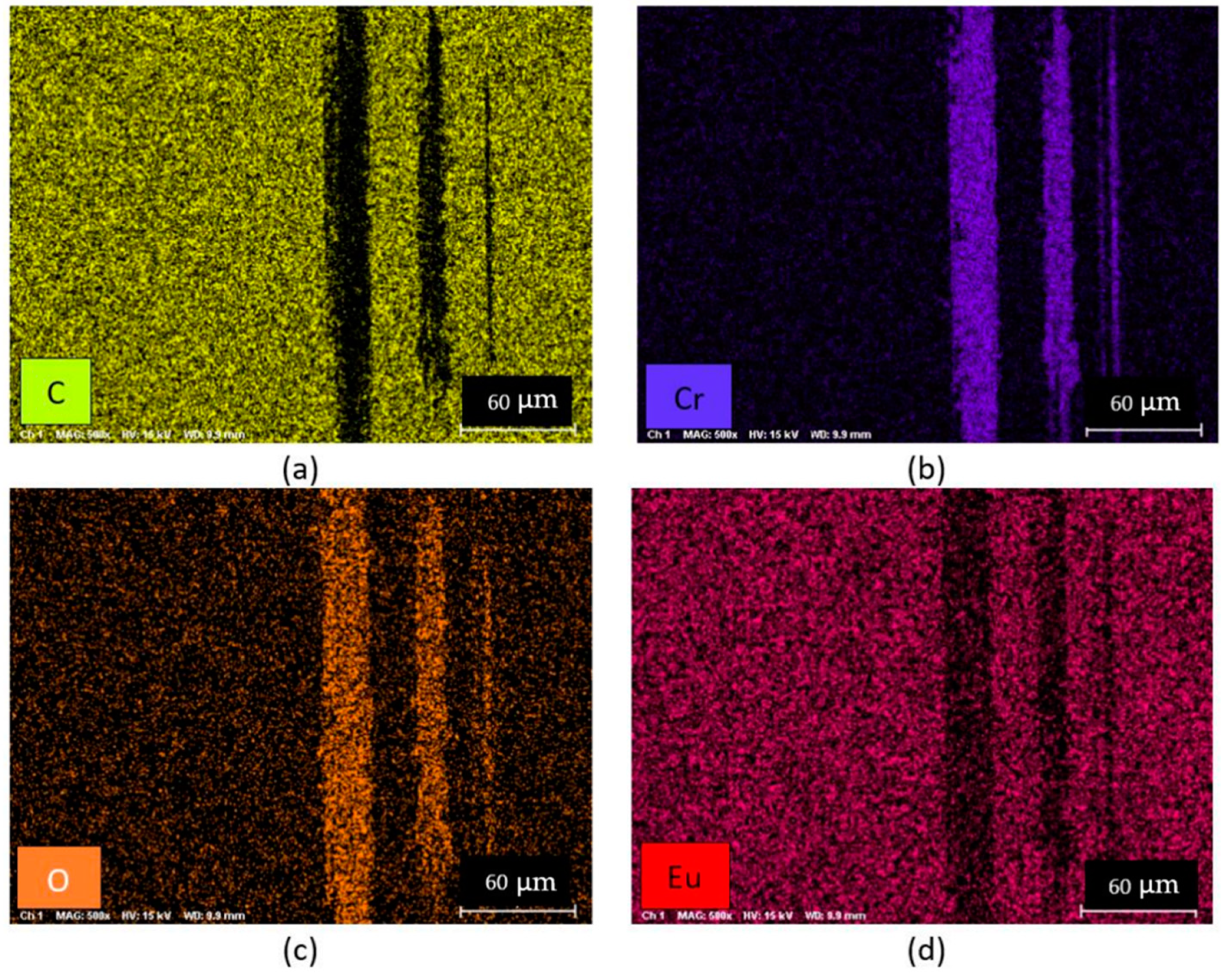

3.5. SEM/EDS Analysis

4. Conclusions

- Among the five coatings examined, the 1.7% Gd-doped DLC coating displayed the highest hardness value. While 1.7% Gd-DLC, 1.7% Eu-DLC, and 2.4% Eu-DLC showed almost similar ID/IG values, 2.3% Gd-DLC has the highest ID/IG value which corresponds to lower percentage of sp3 content in its structure.

- In scenarios where PAO8 served as the primary lubricant without added ionic liquids, the pure diamond-like carbon film demonstrated the least friction when interacting with the opposing surface.

- Upon the addition of 1 wt. % of ionic liquid additive to PAO8, a noteworthy reduction in the CoF was observed across all lubrication conditions for the 1.7% Eu-doped DLC coating, outperforming all other pairs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Reduce Friction, Save Energy-ITAINNOVA. Available online: https://www.itainnova.es/blog/materiales/reduce-friction-save-energy/ (accessed on 14 January 2023).

- Sadeghi, M.; Omiya, T.; Fernandes, F.; Vilhena, L.; Ramalho, A.; Ferreira, F. Tribological Behavior of Doped DLC Coatings in the Presence of Ionic Liquid Additive under Different Lubrication Regimes. Coatings 2023, 13, 891. [Google Scholar] [CrossRef]

- Shaikh, S.; Omiya, T.; Cavaleiro, A.; Vilhena, L.; Ramalho, A.; Ferreira, F. Impact of Temperature Variation on Friction Behaviour of Rare Earth-Doped Diamond-like Carbon Coatings with Ionic Liquid Lubricants. Lubricants 2023, 11, 302. [Google Scholar] [CrossRef]

- Omiya, T.; Fontes, M.; Vuchkov, T.; Cruz, S.; Cavaleiro, A.; Ferreira, F. Tribological Performance of Gd-DLC and Eu-DLC Coatings in the Presence of Synthetic Oils Containing Ionic Liquid Additives Keywords. Tribol. Lett. 2023, 71, 65. [Google Scholar] [CrossRef]

- Khanmohammadi, H.; Wijanarko, W.; Cruz, S.; Evaristo, M.; Espallargas, N. Triboelectrochemical Friction Control of W- and Ag-Doped DLC Coatings in Water-Glycol with Ionic Liquids as Lubricant Additives. RSC Adv. 2022, 12, 3573–3583. [Google Scholar] [CrossRef]

- Spikes, H. The History and Mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Ren, S.; Zheng, S.; Pu, J.; Lu, Z.; Zhang, G. Study of Tribological Mechanisms of Carbon-Based Coatings in Antiwear Additive Containing Lubricants under High Temperature. RSC Adv. 2015, 5, 66426–66437. [Google Scholar] [CrossRef]

- Ratoi, M.; Niste, V.B.; Zekonyte, J. WS2 Nanoparticles—Potential Replacement for ZDDP and Friction Modifier Additives. RSC Adv. 2014, 4, 21238–21245. [Google Scholar] [CrossRef]

- Fontes, M.A.; Serra, R.G.H.; Fernandes, F.D.; Cavaleiro Rodrigues de Carvalho, A.A.; de Sousa Ferreira, F.E. Comparison of Mechanical and Tribological Properties of Diamond-like Carbon Coatings Doped with Europium and Gadolinium Produced by HiPIMS. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2022, 09544054221136528. [Google Scholar] [CrossRef]

- Zhao, F.; Li, H.; Ji, L.; Wang, Y.; Zhou, H.; Chen, J. Ti-DLC Films with Superior Friction Performance. Diam. Relat. Mater. 2010, 19, 342–349. [Google Scholar] [CrossRef]

- Ming, M.Y.; Jiang, X.; Piliptsou, D.G.; Zhuang, Y.; Rogachev, A.V.; Rudenkov, A.S.; Balmakou, A. Chromium-Modified a-C Films with Advanced Structural, Mechanical and Corrosive-Resistant Characteristics. Appl. Surf. Sci. 2016, 379, 424–432. [Google Scholar] [CrossRef]

- Balestra, R.M.; Castro, A.M.G.; Evaristo, M.; Escudeiro, A.; Mutafov, P.; Polcar, T.; Cavaleiro, A. Carbon-Based Coatings Doped by Copper: Tribological and Mechanical Behavior in Olive Oil Lubrication. Surf. Coat. Technol. 2011, 205, S79–S83. [Google Scholar] [CrossRef]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Tribological Behaviour of W-DLC against an Aluminium Alloy Subjected to Lubricated Sliding. Tribol. Ind. 2015, 37, 277–283. [Google Scholar]

- Bociaga, D.; Komorowski, P.; Batory, D.; Szymanski, W.; Olejnik, A.; Jastrzebski, K.; Jakubowski, W. Silver-Doped Nanocomposite Carbon Coatings (Ag-DLC) for Biomedical Applications–Physiochemical and Biological Evaluation. Appl. Surf. Sci. 2015, 355, 388–397. [Google Scholar] [CrossRef]

- Evaristo, M.; Polcar, T.; Cavaleiro, A. Tribological Behaviour of W-Alloyed Carbon-Based Coatings in Dry and Lubricated Sliding Contact. Lubr. Sci. 2014, 26, 428–439. [Google Scholar] [CrossRef]

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration. Coatings 2020, 10, 319. [Google Scholar] [CrossRef]

- Majeed, S.; Siraj, K.; Naseem, S.; Khan, M.F.; Irshad, M.; Faiz, H.; Mahmood, A. Structural and Optical Properties of Gold-Incorporated Diamond-like Carbon Thin Films Deposited by RF Magnetron Sputtering. Mater. Res Express 2017, 4, 076403. [Google Scholar] [CrossRef]

- Liu, N.; Zhu, H.; Wei, Q.; Long, H.; Deng, Z.; Yu, Z.; Xie, Y.; Wang, J.; Ma, L.; Zhou, K. A Niobium and Nitrogen Co-Doped DLC Film Electrode and Its Electrochemical Properties. J Electrochem. Soc. 2017, 164, H1091–H1098. [Google Scholar] [CrossRef]

- Wang, L.; Jin, J.; Zhu, C.; Li, G.; Kuang, X.; Huang, K. Effects of HiPIMS Pulse-Length on Plasma Discharge and on the Properties of WC-DLC Coatings. Appl. Surf. Sci. 2019, 487, 526–538. [Google Scholar] [CrossRef]

- Zia, A.W.; Zhou, Z.; Li, L.K.-Y. Structural, Mechanical, and Tribological Characteristics of Diamond-like Carbon Coatings. In Nanomaterials-Based Coatings; Nguyen Tri, P., Rtimi, S., Ouellet Plamondon, C.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 171–194. ISBN 978-0-12-815884-5. [Google Scholar]

- Zhang, R.; Wang, L. Synergistic Improving of Tribological Properties of Amorphous Carbon Film Enhanced by F–Si-Doped Multilayer Structure under Corrosive Environment. Surf. Coat. Technol. 2015, 276, 626–635. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, M.; Yang, Y.; Zhang, Y.; Yan, F.; Li, H. Excellent Mechanical, Tribological and Anti-Corrosive Performance of Novel Ti-DLC Nanocomposite Thin Films Prepared via Magnetron Sputtering Method. Carbon N. Y. 2019, 151, 136–147. [Google Scholar] [CrossRef]

- Jo, Y.J.; Zhang, T.F.; Son, M.J.; Kim, K.H. Synthesis and Electrochemical Properties of Ti-Doped DLC Films by a Hybrid PVD/PECVD Process. Appl. Surf. Sci. 2018, 433, 1184–1191. [Google Scholar] [CrossRef]

- Rana, R.; Walia, R.S.; Murtaza, Q. Characterization and Parametric Optimization of Performance Parameters of DLC-Coated Tungsten Carbide (WC) Tool Using TOPSIS. Coatings 2021, 11, 760. [Google Scholar] [CrossRef]

- Liu, L.; Huang, J.; He, X.; Wang, T.; He, Z.; Du, K.; Diao, X. Preparation and Characterization of High Quality Diamond like Carbon Films on Si Microspheres. Mater. Lett 2018, 220, 309–312. [Google Scholar] [CrossRef]

- Sharifahmadian, O.; Mahboubi, F.; Yazdani, S. Comparison between Corrosion Behaviour of DLC and N-DLC Coatings Deposited by DC-Pulsed PACVD Technique. Diam. Relat. Mater. 2019, 95, 60–70. [Google Scholar] [CrossRef]

- Carvalho, I.; Dias, N.; Henriques, M.; Calderon, V.S.; Ferreira, P.; Cavaleiro, A.; Carvalho, S. Antibacterial Effects of Bimetallic Clusters Incorporated in Amorphous Carbon for Stent Application. ACS Appl. Mater. Interfaces 2020, 12, 24555–24563. [Google Scholar] [CrossRef]

- Antunes, J.; Matos, K.; Carvalho, I.; Carvalho, S.; Ferreira, F.; Cruz, S.M.A. Physical Vapor Deposition Technology in Personal Protective Equipment Production: Improved Antibacterial and Hydrophobic Character of Textiles. Coatings 2022, 12, 1399. [Google Scholar] [CrossRef]

- Zhou, F.; Liang, Y.; Liu, W. Ionic Liquid Lubricants: Designed Chemistry for Engineering Applications. Chem. Soc. Rev. 2009, 38, 2590–2599. [Google Scholar] [CrossRef]

- Ye, C.; Liu, W.; Chen, Y.; Yu, L. Room-Temperature Ionic Liquids: A Novel Versatile Lubricant. Chem. Commun. 2001, 2244–2245. [Google Scholar] [CrossRef]

- Nanao, H.; Takahashi, K.; Shirai, M. Lubricity Improvement of Imidazolium Cation-Based Ionic Liquids Treated with Carbon Dioxide. J. Jpn. Pet. Inst. 2017, 60, 329–332. [Google Scholar] [CrossRef]

- Milewski, K.; Kudliński, J.; Madej, M.; Ozimina, D.; Kudliński -Trzuskawica, J.; Madej, P.M. The Interaction between Diamond like Carbon (DLC) Coatings and Ionic Liquids under Boundary Lubrication Conditions. 55 METALURGIJA 2017, 56, 55–58. [Google Scholar]

- González, R.; Battez, A.H.; Viesca, J.L.; Higuera-Garrido, A.; Fernández-González, A. Lubrication of DLC Coatings with Two Tris(Pentafluoroethyl)Trifluorophosphate Anion-Based Ionic Liquids. Tribol. Trans. 2013, 56, 887–895. [Google Scholar] [CrossRef]

- Shahid Arshad, M.; Čoga, L.; Geue, T.; Kovač, J.; Cruz, S.M.A.; Kalin, M. Adsorption Mechanism of Tributylmethylphosphonium Dimethylphosphate Ionic Liquid on Diamond-like Carbon Coatings: Neutron Reflectometry Study. Tribol. Int. 2021, 151, 106482. [Google Scholar]

- Arshad, M.S.; Kovač, J.; Cruz, S.; Kalin, M. Physicochemical and Tribological Characterizations of WDLC Coatings and Ionic-Liquid Lubricant Additives: Potential Candidates for Low Friction under Boundary-Lubrication Conditions. Tribol. Int. 2020, 151, 106482. [Google Scholar] [CrossRef]

- Stoy, L.; Xu, J.; Kulkarni, Y.; Huang, C.-H. Ionic Liquid Recovery of Rare-Earth Elements from Coal Fly Ash: Process Efficiency and Sustainability Evaluations. ACS Sustain. Chem. Eng. 2022, 10, 11824–11834. [Google Scholar] [CrossRef]

- Mishra, B.B.; Devi, N. Application of Bifunctional Ionic Liquids for Extraction and Separation of Eu3+ from Chloride Medium. Trans. Nonferrous Met. Soc. China 2022, 32, 2061–2070. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like Carbon: State of the Art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Turanov, A.N.; Karandashev, V.K.; Boltoeva, M. Solvent Extraction of Intra-Lanthanides Using a Mixture of TBP and TODGA in Ionic Liquid. Hydrometallurgy 2020, 195, 105367. [Google Scholar] [CrossRef]

- Bolander, N.W.; Steenwyk, B.D.; Sadeghi, F.; Gerber, G.R. Lubrication Regime Transitions at the Piston Ring-Cylinder Liner Interface. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2005, 219, 19–31. [Google Scholar] [CrossRef]

- Vahidi, A.; Fonseca, D.; Oliveira, J.; Cavaleiro, A.; Ramalho, A.; Ferreira, F. Advanced Tribological Characterization of Dlc Coatings Produced by Ne-Hipims for the Application on the Piston Rings of Internal Combustion Engines. Appl. Sci. 2021, 11, 10498. [Google Scholar] [CrossRef]

- Pusterhofer, M.; Summer, F.; Wuketich, D.; Grün, F. Development of a Model Test System for a Piston Ring/Cylinder Liner-Contact with Focus on near-to-Application Seizure Behaviour. Lubricants 2019, 7, 104. [Google Scholar] [CrossRef]

- Hu, Z. Chapter 6—Characterization of Materials, Nanomaterials, and Thin Films by Nanoindentation. In Microscopy Methods in Nanomaterials Characterization; Thomas, S., Thomas, R., Zachariah, A.K., Mishra, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 165–239. ISBN 978-0-323-46141-2. [Google Scholar]

- Sharma, S. Tribological Behaviour of Laser Treated C-Alloyed TMD Coatings in Rubber Contact Effects of Protein on Tribocorrosion Behavior of Ti-6Al-4V. View Project Construction of Tribocorrosion Setup and Study the Degradation of Ti-Implants View Project; University of Coimbra: Coimbra, Portugal, 2021. [Google Scholar]

- Zhou, X.; Tunmee, S.; Suzuki, T.; Phothongkam, P.; Kanda, K.; Komatsu, K.; Kawahara, S.; Ito, H.; Saitoh, H. Quantitative NEXAFS and Solid-State NMR Studies of Sp3/(Sp2+sp3) Ratio in the Hydrogenated DLC Films. Diam. Relat. Mater. 2017, 73, 232–240. [Google Scholar] [CrossRef]

- Gurbich, A.F. SigmaCalc Recent Development and Present Status of the Evaluated Cross-Sections for IBA. Nucl. Instrum. Methods Phys. Res. B 2016, 371, 27–32. [Google Scholar] [CrossRef]

- ASTM G77-17; Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/g0077-17.html (accessed on 4 January 2024).

- Cardoso, F.; Ferreira, F.; Cavaleiro, A.; Ramalho, A. Performance of Diamond-like Carbon Coatings (Produced by the Innovative Ne-HiPIMS Technology) under Different Lubrication Regimes. Wear 2021, 477, 203775. [Google Scholar] [CrossRef]

- Luo, Q. Electron Microscopy and Spectroscopy in the Analysis of Friction and Wear Mechanisms. Lubricants 2018, 6, 58. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Cavaleiro, A.; Oliveira, J.C. Additional Control of Bombardment by Deep Oscillation Magnetron Sputtering: Effect on the Microstructure and Topography of Cr Thin Films. Thin Solid Films 2016, 619, 250–260. [Google Scholar] [CrossRef]

- Ferreira, F.; Aijaz, A.; Kubart, T.; Cavaleiro, A.; Oliveira, J. Hard and Dense Diamond like Carbon Coatings Deposited by Deep Oscillations Magnetron Sputtering. Surf. Coat. Technol. 2018, 336, 92–98. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, X.; Lee, P.; Wei, R. Thick Diamond like Carbon Coatings Deposited by Deep Oscillation Magnetron Sputtering. Surf. Coat. Technol. 2017, 315, 294–302. [Google Scholar] [CrossRef]

- Hatem, A.; Lin, J.; Wei, R.; Torres, R.D.; Laurindo, C.; Soares, P. Tribocorrosion Behavior of DLC-Coated Ti-6Al-4V Alloy Deposited by PIID and PEMS+PIID Techniques for Biomedical Applications. Surf. Coat. Technol. 2017, 332, 223–232. [Google Scholar] [CrossRef]

- Sharifahmadian, O.; Mahboubi, F.; Oskouie, A. Structural Evolution and Tribological Behavior of Nitrogen-Doped DLC Coatings Deposited by Pulsed DC PACVD Method. Diam. Relat. Mater. 2019, 91, 74–83. [Google Scholar] [CrossRef]

- Kubart, T.; Aijaz, A.; Andersson, J.; Ferreira, F.; Oliveira, J.C.; Sobetkii, A.; Parau, A.C.; Vitelaru, C. High Power Impulse Magnetron Sputtering of Diamond-like Carbon Coatings. J. Vac. Sci. Technol. A 2020, 38, 043408. [Google Scholar] [CrossRef]

- Serra, R.; Ferreira, F.; Cavaleiro, A.; Oliveira, J.C. HiPIMS Pulse Shape Influence on the Deposition of Diamond-like Carbon Films. Surf. Coat. Technol. 2022, 432, 128059. [Google Scholar] [CrossRef]

- Kashyap, A.; Harsha, A.P.; Kondaiah, P.; Barshilia, H.C. Study on Galling Behaviour of HiPIMS Deposited Mo/DLC Multilayer Coatings at Ambient and Elevated Temperature. Wear 2022, 498–499, 204327. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Libassi, A.; Tanner, B.K.; Stolojan, V.; Yuan, J.; Brown, L.M.; Rodil, S.E.; Kleinsorge, B.; Robertson, J. Density, Sp3 Fraction, and Cross-Sectional Structure of Amorphous Carbon Films Determined by x-Ray Reflectivity and Electron Energy-Loss Spectroscopy. Phys. Rev. B 2000, 62, 11089–11103. [Google Scholar] [CrossRef]

- Foong, Y.M.; Hsieh, J.; Li, X.; Chua, D.H.C. Comparative Study between Erbium and Erbium Oxide-Doped Diamondlike Carbon Films Deposited by Pulsed Laser Deposition Technique. J. Vac. Sci. Technol. A 2010, 28, 449–455. [Google Scholar] [CrossRef]

- Schmidt, K.; Laumer, J.; O’Leary, S.K. The D- and G-Branches Associated with the Raman Spectrum of Thin-Film Carbon. Solid State Commun. 2023, 360, 115041. [Google Scholar] [CrossRef]

- Vetter, J. 60years of DLC Coatings: Historical Highlights and Technical Review of Cathodic Arc Processes to Synthesize Various DLC Types, and Their Evolution for Industrial Applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar] [CrossRef]

- Liu, Y.; Erdemir, A.; Meletis, E.I. A Study of the Wear Mechanism of Diamond-like Carbon Films. Surf. Coat. Technol. 1996, 82, 48–56. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like Amorphous Carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Ding, J.C.; Mei, H.; Jeong, S.; Zheng, J.; Wang, Q.M.; Kim, K.H. Effect of Bias Voltage on the Microstructure and Properties of Nb-DLC Films Prepared by a Hybrid Sputtering System. J. Alloys Compd. 2021, 861, 158505. [Google Scholar] [CrossRef]

- Ding, J.C.; Chen, M.; Mei, H.; Jeong, S.; Zheng, J.; Yang, Y.; Wang, Q.; Kim, K.H. Microstructure, Mechanical, and Wettability Properties of Al-Doped Diamond-like Films Deposited Using a Hybrid Deposition Technique: Bias Voltage Effects. Diam. Relat. Mater. 2022, 123, 108861. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.J. Stribeck Curves. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: Boston, MA, USA, 2013; pp. 3365–3370. ISBN 978-0-387-92897-5. [Google Scholar]

- Marinescu, I.D.; Rowe, W.B.; Dimitrov, B.; Inasaki, I. Process Fluids for Abrasive Machining. In Tribology of Abrasive Machining Processes; Marinescu, I.D., Rowe, W.B., Dimitrov, B., Inasaki, I., Eds.; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 531–585. ISBN 978-0-8155-1490-9. [Google Scholar]

- Xin, Q. Friction and Lubrication in Diesel Engine System Design. In Diesel Engine System Design; Xin, Q., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 651–758. ISBN 978-1-84569-715-0. [Google Scholar]

- Kalin, M.; Velkavrh, I.; Vižintin, J. The Stribeck Curve and Lubrication Design for Non-Fully Wetted Surfaces. Wear 2009, 267, 1232–1240. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M.M.; Gelinck, E.R.M. The Stribeck Curve: Experimental Results and Theoretical Prediction. J. Tribol. 2006, 128, 789–794. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.J.; Lin, C.; Shi, F. Development of a Set of Stribeck Curves for Conformal Contacts of Rough Surfaces. Tribol. Trans. 2006, 49, 526–535. [Google Scholar] [CrossRef]

- Kalin, M.; Velkavrh, I. Non-Conventional Inverse-Stribeck-Curve Behaviour and Other Characteristics of DLC Coatings in All Lubrication Regimes. Wear 2013, 297, 911–918. [Google Scholar] [CrossRef]

- Martini, A.; Zhu, D.; Wang, Q. Friction Reduction in Mixed Lubrication. Tribol. Lett. 2007, 28, 139–147. [Google Scholar] [CrossRef]

- Kajdas, C. Importance of Anionic Reactive Intermediates for Lubricant Component Reactions with Friction Surfaces. Lubr. Sci. 1994, 6, 203–228. [Google Scholar] [CrossRef]

- Xiao, H. Ionic Liquid Lubricants: Basics and Applications. Tribol. Trans. 2017, 60, 20–30. [Google Scholar] [CrossRef]

- Atkin, R.; el Abedin, S.Z.; Hayes, R.; Gasparotto, L.H.S.; Borisenko, N.; Endres, F. AFM and STM Studies on the Surface Interaction of [BMP]TFSA and [EMIm]TFSA Ionic Liquids with Au(111). J. Phys. Chem. C 2009, 113, 13266–13272. [Google Scholar] [CrossRef]

- Perkin, S.; Albrecht, T.; Klein, J. Layering and Shear Properties of an Ionic Liquid, 1-Ethyl-3-Methylimidazolium Ethylsulfate, Confined to Nano-Films between Mica Surfaces. Phys. Chem. Chem. Phys. 2010, 12, 1243–1247. [Google Scholar] [CrossRef]

- Marian, M.; Bartz, M.; Wartzack, S.; Rosenkranz, A. Non-Dimensional Groups, Film Thickness Equations and Correction Factors for Elastohydrodynamic Lubrication: A Review. Lubricants 2020, 8, 95. [Google Scholar] [CrossRef]

| Material | Fe | C | Cr | Mo | W | V |

|---|---|---|---|---|---|---|

| M2 Steel (wt. %) | Balance | 1.0 | 0.4 | 5.0 | 6.0 | 2.0 |

| Properties of the Counterpart (Ring) | |

|---|---|

| Material | AISI 3415 steel |

| Diameter | 115 mm |

| Width | 12 mm |

| Young’s modulus | 205 GPa |

| Poisson’s ratio | 0.285 |

| Specimen | Chemical Composition (at. %) | |||

|---|---|---|---|---|

| H | Ar | Gd | Eu | |

| Pure DLC (or DLC) | 6.5 | 3.6 | 0 | 0 |

| 1.7% Gd-doped DLC | 5.8 | 4.3 | 1.7 | 0 |

| 2.3% Gd-doped DLC | 3.1 | 2.3 | 2.3 | 0 |

| 1.7% Eu-doped DLC | 8 | 3.4 | 0 | 1.7 |

| 2.4% Eu-doped DLC | 5.9 | 3.7 | 0 | 2.4 |

| DLC Samples | xD | ID | xG | IG | ID/IG |

|---|---|---|---|---|---|

| Pure DLC | 1367 | 1110.2 | 1554 | 1511.6 | 0.73 |

| 1.7% Gd-DLC | 1387 | 1223.7 | 1547 | 1501.8 | 0.81 |

| 2.3% Gd-DLC | 1376 | 995.5 | 1536 | 1133.4 | 0.88 |

| 1.7% Eu-DLC | 1376 | 1443.9 | 1556 | 1826.1 | 0.79 |

| 2.4% Eu-DLC | 1370 | 1304.8 | 1530 | 1641.3 | 0.80 |

| Lubricant | Dynamic Viscosity (mPa·s) | Kinematic Viscosity (mm2/s) |

|---|---|---|

| PAO 8 | 71.89 | 86.48 |

| PAO 8 + additive (1 wt. %) | 76.89 | 92.49 |

| u (m/s) | 0.02 | 0.05 | 0.07 | 0.13 | 0.18 | 0.4 | 0.66 |

|---|---|---|---|---|---|---|---|

| (m) | 4.44 × | 8.44 × | 1.06 × | 1.64 × | 2.06 × | 3.61 × | 5.13 × |

| λ | 0.92 | 1.75 | 2.22 | 3.42 | 4.30 | 7.53 | 10.69 |

| Lubrication condition | BL | ML | ML | EL | EL | HL | HL |

| Hersey number | 8.08 × | 1.77 × | 2.91 × | 4.50 × | 6.26 × | 1.39 × | 2.26 × |

| u (m/s) | 0.02 | 0.05 | 0.07 | 0.13 | 0.18 | 0.4 | 0.66 |

|---|---|---|---|---|---|---|---|

| (m) | |||||||

| λ | 0.96 | 1.84 | 2.33 | 3.59 | 4.51 | 7.89 | 11.21 |

| Lubrication condition | BL | ML | ML | EL | EL | HL | HL |

| Hersey number | 8.64 × | 1.89 × | 2.87 × | 4.81 × | 6.70 × | 1.49 × | 2.42 × |

| Pure DLC | |

|---|---|

|  |

| (a) PAO 8 | (b) PAO 8 + 1 wt. % additive |

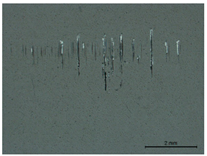

| 1.7% Gd-doped DLC | |

|  |

| (a) PAO 8 | (b) PAO 8 + 1 wt. % additive |

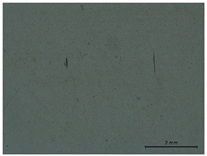

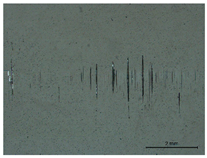

| 2.3% Gd-doped DLC | |

|  |

| (a) PAO 8 | (b) PAO 8 + 1 wt. % additive |

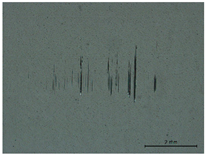

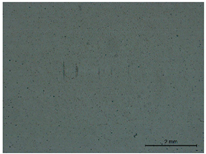

| 1.7% Eu-doped DLC | |

|  |

| (a) PAO 8 | (b) PAO 8 + 1 wt. % additive |

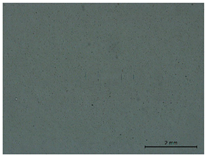

| 2.4% Ed-doped DLC | |

|  |

| (a) PAO 8 | (b) PAO 8 + 1 wt. % additive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghi, M.; Omiya, T.; Fernandes, F.; Vilhena, L.; Ramalho, A.; Ferreira, F. Influence of 1-Ethyl-3-methylimidazolium Diethylphosphate Ionic Liquid on the Performance of Eu- and Gd-Doped Diamond-like Carbon Coatings. Lubricants 2024, 12, 18. https://doi.org/10.3390/lubricants12010018

Sadeghi M, Omiya T, Fernandes F, Vilhena L, Ramalho A, Ferreira F. Influence of 1-Ethyl-3-methylimidazolium Diethylphosphate Ionic Liquid on the Performance of Eu- and Gd-Doped Diamond-like Carbon Coatings. Lubricants. 2024; 12(1):18. https://doi.org/10.3390/lubricants12010018

Chicago/Turabian StyleSadeghi, Mohammadamin, Takeru Omiya, Filipe Fernandes, Luís Vilhena, Amilcar Ramalho, and Fábio Ferreira. 2024. "Influence of 1-Ethyl-3-methylimidazolium Diethylphosphate Ionic Liquid on the Performance of Eu- and Gd-Doped Diamond-like Carbon Coatings" Lubricants 12, no. 1: 18. https://doi.org/10.3390/lubricants12010018

APA StyleSadeghi, M., Omiya, T., Fernandes, F., Vilhena, L., Ramalho, A., & Ferreira, F. (2024). Influence of 1-Ethyl-3-methylimidazolium Diethylphosphate Ionic Liquid on the Performance of Eu- and Gd-Doped Diamond-like Carbon Coatings. Lubricants, 12(1), 18. https://doi.org/10.3390/lubricants12010018