Effect of Operating Parameters on the Mulching Device Wear Behavior of a Ridging and Mulching Machine

Abstract

1. Introduction

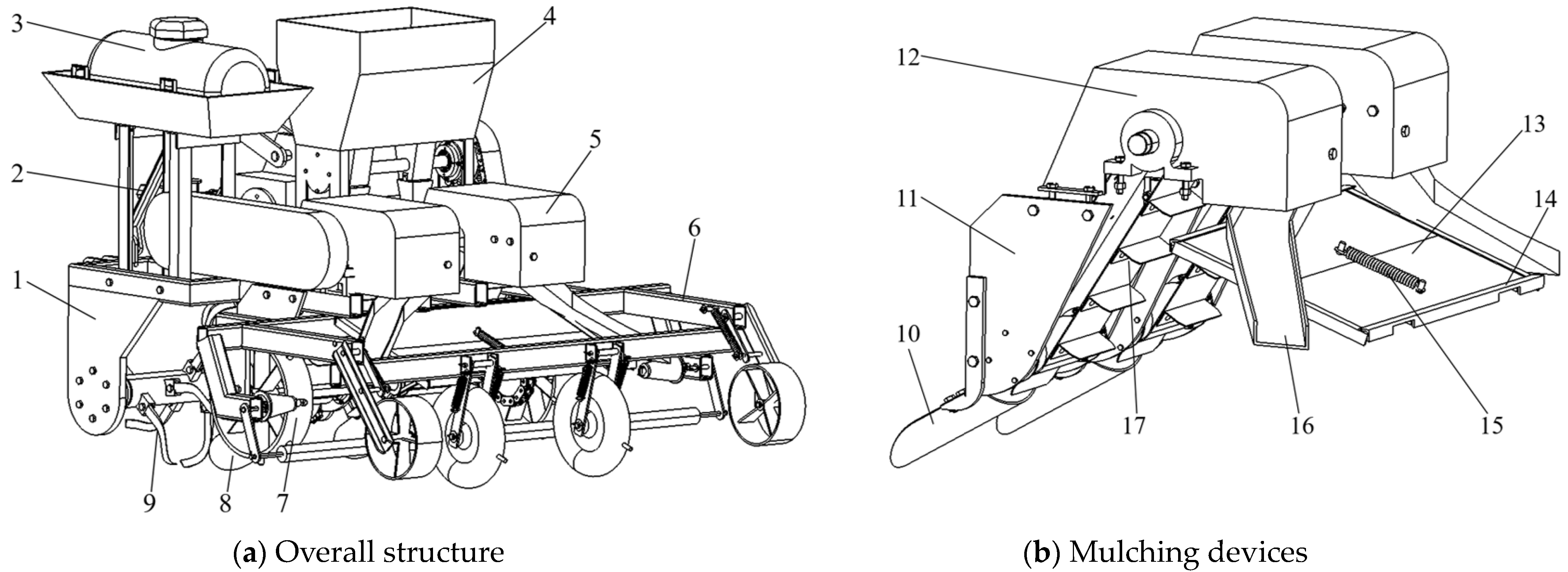

2. Mulching Machine Structure and Mulching Working Principle

3. Wear Analysis Model

Contact Model

4. Discrete Elemental Modeling of Soil Wear for Mulching Devices-Seed Beds

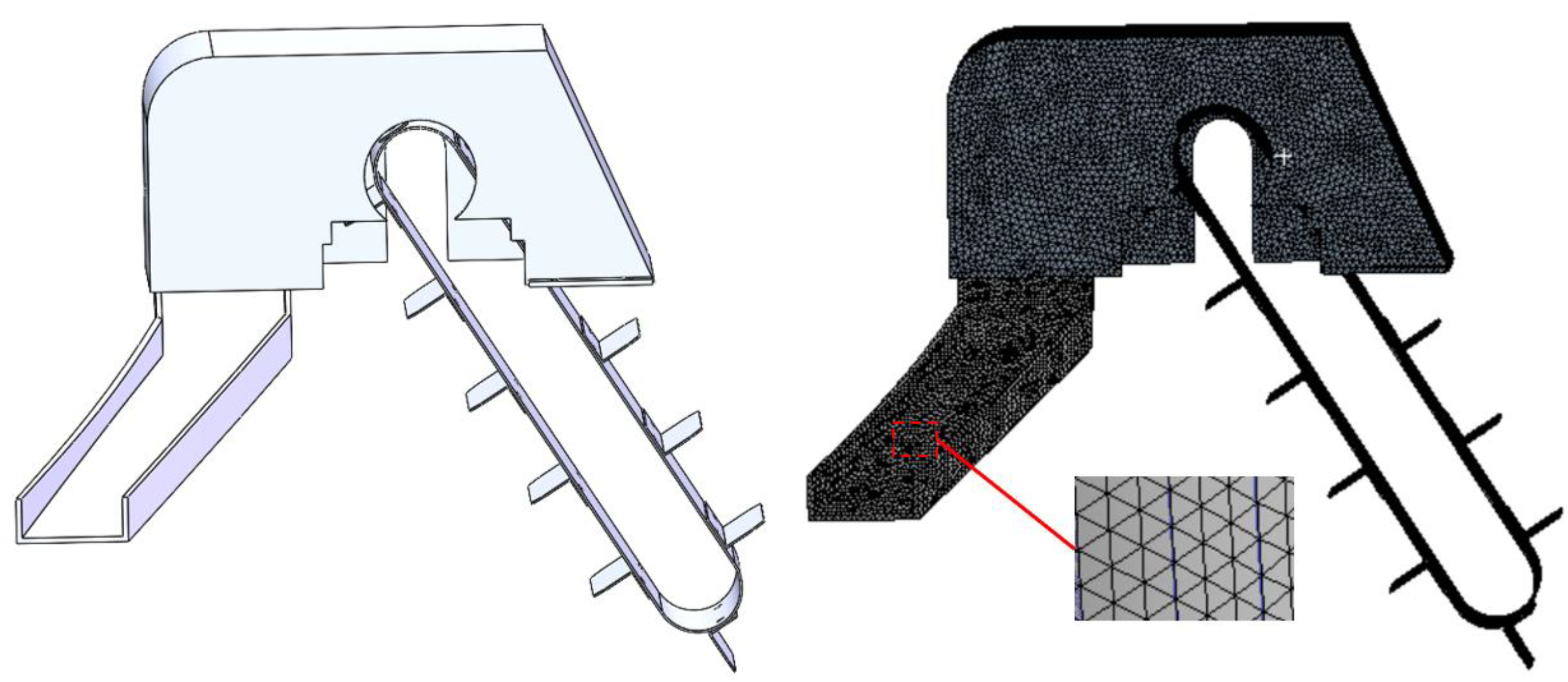

4.1. Discrete Elemental Modeling of Cladding Devices

4.2. Discrete Elemental Modeling of Sandy Soil Particles in Seed Beds

4.3. Discrete Element Model Contact Parameterization

5. Simulated Wear Behavior Analysis of Cladding Devices

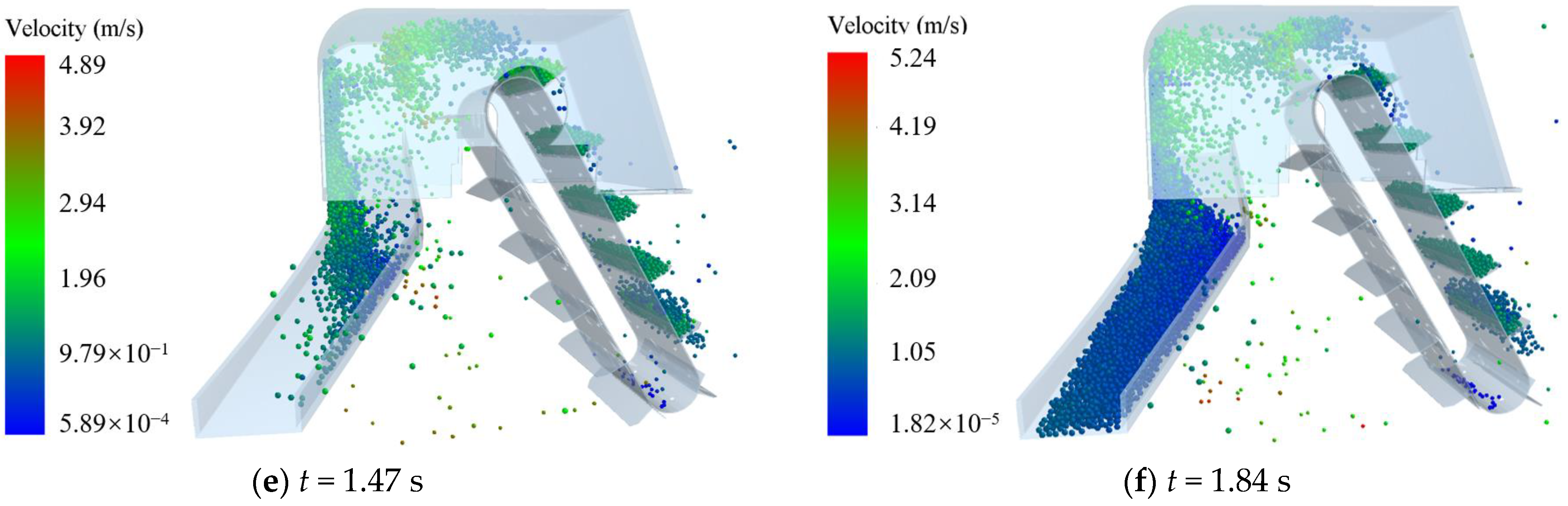

5.1. Laws of Motion of Sand Particles in a Mulching Device

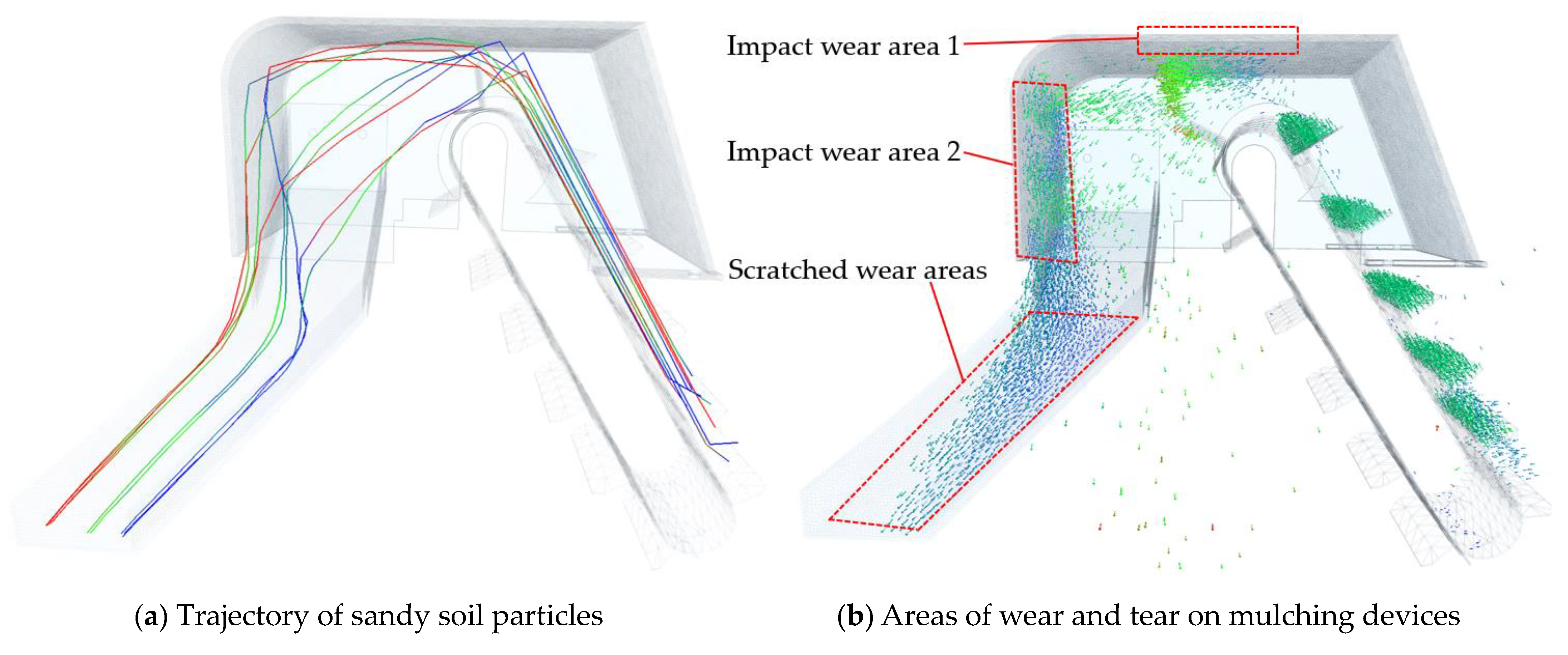

5.2. Trajectory of Sand Particles in the Mulching Device

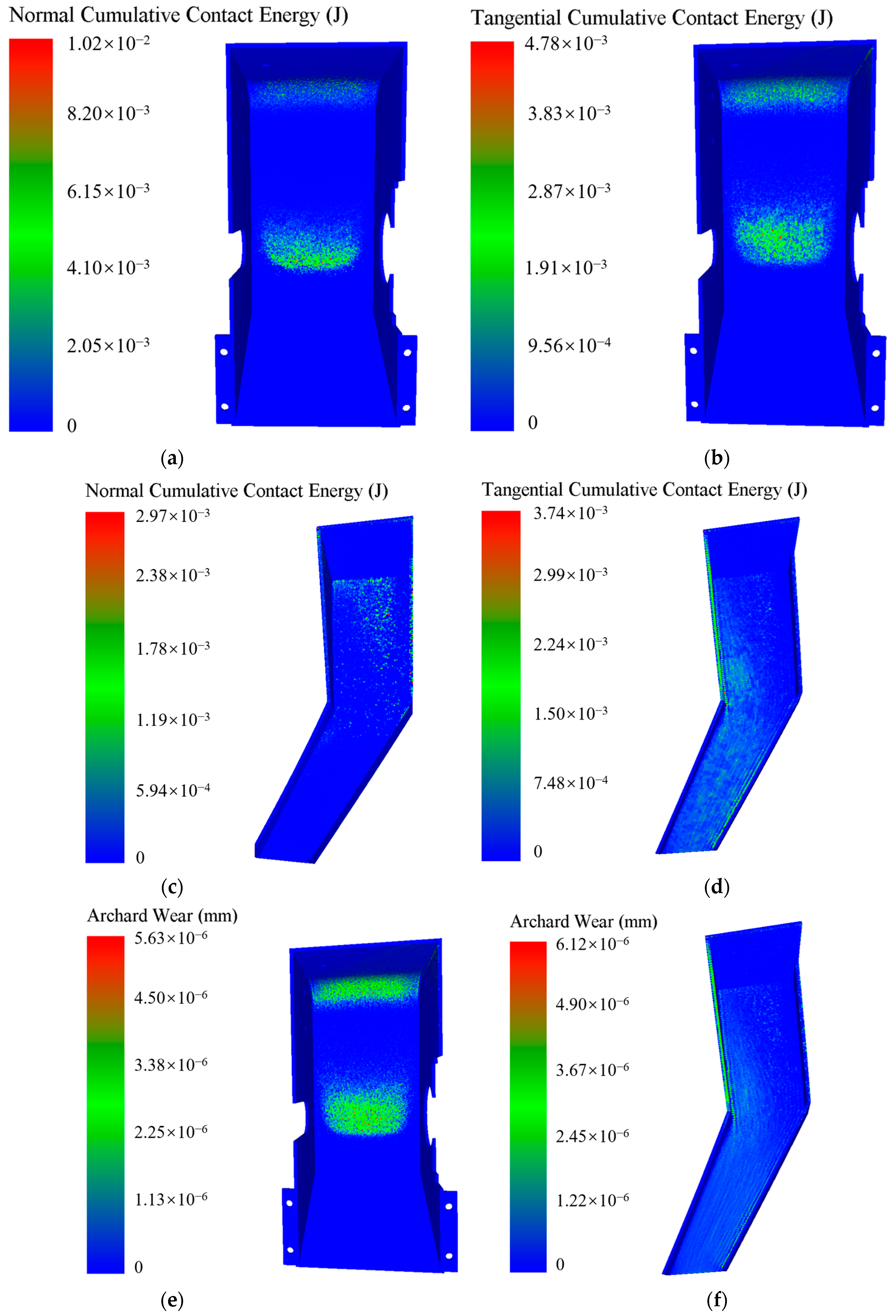

5.3. Analysis of Cladding Device Wear during the Cladding Process

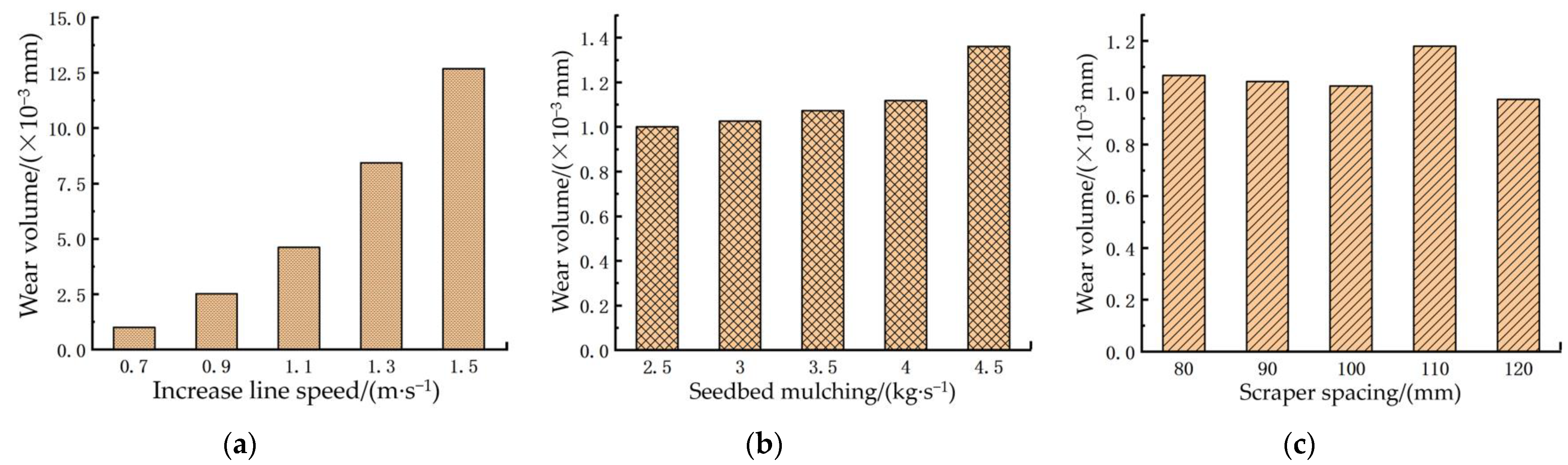

5.4. One-Factor Simulation Test

6. Numerical Simulation Optimization Test

6.1. Box–Behnken Experimental Design

6.2. Test Results and Analysis

6.2.1. Regression Modeling and Testing

6.2.2. Analysis of Variance of Regression Equations

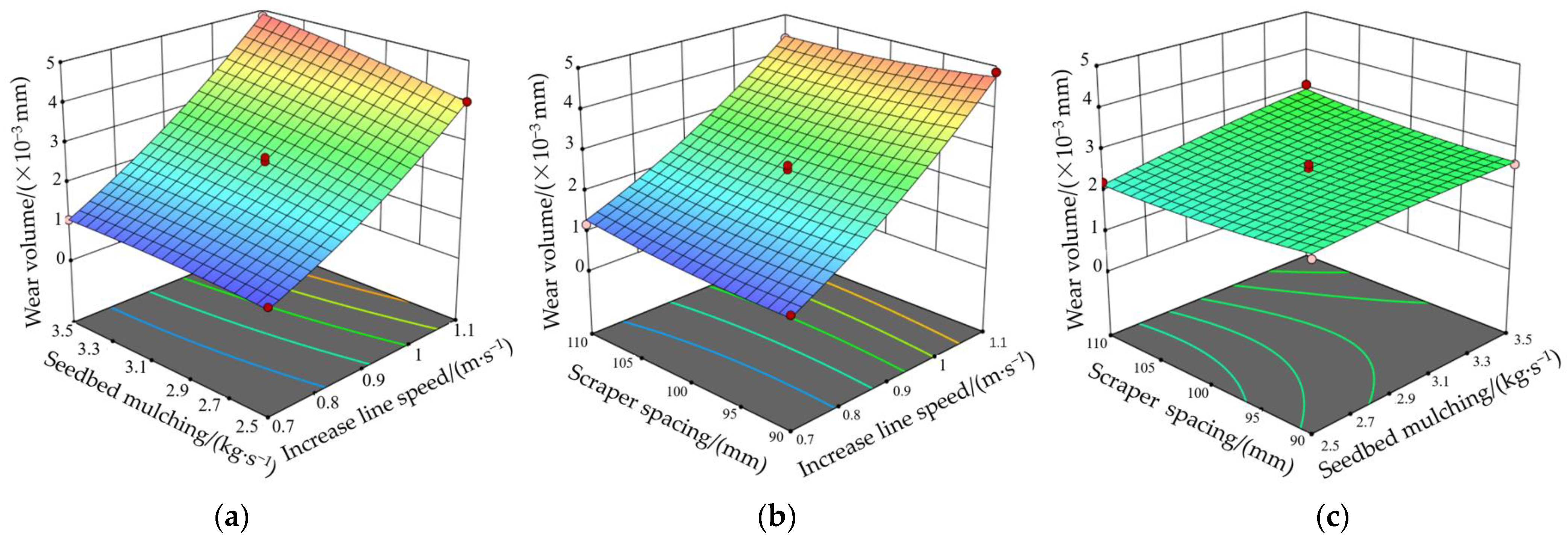

6.2.3. Parsing of Model Interaction Terms

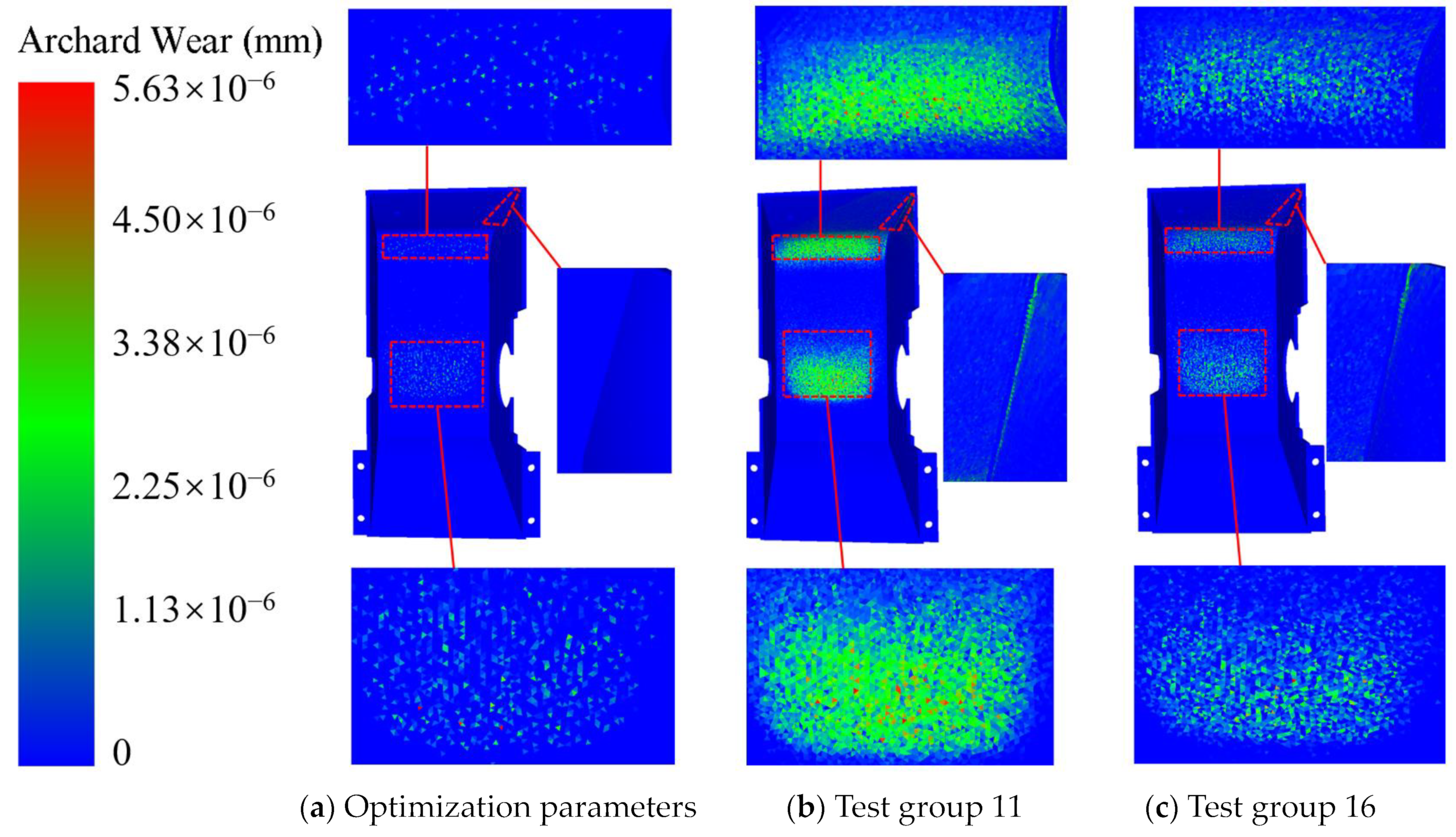

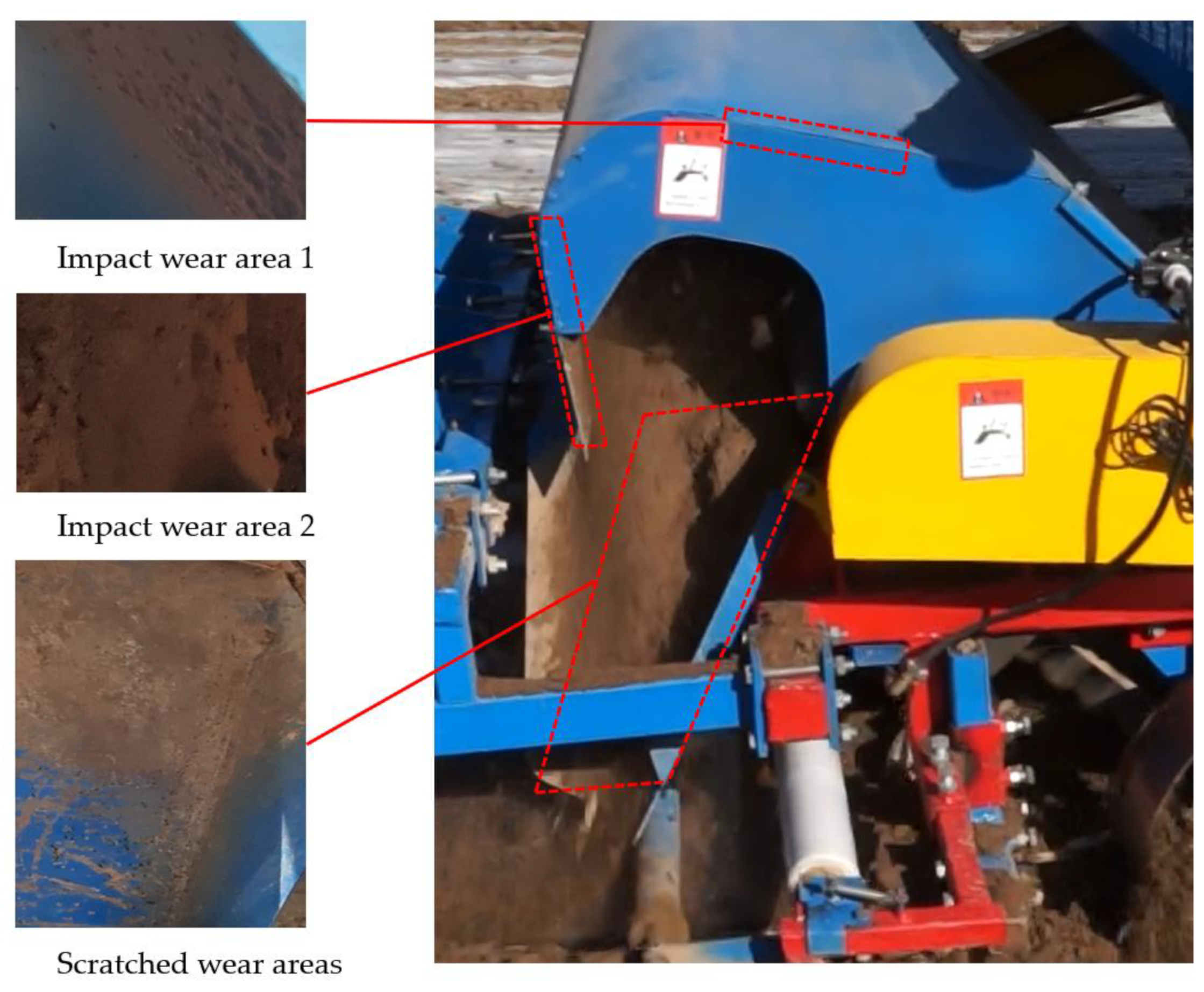

7. Field Validation Tests

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| wear constant | |

| relative sliding distance of the particles/mm | |

| radius of the contact area/mm | |

| reaction force on the particle/N | |

| angle of the center of the corresponding arc/(°) | |

| cross-sectional area of the spherical indentation/mm2 | |

| normal overlap/mm | |

| particle radius/mm | |

| equivalent modulus of elasticity | |

| hardness of the particles/Pa | |

| yield stress of the particle/Pa |

References

- Zhang, X.; Ma, Y.; Wang, H. Effects of different tillage methods on maize water utilization and yield under double ridge-furrow and plastic mulching on semi-arid area of northwest China. Acta Ecol. Sin. 2021, 41, 3603–3611. [Google Scholar]

- Xie, J.; Wang, J.; Li, L. Effects of fertilization method on maize growth and soil respiration under plastic-covered ridge and furrow planting in dry farmland. Agric. Res. Arid Areas 2020, 38, 79–85. [Google Scholar]

- Dai, F.; Zhao, W.; Zhang, F. Current status of mechanization planting technology and equipment for corn whole plastic-film mulching on double ridges in the arid of northwest China. J. Chin. Agric. 2016, 37, 217–222. [Google Scholar]

- Li, L.; Liu, G.; Yang, Q. Research and application development for the techniques of whole plastic-film mulching on double ridges and planting in catchment furrows in dry land. Agric. Res. Arid Areas 2009, 27, 114–118. [Google Scholar]

- Yang, Q.; Liu, G.; Xiong, C. Study on highly efficient water utilizing mechanisms on techniques of whole plastic-film mulching on double ridges and planting in catchment furrows of dry-land maize. Res. Agric. 2010, 31, 113–117. [Google Scholar]

- Zhang, F.; Li, M.; Zhang, W. Ridge-furrow mulched with plastic film increases little in carbon dioxide efflux but much significant in biomass in a semiarid rainfed farming system. Agric. For. Meteorol. 2017, 244–245, 33–41. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, C.; Zhang, F. Research Status and Development Trend of Film-Mulching Machinery. Agric. Equip. Veh. Eng. 2022, 60, 49–54. [Google Scholar]

- Liu, K.; Sun, W.; Zhang, H. General situation of development of mechanized soil covering technology on film. Agric. Equip. Veh. Eng. 2023, 61, 10–13. [Google Scholar]

- Jia, H.; Wang, W.; Chen, Z. Status and prospect of research on optimization of soil-touching components of agricultural machinery. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–13. [Google Scholar]

- Ye, F.; Deng, H.; Qiang, Y. Analysis on wear of transfer chute based on FEM-DEM coupling method. J. Mach. Des. 2022, 39, 81–86. [Google Scholar]

- Lu, Z.; Sun, Y.; Ren, L. Design for and experiment on rotary-tillage ridging filming machine for whole plastic-film double furrow sowing cultivation. J. Gansu Agric. Univ. 2015, 50, 161–165. [Google Scholar]

- Chen, Z.; Wang, X. Analysis of the influence of the amount of wear in the middle groove of the scraper conveyor. Coal Technol. 2017, 36, 227–229. [Google Scholar]

- Zhang, Y. Wear Analysis and Structural Improvement of Bucket Teeth of WK-75 Mining Excavator; Taiyuan University of Technology: Taiyuan, China, 2016. [Google Scholar]

- Cleary, P.; Owen, P. Effect of liner design on performance of a HICOM® mill over the predictedliner life cycle. Int. J. Miner. Process. 2015, 134, 11–22. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, Z.; Wang, J. Study on wear characteristics of plow shovel based on discrete element method. Mod. Agric. Equip. 2021, 42, 25–29. [Google Scholar]

- Yuan, J.; Cai, Y.; Hu, Z. Simulation study on hopper wear of bucket wheel stacker-reclaimer based on discrete element method. J. Mach. Des. 2022, 39, 1–6. [Google Scholar]

- Shi, Z.; Zhao, W.; Ma, H. Establishment and Verification of Discrete Element Model for Seed Furrow Soil-Seed-Covering Device. Agric. Res. Arid Areas 2012, 30, 169–174. [Google Scholar]

- Lu, Q.; Liu, F.; Liu, L. Parameters optimization of operation machine for tillage-fertilization and spraying-filming on double ridges. Trans. Chin. Soc. Agric. Mach. 2023, 54, 46–57. [Google Scholar]

- Zhang, Z.; Chen, Z.; Lai, Q. Design and experiments of the Bouligand structure inspired bionic wear resistant soil-engaging component for agricultural machinery. Trans. CSAE 2023, 39, 28–37. [Google Scholar]

- Zhang, R.; Han, D.; Ji, Q. Research on the calibration method of sand and soil parameters in discrete element simulation. Trans. Chin. Soc. Agric. Mach. 2017, 48, 49–56. [Google Scholar]

- Wang, J.; Wang, Q.; Tang, H. Design and test of rice straw deep burying and whole straw returning device. Trans. Chin. Soc. Agric. Mach. 2015, 46, 112–117. [Google Scholar]

- Barrios, G.; Caravalho, R.; Kwade, A. Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 2013, 248, 84–93. [Google Scholar] [CrossRef]

- Asaf, Z.; Rubinstein, D.; Shmulevich, I. Determination of discrete element model parameters required for soil tillage. Soil Tillage Res. 2007, 92, 227–242. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, L.; Lai, Q. Operation mechanism analysis and experiments of shovel-type rolling soil-engaging components based on DEM-MBD coupling. Trans. CSAE 2022, 38, 10–20. [Google Scholar]

- Wang, X.; Zheng, D.; Huang, Y. Simulation and test of EDEM-based straw treatment press tool in southern paddy field. Mod. Agric. Equip. 2020, 41, 39–43. [Google Scholar]

- Shmulevich, I. State of the art modeling of soiltillage interaction using discrete element method. Soil Tillage Res. 2010, 111, 136–142. [Google Scholar] [CrossRef]

- Ma, T. Study on the wear characteristics of shield tunneling cutter plate based on discrete element numerical simulation in sandy pebble stratum. Railw. Stand. Des. 2017, 61, 85–90. [Google Scholar]

- Yang, L.; Zhang, C.; Zhao, C. Simulation analysis of vertical screw conveyor blade wear based on EDEM. J. Taiyuan Univ. Sci. Technol. Press. 2019, 40, 133–136. [Google Scholar]

- Dai, F.; Song, X.; Zhao, W. Simulated calibration of discrete elemental contact parameters for full-film duopoly furrow-covered soils. Trans. Chin. Soc. Agric. Mach. 2019, 50, 50–56. [Google Scholar]

- Wang, H.; Tian, B.; Sun, W. Design and experiment of the machine for corn ridging, fertilizing, film mulching and sowing. J. Gansu Agric. Univ. 2023, 58, 235–242. [Google Scholar]

- Bradley, D.; Roth, G. Adaptive thresholding using the integral image. J. Graph. Tools 2007, 12, 13–21. [Google Scholar] [CrossRef]

- China Academy of Agricultural Mechanization. Agricultural Machinery Design Manual; China Agricultural Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Xing, C.; Wang, S.; Deng, H. A new filtering algorithm based on the median of the extremes. Chin. J. Image Graph. 2001, 6, 533–536. [Google Scholar]

| Parameters | Value/Mode |

|---|---|

| Overall size (L × W × H)/(m × m × m) | 1.78 × 1.50 × 1.05 |

| Matching power/kW | 18.4 |

| Hook-up method | Rear three-point suspension |

| Overall mass/kg | 166 |

| Operating speed/(km·h−1) | 2.80~3.60 |

| Rotary plowing depth/mm | 100~150 |

| Membrane edge mulch width/mm | 90~110 |

| Ridge cover width/mm | 35~45 |

| Width of cross belt cover/mm | 90~110 |

| Distance between cross belt coverings/mm | 1500 |

| Mulch thickness/mm | 20~30 |

| Typology | Spherical | Elongated | Prismatic |

|---|---|---|---|

| Single ball radius/mm | 1.25 | 0.9 | 0.9 |

| Mass/g | 75 | 50 | 25 |

| Materials | Densities/(kg·m−3) | Poisson’s Ratio | Shear Modulus/Pa |

|---|---|---|---|

| Pellets | 1638 | 0.3 [23] | 1.15 × 107 |

| Steels | 7850 [24] | 0.25 [20] | 1.00 × 1010 [20] |

| Parameters | Value |

|---|---|

| Coefficient of recovery for sand–sand collisions | 0.15 |

| Coefficient of recovery for collision between sand and an overburden device | 0.54 |

| Static friction factor of sand and sandy soil | 0.68 |

| Static friction factor between sand and an overburden device | 0.31 |

| Sand to sand rolling friction factor | 0.27 |

| Rolling friction factor between sand and mulch unit | 0.13 |

| Experimental Factors | Coding Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Lifting line speed X1/(m·s−1) | 0.7 | 0.9 | 1.1 |

| Amount of soil cover X2/(kg·s−1) | 2.5 | 3 | 3.5 |

| Blade spacing X3/mm | 90 | 100 | 110 |

| Serial No. | x1 | x2 | x3 | Mulching Unit Wear/(×10−3 mm) |

|---|---|---|---|---|

| 1 | −1 | 0 | 1 | 1.18 |

| 2 | 0 | 0 | 0 | 2.64 |

| 3 | 0 | 1 | −1 | 2.62 |

| 4 | 1 | 0 | 1 | 4.38 |

| 5 | 0 | −1 | 1 | 2.22 |

| 6 | 0 | 0 | 0 | 2.51 |

| 7 | −1 | 0 | −1 | 1.07 |

| 8 | 0 | 0 | 0 | 2.48 |

| 9 | 0 | −1 | −1 | 2.34 |

| 10 | 0 | 0 | 0 | 2.53 |

| 11 | 1 | 0 | −1 | 4.86 |

| 12 | −1 | 1 | 0 | 1.06 |

| 13 | 1 | 1 | 0 | 4.84 |

| 14 | 1 | −1 | 0 | 4.00 |

| 15 | 0 | 0 | 0 | 2.49 |

| 16 | 0 | 1 | 1 | 3.09 |

| 17 | −1 | −1 | 0 | 0.99 |

| Variation Source | Ss | df | Ms | F | p |

|---|---|---|---|---|---|

| x1 | 23.7300 | 1 | 23.7300 | 1775.4200 | <0.0001 ** |

| x2 | 0.5304 | 1 | 0.5304 | 39.6800 | 0.0004 ** |

| x3 | 0.0000 | 1 | 0.0000 | 0.0034 | 0.9553 |

| x1×2 | 0.1482 | 1 | 0.1482 | 11.0900 | 0.0126 * |

| x1×3 | 0.0873 | 1 | 0.0873 | 6.5300 | 0.0378 * |

| x2×3 | 0.0870 | 1 | 0.0870 | 6.5100 | 0.0380 * |

| x12 | 0.2608 | 1 | 0.2608 | 19.5100 | 0.0031 ** |

| x22 | 0.0131 | 1 | 0.0131 | 0.9834 | 0.3544 |

| x32 | 0.0367 | 1 | 0.0367 | 2.7500 | 0.1414 |

| Model | 24.9000 | 9 | 2.7700 | 206.9700 | <0.0001 ** |

| Residual | 0.0936 | 7 | 0.0134 | ||

| Incoherent | 0.0770 | 3 | 0.0257 | 6.1800 | 0.0554 |

| Inaccuracies | 0.0166 | 4 | 0.0042 | ||

| Sum | 24.9900 | 16 | |||

| Coefficient of determination (CoD) R2 | 0.9963 | ||||

| Research R2 | 0.9914 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Dai, F.; Shi, R.; Zhao, W.; Xu, P.; Deng, H.; Pan, H. Effect of Operating Parameters on the Mulching Device Wear Behavior of a Ridging and Mulching Machine. Lubricants 2024, 12, 19. https://doi.org/10.3390/lubricants12010019

Zhao Q, Dai F, Shi R, Zhao W, Xu P, Deng H, Pan H. Effect of Operating Parameters on the Mulching Device Wear Behavior of a Ridging and Mulching Machine. Lubricants. 2024; 12(1):19. https://doi.org/10.3390/lubricants12010019

Chicago/Turabian StyleZhao, Qinxue, Fei Dai, Ruijie Shi, Wuyun Zhao, Pengqing Xu, Huan Deng, and Haifu Pan. 2024. "Effect of Operating Parameters on the Mulching Device Wear Behavior of a Ridging and Mulching Machine" Lubricants 12, no. 1: 19. https://doi.org/10.3390/lubricants12010019

APA StyleZhao, Q., Dai, F., Shi, R., Zhao, W., Xu, P., Deng, H., & Pan, H. (2024). Effect of Operating Parameters on the Mulching Device Wear Behavior of a Ridging and Mulching Machine. Lubricants, 12(1), 19. https://doi.org/10.3390/lubricants12010019