Multi-Field Coupling Numerical Analysis and Experimental Validation of Surface-Textured Metal Seals in Roller Cone Bits

Abstract

1. Introduction

2. Numerical Model

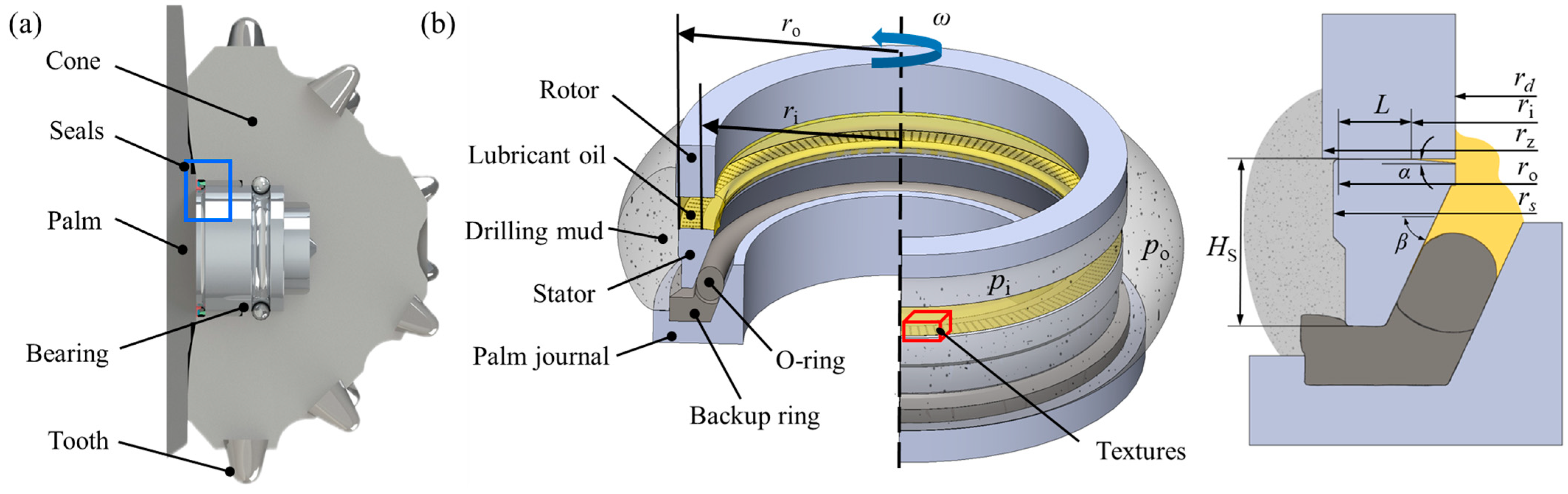

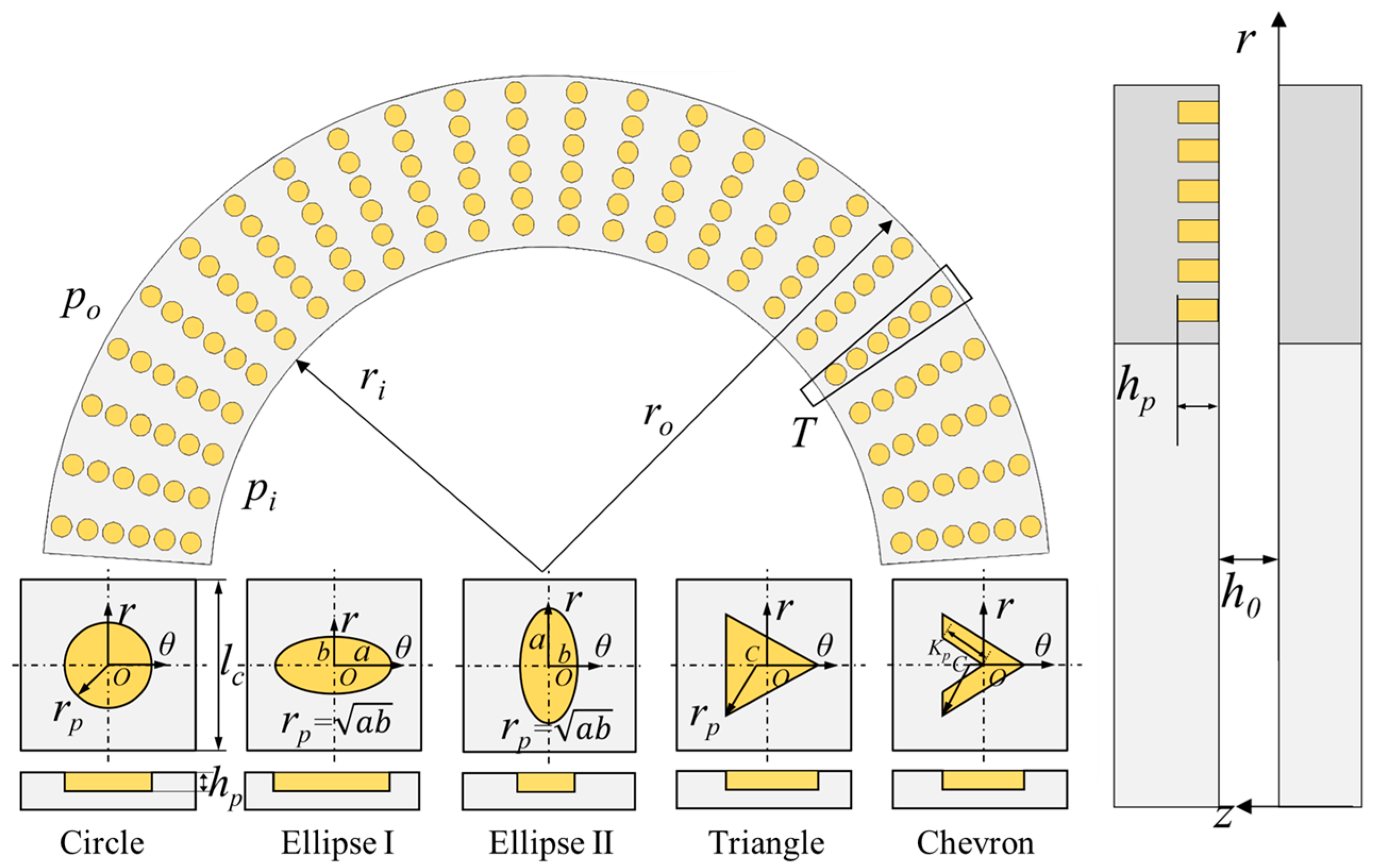

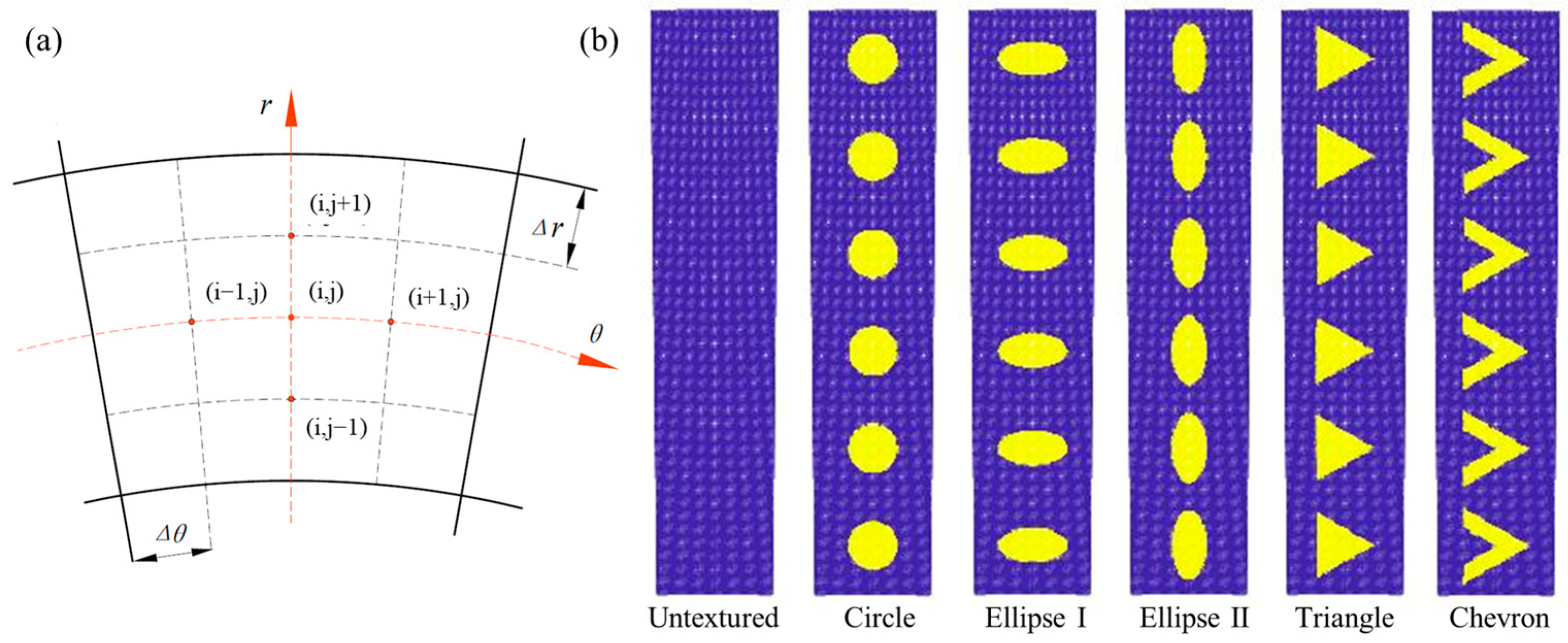

2.1. Geometric Model

2.2. Multi-Field Coupling Model

2.2.1. Fluid Lubrication Analysis

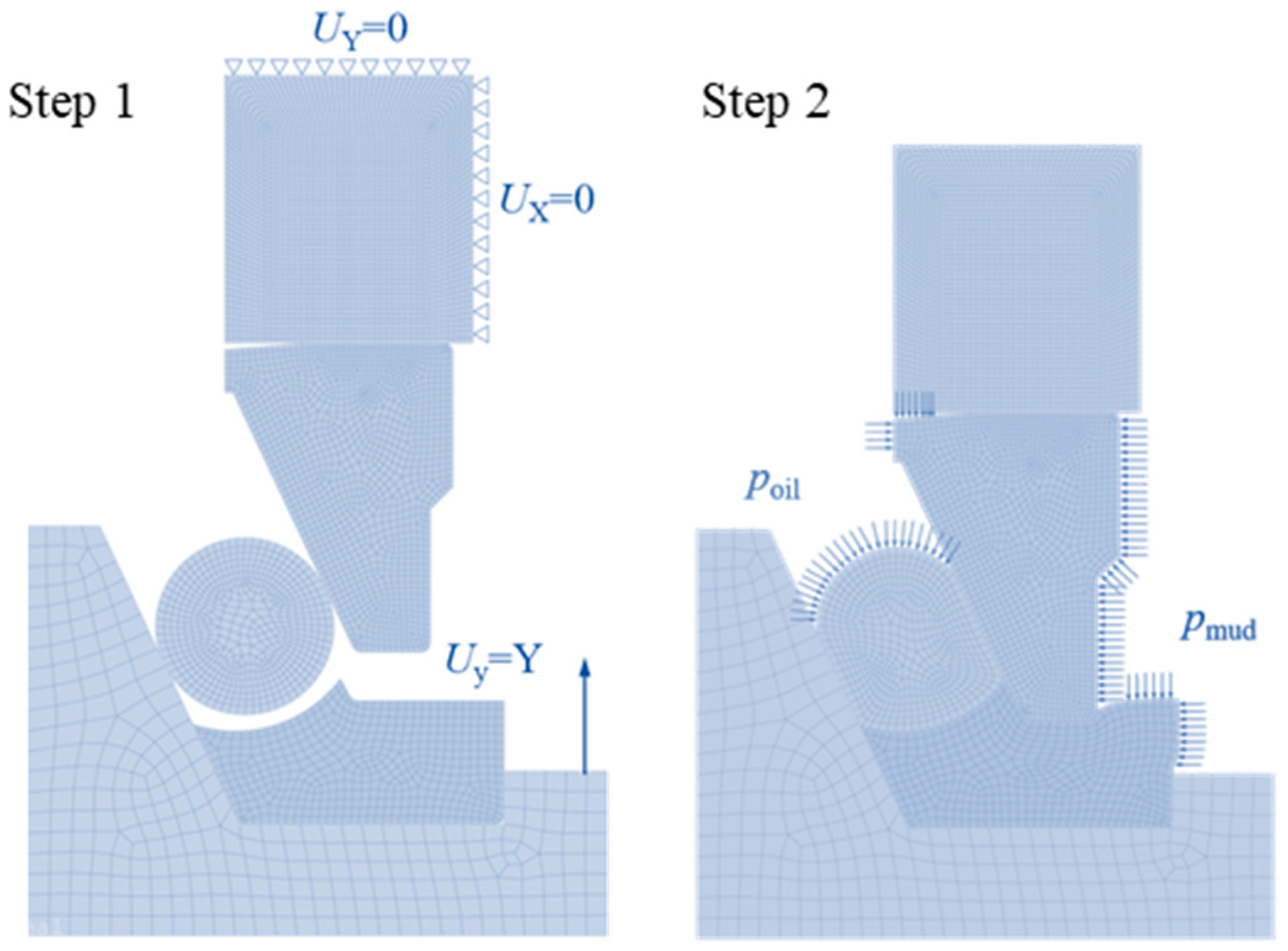

2.2.2. Mechanical Analysis

2.2.3. Thermal Analysis

2.2.4. Deformation Analysis

2.3. Performance Parameters

3. Calculation Procedure

4. Results and Discussions

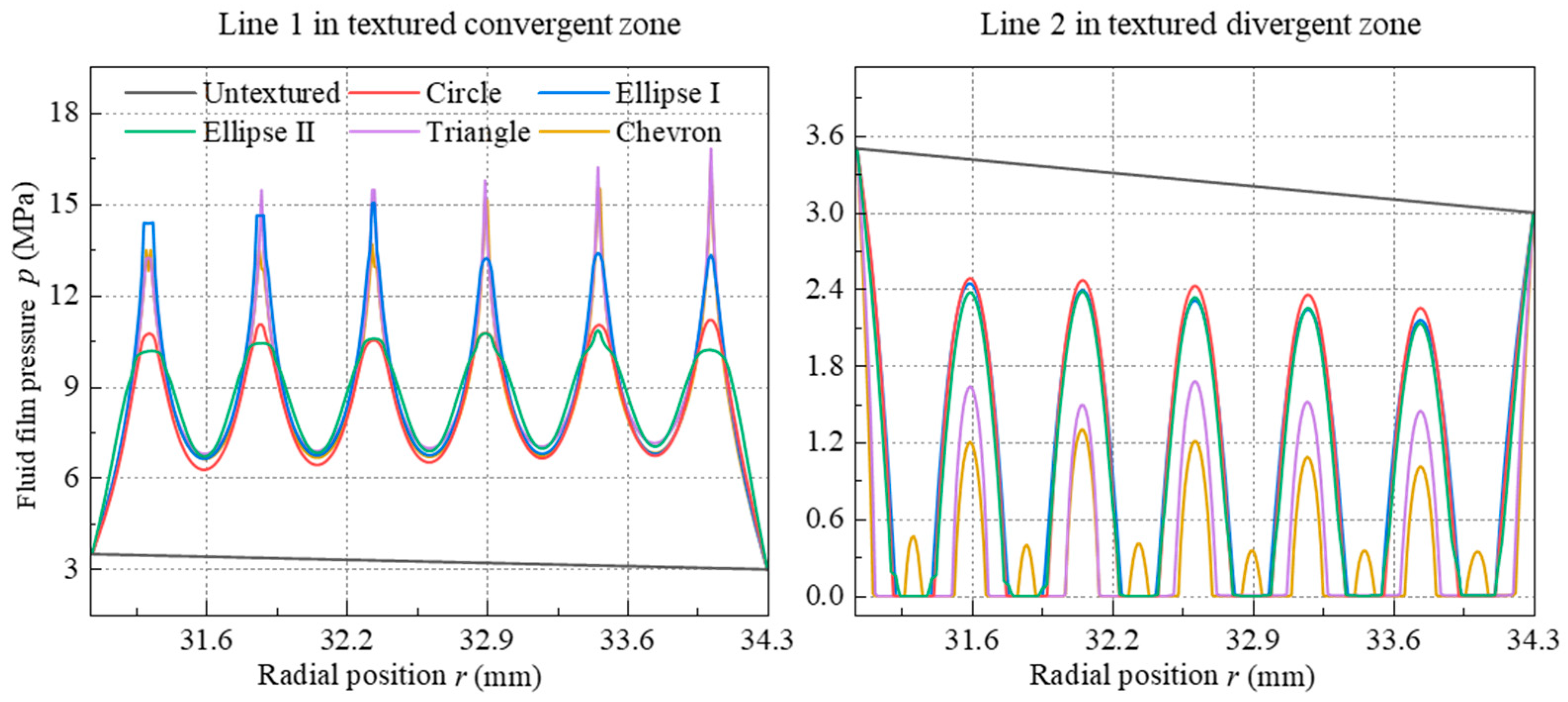

4.1. Liquid Film Pressure on End Faces

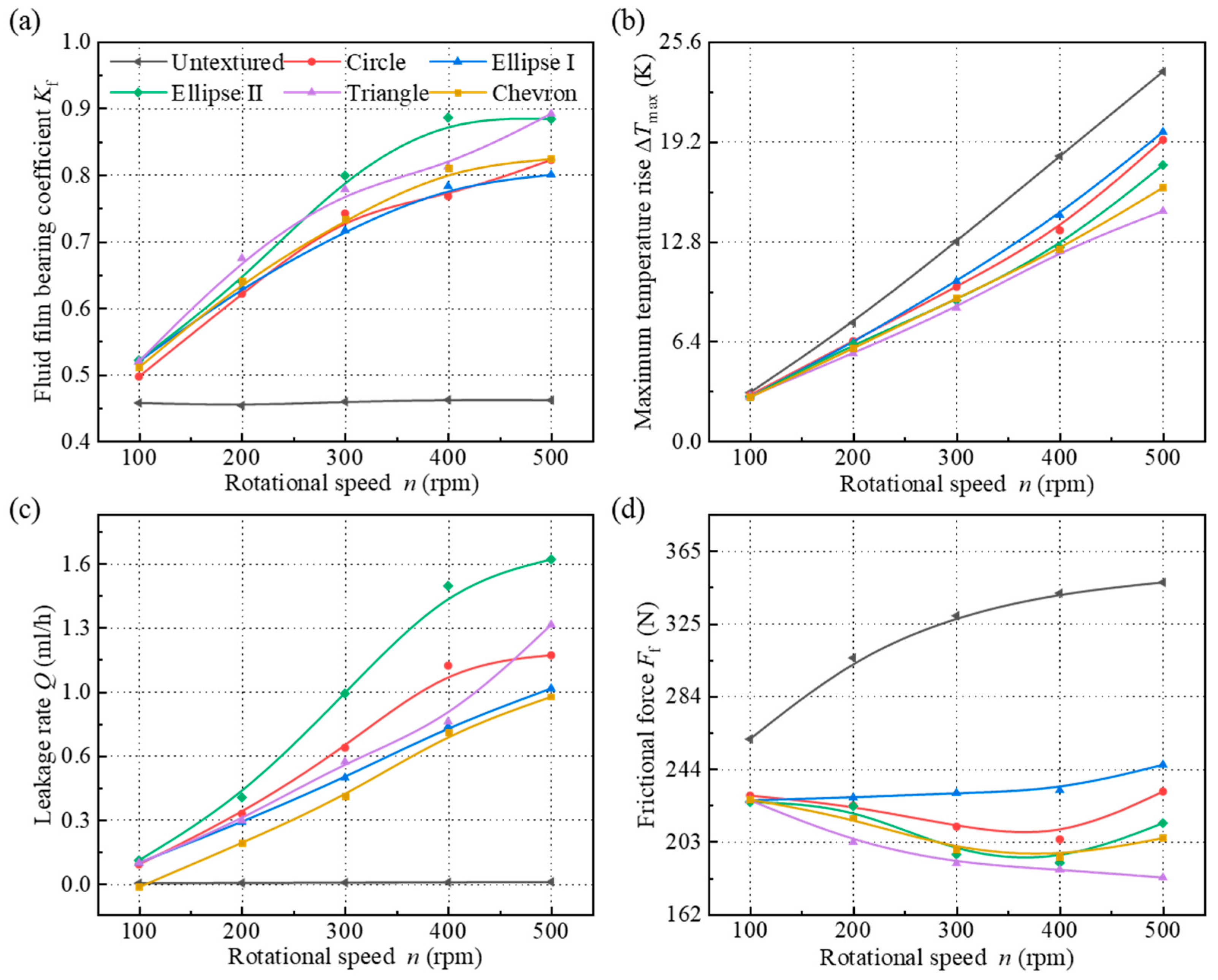

4.2. Influence of Operating Conditions on Sealing Performance

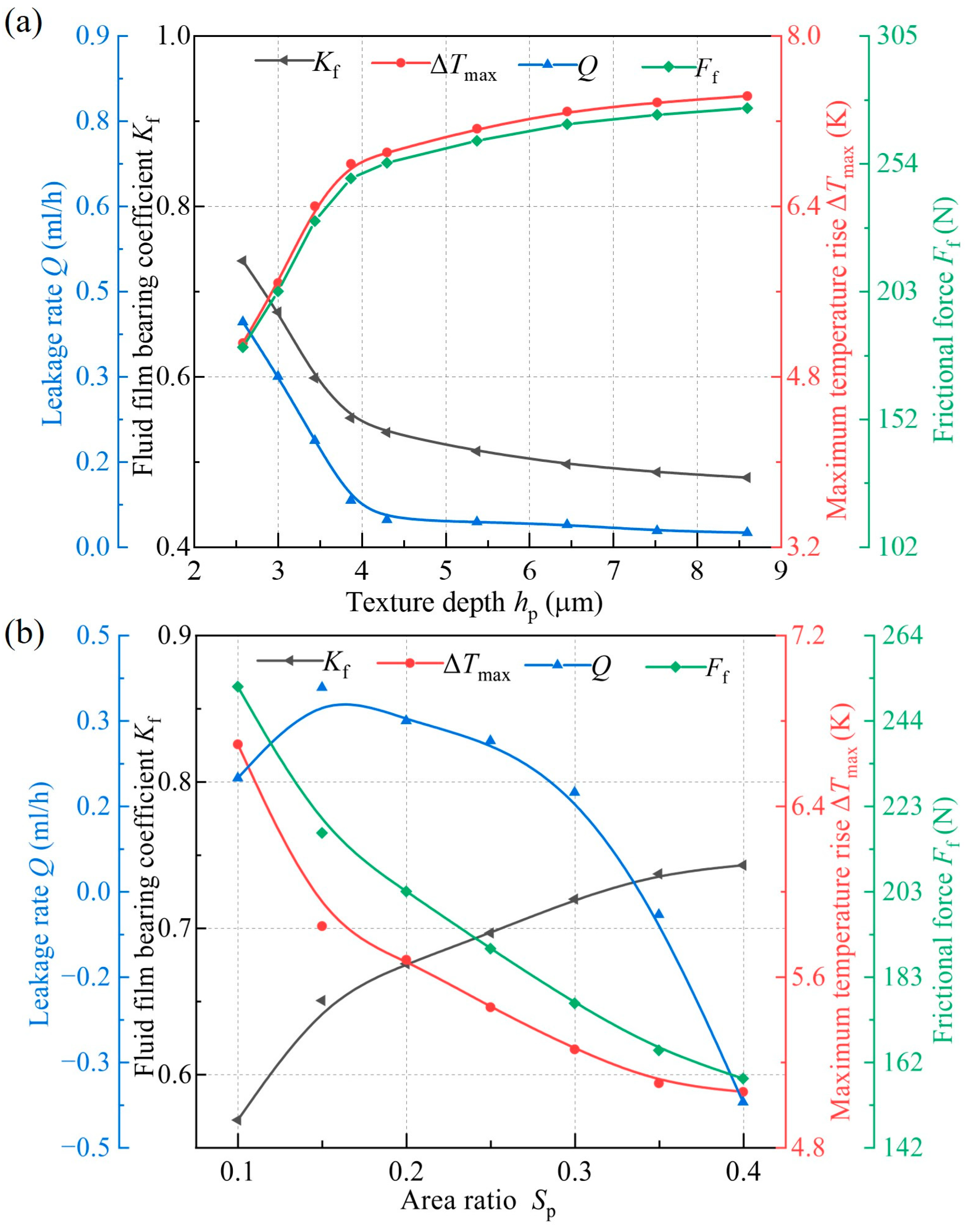

4.3. Influence of Texture Parameters on Sealing Performance

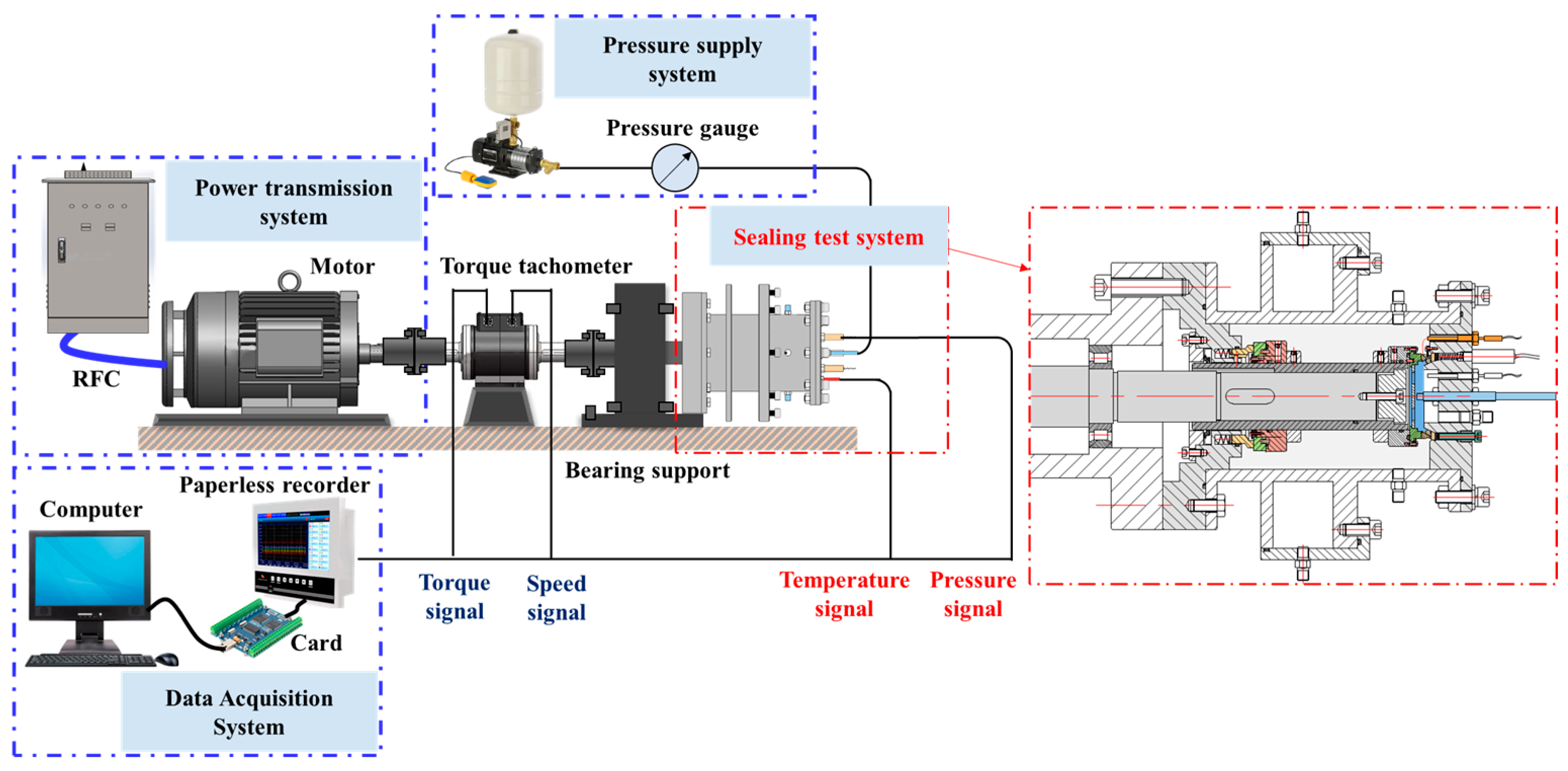

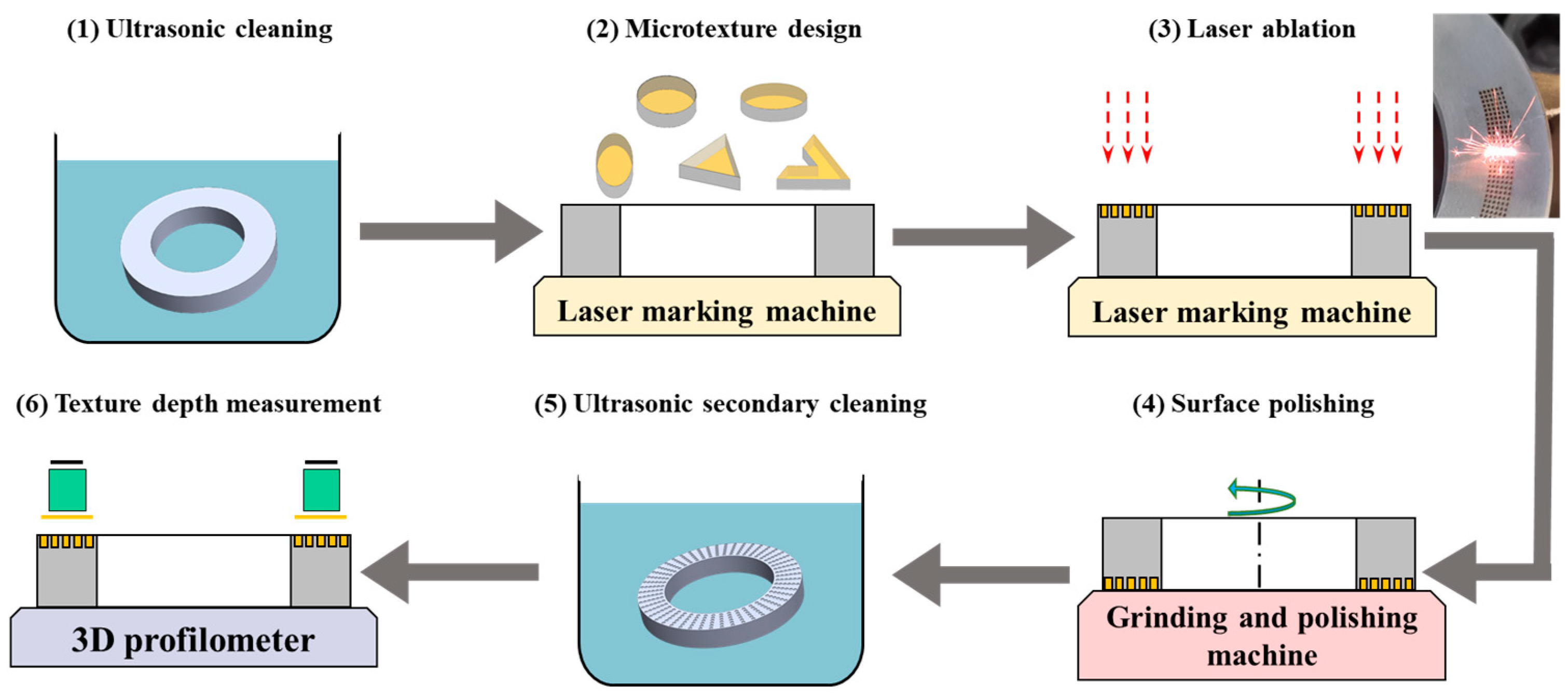

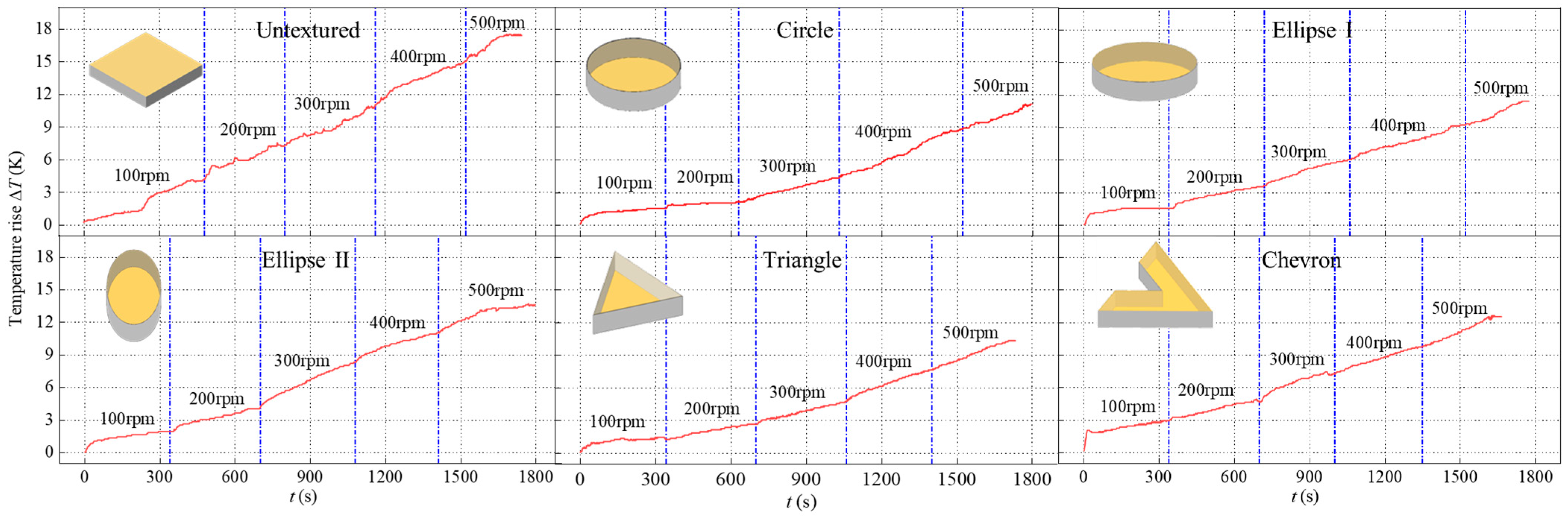

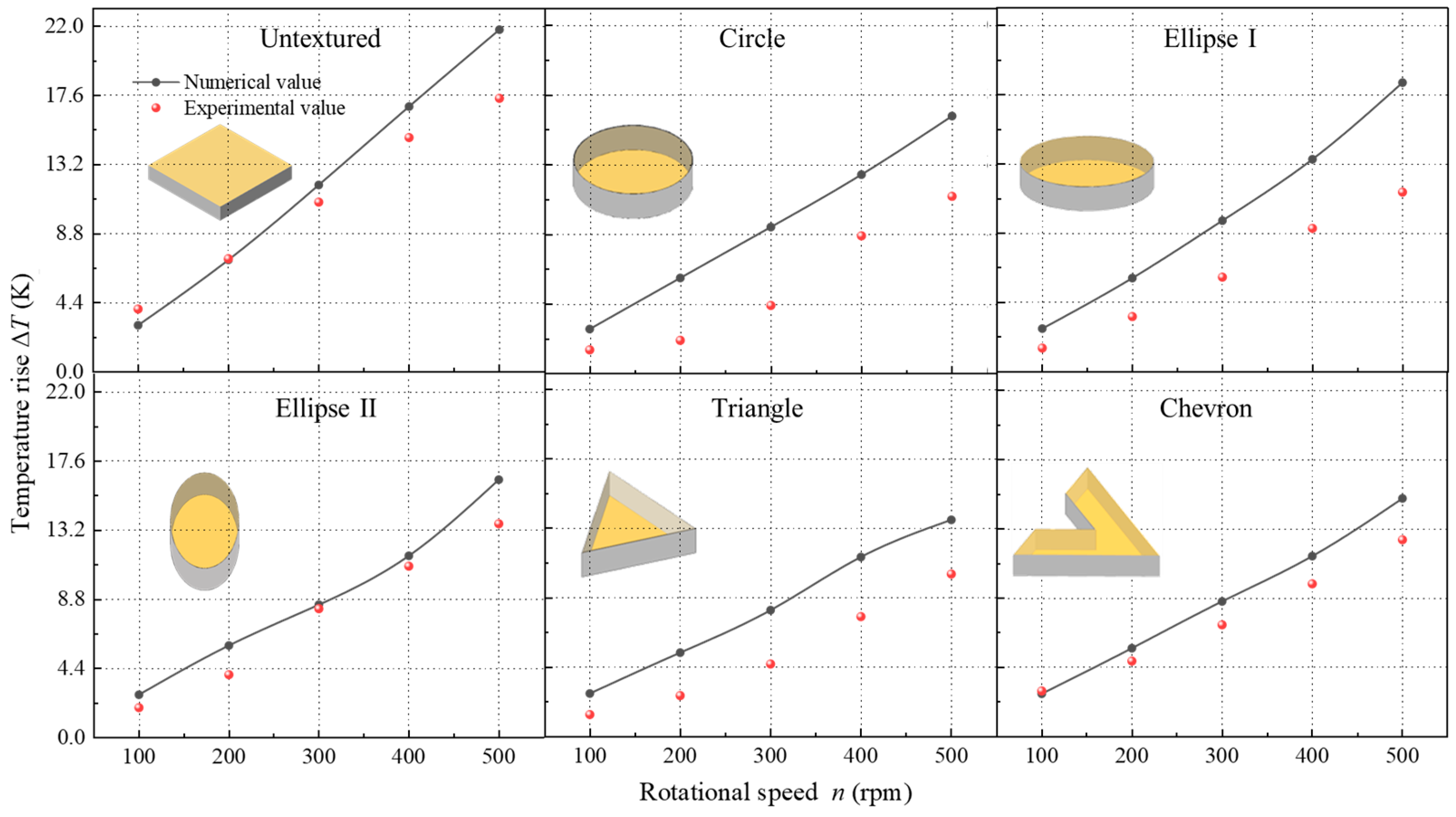

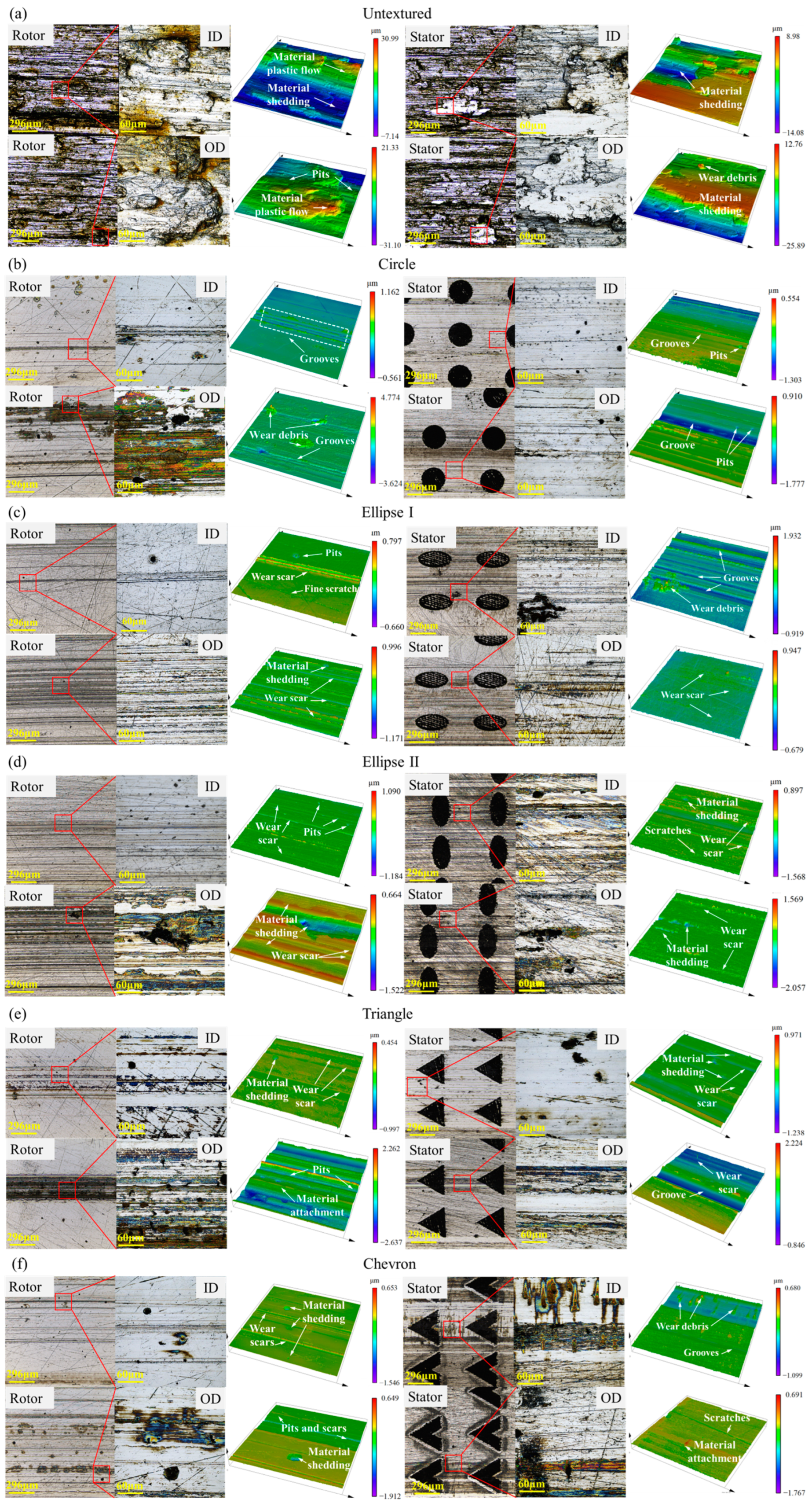

4.4. Experimental Validations

5. Conclusions

- A comprehensive multi-field coupling numerical model for the surface-textured metal seals of roller bits is established, taking into account the influence of surface roughness, asperity contact, micro-deformation, and cavitation. Under the initial condition of poi = 3 MPa and ni = 200 rpm, the textured convergent zones and divergent zones of the liquid film are formed along the rotational direction on end faces with different shape textures. The sharp-angle textures, including triangle and chevron textures, can produce a stronger hydrodynamic pressure effect on the end faces of metal seals. The cavitation area of different shape textures accounts for about 5% to 27% of the total texture area.

- The liquid film bearing coefficient, leakage rate, and maximum temperature rise of the metal seals with five shape textures increase with an increase in the rotational speed (n) from 100 rpm to 500 rpm. The temperature rise and frictional force of the textured end faces under different rotational speeds are significantly improved when compared to the untextured flat end face, particularly in the case of the triangle-textured end face. As the environmental pressure increases, the hydrodynamic pressure effect induced by the textures weakens, although the textures continue to contribute to a reduction in the contact pressure and frictional heat of the sealing rings. However, when the environmental pressure is p ≥ 30 MPa, the textured end face gradually loses its advantage in the sealing performance of metal seals.

- The liquid film characteristics and sealing performance of triangle-textured end faces are significantly affected by texture parameters, specifically the depth and area ratio. The hydrodynamic pressure effect and cavitation phenomenon intensify with a decrease in the depth (hp) from 8.6 μm to 2.6 μm and with an increase in the area ratio (Sp) from 0.1 to 0.4. Consequently, the maximum temperature rise and frictional force (ΔTmax, Ff) decrease with the area ratio (Sp). The effect of depth (hp) on the sealing parameters is significantly weakened when hp ≥ 4.3 μm. The leakage rate (Q) changes from positive to negative in the range of Sp = 0.3~0.35, and the optimal texture parameters of Sp = 0.34 and hp = 3 μm can achieve an ideal state of ‘zero leakage’.

- A sealing performance test bench of surface-textured metal seals is constructed to validate the accuracy of multi-field coupling simulation. The application of surface textures to metal seals offers advantages in terms of reducing temperature rise, friction and wear on the end faces. The untextured and textured end faces are in a semi-dry friction and mixed friction state during the test, respectively, resulting in the occurrence of abrasive wear and adhesive wear on the end faces of the rotor and stator. The triangle texture has proven to have the best hydrodynamic lubrication and wear resistance among the five shape textures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Wang, X.; Li, S.; Jiao, Y.; Yang, R.; Li, G. Evaluation method for tooth wear of roller bits based on the fractal dimension of the rock surface. J. Petrol. Sci. Eng. 2022, 210, 110039. [Google Scholar] [CrossRef]

- Naganawa, S. Feasibility study on roller-cone bit wear detection from axial bit vibration. J. Petrol. Sci. Eng. 2012, 82–83, 140–150. [Google Scholar] [CrossRef]

- Li, B.; Liu, J.; Lu, D.; Wu, M.; Chen, H. Optimization of single metal seal structure of cone bit. Lubr. Eng. 2019, 44, 98–102. [Google Scholar]

- Aminfar, O. Innovations in Rotary Drill Bit Design to Reduce Vibration and Improve Durability. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2008. [Google Scholar]

- Elmgerbi, A.; Thonhauser, G. Holistic autonomous model for early detection of downhole drilling problems in real-time. Process Saf. Environ. 2022, 164, 418–434. [Google Scholar] [CrossRef]

- Keller, A.M.; Feng, T.H.; Demirer, N.; Darbe, R.; Chen, D.M. Rate of penetration estimation downhole with machine learning for drilling position control. Geoenergy Sci. Eng. 2022, 224, 211593. [Google Scholar] [CrossRef]

- Al-Wahedi, T.; Hay, M.A.; Waheed, T.; Grimes, T. New slim hole technology maximizes productivity in middle east horizontal drilling programs. In Proceedings of the SPE/IADC Drilling Conference, SPE-92376-MS, Amsterdam, The Netherlands, 23–25 February 2005. [Google Scholar]

- Zhou, Y.; Hu, J.; Tan, B.; Jiang, Y.; Tang, Y. Wear of spiral seal cone bit in complex formations. SPE J. 2021, 26, 3575–3590. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Chen, T.; Ji, J.; Fu, Y.; Yang, X.; Fu, H.; Fang, L. Tribological performance of UV picosecond laser multi-scale composite textures for C/SiC mechanical seals: Theoretical analysis and experimental verification. Ceram. Int. 2021, 47, 23162–23180. [Google Scholar] [CrossRef]

- Xiong, S.; Salant, R.F. A numerical model of a rock bit bearing seal. Tribol. Trans. 2000, 43, 542–548. [Google Scholar] [CrossRef]

- Xiong, S.; Salant, R.F. A dynamic model of a contacting mechanical seal for down-hole tools. J. Tribol. 2003, 125, 469–479. [Google Scholar] [CrossRef]

- Ma, Y.; Yuan, Z.; Ni, Y.; Meng, X.; Peng, X. Performance prediction and multi-objective optimization of metal seals in roller cone bits. J. Petrol. Sci. Eng. 2022, 208, 109316. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, Y.; Chen, Y.; Meng, X.; Peng, X. Dynamic characteristics of metal seals in roller cone bits. Lubricants 2022, 10, 280. [Google Scholar] [CrossRef]

- Etsion, I.; Kligerman, K.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G. A laser surface textured hydrostatic mechanical seal. Tribol. Trans. 2002, 45, 430–434. [Google Scholar] [CrossRef]

- Brunetiere, N.; Tournerie, B. Numerical analysis of a surface-textured mechanical seal operating in mixed lubrication regime. Tribol. Int. 2012, 49, 80–89. [Google Scholar] [CrossRef]

- Yang, X.; Peng, X.; Meng, X.; Jiang, J.; Wang, Y. Thermo-elasto-hydrodynamic analysis of triangular textured mechanical face seals. J. Zhejiang Univ.-Sci. A 2019, 20, 864–881. [Google Scholar] [CrossRef]

- Qiu, Y.; Khonsari, M.M. Experimental investigation of tribological performance of laser textured stainless steel rings. Tribol. Int. 2011, 44, 635–644. [Google Scholar] [CrossRef]

- Dingui, K.; Brunetière, N.; Bouyer, J.; Adjemout, M. Surface texturing to reduce temperature in mechanical seals. Tribol. Online 2020, 15, 222–229. [Google Scholar] [CrossRef]

- Grimes, B.; Kirkpatrick, B. Step change in performance: Upgraded bit technology significantly improves drilling economics in GOM motor applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Lin, C. Oil and Gas Drilling Bit Tribology. In Encyclopedia of Tribology; Springer: New York, NY, USA, 2013; pp. 2467–2475. [Google Scholar]

- Liu, Z.; Kuang, Y.; Wang, Y. Research on working principle of a roller bit’s seal testing machine. Mach. Des. Manuf. 2009, 47, 191–193. [Google Scholar]

- Qiu, M.; Delic, A.; Raeymaekers, B. The effect of texture shape on the load-carrying capacity of gas-lubricated parallel slider bearings. Tribol. Lett. 2012, 48, 315–327. [Google Scholar] [CrossRef]

- Adjemout, M.; Andrieux, A.; Bouyer, J.; Brunetière, N.; Marcos, G.; Czerwiec, T. Influence of the real dimple shape on the performance of a surface textured mechanical seal. Tribol. Int. 2017, 115, 409–416. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubri. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of average flow model to lubrication between rough sliding surfaces. J. Lubri. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Meng, X.; Bai, S.; Peng, X. Lubrication film flow control by oriented dimples for liquid lubricated mechanical seals. Tribol. Int. 2014, 77, 132–141. [Google Scholar] [CrossRef]

- Yu, H.; Wang, X.; Zhou, F. Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces. Tribol. Lett. 2010, 37, 123–130. [Google Scholar] [CrossRef]

- Jakobsson, B.; Floberg, L. The finite journal bearing considering vaporization. Trans. Chalmers Univ. Technol. 1957, 190, 1–116, Corpus ID: 136822854. [Google Scholar]

- Olsson, K. Cavitation in dynamically loaded bearings. Trans. Chalmers Univ. Technol. 1965, 308, 1–60, Corpus ID: 135904611. [Google Scholar]

- Meng, X.; Tu, Z.; Ma, Y.; Jiang, J.; Peng, X. Topology optimization of liquid lubricating zero-leakage mechanical face seals. Tribol. Int. 2022, 169, 107490. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Texture shape optimization for seal-like parallel surfaces: Theory and experiment. Tribol. Trans. 2016, 59, 698–706. [Google Scholar] [CrossRef]

- Xiong, S.; Wang, Q. Steady-state hydrodynamic lubrication modeled with the Payvar-Salant mass conservation model. J. Tribol. 2012, 134, 031703. [Google Scholar] [CrossRef]

- Abbott, E.J.; Firestone, F.A. Specifying surface quality-A method based on accurate measurement and comparison. J. Mech. Eng. 1933, 55, 569–572. [Google Scholar]

- Harp, S.R.; Salant, R.F. Analysis of mechanical seal behavior during transient operation. J. Tribol. 1998, 120, 191–197. [Google Scholar] [CrossRef]

- Liu, J. Research on Sealing Structure of New Roller Bit Bearing. Master’s Thesis, Degree-Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Qu, J.; Chen, G.; Yang, Y.W. Finite element analysis of rubber sealing ring resilience behavior. Adv. Mater. Res. 2013, 705, 410–414. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S.B.; Lee, J.; Cho, S.; Park, H.; Yeom, S.; Park, S.H. A comparison among Neo-Hookean model, Mooney-Rivlin model, and Ogden model for chloroprene rubber. Int. J. Precis. Eng. Man. 2012, 13, 759–764. [Google Scholar] [CrossRef]

- Ruan, B.; Salant, R.F.; Green, I. A mixed lubrication model of liquid/gas mechanical face seals. Tribol. Trans. 1997, 40, 647–657. [Google Scholar] [CrossRef]

- Li, Y.; Pei, X. Investigation on tribological behaviors of surface micro-forming 20CrNiMo steel under laser shock processing. Laser Technol. 2012, 36, 814–817. [Google Scholar]

- Zhong, L.; Wei, G.; Wang, G.; He, X.; Liao, Y.; Xie, N. Effects of femtosecond laser texture on the tribological properties of 20CrNiMo/beryllium bronze tribo-pairs of rock bit sliding bearings under non-Newtonian lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 1293–1305. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Li, Z.; Xu, L. Effect of slip position on the hydrodynamic performance of liquid film seal. Ind. Lubri. Tribol. 2021, 73, 405–413. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Xu, J.; Chen, R.; Yang, H. The fractal leakage model of contact mechanical seals considering wear and thermal deformation. J. Braz. Soc. Mech. Sci. 2019, 41, 521. [Google Scholar] [CrossRef]

- Ni, X.; Sun, J.; Ma, C.; Zhang, Y. Wear model of a mechanical seal based on piecewise Fractal Theory. Fractal Fract. 2023, 7, 251. [Google Scholar] [CrossRef]

| Structural Parameters | Values | Operating Parameters | Values |

|---|---|---|---|

| Inner diameter of stator rd (mm) | 29 | Environmental pressure po (MPa) | 3~69 |

| Outer diameter of rotor rs (mm) | 34.5 | Pressure difference Δp (MPa) | 0.5 |

| Sealing inner diameter ri (mm) | 31 | Environmental temperature To (°C) | 8~180 |

| Sealing outer diameter ro (mm) | 34.3 | Rotational speed n (rpm) | 100~500 |

| Wedging angle α (°) | 5 | Density of lubricant oil (kg/m3) | 861 |

| Incline angle β (°) | 65 | Density of drilling mud (kg/m3) | 1742 |

| Surface roughness σ (μm) | 0.2 | Viscosity of lubricant oil (Pa·s) | 0.002~0.189 |

| Dry friction coefficient fo | 0.08 | Viscosity of drilling mud (Pa·s) | 0.02~0.03 |

| Type | 3-D Shape | Definition [25] | Parameter | Value |

|---|---|---|---|---|

| Circle |  | Texture depth hp (μm) | 2.6~8.6 | |

| Ellipse I |  | Texture control unit lc (μm) | 550 | |

| Ellipse II |  | Column number T | 300 | |

| Triangle |  | Texture area ratio Sp | 0.1~0.4 | |

| Chevron |  | Texture quantity Nt | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Li, Z.; Yuan, Z.; Meng, X.; Peng, X.; Jiang, J. Multi-Field Coupling Numerical Analysis and Experimental Validation of Surface-Textured Metal Seals in Roller Cone Bits. Lubricants 2024, 12, 15. https://doi.org/10.3390/lubricants12010015

Ma Y, Li Z, Yuan Z, Meng X, Peng X, Jiang J. Multi-Field Coupling Numerical Analysis and Experimental Validation of Surface-Textured Metal Seals in Roller Cone Bits. Lubricants. 2024; 12(1):15. https://doi.org/10.3390/lubricants12010015

Chicago/Turabian StyleMa, Yi, Ziang Li, Ziyang Yuan, Xiangkai Meng, Xudong Peng, and Jinbo Jiang. 2024. "Multi-Field Coupling Numerical Analysis and Experimental Validation of Surface-Textured Metal Seals in Roller Cone Bits" Lubricants 12, no. 1: 15. https://doi.org/10.3390/lubricants12010015

APA StyleMa, Y., Li, Z., Yuan, Z., Meng, X., Peng, X., & Jiang, J. (2024). Multi-Field Coupling Numerical Analysis and Experimental Validation of Surface-Textured Metal Seals in Roller Cone Bits. Lubricants, 12(1), 15. https://doi.org/10.3390/lubricants12010015