Surface Laser Micropatterning of Polyethylene (PE) to Increase the Shearing Strength of Adhesive Joints

Abstract

1. Introduction

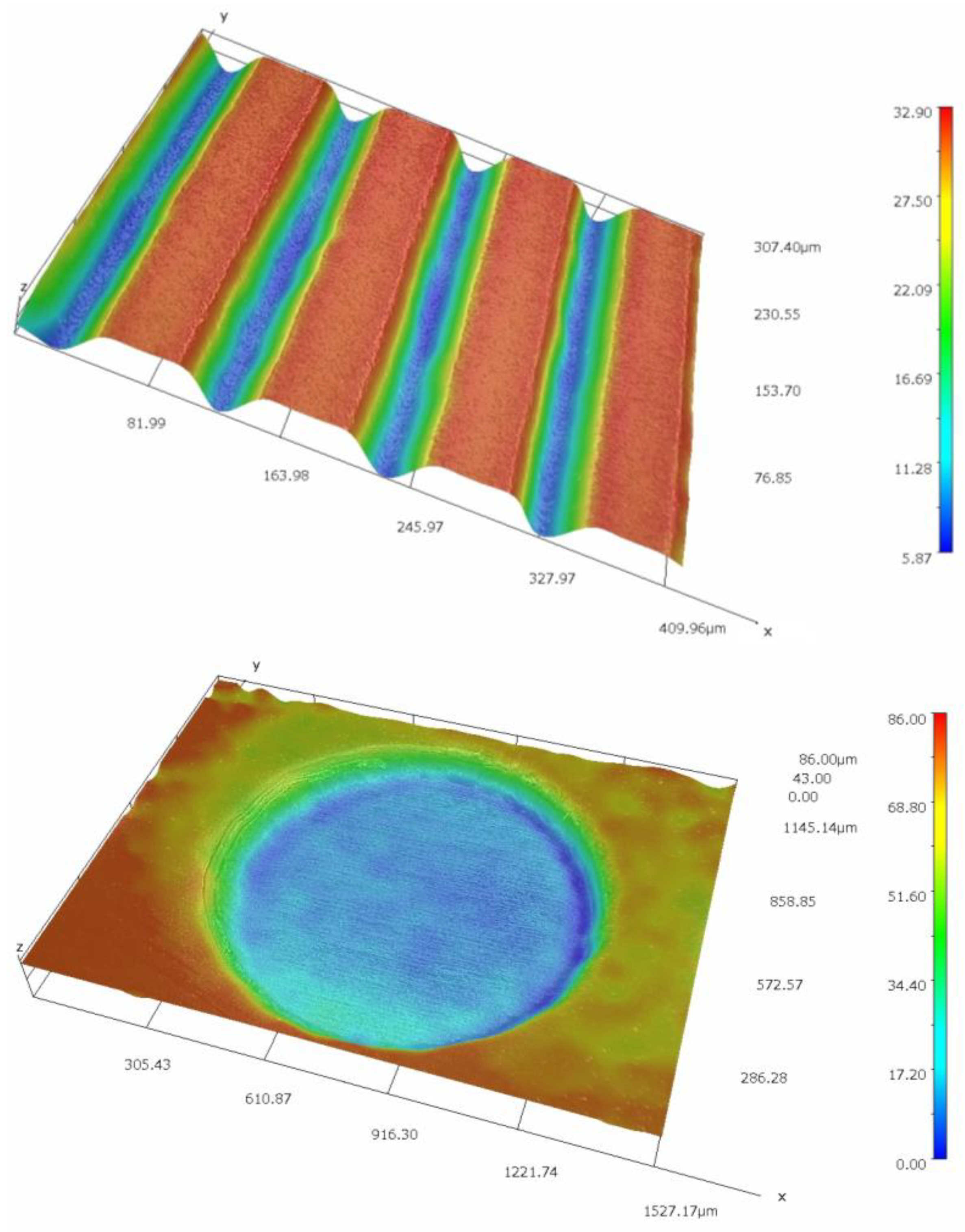

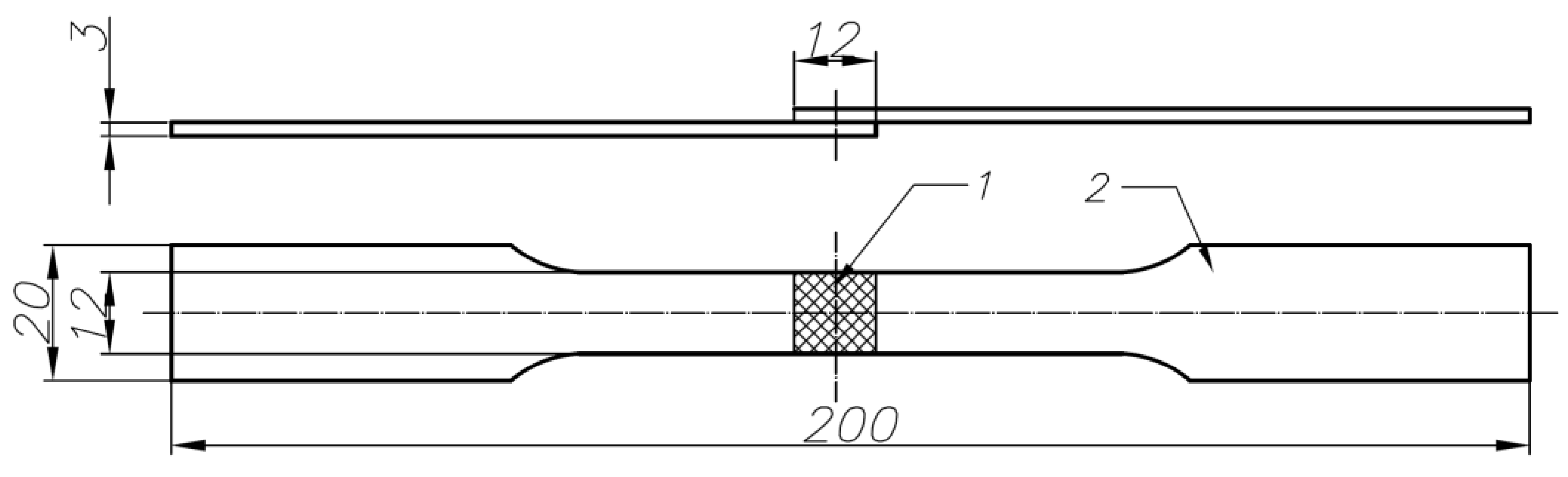

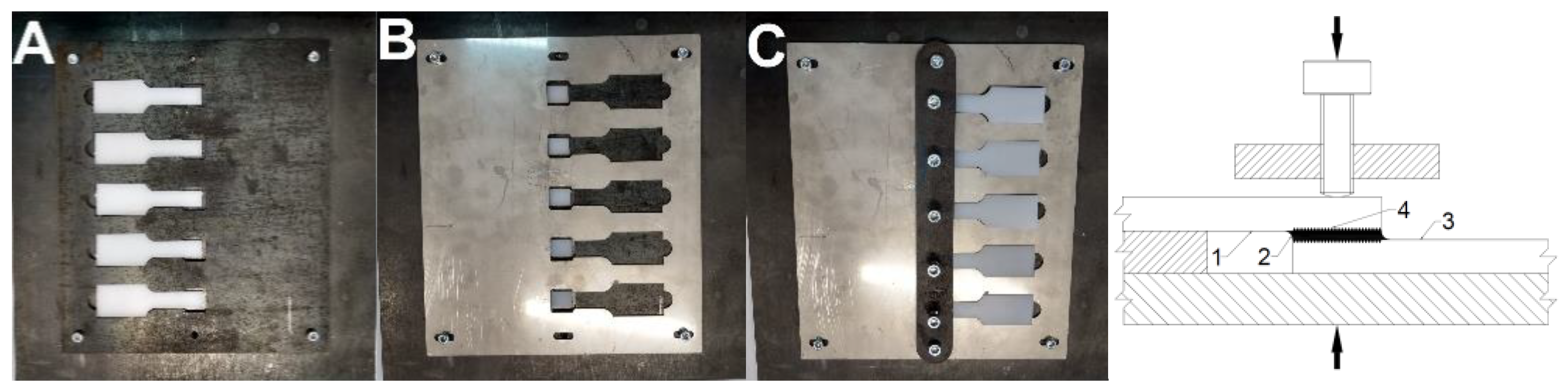

2. Materials and Methods

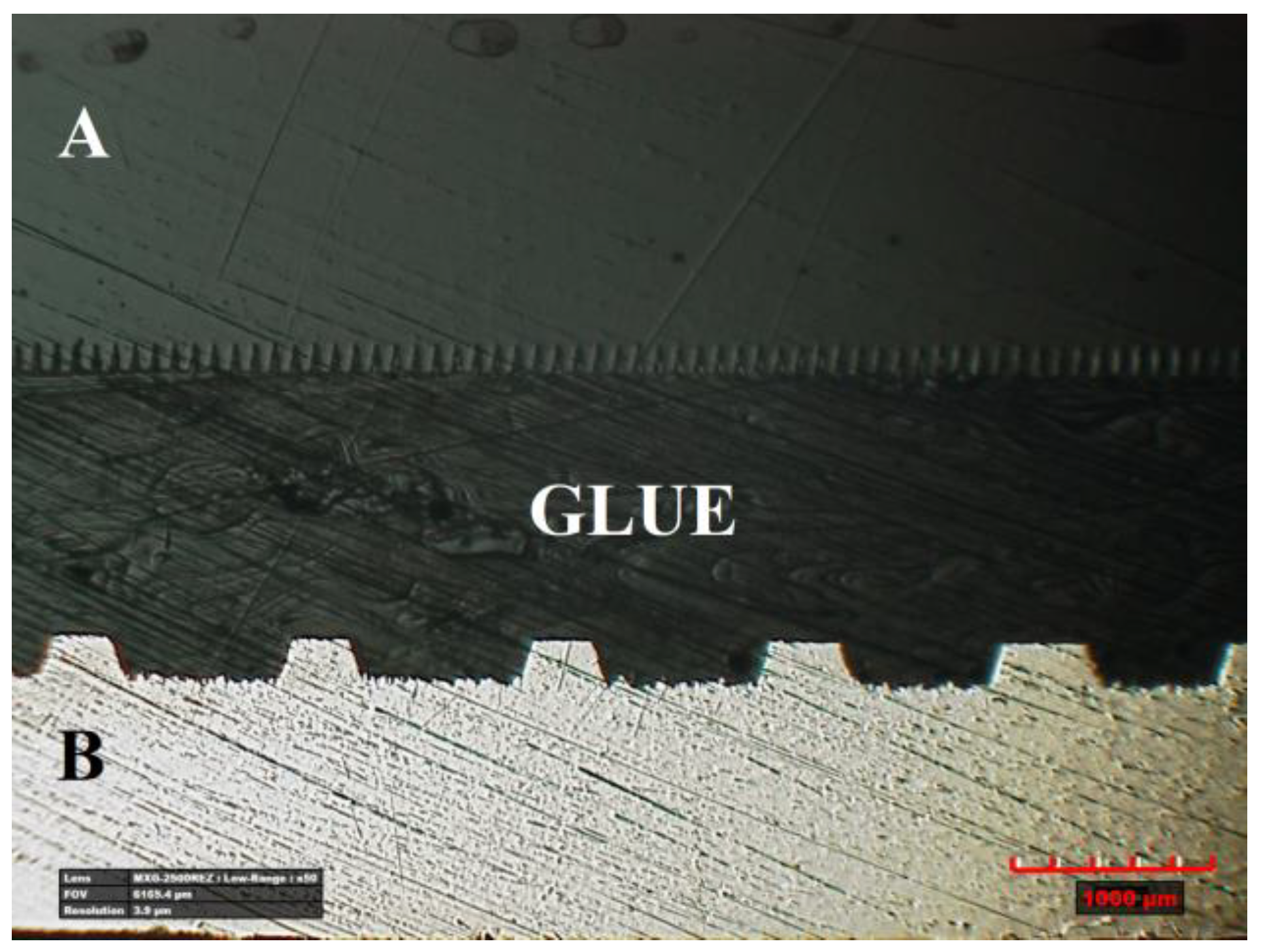

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pietraszek, J.; Radek, N.; Goroshko, A.V. Challenges for the DOE methodology related to the introduction of Industry 4.0. Prod. Eng. Arch. 2020, 4, 190–194. [Google Scholar] [CrossRef]

- Radek, N.; Szczotok, A.; Gądek-Moszczak, A.; Dwornicka, R.; Bronček, J.; Pietraszek, J. The impact of laser processing parameters on the properties of electrospark deposited coatings. Arch. Metall. Mater. 2018, 63, 809–816. [Google Scholar]

- Kurp, P. Ideas and Assumptions of a New Kind Helical Metal Expansion Joints. Mater. Res. Proc. 2022, 24, 236–242. [Google Scholar]

- Gądek-Moszczak, A.; Radek, N.; Wroński, S.; Tarasiuk, J. Application the 3D image analysis techniques for assessment the quality of material surface layer before and after laser treatment. Adv. Mater. Res. 2014, 874, 133–138. [Google Scholar] [CrossRef]

- Lasagni, A.F.; Roch, T.; Berger, J.; Kunze, T.; Lang, V.; Beyer, E. To use or not to use (direct laser interference patterning), that is the question. Proc. SPIE 2015, 9351, 935115. [Google Scholar]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Garcia-Giron, A.; Romano, J.M.; Batal, A.; Dashtbozorg, B.; Dong, H.; Solanas, E.M.; Angos, D.U.; Walker, M.; Penchev, P.; Dimov, S.S. Durability and Wear Resistance of Laser-Textured Hardened Stainless Steel Surfaces with Hydrophobic Properties. Langmuir 2019, 35, 5353–5363. [Google Scholar] [CrossRef]

- Romano, J.-M.; Garcia-Giron, A.; Penchev, P.; Dimov, S. Triangular laser-induced submicron textures for functionalising stainless steel surfaces. Appl. Surf. Sci. 2018, 440, 162–169. [Google Scholar] [CrossRef]

- Krzywicka, M.; Szymańska, J.; Tofil, S.; Malm, A.; Grzegorczyk, A. Surface Properties of Ti6Al7Nb Alloy: Surface Free Energy and Bacteria Adhesion. J. Funct.Biomater. 2022, 13, 26. [Google Scholar] [CrossRef]

- Witkowski, G.; Tofil, S.; Mulczyk, K. Effect of laser beam trajectory on pocket geometry in laser micromachining. Open Eng. 2020, 10, 830–838. [Google Scholar] [CrossRef]

- Antoszewski, B.; Sęk, P. Influence of laser beam intensity on geometry parameters of a single surface texture element. Arch. Met. Mater. 2015, 60, 2215–2219. [Google Scholar] [CrossRef][Green Version]

- Romano, J.-M.; Gulcur, M.; Garcia-Giron, A.; Martinez-Solanas, E.; Whiteside, B.R.; Dimov, S.S. Mechanical durability of hydrophobic surfaces fabricated by injection molding of laser-induced textures. Appl. Surf. Sci. 2019, 476, 850–860. [Google Scholar] [CrossRef]

- Antoszewski, B.; Tofil, S.; Mulczyk, K. The Efficiency of UV Picosecond Laser Processing in the Shaping of Surface Structures on Elastomers. Polymers 2020, 12, 2041. [Google Scholar] [CrossRef] [PubMed]

- Ravi-Kumar, S.; Lies, B.; Zhang, X.; Lyu, H.; Qin, H. Laser ablation of polymers—A review. Polym. Int. 2019, 68, 1391–1401. [Google Scholar] [CrossRef]

- Prakash, J.C.G.; Prasanth, R. Approaches to design a surface with tunable wettability: A review on surface properties. J. Mater. Sci. 2021, 56, 108–135. [Google Scholar] [CrossRef]

- Milles, S.; Voisiat, B.; Nitschke, M.; Lasagni, A.F. Influence of roughness achieved by periodic structures on the wettability of aluminum using direct laser writing and direct laser interference patterning technology. J. Mater. Process. Technol. 2019, 270, 142–151. [Google Scholar] [CrossRef]

- Shen, M.-X.; Zhang, Z.-X.; Yang, J.-T.; Xiong, G.-Y. Wetting Behavior and Tribological Properties of Polymer Brushes on Laser-Textured Surface. Polymers 2019, 11, 981. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Patel, D.S.; Ramkumar, J.; Balani, K. Single step laser surface texturing for enhancing contact angle and tribological properties. Int. J. Adv. Manuf. Technol. 2019, 100, 1253–1267. [Google Scholar] [CrossRef]

- Ruszaj, A.; Cygnar, M.; Grabowski, M. The state of the art in electrochemical machining process modeling and applications. AIP Conf. Proc. 2018, 2017, 020029. [Google Scholar] [CrossRef]

- Patil, D.; Sharma, A.; Aravindan, S.; Rao, P.V. Development of hot embossing setup and fabrication of ordered nanostructures on large area of polymer surface for antibiofouling application. Micro Nano Lett. 2019, 14, 191–195. [Google Scholar] [CrossRef]

- Wang, R.; Wei, J.; Fan, Y. Chalcogenide phase-change thin films used as grayscale photolithography materials. Opt. Express 2014, 22, 4973–4984. [Google Scholar] [CrossRef]

- Kim, C.-S.; Ahn, S.-H.; Jang, D.-Y. Review: Developments in micro/nanoscale fabrication by focused ion beams. Vacuum 2012, 86, 1014–1035. [Google Scholar] [CrossRef]

- Gamaly, E.G. The physics of ultrashort laser interaction with solids at nonrelativistic intensities. Phys. Rep. 2011, 508, 91–243. [Google Scholar] [CrossRef]

- Avino, P.; Petrucci, A.; Schulze, D.; Segebade, C.; Activation, A.A.-P.; Worsfold, P.; Poole, C.; Townshend, A.; Miró, M. Encyclopedia of Analytical Science, 3rd ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 25–39. [Google Scholar] [CrossRef]

- Antoszewski, B.; Kurp, P. Effect of Surface Texture on the Sliding Pair Lubrication Efficiency. Lubricants 2022, 10, 80. [Google Scholar] [CrossRef]

- Assaf, Y.; Kietzig, A.-M. Optical and chemical effects governing femtosecond laser-induced structure formation on polymer surfaces. Mater. Today Commun. 2018, 14, 169–179. [Google Scholar] [CrossRef]

- Wood, M.J.; Coady, M.J.; Aristizabal, F.; Nielsen, K.; Ragogna, P.J.; Kietzig, A.-M. Femtosecond laser micromachining of copolymeric urethane materials. Appl. Surf. Sci. 2019, 483, 633–641. [Google Scholar] [CrossRef]

- Ocaña, J.L.; Morales, M.; Porro, J.A.; Díaz, M.; de Lara, L.R.; Correa, C. Laser Plasma Interaction and Shock Material Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas, B., Eds.; Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 47–74. [Google Scholar] [CrossRef]

- Zhang, Q.; Dong, J.; Peng, M.; Yang, Z.; Wan, Y.; Yao, F.; Zhou, J.; Ouyang, C.; Deng, X.; Luo, H. Laser-induced wettability gradient surface on NiTi alloy for improved hemocompatibility and flow resistance. Mater. Sci. Eng. C 2020, 111, 110847. [Google Scholar] [CrossRef]

- Kulander, K.; Lewenstein, M. Multiphoton and Strong-Field Processes; Drake, G., Ed.; Springer Handbook of Atomic, Molecular, and Optical Physics, Springer Handbooks; Springer: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Ou, Y.; Yang, Q.; Chen, F.; Deng, Z.; Du, G.; Wang, J.; Bian, H.; Yong, J.; Hou, X. Direct Fabrication of Microlens Arrays on PMMA With Laser-Induced Structural Modification. IEEE Photonics Technol. Lett. 2015, 27, 2253–2256. [Google Scholar] [CrossRef]

- Kallepalli, L.N.D.; Soma, V.R.; Desai, N.R. Femtosecond-laser direct writing in polymers and potential applications in microfluidics and memory devices. Opt. Eng. 2012, 51, 073402. [Google Scholar] [CrossRef]

- Guay, J.-M.; Villafranca, A.; Baset, F.; Popov, K.; Ramunno, L.; Bhardwaj, V.R. Polarization-dependent femtosecond laser ablation of poly-methyl methacrylate. New J. Phys. 2012, 14, 085010. [Google Scholar] [CrossRef]

- Voisiat, B.; Aguilar-Morales, A.I.; Kunze, T.; Lasagni, A.F. Development of an Analytical Model for Optimization of Direct Laser Interference Patterning. Materials 2020, 13, 200. [Google Scholar] [CrossRef]

- Alamri, S.; Lasagni, A. Development of a general model for direct laser interference patterning of polymers. Opt. Express 2017, 25, 9603–9616. [Google Scholar] [CrossRef]

- Lasagni, A.; Manzoni, A.; Mücklich, F. Micro/Nano Fabrication of Periodic Hierarchical Structures by Multi-Pulsed Laser Interference Structuring. Adv. Eng. Mater. 2007, 9, 872–875. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z.; Dou, F. Direct Writing of Polymer Lasers Using Interference Ablation. Adv. Mater. 2011, 23, 1860–1864. [Google Scholar] [CrossRef]

- Stankevičius, E.; Malinauskas, M.; Gedvilas, M.; Voisiat, B.; Račiukaitis, G. Fabrication of periodic microstructures by multiphoton polymerization using the femtosecond laser and four-beam interference. Mater. Sci. 2011, 17, 244–248. [Google Scholar] [CrossRef][Green Version]

- Nemani, S.K.; Annavarapu, R.K.; Mohammadian, B.; Raiyan, A.; Heil, J.; Haque, M.A.; Abdelaal, A.; Sojoudi, H. Surface Modification of Polymers: Methods and Applications. Adv. Mater. Interfaces 2018, 5, 1801247. [Google Scholar] [CrossRef]

- Zhong, X.; Zhao, X.; Qian, Y.; Zou, Y. Polyethylene plastic production process. Insight-Mater. Sci. 2018, 1, 1–8. [Google Scholar] [CrossRef]

- Tofil, S.; Manikandan, M.; Arivazhagan, N. Surface Laser Micropatterning of Polyethylene Terephthalate (PET) to Increase the Shearing Strength of Adhesive Joints. Mater. Res. Proc. 2022, 24, 27–33. [Google Scholar]

- Available online: https://www.armetpolska.pl/pe-polietylen/ (accessed on 14 June 2023).

- MULTIBOND-1101 Data Sheet. Available online: www.multibond.pl (accessed on 14 June 2023).

- PN-EN ISO 291:2010; Tworzywa sztuczne—Znormalizowane Warunki Klimatyczne Kondycjonowania I Badania, (in English—Plastics—Standardized Climatic Conditioning And Testing). PKN (Polski Komitet Normalizacyjny): Warsaw, Poland, 2010.

- PN-EN ISO 6892-1:2020-05; Próba Rozciągania—Część 1: Metoda Badania W Temperaturze Pokojowej (in English—Tensile test—Part 1: Test Method At Room Temperature). PKN (Polski Komitet Normalizacyjny): Warsaw, Poland, 2022.

- Tofil, S.; Barbucha, R.; Kocik, M.; Kozera, R.; Tański, M.; Arivazhagan, N.; Yao, J.; Zrak, A. Adhesive Joints with Laser Shaped Surface Microstructures. Materials 2021, 14, 24. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| Abrasion (sand suspension) | ≥90 | % |

| Stress at the yield point | ≥18–20 | MPa |

| Elongation | ~300 | % |

| Young modulus, E | ~700 | MPa |

| Impact strength (Charpy) | >120 | kJ/m2 |

| Thermal conductivity at 23 °C | >0.40 | W/m K |

| Puncture resistance | ~40 | KV/mm |

| Surface resistance | >1012 | Ω |

| Property | Value | Unit |

|---|---|---|

| Viscosity (before it hardens) | 10,600 (component A) 6300 (component B) | mPa·s |

| Specific weight in 25 °C (before it hardens) | 1.16 (component A) 0.98 (component B) | g/mL |

| Shear strength with tensile strength (after it hardens) | 26.0 (metals) 7.0 (plastics) | N/mm2 |

| Peel-off resistance (after it hardens) | 5.0 | N/mm |

| Working temperature range | −60–+100 | °C |

| Property | Value | Unit |

|---|---|---|

| Pulse energy | 12.6 | µJ |

| Pulse repetition frequency | 200 | kHz |

| Laser scanning speed | 1000 | mm/s |

| Shielding gas (air) | 12 | nl/min |

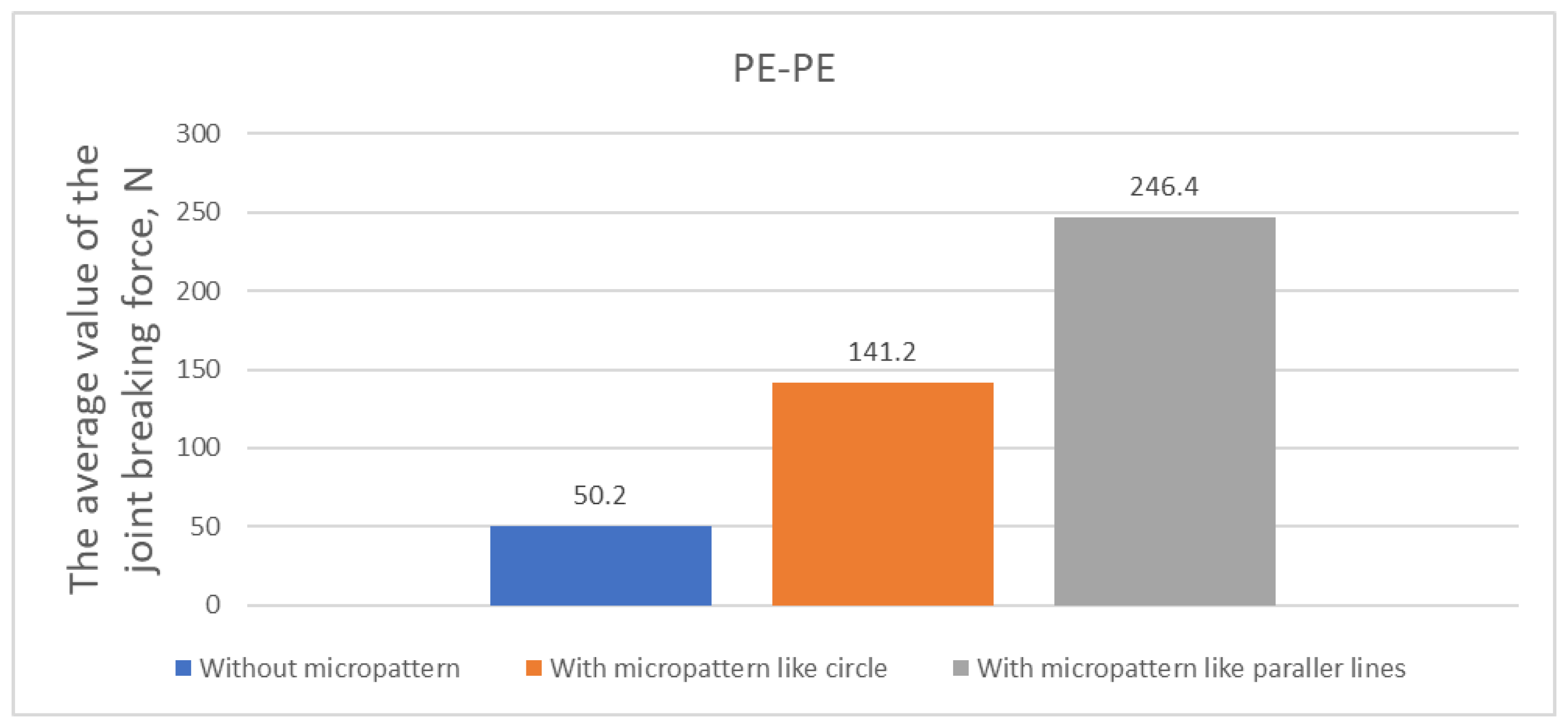

| PE without Micropattern | PE with Circle Micropattern | PE with Perpendicular Lines Micropattern | |

|---|---|---|---|

| Measurement 1, N | 55 | 145 | 252 |

| Measurement 2, N | 42 | 134 | 235 |

| Measurement 3, N | 56 | 140 | 241 |

| Measurement 4, N | 48 | 138 | 249 |

| Measurement 5, N | 50 | 149 | 255 |

| Average, N | 50.2 | 141.2 | 246.4 |

| Standard deviation, N | 5.67 | 5.89 | 8.23 |

| Min, N | 42 | 134 | 235 |

| Max, N | 56 | 149 | 255 |

| The average increase in strength, % | - | 281.27 | 490.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tofil, S.; Kurp, P.; Manikandan, M. Surface Laser Micropatterning of Polyethylene (PE) to Increase the Shearing Strength of Adhesive Joints. Lubricants 2023, 11, 368. https://doi.org/10.3390/lubricants11090368

Tofil S, Kurp P, Manikandan M. Surface Laser Micropatterning of Polyethylene (PE) to Increase the Shearing Strength of Adhesive Joints. Lubricants. 2023; 11(9):368. https://doi.org/10.3390/lubricants11090368

Chicago/Turabian StyleTofil, Szymon, Piotr Kurp, and Manoharan Manikandan. 2023. "Surface Laser Micropatterning of Polyethylene (PE) to Increase the Shearing Strength of Adhesive Joints" Lubricants 11, no. 9: 368. https://doi.org/10.3390/lubricants11090368

APA StyleTofil, S., Kurp, P., & Manikandan, M. (2023). Surface Laser Micropatterning of Polyethylene (PE) to Increase the Shearing Strength of Adhesive Joints. Lubricants, 11(9), 368. https://doi.org/10.3390/lubricants11090368