1. Introduction

Carbon fiber (CF)-reinforced composites have gained significant attention in various engineering applications due to the exceptional mechanical properties of carbon fibers, such as their high strength, high modulus and low density [

1,

2]. These materials are widely used in industries such as aerospace, automotive and sports equipment, where their high performance and durability are critical factors.

Among the various available carbon fiber-reinforced polymer composites, polytetrafluoroethylene (PTFE) has emerged as a prominent choice for tribological applications due to its unique properties. PTFE is a thermoplastic polymer known for its low coefficient of friction, high chemical resistance and excellent electrical insulating properties [

3,

4]. The tribological performance of CF/PTFE composites is especially favorable in dry gas applications, such as in dynamic seals in reciprocating gas compressors and Stirling engines. The friction and wear of PTFE composites filled with carbon fiber or other carbons are currently unchallenged in dry gas environments compared to other fillers [

5,

6]. The mechanism behind the great tribological performance of CF/PTFE sliding against steel in dry gas has recently been discovered by the authors [

7]. In high-purity nitrogen, a super smooth iron fluoride film is tribochemically formed on the steel surface, which has poor adhesion to the non-graphitic carbon film that is formed on the CF/PTFE surface. However, this also makes the system very environmentally sensitive, where the addition of oxygen and moisture may change the tribochemistry in the sliding interface. The literature and a previous study indicate that small changes in the environment significantly affect the tribological performance [

8,

9]. Moreover, the wear rate is typically around one order of magnitude higher in humid air compared to dry nitrogen or hydrogen, and the coefficient of friction is several times higher [

5,

9].

In the last few decades, environmental and human health concerns related to the emissions of per- and polyfluoroalkyl substances (PFAS) have increased substantially. Regulations aiming to reduce harmful PFAS emissions are continuously expanding and several PFAS groups—such as perfluorooctane sulfonic acid (PFOS), perfluorooctanoic acid PFOA and perfluorohexanesulfonate PFHxS—are already globally restricted or banned [

10]. While fluoropolymers, such as PTFE, are not yet regulated globally or in the European Union (EU), the European Chemical Agency (ECHA) is currently considering a restriction of fluoropolymers in several sectors [

11]. As PTFE is the most common material in the dynamic seals used in reciprocating gas compressors [

12], it is of great interest to investigate possible replacements to mitigate possible PFAS emissions from this sector. One potential candidate is polyetheretherketone (PEEK), which is a fluor-free high-performance thermoplastic known for its exceptional mechanical strength, excellent thermal stability and superior creep resistance [

13,

14]. The literature on the tribology of CF/PEEK in dry gas environments is extremely scarce, and no direct comparison with CF/PTFE has been reported. However, one study by Oyamada et al. [

15] indicates that a similar reduction in the friction and wear as for CF/PTFE can be achieved for CF/PEEK in dry gas compared to humid air. Carbon-filled PEEK has shown a similar tendency, where a reduction in its friction and wear has been reported in dry gas compared to humid air [

16,

17].

Extensive research has been carried out by Johansson et al. on the tribology of CF/PTFE in dry gas environments, e.g., [

7,

9,

18]. This paper aims to extend the investigation to CF/PEEK and compare the tribological behavior of the two materials in gas environments with different amounts of moisture and oxygen. The results indicate that while low friction and ultralow wear can be achieved for both materials, the effect of oxygen and moisture varies significantly for CF/PTFE and CF/PEEK. Complementary tests were conducted with a commercial carbon fiber-reinforced composite containing both PTFE and PEEK to investigate how the effects of oxygen and moisture change by combining the two polymers. The commercial material showed reduced sensitivity to oxygen and moisture compared to the single-filled polymers.

2. Materials and Methods

Two carbon fiber (CF)-reinforced polymers, CF20/PTFE and CF20/PEEK, were prepared at Nanjing Tech University (Nanjing, China) into cylindrical pins with a diameter of 8 mm. Each polymer was filled with 20 wt% of polyacrylonitrile (PAN)-based CF, with a diameter of about 7 µm and a length of between about 15 and 150 µm. CF was supplied by Nanjing Fiberglass Research and Design Institute, PTFE powder from Dupont (7A-J) and PEEK powder from Victrex plc (Victrex 450PF). CF and polymer powders were dried at 120 °C, followed by mixing to the desired percentages. CF20/PEEK was prepared through high-temperature compression molding (355 °C and 10 MPa for 90 min). CF20/PTFE was prepared through compression molding (RT and 70 MPa for 5 min), followed by sintering at 380 °C for 4 h and slow cooling to room temperature (40 °C/h).

A commercially available carbon fiber-reinforced PTFE composite was also tested as a reference. Comparing the FTIR spectrum of the commercial material with the pure PTFE and PEEK samples (

Figure 1a) clearly indicates that the composite is filled with particles of PEEK. The commercial material is hereafter denoted as CF/PEEK/PTFE. A micrograph and a layered EDS image of the cross-section (

Figure 1b,c) show the distribution of the carbon fibers and PEEK filler, respectively.

The counterface discs were machined from 34CrNiMo6 alloy steel with a hardness of 460 HV. This material has been extensively studied as a counterface material for CF/PTFE composites and has shown favorable results [

7,

9,

18]. The counterfaces were grinded to a surface roughness of S

a = 0.12 ± 0.02 µm and a random texture, using 400 p silicon carbide abrasive paper in a figure-eight motion.

Due to the low wear rates of the carbon fiber-reinforced materials, the initial conformity between the composite pins and the steel counterface was critical in order to achieve reliable results. Thus, a specific in-situ grinding procedure was conducted prior to each test by lightly sliding the composite pins against the counterface with a very fine abrasive paper in between. This procedure is described in detail in [

9].

The polymer composites were tested against the steel counterface using a custom three-pin-on-disc configuration in a Plint TE92 tribometer (

Figure 2a). The test configuration is enclosed by an environmental chamber, which is connected to a climate control system, as illustrated in

Figure 2b. Three polymer composite pins are mounted on a self-aligning test pin holder (upper specimen). These rotate with their flat end against a fixed counterface, with a mean sliding radius of 25 mm. The displacement between the upper and lower specimens is measured in situ using a displacement sensor, which is used to calculate the wear rate. The near-contact temperature is measured using a thermocouple inserted in a hole just below the sliding surface of the counterface. Heaters underneath the counterface are used to control the near-contact temperature to the set value. A detailed description of the tribometer can be found in a previous publication [

19].

The amount of oxygen and moisture in the climate chamber is measured using an oxygen sensor and a dew point sensor, respectively. The sensors are mounted externally on the climate control unit (

Figure 2b), where a diaphragm pump circulates the gas from the chamber to the climate controller. The climate chamber is continuously filled with nitrogen, where the supply rate is varied depending on the targeted oxygen content using an electronic pressure regulator. Further control of the oxygen content is enabled by an exhaust valve on the circulation loop, which adjusts the leakage to and from the surrounding environment. The moisture content is controlled using a moisture trap or a humidifier, depending on whether a low or high moisture content is required, respectively. With this setup, the oxygen and moisture can be varied independently between about 10 ppm to over 1000 ppm and 1 ppm to over 1000 ppm, respectively.

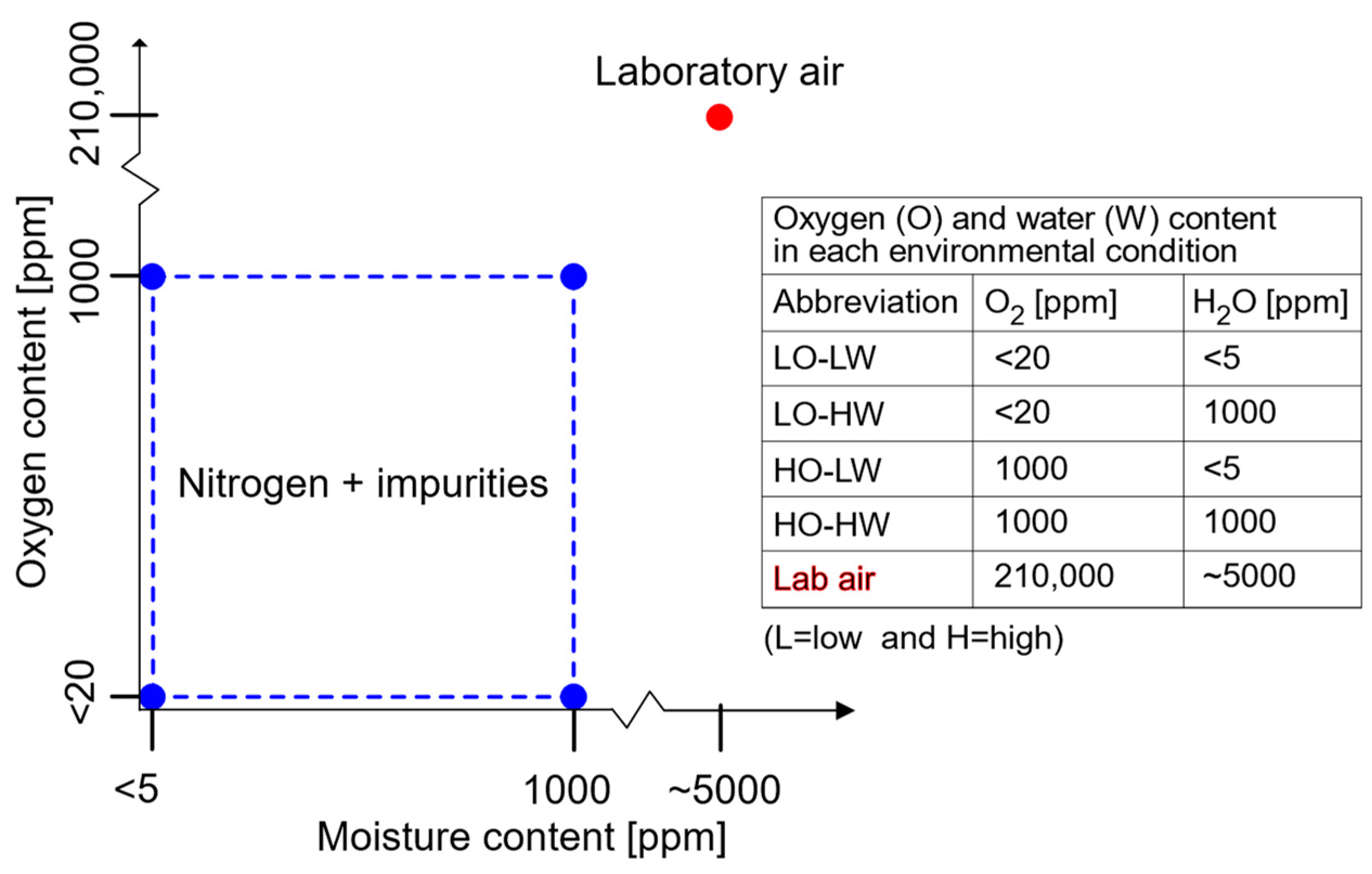

The operating conditions for the tribotesting were as follows. The sliding speed was set to 0.75 m/s, nominal contact pressure to 2 MPa and near-contact temperature to 80 °C. Five environmental test conditions were tested for each material (

Figure 3), whereof one was in laboratory air as a reference. The tested levels of environmental water and oxygen may be regarded as quite extreme for many applications but were chosen in order to highlight the individual and combined effect of each impurity type on the friction and wear. To simplify for the reader, abbreviations are used for the environmental conditions, where, e.g., LO-HW stands for low oxygen content and high water content. The nitrogen environments were tested twice for CF20/PTFE and CF20/PEEK and once for the complementary material, CF/PEEK/PTFE. Reference tests in laboratory air were only conducted once for each material. The sliding distance was 100 km for tests in nitrogen, where only data from the last 50 km were used to calculate the wear rate due to the initial high wear and unstable friction. For tests in humid air, a sliding distance of 50 km was used due to the higher wear. For these tests, data from the last 25 km of sliding were used to calculate the wear rate. The linear wear rate,

[µm/km], was calculated by linearizing the height loss over the sliding distance, as measured by the displacement sensor. The specific wear rate,

[mm

3/Nm], could then be calculated by dividing the linear wear rate with the nominal contact pressure

and a conversion factor,

A light optical microscope (LOM) was used to analyze the worn composite surfaces after testing at different environmental conditions. Micrographs were taken at several locations of each surface at 20× and 50× magnifications. From these, one of the 50× micrographs was selected, which best represented the general surface. Before recording the micrographs, the surfaces were cleaned with ethanol-soaked tissue to remove any loose wear particles. The wear tracks on the counterfaces were analyzed using a digital microscope, which provided a larger field of view than the LOM. Hence, it was possible to record the whole width of the wear track. Micrographs were recorded at 30× magnification and 140× magnification. FTIR absorption spectra of the selected wear tracks were also recorded using a Thermo Scientific Nicolet Summit equipped with an Everest diamond ATR.

3. Results

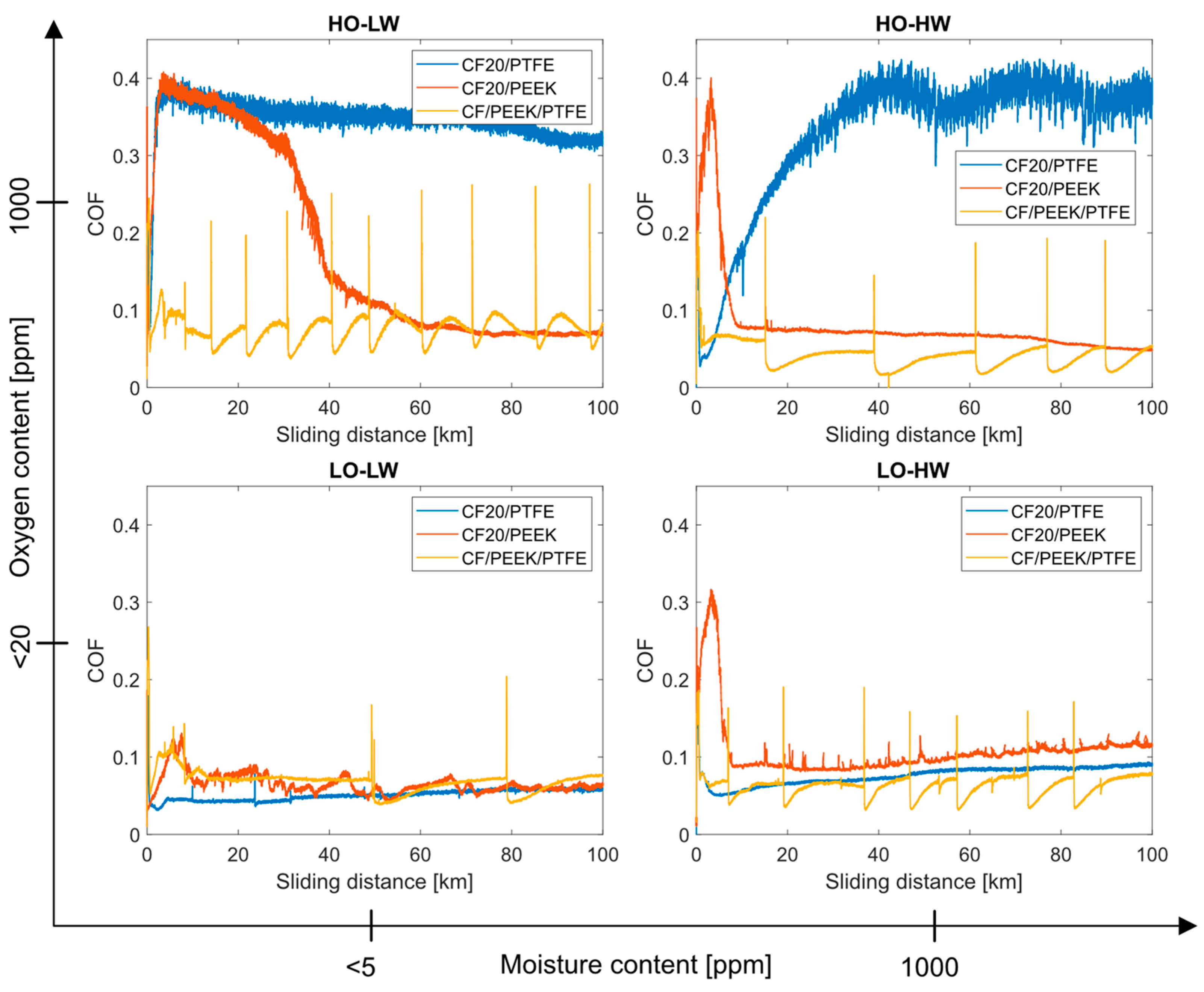

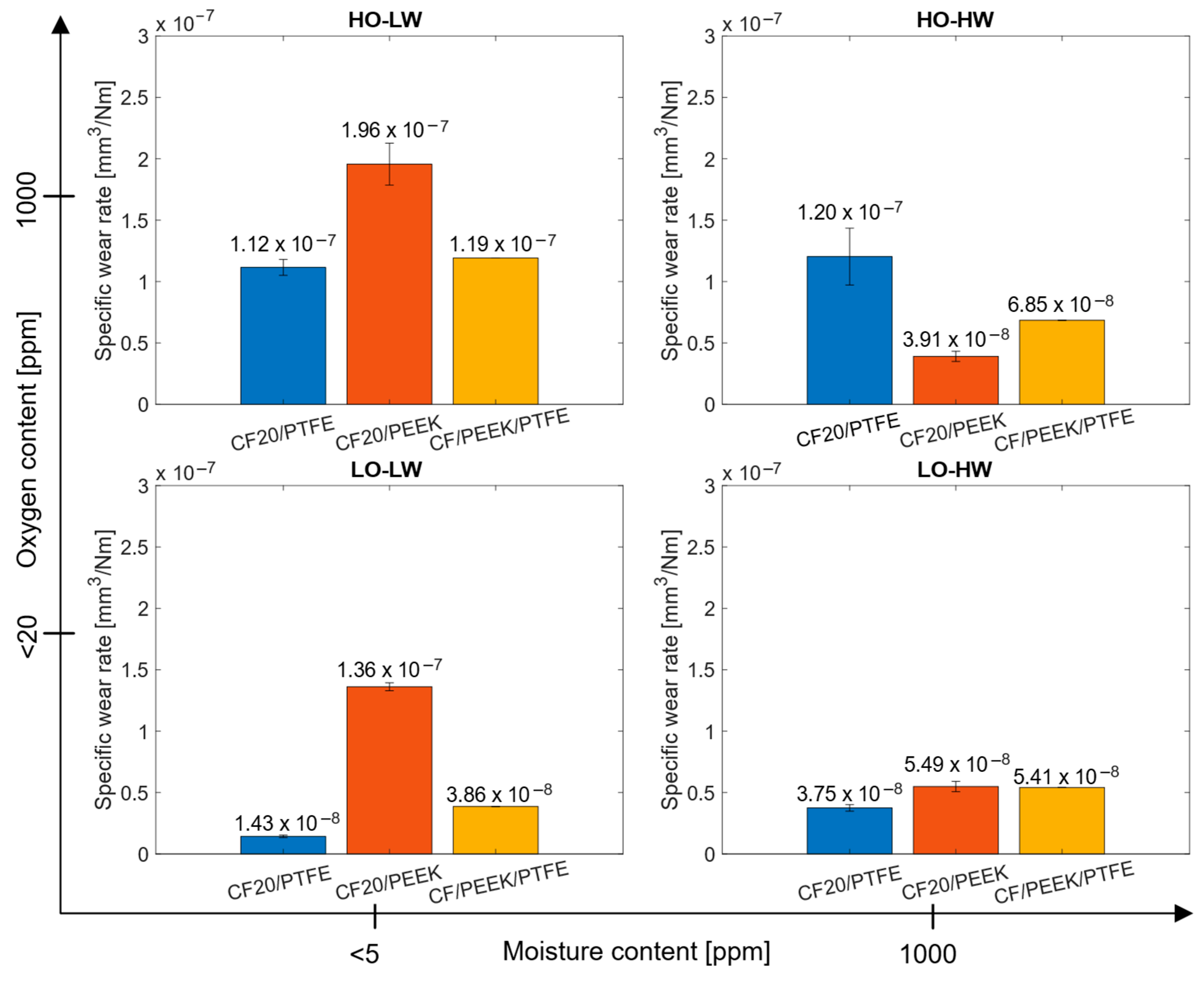

The friction and wear results of the environmentally controlled tests are depicted in

Figure 4 and

Figure 5, respectively. A clear difference in the effect of the oxygen and moisture can be seen when comparing CF20/PTFE and CF20/PEEK. The friction and wear of CF20/PTFE are extremely sensitive to the presence of oxygen, while the moisture only has a slight adverse effect. Contrarily, the wear rate of CF20/PEEK is mainly dependent on the moisture, where a high moisture content is needed to achieve low wear rates. As shown for the HO-HW condition in

Figure 4 and

Figure 5, moisture can even mitigate the detrimental effect of oxygen for CF20/PEEK. Moreover, the coefficient of friction of CF20/PEEK is quite insensitive to both moisture and oxygen and reaches low values at all of the tested contents of oxygen and moisture. Interestingly, the commercial CF/PEEK/PTFE composite provides the best environmental stability. Comparing the wear rates of the three composites in

Figure 5, it is clear that the high impact of certain environmental conditions for the CF-reinforced PTFE and PEEK is limited for the multi-filled commercial composite. However, the CF/PEEK/PTFE composite always shows a slightly higher wear rate than the composite with the lowest wear rate. This is likely related to the periodic friction behavior shown in

Figure 4. This behavior has been observed before both for this material and a commercial PTFE composite with 25 wt% carbon fiber [

9]. The analysis in [

9] indicates that load supporting fibers are lost in the beginning of these friction peaks, which initiates a snowball effect, where the tribofilm is worn off, the matrix is exposed on the surface and a run-in-like behavior commences. This is likely due to poor interfacial adhesion between the fibers and the matrix in the CF/PEEK/PTFE. As no friction peaks were observed for CF/PEEK and CF/PTFE, the fiber/matrix adhesion is likely stronger.

In laboratory air, all of the composites provided a high coefficient of friction and high wear rates, see

Figure 6. Similarly to the moisture deficient conditions, the wear rate of the CF20/PEEK composite in lab air was much more severe compared to the PTFE-containing composites.

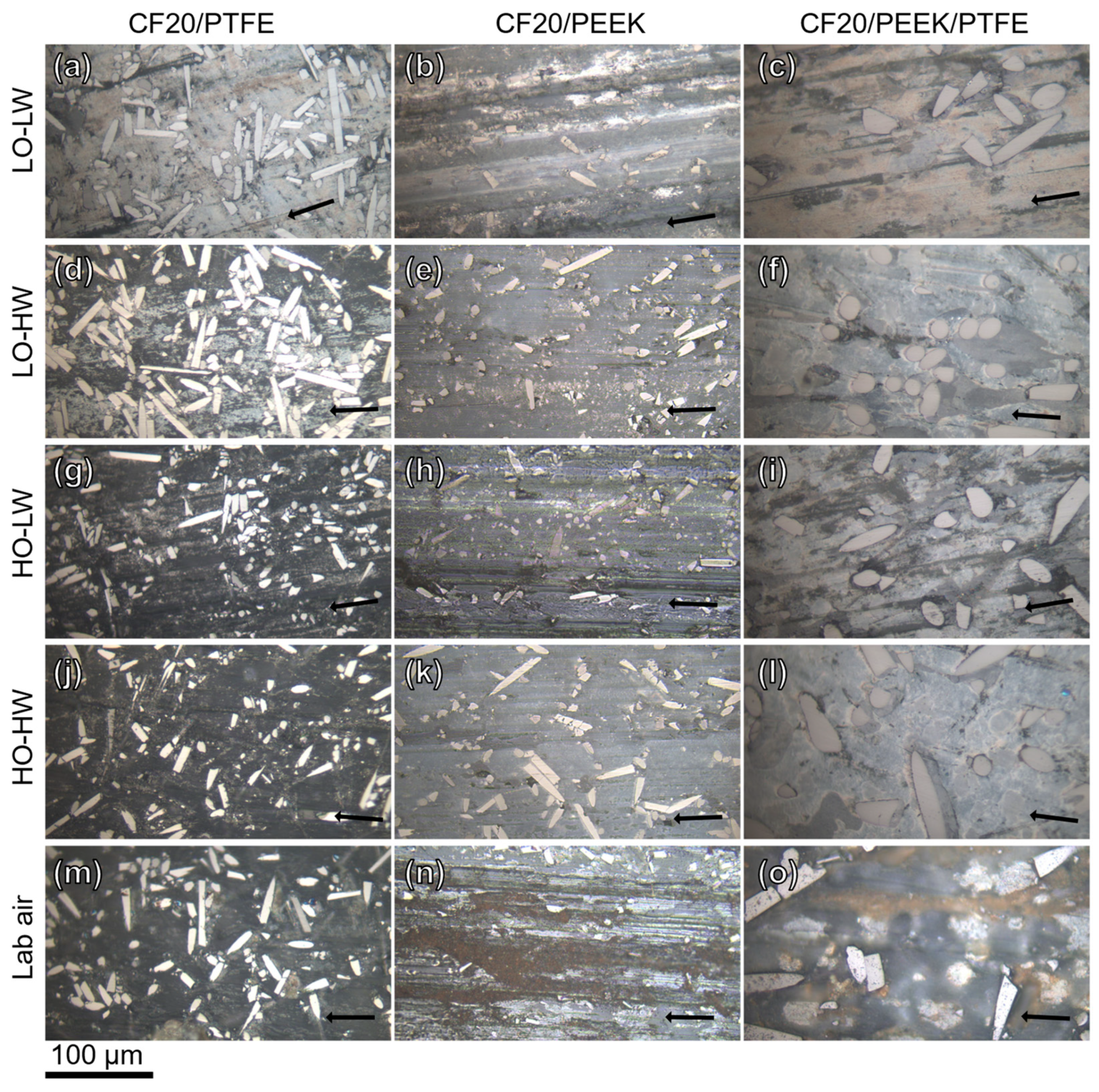

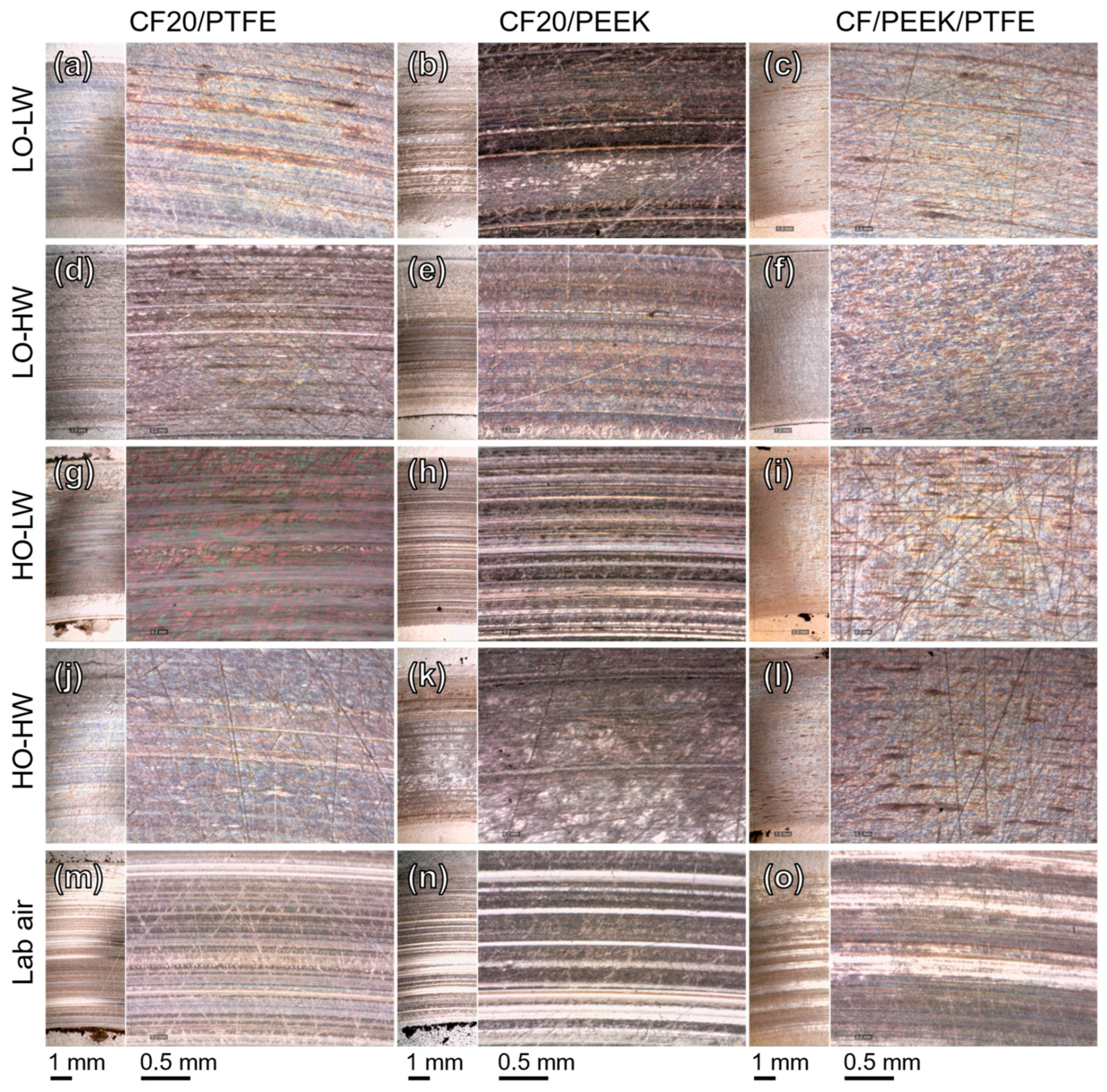

Microscopic images of the worn composite surfaces are shown in

Figure 7. All surfaces were cleaned with ethanol before recording the micrographs. The carbon fibers on the surfaces appear bright as they have been polished against the counterface. Regions with tribofilm typically have a medium-gray appearance, and uncovered or damaged regions of the matrix are typically dark. For the CF20/PTFE composite, only the high-purity condition (LO-LW) could generate a high-quality tribofilm. In the moisture-enriched condition (LO-HW), the tribofilm coverage is significantly reduced. For the conditions with high oxygen contents (HO-LW, HO-HW and lab air), for which the friction and wear were high, the tribofilm coverage is poor and the apparent carbon fiber concentration on the surfaces is lower in comparison to the low oxygen conditions. The difference in the wear trend for CF20/PEEK compared to CF20/PTFE is also reflected on the worn composite surfaces. The CF20/PEEK surfaces from the moisture-enriched conditions (LO-HW and HO-HW), where the wear rates were low, are smooth and evenly covered by tribofilm. In the absence of environmental water (LO-LW and HO-LW), the surfaces show signs of severe abrasion and non-uniform tribofilms. Moreover, the amount of carbon fiber fragments is very high compared to the amount of intact carbon fibers. The commercial material, CF/PEEK/PTFE, showed the least variation on the composite surfaces between the different conditions, which correlates well with the environmentally stable tribological performance of the material. However, the apparent tribofilm quality for the HO-LW condition was the poorest among the environmentally controlled tests, which was also the condition with the highest wear rate.

For the tests in ambient laboratory air, the worn surfaces of the PTFE-based composites are very different from the CF20/PEEK surface (

Figure 7m–o). While the surfaces of the PTFE-based composites mainly show fibers distinctly protruding from the matrices, very few carbon fibers are visible on the CF20/PEEK surface and large damaged regions with a brown/red appearance can be observed. For the PTFE-based composites, the carbon fibers clearly limit the wear rate in ambient air by supporting most of the load. For the CF20/PEEK, weak fiber–matrix adhesion or large-scale delamination seem to prevent predominant load support from the carbon fibers, which would explain the over ten times higher wear rate of the CF20/PEEK than the CF20/PTFE in air.

Comparing the CF20/PTFE and CF20/PEEK, the CF20/PTFE surfaces generally show higher carbon fiber content on the surface, as well as fewer broken fibers and fewer fiber fragments. This may be related to the large difference in the mechanical properties of the polymers, where neat PEEK typically has a more than five times higher elastic modulus than PTFE [

20,

21]. The soft PTFE matrix may prevent the fibers from breaking through a cushioning effect, meaning that damping of the fibers is enabled by the elastic and plastic deformation of the matrix, which may reduce the stress on the fibers in the contact. For the harder PEEK, it appears that fibers are broken off from the surface and then churned between the hard counterface and the relatively hard PEEK composite. The CF20/PTFE also showed significantly fewer signs of abrasion on the composite surface and the counterface compared to CF20/PEEK, as shown in

Figure 7 and

Figure 8, respectively. This may indicate a lesser generation of abrasive third bodies from CF20/PTFE.

Microscopic images of the wear tracks on the counterfaces are shown in

Figure 8. In general, the transfer films, are very thin as indicated by the visible grinding marks. Only the HO-LW condition for the CF20/PTFE composite showed a thicker transfer film, as depicted in

Figure 8g. However, the thicker film only covered about half of the circumference of the counterface, and the other half was extremely thin. Similar to the worn composite surfaces, the wear tracks from the CF20/PEEK tests had the most distinct abrasion marks. The transfer films generated by the CF/PEEK/PTFE composite were quite similar in all of the four environmental conditions, which agrees with the material’s low environmental sensitivity. In laboratory air, the wear tracks showed similar features for all three composites. The transfer films were irregular, with several stripes of polished bare steel.

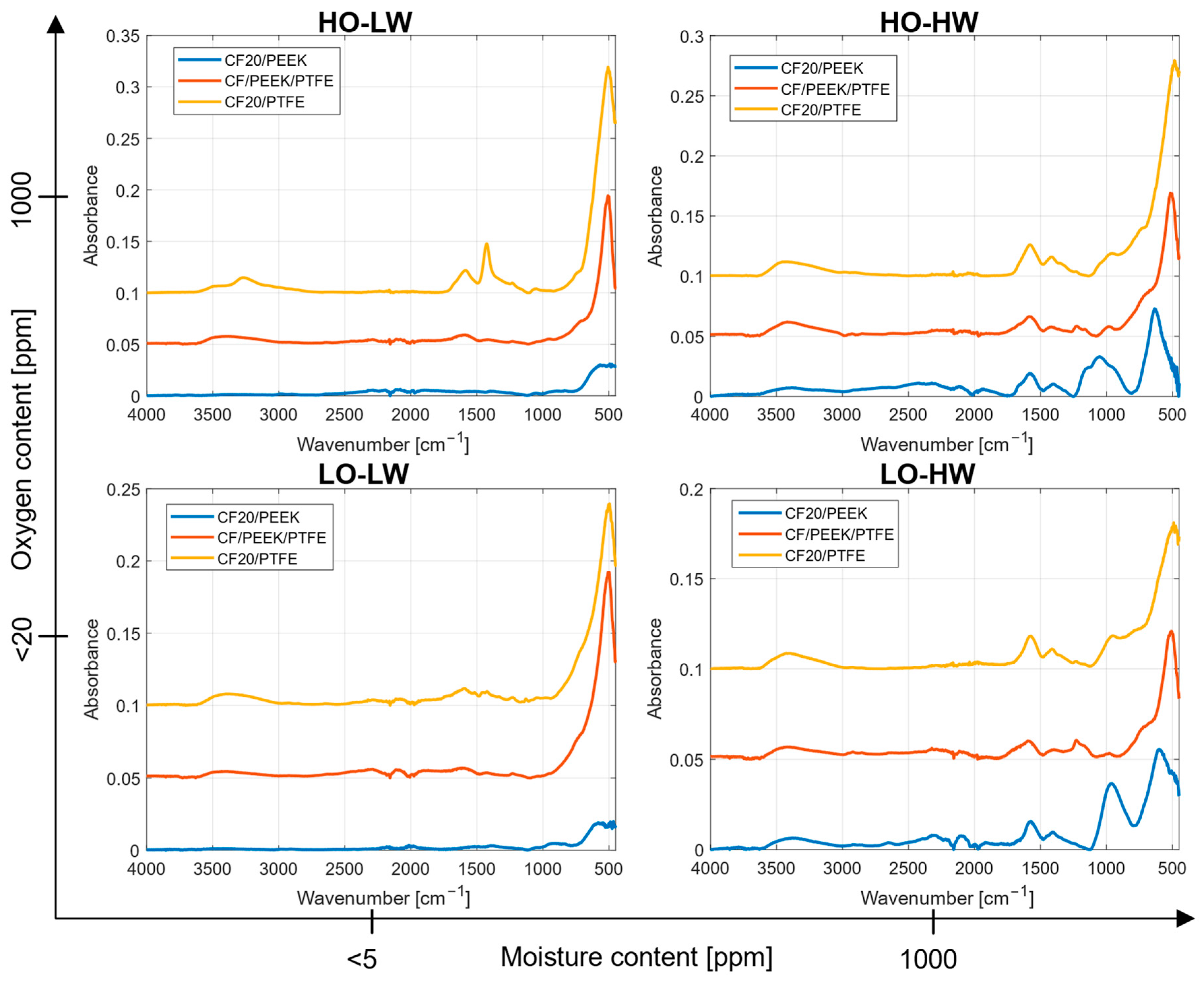

The FTIR absorption spectra for the transfer films from the three tested composites are compared for each nitrogen environment in

Figure 9. For all of the materials and environmental conditions, no sign of transfer of the original polymer can be identified. As discussed in [

7], the term transfer film is therefore incorrect from its definition [

22], and they should instead be referred to as tribofilms. However, to minimize potential confusion, the term transfer film will continue to be used in the remainder of the article. The main peak for the transfer film generated by the PTFE-based composites is at 500 cm

−1, which is characteristic for iron fluoride [

23,

24]. Moreover, a weak and broad peak can be observed at around 3400 cm

−1, indicating the stretching vibration of O-H [

25,

26,

27]. For the oxygen- and moisture-rich conditions, two peaks are shown in the 1600–1400 cm

−1 region, which are characteristic for carboxylate salts [

25,

28,

29,

30]. For the CF20/PTFE material, the presence of the carboxylate peaks is generally associated with increased wear and friction.

For the transfer films from CF20/PEEK, no iron fluoride is present for obvious reasons. Instead, the spectrum for LO-LW and HO-LW only shows a weak peak at around 600 cm

−1, which can be attributed to iron oxide [

24,

31]. In the moisture-rich environments—that is, LO-HW and HO-HW—similar carboxylate and O-H peaks as for the PTFE-based composites are present. Moreover, strong peaks in the 1200–800 cm

−1 region with unknown origin are observed. As no signs of the original polymers can be found in any of the FTIR spectra of the transfer films, the analyzed surfaces should mainly consist of tribochemical products. Contrarily to CF20/PTFE, the presence of carboxylates in the transfer film from CF20/PEEK is associated with a low wear rate.

4. Discussion

It is interesting that the CF20/PEEK composite can maintain low friction in all of the different moisture and oxygen conditions, except in laboratory air. In a recent study by the authors [

7], the low friction and wear of CF20/PTFE in high-purity nitrogen could be linked to the low adhesion between the iron fluoride tribofilm on the steel counterface and the non-graphitic carbon on the tribofilm on the CF20/PTFE surface. Carbon-based tribofilms have previously been observed on CF/PEEK and CF/PTFE composites after sliding in dry gas [

5,

8,

15]. In another recent study by Chen et al. [

32], the transfer films formed by CF/PTFE at different trace moisture contents were analyzed through XPS and Raman. The results showed that the materials in the transfer films were mainly iron fluoride, iron oxides, carboxyl groups and carbon. Moreover, the composition varied over the transfer films, where streaks with a thicker transfer—such as the dark-brown streaks in

Figure 8a—contained more carbon, and the thin general film with a bluish color—also shown in

Figure 8a—contained more iron fluoride. The TEM analysis in [

7] of the thin bluish transfer film, which covered most of the wear track after sliding against CF20/PTFE in LO-LW, confirmed that the surface is almost exclusively iron fluoride. For the CF20/PEEK composite, the formation of beneficial iron fluoride is not possible and the low friction must be accredited to something else. Low friction has been reported for graphite-filled PEEK in dry hydrogen [

17] and for CF/PEEK in semi-dry nitrogen [

15]. The low friction of carbon-filled PEEK may be made possible by the lubricity of sp2 carbons, which rely on the continuous passivation of the dangling bonds created during sliding [

33,

34,

35]. Typically, moisture is needed to enable the low friction of sp2 carbons [

33,

35,

36]. However, as shown by Theiler and Gradt [

17], water, atomic hydrogen and hydroxyl radicals are released during the rubbing of PEEK. These chemical species can likely passivate dangling bonds in the absence of environmental moisture. A similar explanation has been discussed for the low friction of hydrogenated amorphous carbon when rubbing in vacuum, where hydrogen trapped in the carbon material can passivate the dangling bonds on the surface [

33,

37]. The main contribution of the polymer matrix in terms of friction in high-purity gas is therefore different for PEEK and PTFE. For PTFE, it is the creation of an iron fluoride film on the counterface through defluorination, which shows low friction against sp2 carbon surfaces, as shown in [

7]. For PEEK, the role is to provide chemical species to passivate the dangling bonds on the non-graphitic carbon in the sliding interface in order to enable the low friction of the carbon in the absence of environmental moisture. Contrarily, the friction in the moisture-rich environment (LO-HW) had very little dependence on the matrix and the counterface.

Although low friction was achieved for CF20/PEEK in all of the nitrogen environments, the wear rate was strongly affected by the moisture content. For example, a 2.5 times lower wear rate was observed in LO-HW compared to LO-LW conditions. Comparing the FTIR spectra of the transfer film from these conditions suggests that the reduction in wear is associated with the formation of carboxylates. In moisture-deficient environments, the counterfaces had significant wear scars (

Figure 8a,h) and was mainly covered by metal oxides, with no signs of polymer transfer or tribochemical products. As indicated by the worn CF20/PEEK surface (

Figure 7b,h), the direct interaction between the metal oxides and the polymer composite is likely harsh and may promote the delamination of the matrix and the debonding of fibers, causing third-body abrasion. Contrarily, the presence of carboxylates on the counterfaces from the moisture-rich environments typically indicates strong anchoring of the polymer to the surface [

25,

28,

38]. However, as no sign of the original polymer was found on the counterfaces, it may be possible that carbon particles from the decomposed carbon fibers are bonded to the carboxylates, forming a stable transfer film on the counterface. The distinct color difference between the transfer film formed by CF20/PTFE in LO-LW and LO-HW may indicate a significant difference in the material on the surface. As the transfer film with a dark-brown appearance in [

32] contained a substantial amount of carbon and carboxylates, it is likely that the darker transfer film from LO-HW in

Figure 8d also contain carbon. As the carboxylate signals and visual appearance of the transfer films from CF20/PEEK and CF20/PTFE in LO-HW are very similar, as well as the coefficient of friction, it is likely that the composition of the transfer films is similar. A similar mechanism has been proposed by Sun et al. [

39] for graphene-filled PTFE sliding in humid air, where graphene was suggested to form on the surface of the transfer film by bonding to carboxylate end groups. This suggests that the sliding interface in LO-HW for both CF20/PEEK and CF20/PTFE is mainly carbon against carbon, where the high moisture content provides the passivation of the carbon surfaces and low friction.

The mildly abrasive nature of carbon fibers prevents the formation of polymeric transfer layers, which is otherwise typical for polymer composite systems [

28,

40,

41,

42]. The formation of protecting and lubricating tribofilms on the steel surface and the polymer composite surface is therefore highly dependent on tribochemical reactions in the sliding interface. Naturally, such a system is sensitive to reactive species in the surrounding environment, and competing mechanisms will be present even at small concentrations of oxygen and moisture, as has been indicated in [

6,

8,

9,

32]. As observed in this study, the chemical and possibly mechanical differences between PEEK and PTFE change the tribochemistry in the sliding interface and alter the effect of the environment on the friction and wear. By combining the favorable properties of each polymer, the environmental effect can be minimized, as observed for the commercial CF/PEEK/PTFE composite.

5. Concluding Remarks

In this paper, the effect of oxygen and moisture on the friction and wear of CF20/PTFE and CF20/PEEK sliding against a steel counterface have been compared. The results indicate that the effect of oxygen and moisture is different for the CF20/PTFE and CF20/PEEK. The PTFE-based composite performs best in high-purity nitrogen and is very sensitive to oxygen. Contrarily, the PEEK-based composite performs best in moisture-enriched environments and is not sensitive to oxygen as long as the oxygen content is not higher than the moisture content. While the environmental effect was similar on the friction and wear for CF20/PTFE, low friction was achieved for CF20/PEEK in all of the nitrogen environments, regardless of the wear rate.

A complementary investigation was also made with a commercial PTFE composite filled with both PEEK and CF (CF/PEEK/PTFE). Interestingly, the CF/PEEK/PTFE composite inherited the favorable properties from both polymers, which resulted in a significant reduction in the environmental sensitivity of the system. Similar to CF20/PEEK, low friction was achieved in all of the nitrogen environments. Moreover, low wear rates (<107 mm3/Nm) were achieved in both the high-purity nitrogen (LO-LW) and the oxygen- and moisture-enriched (HO-HW) environments.

For all of the tested composites, high friction and wear were achieved in ambient laboratory air.

In conclusion, CF/PEEK could be a suitable replacement for CF/PTFE in moisture-containing gas environments, but not in high-purity gas environments. In high purity, the multi-filled CF/PEEK/PTFE composite may be a suitable replacement for CF/PTFE to reduce the need for PTFE. However, further studies are needed to investigate optimal PEEK content.